engine NISSAN TEANA 2014 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 65 of 4801

![NISSAN TEANA 2014 Owners Manual

BCS-50

< ECU DIAGNOSIS INFORMATION >[BCM]

BCM (BODY CONTROL MODULE)

Fail Safe

INFOID:0000000009462017

DTC Inspection Priority ChartINFOID:0000000009462018

If some DTCs are displayed at the same time, NISSAN TEANA 2014 Owners Manual

BCS-50

< ECU DIAGNOSIS INFORMATION >[BCM]

BCM (BODY CONTROL MODULE)

Fail Safe

INFOID:0000000009462017

DTC Inspection Priority ChartINFOID:0000000009462018

If some DTCs are displayed at the same time,](/img/5/57390/w960_57390-64.png)

BCS-50

< ECU DIAGNOSIS INFORMATION >[BCM]

BCM (BODY CONTROL MODULE)

Fail Safe

INFOID:0000000009462017

DTC Inspection Priority ChartINFOID:0000000009462018

If some DTCs are displayed at the same time, perfo rm inspections one by one based on the following priority

chart.

137

(V) Ground Driver and fuel door

unlock Output Front door LH UNLOCK (actuator is acti-

vated) Battery voltage

Other than UNLOCK (actu-

ator is not activated) 0V

138 (V) Ground Rear door battery Input Push-button ignition switch OFF Battery voltage

139 (W) Ground Fusible link battery

power Input Push-button ignition switch OFF Battery voltage

140

(LG) Ground

Power window igni-

tion power supply Output Push-button ignition switch ON Battery voltage

141 (V) Ground Power window bat-

tery power supply Output Push-button ignition switch OFF Battery voltage

142

(BR) Ground Front door battery Input Push-button ignition switch OFF Battery voltage

143 (B) Ground Ground 1 — Push-button ignition switch ON 0V

Te r m i n a l N o .

(Wire color) Description

Condition Va l u e

(Approx.)

Signal name Input/

Output

(+) (-)

Display contents of CONS ULT Fail-safe Cancellation

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2195: ANTI-SCANNING Inhibit engine cranking Ignition switch ON → OFF

B2560: STARTER CONT RELAY Inhibit engine cranking 500 ms after the following CAN signal communication status has

become consistent

• Starter control relay signal

• Starter relay status signal

B2562: LO VOLTAGE Inhibit engine cranking 100 ms after the power supply voltage increases to more than 8.8 V

B2608: STARTER RELAY Inhibit engine cranking 500 ms after the following signal communication status becomes

consistent

• Starter motor re lay control signal

• Starter relay status signal (CAN)

B260A: IGNITION RELAY Inhibit engine cranking 500 ms after the following conditions are fulfilled

• IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

• Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

• Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B2617: STARTER RELAY CIRC Inhibit engine cranking 1 second after the starter motor

relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking 1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 99 of 4801

PRECAUTIONSBR-3

< PRECAUTION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951709

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000009463677

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000009463678

WARNING:

Clean any dust from the front brake and rear brake wi th a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

• Brake fluid use. Refer to MA-11, "FOR USA AND CANADA : Fluids and Lubricants"

.

• Do not reuse drained brake fluid.

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Always clean with new brake fluid when cleaning th e master cylinder, brake caliper and other com-

ponents.

• Do not use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

• Always loosen the brake tube flar e nut with a flare nut wrench.

PIIB3706J

Revision: November 20132014 Altima NAM

Page 104 of 4801

BR-8

< BASIC INSPECTION >

BRAKE FLUID

BRAKE FLUID

InspectionINFOID:0000000009463683

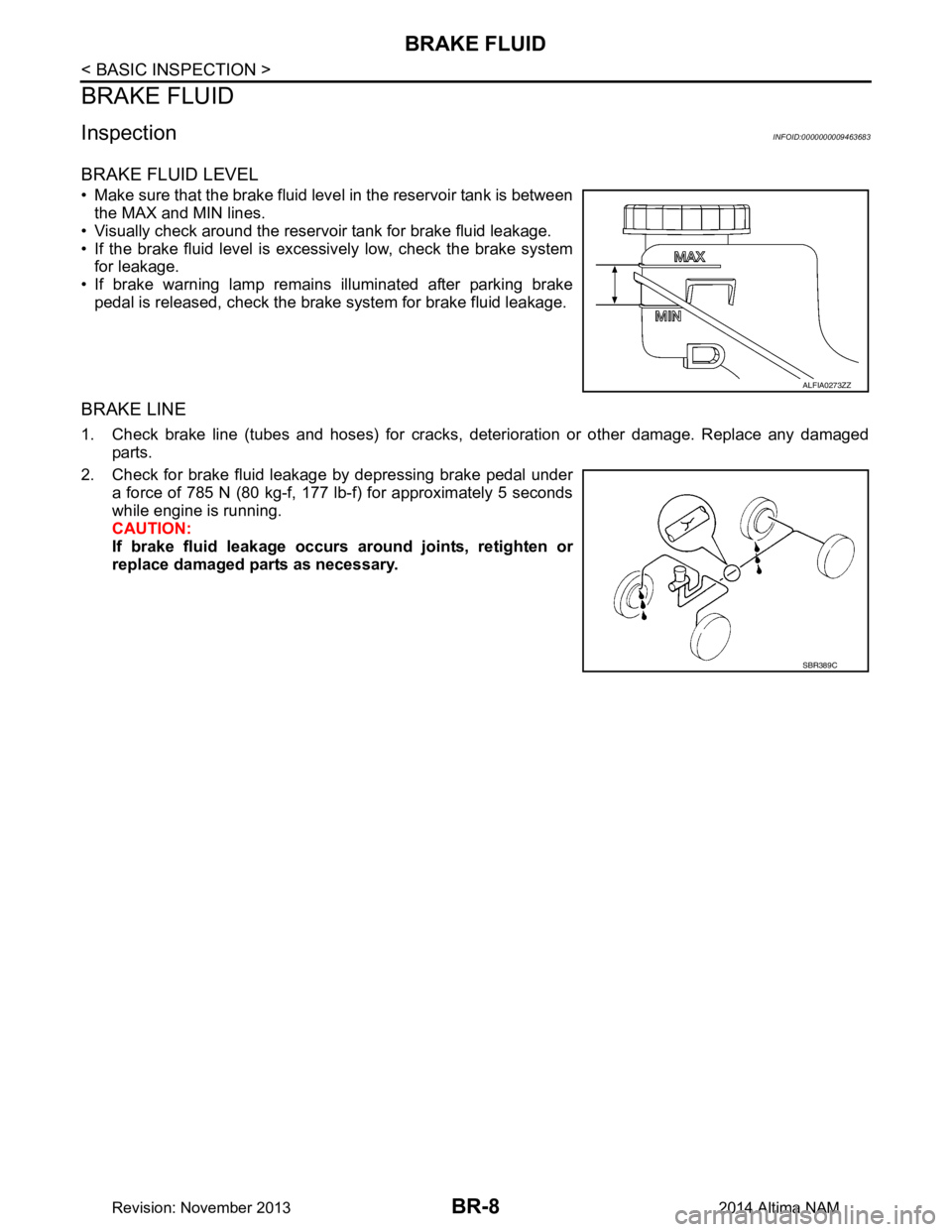

BRAKE FLUID LEVEL

• Make sure that the brake fluid level in the reservoir tank is betweenthe MAX and MIN lines.

• Visually check around the reservoir tank for brake fluid leakage.

• If the brake fluid level is excessively low, check the brake system for leakage.

• If brake warning lamp remains illuminated after parking brake pedal is released, check the brake system for brake fluid leakage.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for brake fluid leakage by depressing brake pedal under a force of 785 N (80 kg-f, 177 lb-f) for approximately 5 seconds

while engine is running.

CAUTION:

If brake fluid leakage occurs around joints, retighten or

replace damaged parts as necessary.

ALFIA0273ZZ

SBR389C

Revision: November 20132014 Altima NAM

Page 106 of 4801

BR-10

< BASIC INSPECTION >

BRAKE BOOSTER

BRAKE BOOSTER

InspectionINFOID:0000000009463686

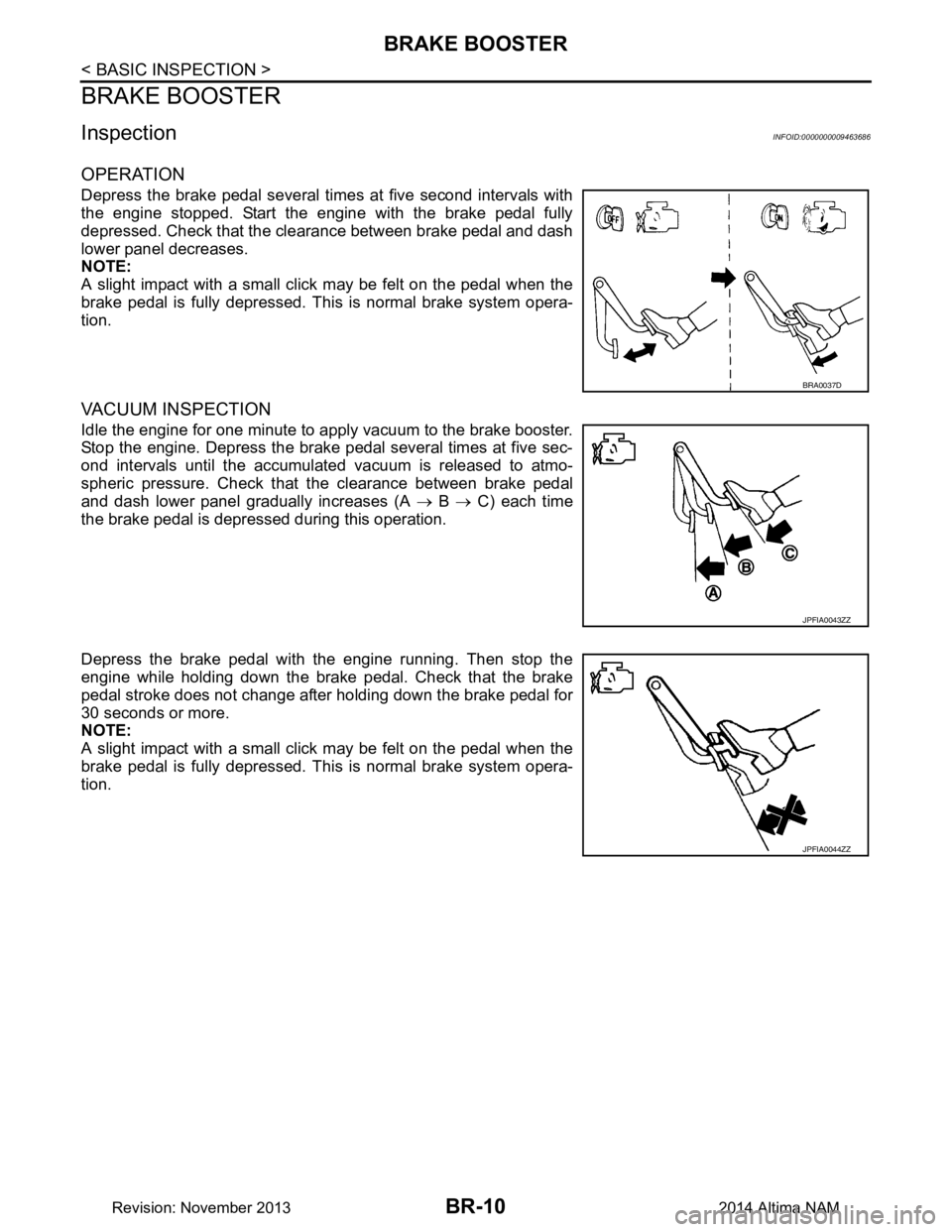

OPERATION

Depress the brake pedal several times at five second intervals with

the engine stopped. Start the engine with the brake pedal fully

depressed. Check that the cl earance between brake pedal and dash

lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. Th is is normal brake system opera-

tion.

VACUUM INSPECTION

Idle the engine for one minute to apply vacuum to the brake booster.

Stop the engine. Depress the brake pedal several times at five sec-

ond intervals until the accumulated vacuum is released to atmo-

spheric pressure. Check that the clearance between brake pedal

and dash lower panel gradually increases (A → B → C) each time

the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal for

30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. Th is is normal brake system opera-

tion.

BRA0037D

JPFIA0043ZZ

JPFIA0044ZZ

Revision: November 20132014 Altima NAM

Page 128 of 4801

BR-32

< REMOVAL AND INSTALLATION >

VACUUM LINES

VQ35DE

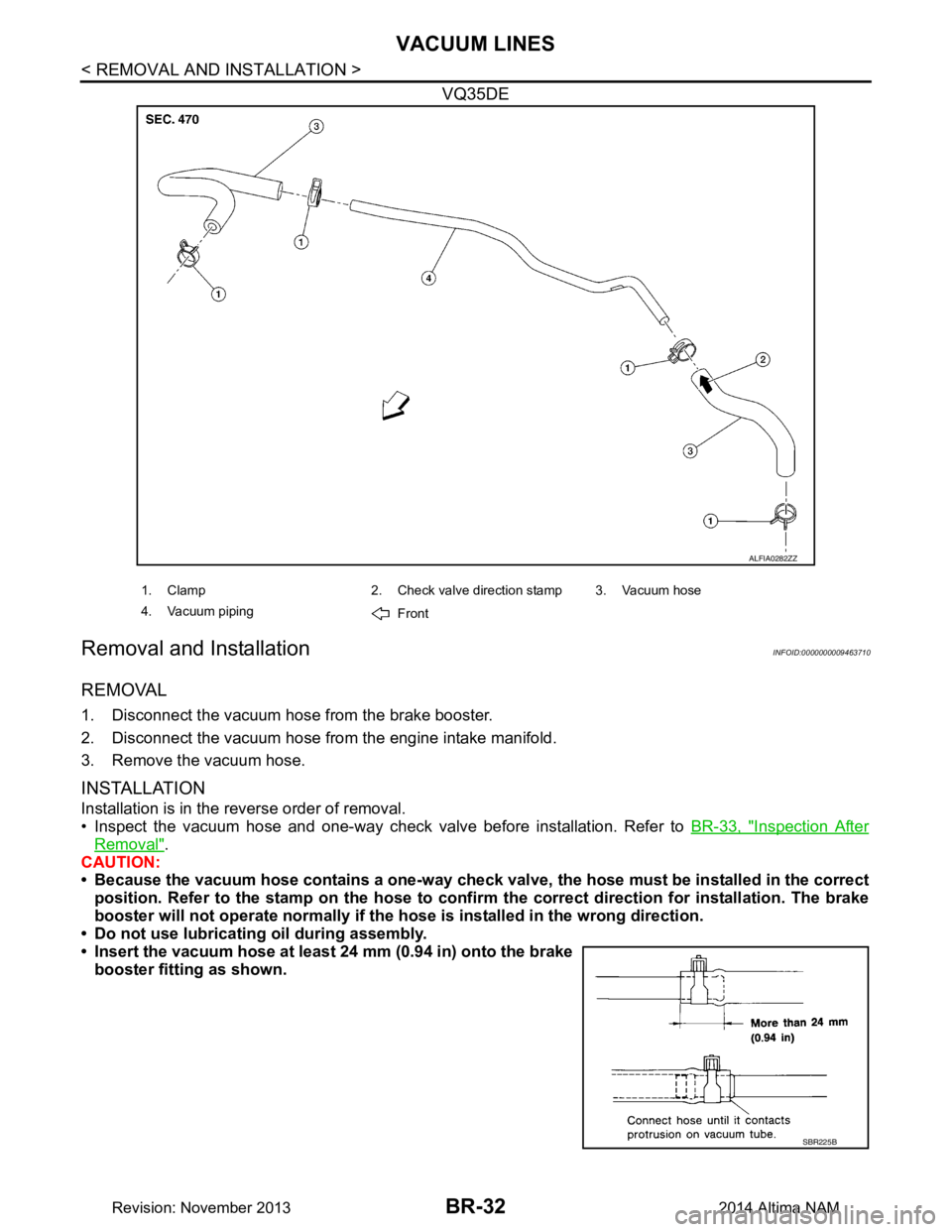

Removal and InstallationINFOID:0000000009463710

REMOVAL

1. Disconnect the vacuum hose from the brake booster.

2. Disconnect the vacuum hose from the engine intake manifold.

3. Remove the vacuum hose.

INSTALLATION

Installation is in the reverse order of removal.

• Inspect the vacuum hose and one-way check valve before installation. Refer to BR-33, "Inspection After

Removal".

CAUTION:

• Because the vacuum hose contains a one-way check val ve, the hose must be installed in the correct

position. Refer to the stamp on the hose to confi rm the correct direction for installation. The brake

booster will not operate normally if the ho se is installed in the wrong direction.

• Do not use lubricating oil during assembly.

• Insert the vacuum hose at least 24 mm (0.94 in) onto the brake booster fitting as shown.

ALFIA0282ZZ

1. Clamp 2. Check valve direction stamp 3. Vacuum hose

4. Vacuum piping Front

SBR225B

Revision: November 20132014 Altima NAM

Page 129 of 4801

VACUUM LINESBR-33

< REMOVAL AND INSTALLATION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

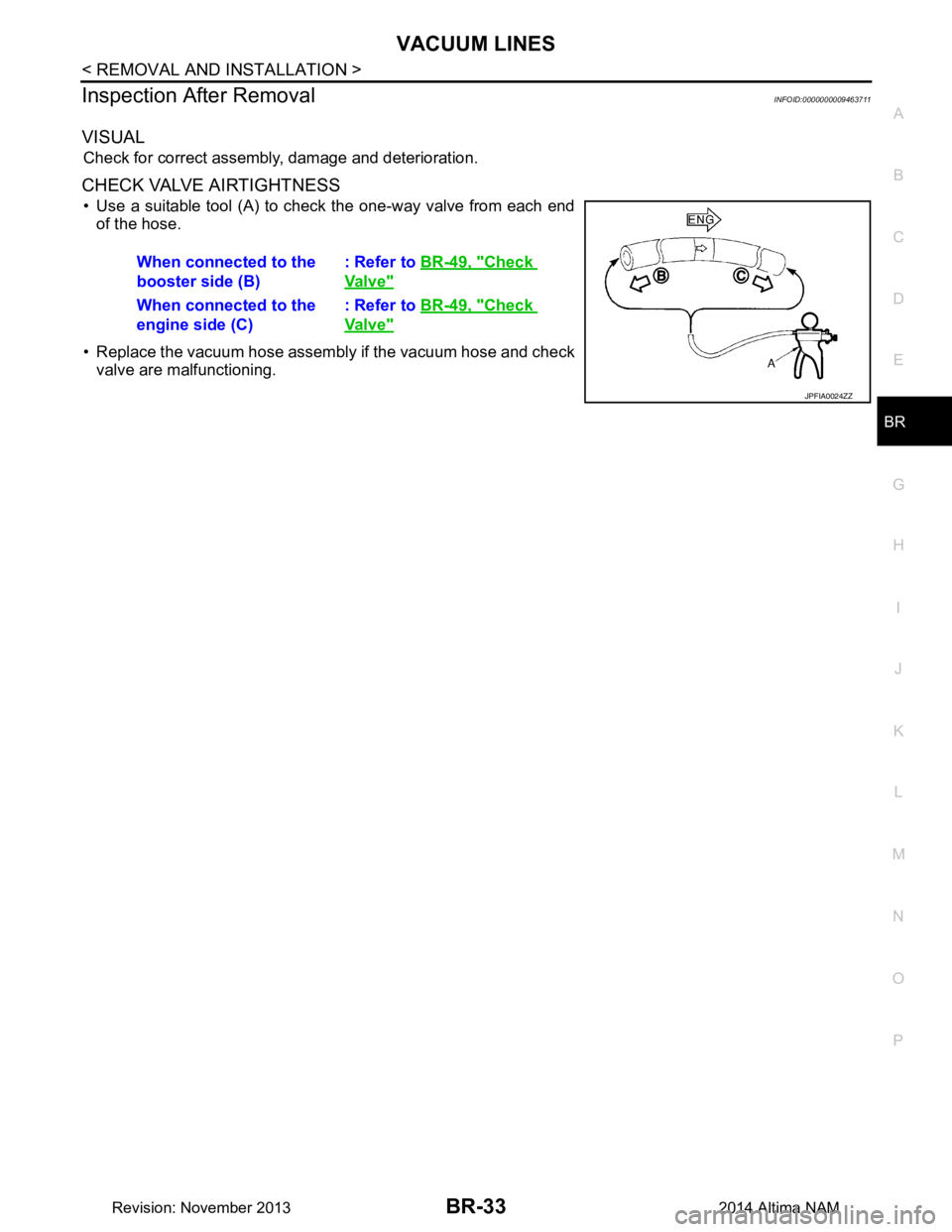

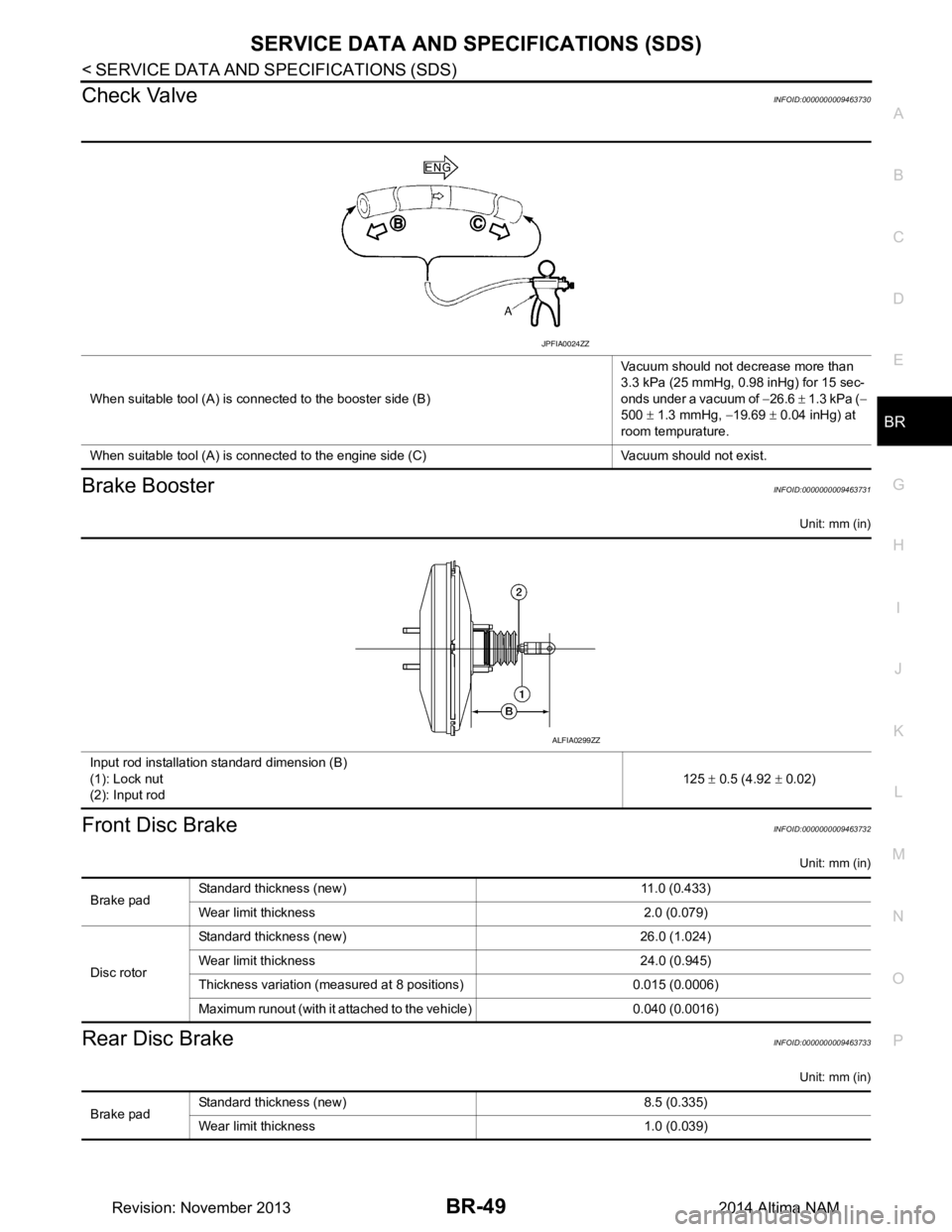

Inspection After RemovalINFOID:0000000009463711

VISUAL

Check for correct assembly, damage and deterioration.

CHECK VALVE AIRTIGHTNESS

• Use a suitable tool (A) to check the one-way valve from each end of the hose.

• Replace the vacuum hose assembly if the vacuum hose and check valve are malfunctioning. When connected to the

booster side (B) : Refer to

BR-49, "Check

Valve"

When connected to the

engine side (C) : Refer to

BR-49, "Check

Valve"

JPFIA0024ZZ

Revision: November 20132014 Altima NAM

Page 145 of 4801

SERVICE DATA AND SPECIFICATIONS (SDS)BR-49

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

G H

I

J

K L

M A

B

BR

N

O P

Check ValveINFOID:0000000009463730

Brake BoosterINFOID:0000000009463731

Unit: mm (in)

Front Disc BrakeINFOID:0000000009463732

Unit: mm (in)

Rear Disc BrakeINFOID:0000000009463733

Unit: mm (in)

When suitable tool (A) is connected to the booster side (B) Vacuum should not decrease more than

3.3 kPa (25 mmHg, 0.98 inHg) for 15 sec-

onds under a vacuum of −26.6 ± 1.3 kPa ( −

500 ± 1.3 mmHg, −19.69 ± 0.04 inHg) at

room tempurature.

When suitable tool (A) is connected to the engine side (C) Vacuum should not exist.

JPFIA0024ZZ

Input rod installation standard dimension (B)

(1): Lock nut

(2): Input rod 125

± 0.5 (4.92 ± 0.02)

ALFIA0299ZZ

Brake pad Standard thickness (new) 11.0 (0.433)

Wear limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new) 26.0 (1.024)

Wear limit thickness 24.0 (0.945)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Maximum runout (with it attached to the vehicle) 0.040 (0.0016)

Brake pad Standard thickness (new) 8.5 (0.335)

Wear limit thickness 1.0 (0.039)

Revision: November 20132014 Altima NAM

Page 148 of 4801

BRC-2

Work Procedure ......................................................62

DTC/CIRCUIT DIAGNOSIS ...................... ...64

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR ................................................................. ...

64

DTC Logic ............................................................ ...64

Diagnosis Procedure ..............................................64

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR ................................................................. ...

68

DTC Logic ............................................................ ...68

Diagnosis Procedure ..............................................68

C1109 POWER AND GROUND SYSTEM .........70

DTC Logic ............................................................ ...70

Diagnosis Procedure ..............................................70

C1110, C1153, C1170 ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) .............. ...

72

DTC Logic ............................................................ ...72

Diagnosis Procedure ..............................................72

C1111 PUMP MOTOR .......................................73

DTC Logic ............................................................ ...73

Diagnosis Procedure ..............................................73

C1113, C1145, C1146 YAW RATE/SIDE/DE-

CEL G SENSOR ............................................. ...

75

DTC Logic ............................................................ ...75

Diagnosis Procedure ..............................................75

C1115 ABS SENSOR [ABNORMAL SIGNAL] ...76

DTC Logic ............................................................ ...76

Diagnosis Procedure ..............................................76

C1116 STOP LAMP SWITCH ............................78

DTC Logic ............................................................ ...78

Diagnosis Procedure ..............................................78

C1120, C1122, C1124, C1126 ABS IN VALVE

SYSTEM ............ .............................................. ...

80

DTC Logic ............................................................ ...80

Diagnosis Procedure ..............................................80

C1121, C1123, C1125, C1127 ABS OUT

VALVE SYSTEM ............................................. ...

82

DTC Logic ............................................................ ...82

Diagnosis Procedure ..............................................82

C1130 ENGINE SIGNAL ...................................84

DTC Logic ............................................................ ...84

Diagnosis Procedure ..............................................84

C1140 ACTUATOR RELAY SYSTEM ...............85

DTC Logic ............................................................ ...85

Diagnosis Procedure ..............................................85

C1142 PRESS SENSOR ...................................87

DTC Logic ............................................................ ...87

Diagnosis Procedure ..............................................87

C1143 STEERING ANGLE SENSOR ...............88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

C1144 INCOMPLETE STEERING ANGLE

SENSOR ADJUSTMENT ............................... ...

90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

C1154 PNP SWITCH .........................................91

Description ........................................................... ...91

DTC Logic ...............................................................91

Diagnosis Procedure ...............................................91

Special Repair Requirement ...................................91

C1155 BR FLUID LEVEL LOW .........................93

DTC Logic ............................................................ ...93

Diagnosis Procedure ...............................................93

Component Inspection ............................................94

C1160 DECEL G SEN SET ...............................95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

C1164, C1165, C1166, C1167 CV/SV SYS-

TEM ................................................................. ...

96

DTC Logic ............................................................ ...96

Diagnosis Procedure ...............................................96

C1197 VACUUM SENSOR ............................. ...98

DTC Logic ............................................................ ...98

Diagnosis Procedure ...............................................98

C1198 VACUUM SENSOR ............................. ..100

DTC Logic ............................................................ .100

Diagnosis Procedure .............................................100

C1199 BRAKE BOOSTER ............................. ..102

DTC Logic ............................................................ .102

Diagnosis Procedure .............................................102

C119A VACUUM SENSOR ..............................104

DTC Logic ............................................................ .104

Diagnosis Procedure .............................................104

U1000 CAN COMM CIRCUIT ...........................106

DTC Logic ............................................................ .106

Diagnosis Procedure .............................................106

U1002 SYSTEM COMM (CAN) ........................107

DTC Logic ............................................................ .107

Diagnosis Procedure .............................................107

PARKING BRAKE SWITCH .............................108

Component Function Check ................................ .108

Diagnosis Procedure .............................................108

Component Inspection ..........................................109

VDC OFF SWITCH ...........................................110

Component Function Check ................................ .110

Diagnosis Procedure .............................................110

Component Inspection ..........................................111

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 150 of 4801

![NISSAN TEANA 2014 Owners Manual

BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951721

The Supplemen NISSAN TEANA 2014 Owners Manual

BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951721

The Supplemen](/img/5/57390/w960_57390-149.png)

BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951721

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Brake SystemINFOID:0000000009463735

WARNING:

Clean any dust from the front brake and rear br ake using a vacuum dust collector. Do not blow by

compressed air.

• Brake fluid use refer to BR-8, "Inspection"

.

• Do not reuse drained brake fluid.

• Do not spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface.

• Always confirm the specified tightening torque when installing the brake pipes.

• After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

• Do not use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

• Always loosen the brake tube flar e nut with a flare nut wrench.

• Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

• Always connect the battery terminal when moving the vehicle.

• Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

• Check that no brake fluid leakage is present after replacing the parts.

JPFIA0001ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 151 of 4801

![NISSAN TEANA 2014 Owners Manual

PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake ControlINFOID:0000000009463736

• During ABS operation, the brake pedal may vibrate lightly and NISSAN TEANA 2014 Owners Manual

PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake ControlINFOID:0000000009463736

• During ABS operation, the brake pedal may vibrate lightly and](/img/5/57390/w960_57390-150.png)

PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake ControlINFOID:0000000009463736

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine

compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check boos ter operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near control module, ABS function may have a malfunction or

error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

• If the following components are replaced with non-genuine components or modified, the VDC OFF indicator

lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorbers, struts, springs , bushings, etc.), tires, wheels (exclude specified

size), components related to brake system (pads, roto rs, calipers, etc.), components related to engine (muf-

fler, ECM, etc.), components related to body reinforcement (roll bar, tower bar, etc.).

• Driving with broken or excessively worn suspensi on components, tires or brake system components may

cause the VDC OFF indicator lamp and the SLIP indicator lamp to turn on, and the VDC system may not

operate properly.

• When the TCS or VDC is activated by sudden acceleration or sudden turn, some noise may occur. The

noise is a result of the normal operation of the TCS and VDC.

• When driving on roads which have extreme slopes (such as mountainous roads) or high banks (such as sharp curves on a freeway), the VDC may not operate no rmally, or the VDC warning lamp and the SLIP indi-

cator lamp may turn on. This is not a problem if normal operation can be resumed after restarting the engine.

• Sudden turns (such as spin turns, acceleration turns), drifting, etc. with VDC turned off may cause the yaw rate/side/decel G sensor to indicate a problem. This is not a problem if normal operation can be resumed

after restarting the engine.

Precaution for CAN SystemINFOID:0000000009463737

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of tester in use must be less than 7.0V.

• Before checking harnesses, turn ignition switch OFF and disconnect battery negative cable.

• Area to be repaired must be soldered and wrapped with tape. Make sure that fraying of twisted wire is within 110 mm (4.33 in).

PKIA0306E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM