run flat NISSAN TEANA 2014 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2101 of 4801

![NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-103

< UNIT DISASSEMBLY AND ASSEMBLY > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CRANKSHAFT RUNOUT

• Place a V-block on a precise flat table to support the journals on

both ends of NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-103

< UNIT DISASSEMBLY AND ASSEMBLY > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CRANKSHAFT RUNOUT

• Place a V-block on a precise flat table to support the journals on

both ends of](/img/5/57390/w960_57390-2100.png)

CYLINDER BLOCKEM-103

< UNIT DISASSEMBLY AND ASSEMBLY > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CRANKSHAFT RUNOUT

• Place a V-block on a precise flat table to support the journals on

both ends of the crankshaft.

• Place a dial gauge (A) straight up on the No. 3 journal.

• While rotating the crankshaft, read the movement of the pointer on the dial gauge (A), the total indicator runout reading.

OIL CLEARANCE OF CONNECTING ROD BEARING

Method of Measurement

• Install the connecting rod bearings (2) to the connecting rod (3)

and the cap (1), and tighten the c onnecting rod bolts to the speci-

fied torque. Using a inside micrometer measure the inner diameter

of connecting rod bearing (B).

(Oil clearance) = (Inner diameter of connecting rod bearing) –

(Outer diameter of crankshaft pin)

• If clearance cannot be adjusted within the standard, grind crankshaft pin and use undersized bearing. Refer

to EM-105, "How to Select Piston and Bearing"

.

Method of Using Plastigage

• Remove oil and dust on the crankshaft pin and the surfaces of

each bearing completely.

• Cut the Plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil holes.

• Install the connecting rod bearings to the connecting rod cap, and tighten the connecting rod bolts to the specified torque.

CAUTION:

Do not rotate the crankshaft.

• Remove the connecting rod cap and bearings, and using the scale on the Plastigage bag, measure the Plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the method by calculation.

OIL CLEARANCE OF MAIN BEARING

Method of Measurement

• Install the main bearings to the cylinder block and bearing cap. Measure the main bearing inner diameter with the bearing cap bolt tightened to the specified torque.

(Oil clearance) = (Inner diameter of main beari ng) – (Outer diameter of crankshaft journal)

• If the measured value exceeds the limit, select main bearings referring to the main bearing inner diameter

and crankshaft journal outer diameter, so that t he oil clearance satisfies the standard. Refer to EM-105,

"How to Select Piston and Bearing".

Limit : Less than 0.05 mm (0.002 in)

AWBIA1367ZZ

(A) Example

Standard : 0.035 - 0.045 mm (0.0014 - 0.0018 in)

Limit : 0.10 mm (0.0039 in)

AWBIA1369ZZ

EM142

Standard:

No. 1, 3, and 5 journals : 0.012 - 0.022 mm (0.0005 - 0.0009 in)

No. 2 and 4 journals : 0.018 - 0.028 mm (0.0007 - 0.0011 in)

Limit : 0.1 mm (0.004 in)

Revision: November 20132014 Altima NAM

Page 2121 of 4801

![NISSAN TEANA 2014 Owners Manual

PRECAUTIONSEM-123

< PRECAUTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0 NISSAN TEANA 2014 Owners Manual

PRECAUTIONSEM-123

< PRECAUTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0](/img/5/57390/w960_57390-2120.png)

PRECAUTIONSEM-123

< PRECAUTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951676

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Draining CoolantINFOID:0000000009460515

• Drain coolant when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000009460516

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and DisassemblyINFOID:0000000009460517

• When instructed to use special service tools, use the spec ified tools. Always be careful to work safely, avoid

forceful or uninstructed operations.

• Exercise maximum care to avoid damage to mating or sliding surfaces.

• Cover openings of engine system with tape or the equiva lent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organized way for easy troubleshooting and assembly.

• When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specif ied, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000009460518

• Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000009460519

• Use torque wrench to tighten bolts or nuts to specification.

Revision: November 20132014 Altima NAM

Page 2197 of 4801

![NISSAN TEANA 2014 Owners Manual

CAMSHAFTEM-199

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Tighten the camshaft brackets in the three steps, in numerical order as shown.

8. Measure difference in level NISSAN TEANA 2014 Owners Manual

CAMSHAFTEM-199

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Tighten the camshaft brackets in the three steps, in numerical order as shown.

8. Measure difference in level](/img/5/57390/w960_57390-2196.png)

CAMSHAFTEM-199

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Tighten the camshaft brackets in the three steps, in numerical order as shown.

8. Measure difference in levels between front end faces of No. 1 camshaft bracket and cylinder head.

• If measurement is outside the specified range, re-install cam-

shaft and camshaft bracket.

9. Install camshaft position sensor bracket (PHASE) (RH and LH bank.)

10. Install the timing chains. Refer to EM-182, "Removal and Installation"

.

INSPECTION AFTER REMOVAL

Camshaft Visual Check

Check camshaft for scratches, seizure and wear. Replace if necessary.

Camshaft Runout

1. Put V-block on precise flat bed and support No. 2 and No. 4 jour-

nal of camshaft as shown.

2. Set dial gauges vertically to No. 3 journal as shown.

3. Turn camshaft in one direction slowly by hand, measure the camshaft runout on the dial gauges.

• Runout is the largest indicator reading after one full revolution.

4. If actual runout exceeds th e limit, replace the camshaft.

1 1.96 N·m (0.2 kg-m, 17 in-lb)

Tighten No. 7 - 10, then

tighten 1 - 6 in numerical order as shown.

2 5.88 N·m (0.6 kg-m, 52 in-lb) Tighten all in numerical or-

der as shown.

3 10.41 N·m (1.10 kg-m, 8 ft-lb) Tighten No. 1 - 10 in nu-

merical order as shown.

SEM885EA

SEM886EA

Standard : – 0.14 (– 0.0055 in)

EMQ0044D

Camshaft Runout

Standard : Less than 0.02 mm (0.0008 in)

Limit : 0.05 mm (0.0020 in)

PBIC0929E

Revision: November 20132014 Altima NAM

Page 2199 of 4801

![NISSAN TEANA 2014 Owners Manual

CAMSHAFTEM-201

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

2. Install dial gauge in thrust direction on front end of camshaft.

Measure end play when camshaft is moved forw NISSAN TEANA 2014 Owners Manual

CAMSHAFTEM-201

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

2. Install dial gauge in thrust direction on front end of camshaft.

Measure end play when camshaft is moved forw](/img/5/57390/w960_57390-2198.png)

CAMSHAFTEM-201

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

2. Install dial gauge in thrust direction on front end of camshaft.

Measure end play when camshaft is moved forward/backward

(in direction to axis) as shown.

• If out of the specified range, replace with new camshaft and mea-

sure again.

• If out of the specified range again, replace with new cylinder head.

Camshaft Sprocket Runout

1. Put V-block on precise flat bed and support No. 2 and No. 4 jour- nal of camshaft as shown.

2. Install camshaft sprocket on camshaft.

3. Measure camshaft sprocket runout.

4. If sprocket runout exceeds the limit, replace camshaft sprocket.

Valve Lifter

• Check if the surface of the valve lifter has any excessive wear or

cracks, replace as necessary.

Valve Lifter Clearance

Outer Diameter of Valve Lifter

• Measure the outer diameter of the valve lifter. Refer to EM-247,

"Camshaft".

• If out of the specified range, replace the valve lifter.

Valve Lifter Bore Diameter Standard : 0.115 - 0.188 mm (0.0045 - 0.0074 in)

Limit : 0.24 mm (0.0094 in)

SEM864E

Runout : Less than 0.15 mm (0.0059 in)

PBIC0930E

KBIA0182E

JEM798G

Revision: November 20132014 Altima NAM

Page 2238 of 4801

![NISSAN TEANA 2014 Owners Manual

EM-240

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

5. Cylinder bore size is determined by adding pi

ston-to-bore clearance to piston diameter (A).

6. Install main bearing caps, and tight NISSAN TEANA 2014 Owners Manual

EM-240

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

5. Cylinder bore size is determined by adding pi

ston-to-bore clearance to piston diameter (A).

6. Install main bearing caps, and tight](/img/5/57390/w960_57390-2237.png)

EM-240

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

5. Cylinder bore size is determined by adding pi

ston-to-bore clearance to piston diameter (A).

6. Install main bearing caps, and tighten to the specified torque. Otherwise, cylinder bores may be distorted after boring.

7. Cut cylinder bores. •When any cylinder needs boring, all ot her cylinders must also be bored.

• Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter

at a time.

8. Hone cylinders to obtain specified piston-to-bore clearance.

9. Measure finished cylinder bore for out-of-round and taper. •Measurement should be done after cylinder bore cools down.

CRANKSHAFT

1. Check the crankshaft main and pin journals for scoring, wear, or

cracks.

2. Measure the journals for taper and out-of-round.

3. Measure crankshaft runout.

a. Place a V-block on a precise flat table to support the journals on the both ends of the crankshaft.

b. Place a dial gauge straight up on the No. 3 journal.

c. While rotating the crankshaft, read the movement of the pointer on the dial gauge.

BEARING CLEARANCE

• Use either of the following two methods, however me thod (A) gives more reliable results and so is the pre-

ferred method.

Method A (Using Bore Gauge and Micrometer )

Main BearingRebored size calculation : D = A + B

− C

where,

D : Bored diameter

A : Piston diameter as measured

B : Piston-to-bore clearance

C : Honing allowance 0.02 mm (0.0008 in)

Standard

Out-of-round (X - Y) : 0.002 mm (0.0001 in)

Taper (A - B) : 0.002 mm (0.0001 in)

SEM316A

Runout limit (total indicator

reading) : 0.10 mm (0.0039 in)

SEM346D

Revision: November 20132014 Altima NAM

Page 2257 of 4801

![NISSAN TEANA 2014 Owners Manual

EX-2

< PRECAUTION >[QR25DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951692

The Supplemental Re NISSAN TEANA 2014 Owners Manual

EX-2

< PRECAUTION >[QR25DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951692

The Supplemental Re](/img/5/57390/w960_57390-2256.png)

EX-2

< PRECAUTION >[QR25DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951692

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: November 20132014 Altima NAM

Page 2262 of 4801

![NISSAN TEANA 2014 Owners Manual

PRECAUTIONSEX-7

< PRECAUTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EX

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000 NISSAN TEANA 2014 Owners Manual

PRECAUTIONSEX-7

< PRECAUTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EX

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000](/img/5/57390/w960_57390-2261.png)

PRECAUTIONSEX-7

< PRECAUTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EX

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951693

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: November 20132014 Altima NAM

Page 2270 of 4801

EXL-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951582

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

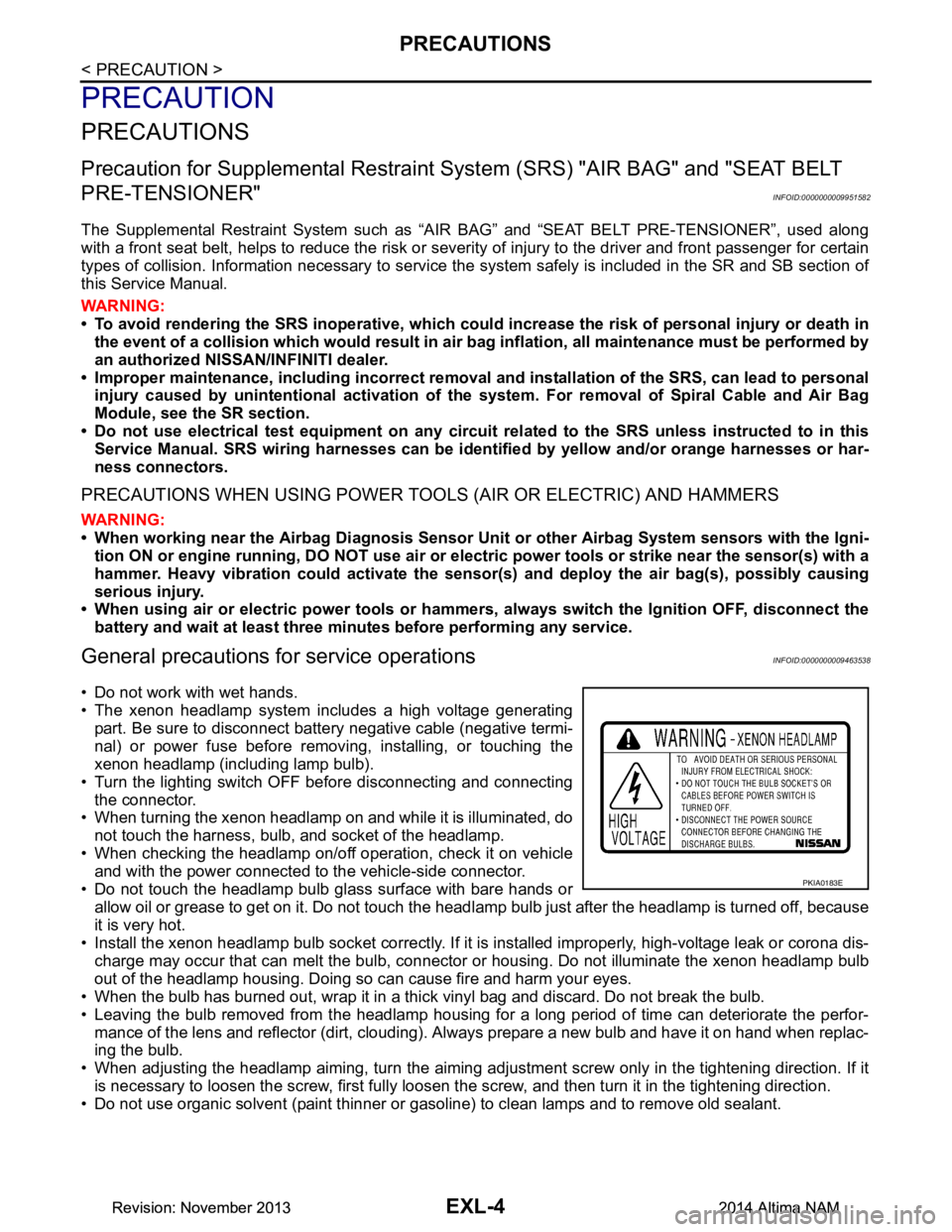

General precautions fo r service operationsINFOID:0000000009463538

• Do not work with wet hands.

• The xenon headlamp system includes a high voltage generating

part. Be sure to disconnect batte ry negative cable (negative termi-

nal) or power fuse before removing, installing, or touching the

xenon headlamp (including lamp bulb).

• Turn the lighting switch OFF before disconnecting and connecting the connector.

• When turning the xenon headlamp on and while it is illuminated, do

not touch the harness, bulb, and socket of the headlamp.

• When checking the headlamp on/off operation, check it on vehicle and with the power connected to the vehicle-side connector.

• Do not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not touch the headl amp bulb just after the headlamp is turned off, because

it is very hot.

• Install the xenon headlamp bulb socket co rrectly. If it is installed improperly, high-voltage leak or corona dis-

charge may occur that can melt the bulb, connector or housing. Do not illuminate the xenon headlamp bulb

out of the headlamp housing. Doing so can cause fire and harm your eyes.

• When the bulb has burned out, wrap it in a thick vinyl bag and discard. Do not break the bulb.

• Leaving the bulb removed from the headlamp housing for a long period of time can deteriorate the perfor- mance of the lens and reflector (dirt, clouding). Al ways prepare a new bulb and have it on hand when replac-

ing the bulb.

• When adjusting the headlamp aiming, turn the aiming adjus tment screw only in the tightening direction. If it

is necessary to loosen the screw, first fully loosen the screw, and then turn it in the tightening direction.

• Do not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

PKIA0183E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2417 of 4801

PRECAUTIONSEXT-3

< PRECAUTION >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951571

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

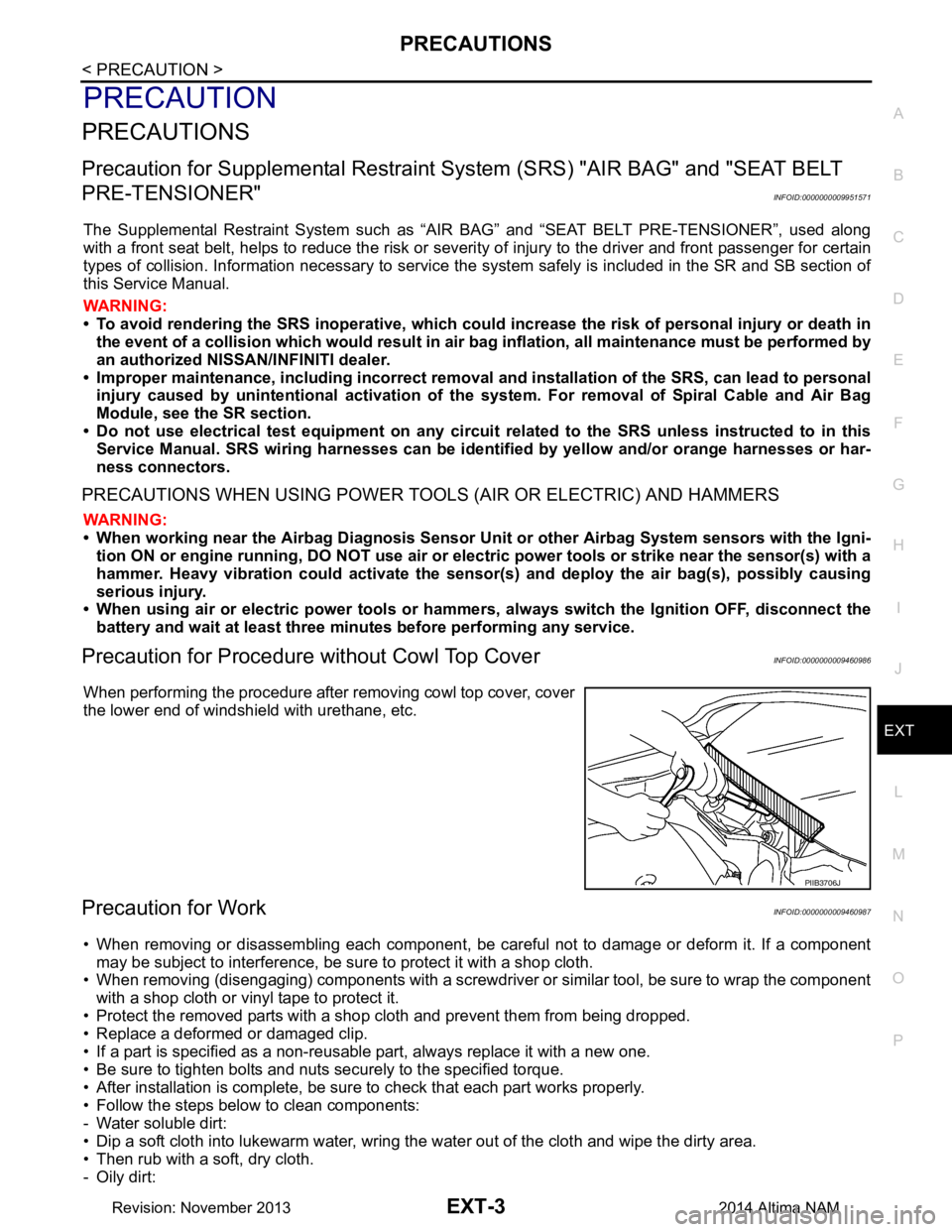

Precaution for Procedure without Cowl Top CoverINFOID:0000000009460986

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for WorkINFOID:0000000009460987

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

PIIB3706J

Revision: November 20132014 Altima NAM

Page 2454 of 4801

FAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951700

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precautions for Drive ShaftINFOID:0000000009464432

Observe the following precautions when disassembling and assembling drive shaft.

• Joint sub-assembly does not disass emble because it is non-overhaul parts.

• Perform work in a location which is as dust-free as possible.

• Before disassembling and assembling, clean the outside of parts.

• Prevention of the entry of foreign objects must be tak en into account during disassembly of the service loca-

tion.

• Disassembled parts must be carefully reassembled in the correct order. If work is interrupted, a clean cover must be placed over parts.

• Paper shop cloths must be used. Fabric shop cloths must not be used because of the danger of lint adhering

to parts.

• Disassembled parts (except for rubber parts) should be cleaned with kerosene which shall be removed by

blowing with air or wiping with paper shop cloths.

Revision: November 20132014 Altima NAM