differential NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4 of 4801

< SERVICE DATA AND SPECIFICATIONS (SDS) 2014

QUICK REFERENCE CHART: ALTIMA

QUICK REFERENCE CHART: ALTIMA

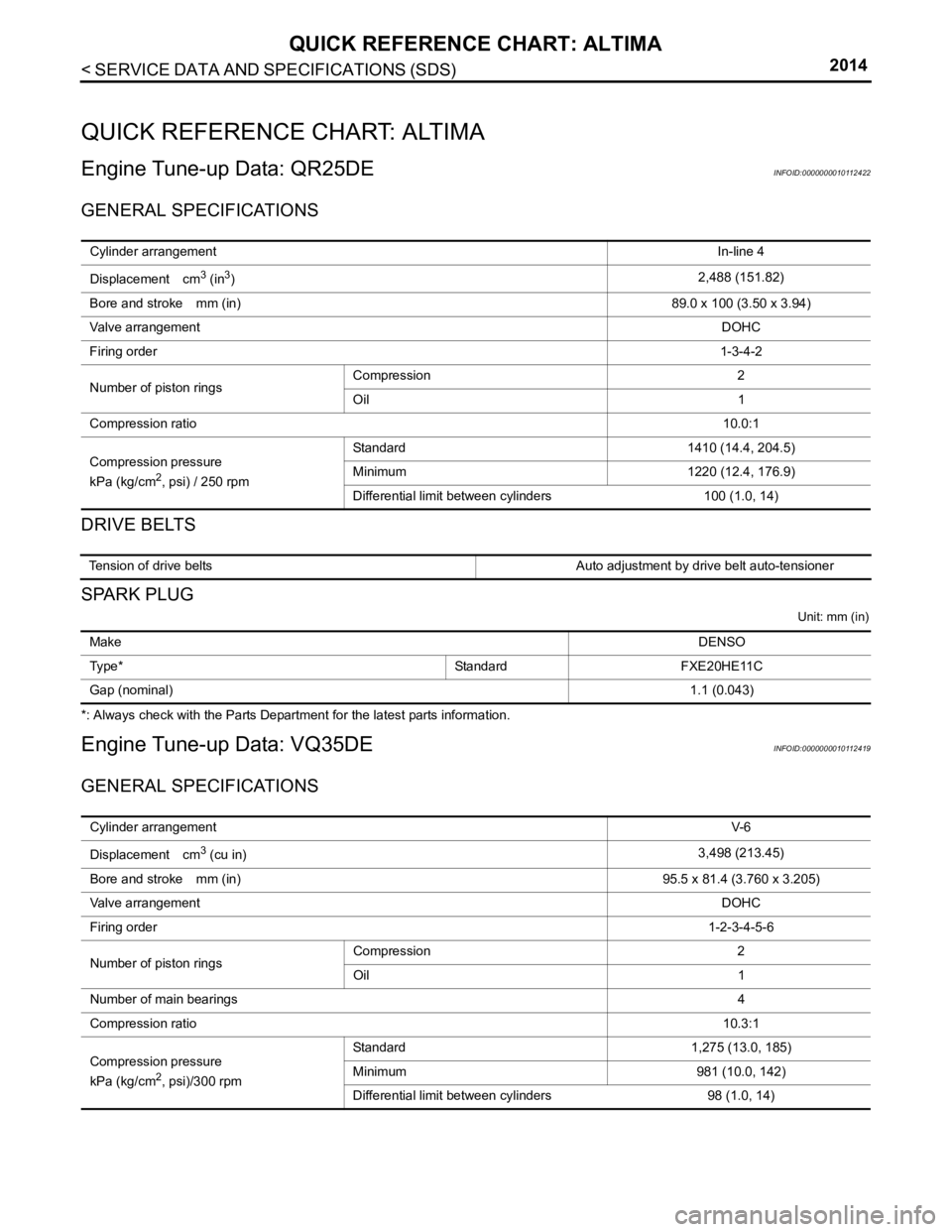

Engine Tune-up Data: QR25DEINFOID:0000000010112422

GENERAL SPECIFICATIONS

DRIVE BELTS

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Engine Tune-up Data: VQ35DEINFOID:0000000010112419

GENERAL SPECIFICATIONS

Cylinder arrangement

In-line 4

Displacement cm

3 (in3) 2,488 (151.82)

Bore and stroke mm (in) 89.0 x 100 (3.50 x 3.94)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression

2

Oil 1

Compression ratio 10.0:1

Compression pressure

kPa (kg/cm

2, psi) / 250 rpm Standard 1410 (14.4, 204.5)

Minimum

1220 (12.4, 176.9)

Differential limit between cylinders 100 (1.0, 14)

Tension of drive belts Auto adjustment by drive belt auto-tensioner

Make DENSO

Type* StandardFXE20HE11C

Gap (nominal) 1.1 (0.043)

Cylinder arrangement V-6

Displacement cm

3 (cu in) 3,498 (213.45)

Bore and stroke mm (in) 95.5 x 81.4 (3.760 x 3.205)

Valve arrangement DOHC

Firing order 1-2-3-4-5-6

Number of piston rings Compression 2

Oil 1

Number of main bearings 4

Compression ratio 10.3:1

Compression pressure

kPa (kg/cm

2, psi)/300 rpm Standard 1,275 (13.0, 185)

Minimum

981 (10.0, 142)

Differential limit between cylinders 98 (1.0, 14)

Page 169 of 4801

![NISSAN TEANA 2014 Service Manual

SYSTEMBRC-23

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VDC/TCS/ABS : VDC FunctionINFOID:0000000009463753

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• Side slip or tail slip m NISSAN TEANA 2014 Service Manual

SYSTEMBRC-23

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VDC/TCS/ABS : VDC FunctionINFOID:0000000009463753

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• Side slip or tail slip m](/img/5/57390/w960_57390-168.png)

SYSTEMBRC-23

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VDC/TCS/ABS : VDC FunctionINFOID:0000000009463753

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• Side slip or tail slip may occur while driving on a slippery road or intending an urgent evasive driving maneu- ver. VDC function detects side slip status using each s ensor when side slip or tail slip is about to occur and

improves vehicle stability by brake c ontrol and engine output control during driving.

• In addition to ABS function, EBD function and TCS functi on, target side slip amount is calculated according

to steering operation amount from steering angle sensor. By comparing this information with vehicle side slip

amount that is calculated from information from yaw rate/side G sensor and wheel sensor, vehicle driving

conditions (conditions of understeer or oversteer) are judged and vehicle stability is improved by brake force

control on all 4 wheels and engine output control.

• VDC function can be switched to non-operational status (OFF) by operating VDC OFF switch. In this case,

VDC OFF indicator lamp turns ON.

• Control unit portion automatically improves driving st ability by performing brake force control as well as

engine output control, by transmitting drive signal to actuator portion according to difference between target

side slip amount and vehicle side slip amount

Brake limited slip differential (BLSD) function

is malfunctioning OFF OFF

VDC function is operating OFF OFF

TCS function is operating OFF OFF Condition (status) ABS warnin

g lamp Brake warning lamp

ALFIA0298GB

JSFIA0672GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2109 of 4801

![NISSAN TEANA 2014 Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)EM-111

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (S NISSAN TEANA 2014 Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)EM-111

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (S](/img/5/57390/w960_57390-2108.png)

SERVICE DATA AND SPECIFICATIONS (SDS)EM-111

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000009460513

GENERAL SPECIFICATIONS

VA LV E T I M I N G

Unit: degree

*1: When running at idle with engine coolant temperature more than 60

°C (140 °F).

Cylinder arrangement

In-line 4

Displacement cm

3 (in3) 2,488 (151.82)

Bore and stroke mm (in) 89.0 x 100 (3.50 x 3.94)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression 2

Oil 1

Compression ratio 10.0:1

Compression pressure

kPa (kg/cm

2, psi) / 250 rpm Standard 1410 (14.4, 204.5)

Minimum 1220 (12.4, 176.9)

Differential limit between cylinders 100 (1.0, 14)

Va l v e t i m i n g : Intake valve

: Exhaust valve

ab c de f

VTC Minimum phasing

(Mechanical)

*1224 244 5 69 3 41

VTC Maximum phasing

(Mechanical)

*2224 244 35 29 48 4

Intermediate lock phasing

(Mechanical)

*3224 244 5 59 3 41

ALBIA0875GBALBIA0876GB

ALBIA0877GB

Revision: November 20132014 Altima NAM

Page 2244 of 4801

![NISSAN TEANA 2014 Service Manual

EM-246

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0 NISSAN TEANA 2014 Service Manual

EM-246

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0](/img/5/57390/w960_57390-2243.png)

EM-246

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000009460584

GENERAL SPECIFICATIONS

Drive BeltINFOID:0000000009460585

DRIVE BELT

Cylinder arrangement

V-6

Displacement cm

3 (cu in) 3,498 (213.45)

Bore and stroke mm (in) 95.5 x 81.4 (3.760 x 3.205)

Valve arrangement DOHC

Firing order 1-2-3-4-5-6

Number of piston rings Compression 2

Oil 1

Number of main bearings 4

Compression ratio 10.3:1

Compression pressure

kPa (kg/cm

2, psi)/300 rpm Standard 1,275 (13.0, 185)

Minimum 981 (10.0, 142)

Differential limit between cylinders 98 (1.0, 14)

Cylinder number

Valve timing

(Valve timing control - “OFF”)

Unit: degree

abcde f

240 240 −

10 (-35)

AT D C 70(25)

ABDC 10 50

SEM713A

PBIC0187E

Revision: November 20132014 Altima NAM

Page 2455 of 4801

PREPARATIONFAX-3

< PREPARATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000009464434

The actual shapes of the tools may differ from those illustrated here.

Commercial Service ToolINFOID:0000000009464435

Tool number

(TechMate No.)

Tool name Description

KV38106700

(J-34296)

KV38106800

(J-34297)

Differential side oil seal protector Installing drive shaft

LH: KV38106700 (J-34296)

RH: KV38106800 (J-34297)

KV40107300

(—)

Boot Band crimping tool Installing boot bands

KV40107500

(—)

Drive shaft attachment Removing drive shaft

NT147

ZZA1229D

ZZA1230D

Tool name

Description

Drive shaft puller Removing drive shaft joint sub assembly

JPDIG0152ZZ

Revision: November 20132014 Altima NAM

Page 2463 of 4801

FRONT DRIVE SHAFTFAX-11

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

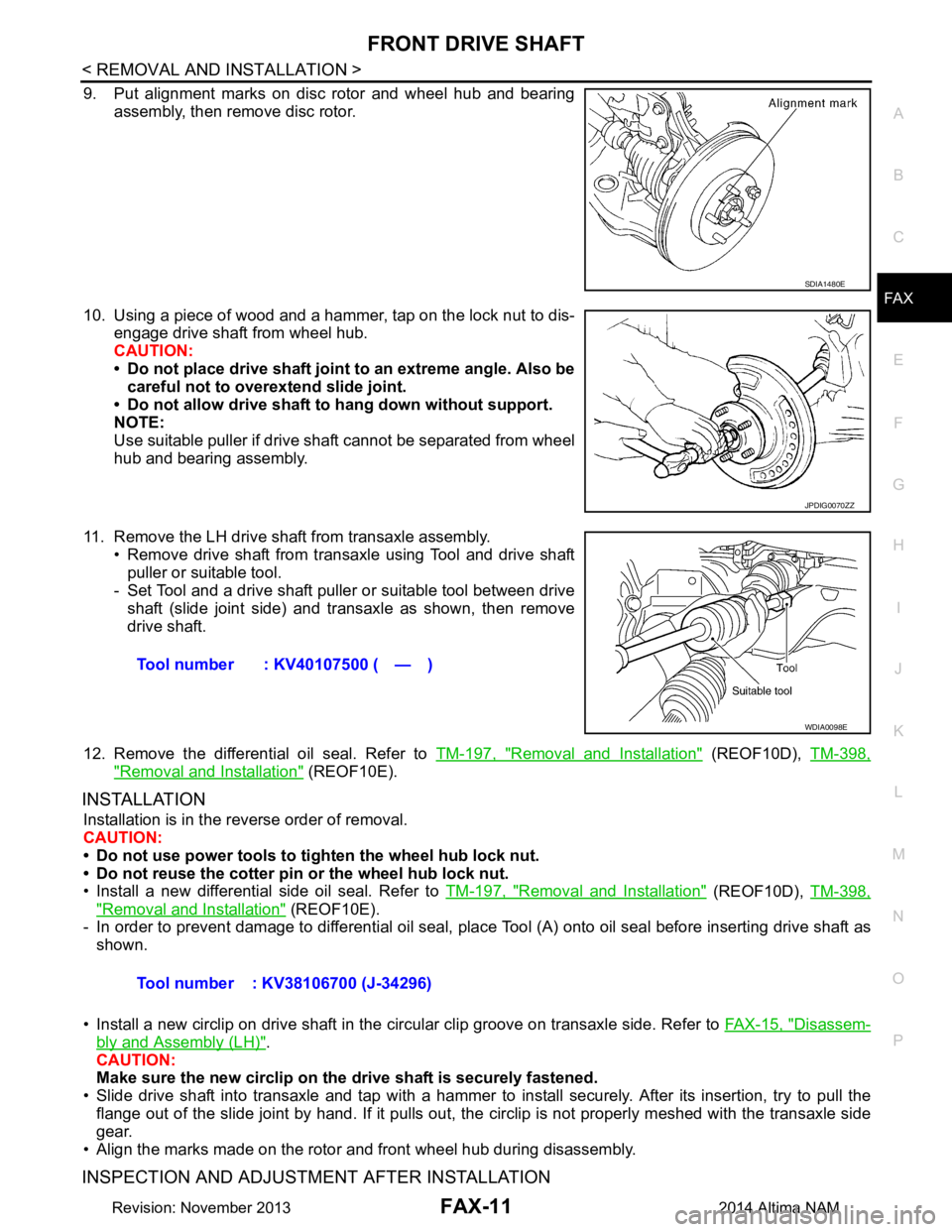

9. Put alignment marks on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

10. Using a piece of wood and a hammer, tap on the lock nut to dis- engage drive shaft from wheel hub.

CAUTION:

• Do not place drive shaft joint to an extreme angle. Also be careful not to over extend slide joint.

• Do not allow drive shaft to hang down without support.

NOTE:

Use suitable puller if drive shaft cannot be separated from wheel

hub and bearing assembly.

11. Remove the LH drive shaf t from transaxle assembly.

• Remove drive shaft from transaxle using Tool and drive shaft puller or suitable tool.

- Set Tool and a drive shaft puller or suitable tool between drive

shaft (slide joint side) and transaxle as shown, then remove

drive shaft.

12. Remove the differential oil seal. Refer to TM-197, "Removal and Installation"

(REOF10D), TM-398,

"Removal and Installation" (REOF10E).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not use power tools to ti ghten the wheel hub lock nut.

• Do not reuse the cotter pin or the wheel hub lock nut.

• Install a new differential side oil seal. Refer to TM-197, "Removal and Installation"

(REOF10D), TM-398,

"Removal and Installation" (REOF10E).

- In order to prevent damage to differential oil seal, plac e Tool (A) onto oil seal before inserting drive shaft as

shown.

• Install a new circlip on drive shaft in the circular clip groove on transaxle side. Refer to FAX-15, "Disassem-

bly and Assembly (LH)".

CAUTION:

Make sure the new circlip on the drive shaft is securely fastened.

• Slide drive shaft into transaxle and tap with a hammer to install securely. After its insertion, try to pull the

flange out of the slide joint by hand. If it pulls out, t he circlip is not properly meshed with the transaxle side

gear.

• Align the marks made on the rotor and front wheel hub during disassembly.

INSPECTION AND ADJUSTMENT AFTER INSTALLATION

SDIA1480E

JPDIG0070ZZ

Tool number : KV40107500 ( — )

WDIA0098E

Tool number : KV38106700 (J-34296)

Revision: November 20132014 Altima NAM

Page 2465 of 4801

FRONT DRIVE SHAFTFAX-13

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

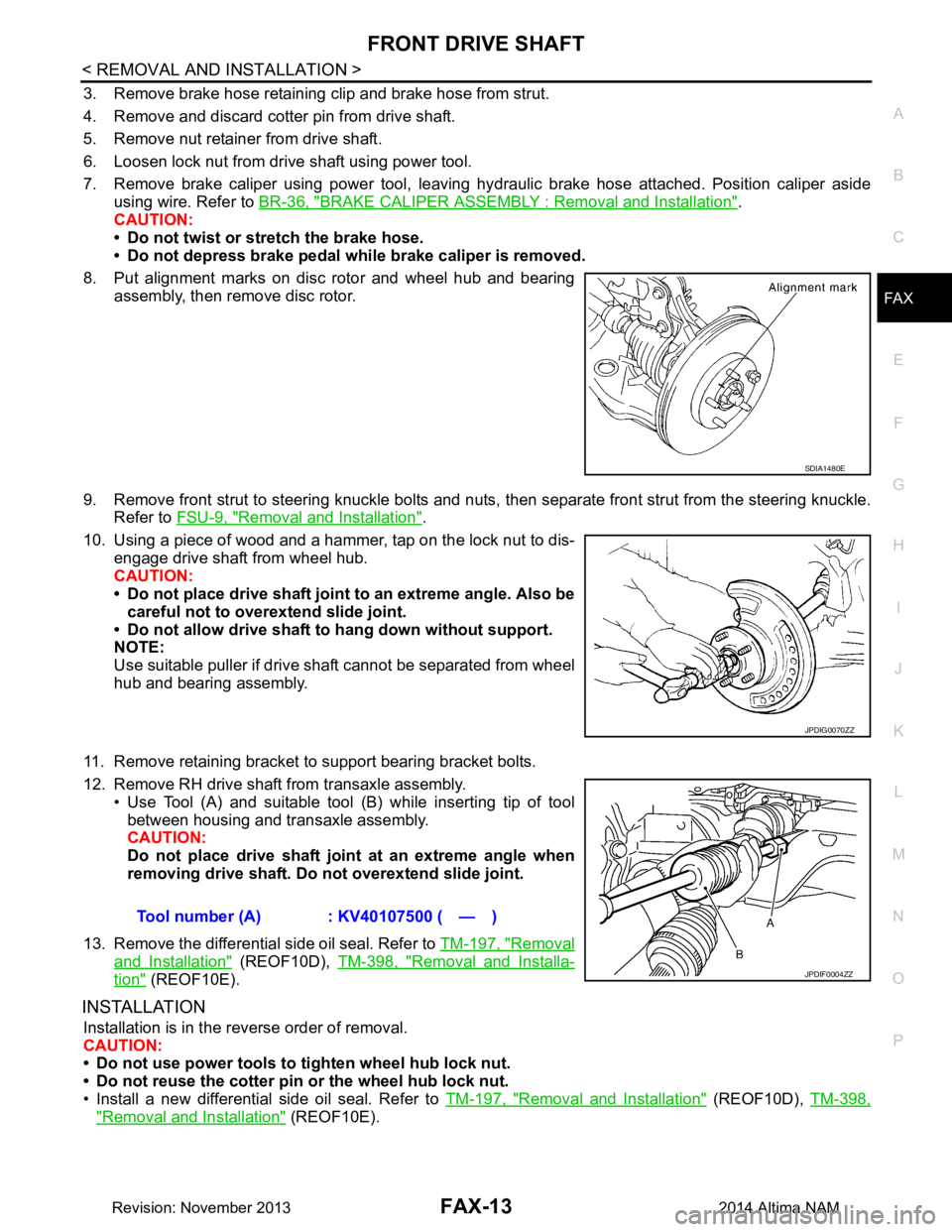

3. Remove brake hose retaining clip and brake hose from strut.

4. Remove and discard cotter pin from drive shaft.

5. Remove nut retainer from drive shaft.

6. Loosen lock nut from drive shaft using power tool.

7. Remove brake caliper using power tool, leaving hy draulic brake hose attached. Position caliper aside

using wire. Refer to BR-36, "BRAKE CALIPER ASSEMBLY : Removal and Installation"

.

CAUTION:

• Do not twist or stretch the brake hose.

• Do not depress brake pedal while brake caliper is removed.

8. Put alignment marks on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

9. Remove front strut to steering knuckle bolts and nuts, then separate front strut from the steering knuckle.

Refer to FSU-9, "Removal and Installation"

.

10. Using a piece of wood and a hammer, tap on the lock nut to dis- engage drive shaft from wheel hub.

CAUTION:

• Do not place drive shaft joint to an extreme angle. Also be careful not to over extend slide joint.

• Do not allow drive shaft to hang down without support.

NOTE:

Use suitable puller if drive shaft cannot be separated from wheel

hub and bearing assembly.

11. Remove retaining bracket to support bearing bracket bolts.

12. Remove RH drive shaft from transaxle assembly. • Use Tool (A) and suitable tool (B) while inserting tip of tool

between housing and transaxle assembly.

CAUTION:

Do not place drive shaft join t at an extreme angle when

removing drive shaft. Do not overextend slide joint.

13. Remove the differential side oil seal. Refer to TM-197, "Removal

and Installation" (REOF10D), TM-398, "Removal and Installa-

tion" (REOF10E).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not use power tools to tighten wheel hub lock nut.

• Do not reuse the cotter pin or the wheel hub lock nut.

• Install a new differential side oil seal. Refer to TM-197, "Removal and Installation"

(REOF10D), TM-398,

"Removal and Installation" (REOF10E).

SDIA1480E

JPDIG0070ZZ

Tool number (A) : KV40107500 ( — )

JPDIF0004ZZ

Revision: November 20132014 Altima NAM

Page 2466 of 4801

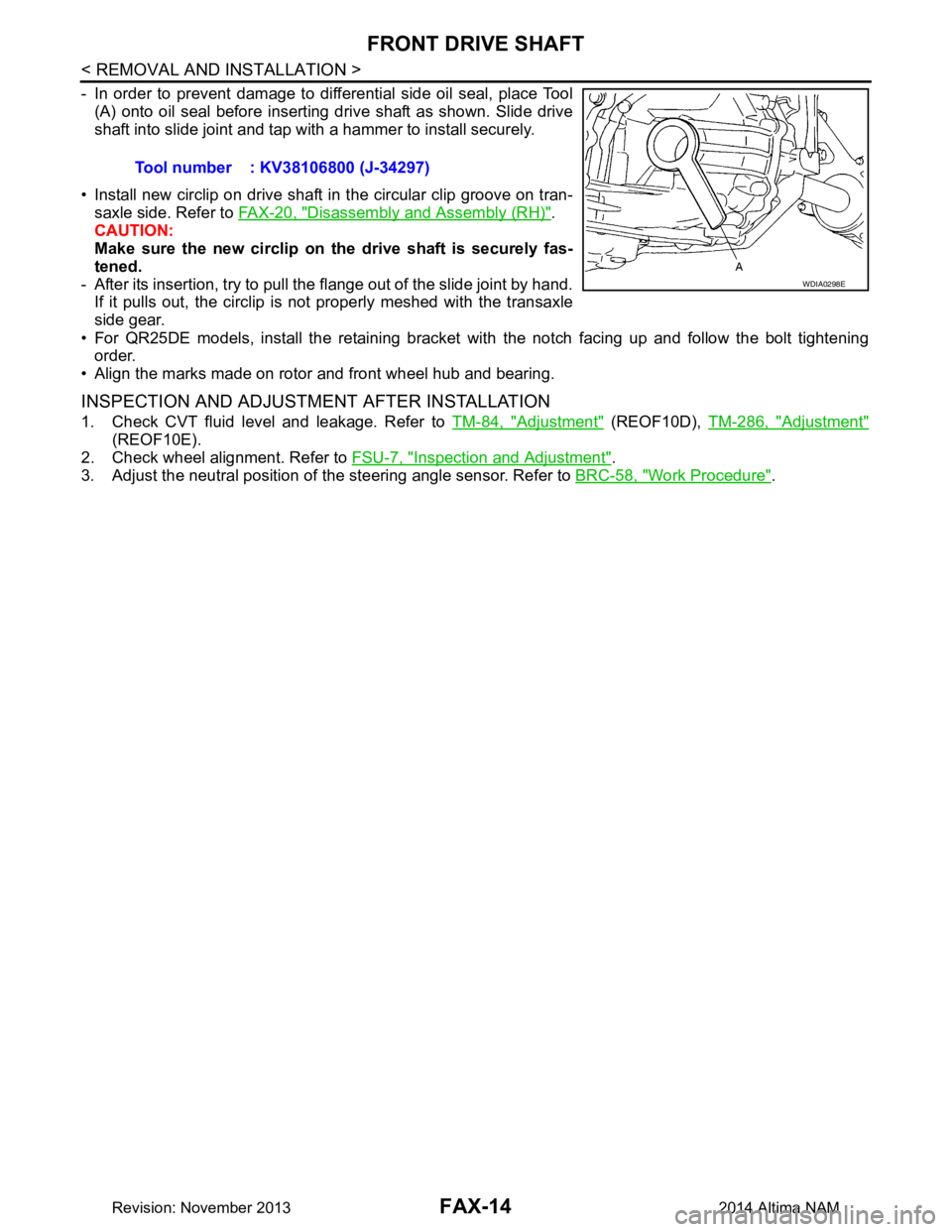

FAX-14

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

- In order to prevent damage to differential side oil seal, place Tool(A) onto oil seal before inserting drive shaft as shown. Slide drive

shaft into slide joint and tap with a hammer to install securely.

• Install new circlip on drive shaft in the circular clip groove on tran- saxle side. Refer to FAX-20, "Disassembly and Assembly (RH)"

.

CAUTION:

Make sure the new circlip on the drive shaft is securely fas-

tened.

- After its insertion, try to pull the flange out of the slide joint by hand. If it pulls out, the circlip is not properly meshed with the transaxle

side gear.

• For QR25DE models, install the retaining bracket with the notch facing up and follow the bolt tightening

order.

• Align the marks made on rotor and front wheel hub and bearing.

INSPECTION AND ADJUSTMENT AFTER INSTALLATION

1. Check CVT fluid level and leakage. Refer to TM-84, "Adjustment" (REOF10D), TM-286, "Adjustment"

(REOF10E).

2. Check wheel alignment. Refer to FSU-7, "Inspection and Adjustment"

.

3. Adjust the neutral position of the steering angle sensor. Refer to BRC-58, "Work Procedure"

.

Tool number : KV38106800 (J-34297)

WDIA0298E

Revision: November 20132014 Altima NAM

Page 2541 of 4801

ABBREVIATIONSGI-13

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O PABBREVIATIONS

Abbreviation ListINFOID:0000000009462979

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position AV Audio visual

AVM Around view monitor

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCI Backup collision intervention

BCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist

DDS Downhill drive support DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4219 of 4801

TM-4

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ................................................................ .

164

Diagnosis Procedure ........................................... ..164

OVERDRIVE CONTROL SWITCH ..................166

Component Function Check ................................ ..166

Diagnosis Procedure .............................................166

Component Inspection ...........................................167

OD OFF INDICATOR LAMP ............................168

Component Function Check ................................ ..168

Diagnosis Procedure .............................................168

SHIFT POSITION INDICATOR CIRCUIT ........169

Component Parts Function Inspection ................ ..169

Diagnosis Procedure .............................................169

SHIFT LOCK SYSTEM ................................... .170

Component Function Check ................................ ..170

Diagnosis Procedure .............................................170

Component Inspection (Shift Lock Solenoid) ........172

Component Inspection (Park Position Switch) ......172

Component Inspection (Stop Lamp Switch) ..........173

SYMPTOM DIAGNOSIS ............................174

CVT CONTROL SYSTEM ............................... .174

Symptom Table ................................................... ..174

PERIODIC MAINTENANCE ..................... ..178

CVT FLUID ...................................................... .178

Inspection ............................................................ ..178

REMOVAL AND INSTALLATION ..............179

CVT SHIFT SELECTOR ................................. .179

Exploded View ..................................................... ..179

Removal and Installation .......................................179

Inspection ..............................................................180

CONTROL CABLE ..........................................181

Exploded View ..................................................... ..181

Removal and Installation .......................................181

Inspection and Adjustment ....................................182

TCM ..................................................................183

Exploded View ..................................................... ..183

Removal and Installation .......................................183

Adjustment .............................................................184

AIR BREATHER HOSE ...................................185

Removal and Installation ..................................... ..185

CONTROL VALVE ...........................................186

Exploded View ..................................................... ..186

Removal and Installation .......................................187

Inspection ..............................................................191

INPUT SPEED SENSOR .................................192

Exploded View ..................................................... ..192

Removal and Installation .......................................192

Inspection and Adjustment ................................... .192

PRIMARY SPEED SENSOR .......................... ..194

Exploded View ..................................................... .194

Removal and Installation .......................................194

Inspection and Adjustment ................................... .194

OUTPUT SPEED SENSOR ..............................196

Exploded View ..................................................... .196

Removal and Installation .......................................196

Inspection and Adjustment ................................... .196

DIFFERENTIAL SIDE OIL SEAL .....................197

Exploded View ..................................................... .197

Removal and Installation .......................................197

Inspection and Adjustment ................................... .198

CVT OIL WARMER SYSTEM ...........................199

WATER HOSE ........................................................ .199

WATER HOSE : Exploded View ...........................199

WATER HOSE : Removal and Installation ...........199

WATER HOSE : Inspection ..................................201

CVT FLUID COOLER HOSE .................................. .201

CVT FLUID COOLER HOSE : Exploded View .....201

CVT FLUID COOLER HOSE : Removal and In-

stallation ............................................................... .

202

CVT FLUID COOLER HOSE : Inspection .............203

CVT OIL WARMER ................................................ .203

CVT OIL WARMER : Exploded View ....................203

CVT OIL WARMER : Removal and Installation ....203

CVT OIL WARMER : Inspection .......................... .204

PLUG ................................................................205

Description ........................................................... .205

Exploded View ......................................................205

Removal and Installation .......................................205

Inspection and Adjustment ................................... .205

UNIT REMOVAL AND INSTALLATION ...206

TRANSAXLE ASSEMBLY ............................. ..206

Exploded View ..................................................... .206

Removal and Installation .......................................206

Inspection and Adjustment ................................... .208

UNIT DISASSEMBLY AND ASSEMBLY ..209

TORQUE CONVERTER AND CONVERTER

HOUSING OIL SEAL ...................................... ..

209

Exploded View ..................................................... .209

Disassembly ..........................................................209

Assembly ..............................................................209

Inspection ..............................................................210

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..........................................

212

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

212

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM