esp NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 687 of 4801

![NISSAN TEANA 2014 User Guide

DAS-254

< BASIC INSPECTION >[MOD]

ACTION TEST

ACTION TEST

DescriptionINFOID:0000000009464902

• Perform action test to verify the customers concern.

• Perform action test and check the syst em o NISSAN TEANA 2014 User Guide

DAS-254

< BASIC INSPECTION >[MOD]

ACTION TEST

ACTION TEST

DescriptionINFOID:0000000009464902

• Perform action test to verify the customers concern.

• Perform action test and check the syst em o](/img/5/57390/w960_57390-686.png)

DAS-254

< BASIC INSPECTION >[MOD]

ACTION TEST

ACTION TEST

DescriptionINFOID:0000000009464902

• Perform action test to verify the customer's concern.

• Perform action test and check the syst em operation after system diagnosis.

WARNING:

Be careful of traffic conditions and safety ar ound the vehicle when performing road test.

CAUTION:

• Fully understand the following it ems well before the road test;

- Precautions: Refer to DAS-73, "Precaution for LDW System Service"

.

- System description for LDW: Refer to DAS-77, "System Description"

.

- System description for BSW: Refer to DAS-152, "System Description"

.

- System description for MOD: Refer to DAS-228, "System Description"

.

- Handling precaution: Refer to DAS-82, "Precautions for Lane Departure Warning"

.

Inspection ProcedureINFOID:0000000009464903

WARNING:

Be careful of traffic conditions and safety ar ound the vehicle when performing road test.

CAUTION:

• Fully understand the following it ems well before the road test;

- Precautions: Refer to DAS-73, "Precaution for LDW System Service"

.

- System description for LDW: Refer to DAS-77, "System Description"

.

- System description for BSW: Refer to DAS-152, "System Description"

.

- System description for MOD: Refer to DAS-228, "System Description"

.

- Handling precaution: Refer to DAS-232, "Precautions for Moving Objects Detection"

.

1.CHECK MOD SYSTEM SETTING

1. Start the engine.

2. Check that the MOD system setting can be enabl ed/disabled on the vehicle information display.

3. Turn OFF the ignition switch and wait for 30 seconds or more.

4. Check that the previous setting is saved when the engine starts again.

>> GO TO 2.

2.ACTION TEST FOR MOD

1. Enable the setting of the MOD system on the vehicle information display.

2. Turn warning systems switch ON (w arning systems ON indicator is ON).

3. Check the MOD operation according to the following table.

NOTE:

After the operating conditions of warning are satisfi ed, the warning continues until the vehicle reaches a

higher speed. Refer to DAS-228, "System Description"

.

>> Inspection End.

Vehicle condition/ Driver's operation Vehicle response

Moving Object De-

tection ON indicator Vehicle speed

(Approx.)

[km/h (MPH)] Status of vehicle detection

within detection area Indication on the Moving Object Detection

indicator Buzzer

OFF — — OFF OFF

Blue Less than approx.

8 km/h (5 MPH) Vehicle is detected ON ON

Approx. 8 km/h (5

MPH) or more Vehicle is absent ON OFF

Vehicle is detected ON OFF

Vehicle is not detected ON OFF

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 793 of 4801

SYSTEM (INTELLIGENT KEY SYSTEM)DLK-25

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

OPERATION DESCRIPTION

• When the BCM detects that each door request switch (if equipped) is pressed, it activates the outside key

antenna and inside key antenna corresponding to the pres sed door request switch (if equipped) and trans-

mits the request signal to the Intelligent Key. T hen check that the Intelligent Key is near the door.

• If the Intelligent Key is within the outside key ant enna detection area, it receives the request signal and

transmits the key ID signal to the BCM via remote keyless entry receiver.

• BCM receives the key ID signal and compares it with the registered key ID.

• BCM locks/unlocks each door.

• BCM sounds Intelligent Key warning buzzer (lock: 2 ti mes, unlock: 1 time) and blinks hazard warning lamps

(lock: 2 times, unlock: 1 time) at the same time as a reminder.

OPERATION CONDITION

If the following conditions are satisfied, door lock/unl ock operation is performed if the door request switch (if

equipped) is operated.

*: Even with a registered Intelligent Key remaining inside the vehicle, door locks can be locked/unlocked from outside of the v ehicle with

a spare Intelligent Key as long as key IDs are different.

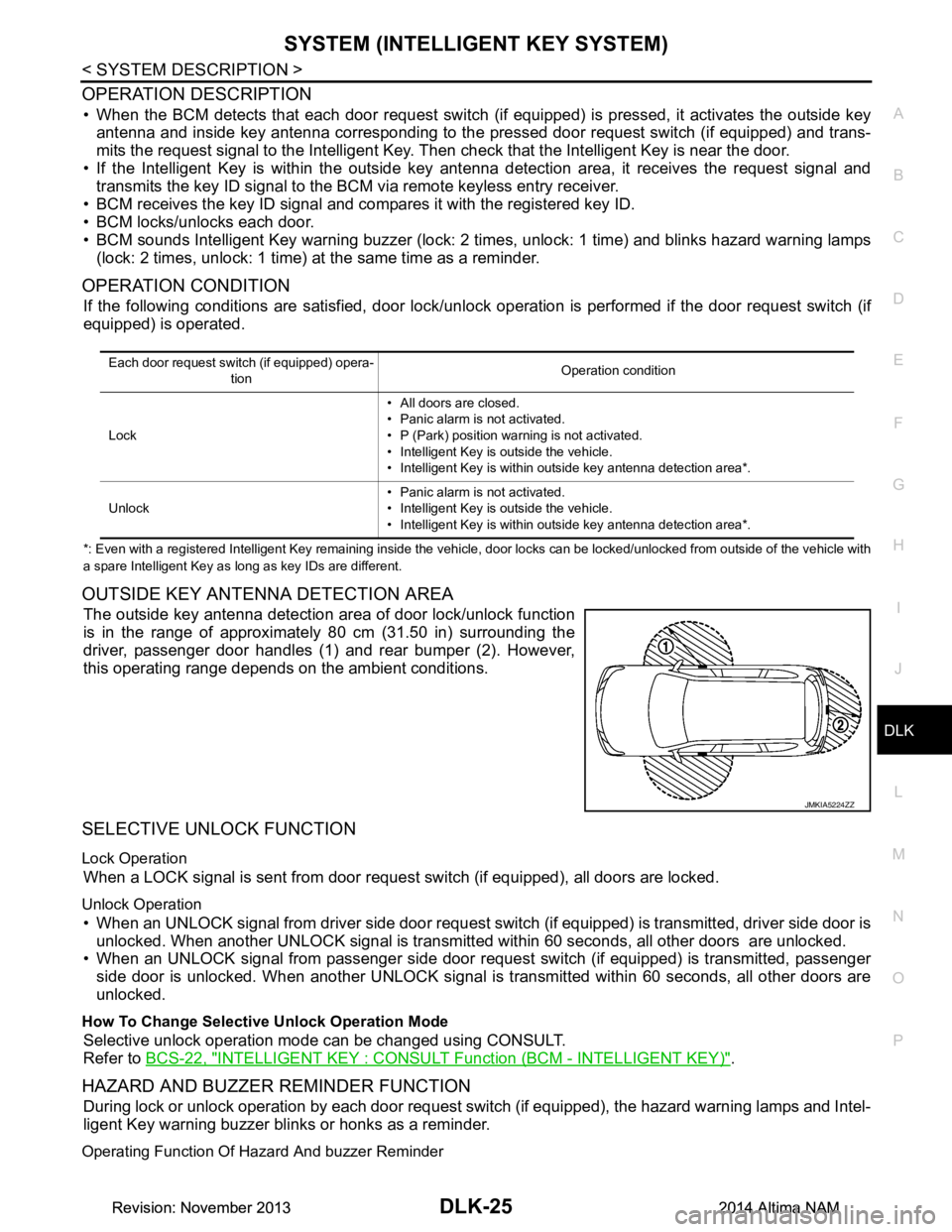

OUTSIDE KEY ANTENNA DETECTION AREA

The outside key antenna detection area of door lock/unlock function

is in the range of approximately 80 cm (31.50 in) surrounding the

driver, passenger door handles (1) and rear bumper (2). However,

this operating range depends on the ambient conditions.

SELECTIVE UNLOCK FUNCTION

Lock Operation

When a LOCK signal is sent from door r equest switch (if equipped), all doors are locked.

Unlock Operation

• When an UNLOCK signal from driver side door request swit ch (if equipped) is transmitted, driver side door is

unlocked. When another UNLOCK signal is transmitted within 60 seconds, all other doors are unlocked.

• When an UNLOCK signal from passenger side door reques t switch (if equipped) is transmitted, passenger

side door is unlocked. When another UNLOCK signal is transmitted within 60 seconds, all other doors are

unlocked.

How To Change Selective Unlock Operation Mode

Selective unlock operation mode can be changed using CONSULT.

Refer to BCS-22, "INTELLIGENT KEY : CONSUL T Function (BCM - INTELLIGENT KEY)"

.

HAZARD AND BUZZER REMINDER FUNCTION

During lock or unlock operation by each door request switch (if equipped), the hazard warning lamps and Intel-

ligent Key warning buzzer blinks or honks as a reminder.

Operating Function Of Hazard And buzzer Reminder

Each door request switch (if equipped) opera-

tion Operation condition

Lock • All doors are closed.

• Panic alarm is not activated.

• P (Park) position warning is not activated.

• Intelligent Key is outside the vehicle.

• Intelligent Key is within outside key antenna detection area*.

Unlock • Panic alarm is not activated.

• Intelligent Key is outside the vehicle.

• Intelligent Key is within outside key antenna detection area*.

JMKIA5224ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 805 of 4801

SYSTEM (INTELLIGENT KEY SYSTEM)DLK-37

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

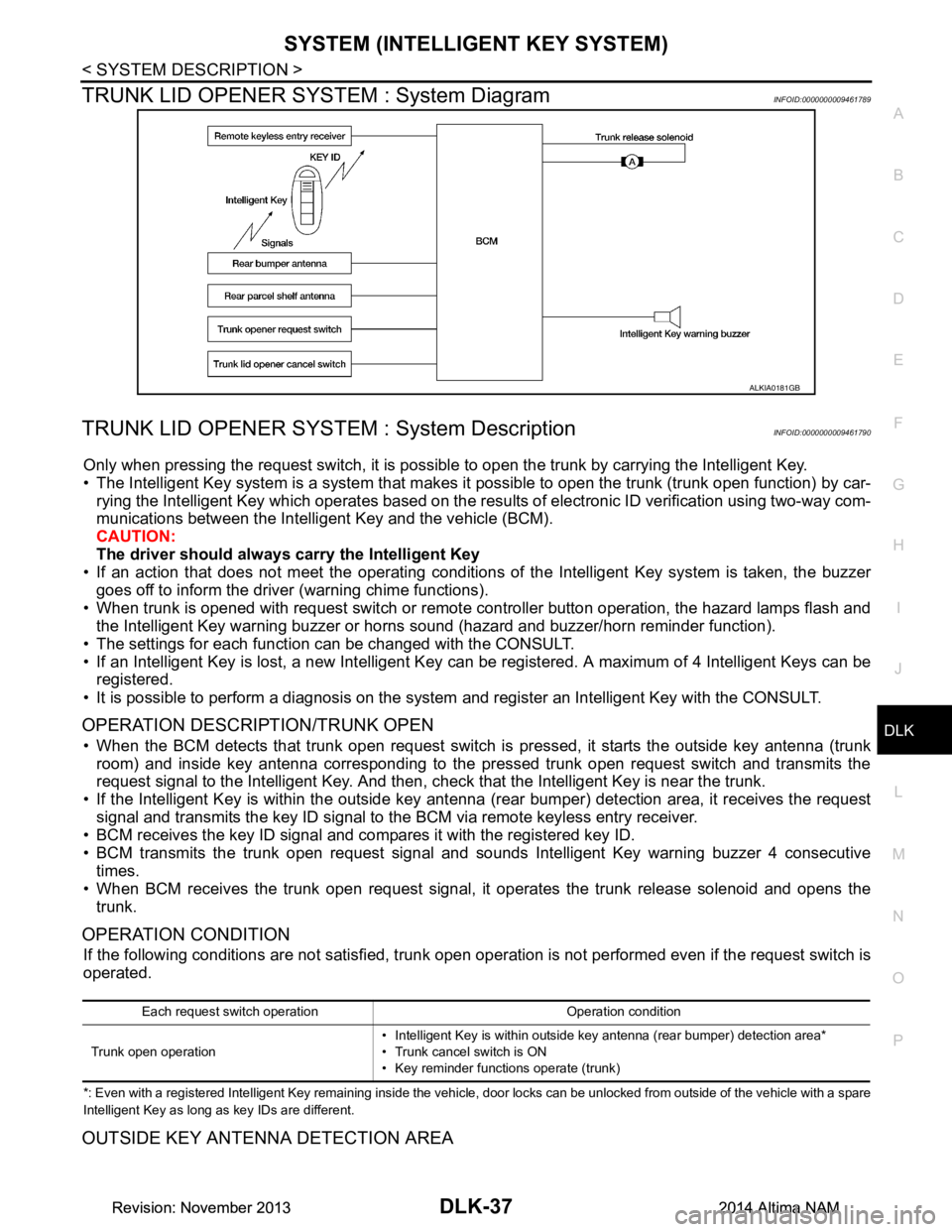

TRUNK LID OPENER SYSTEM : System DiagramINFOID:0000000009461789

TRUNK LID OPENER SYSTEM : System DescriptionINFOID:0000000009461790

Only when pressing the request switch, it is possibl e to open the trunk by carrying the Intelligent Key.

• The Intelligent Key system is a system that makes it possible to open the trunk (trunk open function) by car-

rying the Intelligent Key which operates based on the resu lts of electronic ID verification using two-way com-

munications between the Intelli gent Key and the vehicle (BCM).

CAUTION:

The driver should always carry the Intelligent Key

• If an action that does not meet the operating conditions of the Intelligent Key system is taken, the buzzer

goes off to inform the driver (warning chime functions).

• When trunk is opened with request switch or remote controller button operation, the hazard lamps flash and the Intelligent Key warning buzzer or horns sound (hazard and buzzer/horn reminder function).

• The settings for each functi on can be changed with the CONSULT.

• If an Intelligent Key is lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be registered.

• It is possible to perform a diagnosis on the system and register an Intelligent Key with the CONSULT.

OPERATION DESCRIPTION/TRUNK OPEN

• When the BCM detects that trunk open request switch is pressed, it starts the outside key antenna (trunk

room) and inside key antenna corresponding to the pressed trunk open request switch and transmits the

request signal to the Intelligent Key. And then, c heck that the Intelligent Key is near the trunk.

• If the Intelligent Key is within the outside key ant enna (rear bumper) detection area, it receives the request

signal and transmits the key ID signal to the BCM via remote keyless entry receiver.

• BCM receives the key ID signal and compares it with the registered key ID.

• BCM transmits the trunk open request signal and sounds Intelligent Key warning buzzer 4 consecutive

times.

• When BCM receives the trunk open request signal, it operates the trunk release solenoid and opens the trunk.

OPERATION CONDITION

If the following conditions are not satisfied, trunk open operation is not performed even if the request switch is

operated.

*: Even with a registered Intelligent Key remaining inside the vehicle, door locks can be unlocked from outside of the vehicle with a spare

Intelligent Key as long as key IDs are different.

OUTSIDE KEY ANTENNA DETECTION AREA

ALKIA0181GB

Each request switch operation Operation condition

Trunk open operation • Intelligent Key is within outside key antenna (rear bumper) detection area*

• Trunk cancel switch is ON

• Key reminder functions operate (trunk)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 932 of 4801

DLK-164

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

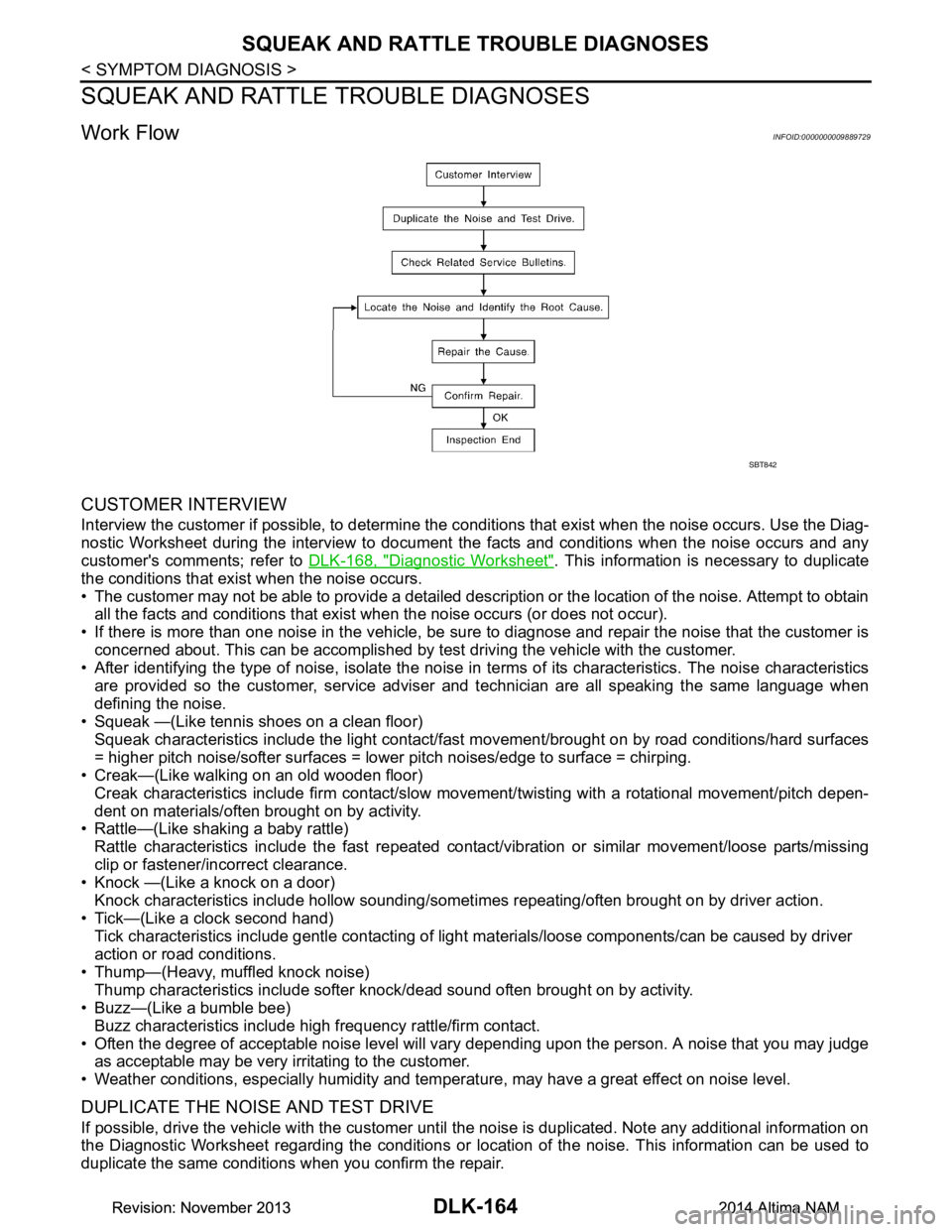

Work FlowINFOID:0000000009889729

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to DLK-168, "Diagnostic Worksheet"

. This information is necessary to duplicate

the conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1015 of 4801

![NISSAN TEANA 2014 User Guide

PRECAUTIONSEC-15

< PRECAUTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00 NISSAN TEANA 2014 User Guide

PRECAUTIONSEC-15

< PRECAUTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00](/img/5/57390/w960_57390-1014.png)

PRECAUTIONSEC-15

< PRECAUTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951805

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000009462048

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

On Board Diagnostic (OBD) S ystem of Engine and CVTINFOID:0000000009462049

The ECM has an on board diagnostic system . It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and di sconnect the negative battery cable before any repair

or inspection work. The open/short circuit of re lated switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to PG-65, "Description"

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

PIIB3706J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1026 of 4801

![NISSAN TEANA 2014 User Guide

EC-26

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

THROTTLE CONTROL MOTOR RELAY

Power supply for the throttle control motor is provided to

the ECM via throttle control motor relay. The throttle

co NISSAN TEANA 2014 User Guide

EC-26

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

THROTTLE CONTROL MOTOR RELAY

Power supply for the throttle control motor is provided to

the ECM via throttle control motor relay. The throttle

co](/img/5/57390/w960_57390-1025.png)

EC-26

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

THROTTLE CONTROL MOTOR RELAY

Power supply for the throttle control motor is provided to

the ECM via throttle control motor relay. The throttle

control motor relay is ON/OFF controlled by the ECM. When the ignition switch is turned ON, the ECM sends

an ON signal to throttle control motor relay and battery voltage is provided to the ECM. When the ignition

switch is turned OFF, the ECM sends an OFF signal to throttle control motor relay and battery voltage is not

provided to the ECM.

THROTTLE CONTROL MOTOR

The throttle control motor is operated by the ECM and it opens and closes the throttle valve.

The current opening angle of the throttle valve is detected by the throttle position sensor and it provides feed-

back to the ECM to control the throttle control mo tor to make the throttle valve opening angle properly in

response to driving condition.

THROTTLE POSITION SENSOR

The throttle position sensor responds to the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

Ignition Coil With Power TransistorINFOID:0000000009462057

The ignition signal from the ECM is sent to and amplified by the

power transistor. The power transistor turns ON and OFF the ignition

coil primary circuit. This ON/OFF operation induces the proper high

voltage in the coil secondary circuit.

Fuel InjectorINFOID:0000000009462058

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

Fuel Level Sensor Unit and Fuel PumpINFOID:0000000009462059

FUEL PUMP

PBIB0145E

JPBIA4613ZZ

JPBIA5845ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1032 of 4801

![NISSAN TEANA 2014 User Guide

EC-32

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Air Fuel Ratio (A/F) Sensor 1

INFOID:0000000009462072

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ion NISSAN TEANA 2014 User Guide

EC-32

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Air Fuel Ratio (A/F) Sensor 1

INFOID:0000000009462072

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ion](/img/5/57390/w960_57390-1031.png)

EC-32

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Air Fuel Ratio (A/F) Sensor 1

INFOID:0000000009462072

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the lean and rich range. Together with its

control electronics, the sensor outputs a cl ear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusi on layer at the sensor cell. An electrode layer is

applied voltage, and this current relati ve oxygen density in lean. Also this current relative hydrocarbon density

in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In additi on, a heater is integrated in the

sensor to ensure the required operating temperature of approxi-

mately 760 °C (1,400 °F).

A/F SENSOR 1 HEATER

A/F sensor 1 heater is integrated in the sensor.

The ECM performs ON/OFF duty control of the A/F sensor 1 heater corresponding to the engine operating

condition to keep the temperature of A/F s ensor 1 element within the specified range.

Heated Oxygen Sensor 2INFOID:0000000009462073

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated ox ygen sensor 2 is not used for

engine control operation.

HEATED OXYGEN SENSOR 2 HEATER

Heated oxygen sensor 2 heater is integrated in the sensor.

The ECM performs ON/OFF control of the heated oxy gen sensor 2 heater corresponding to the engine speed,

amount of intake air and engine coolant temperature.

JPBIA4038GB

JPBIA5446GB

SEF327R

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1034 of 4801

![NISSAN TEANA 2014 User Guide

EC-34

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Cooling FanINFOID:0000000009462077

The ECM controls th NISSAN TEANA 2014 User Guide

EC-34

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Cooling FanINFOID:0000000009462077

The ECM controls th](/img/5/57390/w960_57390-1033.png)

EC-34

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

*: These data are reference values and are measured between ECM terminals.

Cooling FanINFOID:0000000009462077

The ECM controls the cooling fan corresponding to the

vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 4-step control [HIGH/MIDDLE/LOW/OFF].

Cooling fan operates at each speed when the current flows in the cooling fan motor.

Refer to EC-59, "COOLING FAN CONTROL : System De scription (with automatic air conditioner)"

for cooling

fan operation.

EVAP CanisterINFOID:0000000009462078

EVAP canister stores the generat ed fuel vapors in the sealed fuel

tank to activated charcoals of EVAP canister when the engine is not

operating or when refueling to the fuel tank.

EVAP Canister Purge Volume Control Solenoid ValveINFOID:0000000009462079

The EVAP canister purge volume control solenoid valve uses a ON/

OFF duty to control the flow rate of fuel vapor from the EVAP canis-

ter. The EVAP canister purge volume control solenoid valve is

moved by ON/OFF pulses from the ECM. The longer the ON pulse,

the greater the amount of fuel vapor that will flow through the valve.

Engine oil temperature

[° C ( °F)] Vol tag e* (V)

Resistance (k

Ω)

–10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.37 - 2.63

50 (122) 2.2 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

110 (230) 0.6 0.143 - 0.153

SEF012P

JPBIA5851ZZ

JMBIA0069ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1035 of 4801

![NISSAN TEANA 2014 User Guide

COMPONENT PARTSEC-35

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

EVAP Canister Vent Control ValveINFOID:0000000009462080

The EVAP canister vent control valve is located on the EV NISSAN TEANA 2014 User Guide

COMPONENT PARTSEC-35

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

EVAP Canister Vent Control ValveINFOID:0000000009462080

The EVAP canister vent control valve is located on the EV](/img/5/57390/w960_57390-1034.png)

COMPONENT PARTSEC-35

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

EVAP Canister Vent Control ValveINFOID:0000000009462080

The EVAP canister vent control valve is located on the EVAP canis-

ter and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows “EVAP

Control System” diagnosis.

EVAP Control System Pressure SensorINFOID:0000000009462081

The EVAP control system pressure sensor detects pressure in the

purge line. The sensor output voltage to the ECM increases as pres-

sure increases.

Battery Current Sensor (With Battery Temperature Sensor)INFOID:0000000009462082

OUTLINE

The power generation voltage variable control enables fuel con-

sumption to be decreased by reducing the engine load which is

caused by the power generation of the generator.

Based on sensor signals, ECM judges whether or not the power

generation voltage variable contro l is performed. When performing

the power generation voltage variable control, ECM calculates the

target power generation voltage based on the sensor signal. And

ECM sends the calculated value as the power generation command

value to IPDM E/R. For the details of the power generation voltage

variable control, refer to CHG-10, "System Description"

.

CAUTION:

Never connect the electrical co mponent or the ground wire

directly to the battery terminal. The connection cau ses the malfunction of the power generation volt-

age variable control, and then the battery discharge may occur.

BATTERY CURRENT SENSOR

The battery current sensor is installed to the battery negative cable. The sensor measures the charging/dis-

charging current of the battery.

BATTERY TEMPERATURE SENSOR

PBIB1263E

PBIB3370E

JPBIA3262ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1059 of 4801

![NISSAN TEANA 2014 User Guide

SYSTEMEC-59

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN CONTROL : System Descripti

on (with automatic air conditioner)

INFOID:0000000009462104

SYSTEM DIAGRAM

SYSTEM NISSAN TEANA 2014 User Guide

SYSTEMEC-59

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN CONTROL : System Descripti

on (with automatic air conditioner)

INFOID:0000000009462104

SYSTEM DIAGRAM

SYSTEM](/img/5/57390/w960_57390-1058.png)

SYSTEMEC-59

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN CONTROL : System Descripti

on (with automatic air conditioner)

INFOID:0000000009462104

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

ECM controls cooling fan speed corresponding to vehicle speed, engine coolant temperature, refrigerant pres-

sure, air conditioner ON signal. Then control syst em has 4-step control [HIGH/MIDDLE/LOW/OFF].

Cooling Fan Operation

Cooling Fan Relay Operation

The ECM controls cooling fan relays through CAN communication line.

JPBIA3233GB

JMBIA0179GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM