open hood NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 770 of 4801

DLK-2

TRUNK LID OPENER SYSTEM ............................ ...36

TRUNK LID OPENER SYSTEM : System Dia-

gram .................................................................... ...

37

TRUNK LID OPENER SYSTEM : System De-

scription ............................................................... ...

37

SYSTEM (INTEGRATED HOMELINK

TRANSMITTER) ............................................. ...

40

System Description .............................................. ...40

SYSTEM (TRUNK LID OPENER SYSTEM) ......41

System Diagram .................................................. ...41

System Description .................................................41

DIAGNOSIS SYSTEM (BCM) ............................42

COMMON ITEM ..................................................... ...42

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) ................................................. ...

42

DOOR LOCK .......................................................... ...43

DOOR LOCK : CONSULT Function (BCM -

DOOR LOCK) ...................................................... ...

43

INTELLIGENT KEY ................................................ ...44

INTELLIGENT KEY : CONSULT Function (BCM -

INTELLIGENT KEY) ........ .......................................

44

TRUNK ................................................................... ...47

TRUNK : CONSULT Function (BCM - TRUNK) .....47

ECU DIAGNOSIS INFORMATION ..............48

ECM, IPDM E/R, BCM .................................... ...48

List of ECU Reference ......................................... ...48

WIRING DIAGRAM .....................................49

HOMELINK UNIVERSAL TRANSCEIVER ..... ...49

Wiring Diagram .................................................... ...49

POWER DOOR LOCK SYSTEM .......................51

Wiring Diagram .................................................... ...51

INTELLIGENT KEY SYSTEM ............................61

Wiring Diagram .................................................... ...61

TRUNK LID OPENER ........................................77

Wiring Diagram .................................................... ...77

BASIC INSPECTION ...................................81

DIAGNOSIS AND REPAIR WORKFLOW ...... ...81

Work Flow ............................................................ ...81

INSPECTION AND ADJUSTMENT ...................84

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ..................................................... ...

84

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ............................. ...

84

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

84

DTC/CIRCUIT DIAGNOSIS ........................85

U1000 CAN COMM CIRCUIT ......................... ...85

Description ........................................................... ...85

DTC Logic ...............................................................85

Diagnosis Procedure ...............................................85

U1010 CONTROL UNIT (CAN) .........................86

DTC Logic ............................................................ ...86

Diagnosis Procedure ...............................................86

Special Repair Requirement ...................................86

B261B REMOTE ENGINE START ....................87

DTC Logic ............................................................ ...87

Diagnosis Procedure ...............................................87

B2621 INSIDE ANTENNA .............................. ...88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

B2622 INSIDE ANTENNA .............................. ...90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

B26FD SHIFT LOCK SOLENOID .....................92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

B26FE HOOD SWITCH .....................................95

DTC Logic ............................................................ ...95

Diagnosis Procedure ..............................................95

Component Inspection ............................................96

B26FF REMOTE KEYLESS ENTRY RECEIV-

ER ................................................................... ...

97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

POWER SUPPLY AND GROUND CIRCUIT .....99

Diagnosis Procedure ............................................ ...99

DOOR SWITCH ................................................100

Description ........................................................... .100

Component Function Check ................................100

Diagnosis Procedure .............................................100

Component Inspection ..........................................102

DOOR LOCK AND UNLOCK SWITCH ............103

DRIVER SIDE ......................................................... .103

DRIVER SIDE : Description ..................................103

DRIVER SIDE : Component Function Check ......103

DRIVER SIDE : Diagnosis Procedure (With LH

and RH Anti-Pinch) .............................................. .

103

DRIVER SIDE : Diagnosis Procedure (With LH

Anti-Pinch Only) ................................................... .

104

PASSENGER SIDE .................................................105

PASSENGER SIDE : Descripti on .........................105

PASSENGER SIDE :

Component Function Check ............................... .

106

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 772 of 4801

DLK-4

INTELLIGENT KEY SYSTEM SYMPTOMS ....152

Symptom Table ................................................... ..152

DOOR LOCK FUNCTION SYMPTOMS ..........153

DOOR LOCK AND UNLOCK SWITCH ................. ..153

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table .................................................................... ..

153

DOOR REQUEST SWITCH ................................... ..153

DOOR REQUEST SWITCH : Symptom Table ......153

INTELLIGENT KEY ................................................ ..154

INTELLIGENT KEY : Symptom Table ...................154

TRUNK OPEN FUNCTION SYMPTOMS ....... .156

TRUNK LID OPENER SWITCH ............................. ..156

TRUNK LID OPENER SWITCH : Symptom Table ..156

TRUNK REQUEST SWITCH .................................. ..156

TRUNK REQUEST SWITCH : Symptom Table .....156

INTELLIGENT KEY ................................................ ..156

INTELLIGENT KEY : Symptom Table ...................156

WARNING FUNCTION SYMPTOMS .............. .158

Symptom Table ................................................... ..158

KEY REMINDER FUNCTION SYMPTOMS .....160

Symptom Table ................................................... ..160

HAZARD FUNCTION .......................................161

Symptom Table ................................................... ..161

HORN FUNCTION ...........................................162

Symptom Table ................................................... ..162

INTEGRATED HOMELINK TRANSMITTER ...163

Symptom Table ................................................... ..163

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ......................... ....................................

164

Work Flow ............................................................ ..164

Generic Squeak and Rattle Troubleshooting .........165

Diagnostic Worksheet ............................................168

REMOVAL AND INSTALLATION ..............170

HOOD .............................................................. .170

HOOD ASSEMBLY ................................................ ..170

HOOD ASSEMBLY : Exploded View ................... ..170

HOOD ASSEMBLY : Removal and Installation .....170

HOOD ASSEMBLY : Adjustme nt ........................ ..172

HOOD HINGE ......................................................... ..174

HOOD HINGE : Removal and Installation .............174

HOOD SUPPORT ROD .......................................... ..175

HOOD SUPPORT ROD : Removal and Installa-

tion ....................................................................... ..

175

HOOD LOCK CONTROL ....................................... ..175

HOOD LOCK CONTROL : Component Parts Lo-

cation ................................................................... .

175

HOOD LOCK CONTROL : Removal and Installa-

tion ....................................................................... .

176

RADIATOR CORE SUPPORT .........................179

Removal and Installation .......................................179

FRONT FENDER ............................................ ..181

Exploded View ..................................................... .181

Removal and Installation .......................................181

Adjustment ........................................................... .182

FRONT DOOR ..................................................184

DOOR ASSEMBLY .................................................184

DOOR ASSEMBLY : Removal and Installation ....184

DOOR ASSEMBLY : Adjustme nt ..........................186

DOOR STRIKER .................................................... .188

DOOR STRIKER : Removal and Installation ........188

DOOR HINGE ......................................................... .188

DOOR HINGE : Removal and Installation ............188

DOOR CHECK LINK .............................................. .189

DOOR CHECK LINK : Removal and Installation ..189

REAR DOOR ....................................................190

DOOR ASSEMBLY .................................................190

DOOR ASSEMBLY : Removal and Installation ....190

DOOR ASSEMBLY : Adjustme nt ..........................191

DOOR STRIKER .................................................... .194

DOOR STRIKER : Removal and Installation ........194

DOOR HINGE ......................................................... .194

DOOR HINGE : Removal and Installation ............194

DOOR CHECK LINK .............................................. .195

DOOR CHECK LINK : Removal and Installation ..195

DOOR HANDLE ...............................................197

FRONT DOOR HANDLE ........................................ .197

FRONT DOOR HANDLE : Exploded View ...........197

FRONT DOOR HANDLE : Removal and Installa-

tion - Inside Handle .............................................. .

197

FRONT DOOR HANDLE : Removal and Installa-

tion - Outside Handle ........................................... .

198

REAR DOOR HANDLE .......................................... .200

REAR DOOR HANDLE : Exploded View ..............200

REAR DOOR HANDLE : Removal and Installation

- Inside Handle ..................................................... .

200

REAR DOOR HANDLE : Removal and Installation

- Outside Handle .................................................. .

201

DOOR LOCK ....................................................203

FRONT DOOR LOCK ............................................. .203

FRONT DOOR LOCK : Exploded View ................203

FRONT DOOR LOCK : Removal and Installation .203

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 786 of 4801

DLK-18

< SYSTEM DESCRIPTION >

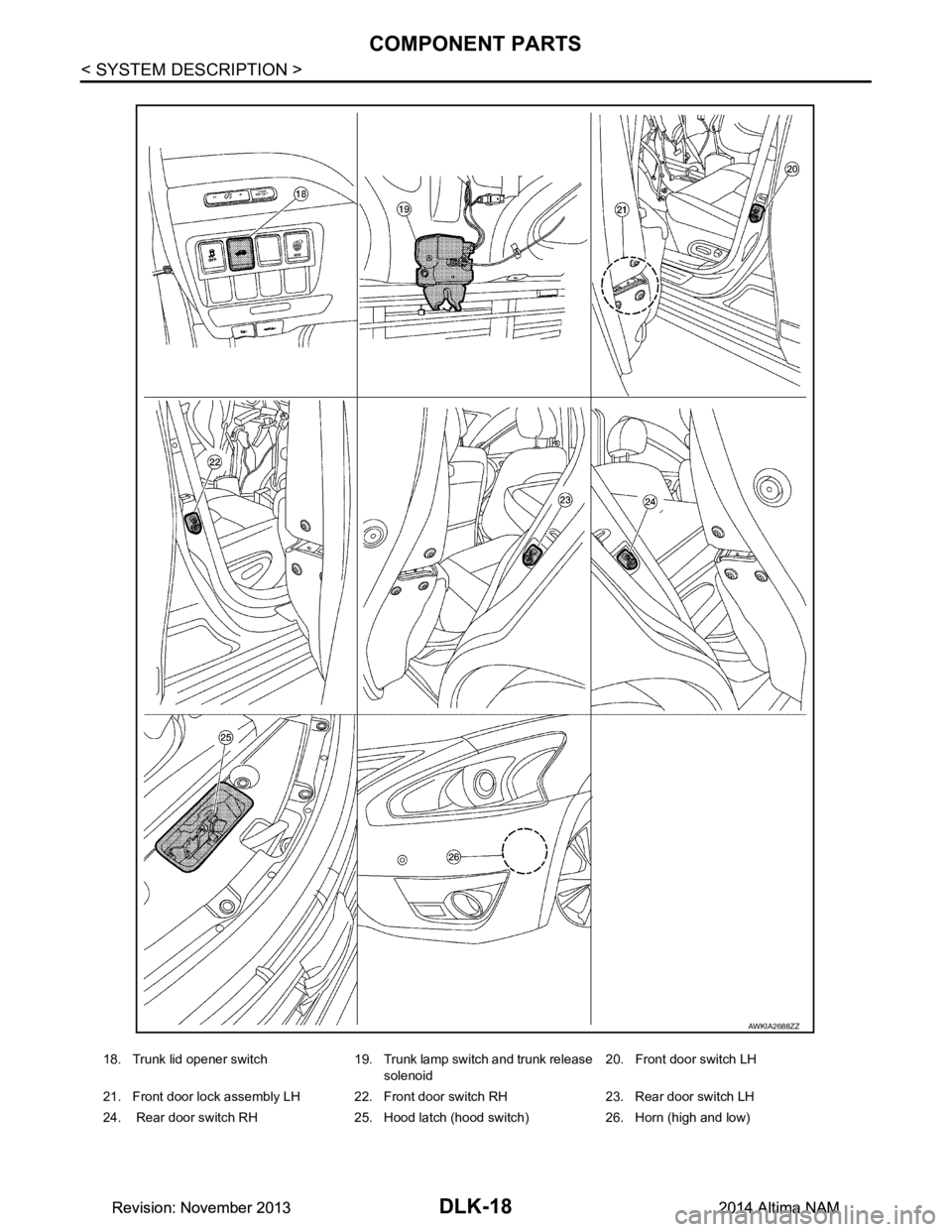

COMPONENT PARTS

18. Trunk lid opener switch 19. Trunk lamp switch and trunk release solenoid 20. Front door switch LH

21. Front door lock assembly LH 22. Front door switch RH 23. Rear door switch LH

24. Rear door switch RH 25. Hood latch (hood switch) 26. Horn (high and low)

AWKIA2688ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 787 of 4801

COMPONENT PARTSDLK-19

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

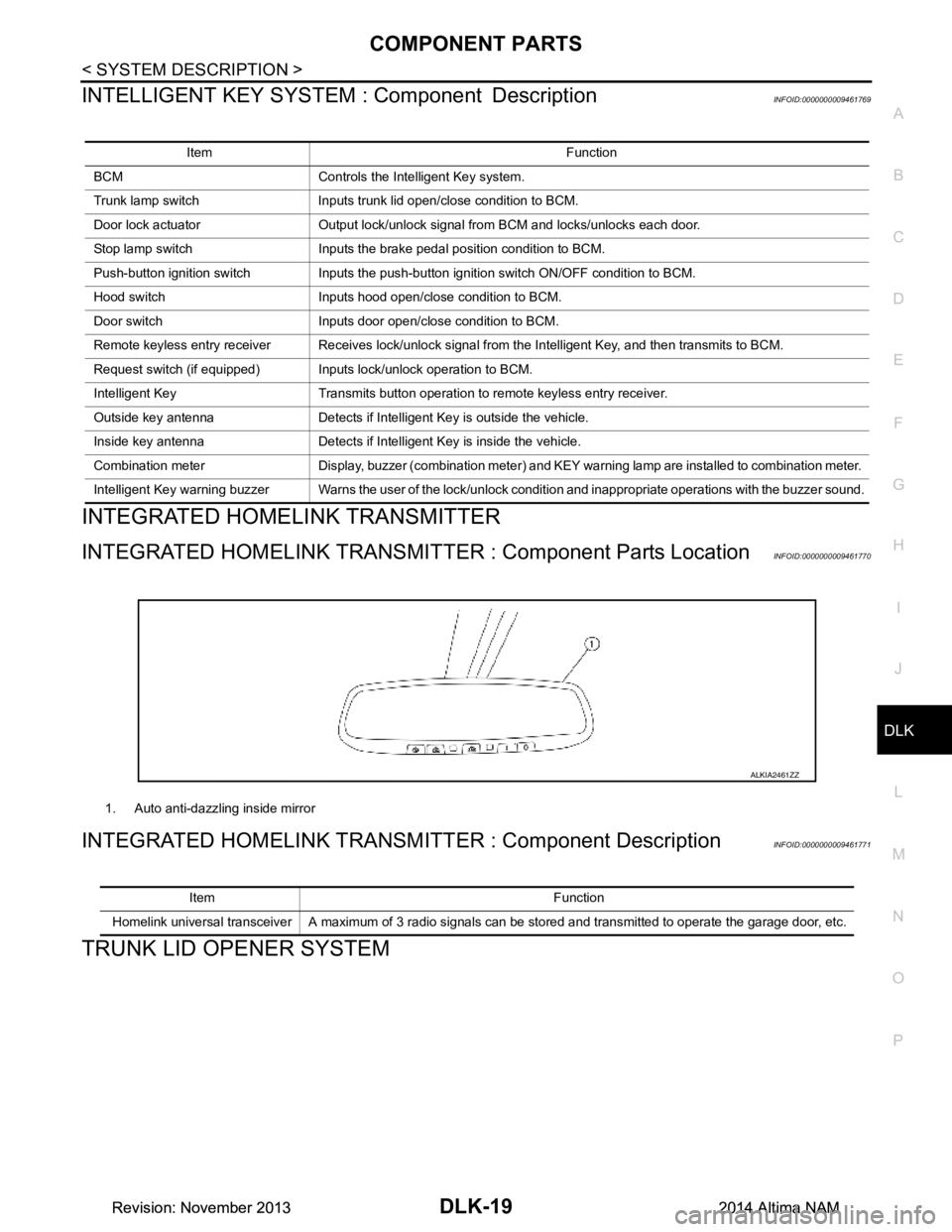

INTELLIGENT KEY SYSTEM : Component DescriptionINFOID:0000000009461769

INTEGRATED HOMELINK TRANSMITTER

INTEGRATED HOMELINK TRANSMI TTER : Component Parts LocationINFOID:0000000009461770

INTEGRATED HOMELINK TRANSM ITTER : Component DescriptionINFOID:0000000009461771

TRUNK LID OPENER SYSTEM

Item Function

BCM Controls the Intelligent Key system.

Trunk lamp switch Inputs trunk lid open/close condition to BCM.

Door lock actuator Output lock/unlock signal from BCM and locks/unlocks each door.

Stop lamp switch Inputs the brake pedal position condition to BCM.

Push-button ignition switch Inputs the push-button ignition switch ON/OFF condition to BCM.

Hood switch Inputs hood open/close condition to BCM.

Door switch Inputs door open/close condition to BCM.

Remote keyless entry receiver Receives lock/unlock signal from the Intelligent Key, and then transmits to BCM.

Request switch (if equipped) Inputs lock/unlock operation to BCM.

Intelligent Key Transmits button operation to remote keyless entry receiver.

Outside key antenna Detects if Intelligent Key is outside the vehicle.

Inside key antenna Detects if Intelligent Key is inside the vehicle.

Combination meter Display, buzzer (combination meter) and KEY warning lamp are installed to combination meter.

Intelligent Key warning buzzer Warns the user of the lock/unlock condition and inappropriate operations with the buzzer sound.

1. Auto anti-dazzling inside mirror

ALKIA2461ZZ

Item Function

Homelink universal transceiver A maximum of 3 radio signals can be stored and transmitted to operate the garage door, etc.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 795 of 4801

SYSTEM (INTELLIGENT KEY SYSTEM)DLK-27

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

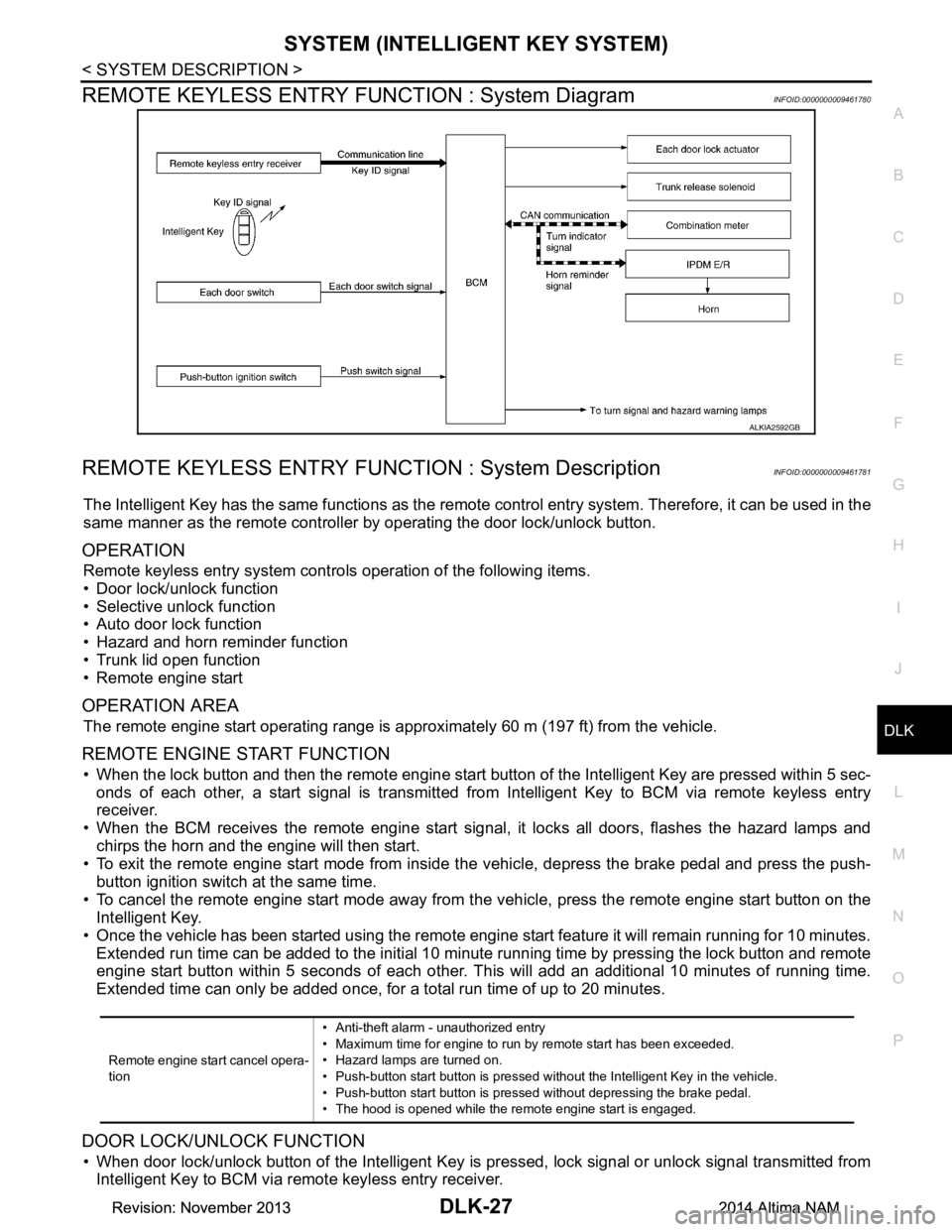

REMOTE KEYLESS ENTRY F UNCTION : System DiagramINFOID:0000000009461780

REMOTE KEYLESS ENTRY FUNCT ION : System DescriptionINFOID:0000000009461781

The Intelligent Key has the same functions as the remote control entry system. Therefore, it can be used in the

same manner as the remote controller by operating the door lock/unlock button.

OPERATION

Remote keyless entry system controls operation of the following items.

• Door lock/unlock function

• Selective unlock function

• Auto door lock function

• Hazard and horn reminder function

• Trunk lid open function

• Remote engine start

OPERATION AREA

The remote engine start operating range is appr oximately 60 m (197 ft) from the vehicle.

REMOTE ENGINE START FUNCTION

• When the lock button and then the remote engine start butt on of the Intelligent Key are pressed within 5 sec-

onds of each other, a start signal is transmitted from Intelligent Key to BCM via remote keyless entry

receiver.

• When the BCM receives the remote engine start signal , it locks all doors, flashes the hazard lamps and

chirps the horn and the engine will then start.

• To exit the remote engine start mode from inside t he vehicle, depress the brake pedal and press the push-

button ignition switch at the same time.

• To cancel the remote engine start mode away from t he vehicle, press the remote engine start button on the

Intelligent Key.

• Once the vehicle has been started using the remote engi ne start feature it will remain running for 10 minutes.

Extended run time can be added to the initial 10 minute running time by pressing the lock button and remote

engine start button within 5 seconds of each other. Th is will add an additional 10 minutes of running time.

Extended time can only be added once, for a total run time of up to 20 minutes.

DOOR LOCK/UNLOCK FUNCTION

• When door lock/unlock button of the Intelligent Key is pr essed, lock signal or unlock signal transmitted from

Intelligent Key to BCM via remote keyless entry receiver.

ALKIA2592GB

Remote engine start cancel opera-

tion • Anti-theft alarm - unauthorized entry

• Maximum time for engine to run by remote start has been exceeded.

• Hazard lamps are turned on.

• Push-button start button is pressed without the Intelligent Key in the vehicle.

• Push-button start button is pressed without depressing the brake pedal.

• The hood is opened while the remote engine start is engaged.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 799 of 4801

SYSTEM (INTELLIGENT KEY SYSTEM)DLK-31

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

• To exit the remote engine start mode from inside t he vehicle, depress the brake pedal and press the push-

button ignition switch at the same time.

• To cancel the remote engine start mode away from t he vehicle, press the remote engine start button on the

Intelligent Key.

• Once the vehicle has been started using the remote engi ne start feature it will remain running for 10 minutes.

Extended run time can be added to the initial 10 minute running time by pressing the lock button and remote

engine start button within 5 seconds of each other. Th is will add an additional 10 minutes of running time.

Extended time can only be added once, for a total run time of up to 20 minutes.

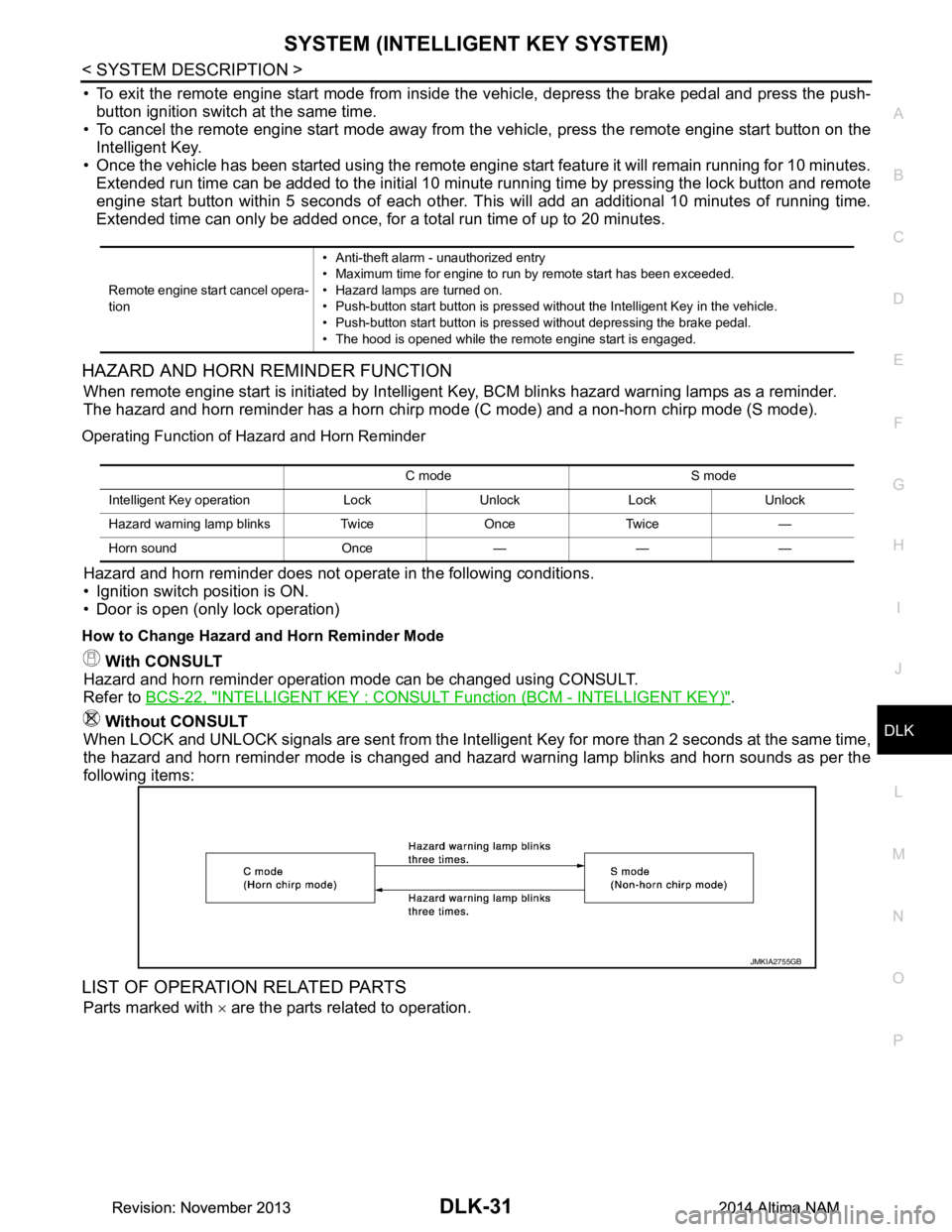

HAZARD AND HORN REMINDER FUNCTION

When remote engine start is initiated by Intelligent Key, BCM blinks hazard warning lamps as a reminder.

The hazard and horn reminder has a horn chirp m ode (C mode) and a non-horn chirp mode (S mode).

Operating Function of Hazard and Horn Reminder

Hazard and horn reminder does not operate in the following conditions.

• Ignition switch position is ON.

• Door is open (only lock operation)

How to Change Hazard and Horn Reminder Mode

With CONSULT

Hazard and horn reminder operation mode can be changed using CONSULT.

Refer to BCS-22, "INTELLIGENT KEY : CONSUL T Function (BCM - INTELLIGENT KEY)"

.

Without CONSULT

When LOCK and UNLOCK signals are sent from the Intelligent Key for more than 2 seconds at the same time,

the hazard and horn reminder mode is changed and hazard warning lamp blinks and horn sounds as per the

following items:

LIST OF OPERATION RELATED PARTS

Parts marked with × are the parts related to operation.

Remote engine start cancel opera-

tion • Anti-theft alarm - unauthorized entry

• Maximum time for engine to run by remote start has been exceeded.

• Hazard lamps are turned on.

• Push-button start button is pressed without the Intelligent Key in the vehicle.

• Push-button start button is pressed without depressing the brake pedal.

• The hood is opened while the remote engine start is engaged.

C mode S mode

Intelligent Key operation Lock Unlock Lock Unlock

Hazard warning lamp blinks Twice Once Twice —

Horn sound Once — — —

JMKIA2755GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 863 of 4801

B26FE HOOD SWITCHDLK-95

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

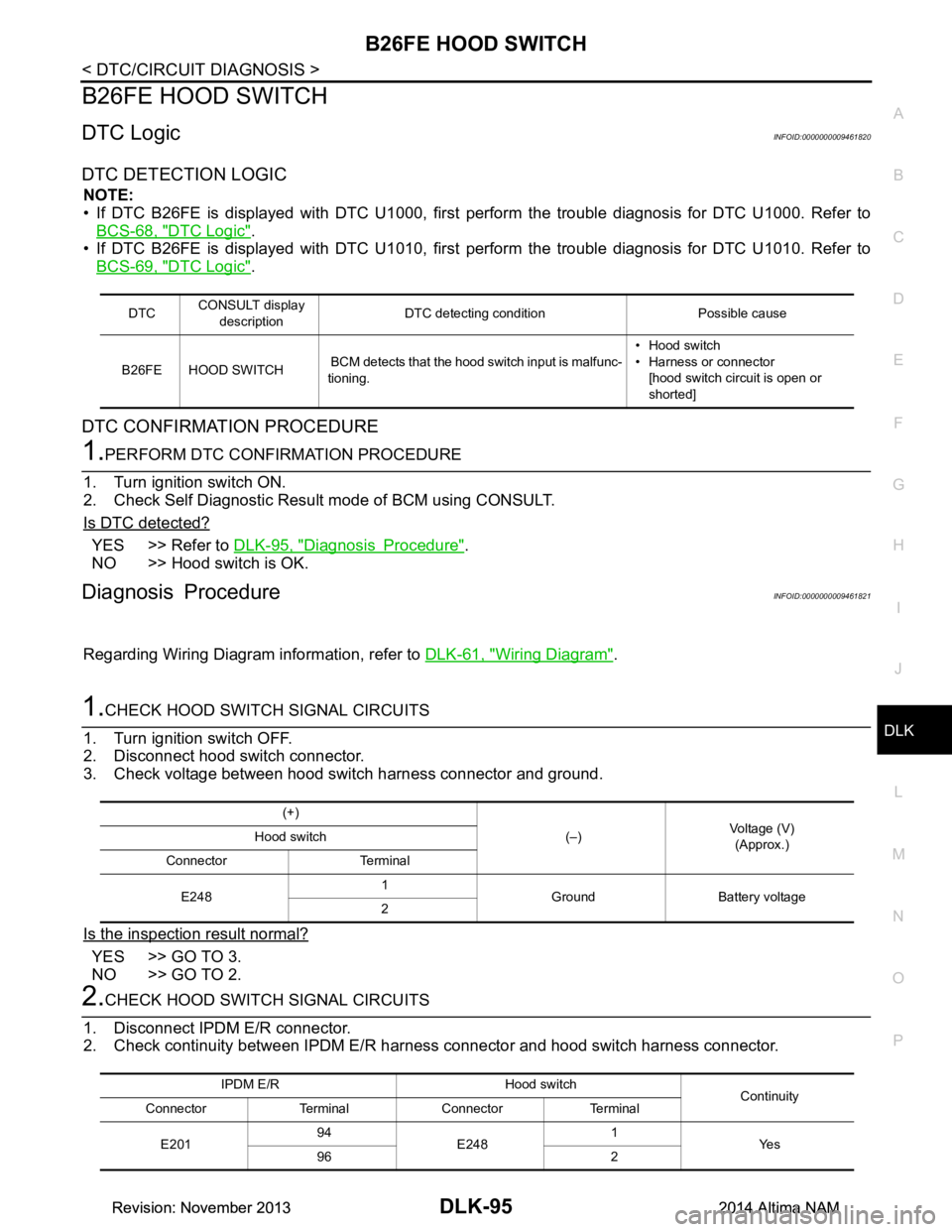

B26FE HOOD SWITCH

DTC LogicINFOID:0000000009461820

DTC DETECTION LOGIC

NOTE:

• If DTC B26FE is displayed with DTC U1000, firs t perform the trouble diagnosis for DTC U1000. Refer to

BCS-68, "DTC Logic"

.

• If DTC B26FE is displayed with DTC U1010, firs t perform the trouble diagnosis for DTC U1010. Refer to

BCS-69, "DTC Logic"

.

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check Self Diagnostic Result mode of BCM using CONSULT.

Is DTC detected?

YES >> Refer to DLK-95, "Diagnosis Procedure".

NO >> Hood switch is OK.

Diagnosis ProcedureINFOID:0000000009461821

Regarding Wiring Diagram information, refer to DLK-61, "Wiring Diagram".

1.CHECK HOOD SWITCH SIGNAL CIRCUITS

1. Turn ignition switch OFF.

2. Disconnect hood switch connector.

3. Check voltage between hood switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK HOOD SWITCH SIGNAL CIRCUITS

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R har ness connector and hood switch harness connector.

DTCCONSULT display

description DTC detecting condition Possible cause

B26FE HOOD SWITCH BCM detects that the hood switch input is malfunc-

tioning. • Hood switch

• Harness or connector

[hood switch circuit is open or

shorted]

(+)

(–)Voltage (V)

(Approx.)

Hood switch

Connector Terminal

E248 1

Ground Battery voltage

2

IPDM E/R Hood switch Continuity

Connector Terminal Connector Terminal

E201 94

E248 1

Ye s

96 2

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 978 of 4801

DLK-210

< REMOVAL AND INSTALLATION >

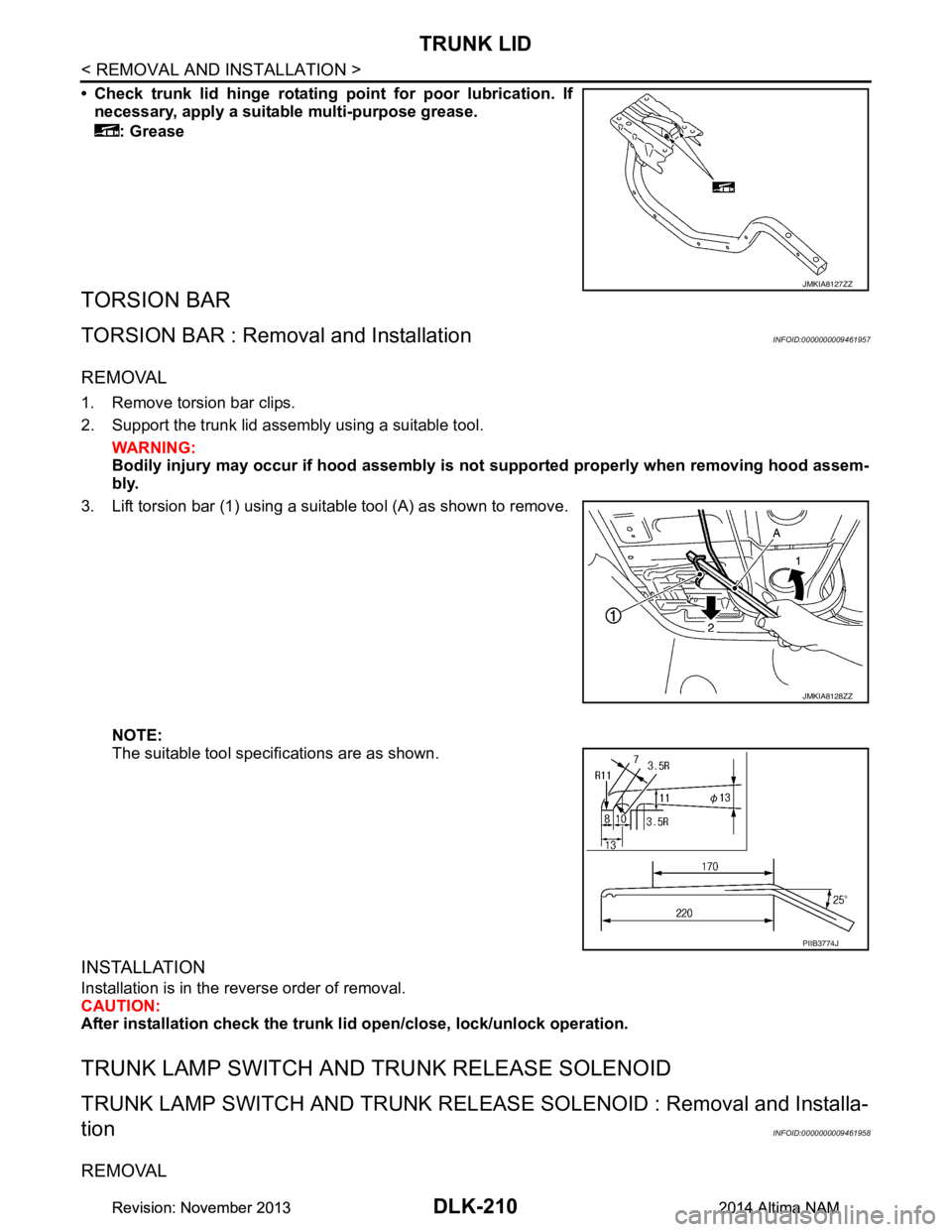

TRUNK LID

• Check trunk lid hinge rotating point for poor lubrication. If

necessary, apply a suitable multi-purpose grease.

: Grease

TORSION BAR

TORSION BAR : Remova l and InstallationINFOID:0000000009461957

REMOVAL

1. Remove torsion bar clips.

2. Support the trunk lid assembly using a suitable tool. WARNING:

Bodily injury may occur if hood assembly is not supported properly when removing hood assem-

bly.

3. Lift torsion bar (1) using a suitable tool (A) as shown to remove.

NOTE:

The suitable tool specifications are as shown.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation check the trunk li d open/close, lock/unlock operation.

TRUNK LAMP SWITCH AND TRUNK RELEASE SOLENOID

TRUNK LAMP SWITCH AND TRUNK RELEASE SOLENOID : Removal and Installa-

tion

INFOID:0000000009461958

REMOVAL

JMKIA8127ZZ

JMKIA8128ZZ

PIIB3774J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 982 of 4801

DLK-214

< REMOVAL AND INSTALLATION >

FUEL FILLER LID OPENER

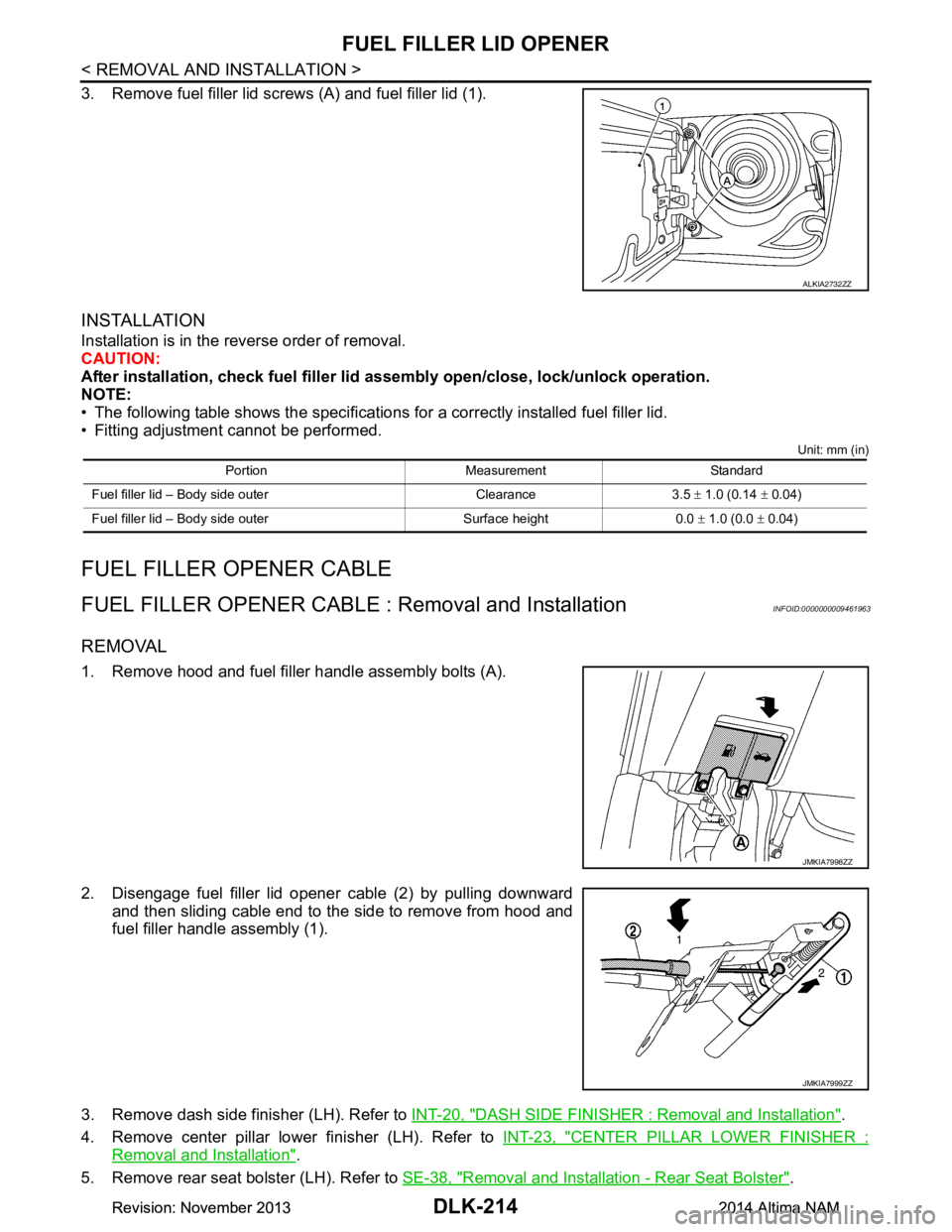

3. Remove fuel filler lid screws (A) and fuel filler lid (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, check fuel filler li d assembly open/close, lock/unlock operation.

NOTE:

• The following table shows the specifications for a correctly installed fuel filler lid.

• Fitting adjustment cannot be performed.

Unit: mm (in)

FUEL FILLER OP ENER CABLE

FUEL FILLER OPENER CABLE : Removal and InstallationINFOID:0000000009461963

REMOVAL

1. Remove hood and fuel filler handle assembly bolts (A).

2. Disengage fuel filler lid opener cable (2) by pulling downward and then sliding cable end to the side to remove from hood and

fuel filler handle assembly (1).

3. Remove dash side finisher (LH). Refer to INT-20, "DASH SIDE FINISHER : Removal and Installation"

.

4. Remove center pillar lower finisher (LH). Refer to INT-23, "CENTER PILLAR LOWER FINISHER :

Removal and Installation".

5. Remove rear seat bolster (LH). Refer to SE-38, "Removal and Installation - Rear Seat Bolster"

.

ALKIA2732ZZ

Portion Measurement Standard

Fuel filler lid – Body side outer Clearance 3.5 ± 1.0 (0.14 ± 0.04)

Fuel filler lid – Body side outer Surface height 0.0 ± 1.0 (0.0 ± 0.04)

JMKIA7998ZZ

JMKIA7999ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1170 of 4801

![NISSAN TEANA 2014 Service Manual

EC-170

< BASIC INSPECTION >[QR25DE]

BASIC INSPECTION

BASIC INSPECTION

Work ProcedureINFOID:0000000009462129

1.INSPECTION START

1. Check service records for any recent repairs that ma y indicate a rel NISSAN TEANA 2014 Service Manual

EC-170

< BASIC INSPECTION >[QR25DE]

BASIC INSPECTION

BASIC INSPECTION

Work ProcedureINFOID:0000000009462129

1.INSPECTION START

1. Check service records for any recent repairs that ma y indicate a rel](/img/5/57390/w960_57390-1169.png)

EC-170

< BASIC INSPECTION >[QR25DE]

BASIC INSPECTION

BASIC INSPECTION

Work ProcedureINFOID:0000000009462129

1.INSPECTION START

1. Check service records for any recent repairs that ma y indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT or GST.

Is any DTC detected?

YES >> GO TO 2.

NO >> GO TO 3.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.CHECK TARGET IDLE SPEED

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM