Ignition pump wiring NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 490 of 1767

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

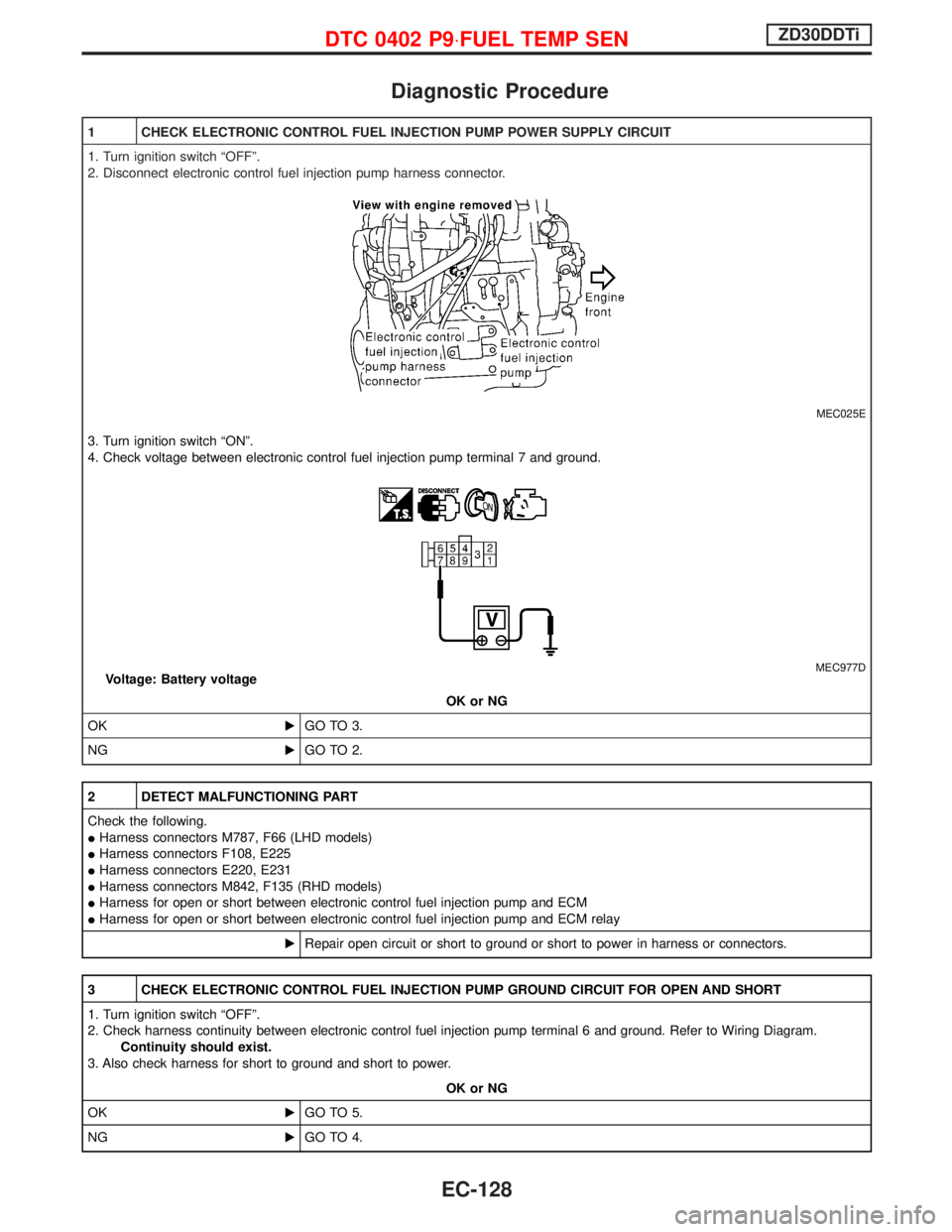

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-128

Page 528 of 1767

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

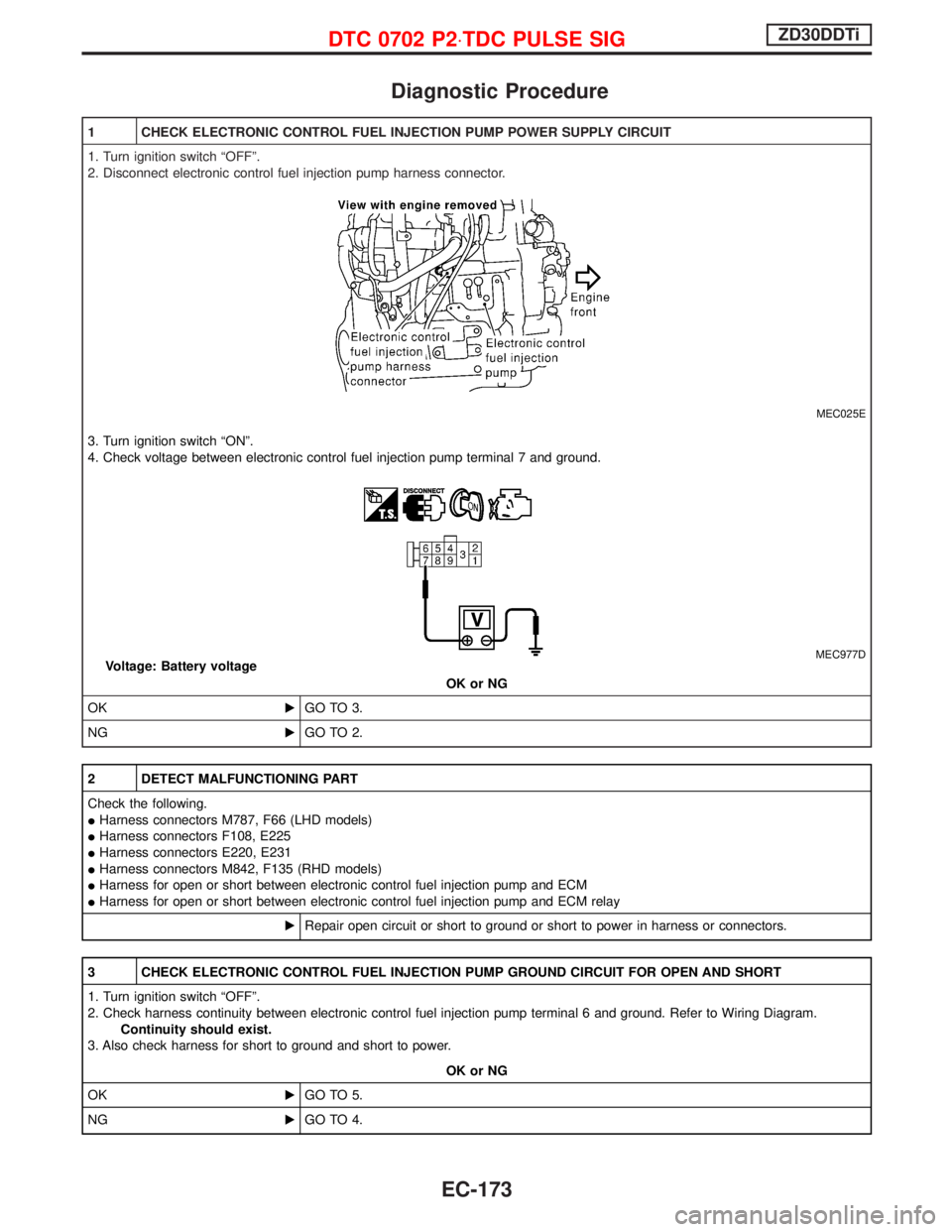

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0701 P1×CAM POS SENZD30DDTi

EC-166

Page 535 of 1767

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

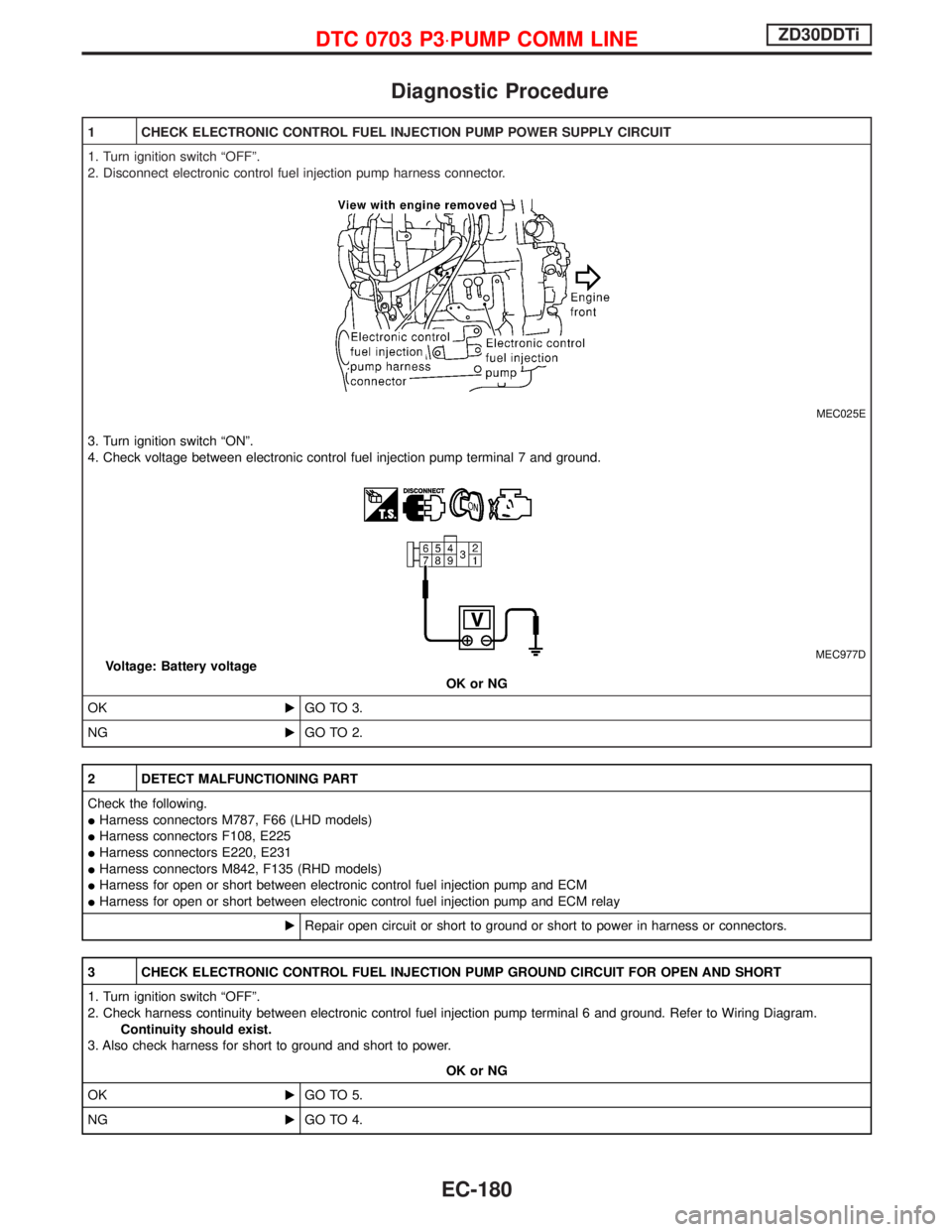

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0702 P2×TDC PULSE SIGZD30DDTi

EC-173

Page 542 of 1767

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

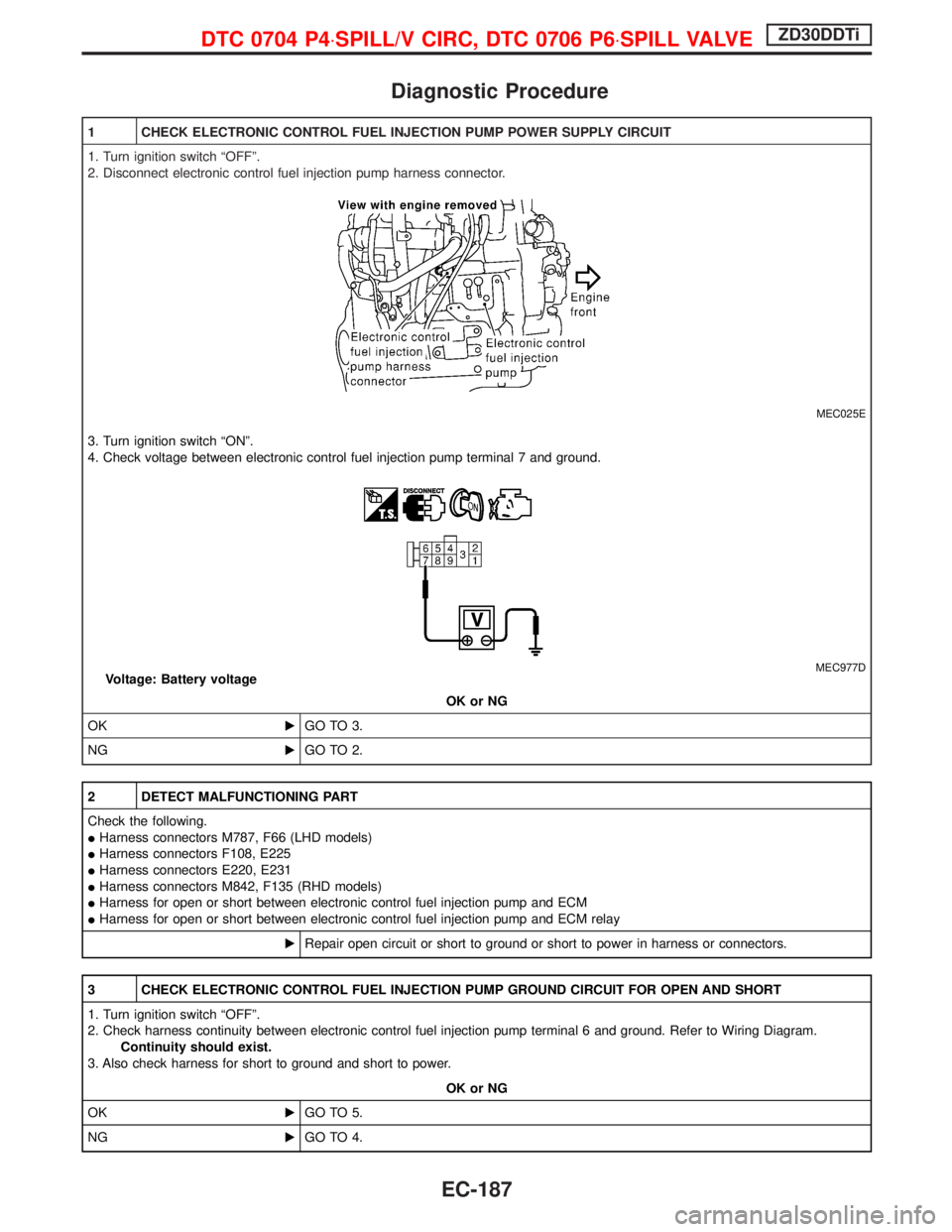

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0703 P3×PUMP COMM LINEZD30DDTi

EC-180

Page 549 of 1767

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0704 P4×SPILL/V CIRC, DTC 0706 P6×SPILL VALVEZD30DDTi

EC-187

Page 560 of 1767

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 7.

NGEGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E231, E220

IHarness for open or short between electronic control fuel injection pump and engine ground

ERepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 9.

NGEGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E231, E220

IHarness connectors E227, F106

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0707 P7×F/INJ TIMG FBZD30DDTi

Diagnostic Procedure (Cont'd)

EC-198

Page 582 of 1767

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M852 (RHD models)

IHarness for open or short between ECM and charge air pressure sensor

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK CHARGE AIR PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and charge air pressure sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 7.

NGEGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between charge air pressure sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

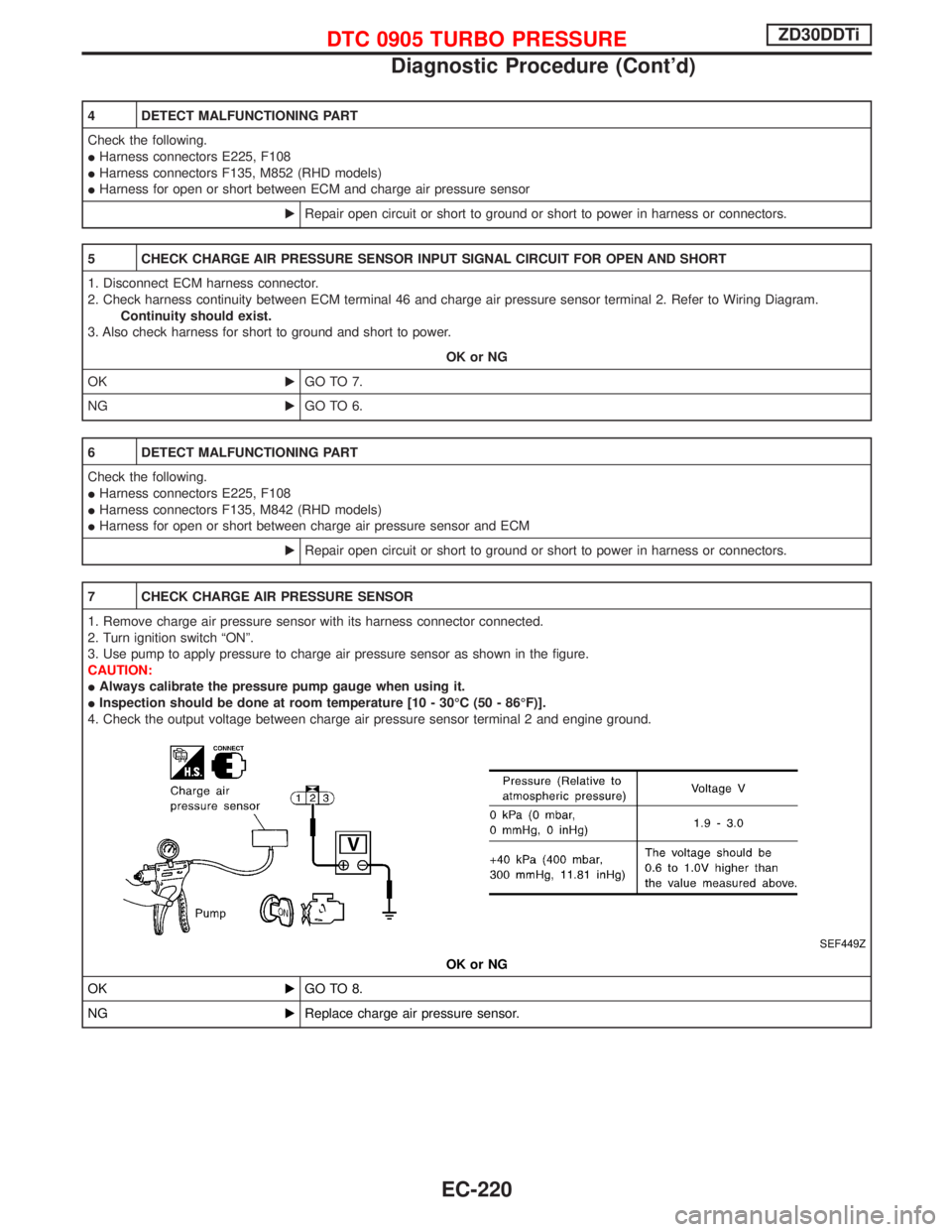

7 CHECK CHARGE AIR PRESSURE SENSOR

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

IAlways calibrate the pressure pump gauge when using it.

IInspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OKEGO TO 8.

NGEReplace charge air pressure sensor.

DTC 0905 TURBO PRESSUREZD30DDTi

Diagnostic Procedure (Cont'd)

EC-220

Page 599 of 1767

Diagnostic Procedure

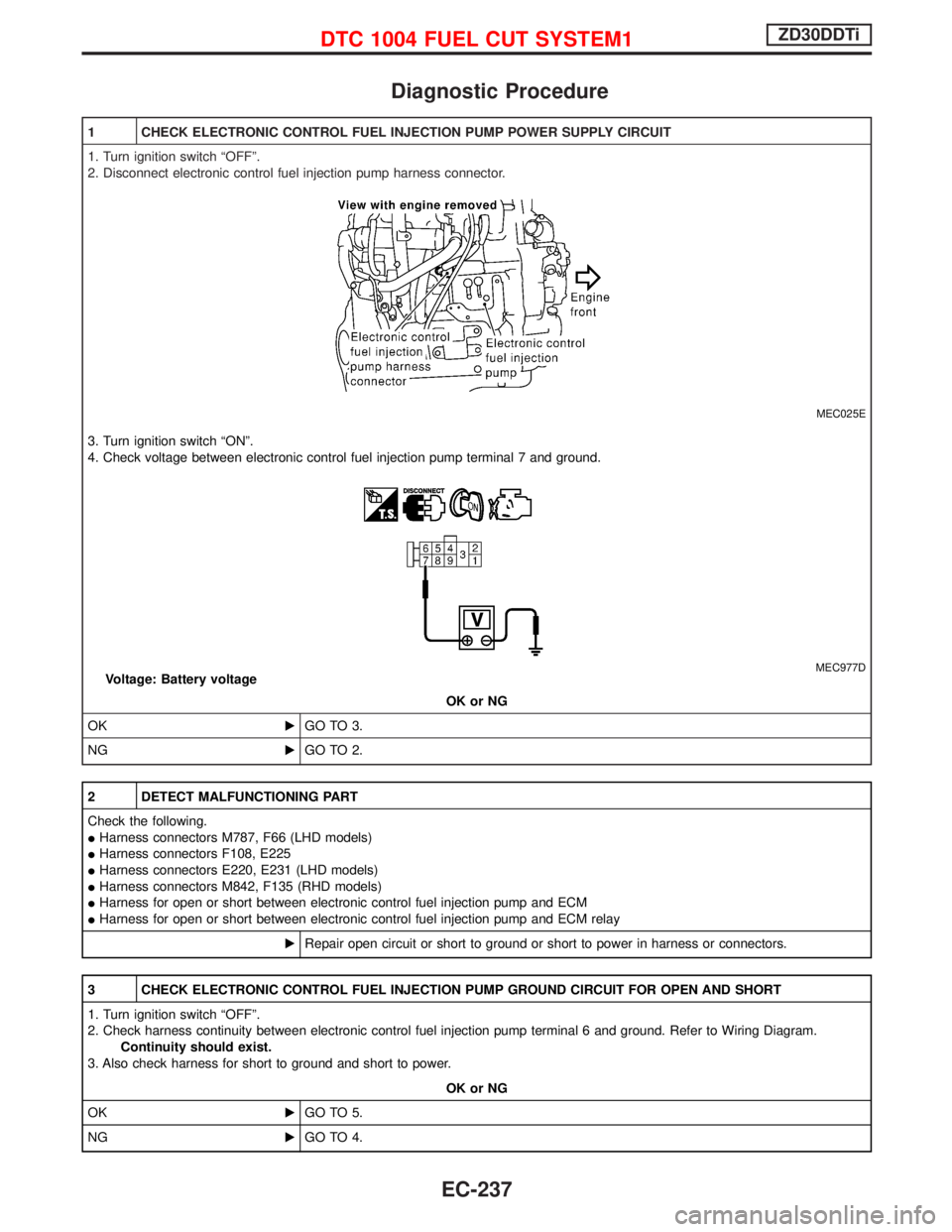

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231 (LHD models)

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 1004 FUEL CUT SYSTEM1ZD30DDTi

EC-237

Page 700 of 1767

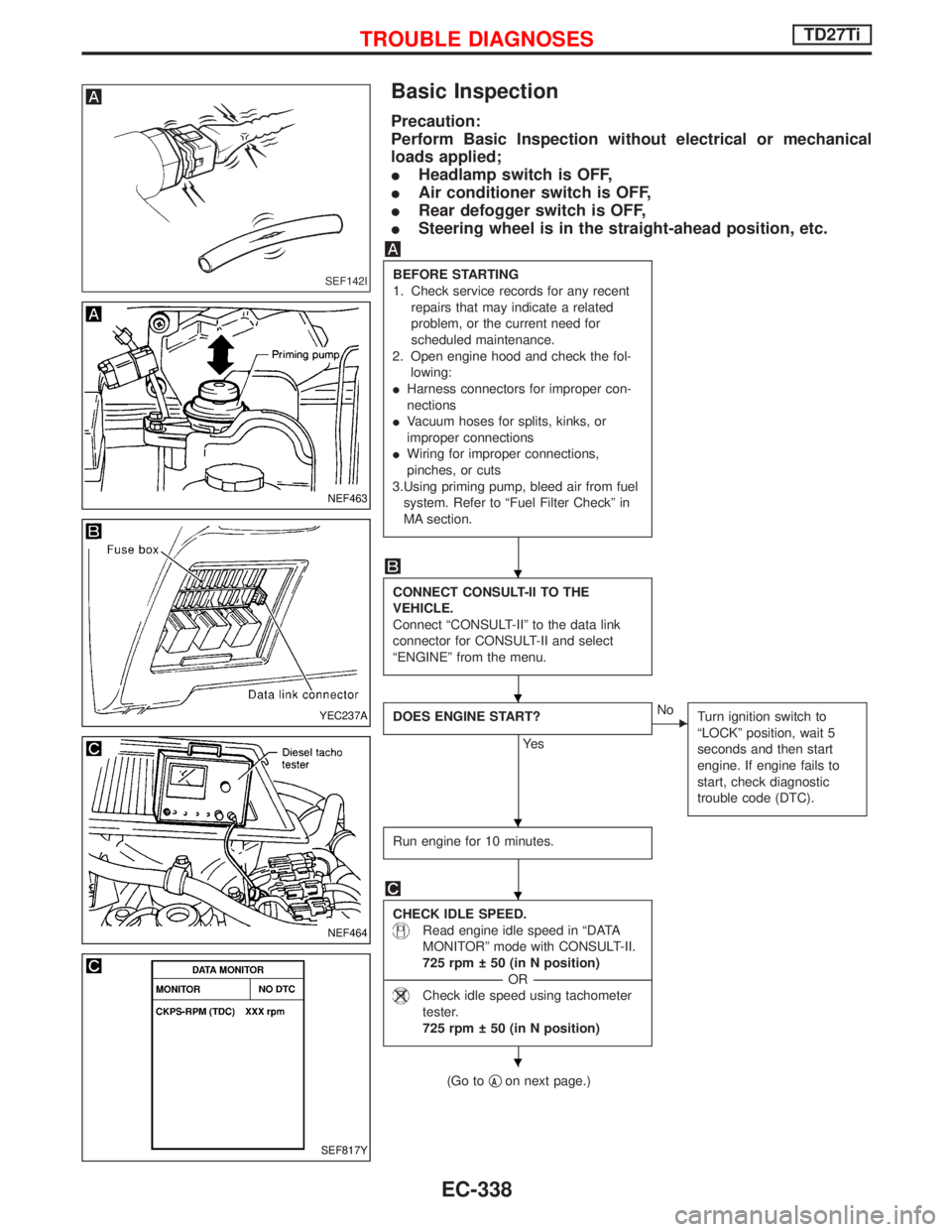

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

IAir conditioner switch is OFF,

IRear defogger switch is OFF,

ISteering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for

scheduled maintenance.

2. Open engine hood and check the fol-

lowing:

IHarness connectors for improper con-

nections

IVacuum hoses for splits, kinks, or

improper connections

IWiring for improper connections,

pinches, or cuts

3.Using priming pump, bleed air from fuel

system. Refer to ªFuel Filter Checkº in

MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu.

DOES ENGINE START?

Ye s

ENo

Turn ignition switch to

ªLOCKº position, wait 5

seconds and then start

engine. If engine fails to

start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in ªDATA

MONITORº mode with CONSULT-II.

725 rpm 50 (in N position)

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachometer

tester.

725 rpm 50 (in N position)

(Go toqAon next page.)

SEF142I

NEF463

YEC237A

NEF464

SEF817Y

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-338

Page 736 of 1767

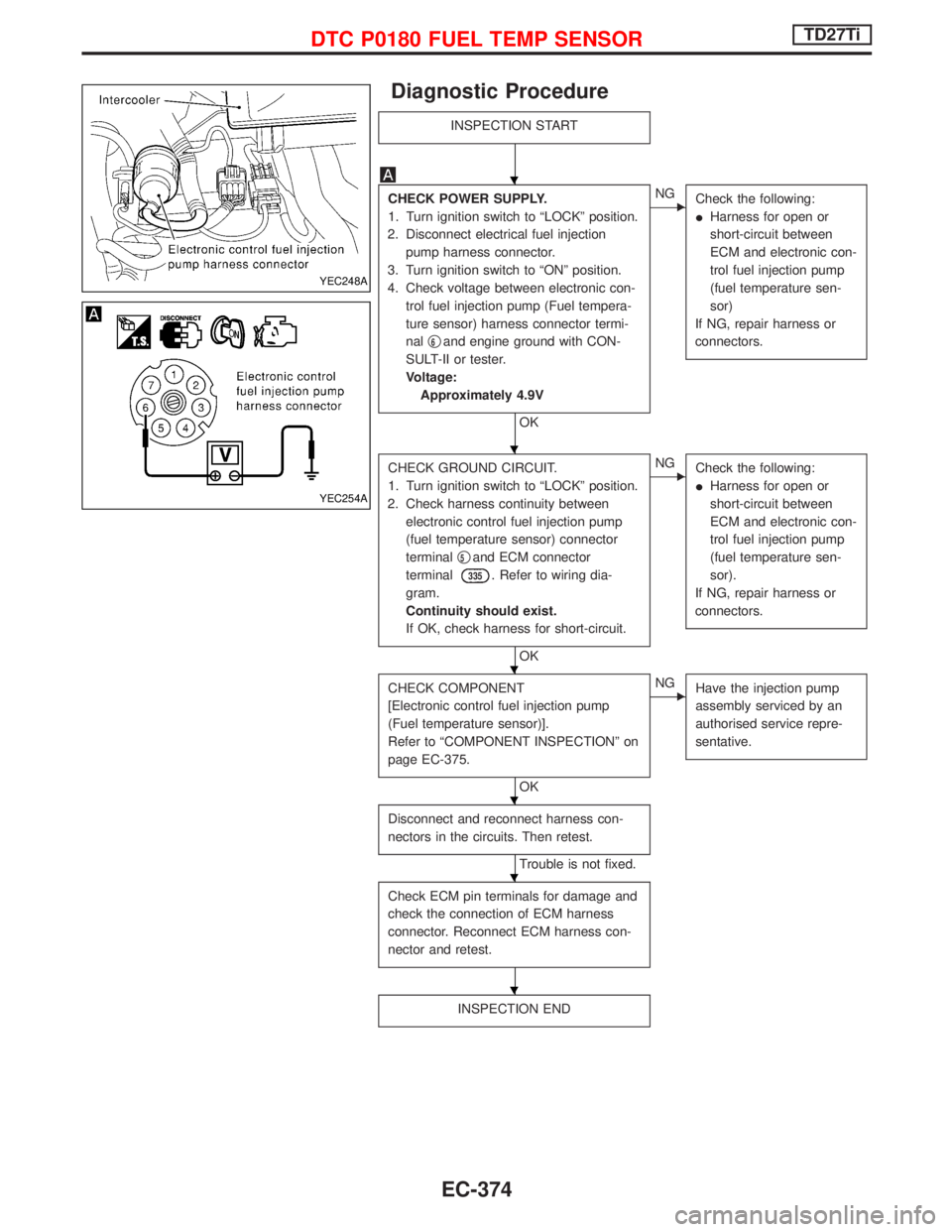

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect electrical fuel injection

pump harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between electronic con-

trol fuel injection pump (Fuel tempera-

ture sensor) harness connector termi-

nalq

6and engine ground with CON-

SULT-II or tester.

Voltage:

Approximately 4.9V

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor)

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between

electronic control fuel injection pump

(fuel temperature sensor) connector

terminalq

5and ECM connector

terminal

335. Refer to wiring dia-

gram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor).

If NG, repair harness or

connectors.

CHECK COMPONENT

[Electronic control fuel injection pump

(Fuel temperature sensor)].

Refer to ªCOMPONENT INSPECTIONº on

page EC-375.

OK

ENG

Have the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC248A

YEC254A

H

H

H

H

H

H

DTC P0180 FUEL TEMP SENSORTD27Ti

EC-374