battery location NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 282 of 4801

BRM-4

< PRECAUTION >

HANDLING PRECAUTIONS FOR PLASTICS

HANDLING PRECAUTIONS FOR PLASTICS

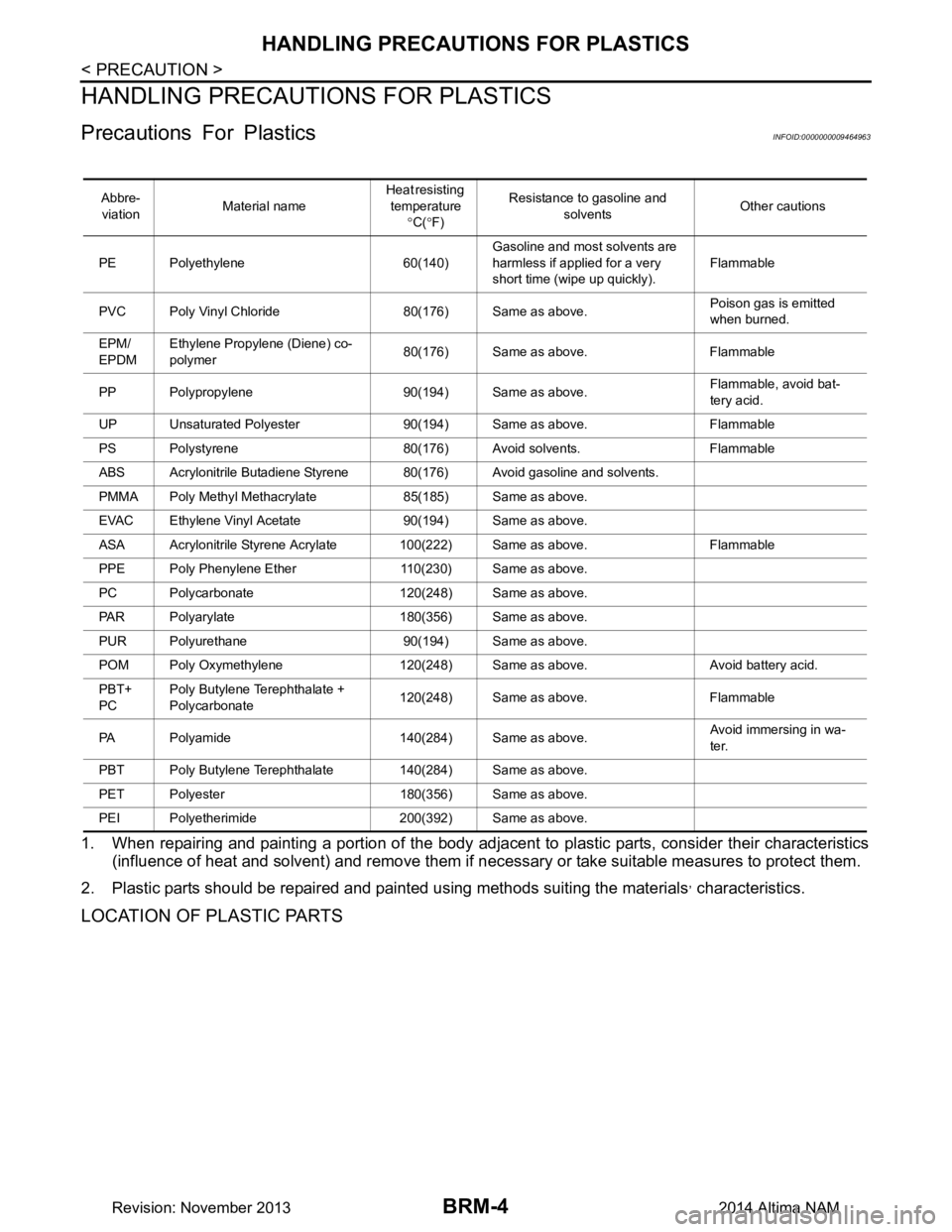

Precautions For PlasticsINFOID:0000000009464963

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if neces sary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

LOCATION OF PLASTIC PARTS

Abbre- viation Material name Heat resisting

temperature °C( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60(140) Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PVC Poly Vinyl Chloride 80(176) Same as above. Poison gas is emitted

when burned.

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer 80(176) Same as above. Flammable

PP Polypropylene 90(194) Same as above. Flammable, avoid bat-

tery acid.

UP Unsaturated Polyester 90(194) Same as above. Flammable

PS Polystyrene 80(176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene 80(176) Avoid gasoline and solvents.

PMMA Poly Methyl Methacrylate 85(185) Same as above.

EVAC Ethylene Vinyl Acetate 90(194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100(222) Same as above. Flammable

PPE Poly Phenylene Ether 110(230) Same as above.

PC Polycarbonate 120(248) Same as above.

PAR Polyarylate 180(356) Same as above.

PUR Polyurethane 90(194) Same as above.

POM Poly Oxymethylene 120(248) Same as above. Avoid battery acid.

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate 120(248) Same as above. Flammable

PA Polyamide 140(284) Same as above. Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140(284) Same as above.

PET Polyester 180(356) Same as above.

PEI Polyetherimide 200(392) Same as above.

Revision: November 20132014 Altima NAM

Page 350 of 4801

CHG

COMPONENT PARTSCHG-5

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

B

A

O P

N

SYSTEM DESCRIPTION

COMPONENT PARTS

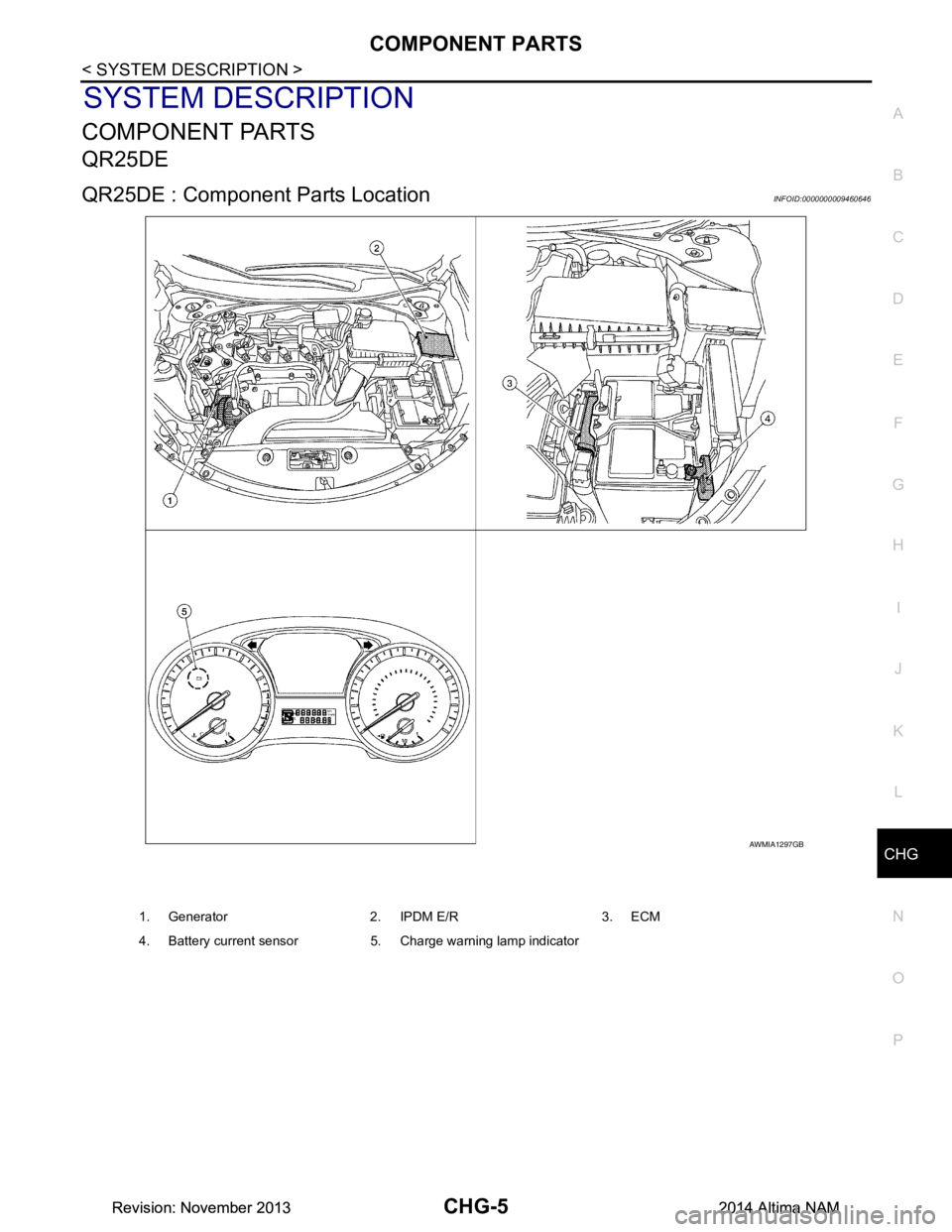

QR25DE

QR25DE : Component Parts LocationINFOID:0000000009460646

AWMIA1297GB

1. Generator 2. IPDM E/R 3. ECM

4. Battery current sensor 5. Charge warning lamp indicator

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 352 of 4801

CHG

COMPONENT PARTSCHG-7

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

B

A

O P

N

VQ35DE : Component Parts LocationINFOID:0000000009460648

AWMIA1304ZZ

1. Generator 2. IPDM E/R 3. ECM

4. Battery current sensor 5. Charge warning lamp indicator

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1001 of 4801

EC-1

ENGINE

C

D E

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

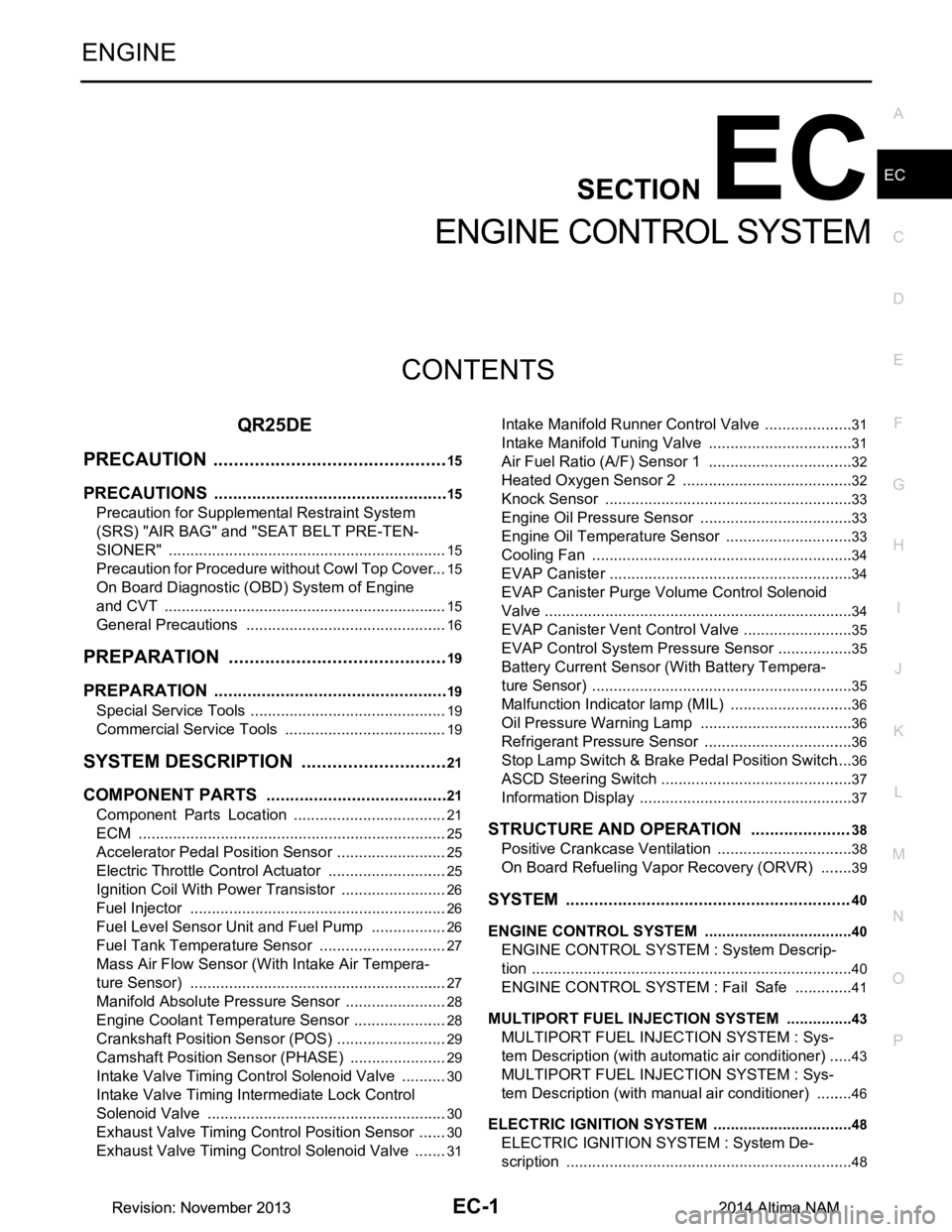

CONTENTS

ENGINE CONTROL SYSTEM

QR25DE

PRECAUTION ................ ..............................

15

PRECAUTIONS .............................................. ....15

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

15

Precaution for Procedure without Cowl Top Cover ....15

On Board Diagnostic (OBD) System of Engine

and CVT .............................................................. ....

15

General Precautions ...............................................16

PREPARATION ...........................................19

PREPARATION .............................................. ....19

Special Service Tools .......................................... ....19

Commercial Service Tools ......................................19

SYSTEM DESCRIPTION .............................21

COMPONENT PARTS ................................... ....21

Component Parts Location ................................ ....21

ECM ........................................................................25

Accelerator Pedal Position Sensor ...................... ....25

Electric Throttle Control Actuator ........................ ....25

Ignition Coil With Power Transistor .........................26

Fuel Injector ........................................................ ....26

Fuel Level Sensor Unit and Fuel Pump .............. ....26

Fuel Tank Temperature Sensor .......................... ....27

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) ........................................................ ....

27

Manifold Absolute Pressure Sensor ........................28

Engine Coolant Temperature Sensor .................. ....28

Crankshaft Position Sensor (POS) ..........................29

Camshaft Position Sens or (PHASE) .......................29

Intake Valve Timing Cont rol Solenoid Valve ...........30

Intake Valve Timing Intermediate Lock Control

Solenoid Valve .................................................... ....

30

Exhaust Valve Timing Control Position Sensor .......30

Exhaust Valve Timing Control Solenoid Valve ........31

Intake Manifold Runner Control Valve ................. ....31

Intake Manifold Tuning Valve ..................................31

Air Fuel Ratio (A/F) Sensor 1 ..................................32

Heated Oxygen Sensor 2 ........................................32

Knock Sensor ..........................................................33

Engine Oil Pressure Sensor ....................................33

Engine Oil Temperature Sensor .......................... ....33

Cooling Fan .............................................................34

EVAP Canister .........................................................34

EVAP Canister Purge Volu me Control Solenoid

Valve .................................................................... ....

34

EVAP Canister Vent Control Valve ..........................35

EVAP Control System Pres sure Sensor ..................35

Battery Current Sensor (With Battery Tempera-

ture Sensor) ......................................................... ....

35

Malfunction Indicator lamp (MIL) .............................36

Oil Pressure Warning Lamp ....................................36

Refrigerant Pressure Sensor ............................... ....36

Stop Lamp Switch & Brake Pedal Position Switch ....36

ASCD Steering Switch .............................................37

Information Display ..................................................37

STRUCTURE AND OPERATION .....................38

Positive Crankcase Ventilation ................................38

On Board Refueling Vapor Recovery (ORVR) ........39

SYSTEM ............................................................40

ENGINE CONTROL SYSTEM ........................ ...........40

ENGINE CONTROL SYSTEM : System Descrip-

tion ....................................................................... ....

40

ENGINE CONTROL SYSTEM : Fail Safe ..............41

MULTIPORT FUEL INJECTION SYSTEM ................43

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description (with auto matic air conditioner) ......

43

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description (with manual air conditioner) .........

46

ELECTRIC IGNITION SYSTEM .................................48

ELECTRIC IGNITION SYSTEM : System De-

scription ............................................................... ....

48

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1008 of 4801

EC-8

POSITIVE CRANKCASE VENTILATION ........539

Inspection ............................................................ ..539

REMOVAL AND INSTALLATION ..............540

ECM ................................................................ .540

Removal and Installation ..................................... ..540

SERVICE DATA AND SPECIFICATIONS

(SDS) .............. ............................................

541

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

541

Idle Speed ........................................................... ..541

Ignition Timing .......................................................541

Calculated Load Value ..........................................541

Mass Air Flow Sensor ............................................541

VQ35DE

PRECAUTION .............. ..............................

542

PRECAUTIONS .............................................. .542

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ..

542

On Board Diagnostic (OBD) System of Engine

and CVT .............................................................. ..

542

General Precautions ..............................................543

PREPARATION ..........................................546

PREPARATION .............................................. .546

Special Service Tools .......................................... ..546

Commercial Service Tools .....................................546

SYSTEM DESCRIPTION ...........................548

COMPONENT PARTS .................................... .548

ENGINE CONTROL SYSTEM .................................548

ENGINE CONTROL SYSTEM : Component Parts

Location ............................................................... ..

548

Accelerator Pedal Position Sensor ........................552

Air Fuel Ratio (A/F) Sensor 1 ................................552

ASCD Steering Switch ...........................................553

Battery Current Sensor (With Battery Tempera-

ture Sensor) ......................................................... ..

553

Camshaft Position Sensor (PHASE) .....................554

Cooling Fan ......................................................... ..554

Crankshaft Position Sensor (POS) ........................554

ECM .......................................................................555

Electric Throttle Control Actuator ......................... ..555

Electronic Controlled Engine Mount .................... ..556

Engine Coolant Temperature Sensor ....................556

Engine Oil Pressure Sensor ................................ ..557

Engine Oil Temperature Sensor ............................557

EVAP Canister ..................................... ..................557

EVAP Canister Purge Volu me Control Solenoid

Valve .................................................................... ..

557

EVAP Canister Vent Control Valve ........................558

EVAP Control System Pressu re Sensor ................558

Fuel Injector ......................................................... .558

Fuel Level Sensor Unit and Fuel Pump (With Fuel

Tank Temperature Sensor) .................................. .

558

Heated Oxygen Sensor 2 ......................................559

Ignition Coil (With Power Transistor) ....................560

Intake Valve Timing Control Solenoid Valve .........560

Knock Sensor ....................................................... .560

Malfunction Indicator lamp (MIL) ...........................560

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) ......................................................... .

560

Oil Pressure Warning Lamp ..................................561

Power Valve Actuator 1 and 2 ..............................561

Refrigerant Pressure Sensor ................................562

Stop Lamp Switch & Brak e Pedal Position Switch .562

VIAS Control Solenoid Valve 1 and 2 .................. .562

STRUCTURE AND OPERATION .....................563

Positive Crankcase Ventilation (PCV) ...................563

On Board Refueling Vapor Recovery (ORVR) ..... .564

SYSTEM ...........................................................565

ENGINE CONTROL SYSTEM ................................ .565

ENGINE CONTROL SYSTEM : System Descrip-

tion ....................................................................... .

565

ENGINE CONTROL SYSTEM : Fail-safe .............566

MULTIPORT FUEL INJECTION SYSTEM ............. .568

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description .................................................... .

568

ELECTRIC IGNITION SYSTEM ............................. .571

ELECTRIC IGNITION SYSTEM : System De-

scription ................................................................ .

571

AIR CONDITIONING CUT CONTROL ................... .572

AIR CONDITIONING CUT CONTROL : System

Description ........................................................... .

573

AUTOMATIC SPEED CONTROL DEVICE (ASCD) .574

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : System Description ..................................... .

574

COOLING FAN CONTROL .................................... .575

COOLING FAN CONTROL : System Description .575

ELECTRONIC CONTROLLED ENGINE MOUNT .. .577

ELECTRONIC CONTROLLED ENGINE MOUNT

: System Description ............................................ .

577

EVAPORATIVE EMISSION SYSTEM .....................579

EVAPORATIVE EMISSION SYSTEM : System

Description ........................................................... .

580

THROTTLE CONTROL ...........................................581

THROTTLE CONTROL : Syst em Description ......581

INTAKE VALVE TIMING CONTROL ..................... .582

INTAKE VALVE TIMING CONTROL : System De-

scription ................................................................ .

583

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE ........................................... .

583

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1021 of 4801

![NISSAN TEANA 2014 Service Manual

COMPONENT PARTSEC-21

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000009462053

ENGINE ROOM COMPARTMENT

ALBIA0 NISSAN TEANA 2014 Service Manual

COMPONENT PARTSEC-21

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000009462053

ENGINE ROOM COMPARTMENT

ALBIA0](/img/5/57390/w960_57390-1020.png)

COMPONENT PARTSEC-21

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000009462053

ENGINE ROOM COMPARTMENT

ALBIA0804ZZ

No. Component Function

EVAP canister purge volume control solenoid valve EC-34, "EVAP Canister Purge Volume Control Solenoid

Va l v e "

Transmission range switch• The transmission range switch is installed to upper part

of transaxle case.

• ECM detects the selector lever position because the continuity of the transmission range switch line (the

ON) exists.

ECM EC-25, "ECM"

Refrigerant pressure sensorEC-36, "Refrigerant Pressure Sensor"

Battery current sensor

(with battery temperature sensor) EC-35, "Battery Current Se

nsor (With Battery Tempera-

ture Sensor)"

IPDM E/R • IPDM E/R control the internal relays and the actuators.

-Refer to PCS-6, "RELAY CONTROL SYSTEM : Sys-tem Description".

• When CAN communication with ECM is impossible,

IPDM E/R performs fail-safe control.

-Refer to PCS-19, "Fail Safe"

.

Mass air flow sensor

(with intake air temperature sensor) EC-27, "Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor)"

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1203 of 4801

![NISSAN TEANA 2014 Service Manual

POWER SUPPLY AND GROUND CIRCUITEC-203

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462152

1.CHECK FUSE

Check NISSAN TEANA 2014 Service Manual

POWER SUPPLY AND GROUND CIRCUITEC-203

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462152

1.CHECK FUSE

Check](/img/5/57390/w960_57390-1202.png)

POWER SUPPLY AND GROUND CIRCUITEC-203

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462152

1.CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing?

YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to GI-46, "Circuit Inspection"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace ground connection.

3.CHECK ECM GROUND CIRCUIT

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ECM POWER SUPPLY (MAIN)-1

1. Reconnect ECM harness connector.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector terminals.

*1: Except for California

*2: For California

Location Fuse No. Capacity

IPDM E/R #38 10 A

#56 10 A

+ −Continuity

ECM

Connector Terminal

F14

*1

F91*2

12

Ground Existed

16

F13

*1

F90*252

E10

*1

E31*2128

ECM Vo l ta g e

Connector +

−

Te r m i n a l

E10

*1

E31*2121 128 Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1382 of 4801

![NISSAN TEANA 2014 Service Manual

EC-382

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0506 ISC SYSTEM

P0506 ISC SYSTEM

DescriptionINFOID:0000000009462306

The ECM controls the engine idle speed to a specified leve

l through the fine adjustment NISSAN TEANA 2014 Service Manual

EC-382

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0506 ISC SYSTEM

P0506 ISC SYSTEM

DescriptionINFOID:0000000009462306

The ECM controls the engine idle speed to a specified leve

l through the fine adjustment](/img/5/57390/w960_57390-1381.png)

EC-382

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0506 ISC SYSTEM

P0506 ISC SYSTEM

DescriptionINFOID:0000000009462306

The ECM controls the engine idle speed to a specified leve

l through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is t he lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine l oad (air conditioner, power steering and cooling fan

operation, etc.).

DTC LogicINFOID:0000000009462307

DTC DETECTION LOGIC

NOTE:

If DTC P0506 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

If the target idle speed is ou t of the specified value, perform EC-179, "Work Procedure"

, before con-

ducting DTC Confirmation Procedure.

TESTING CONDITION:

• Before performing the following procedure, confirm th at battery voltage is more than 11 V at idle.

• Always perform the test at a temperature above −10 °C (14 °F).

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and run it for at least 1 minute at idle speed.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-382, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000009462308

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES >> Discover air leak location and repair.

DTC No. CONSULT screen terms

(Trouble diagnosis content) DTC detecting condition Possible cause

P0506 ISC SYSTEM

(Idle air control system RPM lower

than expected) The idle speed is less than the target idle

speed by 100 rpm or more. • Electric throttle control actuator

• Intake air leak

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1446 of 4801

![NISSAN TEANA 2014 Service Manual

EC-446

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1572 ASCD BRAKE SWITCH

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

1. Drive the vehicle for at least 5 consecut ive seconds as per the following c NISSAN TEANA 2014 Service Manual

EC-446

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1572 ASCD BRAKE SWITCH

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

1. Drive the vehicle for at least 5 consecut ive seconds as per the following c](/img/5/57390/w960_57390-1445.png)

EC-446

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1572 ASCD BRAKE SWITCH

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

1. Drive the vehicle for at least 5 consecut ive seconds as per the following conditions.

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheel s lifted in the shop or by driving the vehicle.

If a road test is expected to be easier , it is unnecessary to lift the vehicle.

2. Check DTC.

Is DTC detected?

YES >> Proceed to EC-452, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000009462379

1.CHECK OVERALL FUNCTION-1

With CONSULT

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONI TOR” mode of “ENGINE” using CONSULT.

3. Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK OVERALL FUNCTION-2

With CONSULT

Select “BRAKE SW2” and check indication as per the following conditions.

Vehicle speed More than 30 km/h (19 mph)

Selector lever Suitable position

Driving location Depress the brake pedal for more

than five seconds so as not to come

off from the above-mentioned vehi-

cle speed.

Monitor item Condition Indication

BRAKE SW1 Brake pedal Slightly depressed OFF

Fully released ON

ECM ConditionVo l ta g e

(Approx.)

Connector +–

Te r m i n a l

E10

*1

E31*2116 128 Brake pedal Slightly depressed 0 V

Fully released Battery voltage

Monitor item Condition Indication

BRAKE SW2 Brake pedal Slightly depressed ON

Fully released OFF

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1548 of 4801

![NISSAN TEANA 2014 Service Manual

EC-548

< SYSTEM DESCRIPTION >[VQ35DE]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM :

Component Parts LocationINFOID:0000000009462480

ENGINE ROOM

ALB NISSAN TEANA 2014 Service Manual

EC-548

< SYSTEM DESCRIPTION >[VQ35DE]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM :

Component Parts LocationINFOID:0000000009462480

ENGINE ROOM

ALB](/img/5/57390/w960_57390-1547.png)

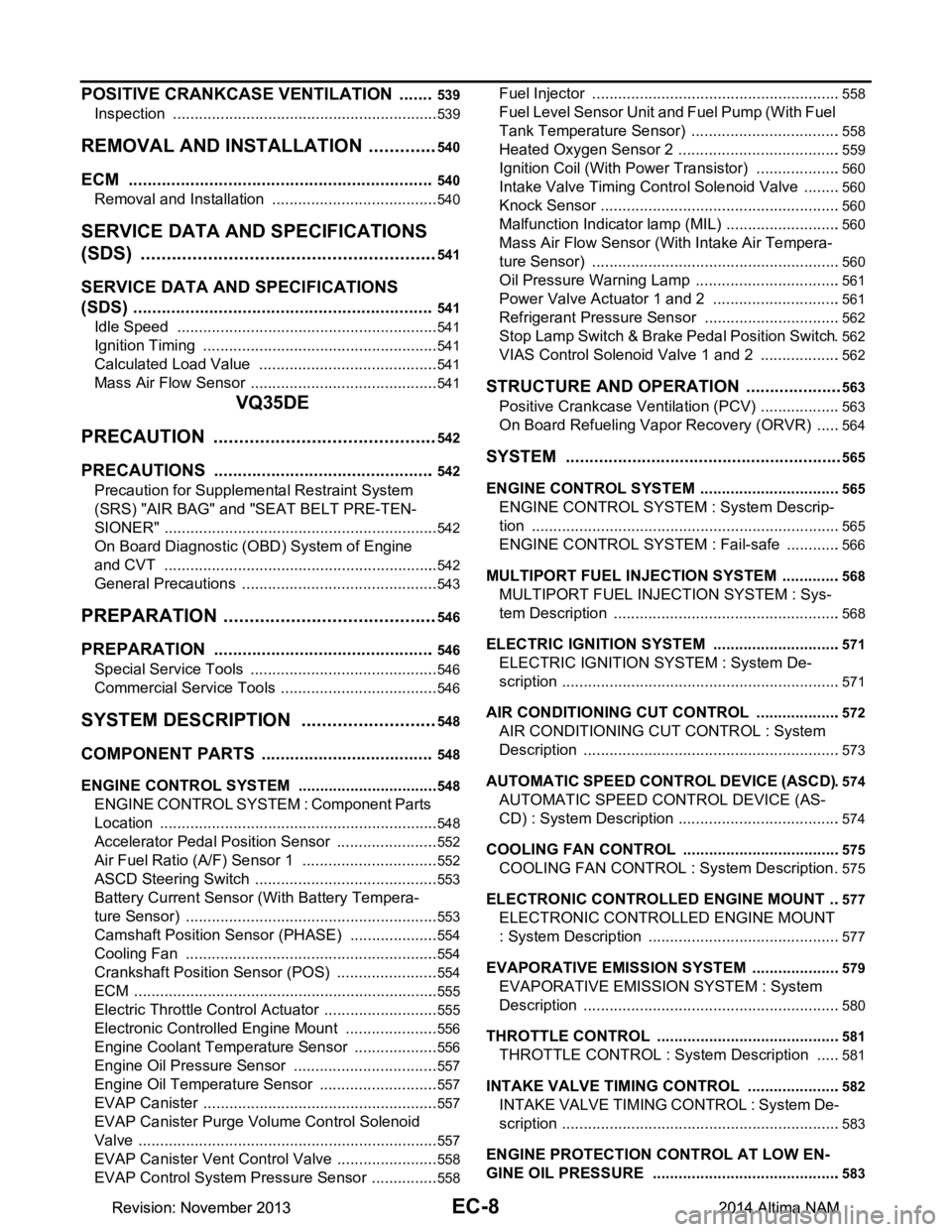

EC-548

< SYSTEM DESCRIPTION >[VQ35DE]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM :

Component Parts LocationINFOID:0000000009462480

ENGINE ROOM

ALBIA0805ZZ

No. Component Function

1. Power valve actuator 1 EC-561, "Power Valve Actuator 1 and 2"

2. Electronic controlled engine mount control solenoid valveEC-556, "Electronic Controlled Engine Mount"

3. Cooling fan motor-2EC-554, "Cooling Fan"

4. Cooling fan motor-1EC-554, "Cooling Fan"

5. ECMEC-555, "ECM"

6. Refrigerant pressure sensorEC-562, "Refrigerant

Pressure Sensor"Refer to HAC-9, "Component Part Location" for detailed installa-

tionlocation.

7. Battery current sensor (with battery temperature sensor) EC-553, "Battery Current Sensor (With Battery Temperature Sen-

sor)"

8. Cooling fan motor relay-2

EC-554, "Cooling Fan"

9. Cooling fan motor relay-3EC-554, "Cooling Fan"

10. IPDM E/RIPDM E/R activates the internal control circuit to perform the relay

ON-OFF control according to the input signals from various sen-

sors and the request signals received from control units via CAN

communication.

Refer to PCS-4, "Component Parts Location"

for detailed installa-

tionlocation.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM