engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1547 of 1767

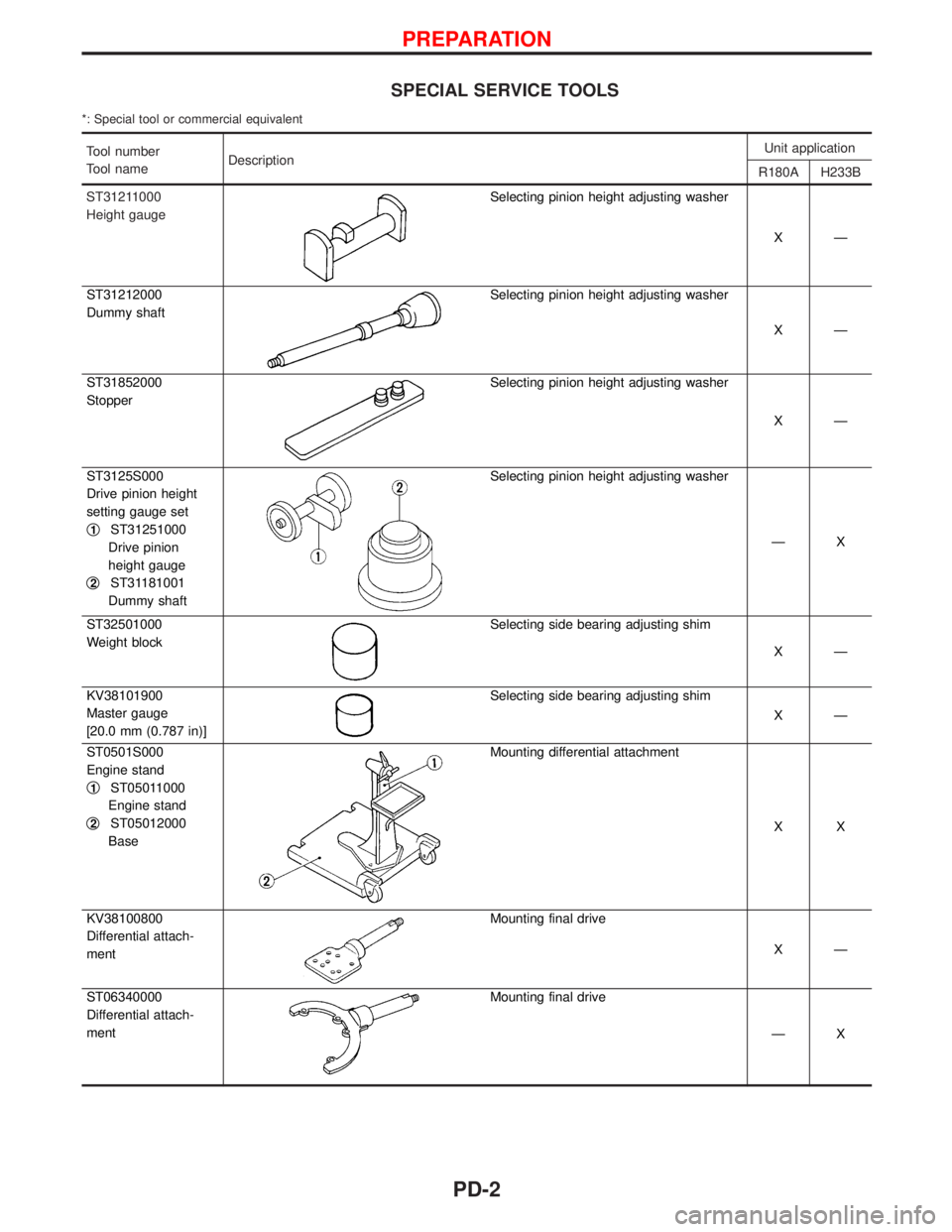

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescriptionUnit application

R180A H233B

ST31211000

Height gauge

Selecting pinion height adjusting washer

XÐ

ST31212000

Dummy shaft

Selecting pinion height adjusting washer

XÐ

ST31852000

Stopper

Selecting pinion height adjusting washer

XÐ

ST3125S000

Drive pinion height

setting gauge set

q

1ST31251000

Drive pinion

height gauge

q

2ST31181001

Dummy shaft

Selecting pinion height adjusting washer

ÐX

ST32501000

Weight block

Selecting side bearing adjusting shim

XÐ

KV38101900

Master gauge

[20.0 mm (0.787 in)]

Selecting side bearing adjusting shim

XÐ

ST0501S000

Engine stand

q

1ST05011000

Engine stand

q

2ST05012000

Base

Mounting differential attachment

XX

KV38100800

Differential attach-

ment

Mounting final drive

XÐ

ST06340000

Differential attach-

ment

Mounting final drive

ÐX

PREPARATION

PD-2

Page 1557 of 1767

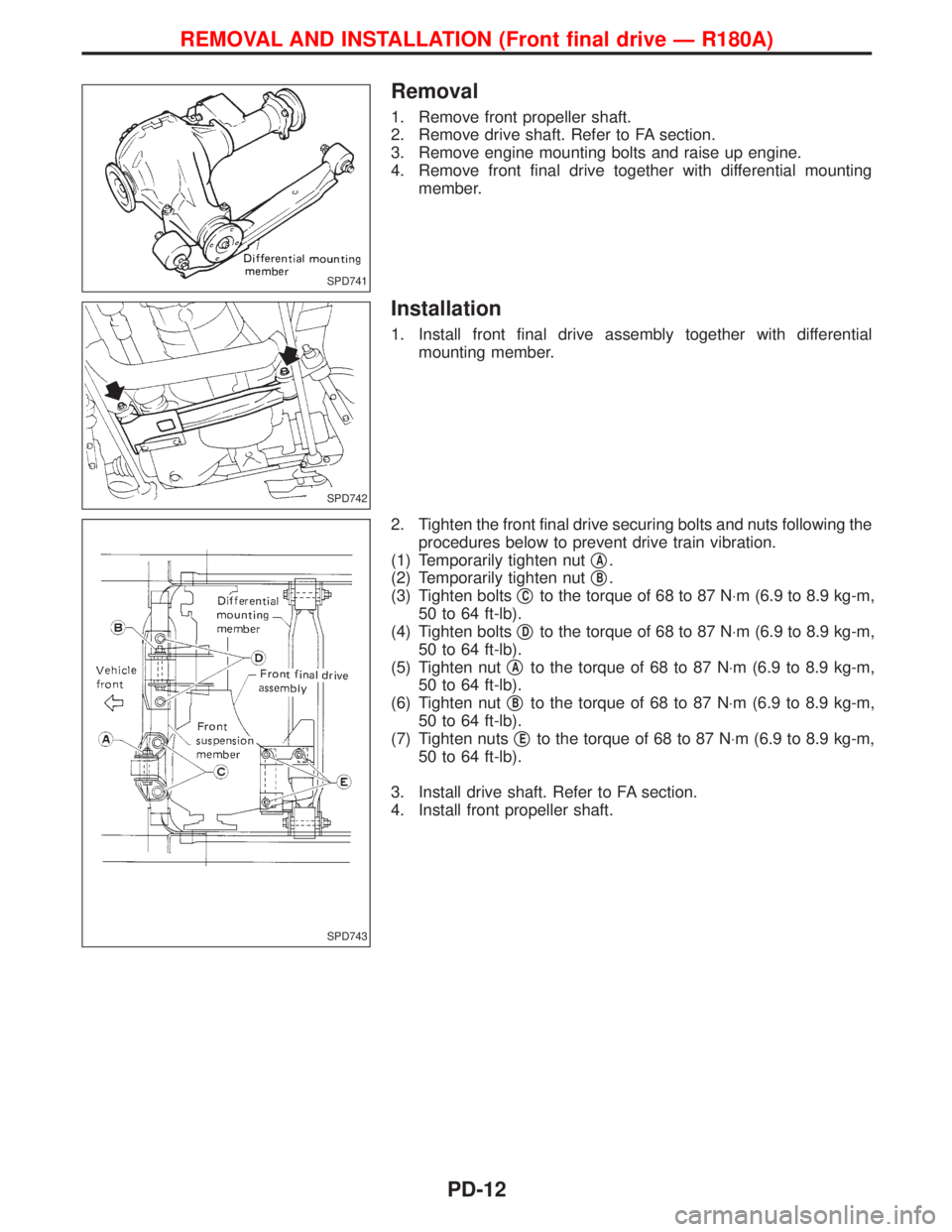

Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section.

3. Remove engine mounting bolts and raise up engine.

4. Remove front final drive together with differential mounting

member.

Installation

1. Install front final drive assembly together with differential

mounting member.

2. Tighten the front final drive securing bolts and nuts following the

procedures below to prevent drive train vibration.

(1) Temporarily tighten nutq

A.

(2) Temporarily tighten nutq

B.

(3) Tighten boltsq

Cto the torque of 68 to 87 N×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(4) Tighten boltsq

Dto the torque of 68 to 87 N×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(5) Tighten nutq

Ato the torque of 68 to 87 N×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(6) Tighten nutq

Bto the torque of 68 to 87 N×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(7) Tighten nutsq

Eto the torque of 68 to 87 N×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

3. Install drive shaft. Refer to FA section.

4. Install front propeller shaft.

SPD741

SPD742

SPD743

REMOVAL AND INSTALLATION (Front final drive Ð R180A)

PD-12

Page 1588 of 1767

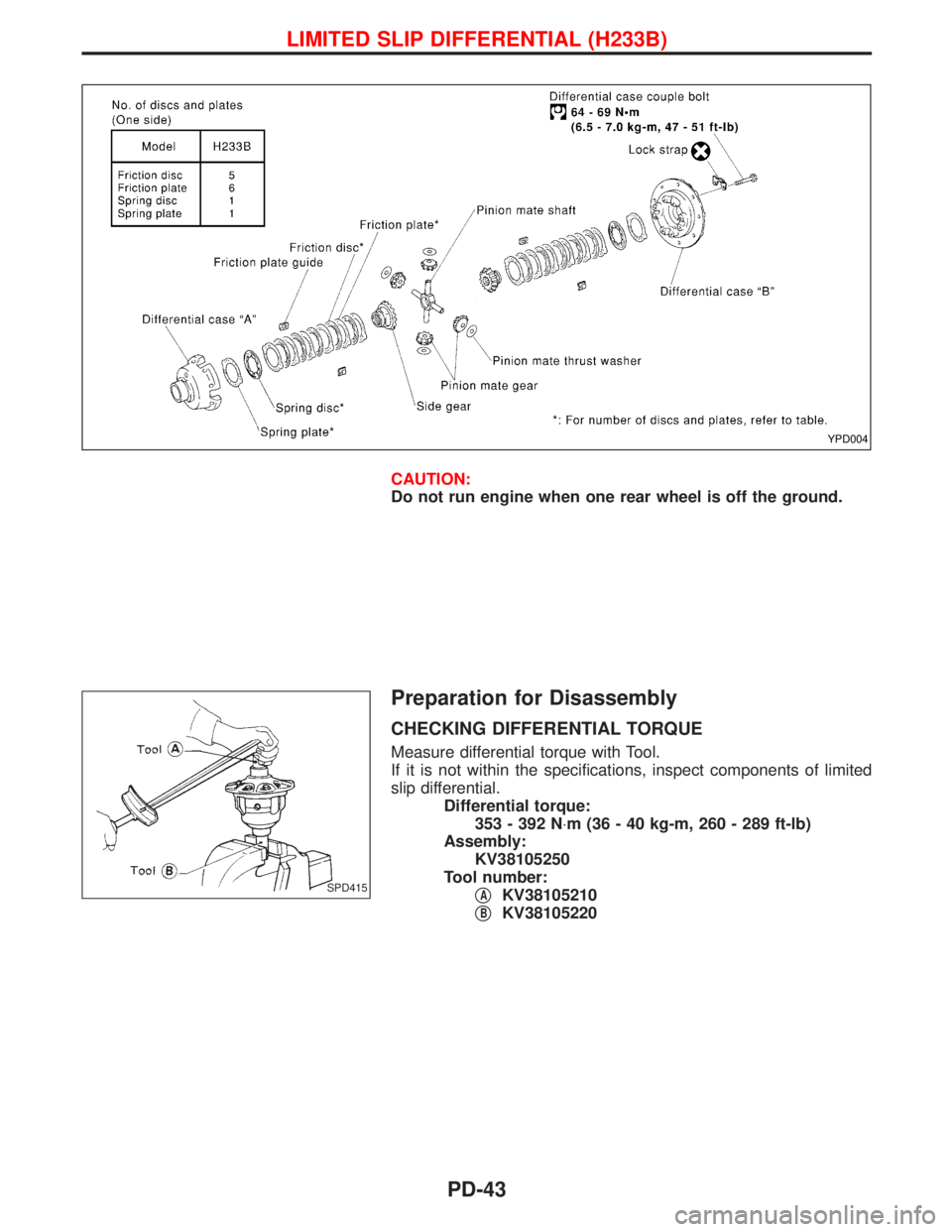

CAUTION:

Do not run engine when one rear wheel is off the ground.

Preparation for Disassembly

CHECKING DIFFERENTIAL TORQUE

Measure differential torque with Tool.

If it is not within the specifications, inspect components of limited

slip differential.

Differential torque:

353 - 392 N×m (36 - 40 kg-m, 260 - 289 ft-lb)

Assembly:

KV38105250

Tool number:

q

AKV38105210

q

BKV38105220

YPD004

SPD415

LIMITED SLIP DIFFERENTIAL (H233B)

PD-43

Page 1607 of 1767

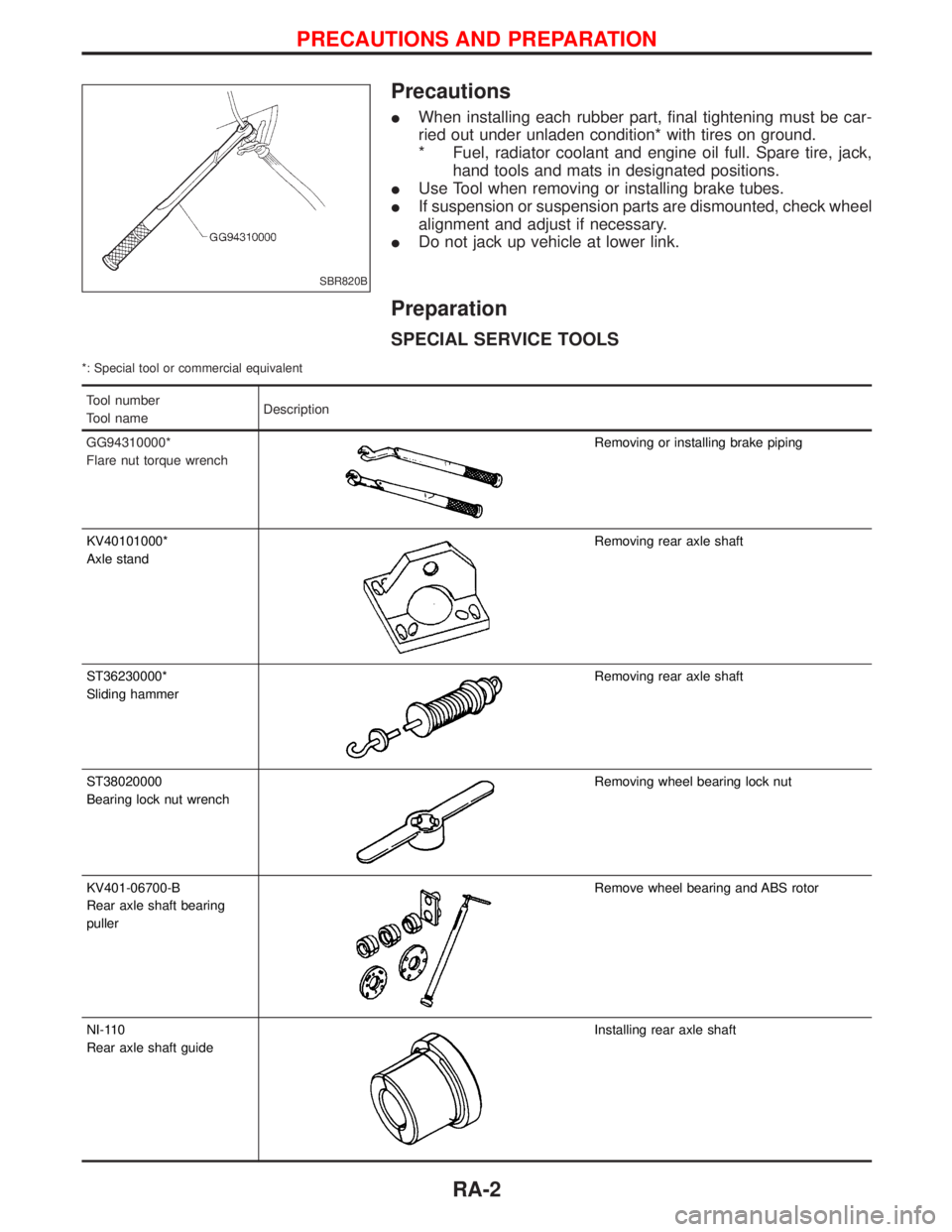

Precautions

IWhen installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse Tool when removing or installing brake tubes.

IIf suspension or suspension parts are dismounted, check wheel

alignment and adjust if necessary.

IDo not jack up vehicle at lower link.

Preparation

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

GG94310000*

Flare nut torque wrench

Removing or installing brake piping

KV40101000*

Axle stand

Removing rear axle shaft

ST36230000*

Sliding hammer

Removing rear axle shaft

ST38020000

Bearing lock nut wrench

Removing wheel bearing lock nut

KV401-06700-B

Rear axle shaft bearing

puller

Remove wheel bearing and ABS rotor

NI-110

Rear axle shaft guide

Installing rear axle shaft

SBR820B

PRECAUTIONS AND PREPARATION

RA-2

Page 1684 of 1767

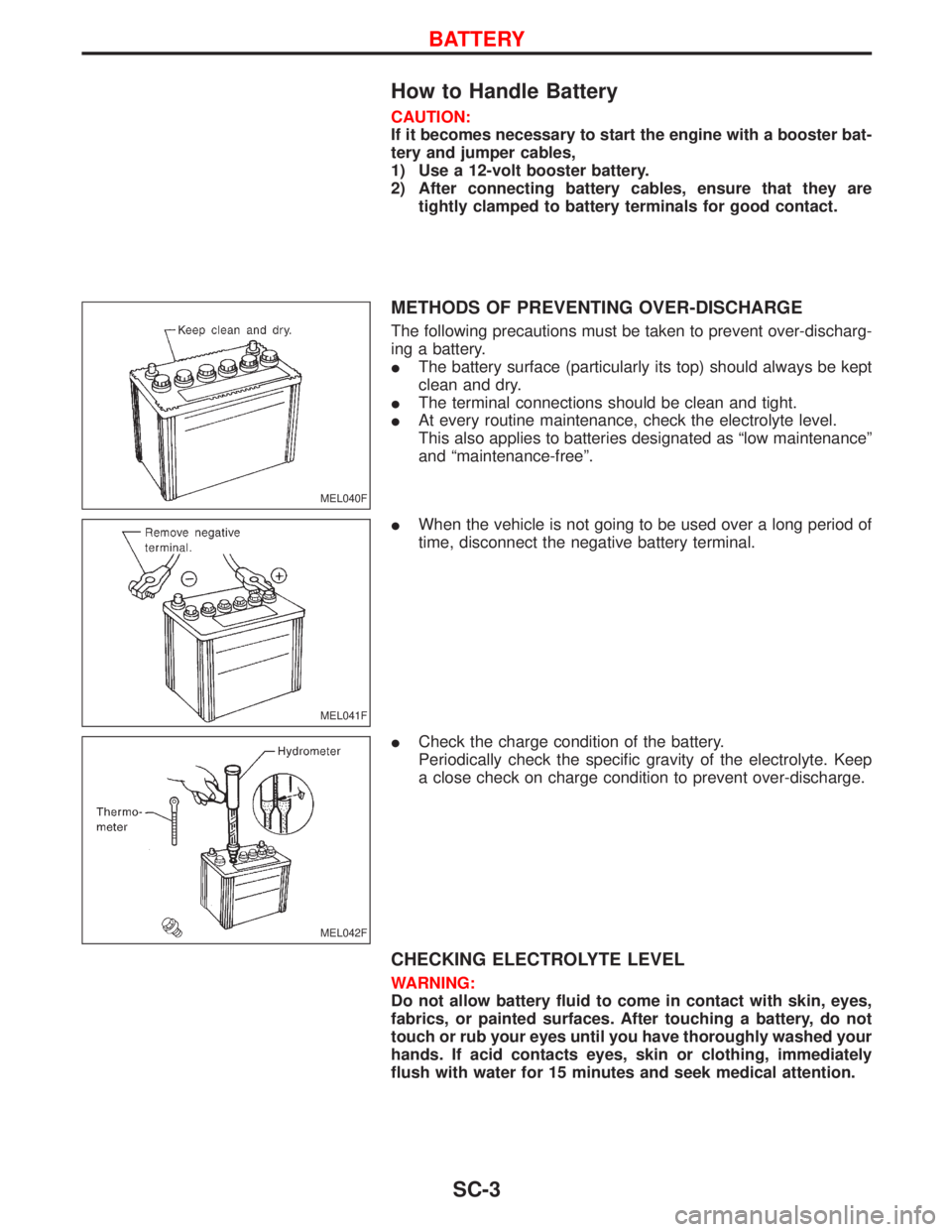

How to Handle Battery

CAUTION:

If it becomes necessary to start the engine with a booster bat-

tery and jumper cables,

1) Use a 12-volt booster battery.

2) After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharg-

ing a battery.

IThe battery surface (particularly its top) should always be kept

clean and dry.

IThe terminal connections should be clean and tight.

IAt every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

IWhen the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

ICheck the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

BATTERY

SC-3

Page 1694 of 1767

System Description

M/T MODELS

Power is supplied at all times

Ithrough 40A fusible link (letterC, located in the fuse and fusible link box)

Ito ignition switch terminal 1.

With the ignition switch in START position, power is supplied

Ifrom ignition switch terminal 1

Ito starter motor harness connector terminal 4.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

A/T MODELS

Power is supplied at all times

Ithrough 40A fusible link (letterC, located in the fuse and fusible link box)

Ito ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

Ifrom ignition switch terminal 1

Ito park/neutral position relay terminal 4.

With the ignition switch ON or START position, power is supplied

Ithrough 10A fuse [No. 8, located in the fuse block (J/B)]

Ito park/neutral position (PNP) relay terminal 1.

With the selector lever in the P or N position, ground is supplied

Ito park/neutral position relay terminal 2 through the park/neutral position switch

Ifrom body grounds, M754 and M33.

Then park/neutral position relay is energized and power is supplied

Ifrom park/neutral position relay terminal 3

Ito starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

STARTING SYSTEM

SC-13

Page 1695 of 1767

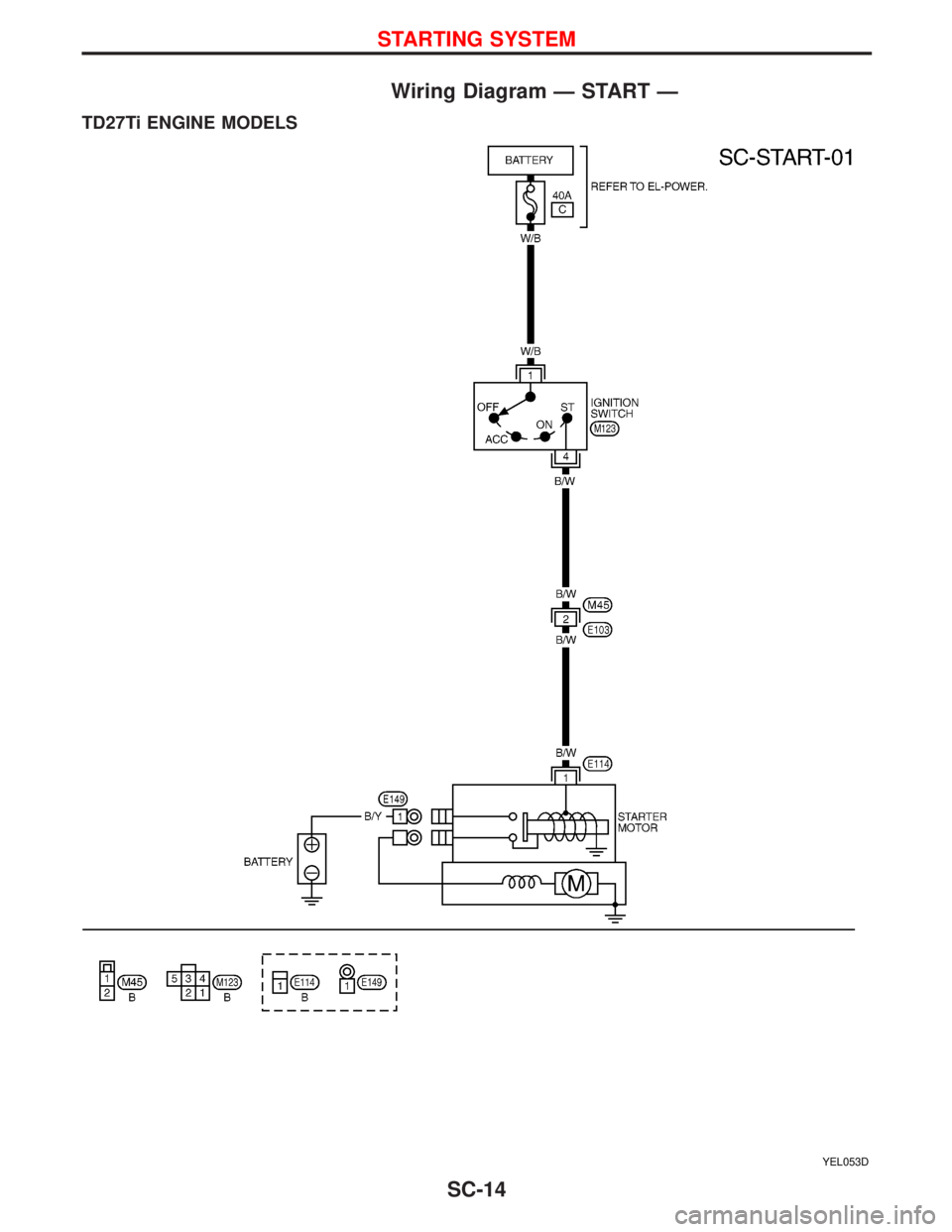

Wiring Diagram Ð START Ð

TD27Ti ENGINE MODELS

YEL053D

STARTING SYSTEM

SC-14

Page 1696 of 1767

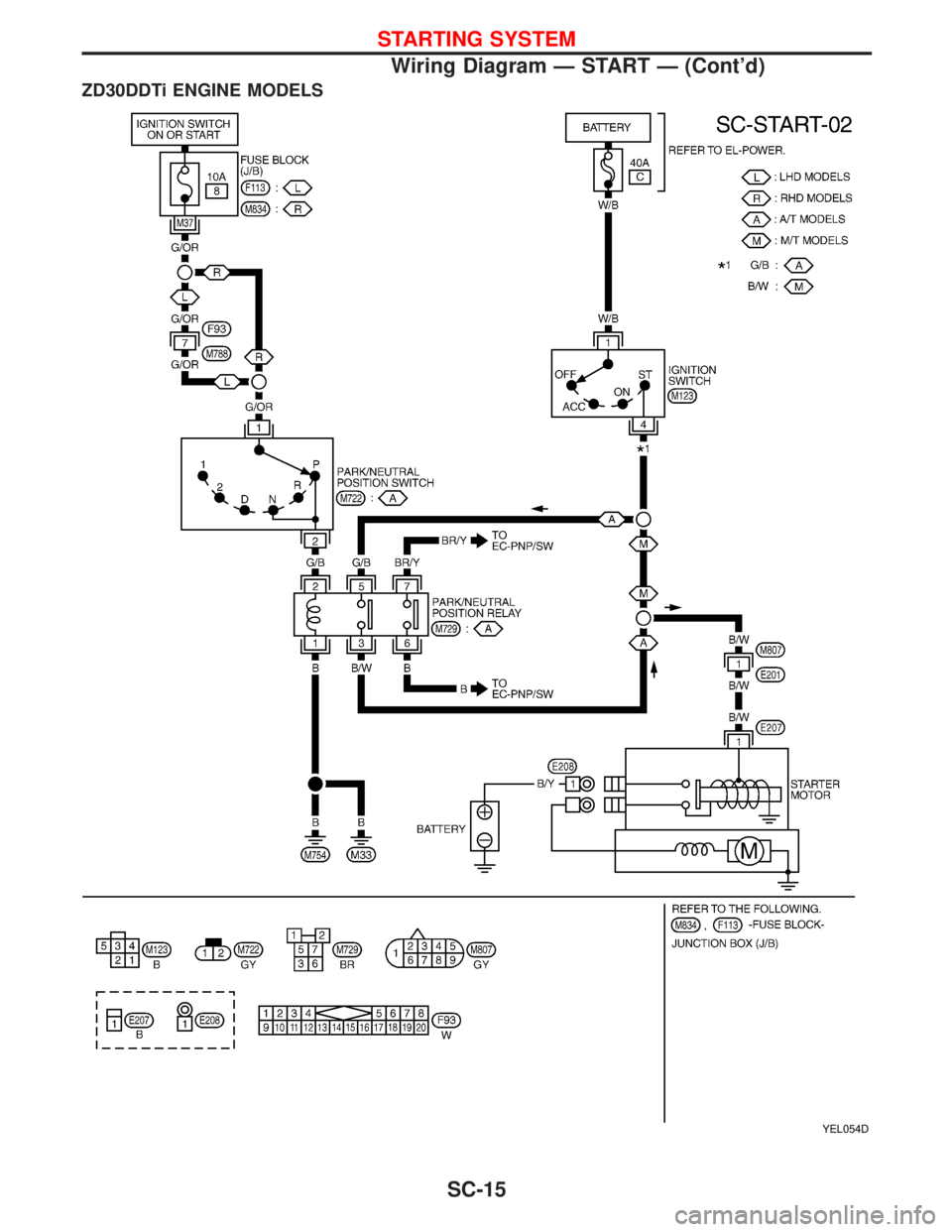

ZD30DDTi ENGINE MODELS

YEL054D

STARTING SYSTEM

Wiring Diagram Ð START Ð (Cont'd)

SC-15

Page 1704 of 1767

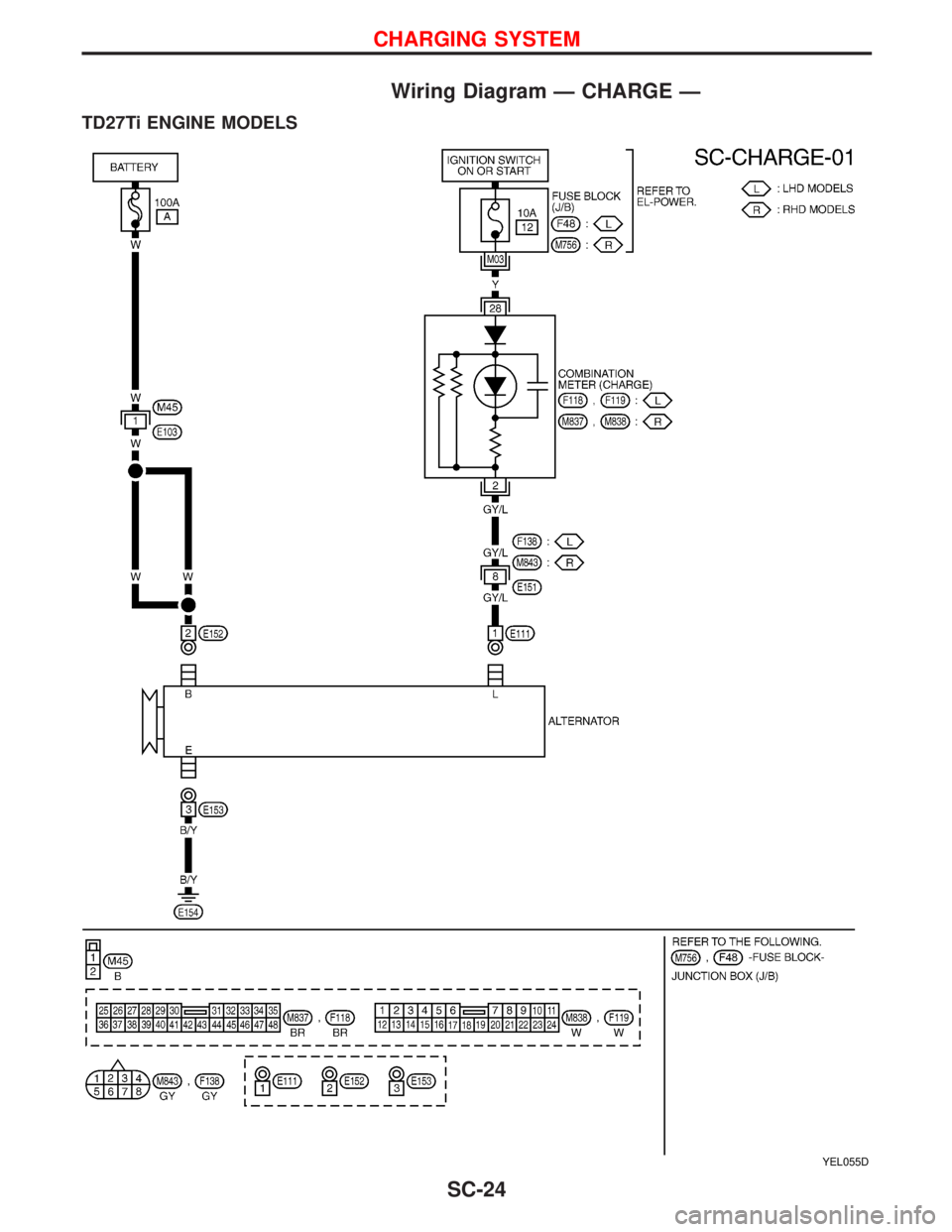

System Description

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

I10A fuse (No. 31, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage (ZD30DDTi engine models). The

charging circuit is protected by the 100A (A/T models) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

Ithrough 10A fuse [No. 12, located in the fuse block (J/B)]

Ito combination meter terminal 28 for the charge warning lamp.

Ground is supplied to terminal 2 of the combination meter through terminal 1(L) (TD27Ti engine models) or

3(L) (ZD30DDTi engine model) of the alternator. With power and ground supplied, the charge warning lamp

will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened

and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

CHARGING SYSTEM

SC-23

Page 1705 of 1767

Wiring Diagram Ð CHARGE Ð

TD27Ti ENGINE MODELS

YEL055D

CHARGING SYSTEM

SC-24