engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1493 of 1767

4. Wipe clean fuel filter mounting surface on fuel filter bracket and

smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 or a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

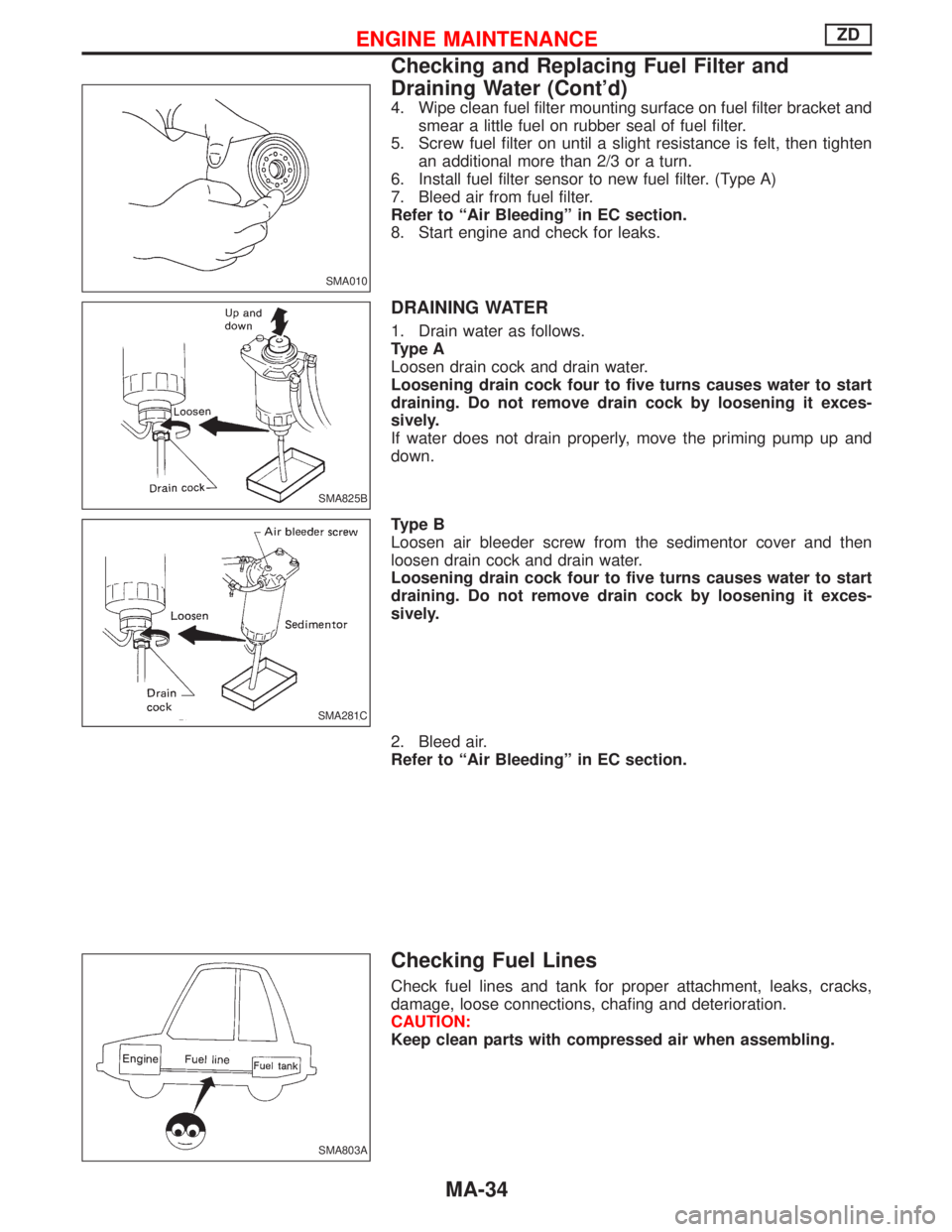

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-34

Page 1494 of 1767

Cleaning and Replacing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any clean-

ing operation between renewal.

SMA151D

ENGINE MAINTENANCEZD

MA-35

Page 1496 of 1767

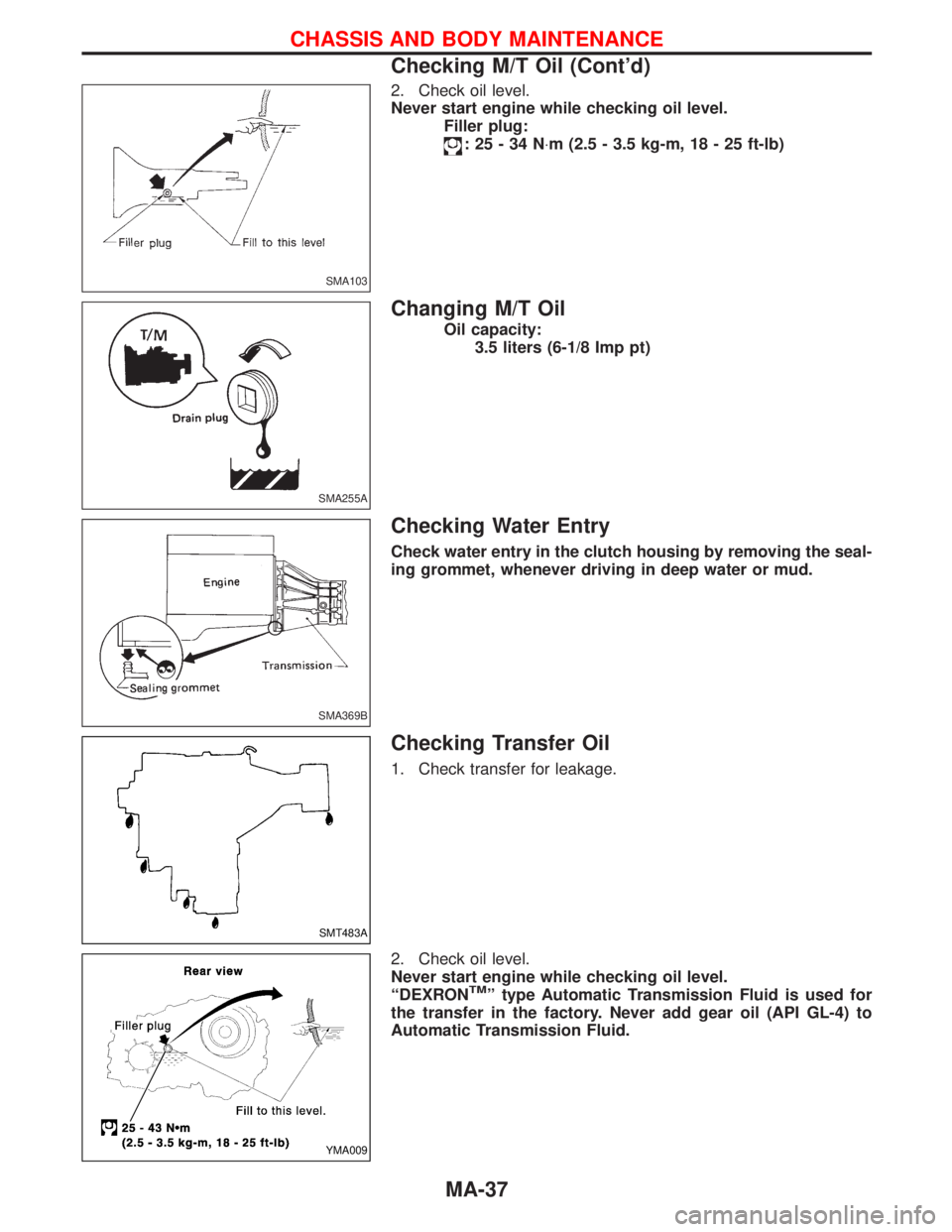

2. Check oil level.

Never start engine while checking oil level.

Filler plug:

:25-34N×m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

Oil capacity:

3.5 liters (6-1/8 Imp pt)

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Oil

1. Check transfer for leakage.

2. Check oil level.

Never start engine while checking oil level.

ªDEXRON

TMº type Automatic Transmission Fluid is used for

the transfer in the factory. Never add gear oil (API GL-4) to

Automatic Transmission Fluid.

SMA103

SMA255A

SMA369B

SMT483A

YMA009

CHASSIS AND BODY MAINTENANCE

Checking M/T Oil (Cont'd)

MA-37

Page 1501 of 1767

TEMPORARY METHOD FOR CHECKING LINING WEAR

Remove inspection hole plug and check for lining wear.

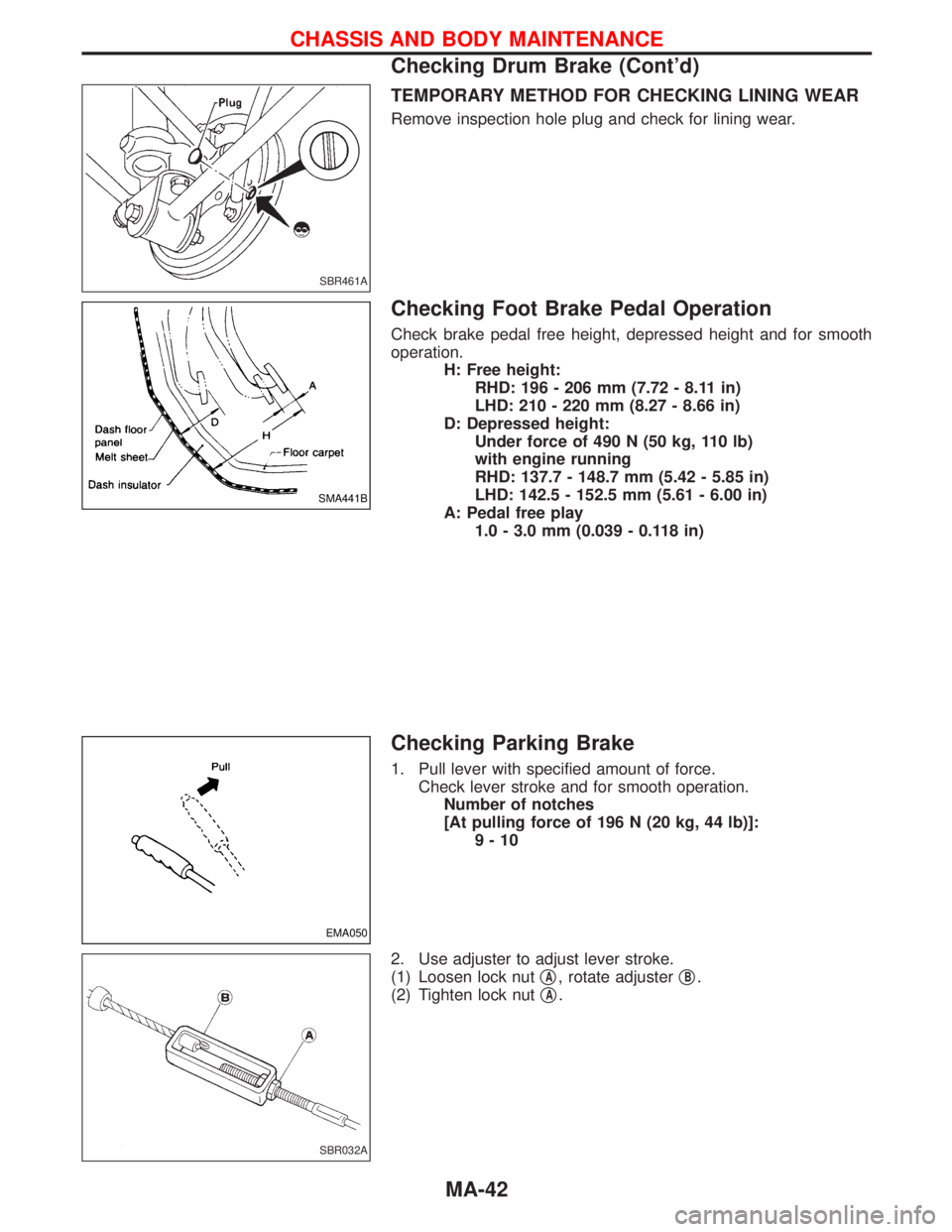

Checking Foot Brake Pedal Operation

Check brake pedal free height, depressed height and for smooth

operation.

H: Free height:

RHD: 196 - 206 mm (7.72 - 8.11 in)

LHD: 210 - 220 mm (8.27 - 8.66 in)

D: Depressed height:

Under force of 490 N (50 kg, 110 lb)

with engine running

RHD: 137.7 - 148.7 mm (5.42 - 5.85 in)

LHD: 142.5 - 152.5 mm (5.61 - 6.00 in)

A: Pedal free play

1.0 - 3.0 mm (0.039 - 0.118 in)

Checking Parking Brake

1. Pull lever with specified amount of force.

Check lever stroke and for smooth operation.

Number of notches

[At pulling force of 196 N (20 kg, 44 lb)]:

9-10

2. Use adjuster to adjust lever stroke.

(1) Loosen lock nutq

A, rotate adjusterqB.

(2) Tighten lock nutq

A.

SBR461A

SMA441B

EMA050

SBR032A

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-42

Page 1506 of 1767

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut lower in engine

compartment, etc.

Panel edge

Trunk lid opening, sun roof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-47

Page 1507 of 1767

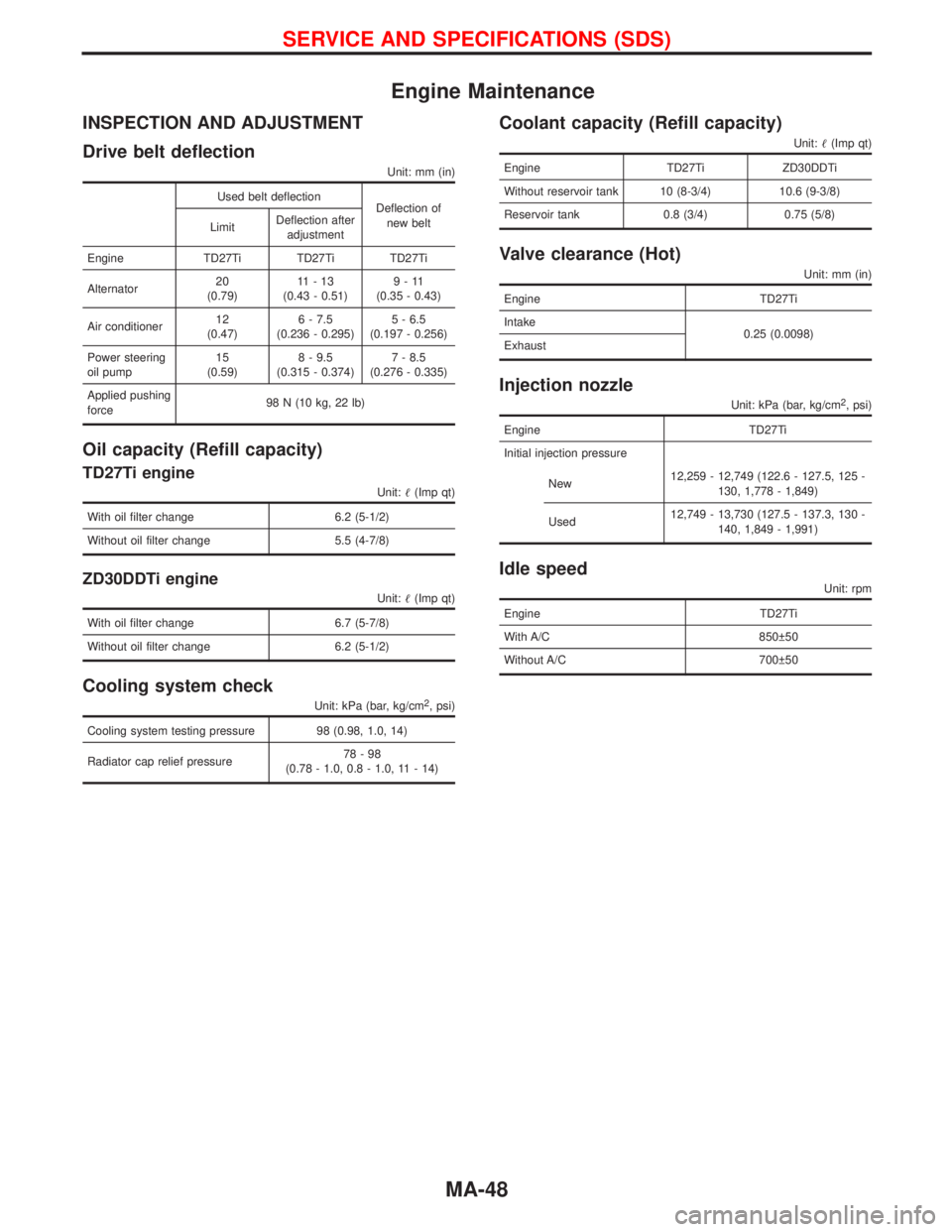

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflection

Deflection of

new belt

LimitDeflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator20

(0.79)11-13

(0.43 - 0.51)9-11

(0.35 - 0.43)

Air conditioner12

(0.47)6 - 7.5

(0.236 - 0.295)5 - 6.5

(0.197 - 0.256)

Power steering

oil pump15

(0.59)8 - 9.5

(0.315 - 0.374)7 - 8.5

(0.276 - 0.335)

Applied pushing

force98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit:(Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 98 (0.98, 1.0, 14)

Radiator cap relief pressure78-98

(0.78 - 1.0, 0.8 - 1.0, 11 - 14)

Coolant capacity (Refill capacity)

Unit:(Imp qt)

Engine TD27Ti ZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake

0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

Page 1508 of 1767

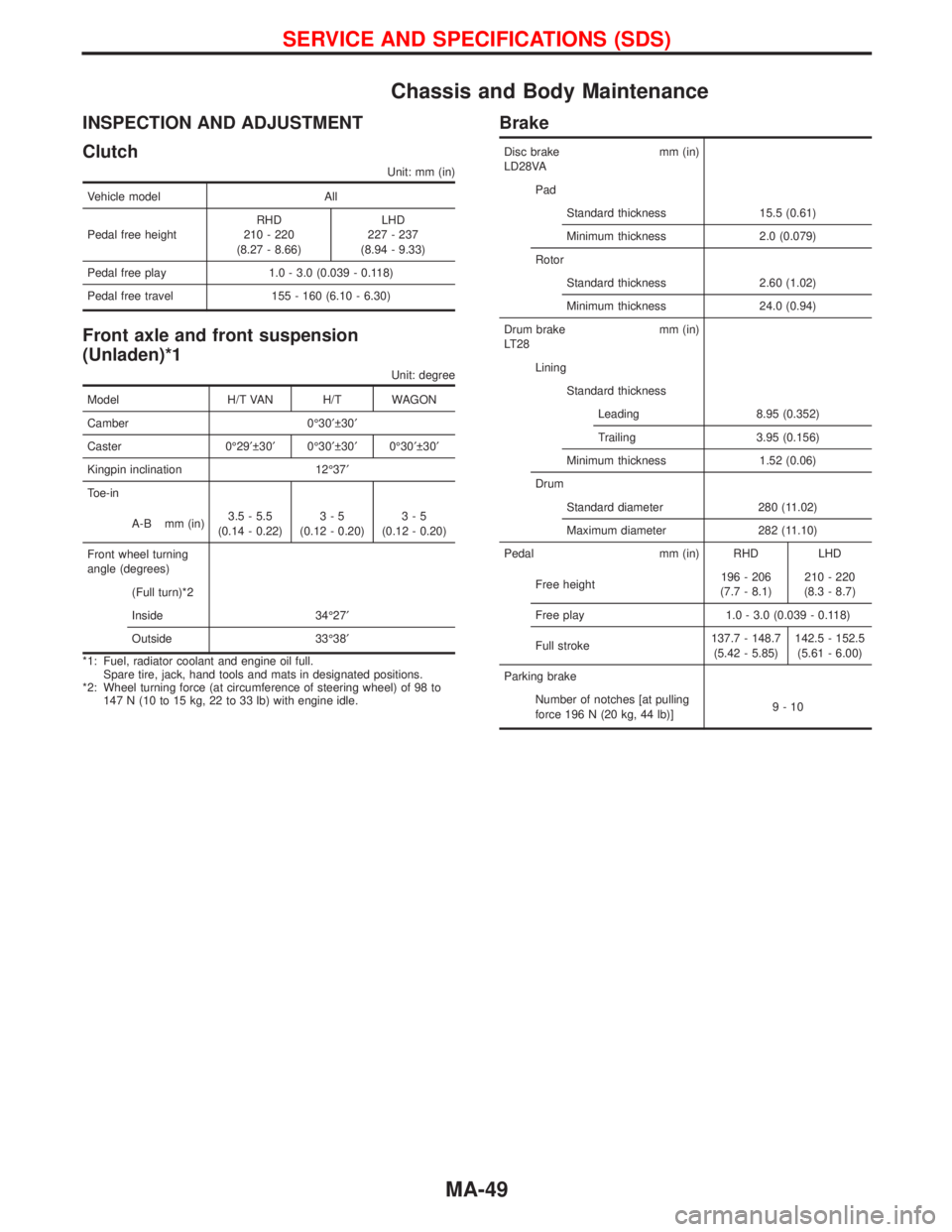

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle model All

Pedal free heightRHD

210 - 220

(8.27 - 8.66)LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢0É30¢ 30¢0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in)3.5 - 5.5

(0.14 - 0.22)3-5

(0.12 - 0.20)3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees)

(Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to

147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

Pad

Standard thickness 15.5 (0.61)

Minimum thickness 2.0 (0.079)

Rotor

Standard thickness 2.60 (1.02)

Minimum thickness 24.0 (0.94)

Drum brake mm (in)

LT28

Lining

Standard thickness

Leading 8.95 (0.352)

Trailing 3.95 (0.156)

Minimum thickness 1.52 (0.06)

Drum

Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height196 - 206

(7.7 - 8.1)210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke137.7 - 148.7

(5.42 - 5.85)142.5 - 152.5

(5.61 - 6.00)

Parking brake

Number of notches [at pulling

force 196 N (20 kg, 44 lb)]9-10

SERVICE AND SPECIFICATIONS (SDS)

MA-49

Page 1516 of 1767

Removal

Transmission has to be removed as a unit together with transfer

box.

Remove transmission assembly as follows:

IDisconnect negative battery terminal.

IRemove shift levers of transmission and transfer.

IRemove front and rear propeller shafts. Ð Refer to PD section.

IInsert plug into rear oil seal after removing propeller shaft.

IRemove RPM-sensor from transmission upper side.

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal,

when removing propeller shaft.

IRemove torsion bar spring. Ð Refer to FA Section.

IRemove third crossmember (the one supporting front differen-

tial).

IRemove fifth crossmember (the one situated at the rear of

transfer).

ISupport transmission and transfer with a suitable transmission

jack.

WARNING:

Support transmission and transfer with suitable jacks, while

removing them.

IRemove fourth crossmember (the one supporting transmis-

sion).

IRemove clutch operating cylinder.

IRemove starter motor.

IRemove exhaust tube bracket from transmission.

IDisconnect electrical connectors.

IRemove transmission from engine.

REMOVAL AND INSTALLATIONFS5R30A

MT-7

Page 1518 of 1767

IRaise the unit with a hoist.

IPosition the transmission assembly on a portable jack and

secure it with a suitable tool.

Lift the assembly until the gearbox input shaft faces its hous-

ing.

Move the assembly towards the engine. The assembly must be

rotated slightly so that the starter motor housing clears the

projection on the companion floor. Insert input shaft into its

housing (slightly raising the rear of the transfer box may facili-

tate the introduction of the shaft into its housing).

ITighten the screws securing the gearbox to the engine.

:39-49N×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

IConnect the electrical wiring. Secure with the respective clips.

IFit the RPM-sensor to the transmission upper side.

IFit the exhaust pipe support bracket to the transfer box.

:13-16N×m (1.3 - 1.6 kg-m,9-12ft-lb)

IFit the starter motor. Secure the earth wire to the starter motor

lower screw.

:31-41N×m (3.2 - 4.2 kg-m, 23 - 30 ft-lb)

IFit the clutch slave cylinder.

:30-40N×m (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

IInstall fourth crossmember (Note the ªfrontº mark).

Crossmember fixing bolts to chassis:

:41-52N×m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

Crossmember fixing bolts to transmission:

:68-87N×m (6.9 - 8.9 kg-m, 50 - 64 ft-lb)

ITake away the portable jack holding boxes assembly.

IInstall fifth crossmember.

:59-78N×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

IInstall third crossmember.

: Screws: 41 - 52 N×m (4.2 - 5.3 kg-m,

30 - 38 ft-lb)

Nuts: 68 - 87 N×m (6.9 - 8.9 kg-m,

50 - 64 ft-lb)

IInstall torsion bar springs. Ð Refer to FA section.

IInstall front and rear propeller shafts. Ð Refer to PD section.

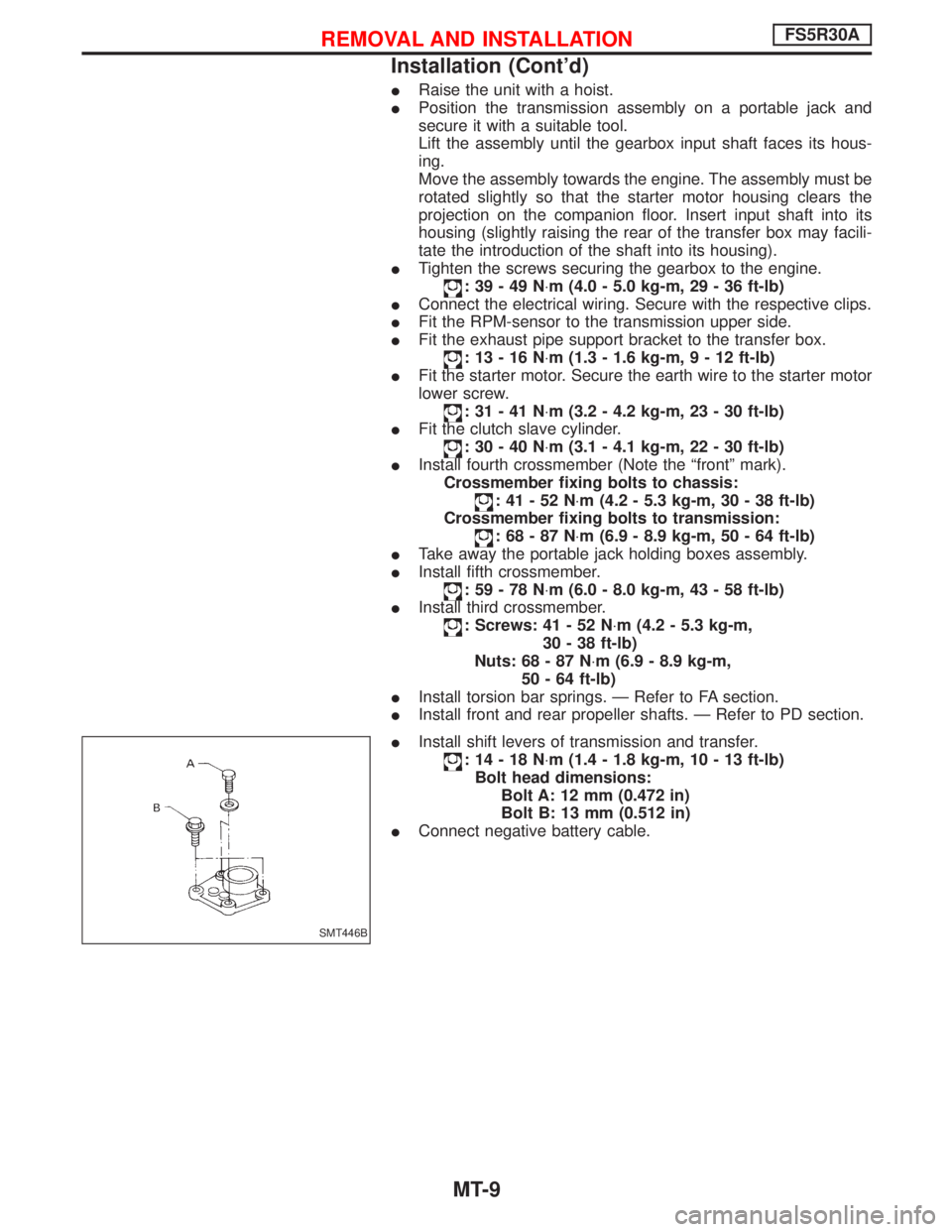

IInstall shift levers of transmission and transfer.

:14-18N×m (1.4 - 1.8 kg-m, 10 - 13 ft-lb)

Bolt head dimensions:

Bolt A: 12 mm (0.472 in)

Bolt B: 13 mm (0.512 in)

IConnect negative battery cable.

SMT446B

REMOVAL AND INSTALLATIONFS5R30A

Installation (Cont'd)

MT-9

Page 1543 of 1767

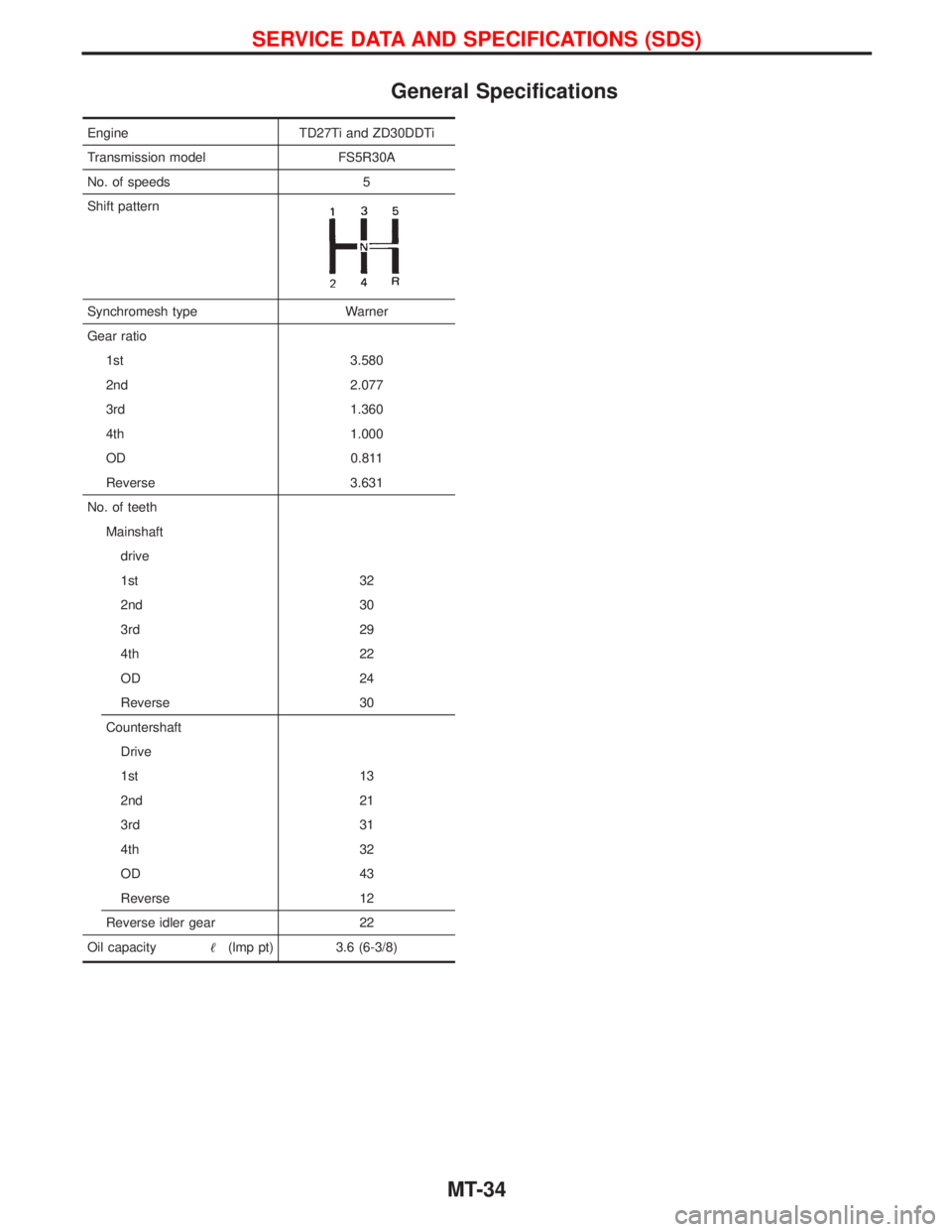

General Specifications

Engine TD27Ti and ZD30DDTi

Transmission model FS5R30A

No. of speeds 5

Shift pattern

Synchromesh type Warner

Gear ratio

1st 3.580

2nd 2.077

3rd 1.360

4th 1.000

OD 0.811

Reverse 3.631

No. of teeth

Mainshaft

drive

1st 32

2nd 30

3rd 29

4th 22

OD 24

Reverse 30

Countershaft

Drive

1st 13

2nd 21

3rd 31

4th 32

OD 43

Reverse 12

Reverse idler gear 22

Oil capacity(lmp pt) 3.6 (6-3/8)

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-34