Side mirror NISSAN TEANA 2014 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2165 of 4801

![NISSAN TEANA 2014 Owners Manual

FUEL INJECTOR AND FUEL TUBEEM-167

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

b. Thinly apply new engine oil around fuel tube from tip end to spool end.

c. Align center to NISSAN TEANA 2014 Owners Manual

FUEL INJECTOR AND FUEL TUBEEM-167

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

b. Thinly apply new engine oil around fuel tube from tip end to spool end.

c. Align center to](/img/5/57390/w960_57390-2164.png)

FUEL INJECTOR AND FUEL TUBEEM-167

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

b. Thinly apply new engine oil around fuel tube from tip end to spool end.

c. Align center to insert quick connector straightly into fuel tube. • Insert quick connector (1) to fuel tube until top spool (2) is

completely inside quick connector, and 2nd level spool (3)

exposes right below quick connector.

CAUTION:

• Do not reuse O-ring.

• Hold (A) position as shown when inserting fuel tube into quick connector.

• Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

• Insert until you hear a “click” sound and actually feel the engagement.

• To avoid misidentification of enga gement with a similar sound, be sure to perform the next step.

d. Pull quick connector by hand holding position. Check it is completely engaged (connected) so that it does

not come out from fuel tube.

e. Install quick connector cap (3) to quick connector.

• Install quick connector cap with arrow (A) on surface facing indirection of quick connector (fuel feed hose side).

CAUTION:

If quick connector cap cannot be installed smoothly, quick

connector may have not been installed correctly. Check

connection again.

f. Secure fuel feed hose to clamp of quick connector cap.

8. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections as follows:

1. Apply fuel pressure to fuel lines by turning i gnition switch ON (with engine stopped). Then check for fuel

leaks at connections.

2. Start the engine and rev it up and check for fuel leaks at connections. WARNING:

Do not touch engine immediately after stopping as engine is extremely hot.

NOTE:

Use mirrors for checking on connections out of the direct line of sight.

• Perform procedures for “Throttle Valve Closed Position Learning” after finishing repairs. Refer to EC-

682, "Work Procedure".

• If electric throttle control actuator is replaced, perform procedures for “Idle Air Volume Learning” after

finishing repairs. Refer to EC-683, "Work Procedure"

.

(B) : Installed condition

: Upright insertion

(1) : Fuel feed hose

(2) : Fuel tube

(B) : Upper view

JPBIA0275ZZ

JPBIA0039ZZ

Revision: November 20132014 Altima NAM

Page 2269 of 4801

EXL-3

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

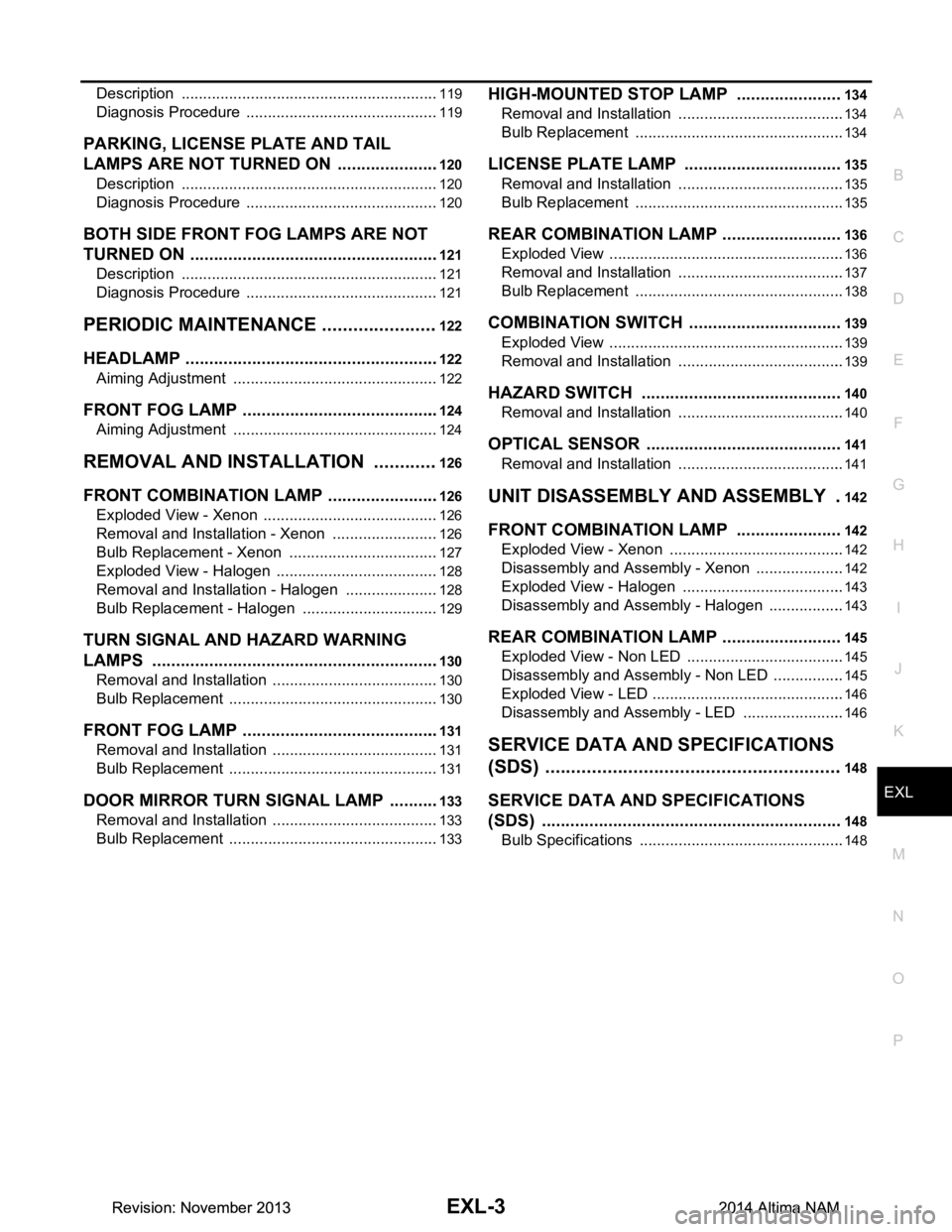

Description ..........................................................

..

119

Diagnosis Procedure .............................................119

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON .................... ..

120

Description .......................................................... ..120

Diagnosis Procedure .............................................120

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ................................................... ..

121

Description .......................................................... ..121

Diagnosis Procedure .............................................121

PERIODIC MAINTENANCE .......................122

HEADLAMP .................................................... ..122

Aiming Adjustment .............................................. ..122

FRONT FOG LAMP ..........................................124

Aiming Adjustment .............................................. ..124

REMOVAL AND INSTALLATION .............126

FRONT COMBINATION LAMP ...................... ..126

Exploded View - Xenon ....................................... ..126

Removal and Installation - Xenon .........................126

Bulb Replacement - Xenon ...................................127

Exploded View - Halogen ......................................128

Removal and Installation - Halogen ......................128

Bulb Replacement - Halo gen ................................129

TURN SIGNAL AND HAZARD WARNING

LAMPS ........................................................... ..

130

Removal and Installation .......................................130

Bulb Replacement ........ .........................................130

FRONT FOG LAMP ........................................ ..131

Removal and Installation .......................................131

Bulb Replacement ........ .........................................131

DOOR MIRROR TURN SIGNAL LAMP ......... ..133

Removal and Installation .......................................133

Bulb Replacement ........ .........................................133

HIGH-MOUNTED STOP LAMP ......................134

Removal and Installation ..................................... ..134

Bulb Replacement .................................................134

LICENSE PLATE LAMP .................................135

Removal and Installation .......................................135

Bulb Replacement .................................................135

REAR COMBINATION LAMP .........................136

Exploded View .......................................................136

Removal and Installation .......................................137

Bulb Replacement .................................................138

COMBINATION SWITCH ................................139

Exploded View .......................................................139

Removal and Installation .......................................139

HAZARD SWITCH ..........................................140

Removal and Installation .......................................140

OPTICAL SENSOR .........................................141

Removal and Installation .......................................141

UNIT DISASSEMBLY AND ASSEMBLY ..142

FRONT COMBINATION LAMP ......................142

Exploded View - Xenon ....................................... ..142

Disassembly and Assembly - Xenon .....................142

Exploded View - Halogen ......................................143

Disassembly and Assembly - Halogen ..................143

REAR COMBINATION LAMP .........................145

Exploded View - Non LED .....................................145

Disassembly and Assembly - Non LED .................145

Exploded View - LED .............................................146

Disassembly and Assembly - LED ........................146

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

148

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

148

Bulb Specifications .............................................. ..148

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2381 of 4801

EXTERIOR LIGHTING SYSTEM SYMPTOMSEXL-115

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

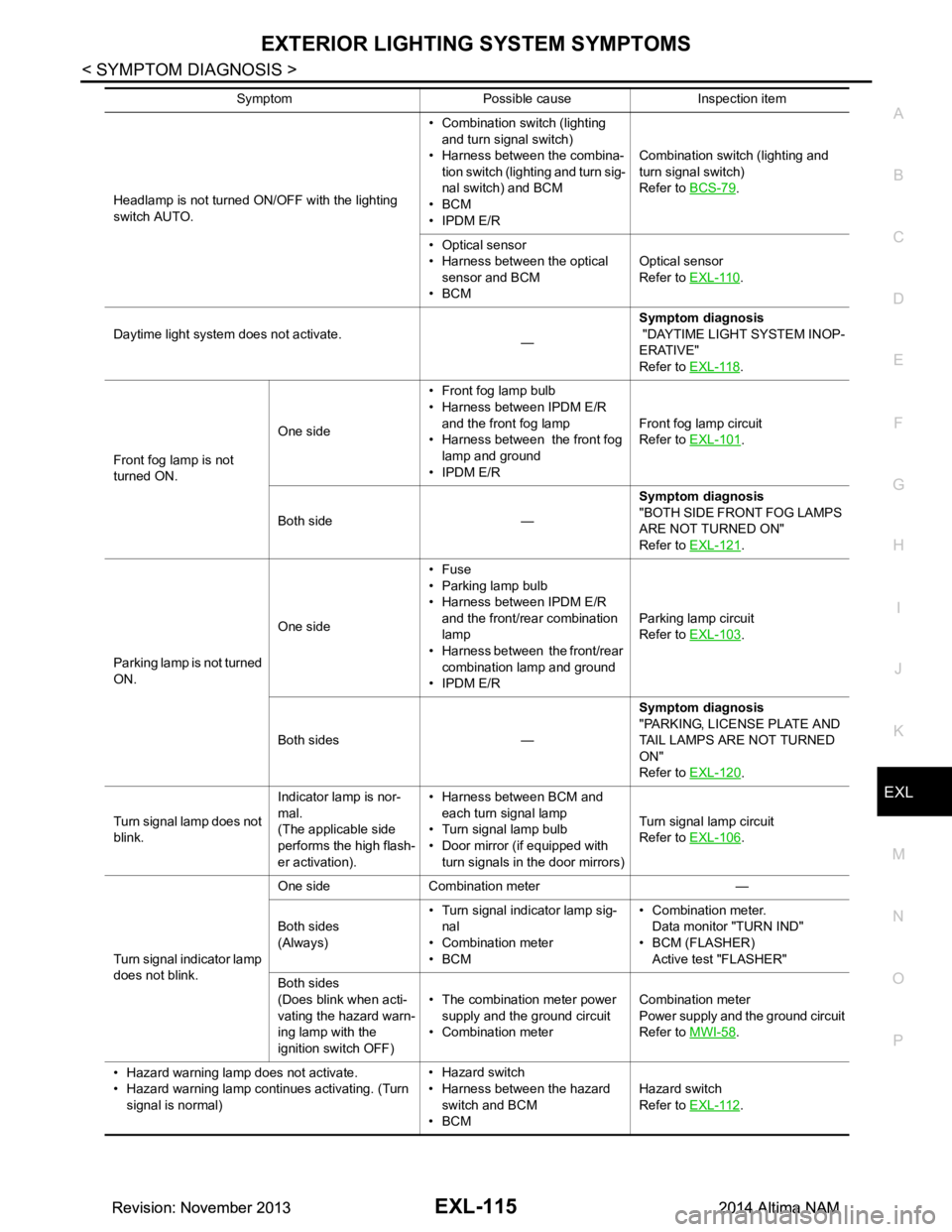

Headlamp is not turned ON/OFF with the lighting

switch AUTO. • Combination switch (lighting

and turn signal switch)

• Harness between the combina- tion switch (lighting and turn sig-

nal switch) and BCM

•BCM

• IPDM E/R Combination switch (lighting and

turn signal switch)

Refer to BCS-79.

• Optical sensor

• Harness between the optical

sensor and BCM

•BCM Optical sensor

Refer to EXL-110

.

Daytime light system does not activate. —Symptom diagnosis

"DAYTIME LIGHT SYSTEM INOP-

ERATIVE"

Refer to EXL-118

.

Front fog lamp is not

turned ON. One side

• Front fog lamp bulb

• Harness between IPDM E/R

and the front fog lamp

• Harness between the front fog lamp and ground

• IPDM E/R Front fog lamp circuit

Refer to EXL-101

.

Both side — Symptom diagnosis

"BOTH SIDE FRONT FOG LAMPS

ARE NOT TURNED ON"

Refer to EXL-121

.

Parking lamp is not turned

ON. One side•Fuse

• Parking lamp bulb

• Harness between IPDM E/R

and the front/rear combination

lamp

• Harness between the front/rear

combination lamp and ground

• IPDM E/R Parking lamp circuit

Refer to EXL-103

.

Both sides — Symptom diagnosis

"PARKING, LICENSE PLATE AND

TAIL LAMPS ARE NOT TURNED

ON"

Refer to EXL-120

.

Turn signal lamp does not

blink. Indicator lamp is nor-

mal.

(The applicable side

performs the high flash-

er activation). • Harness between BCM and

each turn signal lamp

• Turn signal lamp bulb

• Door mirror (if equipped with

turn signals in the door mirrors) Turn signal lamp circuit

Refer to EXL-106

.

Turn signal indicator lamp

does not blink. One side Combination meter —

Both sides

(Always) • Turn signal indicator lamp sig-

nal

• Combination meter

•BCM • Combination meter.

Data monitor "TURN IND"

• BCM (FLASHER) Active test "FLASHER"

Both sides

(Does blink when acti-

vating the hazard warn-

ing lamp with the

ignition switch OFF) • The combination meter power

supply and the ground circuit

• Combination meter Combination meter

Power supply and the ground circuit

Refer to MWI-58

.

• Hazard warning lamp does not activate.

• Hazard warning lamp continues activating. (Turn signal is normal) • Hazard switch

• Harness between the hazard switch and BCM

•BCM Hazard switch

Refer to EXL-112

.

Symptom Possible cause Inspection item

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2399 of 4801

DOOR MIRROR TURN SIGNAL LAMPEXL-133

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

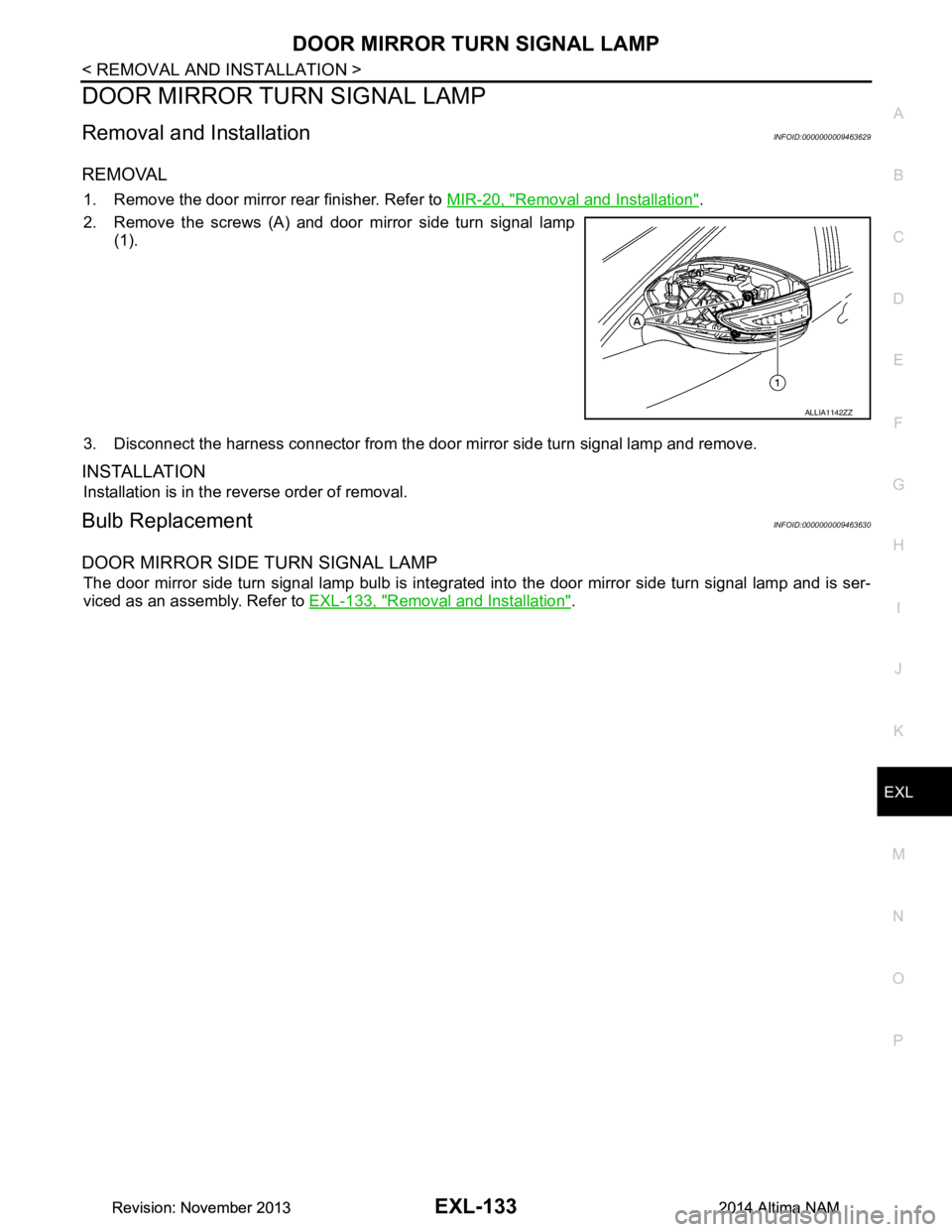

DOOR MIRROR TURN SIGNAL LAMP

Removal and InstallationINFOID:0000000009463629

REMOVAL

1. Remove the door mirror rear finisher. Refer to MIR-20, "Removal and Installation".

2. Remove the screws (A) and door mirror side turn signal lamp (1).

3. Disconnect the harness connector from the door mirror side turn signal lamp and remove.

INSTALLATION

Installation is in the reverse order of removal.

Bulb ReplacementINFOID:0000000009463630

DOOR MIRROR SIDE TURN SIGNAL LAMP

The door mirror side turn signal lamp bulb is integrated into the door mirror side turn signal lamp and is ser-

viced as an assembly. Refer to EXL-133, "Removal and Installation"

.

ALLIA1142ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2414 of 4801

EXL-148

< SERVICE DATA AND SPECIFICATIONS (SDS)

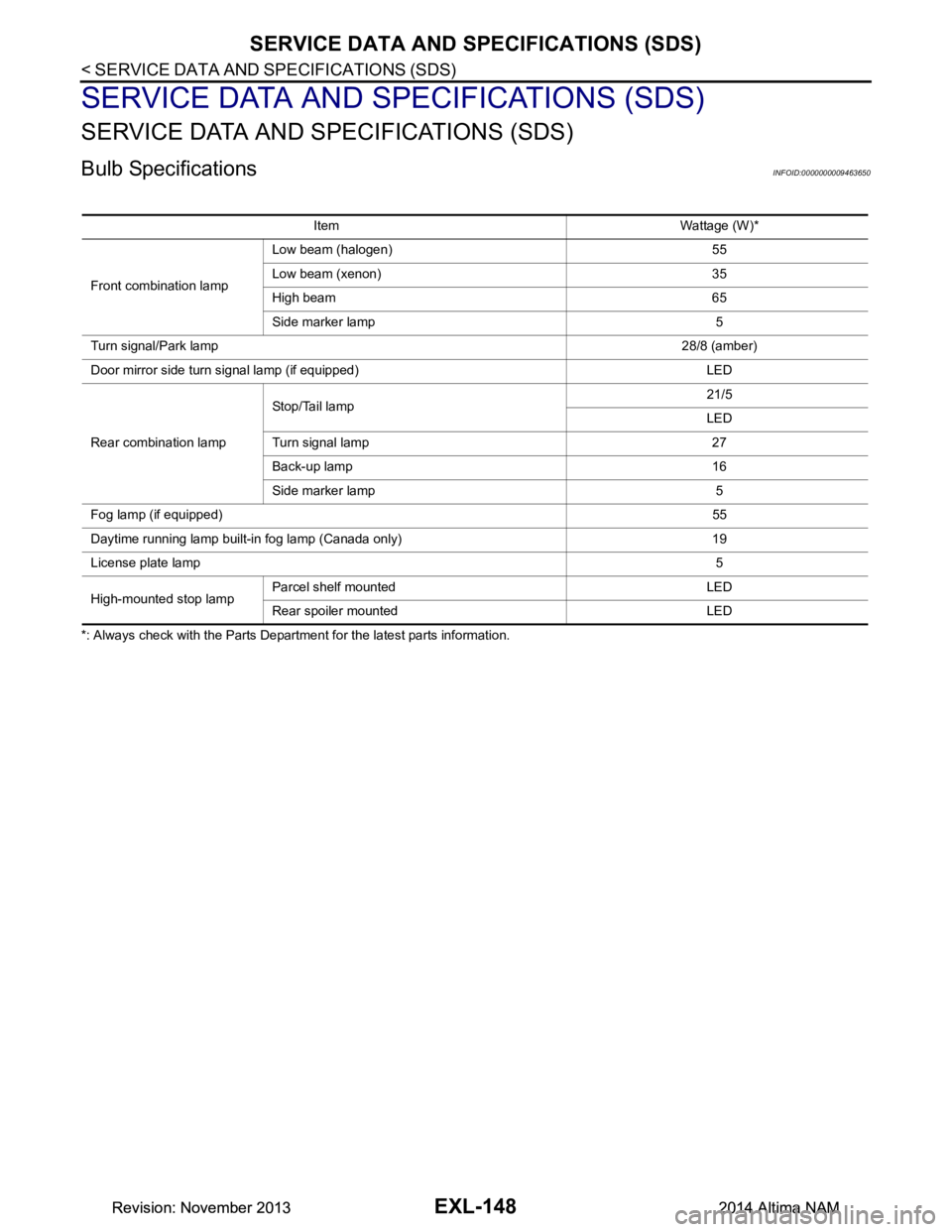

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Bulb SpecificationsINFOID:0000000009463650

*: Always check with the Parts Department for the latest parts information.Item Wattage (W)*

Front combination lamp Low beam (halogen) 55

Low beam (xenon) 35

High beam 65

Side marker lamp 5

Turn signal/Park lamp 28/8 (amber)

Door mirror side turn signal lamp (if equipped) LED

Rear combination lamp St op /Ta il la mp

21/5

LED

Turn signal lamp 27

Back-up lamp 16

Side marker lamp 5

Fog lamp (if equipped) 55

Daytime running lamp built-in fog lamp (Canada only) 19

License plate lamp 5

High-mounted stop lamp Parcel shelf mounted LED

Rear spoiler mounted LED

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2445 of 4801

DOOR SASH MOLDINGEXT-31

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

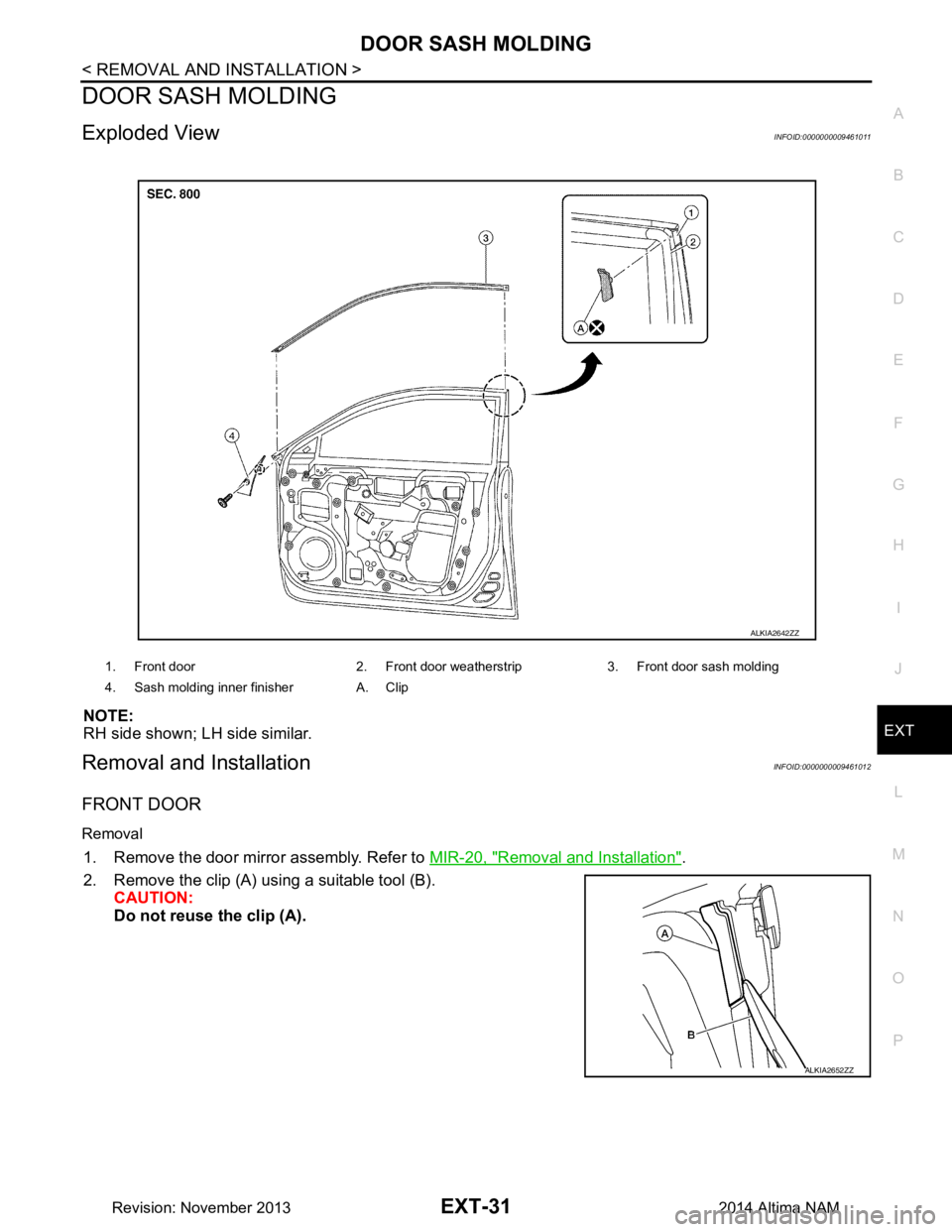

DOOR SASH MOLDING

Exploded ViewINFOID:0000000009461011

NOTE:

RH side shown; LH side similar.

Removal and Installation INFOID:0000000009461012

FRONT DOOR

Removal

1. Remove the door mirror assembly. Refer to MIR-20, "Removal and Installation".

2. Remove the clip (A) using a suitable tool (B). CAUTION:

Do not reuse the clip (A).

1. Front door 2. Front door weatherstrip 3. Front door sash molding

4. Sash molding inner finisher A. Clip

ALKIA2642ZZ

ALKIA2652ZZ

Revision: November 20132014 Altima NAM

Page 2449 of 4801

DOOR OUTSIDE MOLDINGEXT-35

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

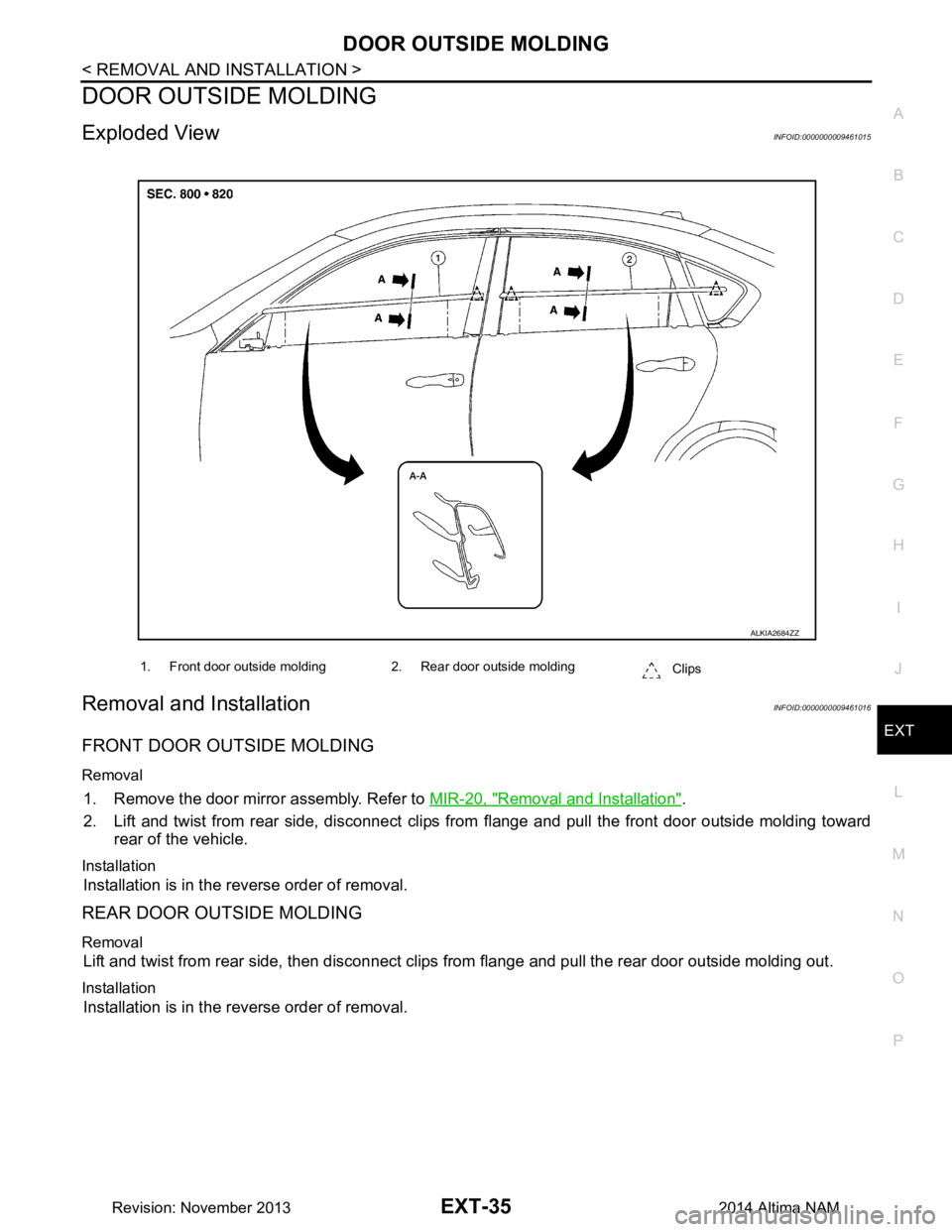

DOOR OUTSIDE MOLDING

Exploded ViewINFOID:0000000009461015

Removal and InstallationINFOID:0000000009461016

FRONT DOOR OUTSIDE MOLDING

Removal

1. Remove the door mirror assembly. Refer to MIR-20, "Removal and Installation".

2. Lift and twist from rear side, disconnect clips fr om flange and pull the front door outside molding toward

rear of the vehicle.

Installation

Installation is in the reverse order of removal.

REAR DOOR OUTSIDE MOLDING

Removal

Lift and twist from rear side, then disconnect clips from flange and pull the rear door outside molding out.

Installation

Installation is in the reverse order of removal.

1. Front door outside molding 2. Rear door outside molding

Clips

ALKIA2684ZZ

Revision: November 20132014 Altima NAM

Page 2591 of 4801

WINDSHIELD GLASSGW-11

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

GW

N

O P

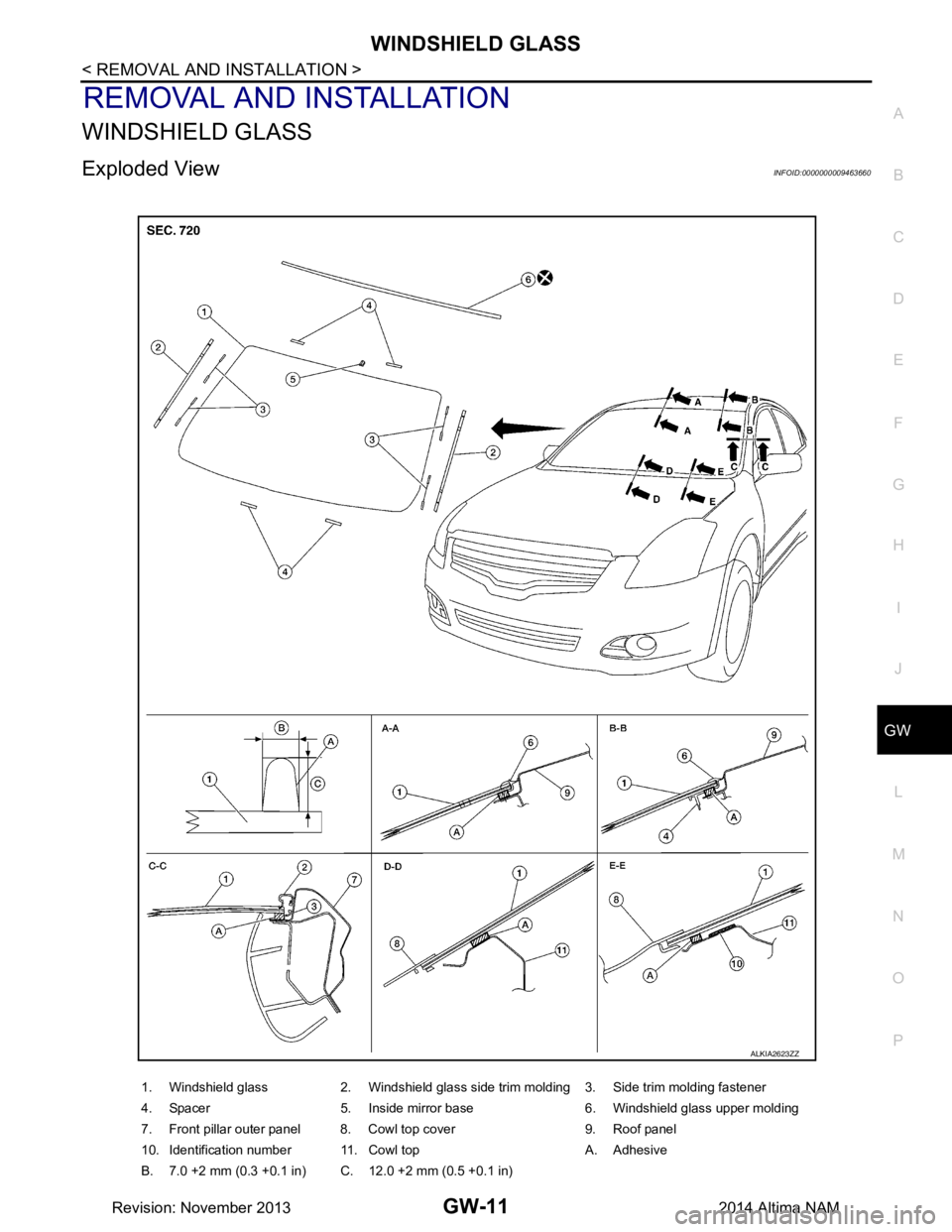

REMOVAL AND INSTALLATION

WINDSHIELD GLASS

Exploded ViewINFOID:0000000009463660

1. Windshield glass 2. Windshield glass side trim molding 3. Side trim molding fastener

4. Spacer 5. Inside mirror base 6. Windshield glass upper molding

7. Front pillar outer panel 8. Cowl top cover 9. Roof panel

10. Identification number 11. Cowl top A. Adhesive

B. 7.0 +2 mm (0.3 +0.1 in) C. 12.0 +2 mm (0.5 +0.1 in)

ALKIA2623ZZ

Revision: November 20132014 Altima NAM

Page 2592 of 4801

GW-12

< REMOVAL AND INSTALLATION >

WINDSHIELD GLASS

Removal and Installation

INFOID:0000000009463661

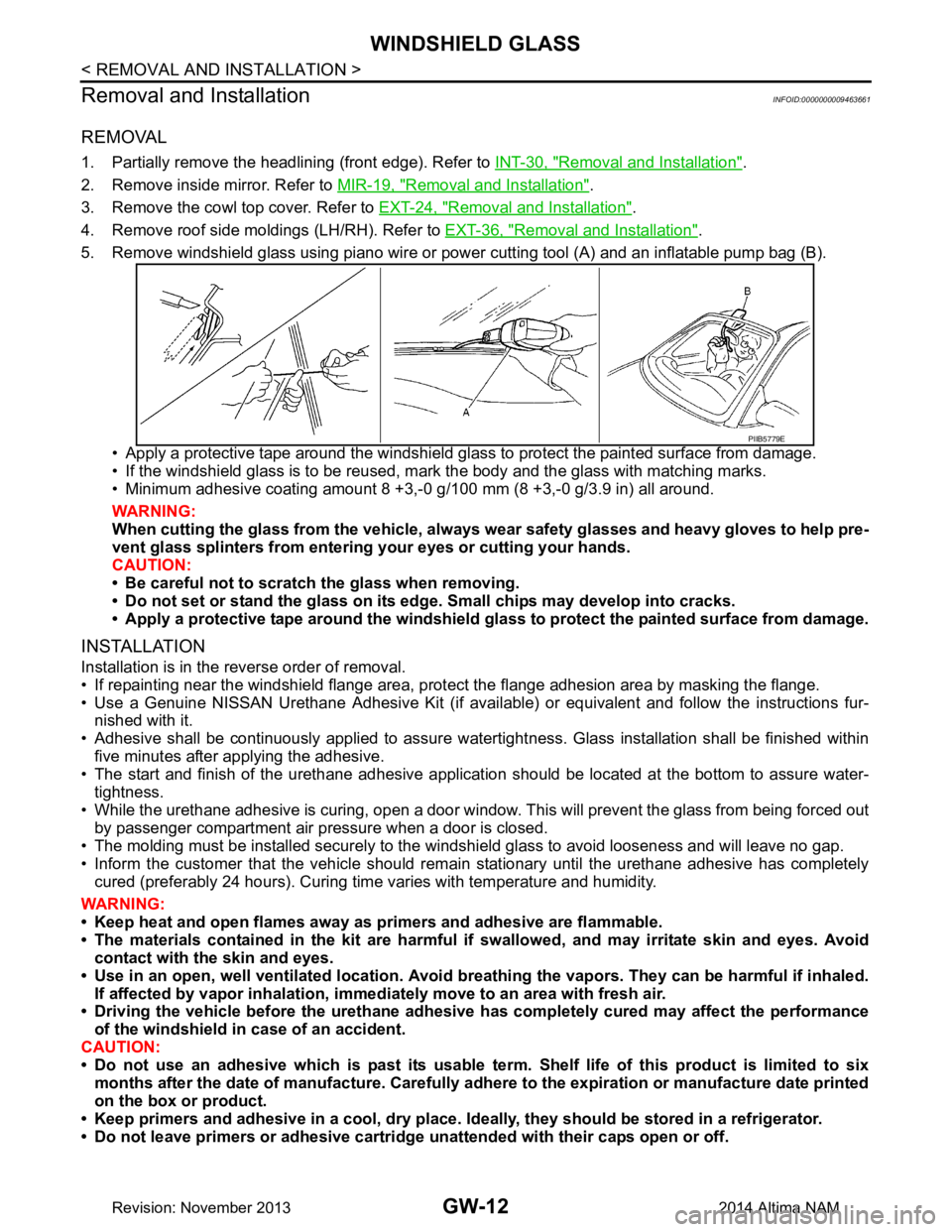

REMOVAL

1. Partially remove the headlining (front edge). Refer to INT-30, "Removal and Installation".

2. Remove inside mirror. Refer to MIR-19, "Removal and Installation"

.

3. Remove the cowl top cover. Refer to EXT-24, "Removal and Installation"

.

4. Remove roof side moldings (LH/RH). Refer to EXT-36, "Removal and Installation"

.

5. Remove windshield glass using piano wire or pow er cutting tool (A) and an inflatable pump bag (B).

• Apply a protective tape around the windshield gla ss to protect the painted surface from damage.

• If the windshield glass is to be reused, mark the body and the glass with matching marks.

• Minimum adhesive coating amount 8 +3,- 0 g/100 mm (8 +3,-0 g/3.9 in) all around.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help pre-

vent glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

• Apply a protective tape around the windshield glass to protect the painted surface from damage.

INSTALLATION

Installation is in the reverse order of removal.

• If repainting near the windshield flange area, pr otect the flange adhesion area by masking the flange.

• Use a Genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• The start and finish of the urethane adhesive application should be located at the bottom to assure water-

tightness.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely to the windshield glass to avoid looseness and will leave no gap.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid br eathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully a dhere to the expiration or manufacture date printed

on the box or product.

• Keep primers and adhesive in a c ool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

PIIB5779E

Revision: November 20132014 Altima NAM

Page 2628 of 4801

HA-22

< PERIODIC MAINTENANCE >

REFRIGERANT

4. Press UV lamp switch (5) and check A/C system for refrigerant leakage. (Where refrigerant leakage

occurs, fluorescent leak detec tion dye appears in green color.)

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, follow the manufacturer operating instructions.

• Illuminate piping joints from different angles using UV lamp and check that there is no leakage.

• Use a mirror in area that is difficult to see to check refrigerant leakage.

• Refrigerant leakage from evaporator can be detected by soaking cotton swab or a similar material with

drain hose water and illuminating it using UV lamp.

• Dust, dirt and packing materials adhesive used for condenser, evaporator, and other locations may fluo- resce. Be careful not to misidentify leakage.

5. Repair or replace parts where refrigerant leakage occurs and wipe off fluorescent leak detection dye. NOTE:

Completely wipe off fluorescent leak detection dy e from gaps between parts, screw threads, and others

using a cotton swab or similar materials.

6. Use a UV lamp to check that no fluorescent leak detection dye remains after finishing work.

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, follow the manufacturer operating instructions.

• Dust, dirt, and packing materials adhesive used for condenser, evaporator, and other locations may flu-

oresce. Be careful not to misidentify leakage.

CHECK REFRIGERANT LEAKAGE USING ELECTRICAL LEAK DETECTOR

WARNING:

Do not check refrigerant leakage while the engine is running.

CAUTION:

Be careful of the following it ems so that inaccurate checks or misidentifications are avoided.

• Do not allow refrigerant vapor, shop chemical vapor s, cigarette smoke or others around the vehicle.

• Always check refrigerant leakage in a low air flow en vironment so that refrigerant may not disperse

when leakage occurs.

1. Stop the engine.

2. Connect recovery/recycling/recharging equipment or manifold gauge set (J-39183-C) to A/C service

valve.

3. Check that A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or more when temperature is 16 °C

(61 °F) or more. When pressure is lower than the specif ied value, recycle refrigerant completely and fill

refrigerant to the specified level.

NOTE:

Leakages may not be detected if A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or less when

temperature is less than 16 °C (61 °F).

4. Clean area where refrigerant leakage check is performed and check refrigerant leakage along all surfaces of pipe connections and A/C system components us ing electrical leak detector (J-41995) probe.

CAUTION:

• Continue checking when a leakag e is found. Always continue and complete checking along all

pipe connections and A/C system components for additional leakage.

• When a leakage is detected, clean leakage area using compressed air and check again.

• When checking leakage of cooling unit inside, always clean inside of drain hose so that the

probe surface may not be exposed to water or dirt.

NOTE:

• Always check leakage starting from high-pressure side and continue to low-pressure side.

• When checking leakage of cooling unit inside, operate bl ower fan motor for 15 minutes or more at the

maximum fan speed while the engine is stopped, and then in sert electrical leak detector probe into drain

hose and hold for 10 minutes or more.

• When disconnecting shut-off valve that is connected to A/C service valve, always evacuate remaining

refrigerant so that misidentification can be avoided.

5. Repair or replace parts where refrigerant leak age is detected. (Leakage is detected but leakage area is

unknown.)

Revision: November 20132014 Altima NAM