engine NISSAN TEANA 2014 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 281 of 4801

PRECAUTIONSBRM-3

< PRECAUTION >

C

D E

F

G H

I

J

L

M A

B

BRM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951573

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: November 20132014 Altima NAM

Page 332 of 4801

BRM-54

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

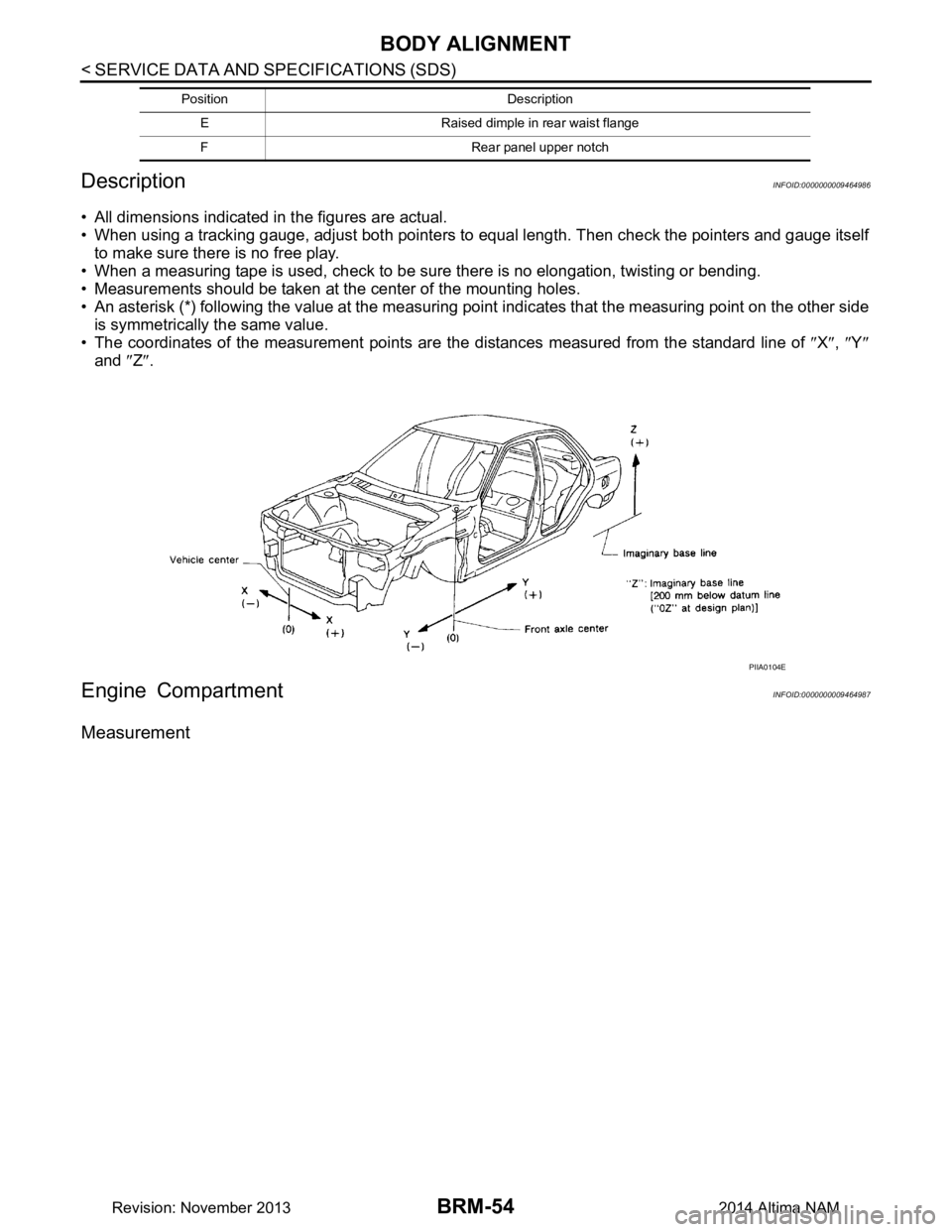

Description

INFOID:0000000009464986

• All dimensions indicated in the figures are actual.

• When using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge itself

to make sure there is no free play.

• When a measuring tape is used, check to be sure there is no elongation, twisting or bending.

• Measurements should be taken at the center of the mounting holes.

• An asterisk (*) following the value at the measuring point indicates that the measuring point on the other side

is symmetrically the same value.

• The coordinates of the measurement points are the distances measured from the standard line of ″X ″, ″Y ″

and ″Z ″.

Engine CompartmentINFOID:0000000009464987

Measurement

E Raised dimple in rear waist flange

F Rear panel upper notch

Position Description

PIIA0104E

Revision: November 20132014 Altima NAM

Page 343 of 4801

CCS-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951633

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: November 20132014 Altima NAM

Page 348 of 4801

CHG

PRECAUTIONSCHG-3

< PRECAUTION >

C

D E

F

G H

I

J

K L

B

A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951598

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Power Generation Voltage Variable Control SystemINFOID:0000000009460643

CAUTION:

For this model, the battery current sensor that is in stalled to the battery cable at the negative terminal

measures the charging/discharging cu rrent of the battery, and performs various controls. If the electri-

cal component or the ground wire is connected direct ly to the battery terminal, the current other than

that being measured with the battery current sensor is charging to or discharging from the battery.

This condition causes the malfunction of the control, and then the battery discharge may occur. Do

not connect the electrical component or the gr ound wire directly to the battery terminal.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 355 of 4801

CHG-10

< SYSTEM DESCRIPTION >

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

System DiagramINFOID:0000000009460653

System DescriptionINFOID:0000000009460654

Power generation variable voltage control system has been adopted. By varying the voltage to the generator,

engine load due to power generation of the generator is reduced and fuel consumption is decreased.

NOTE:

When any malfunction is detected in the power generat ion variable voltage control system, power generation

is performed according to the characteristic of the IC regulator in the generator.

Component DescriptionINFOID:0000000009460655

ALMIA0566GB

Component part Description

Generator (IC regulator) The IC regulator controls the power generation voltage by the tar-

get power generation voltage based on the received PWM com-

mand signal.

When there is no PWM command signal, the generator performs

the normal power generation according to the characteristic of the

IC regulator.

ECM The battery current sensor detects the charging/discharging cur-

rent of the battery. The ECM judges the battery condition based on

this signal.

The ECM judges whether to request more output via the power

generation voltage variable control according to the battery condi-

tion.

When performing the power generation voltage variable control,

the ECM calculates the target power generation voltage according

to the battery condition and sends the calculated value as the pow-

er generation command value to the IPDM E/R.

IPDM E/R The IPDM E/R converts the received power generation command

value into a pulse width modulated (PWM) command signal and

sends it to the IC regulator.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 364 of 4801

CHG

DIAGNOSIS AND REPAIR WORKFLOWCHG-19

< BASIC INSPECTION >

C

D E

F

G H

I

J

K L

B

A

O P

N

>> GO TO 2.

2.STOP POWER GENERATION VOLT

AGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variabl e control in either of the following procedures.

• After selecting “ENGINE” using CONSULT, set the DUTY value of “ALTERNATOR DUTY” to 0 % by select- ing “ALTERNATOR DUTY” of “Active Test”. Continue “Active Test” until the end of inspection. (When the

DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the

IC regulator of the generator.)

• Turn the ignition switch OFF, and disconnect the batte ry current sensor connector. [However, DTC (P1550–

P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connec-

tor and erase the self diagnosis results history of the engine using CONSULT.]

>> GO TO 3.

3.DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

Perform the charging system test using Multitasking battery and electrical diagnostic station GR8-1200 NI or

Battery and electrical diagnostic analyzer EXP-800 NI. Re fer to the applicable Instruction Manual for proper

testing procedures.

Test result

NO PROBLEMS>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO VOLTAGE>>GO TO 4.

LOW VOLTAGE>>GO TO 12.

HIGH VOLTAGE>>GO TO 14.

EXCESSIVE RIPPLE, OPEN PHASE, OPEN DIODE or SHORTED DIODE>>Replace the generator. Refer

to CHG-32, "Removal and Installation"

. Perform “DIODE RIPPLE” test again using Multitasking

battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer

EXP-800 NI to confirm repair.

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES >> GO TO 6.

NO >> GO TO 5.

5.“L” TERMINAL CIRCUIT (OPEN) INSPECTION

Check “L” terminal circuit (open). Refer to CHG-27, "Diagnosis Procedure"

.

Is the

“L” terminal circuit normal?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES >> GO TO 9.

NO >> GO TO 7.

7.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to CHG-29, "Diagnosis Procedure"

.

Is the

“L” terminal circuit normal?

YES >> GO TO 8.

NO >> Repair as needed.

8.“S” TERMINAL CIRCUIT INSPECTION

Check “S” terminal circuit. Refer to CHG-30, "Diagnosis Procedure"

.

Is the

“S” terminal circuit normal?

YES >> GO TO 10.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 365 of 4801

CHG-20

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NO >> Repair as needed.

9.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

Does the charge warning lamp remain off?

YES >> GO TO 11.

NO >> GO TO 10.

10.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to CHG-32, "Removal and Installation"

.

Is generator pulley normal?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> Repair as needed.

11 .“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-26, "Diagnosis Procedure"

.

Is

“B” terminal circuit normal?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> Repair as needed.

12.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-26, "Diagnosis Procedure"

.

Is

“B” terminal circuit normal?

YES >> GO TO 13.

NO >> Repair as needed.

13.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to CHG-32, "Removal and Installation"

.

Is generator pulley normal?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> Repair as needed.

14.“S” TERMINAL CIRCUIT INSPECTION

Check “S” terminal circuit. Refer to CHG-30, "Diagnosis Procedure"

.

Is the

“S” terminal circuit normal?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> Repair as needed.

Work Flow (Without EXP- 800 NI or GR8-1200 NI)INFOID:0000000009460658

OVERALL SEQUENCE

Before performing a generator test, make sure that the battery is fully charged. A 30-volt voltmeter and suit-

able test probes are necessary for the test.

• Before starting, inspect the fusible link.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 366 of 4801

CHG

DIAGNOSIS AND REPAIR WORKFLOWCHG-21

< BASIC INSPECTION >

C

D E

F

G H

I

J

K L

B

A

O P

N

• Use fully charged battery.

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-23, "Diagnosis Procedure"

.

>> GO TO 2.

2.STOP POWER GENERATION VOLT AGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variabl e control in either of the following procedures:

• After selecting “ENGINE” using CONSULT, set the DUTY value of “ALTERNATOR DUTY” to 0 % by select- ing “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of inspection. (When the

DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the

IC regulator of the generator.)

• Turn the ignition switch OFF, and disconnect the batte ry current sensor connector. [However, DTC (P1550 -

P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connec-

tor and erase the self-diagnostic results history of the engine using CONSULT.]

>> GO TO 3.

3.INSPECTION WITH CHARGE WARNING LA MP (IGNITION SWITCH IS TURNED ON)

When ignition switch is turned ON.

Does the charge warning lamp illuminate?

ALMIA0577GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 367 of 4801

CHG-22

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

YES >> GO TO 4.

NO >> GO TO 10.

4.INSPECTION WITH CHARGE WA RNING LAMP (IDLING)

Start the engine and run it at idle

Does the charge warning lamp turn OFF?

YES >> GO TO 5.

NO >> GO TO 6.

5.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate?

YES >> GO TO 8.

NO >> Inspection End.

6.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check terminal “L” circuit for (short). Refer to CHG-29, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair as needed.

7.“S” TERMINAL CIRCUIT INSPECTION

Check terminal “S” circuit. Refer to CHG-30, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair as needed.

8.MEASURE “B” TERMINAL VOLTAGE

Start engine. With engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show?

Less than 13.0 V>>GO TO 9.

More than 16.0 V>>Replace generator. Refer to CHG-32, "Removal and Installation"

.

9.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-26, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> Repair as needed.

10.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

1. Disconnect generator connector and apply ground to “L” terminal.

2. Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES >> Replace generator. Refer to CHG-32, "Removal and Installation".

NO >> GO TO 11.

11 .CHECK “L” TERMINAL CIRCUIT (OPEN)

Check “L” terminal circuit (OPEN). Refer to CHG-27, "Diagnosis Procedure"

.

>> Repair as needed.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 369 of 4801

CHG-24

< DTC/CIRCUIT DIAGNOSIS >

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

POWER GENERATION VOLTAGE VA RIABLE CONTROL SYSTEM OPER-

ATION INSPECTION

Diagnosis ProcedureINFOID:0000000009460660

Regarding Wiring Diagram information. Refer to CHG-12, "Wiring Diagram".

CAUTION:

When performing this in spection, always use a charged battery that has completed the battery inspec-

tion. (When the charging rate of the battery is lo w, the response speed of the voltage change will

become slow. This can cause an incorrect inspection.)

1.CHECK ECM (CONSULT)

Perform ECM self-diagnosis with CONSULT. Refer to EC-77, "CONSULT Function"

(QR25DE) or EC-601,

"CONSULT Function" (VQ35DE).

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT and start the engine.

2. The selector lever is in “P” or “N” position and al l of the electric loads and A/C, etc. are turned OFF.

3. Select “ALTERNATOR DUTY” in “Active Test” of “ENGINE”, and then check the value of “BATTERY

VOLT” monitor when DUTY value of “DUTY” is set to 40.0 %.

4. Check the value of “BATTERY VOLT” monitor when DUTY value of “DUTY” is set to 80.0%.

Is the inspection result normal?

YES >> Inspection End.

NO >> GO TO 3.

3.CHECK IPDM E/R (CONSULT)

Perform IPDM E/R self-diagnosis with CONSULT. Refer to PCS-9, "CONSULT Function (IPDM E/R)"

.

Is the inspection result normal?

No malfunction detected>> GO TO 4.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

4.CHECK HARNESS BETWEEN GE NERATOR AND IPDM E/R

1. Turn ignition switch OFF.

2. Disconnect generator connector and IPDM E/R connector.

3. Check continuity between generator harnes s connector and IPDM E/R harness connector.

“BATTERY VOLT”

2 seconds after setting the

DUTY value of “ALTERNA-

TOR DUTY” to 40.0 % : 12 - 13.6 V

“BATTERY VOLT”

20 seconds after setting

the DUTY value of “ALTER-

NATOR DUTY” to 80.0 % : +0.5 V or more against

the value of “BATTERY

VOLT” monitor when

DUTY value is 40.0 %

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM