fuses NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 753 of 4801

DEF-28

< DTC/CIRCUIT DIAGNOSIS >

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

DescriptionINFOID:0000000009463041

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window

from fogging up.

Component Function CheckINFOID:0000000009463042

1. CHECK REAR WINDOW DEFOGGER

Check that the heating wire of rear window defogger is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Rear window defogger is OK.

NO >> Refer to DEF-28, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463043

Regarding Wiring Diagram information, refer to DEF-11, "Wiring Diagram".

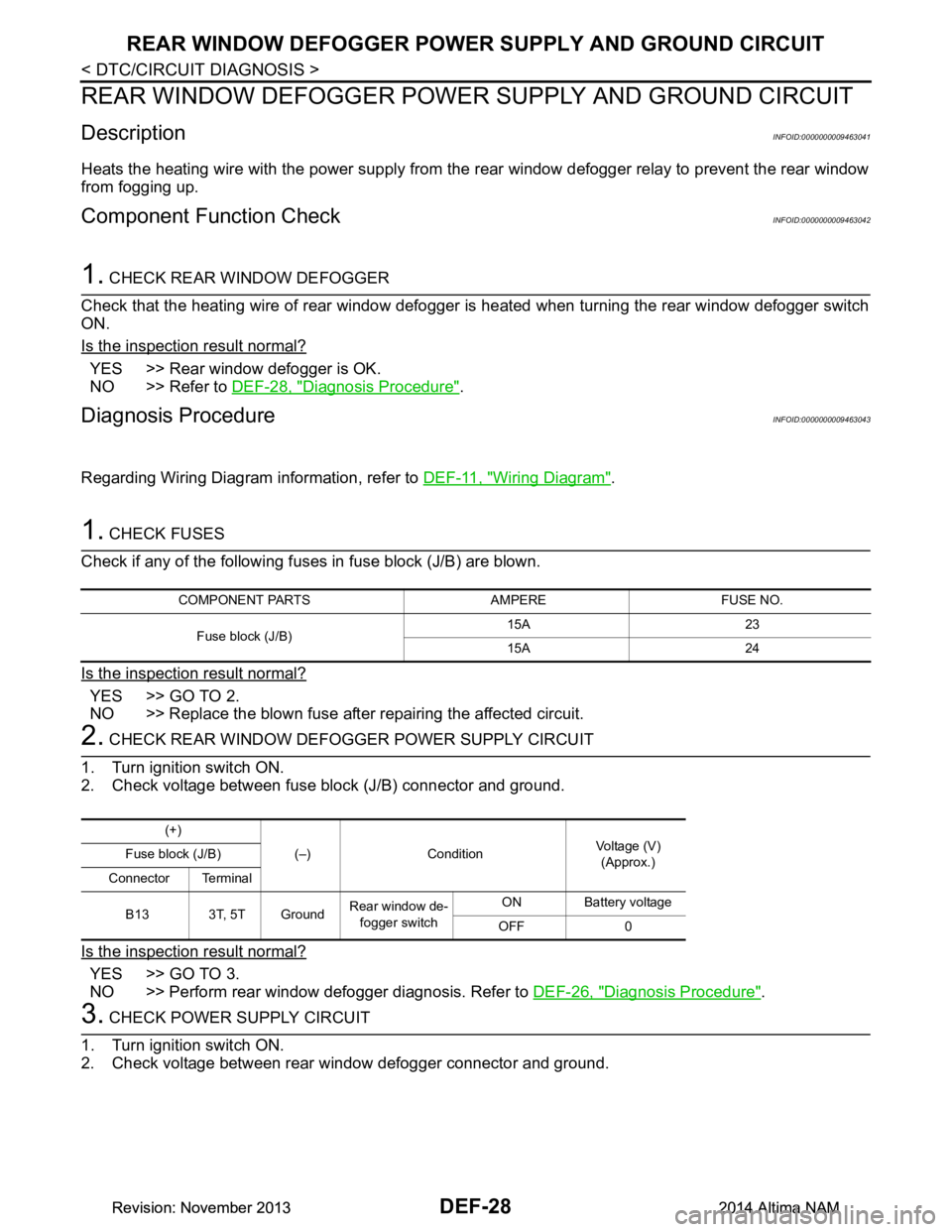

1. CHECK FUSES

Check if any of the following fuses in fuse block (J/B) are blown.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2. CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between fuse block (J/B) connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Perform rear window defogger diagnosis. Refer to DEF-26, "Diagnosis Procedure"

.

3. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between rear window defogger connector and ground.

COMPONENT PARTS AMPERE FUSE NO.

Fuse block (J/B) 15A 23

15A 24

(+) (–) Condition Voltage (V)

(Approx.)

Fuse block (J/B)

Connector Terminal

B13 3T, 5T Ground Rear window de-

fogger switch ON Battery voltage

OFF 0

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1709 of 4801

![NISSAN TEANA 2014 Service Manual

POWER SUPPLY AND GROUND CIRCUITEC-709

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462573

1.CHECK FUSE

Check NISSAN TEANA 2014 Service Manual

POWER SUPPLY AND GROUND CIRCUITEC-709

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462573

1.CHECK FUSE

Check](/img/5/57390/w960_57390-1708.png)

POWER SUPPLY AND GROUND CIRCUITEC-709

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462573

1.CHECK FUSE

Check that there is no blowout in the following fuses.

Is the fuse fusing?

YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to GI-46, "Circuit Inspection"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace ground connection.

3.CHECK ECM GROUND CIRCUIT

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ECM POWER SUPPLY (MAIN)-I

1. Reconnect ECM harness connector.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector terminals.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK ECM POWER SUPPLY (MAIN) CIRCUIT

Location Fuse No. Capacity

IPDM E/R #38 10 A

#45 10 A

+ −Continuity

ECM

Connector Terminal

F78 12

Ground Existed

16

E32 123

124

127

128

ECM Vo l ta g e

Connector +

−

Te r m i n a l

E32 121 128 Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2357 of 4801

HEADLAMP (HI) CIRCUITEXL-91

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (HI) CIRCUIT

DescriptionINFOID:0000000009463577

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp high relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp high relay is energized, power

flows through fuses 34 and 35, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp high beam.

Component Function CheckINFOID:0000000009463578

1.CHECK HEADLAMP (HI) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp switches to the high beam. NOTE:

HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check t hat the headlamp switches to the high beam.

Is the inspection result normal?

YES >> Headlamp (HI) circuit is normal.

NO >> Refer to EXL-91, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463579

Regarding Wiring Diagram information, refer to EXL-27, "Wiring Diagram - Halogen" or EXL-33, "Wiring Dia-

gram - Xenon".

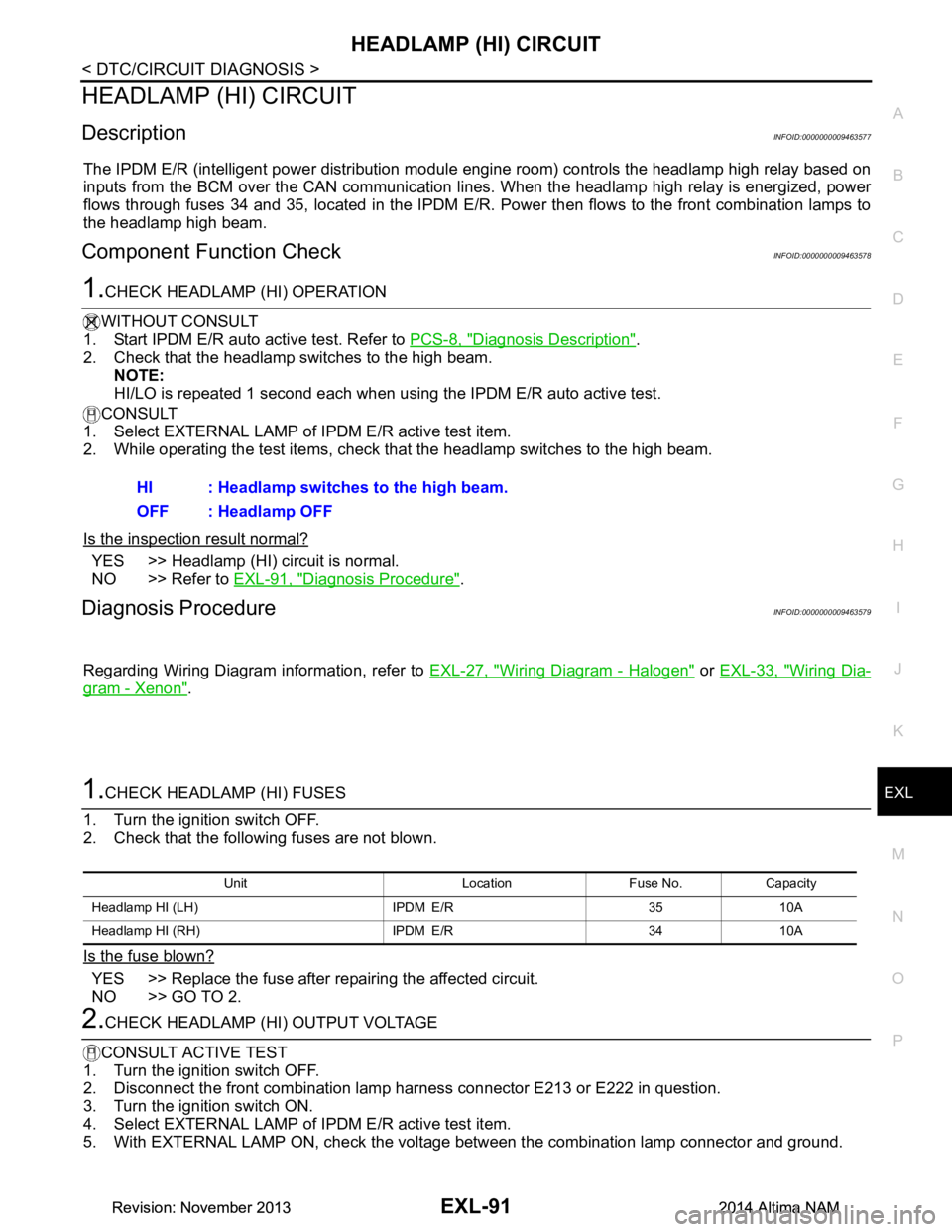

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

CONSULT ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp harness connector E213 or E222 in question.

3. Turn the ignition switch ON.

4. Select EXTERNAL LAMP of IP DM E/R active test item.

5. With EXTERNAL LAMP ON, check the voltage between the combination lamp connector and ground.

HI : Headlamp switches to the high beam.

OFF : Headlamp OFF

Unit Location Fuse No. Capacity

Headlamp HI (LH) IPDM E/R 35 10A

Headlamp HI (RH) IPDM E/R 34 10A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2359 of 4801

HEADLAMP (LO) CIRCUITEXL-93

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (LO) CIRCUIT

HEADLAMP (HALOGEN)

HEADLAMP (HALOGEN) : DescriptionINFOID:0000000009463580

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 36 and 37, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

HEADLAMP (HALOGEN) : Component Function CheckINFOID:0000000009463581

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp is turned ON.

NOTE:

HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check that the headlamp is turned ON.

Is the inspection result normal?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-93, "HEADLAMP (HALOGEN) : Diagnosis Procedure"

.

HEADLAMP (HALOGEN) : Diagnosis ProcedureINFOID:0000000009463582

Regarding Wiring Diagram information, refer to EXL-27, "Wiring Diagram - Halogen".

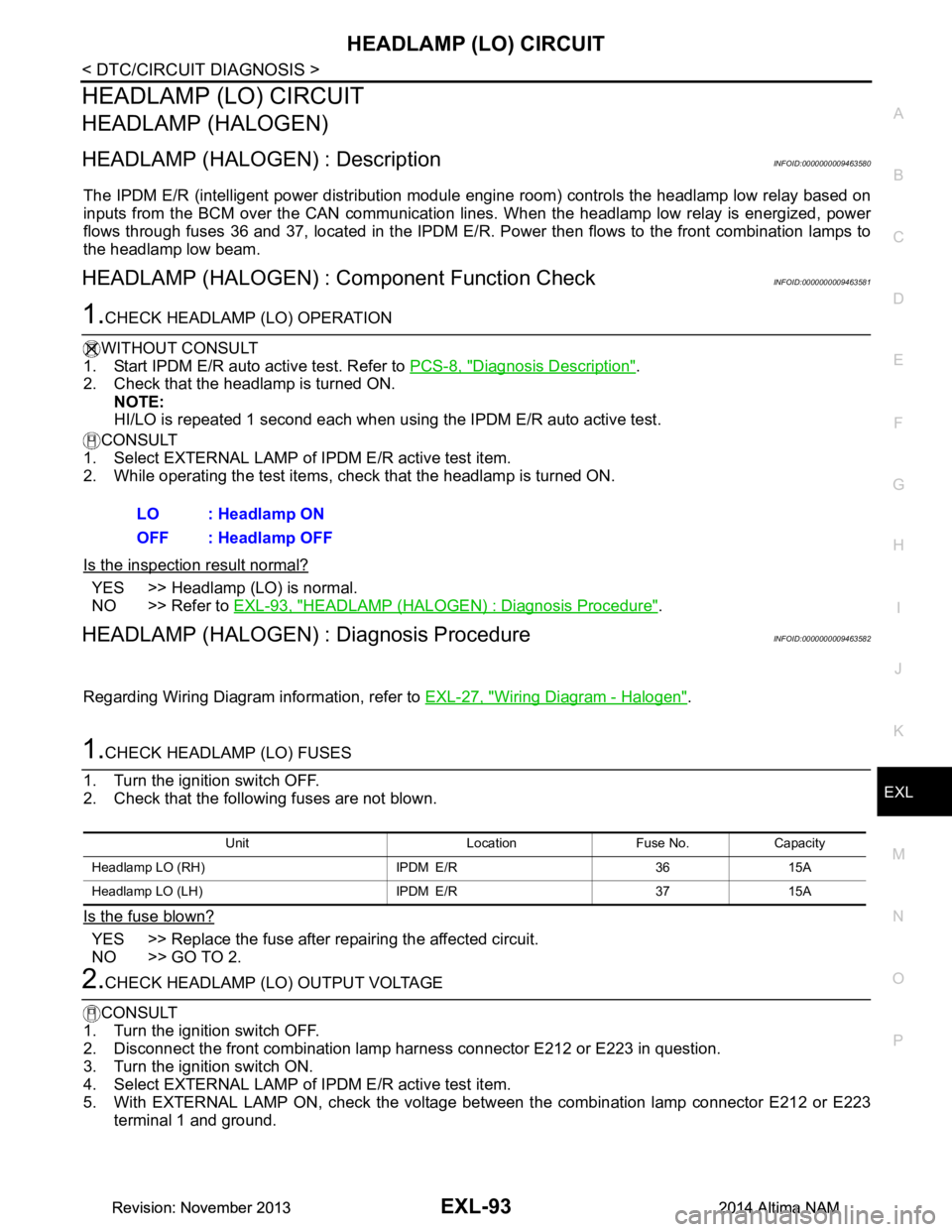

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

CONSULT

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp harness connector E212 or E223 in question.

3. Turn the ignition switch ON.

4. Select EXTERNAL LAMP of IP DM E/R active test item.

5. With EXTERNAL LAMP ON, check the voltage betw een the combination lamp connector E212 or E223

terminal 1 and ground. LO : Headlamp ON

OFF : Headlamp OFF

Unit Location Fuse No. Capacity

Headlamp LO (RH) IPDM E/R 36 15A

Headlamp LO (L H) IPDM E/R 37 15A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2360 of 4801

EXL-94

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

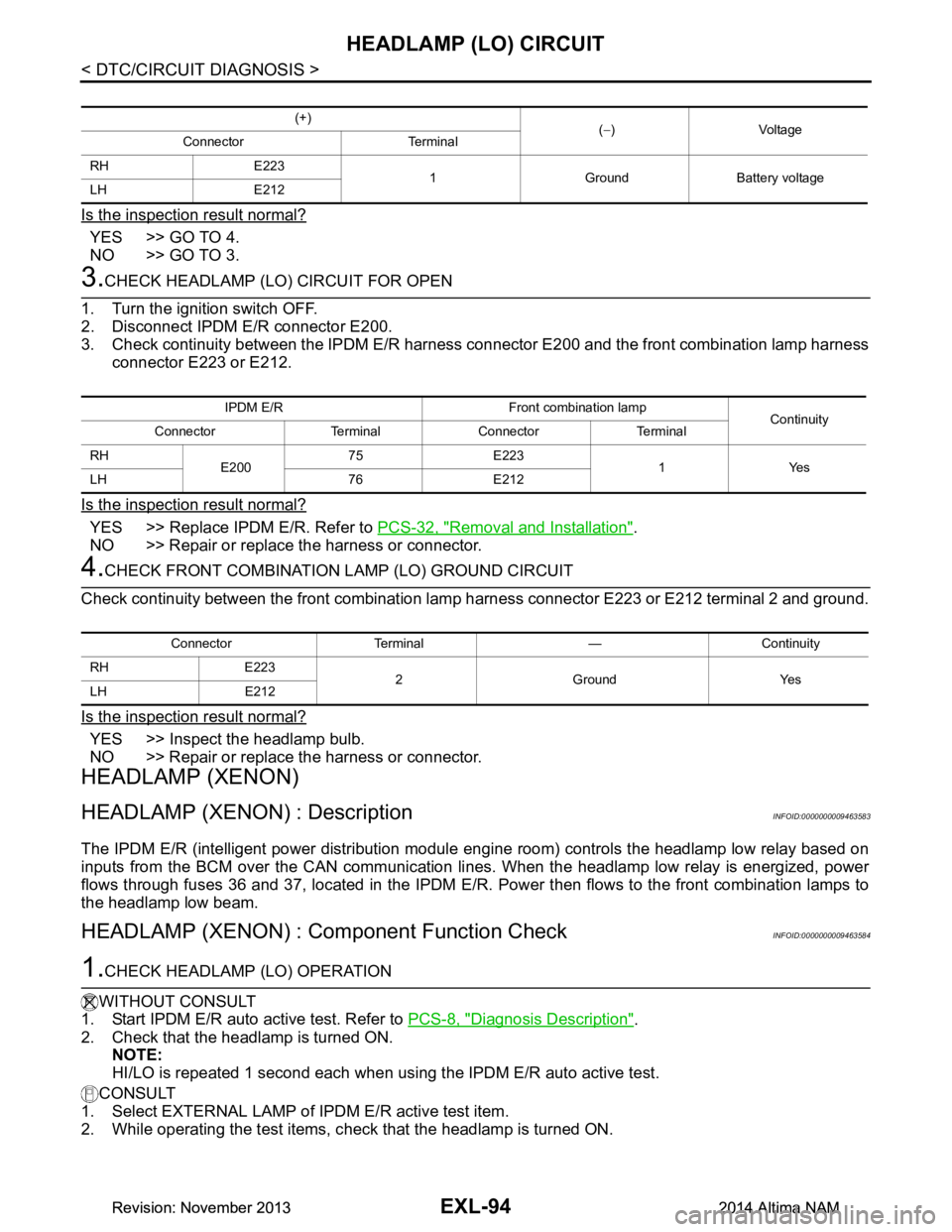

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E200.

3. Check continuity between the IPDM E/R harness c onnector E200 and the front combination lamp harness

connector E223 or E212.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace the harness or connector.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination la mp harness connector E223 or E212 terminal 2 and ground.

Is the inspection result normal?

YES >> Inspect the headlamp bulb.

NO >> Repair or replace the harness or connector.

HEADLAMP (XENON)

HEADLAMP (XENON) : DescriptionINFOID:0000000009463583

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 36 and 37, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

HEADLAMP (XENON) : Component Function CheckINFOID:0000000009463584

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp is turned ON. NOTE:

HI/LO is repeated 1 second each when usi ng the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, c heck that the headlamp is turned ON.

(+)

(− )Voltage

Connector Terminal

RH E223 1 Ground Battery voltage

LH E212

IPDM E/R Front combination lamp Continuity

Connector Terminal Connector Terminal

RH E20075 E223

1Yes

LH 76 E212

Connector Terminal — Continuity

RH E223 2GroundYes

LH E212

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2361 of 4801

HEADLAMP (LO) CIRCUITEXL-95

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

Is the inspection result normal?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-95, "HEADLAMP (XEN ON) : Diagnosis Procedure"

.

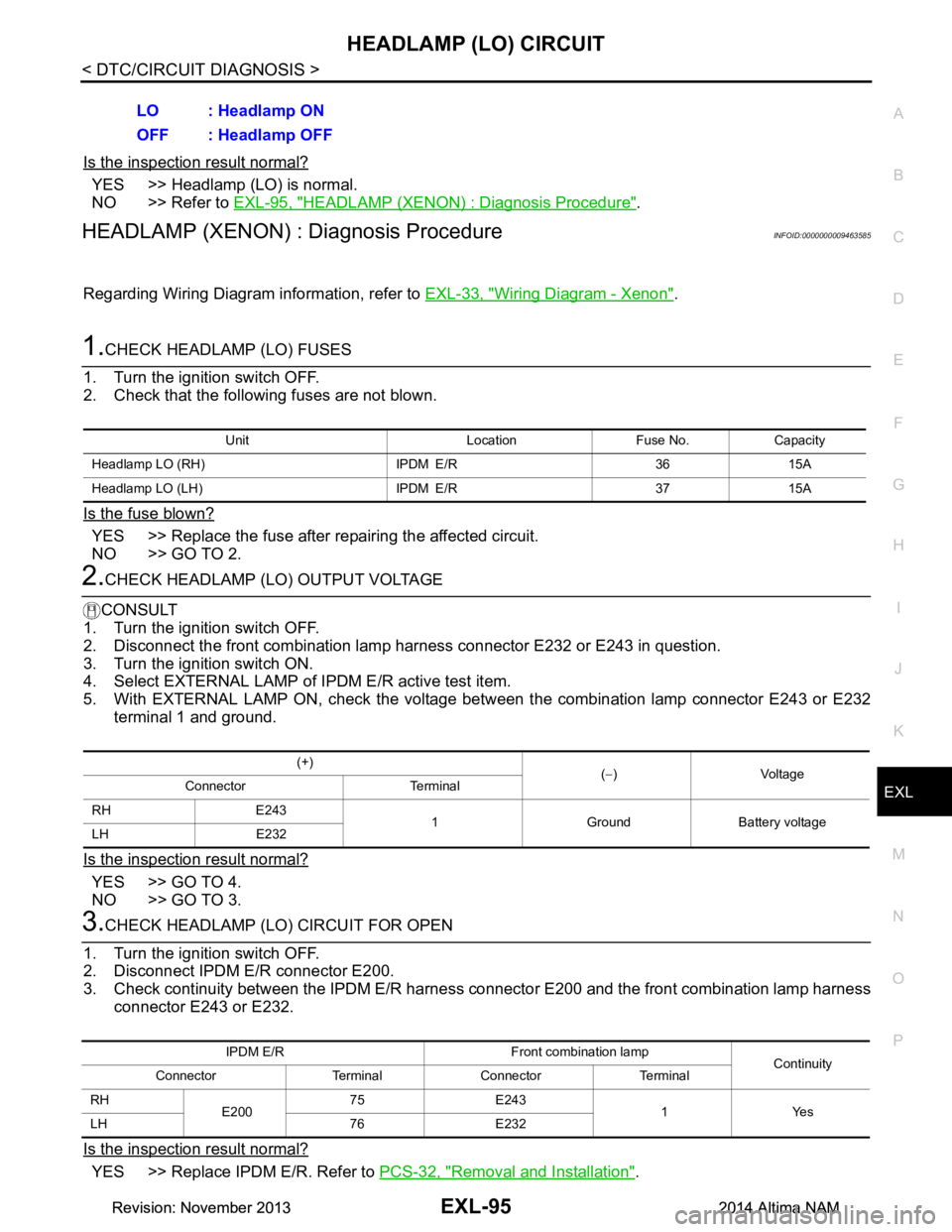

HEADLAMP (XENON) : Diagnosis ProcedureINFOID:0000000009463585

Regarding Wiring Diagram information, refer to EXL-33, "Wiring Diagram - Xenon".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

CONSULT

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp harness connector E232 or E243 in question.

3. Turn the ignition switch ON.

4. Select EXTERNAL LAMP of IP DM E/R active test item.

5. With EXTERNAL LAMP ON, check the voltage betw een the combination lamp connector E243 or E232

terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E200.

3. Check continuity between the IPDM E/R harness c onnector E200 and the front combination lamp harness

connector E243 or E232.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

LO : Headlamp ON

OFF : Headlamp OFF

Unit Location Fuse No. Capacity

Headlamp LO (RH) IPDM E/R 36 15A

Headlamp LO (L H) IPDM E/R 37 15A

(+)

(− )Voltage

Connector Terminal

RH E243 1 Ground Battery voltage

LH E232

IPDM E/R Front combination lamp Continuity

Connector Terminal Connector Terminal

RH E20075 E243

1Yes

LH 76 E232

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2363 of 4801

XENON HEADLAMPEXL-97

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

XENON HEADLAMP

DescriptionINFOID:0000000009463586

OPERATION

Refer to EXL-9, "HEADLAMP SYSTEM : System Description".

PRECAUTIONS FOR TROUBLE DIAGNOSIS

• Installation or removal of the connecto r must be done with the lighting switch OFF.

• When the lamp is illuminated (when the lighting switch is ON), do not touch the harness, HID control unit,

inside of the lamp, or the lamp metal parts.

• To check illumination, temporarily install lamp in the vehicle. Be sure to connect power at the vehicle-side

connector.

• If the malfunction can be traced directly to the electrical system, first check for items such as blown fuses

and fusible links, broken wires or loose connectors , pulled-out terminals, and improper connections.

• Do not work with wet hands.

• Using a tester for HID control unit circuit trouble diagnosis is prohibited.

• Disassembling the HID control unit or harnesses (bul b socket harness, ballast harness) is prohibited.

• Immediately after illumination, the light int ensity and color will fluctuate, this is normal.

• When the bulb has reached the end of its lifetime, the br ightness may drop significantly, it may flash repeat-

edly, or the light may turn a reddish color.

Diagnosis ProcedureINFOID:0000000009463587

1.CHECK XENON BULB

Install a known good bulb to the applicable headlamp. Check that the headlamp operates.

Is the inspection result normal?

YES >> Replace the xenon bulb.

NO >> GO TO 2.

2.CHECK HID CONTROL UNIT

Install a known good HID control unit to the appl icable headlamp. Check that the headlamp operates.

Is the inspection result normal?

YES >> Replace HID control unit.

NO >> Inspection End.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2369 of 4801

PARKING LAMP CIRCUITEXL-103

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

PARKING LAMP CIRCUIT

DescriptionINFOID:0000000009463594

The IPDM E/R (intelligent power distribution module engi ne room) controls the tail lamp relay based on inputs

from the BCM over the CAN communication lines. When t he tail lamp relay is energized, power flows through

fuses 51 and 52, located in the IPDM E/R. Power then fl ows to the front and rear combination lamps, license

plate lamps.

Component Function CheckINFOID:0000000009463595

1.CHECK PARKING LAMP OPERATION

WITHOUT CONSULT

1. Activate IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the parking lamp is turned ON.

WITH CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check that the parking lamp is turned ON.

Is the inspection result normal?

YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-103, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463596

Regarding Wiring Diagram information, refer to EXL-68, "Wiring Diagram".

1.CHECK PARKING LAMP FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK TAIL LAMP RELAY OUTPUT (VOLTAGE)

1. Disconnect the front or rear combination lamp connector or license plate lamp connector in question.

2. Turn the ignition switch ON.

3. Turn the parking lamps ON.

4. With the parking lamps ON, check voltage between t he front combination lamp front (parking) connector

and ground. TAIL : Parking lamp ON

OFF : Parking lamp OFF

Unit Location Fuse No. Capacity

Parking lamps IPDM E/R 51 10A

52 10A

(+) (− ) Vo l ta g e

(Approx.)

Connector Terminal

LH E217 6 Ground Battery voltage

RH E224 (without front fog lamps)

E351 (with front fog lamps)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2660 of 4801

![NISSAN TEANA 2014 Service Manual

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters th NISSAN TEANA 2014 Service Manual

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters th](/img/5/57390/w960_57390-2659.png)

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor RH re-

ceives position commands from the A/C auto amp. and reports actual door position back via an LCU

(Local Control Unit) installed inside the motor. Commands and responses are sent across the LIN (Lo-

cal Interconnect Network) to each motor simultaneously, with each motor having its own unique ad-

dress, thereby only responding to requests sent to its specific address. The LCU reads the door

position from a Position Balanced Resistor (PBR), also part of the motor, and returns that information

to the A/C auto amp. The LCU switches the polarity of the circuits connected to the DC motor to drive

the motor forward or backward as requested by the A/C auto amp. If the air mix door moves to a po-

sition less than 5% or more than 95% of its expected or allowed positions, the A/C auto amp. will set

a DTC.

Ambient sensor The ambient sensor measures the temperature of the air surrounding the vehicle. The sensor uses a

thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

BCM The BCM receives the fan ON and A/C ON signals from the A/C auto amp. and sends a compressor

ON request to the ECM.

Blower motor The blower motor varies the speed at which the air flows through the ventilation system.

ECM The ECM sends a compressor ON request to the IPDM E/R based on the status of engine operation

and load as well as refrigerant pressure information. If all the conditions are met for A/C operation,

the ECM transmits the compressor ON request to the IPDM E/R. The ECM shares the refrigerant

pressure sensor signal, engine RPM, and engine coolant temperature with the A/C auto amp. via

CAN communication line.

Front blower motor relay The front blower motor relay controls the flow of current to fuse 17 and 27 in the Fuse Block (J/B).

The relay is connected directly to ground, and is energized when the ignition switch is in the ON or

START position.

Fuse Block (J/B) Located in the passenger compartment, behind the left lower IP, the Fuse Block (J/B) contains the

front blower motor relay and several fuses required for the air conditioner control system.

Intake door motor The intake door motor controls the position of the intake door. Fresh air is allowed to enter the cabin

in one position, and recirculated inside air is allowed to enter in the other position. At times the A/C

auto amp. may command partial fresh or recirculation based on evaporator or coolant temperatures.

The intake door motor receives position commands from the A/C auto amp. and reports actual door

position back via an LCU (Local Control Unit) installed inside the motor. Commands and responses

are sent across the LIN (Local Interconnect Network) to each motor simultaneously, with each motor

having its own unique address, thereby only responding to requests sent to its specific address. The

LCU reads the door position from a Position Balanced Resistor (PBR), also part of the motor, and re-

turns that information to the A/C auto amp. The LCU switches the polarity of the circuits connected to

the DC motor to drive the motor forward or backward as requested by the A/C auto amp. If the recir-

culation door moves to a position less than 5% or more than 95% of its expected or allowed positions,

the A/C auto amp. will set a DTC.

Intake sensor The intake sensor measures the temperature of the front evaporator fins. The sensor uses a ther-

mistor which is sensitive to the change in temperature. The electrical resistance of the thermistor de-

creases as temperature increases.

In-vehicle sensor In-vehicle sensor measures temperature of intake air that flows through aspirator to passenger room.

The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resis-

tance of the thermistor decreases as temperature increases.

IPDM E/R Refer to PCS-6, "RELAY CONTROL SYSTEM : System Description"

.

Mode door motor The mode door controls the direction the conditioned air passes through the ventilation system.

Through a series of levers and gears, the mode door controls the defrost door, the foot door, and the

vent door. There are 5 preset positions: VENT, B/L, FOOT, D/F, and DEF. The FOOT position can be

set to allow some airflow through to the defroster vent, or to completely block the defroster vent using

the CONSULT. The mode door motor receives position commands from the A/C auto amp. and re-

ports actual door position back via an LCU (Local Control Unit) installed inside the motor. Commands

and responses are sent across the LIN (Local Interconnect Network) to each motor simultaneously,

with each motor having its own unique address, thereby only responding to requests sent to its spe-

cific address. The LCU reads the door position from a Position Balanced Resistor (PBR), also part of

the motor, and returns that information to the A/C auto amp. The LCU switches the polarity of the cir-

cuits connected to the DC motor to drive the motor forward or backward as requested by the A/C auto

amp. The mode door has 5 expected positions and, therefore, can set up to 5 DTCs if the expected

position is not reported back to the A/C auto amp.

Component Description

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2727 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-78

< DTC/CIRCUIT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

A/C AUTO AMP.

A/C AUTO AMP. : Diagnosis ProcedureINFOID:0000000009463149

Re NISSAN TEANA 2014 Service Manual

HAC-78

< DTC/CIRCUIT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

A/C AUTO AMP.

A/C AUTO AMP. : Diagnosis ProcedureINFOID:0000000009463149

Re](/img/5/57390/w960_57390-2726.png)

HAC-78

< DTC/CIRCUIT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

A/C AUTO AMP.

A/C AUTO AMP. : Diagnosis ProcedureINFOID:0000000009463149

Regarding Wiring Diagram information, refer to

HAC-34, "Wiring Diagram".

1.CHECK FUSE

Check fuses [No. 14, 25 and 30, loca ted in the fuse block (J/B)].

NOTE:

Refer to PG-70, "Terminal Arrangement"

.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2.CHECK A/C AUTO AMP. POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector.

3. Check voltage between A/C auto amp. harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector between A/C auto amp. and fuse block (J/B).

3.CHECK A/C AUTO AMP. GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between A/C auto amp. harness connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

AIR MIX DOOR MOTOR (DRIVER SIDE)

AIR MIX DOOR MOTOR (DRIVE R SIDE) : Diagnosis ProcedureINFOID:0000000009463150

Regarding Wiring Diagram information, refer to HAC-34, "Wiring Diagram".

+

− Vo l ta g e

A/C auto amp. Ignition switch position

Connector Terminal OFF ACC ON

M152 3

GroundBattery voltage Battery voltage Battery voltage

13 Approx. 0 V Battery voltage Battery voltage

23 Approx. 0 V Approx. 0 V Battery voltage

40 Approx. 0 V Approx. 0 V Battery voltage

A/C auto amp. —Continuity

Connector Terminal

M152 2

Ground Yes

22

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM