coolant reservoir NISSAN TEANA 2014 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3183 of 4801

![NISSAN TEANA 2014 Owners Guide

OIL COOLERLU-33

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

LU

NP

O

When removing components such as hoses, tubes/lines, etc.

, cap or plug openings to prevent fluid from spill-

in NISSAN TEANA 2014 Owners Guide

OIL COOLERLU-33

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

LU

NP

O

When removing components such as hoses, tubes/lines, etc.

, cap or plug openings to prevent fluid from spill-

in](/img/5/57390/w960_57390-3182.png)

OIL COOLERLU-33

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

LU

NP

O

When removing components such as hoses, tubes/lines, etc.

, cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine under cover. Refer to EXT-17, "Removal and Installation".

2. Remove the RH wheel and tire. Refer to WT-53, "Inspection"

.

3. Remove the front fender protector side cover RH. Refer to EXT-26, "FENDER PROTECTOR : Exploded

View".

4. Drain engine coolant. Refer to CO-36, "Changing Engine Coolant"

.

CAUTION:

Do not spill coolant on the drive belt.

5. Disconnect water hoses from oil cooler.

6. Remove the oil filter. Refer to LU-27, "Removal and Installation"

.

7. Remove oil cooler.

8. Remove core support cover. Refer to DLK-179, "Removal and Installation"

.

9. Remove front air duct. Refer to EM-84, "Removal and Installation"

.

10. Remove reservoir tank. Refer to CO-40, "Exploded View"

.

INSPECTION AFTER REMOVAL

1. Check oil cooler for cracks.

2. Check oil cooler for clogging by blowing through coolant inlet. If necessary, replace oil cooler.

Oil Pressure Relief Valve

Inspect oil pressure relief valve for movement, cracks and breaks by pushing the ball. If replacement is neces-

sary, remove valve by prying it out with a suitable tool. Install a new valve in place by tapping it.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Do not reuse copper gasket.

• When installing the oil cooler, align the oil cooler slot with the stopper of the oil pan.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to LU-9, "Inspection"

and CO-11, "System Inspection".

2. Start the engine, and check that there is no leakage of engine oil or engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and the engine coolant level again. Refer to LU-9, "Inspection"

and CO-11,

"System Inspection".

Revision: November 20132014 Altima NAM

Page 3190 of 4801

MA-6

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restrains move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. SB-5, "Inspection"

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

the floor mats away from the pedal. BR-48

,

BR-49

Parking brake Check that the pedal has the proper travel and make sure that the vehicle is held

securely on a fairly steep hill when only the parking brake is applied. PB-4

CVT P (Park) position

mechanism On a fairly steep hill check that the vehicle is held securely with the shift selector

in the P (Park) position without applying any brakes. —

Item

Reference page

ItemReference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-14

(QR25DE)

MA-23

(VQ35DE)

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. —

Brake and clutch fluid

levels Make sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoir. MA-41

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. —

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. MA-13

(QR25DE)

MA-22

(VQ35DE)

Engine oil level Check the level on the oil level gauge after parking the vehicle on a level spot and

turning off the engine. MA-17

(QR25DE)

MA-26

(VQ35DE)

Power steering fluid

level and lines Check the level when the fluid is cold, with the engine off. Check the lines for im-

proper attachment, leaks, cracks, etc. MA-44

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate the

trouble and correct it. MA-31

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: November 20132014 Altima NAM

Page 3195 of 4801

RECOMMENDED FLUIDS AND LUBRICANTSMA-11

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

RECOMMENDED FLUIDS AND LUBRICANTS

FOR USA AND CANADA

FOR USA AND CANADA :

Fluids and LubricantsINFOID:0000000009464536

*1: For additional information, see “Engine Oil Recommendation”.

*2: As an alternative to this recommended oil, SAE 5W-30 conventional petroleum based oil may be used and meet all specificatio ns

and requirements necessary to maintain the New Vehicle Limited Warranty.

*3: NISSAN recommen ds Genuine NISSAN Ester Oil av ailable at a NISSAN dealer.

*4: Use only Genuine NISSAN CVT Fluid NS -3, using automatic transmission fluid other than Genuine NISSAN CVT Fluid NS-3

will damage the CVT, which is not covered by the NISSAN new vehicle limited warranty.

*5: Use of a power steering fluid other than Genuine NISSAN E-PSF will prevent the power steering system from operating properly.

*6: Available in mainland U. S.A. through a NISSAN dealer.

*7: For additional information, see "Air conditioner specification label".

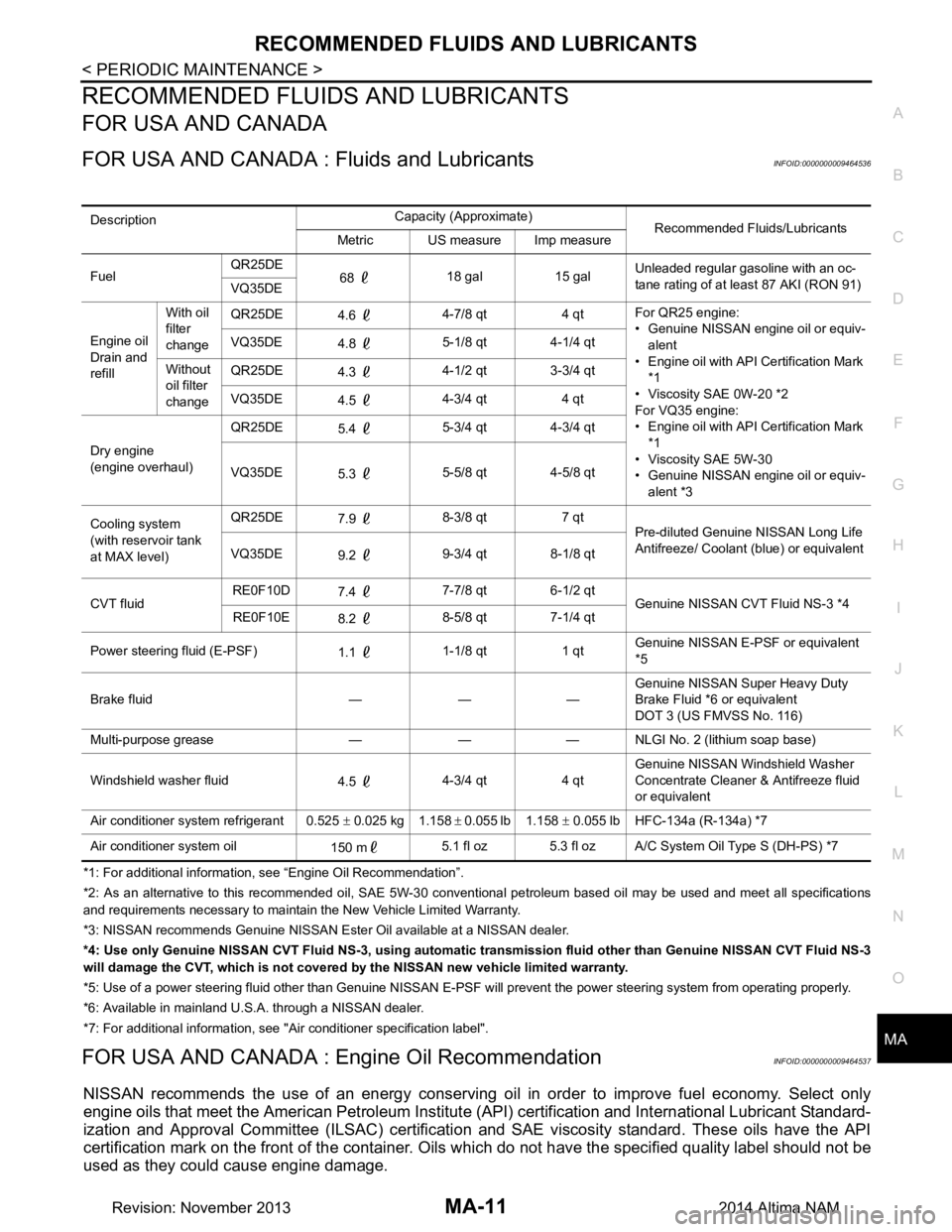

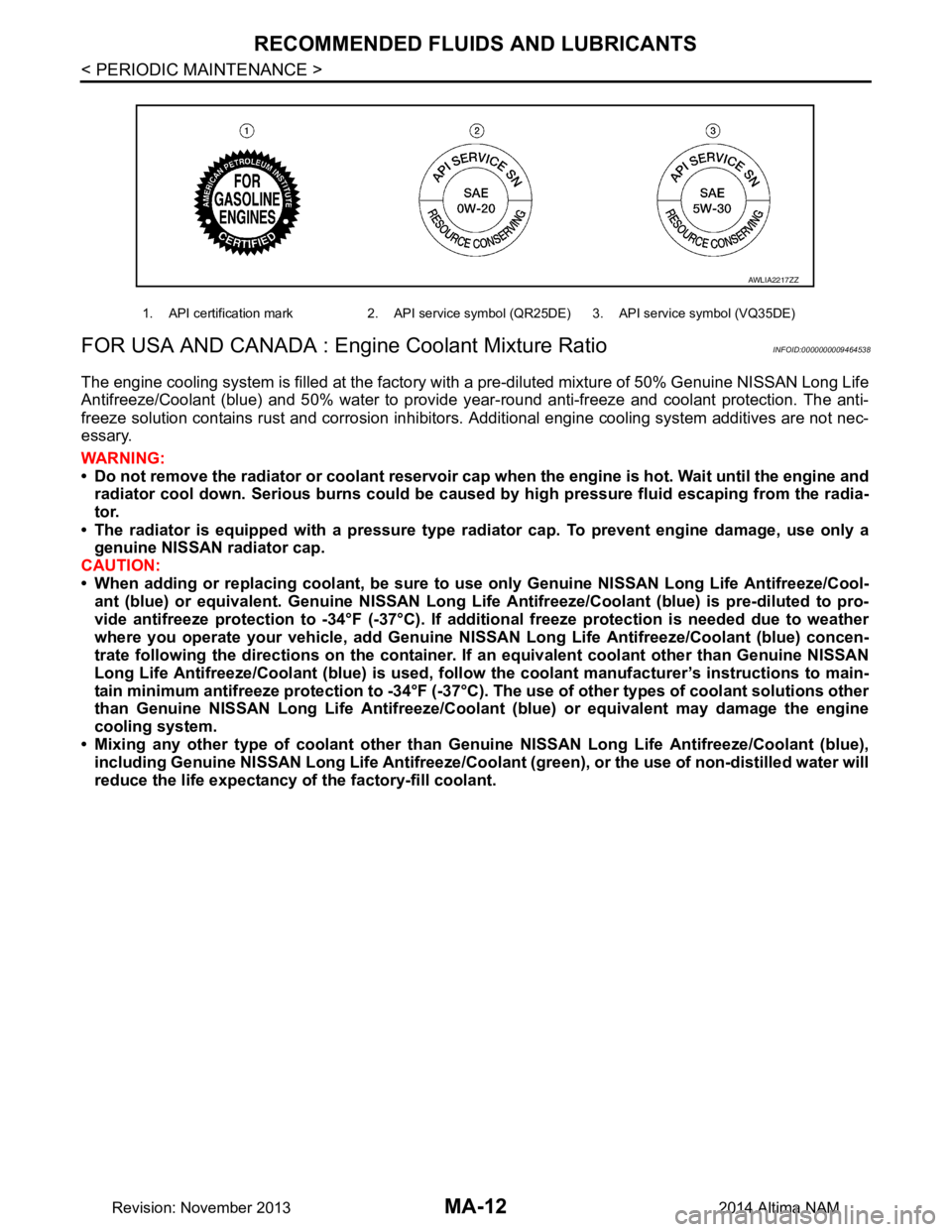

FOR USA AND CANADA : En gine Oil RecommendationINFOID:0000000009464537

NISSAN recommends the use of an energy conserving o il in order to improve fuel economy. Select only

engine oils that meet the American Petroleum Institut e (API) certification and International Lubricant Standard-

ization and Approval Committee (ILSAC) certificati on and SAE viscosity standard. These oils have the API

certification mark on the front of the container. Oils which do not have the specified quality label should not be

used as they could cause engine damage.

Description Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel QR25DE

68 18 gal 15 gal Unleaded regular gasoline with an oc-

tane rating of at least 87 AKI (RON 91)

VQ35DE

Engine oil

Drain and

refill With oil

filter

change QR25DE

4.6 4-7/8 qt 4 qt For QR25 engine:

• Genuine NISSAN engine oil or equiv- alent

• Engine oil with API Certification Mark

*1

• Viscosity SAE 0W-20 *2

For VQ35 engine:

• Engine oil with API Certification Mark

*1

• Viscosity SAE 5W-30

• Genuine NISSAN engine oil or equiv-

alent *3

VQ35DE

4.8 5-1/8 qt 4-1/4 qt

Without

oil filter

change QR25DE

4.3 4-1/2 qt 3-3/4 qt

VQ35DE 4.5 4-3/4 qt 4 qt

Dry engine

(engine overhaul) QR25DE

5.4 5-3/4 qt 4-3/4 qt

VQ35DE 5.3 5-5/8 qt 4-5/8 qt

Cooling system

(with reservoir tank

at MAX level) QR25DE

7.9 8-3/8 qt 7 qt

Pre-diluted Genuine NISSAN Long Life

Antifreeze/ Coolant (blue) or equivalent

VQ35DE 9.2 9-3/4 qt 8-1/8 qt

CVT fluid RE0F10D

7.4 7-7/8 qt 6-1/2 qt

Genuine NISSAN CVT Fluid NS-3 *4

RE0F10E 8.2 8-5/8 qt 7-1/4 qt

Power steering fluid (E-PSF) 1.1 1-1/8 qt 1 qt Genuine NISSAN E-PSF or equivalent

*5

Brake fluid — — — Genuine NISSAN Super Heavy Duty

Brake Fluid *6 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease — — — NLGI No. 2 (lithium soap base)

Windshield washer fluid 4.5 4-3/4 qt 4 qt Genuine NISSAN Windshield Washer

Concentrate Cleaner & Antifreeze fluid

or equivalent

Air conditioner system refrigerant 0.525 ± 0.025 kg 1.158 ± 0.055 lb 1.158 ± 0.055 lb HFC-134a (R-134a) *7

Air conditioner system oil 150 m5.1 fl oz 5.3 fl oz A/C System Oil Type S (DH-PS) *7

Revision: November 20132014 Altima NAM

Page 3196 of 4801

MA-12

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

FOR USA AND CANADA : Engi ne Coolant Mixture Ratio

INFOID:0000000009464538

The engine cooling system is filled at the factory with a pre-diluted mixture of 50% Genuine NISSAN Long Life

Antifreeze/Coolant (blue) and 50% water to provide year-round anti-freeze and coolant protection. The anti-

freeze solution contains rust and corrosion inhibitors. Additional engine cooling system additives are not nec-

essary.

WARNING:

• Do not remove the radiator or coolant reservoir cap wh en the engine is hot. Wait until the engine and

radiator cool down. Serious burns could be caused by high pressure fluid escaping from the radia-

tor.

• The radiator is equipped with a pressure type radiator cap. To prevent engine damage, use only a

genuine NISSAN radiator cap.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Long Life Antifreeze/Cool-

ant (blue) or equivalent. Genuine NISSAN Long Life Antifreeze/Coolant (blue) is pre-diluted to pro-

vide antifreeze protection to -34°F (-37°C). If additional freeze protection is needed due to weather

where you operate your vehicle, add Genuine NISS AN Long Life Antifreeze/Coolant (blue) concen-

trate following the directions on the container. If an equivalent coolant other than Genuine NISSAN

Long Life Antifreeze/Coolant (blue) is used, follow the coolant manufacturer’s instructions to main-

tain minimum antifreeze protection to -34°F (-37°C). The use of other types of coolant solutions other

than Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent may damage the engine

cooling system.

• Mixing any other type of coolant other than Genu ine NISSAN Long Life Antifreeze/Coolant (blue),

including Genuine NISSAN Long Life Antifreeze/Coolant (green), or the use of non-distilled water will

reduce the life expectancy of the factory-fill coolant.

1. API certification mark 2. API service symbol (QR25DE) 3. API service symbol (VQ35DE)

AWLIA2217ZZ

Revision: November 20132014 Altima NAM

Page 3198 of 4801

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (QR25DE)

• Loose connections

• Chafing

• Deterioration

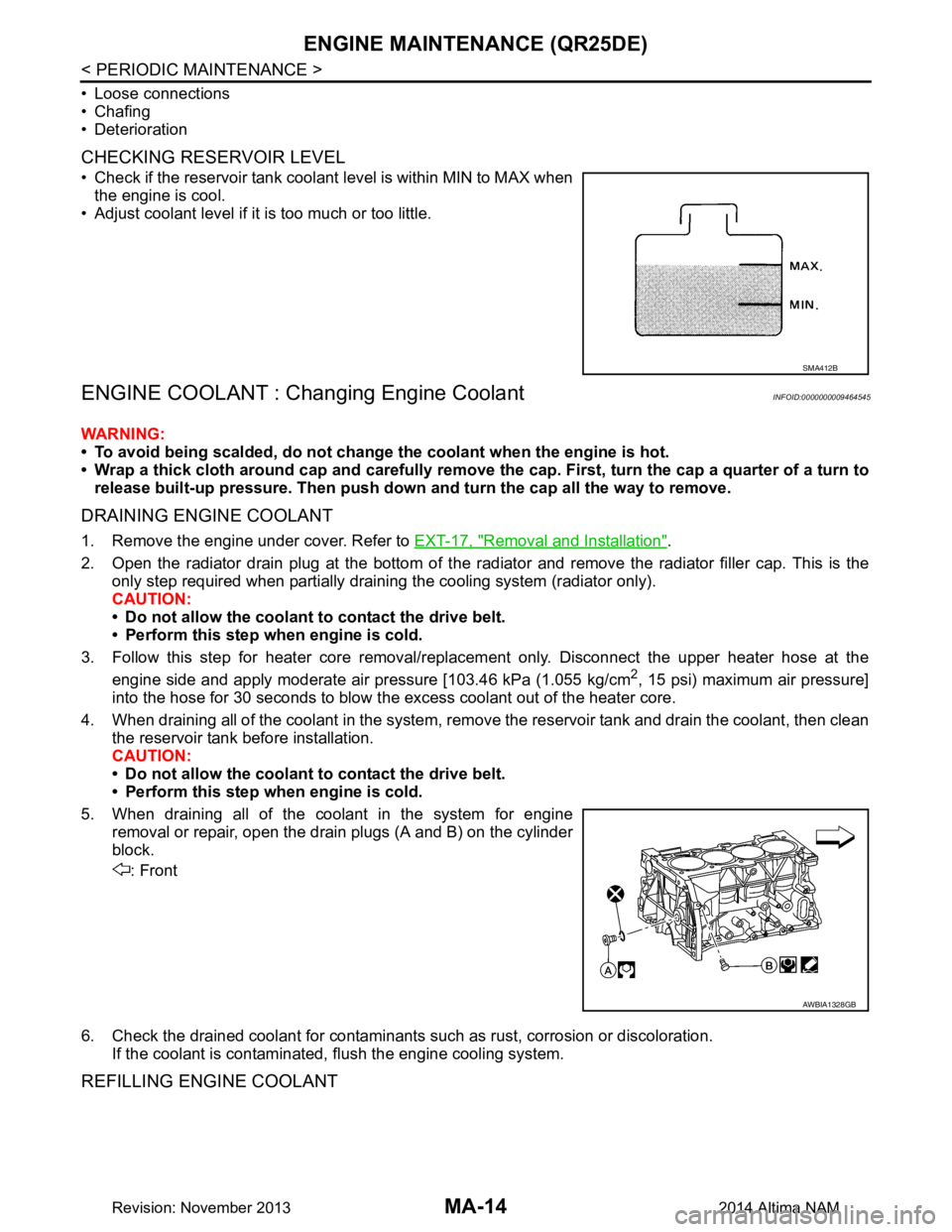

CHECKING RESERVOIR LEVEL

• Check if the reservoir tank coolant level is within MIN to MAX when the engine is cool.

• Adjust coolant level if it is too much or too little.

ENGINE COOLANT : Changing Engine CoolantINFOID:0000000009464545

WARNING:

• To avoid being scalded, do not change the coolant when the engine is hot.

• Wrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn to

release built-up pressure. Then push down and turn the cap all the way to remove.

DRAINING ENGINE COOLANT

1. Remove the engine under cover. Refer to EXT-17, "Removal and Installation".

2. Open the radiator drain plug at the bottom of the radi ator and remove the radiator filler cap. This is the

only step required when partially draining the cooling system (radiator only).

CAUTION:

• Do not allow the coolant to contact the drive belt.

• Perform this step when engine is cold.

3. Follow this step for heater core removal/replac ement only. Disconnect the upper heater hose at the

engine side and apply moderate air pressure [103.46 kPa (1.055 kg/cm

2, 15 psi) maximum air pressure]

into the hose for 30 seconds to blow t he excess coolant out of the heater core.

4. When draining all of the coolant in the system, re move the reservoir tank and drain the coolant, then clean

the reservoir tank before installation.

CAUTION:

• Do not allow the coolant to contact the drive belt.

• Perform this step when engine is cold.

5. When draining all of the coolant in the system for engine removal or repair, open the drain plugs (A and B) on the cylinder

block.

: Front

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

SMA412B

AWBIA1328GB

Revision: November 20132014 Altima NAM

Page 3199 of 4801

ENGINE MAINTENANCE (QR25DE)MA-15

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

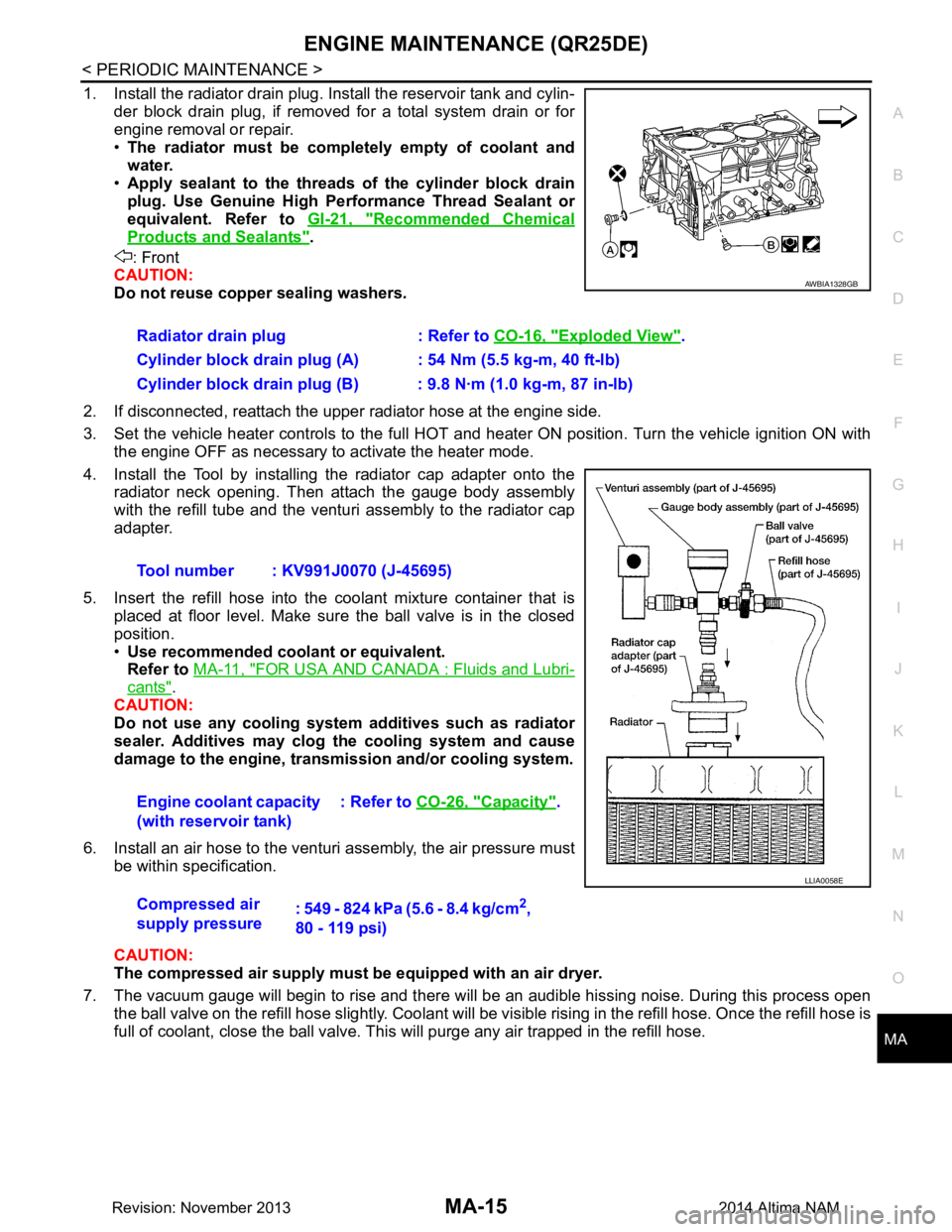

1. Install the radiator drain plug. Install the reservoir tank and cylin-

der block drain plug, if removed for a total system drain or for

engine removal or repair.

• The radiator must be completely empty of coolant and

water.

• Apply sealant to the threads of the cylinder block drain

plug. Use Genuine High Pe rformance Thread Sealant or

equivalent. Refer to GI-21, "Recommended Chemical

Products and Sealants".

: Front

CAUTION:

Do not reuse copper sealing washers.

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

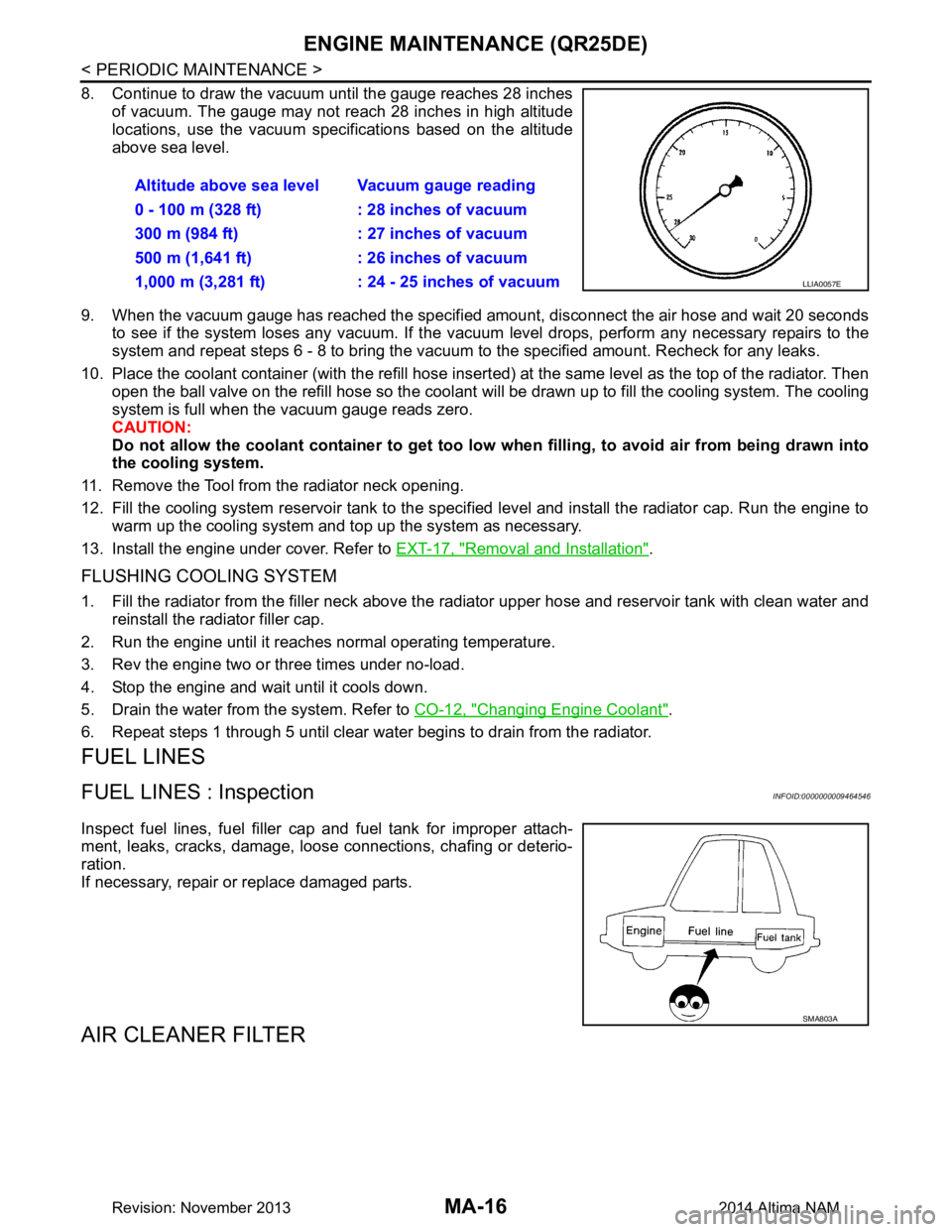

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is

placed at floor level. Make sure the ball valve is in the closed

position.

• Use recommended coolant or equivalent.

Refer to MA-11, "FOR USA AND CANADA : Fluids and Lubri-

cants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog th e cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. Th is will purge any air trapped in the refill hose.

Radiator drain plug : Refer to

CO-16, "Exploded View"

.

Cylinder block drain plug (A) : 54 Nm (5.5 kg-m, 40 ft-lb)

Cylinder block drain plug (B) : 9.8 N·m (1.0 kg-m, 87 in-lb)

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

CO-26, "Capacity"

.

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

AWBIA1328GB

LLIA0058E

Revision: November 20132014 Altima NAM

Page 3200 of 4801

MA-16

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (QR25DE)

8. Continue to draw the vacuum until the gauge reaches 28 inchesof vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose insert ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and t op up the system as necessary.

13. Install the engine under cover. Refer to EXT-17, "Removal and Installation"

.

FLUSHING COOLING SYSTEM

1. Fill the radiator from the filler neck above the radiator upper hose and reservoir tank with clean water and

reinstall the radiator filler cap.

2. Run the engine until it reaches normal operating temperature.

3. Rev the engine two or three times under no-load.

4. Stop the engine and wait until it cools down.

5. Drain the water from the system. Refer to CO-12, "Changing Engine Coolant"

.

6. Repeat steps 1 through 5 until clear water begins to drain from the radiator.

FUEL LINES

FUEL LINES : InspectionINFOID:0000000009464546

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

SMA803A

Revision: November 20132014 Altima NAM

Page 3206 of 4801

MA-22

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (VQ35DE)

ENGINE MAINTENANCE (VQ35DE)

DRIVE BELTS

DRIVE BELTS : Checking Drive BeltsINFOID:0000000009464553

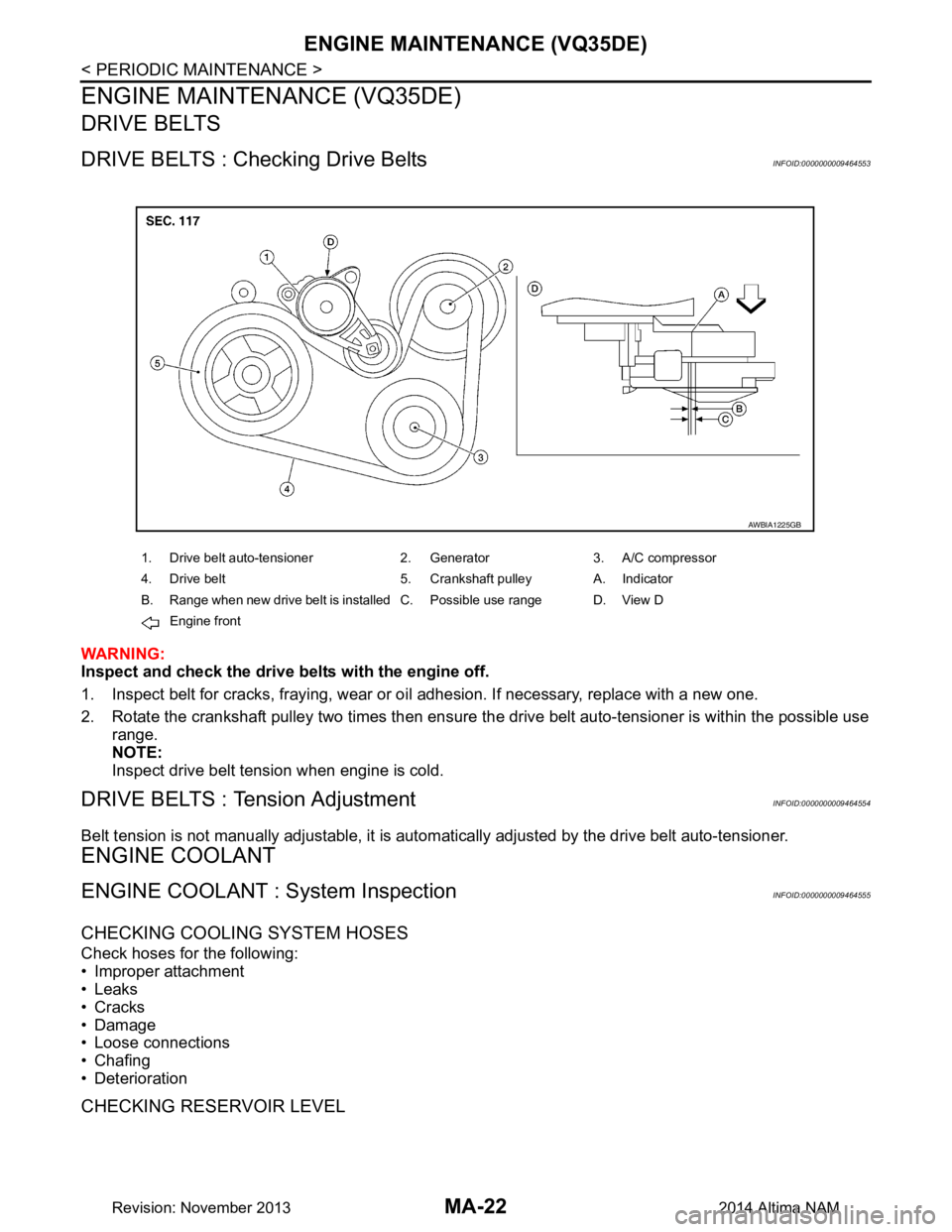

WARNING:

Inspect and check the drive belts with the engine off.

1. Inspect belt for cracks, fraying, wear or o il adhesion. If necessary, replace with a new one.

2. Rotate the crankshaft pulley two times then ensure t he drive belt auto-tensioner is within the possible use

range.

NOTE:

Inspect drive belt tension when engine is cold.

DRIVE BELTS : Tension AdjustmentINFOID:0000000009464554

Belt tension is not manually adjustable, it is aut omatically adjusted by the drive belt auto-tensioner.

ENGINE COOLANT

ENGINE COOLANT : System InspectionINFOID:0000000009464555

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

• Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

CHECKING RESERVOIR LEVEL

1. Drive belt auto-tensioner 2. Generator 3. A/C compressor

4. Drive belt 5. Crankshaft pulley A. Indicator

B. Range when new drive belt is installed C. Possible use range D. View D Engine front

AWBIA1225GB

Revision: November 20132014 Altima NAM

Page 3207 of 4801

ENGINE MAINTENANCE (VQ35DE)MA-23

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

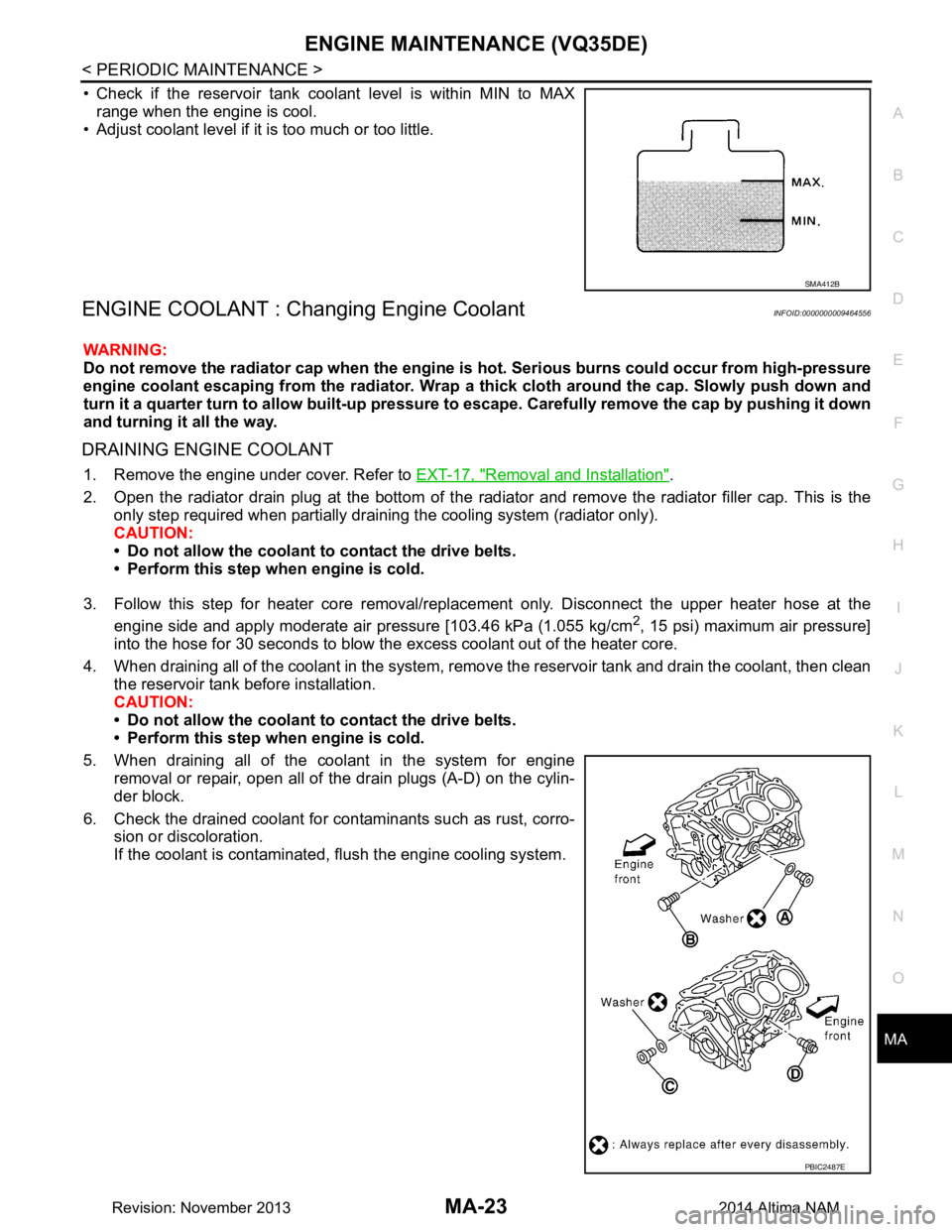

• Check if the reservoir tank coolant level is within MIN to MAX

range when the engine is cool.

• Adjust coolant level if it is too much or too little.

ENGINE COOLANT : Chang ing Engine CoolantINFOID:0000000009464556

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

DRAINING ENGINE COOLANT

1. Remove the engine under cover. Refer to EXT-17, "Removal and Installation".

2. Open the radiator drain plug at the bottom of the radiat or and remove the radiator filler cap. This is the

only step required when partially draining the cooling system (radiator only).

CAUTION:

• Do not allow the coolant to contact the drive belts.

• Perform this step when engine is cold.

3. Follow this step for heater core removal/repl acement only. Disconnect the upper heater hose at the

engine side and apply moderate air pressure [103.46 kPa (1.055 kg/cm

2, 15 psi) maximum air pressure]

into the hose for 30 seconds to blow the excess coolant out of the heater core.

4. When draining all of the coolant in the system, remo ve the reservoir tank and drain the coolant, then clean

the reservoir tank before installation.

CAUTION:

• Do not allow the coolant to contact the drive belts.

• Perform this step when engine is cold.

5. When draining all of the coolant in the system for engine removal or repair, open all of the drain plugs (A-D) on the cylin-

der block.

6. Check the drained coolant for contaminants such as rust, corro- sion or discoloration.

If the coolant is contaminated, flush the engine cooling system.

SMA412B

PBIC2487E

Revision: November 20132014 Altima NAM

Page 3208 of 4801

MA-24

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (VQ35DE)

REFILLING ENGINE COOLANT

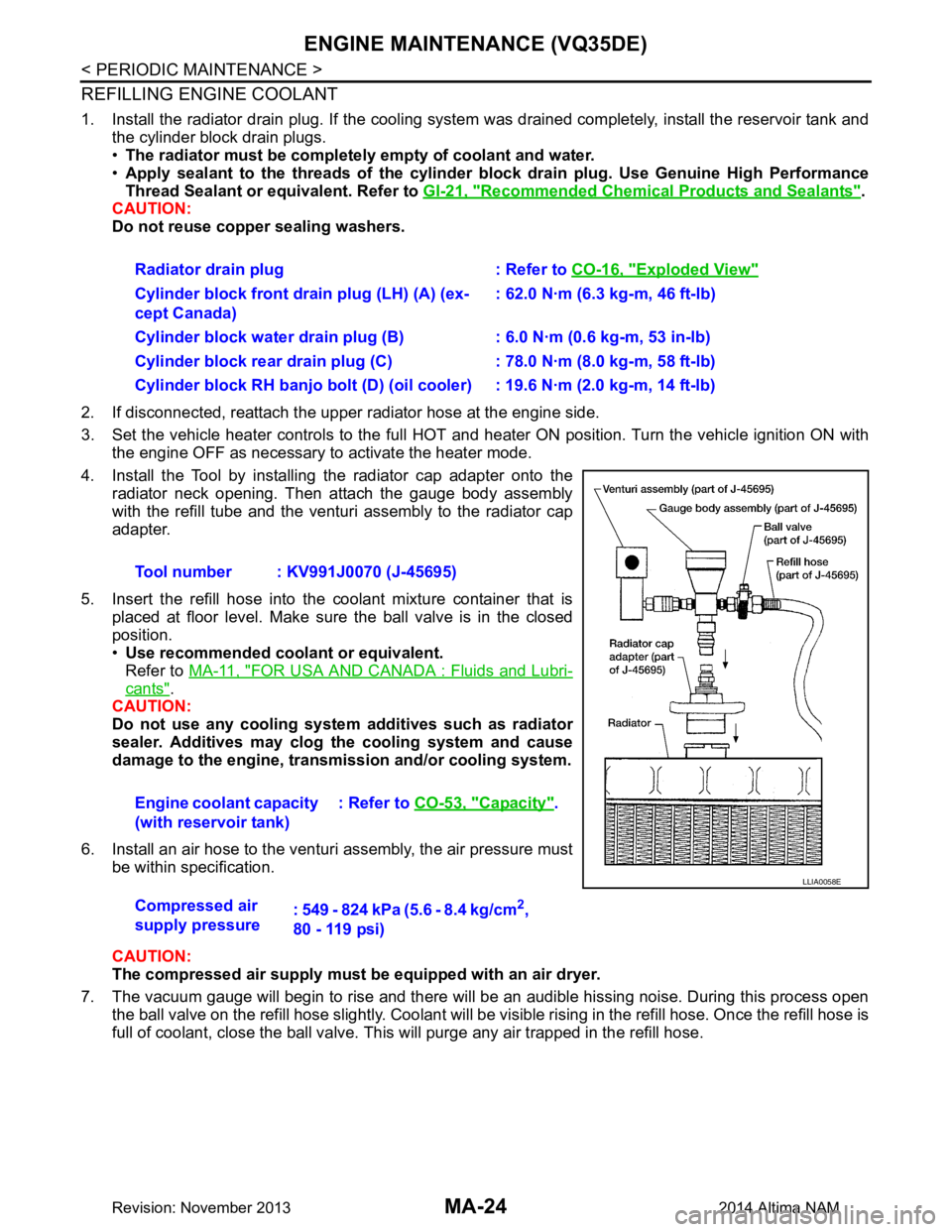

1. Install the radiator drain plug. If the cooling system was drained completely, install the reservoir tank and

the cylinder block drain plugs.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants"

.

CAUTION:

Do not reuse copp er sealing washers.

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use recommended coolant or equivalent.

Refer to MA-11, "FOR USA AND CANADA : Fluids and Lubri-

cants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog th e cooling system and cause

damage to the engine, transm ission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose. Radiator drain plug : Refer to

CO-16, "Exploded View"

Cylinder block front drain plug (LH) (A) (ex-

cept Canada) : 62.0 N·m (6.3 kg-m, 46 ft-lb)

Cylinder block water drain plug (B) : 6.0 N·m (0.6 kg-m, 53 in-lb)

Cylinder block rear drain plug (C) : 78.0 N·m (8.0 kg-m, 58 ft-lb)

Cylinder block RH banjo bolt (D) (oil cooler) : 19.6 N·m (2.0 kg-m, 14 ft-lb)

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

CO-53, "Capacity"

.

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Revision: November 20132014 Altima NAM