battery NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3903 of 4801

SEC-78

< DTC/CIRCUIT DIAGNOSIS >

B210E STARTER RELAY

B210E STARTER RELAY

DTC LogicINFOID:0000000009461125

DTC DETECTION LOGIC

NOTE:

• If DTC B210E is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

BCS-68, "DTC Logic"

.

• If DTC B210E is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

BCS-69, "DTC Logic"

.

• When IPDM E/R power supply voltage is low (Approx. 7 - 8 V for about 1 second), the DTC B210F may be

detected.

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions and wait for at least 1 second.

- CVT selector lever is in the P (Park) or N (Neutral) position

- Do not depress the brake pedal

2. Check Self-diagnostic result with CONSULT.

Is DTC detected?

YES >> Refer to SEC-78, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461126

Regarding Wiring Diagram information, refer to SEC-29, "Wiring Diagram".

1. PERFORM SELF DIAGNOSTIC RESULT

Perform Self Diagnostic Result of IPDM E/R using CONSULT.

Is display history of DTC B210E CRNT?

YES >> GO TO 2.

NO >> Refer to GI-43, "Intermittent Incident"

.

2.CHECK STARTER CONTROL RELA Y CONTROL CIRCUITS VOLTAGE

Check voltage between IPDM E/R connectors and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> GO TO 3.

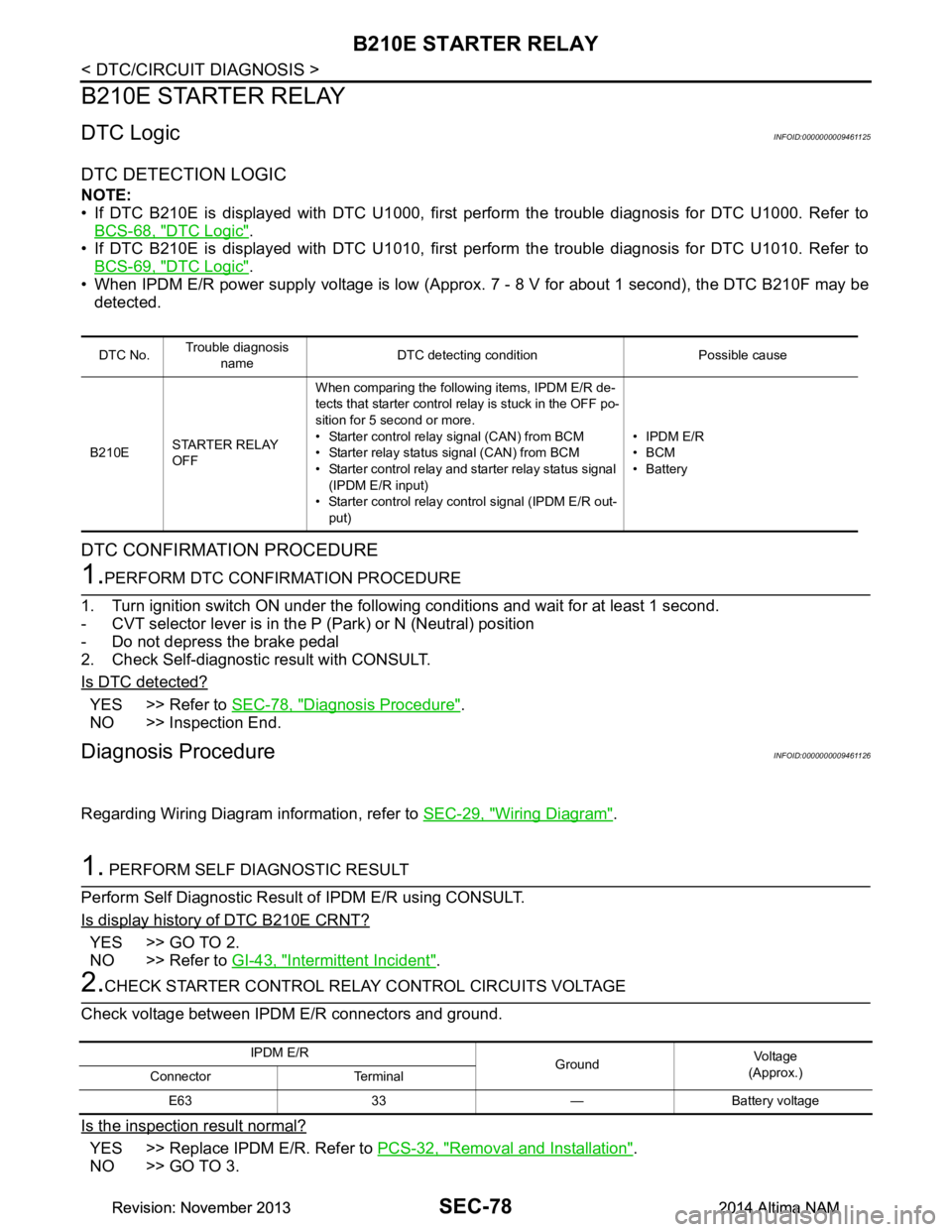

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B210E STARTER RELAY

OFF When comparing the following items, IPDM E/R de-

tects that starter control relay is stuck in the OFF po-

sition for 5 second or more.

• Starter control relay signal (CAN) from BCM

• Starter relay status signal (CAN) from BCM

• Starter control relay and st arter relay status signal

(IPDM E/R input)

• Starter control relay cont rol signal (IPDM E/R out-

put) • IPDM E/R

•BCM

•Battery

IPDM E/R GroundVo l ta g e

(Approx.)

Connector Terminal

E63 33 — Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3906 of 4801

B210F TRANSMISSION RANGE SWITCHSEC-81

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

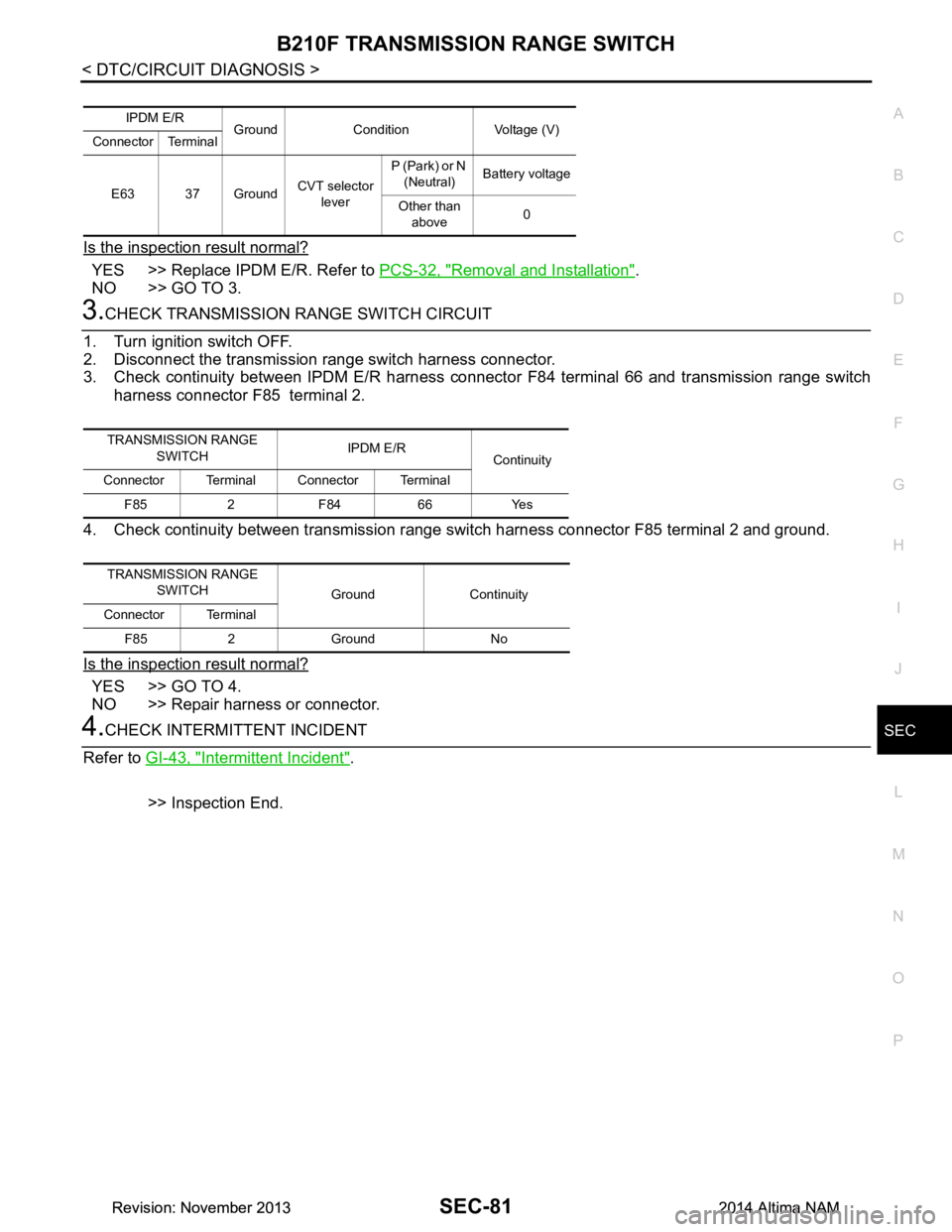

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> GO TO 3.

3.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the transmission range switch harness connector.

3. Check continuity between IPDM E/R harness connec tor F84 terminal 66 and transmission range switch

harness connector F85 terminal 2.

4. Check continuity between transmission range s witch harness connector F85 terminal 2 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-43, "Intermittent Incident"

.

>> Inspection End.

IPDM E/R Ground Condition Voltage (V)

Connector Terminal

E63 37 Ground CVT selector

lever P (Park) or N

(Neutral) Battery voltage

Other than above 0

TRANSMISSION RANGE

SWITCH IPDM E/R

Continuity

Connector Terminal Connector Terminal

F85 2 F84 66 Yes

TRANSMISSION RANGE SWITCH Ground Continuity

Connector Terminal

F85 2 Ground No

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3908 of 4801

B2110 TRANSMISSION RANGE SWITCHSEC-83

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

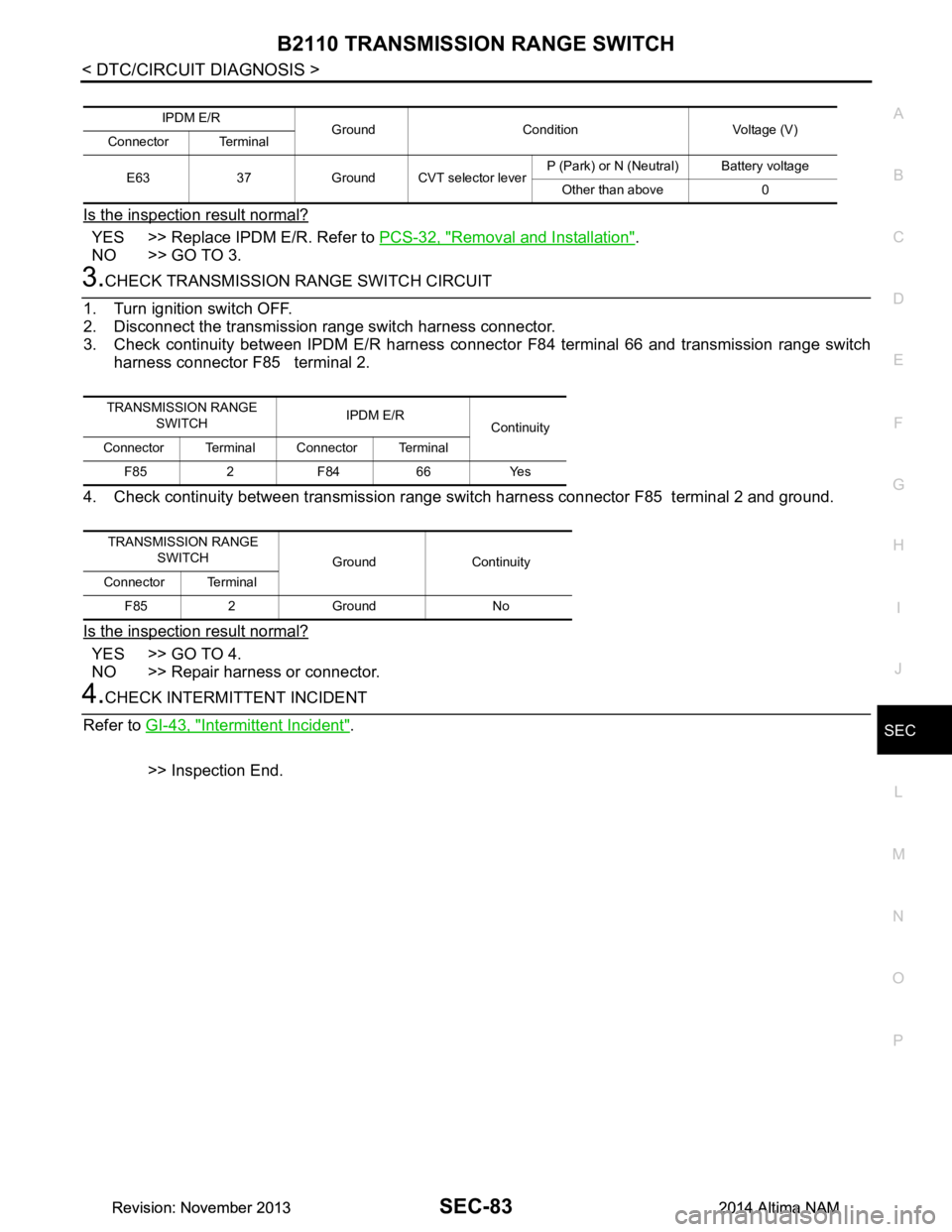

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> GO TO 3.

3.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the transmission range switch harness connector.

3. Check continuity between IPDM E/R harness connec tor F84 terminal 66 and transmission range switch

harness connector F85 terminal 2.

4. Check continuity between transmission range s witch harness connector F85 terminal 2 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-43, "Intermittent Incident"

.

>> Inspection End.

IPDM E/R Ground Condition Voltage (V)

Connector Terminal

E63 37 Ground CVT selector lever P (Park) or N (Neutral) Battery voltage

Other than above 0

TRANSMISSION RANGE SWITCH IPDM E/R

Continuity

Connector Terminal Connector Terminal

F85 2 F84 66 Yes

TRANSMISSION RANGE SWITCH Ground Continuity

Connector Terminal

F85 2 Ground No

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3919 of 4801

SEC-94

< DTC/CIRCUIT DIAGNOSIS >

B2555 STOP LAMP

B2555 STOP LAMP

DTC LogicINFOID:0000000009461150

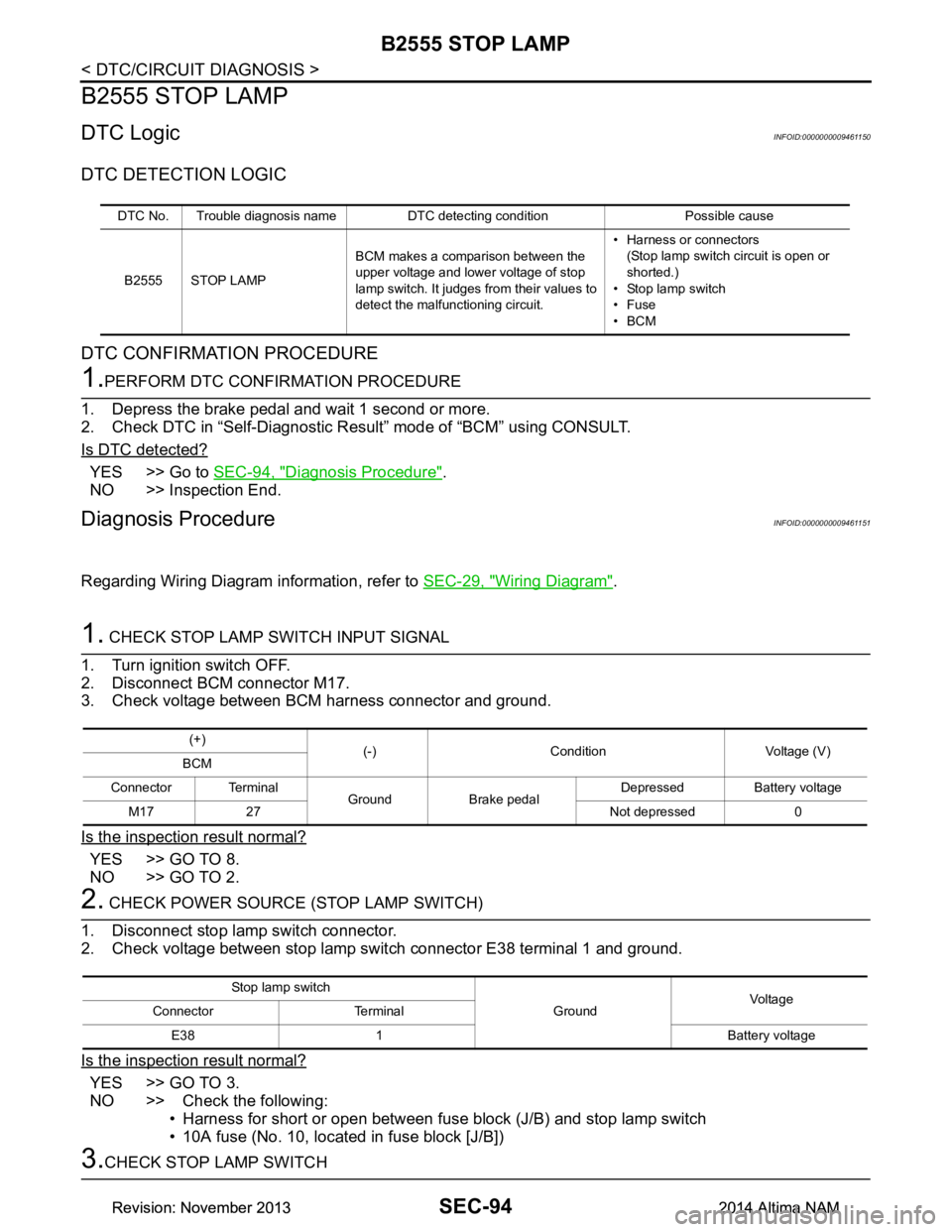

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Depress the brake pedal and wait 1 second or more.

2. Check DTC in “Self-Diagnostic Result” mode of “BCM” using CONSULT.

Is DTC detected?

YES >> Go to SEC-94, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461151

Regarding Wiring Diagram information, refer to SEC-29, "Wiring Diagram".

1. CHECK STOP LAMP SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect BCM connector M17.

3. Check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 2.

2. CHECK POWER SOURCE (STOP LAMP SWITCH)

1. Disconnect stop lamp switch connector.

2. Check voltage between stop lamp switch connector E38 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the following: • Harness for short or open between fuse block (J/B) and stop lamp switch

• 10A fuse (No. 10, located in fuse block [J/B])

3.CHECK STOP LAMP SWITCH

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B2555 STOP LAMP BCM makes a comparison between the

upper voltage and lower voltage of stop

lamp switch. It judges from their values to

detect the malfunctioning circuit. • Harness or connectors

(Stop lamp switch circuit is open or

shorted.)

• Stop lamp switch

•Fuse

•BCM

(+) (-) Condition Voltage (V)

BCM

Connector Terminal Ground Brake pedal Depressed Battery voltage

M17 27 Not depressed 0

Stop lamp switch GroundVoltage

Connector Terminal

E38 1 Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3920 of 4801

B2555 STOP LAMPSEC-95

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

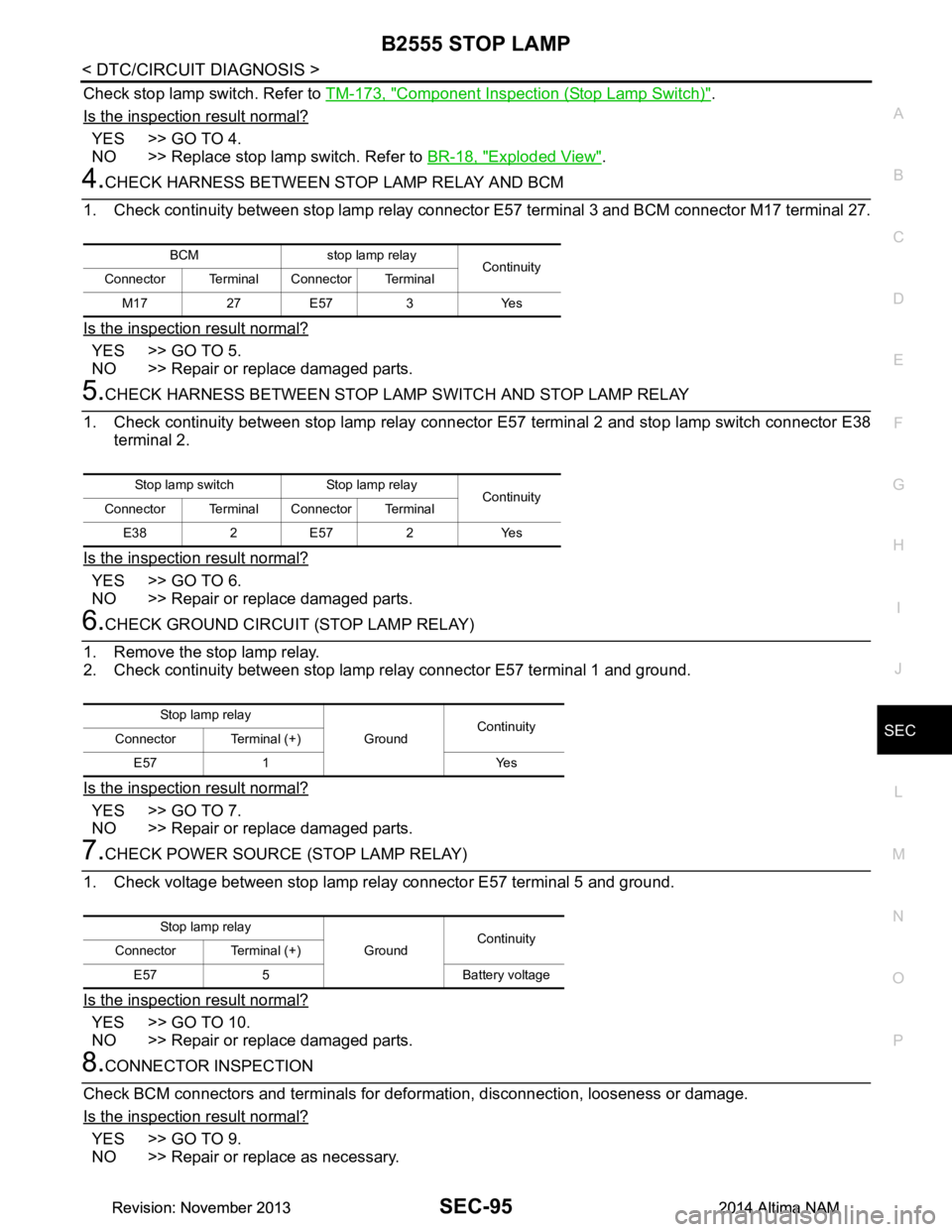

Check stop lamp switch. Refer to TM-173, "Component Inspection (Stop Lamp Switch)".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace stop lamp switch. Refer to BR-18, "Exploded View"

.

4.CHECK HARNESS BETWEEN STOP LAMP RELAY AND BCM

1. Check continuity between stop lamp relay connecto r E57 terminal 3 and BCM connector M17 terminal 27.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK HARNESS BETWEEN STOP LAMP SWITCH AND STOP LAMP RELAY

1. Check continuity between stop lamp relay connector E57 terminal 2 and stop lamp switch connector E38

terminal 2.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace damaged parts.

6.CHECK GROUND CIRCUIT (STOP LAMP RELAY)

1. Remove the stop lamp relay.

2. Check continuity between stop lamp relay connector E57 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace damaged parts.

7.CHECK POWER SOURCE (STOP LAMP RELAY)

1. Check voltage between stop lamp relay connector E57 terminal 5 and ground.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Repair or replace damaged parts.

8.CONNECTOR INSPECTION

Check BCM connectors and terminals for def ormation, disconnection, looseness or damage.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace as necessary.

BCM stop lamp relay Continuity

Connector Terminal Connector Terminal

M17 27 E57 3 Yes

Stop lamp switch Stop lamp relay Continuity

Connector Terminal Connector Terminal

E38 2 E57 2 Yes

St op la mp rel ay GroundContinuity

Connector Terminal (+)

E57 1 Yes

St op la mp rel ay GroundContinuity

Connector Terminal (+)

E57 5 Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3943 of 4801

SEC-118

< DTC/CIRCUIT DIAGNOSIS >

B2617 STARTER RELAY CIRCUIT

B2617 STARTER RELAY CIRCUIT

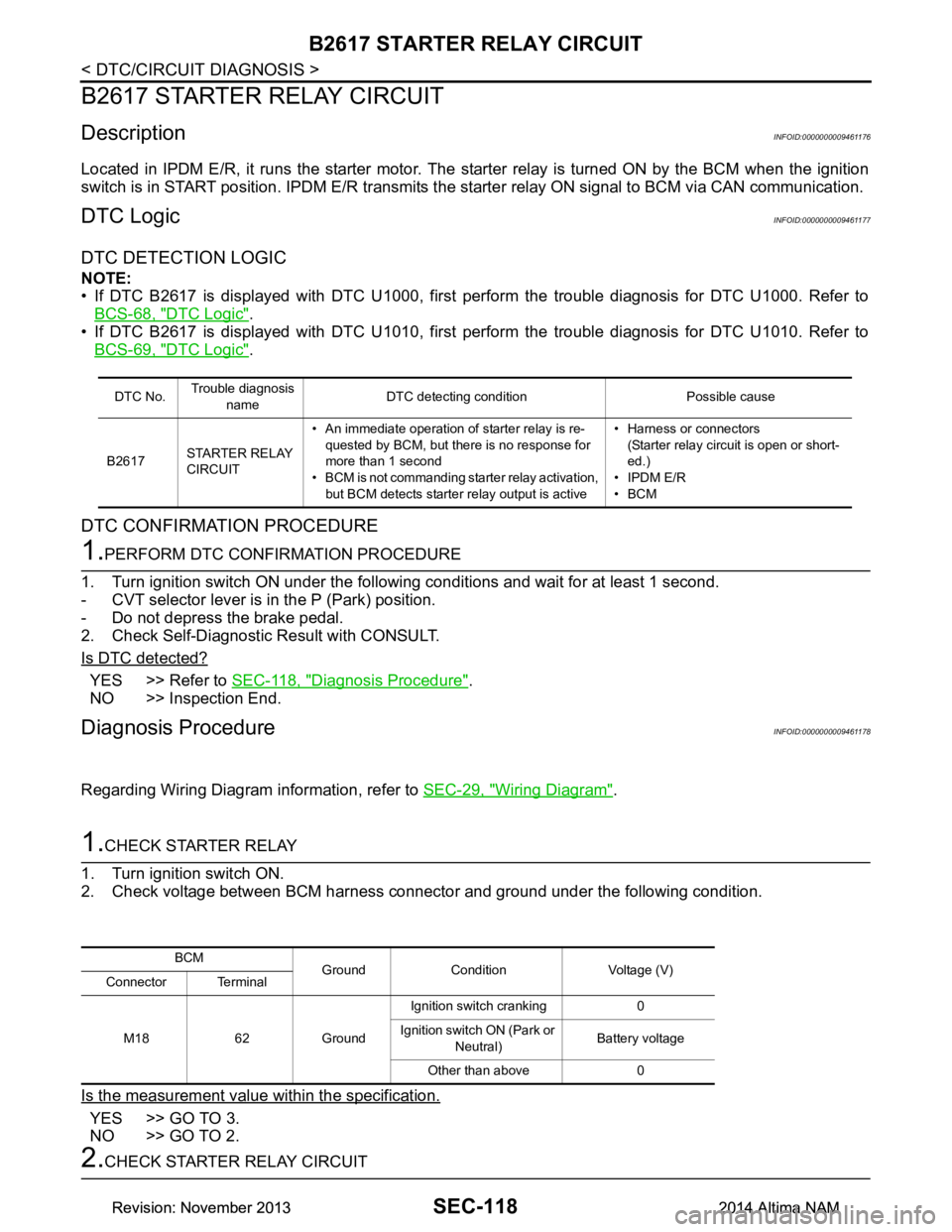

DescriptionINFOID:0000000009461176

Located in IPDM E/R, it runs the starter motor. The starter relay is turned ON by the BCM when the ignition

switch is in START position. IPDM E/R transmits t he starter relay ON signal to BCM via CAN communication.

DTC LogicINFOID:0000000009461177

DTC DETECTION LOGIC

NOTE:

• If DTC B2617 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

BCS-68, "DTC Logic"

.

• If DTC B2617 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-69, "DTC Logic"

.

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions and wait for at least 1 second.

- CVT selector lever is in the P (Park) position.

- Do not depress the brake pedal.

2. Check Self-Diagnostic Result with CONSULT.

Is DTC detected?

YES >> Refer to SEC-118, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461178

Regarding Wiring Diagram information, refer to SEC-29, "Wiring Diagram".

1.CHECK STARTER RELAY

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector and ground under the following condition.

Is the measurement value within the specification.

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK STARTER RELAY CIRCUIT

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2617 STARTER RELAY

CIRCUIT • An immediate operation of starter relay is re-

quested by BCM, but there is no response for

more than 1 second

• BCM is not commanding starter relay activation, but BCM detects starter relay output is active • Harness or connectors

(Starter relay circuit is open or short-

ed.)

• IPDM E/R

•BCM

BCM Ground Condition Voltage (V)

Connector Terminal

M18 62 Ground Ignition switch cranking 0

Ignition switch ON (Park or Neutral) Battery voltage

Other than above 0

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3947 of 4801

SEC-122

< DTC/CIRCUIT DIAGNOSIS >

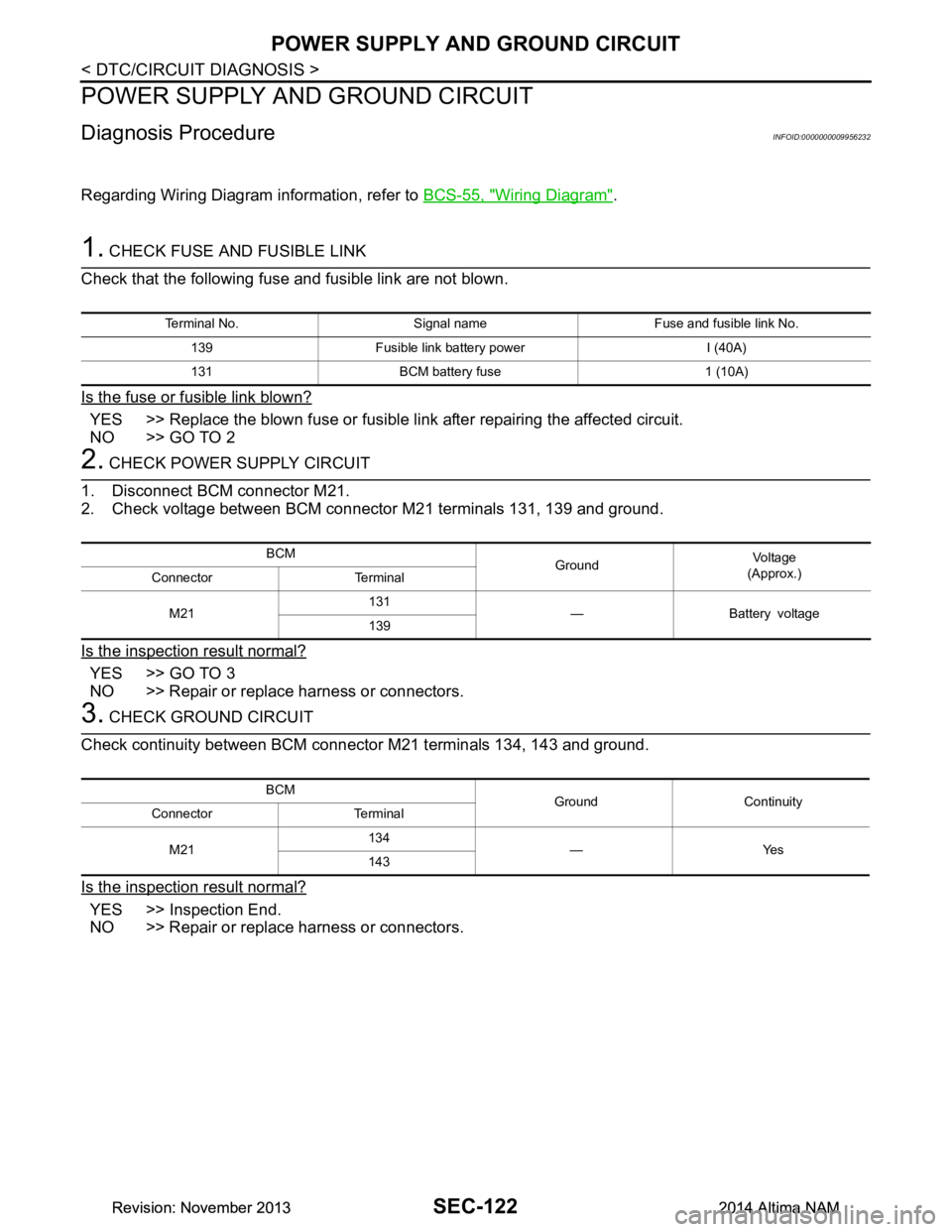

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009956232

Regarding Wiring Diagram information, refer to BCS-55, "Wiring Diagram".

1. CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse or fusible link blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connector M21.

2. Check voltage between BCM connector M21 terminals 131, 139 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M21 terminals 134, 143 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

Terminal No. Signal name Fuse and fusible link No.

139 Fusible link battery power I (40A)

131 BCM battery fuse 1 (10A)

BCM GroundVo l ta g e

(Approx.)

Connector Terminal

M21 131

— Battery voltage

139

BCM Ground Continuity

Connector Terminal

M21 134

—Yes

143

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3948 of 4801

POWER SUPPLY AND GROUND CIRCUITSEC-123

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

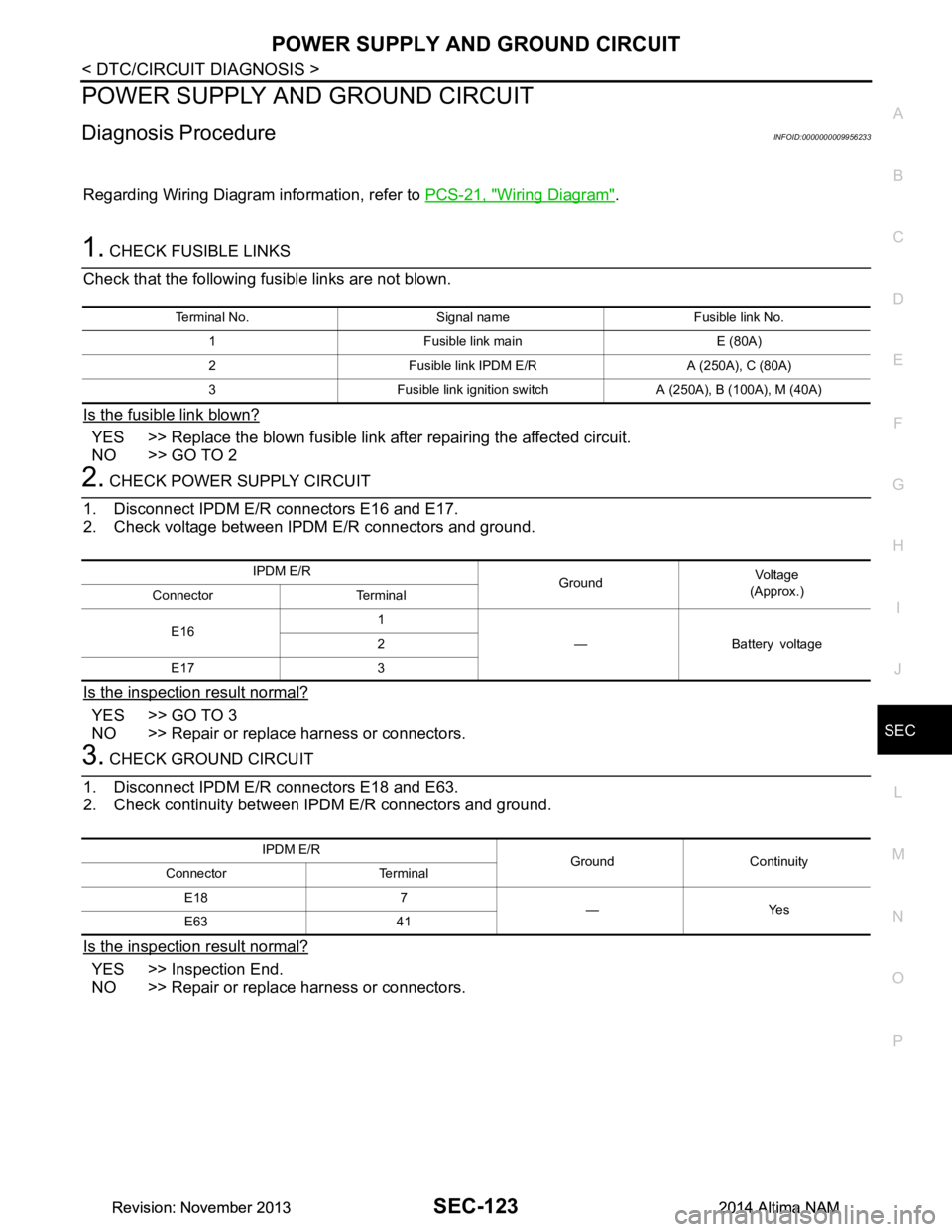

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009956233

Regarding Wiring Diagram information, refer to PCS-21, "Wiring Diagram".

1. CHECK FUSIBLE LINKS

Check that the following fusible links are not blown.

Is the fusible link blown?

YES >> Replace the blown fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect IPDM E/R connectors E16 and E17.

2. Check voltage between IPDM E/R connectors and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R connectors E18 and E63.

2. Check continuity between IPDM E/R connectors and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

Terminal No. Signal name Fusible link No.

1 Fusible link main E (80A)

2 Fusible link IPDM E/R A (250A), C (80A)

3 Fusible link ignition switch A (250A), B (100A), M (40A)

IPDM E/R GroundVol tag e

(Approx.)

Connector Terminal

E16 1

— Battery voltage

2

E17 3

IPDM E/R Ground Continuity

Connector Terminal

E18 7 —Yes

E63 41

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3950 of 4801

HOOD SWITCHSEC-125

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

HOOD SWITCH

Component Function CheckINFOID:0000000009461186

1.CHECK FUNCTION

1. Select HOOD SW in Data Monito r mode of IPDM E/R using CONSULT.

2. Check HOOD SW indication under the following condition.

Is the indication normal?

YES >> Hood switch is OK.

NO >> Go to SEC-125, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009461187

Regarding Wiring Diagram information, refer to SEC-50, "Wiring Diagram".

1.CHECK HOOD SWITCH SIGNAL CIRCUITS

1. Turn ignition switch OFF.

2. Disconnect hood switch connector.

3. Check voltage between hood switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK HOOD SWITCH SIGNAL CIRCUITS

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R har ness connector and hood switch harness connector.

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace harness.

Monitor item Condition Indication

HOOD SW Hood Open ON

Close OFF

(+) (–) Voltage (V)

IPDM E/R

Connector Terminal

E201 94

Ground Battery voltage

96

IPDM E/R Hood switch Continuity

Connector Terminal Connector Terminal

E201 94

E248 1

Ye s

96 2

IPDM E/R GroundContinuity

Connector Terminal

E201 94

No

96

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3952 of 4801

SECURITY INDICATOR LAMPSEC-127

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

SECURITY INDICATOR LAMP

Component Function CheckINFOID:0000000009461192

1.CHECK FUNCTION

1. Perform THEFT IND in ACTIVE TEST mode of IMMU of BCM using CONSULT.

2. Check security indicator lamp operation.

Is the inspection result normal?

YES >> Inspection End.

NO >> Go to SEC-127, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009461193

Regarding Wiring Diagram information, refer to SEC-50, "Wiring Diagram".

1.CHECK SECURITY INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check voltage between combination meter harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Check 10 A fuse [No. 13, lo cated in the fuse block (J/B)].

NO-2 >> Check harness for open or short between combination meter and fuse.

2.CHECK SECURITY INDICATOR LAMP SIGNAL

1. Connect combination meter connector.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 4.

3.REPLACE BCM

1. Replace BCM. Refer to BCS-80, "Removal and Installation"

.

2. Perform initialization of BCM and registration of all Intelligent Keys using CONSULT.

>> Inspection End.

Test item Description

THEFT IND ON

Security indicator lamp Illuminates

OFF Does not illuminate

(+) (–) Voltage (V)

Combination meter

Connector Terminal M24 22 Ground Battery voltage

(+) (–) Voltage (V)

BCM

Connector Terminal M17 18 Ground Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM