manual transmission NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1 of 1767

Edition: February 2002

Release: February 2002 (01)

Publication No.: SM2E00-1R20E0E

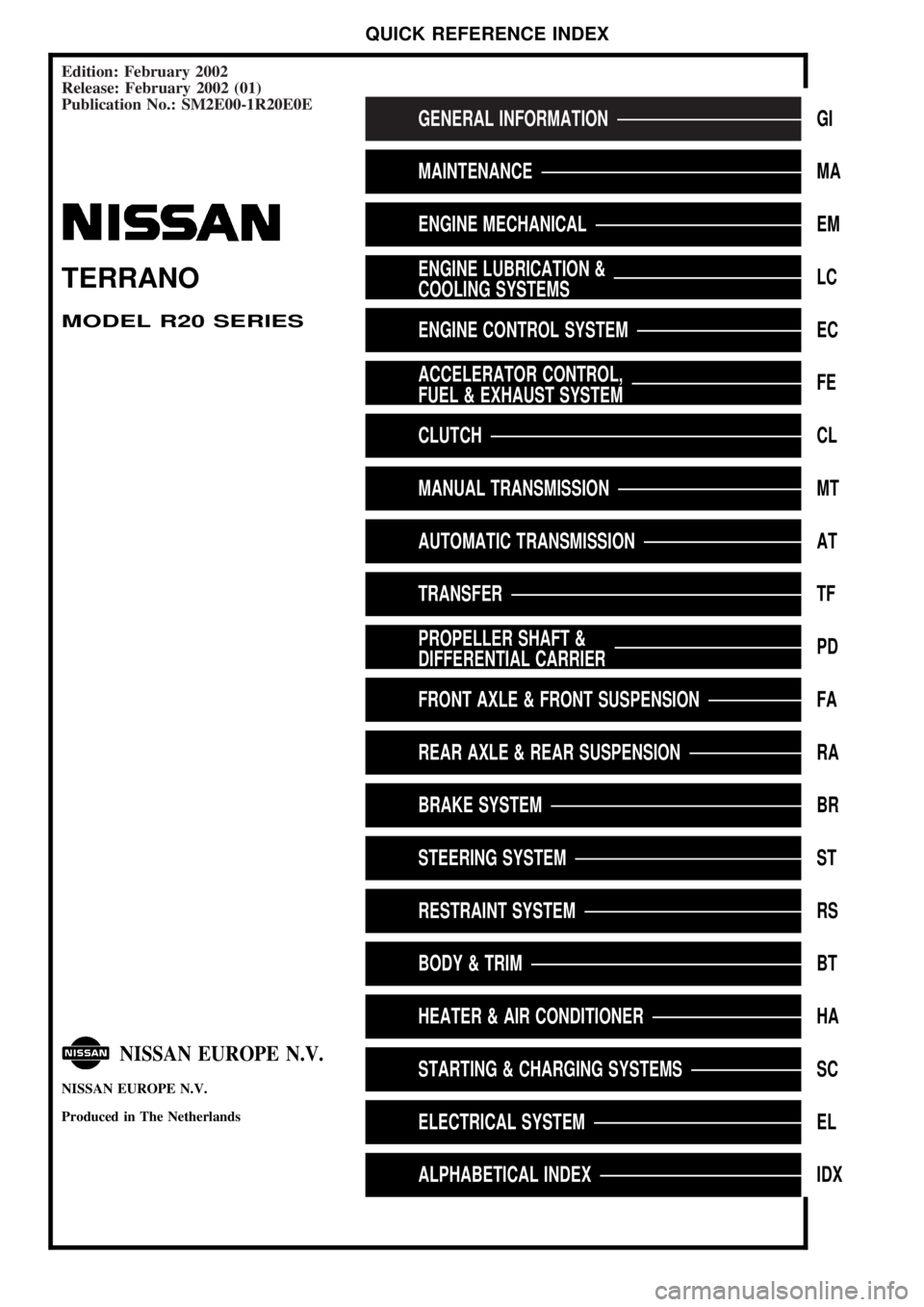

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

STARTING & CHARGING SYSTEMSSC

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

TERRANO

MODEL R20 SERIES

NISSAN EUROPE N.V.

NISSAN EUROPE N.V.

Produced in The Netherlands

QUICK REFERENCE INDEX

Page 6 of 1767

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL R20 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

IDisassembly should be done in a clean work area.

IUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

IPlace disassembled parts in order for easier and proper assembly.

IAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

IGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

IIt is very important to perform functional tests whenever they are indicated.

IThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

IProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

IExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

PREPARATION AND PRECAUTIONS

AT- 4

Page 116 of 1767

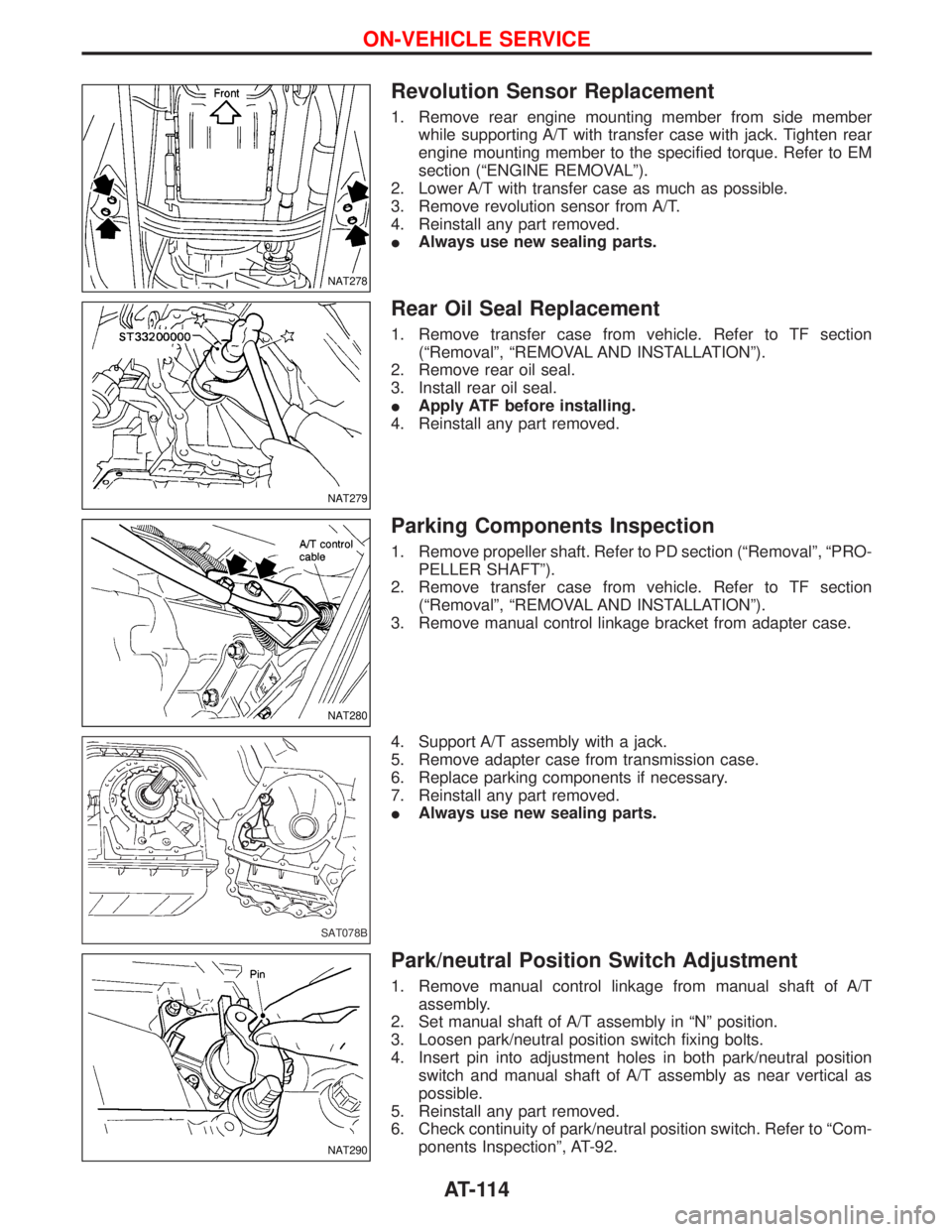

Revolution Sensor Replacement

1. Remove rear engine mounting member from side member

while supporting A/T with transfer case with jack. Tighten rear

engine mounting member to the specified torque. Refer to EM

section (ªENGINE REMOVALº).

2. Lower A/T with transfer case as much as possible.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

IAlways use new sealing parts.

Rear Oil Seal Replacement

1. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

2. Remove rear oil seal.

3. Install rear oil seal.

IApply ATF before installing.

4. Reinstall any part removed.

Parking Components Inspection

1. Remove propeller shaft. Refer to PD section (ªRemovalº, ªPRO-

PELLER SHAFTº).

2. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

3. Remove manual control linkage bracket from adapter case.

4. Support A/T assembly with a jack.

5. Remove adapter case from transmission case.

6. Replace parking components if necessary.

7. Reinstall any part removed.

IAlways use new sealing parts.

Park/neutral Position Switch Adjustment

1. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen park/neutral position switch fixing bolts.

4. Insert pin into adjustment holes in both park/neutral position

switch and manual shaft of A/T assembly as near vertical as

possible.

5. Reinstall any part removed.

6. Check continuity of park/neutral position switch. Refer to ªCom-

ponents Inspectionº, AT-92.

NAT278

NAT279

NAT280

SAT078B

NAT290

ON-VEHICLE SERVICE

AT-114

Page 127 of 1767

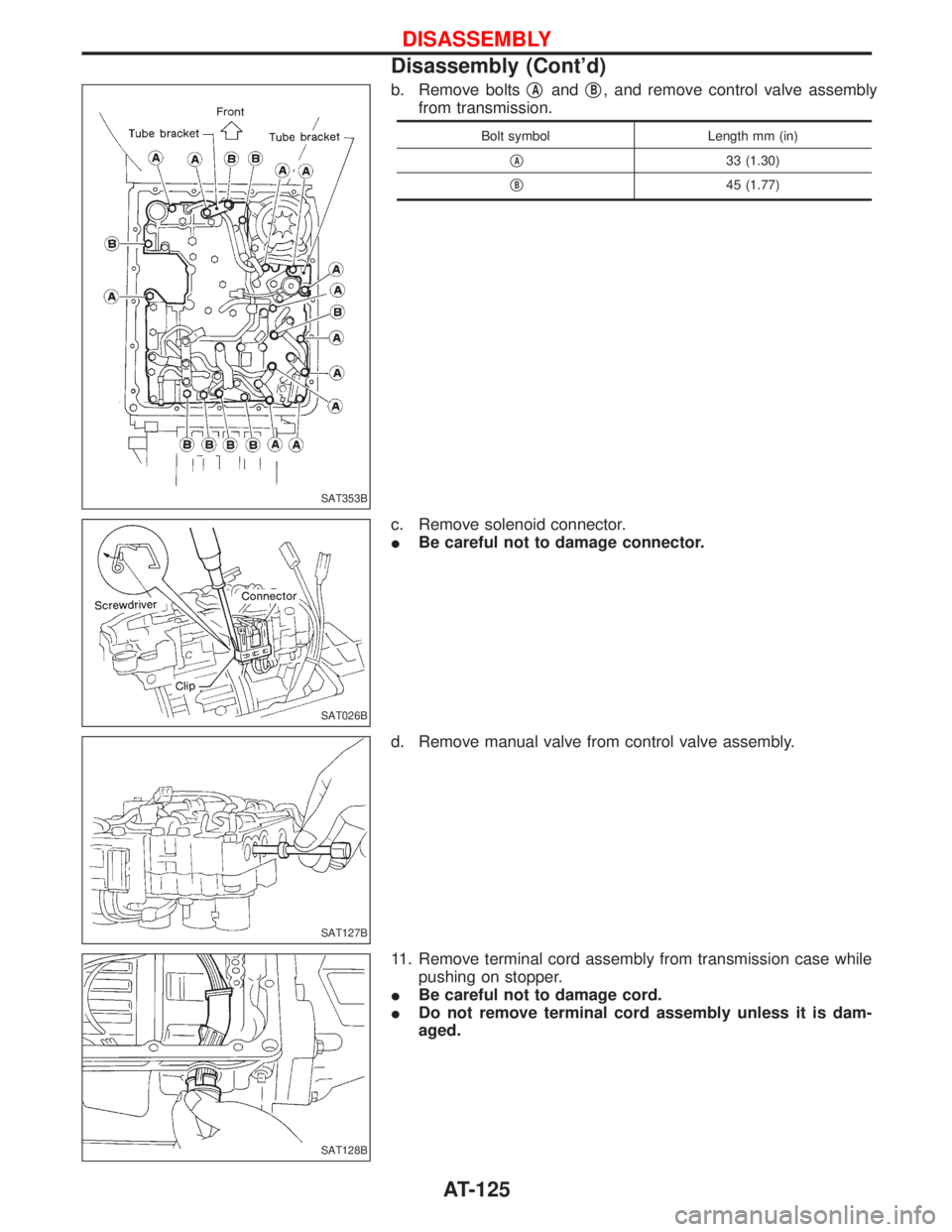

b. Remove boltsqAandqB, and remove control valve assembly

from transmission.

Bolt symbol Length mm (in)

q

A33 (1.30)

q

B45 (1.77)

c. Remove solenoid connector.

IBe careful not to damage connector.

d. Remove manual valve from control valve assembly.

11. Remove terminal cord assembly from transmission case while

pushing on stopper.

IBe careful not to damage cord.

IDo not remove terminal cord assembly unless it is dam-

aged.

SAT353B

SAT026B

SAT127B

SAT128B

DISASSEMBLY

Disassembly (Cont'd)

AT-125

Page 134 of 1767

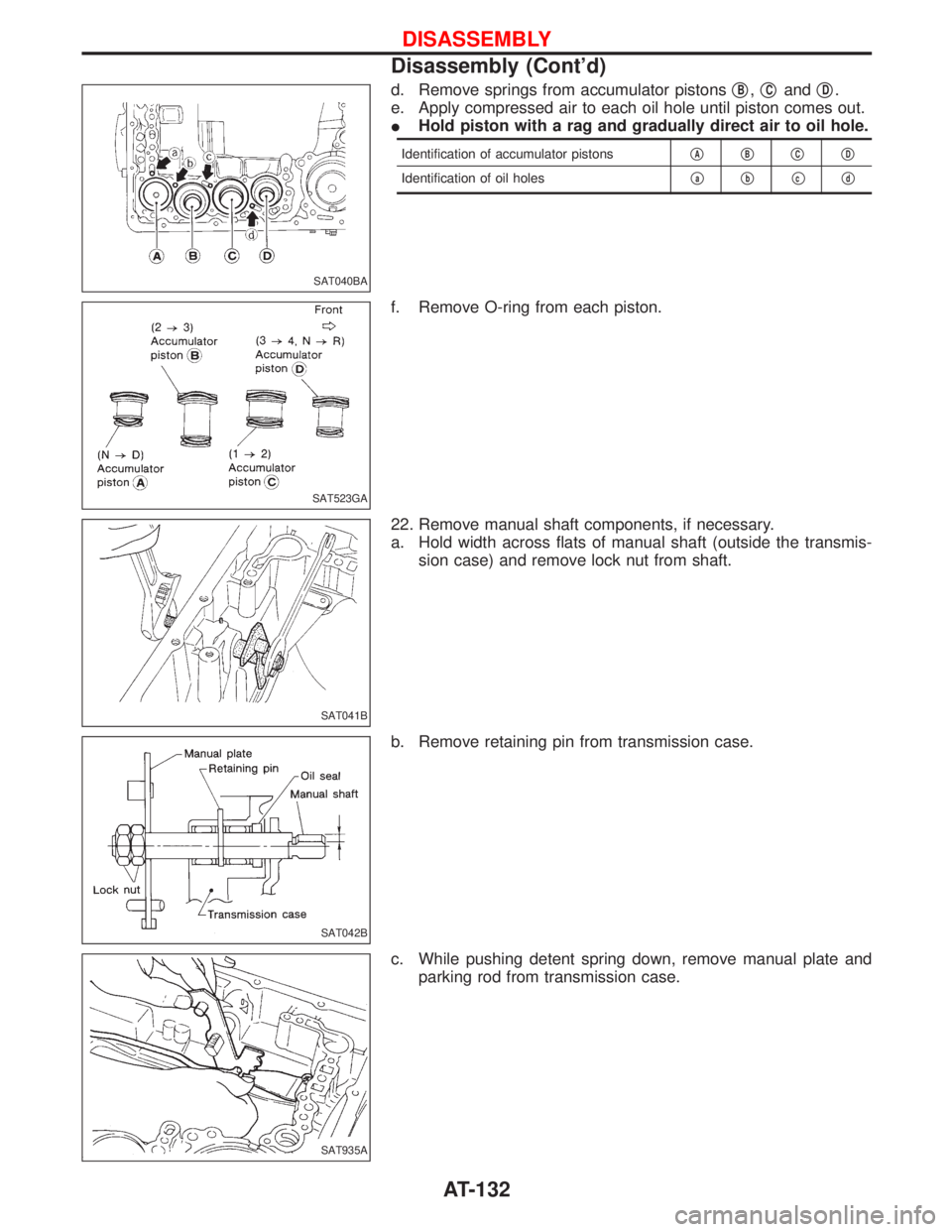

d. Remove springs from accumulator pistonsqB,qCandqD.

e. Apply compressed air to each oil hole until piston comes out.

IHold piston with a rag and gradually direct air to oil hole.

Identification of accumulator pistonsqAqBqCqD

Identification of oil holesqaqbqcqd

f. Remove O-ring from each piston.

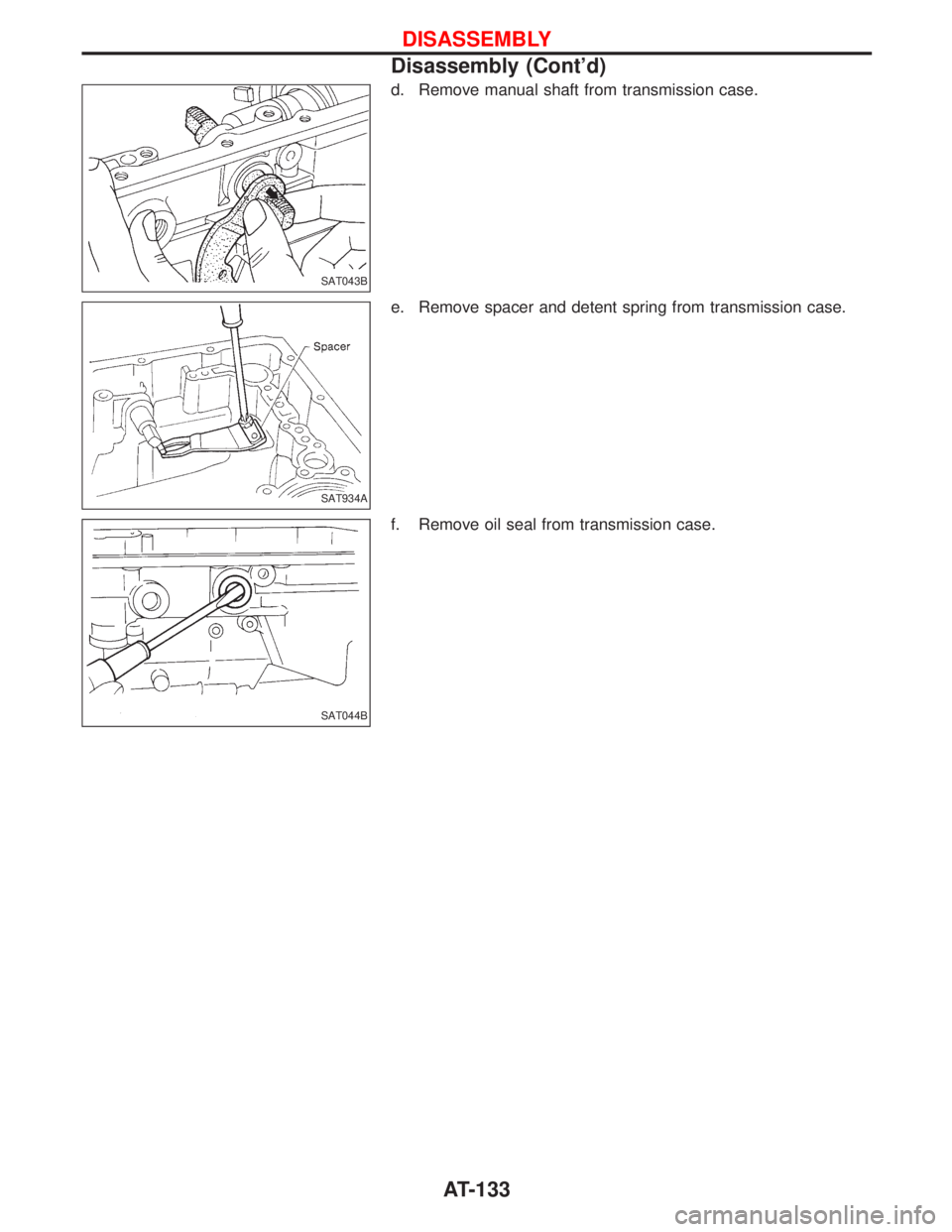

22. Remove manual shaft components, if necessary.

a. Hold width across flats of manual shaft (outside the transmis-

sion case) and remove lock nut from shaft.

b. Remove retaining pin from transmission case.

c. While pushing detent spring down, remove manual plate and

parking rod from transmission case.

SAT040BA

SAT523GA

SAT041B

SAT042B

SAT935A

DISASSEMBLY

Disassembly (Cont'd)

AT-132

Page 135 of 1767

d. Remove manual shaft from transmission case.

e. Remove spacer and detent spring from transmission case.

f. Remove oil seal from transmission case.

SAT043B

SAT934A

SAT044B

DISASSEMBLY

Disassembly (Cont'd)

AT-133

Page 179 of 1767

Assembly (1)

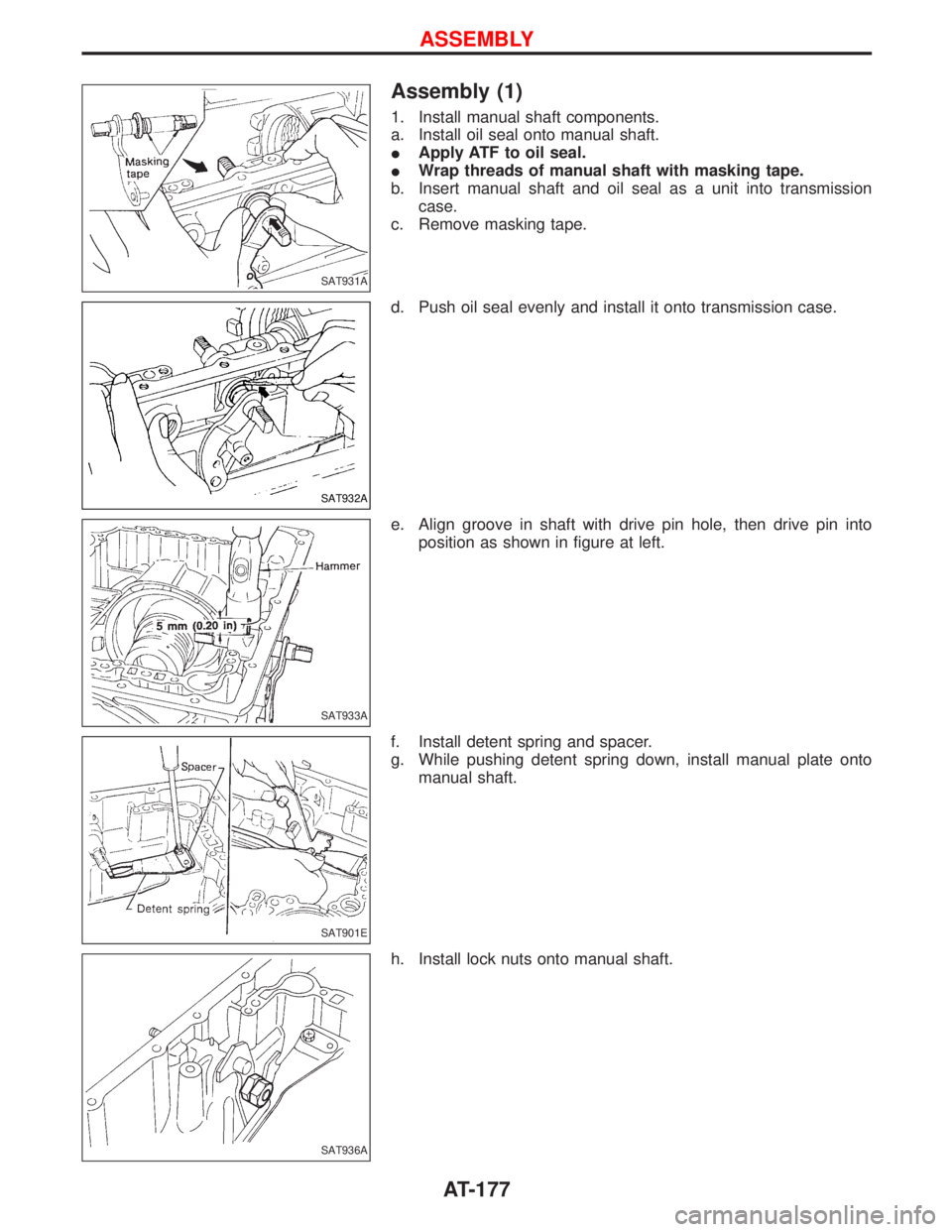

1. Install manual shaft components.

a. Install oil seal onto manual shaft.

IApply ATF to oil seal.

IWrap threads of manual shaft with masking tape.

b. Insert manual shaft and oil seal as a unit into transmission

case.

c. Remove masking tape.

d. Push oil seal evenly and install it onto transmission case.

e. Align groove in shaft with drive pin hole, then drive pin into

position as shown in figure at left.

f. Install detent spring and spacer.

g. While pushing detent spring down, install manual plate onto

manual shaft.

h. Install lock nuts onto manual shaft.

SAT931A

SAT932A

SAT933A

SAT901E

SAT936A

ASSEMBLY

AT-177

Page 193 of 1767

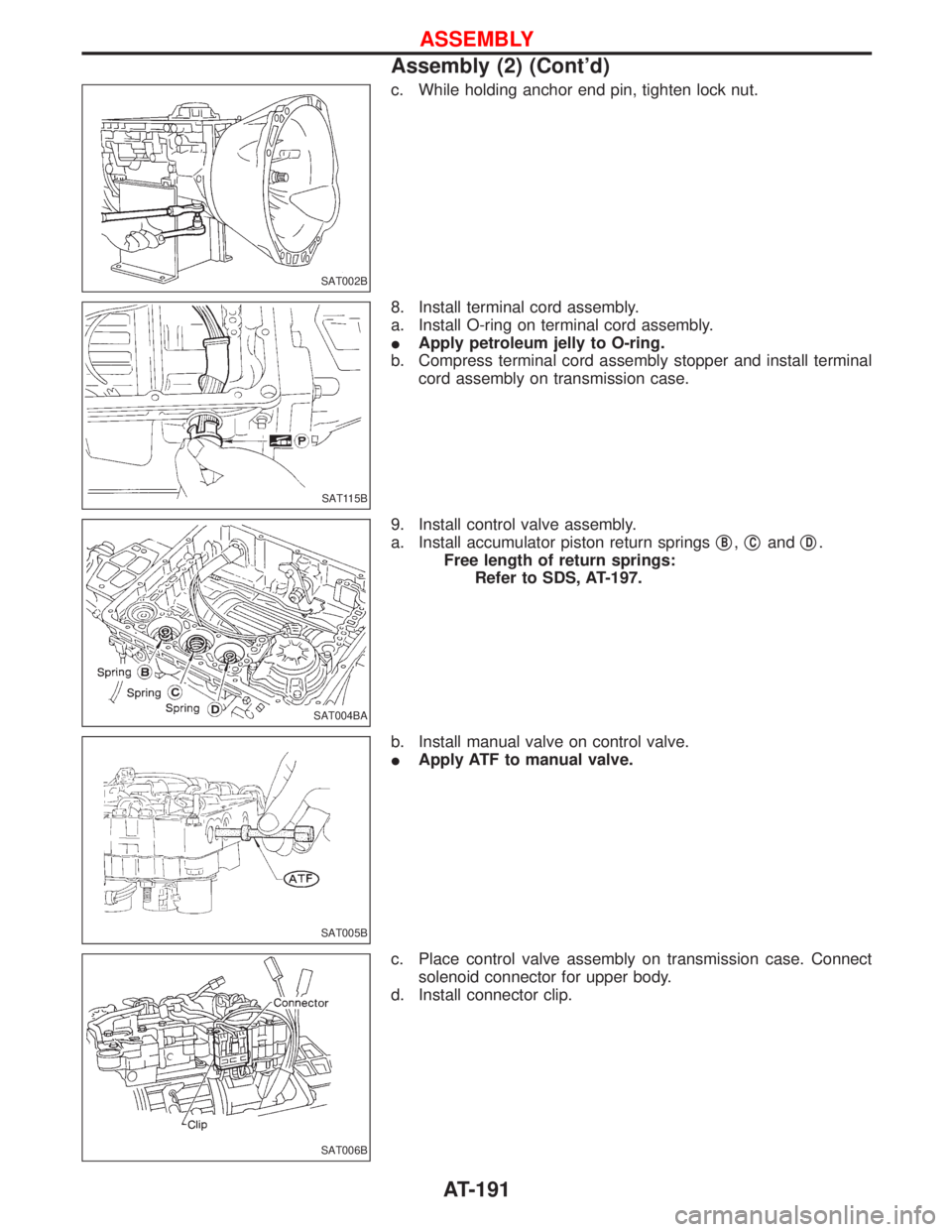

c. While holding anchor end pin, tighten lock nut.

8. Install terminal cord assembly.

a. Install O-ring on terminal cord assembly.

IApply petroleum jelly to O-ring.

b. Compress terminal cord assembly stopper and install terminal

cord assembly on transmission case.

9. Install control valve assembly.

a. Install accumulator piston return springsq

B,qCandqD.

Free length of return springs:

Refer to SDS, AT-197.

b. Install manual valve on control valve.

IApply ATF to manual valve.

c. Place control valve assembly on transmission case. Connect

solenoid connector for upper body.

d. Install connector clip.

SAT002B

SAT115B

SAT004BA

SAT005B

SAT006B

ASSEMBLY

Assembly (2) (Cont'd)

AT-191

Page 195 of 1767

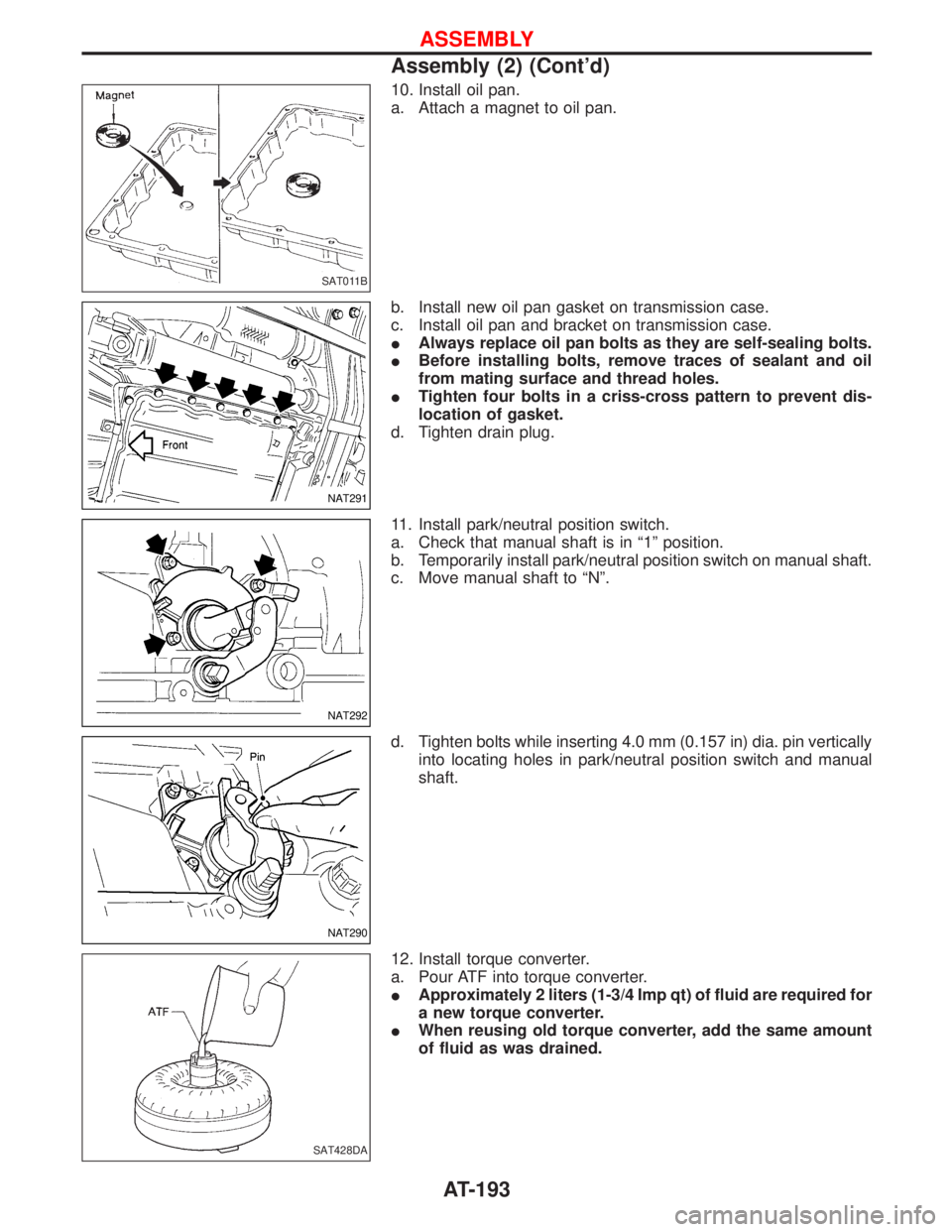

10. Install oil pan.

a. Attach a magnet to oil pan.

b. Install new oil pan gasket on transmission case.

c. Install oil pan and bracket on transmission case.

IAlways replace oil pan bolts as they are self-sealing bolts.

IBefore installing bolts, remove traces of sealant and oil

from mating surface and thread holes.

ITighten four bolts in a criss-cross pattern to prevent dis-

location of gasket.

d. Tighten drain plug.

11. Install park/neutral position switch.

a. Check that manual shaft is in ª1º position.

b. Temporarily install park/neutral position switch on manual shaft.

c. Move manual shaft to ªNº.

d. Tighten bolts while inserting 4.0 mm (0.157 in) dia. pin vertically

into locating holes in park/neutral position switch and manual

shaft.

12. Install torque converter.

a. Pour ATF into torque converter.

IApproximately 2 liters (1-3/4 Imp qt) of fluid are required for

a new torque converter.

IWhen reusing old torque converter, add the same amount

of fluid as was drained.

SAT011B

NAT291

NAT292

NAT290

SAT428DA

ASSEMBLY

Assembly (2) (Cont'd)

AT-193

Page 1175 of 1767

Selection Procedure for Selective Part

Combination

Location Selective part combination Item Method

Cylinder block - pistonPiston and piston assembly

(Part No. is given to a piston

and piston pin as a set.)Piston grade (Piston outer

diameter)Refer to ªSelective combination

chartº.

IIdentification grade stamped on each part represents initial

dimension of new part. This grade will not be applied to a

reused part.

IMeasure correct dimensions of a reused or modified part, then

refer to ªSelective combination chartº in this manual to identify

the grade.

IRefer to the applicable pages for measurement method for

each part, standards for reuse, and selecting method for selec-

tive part combination.

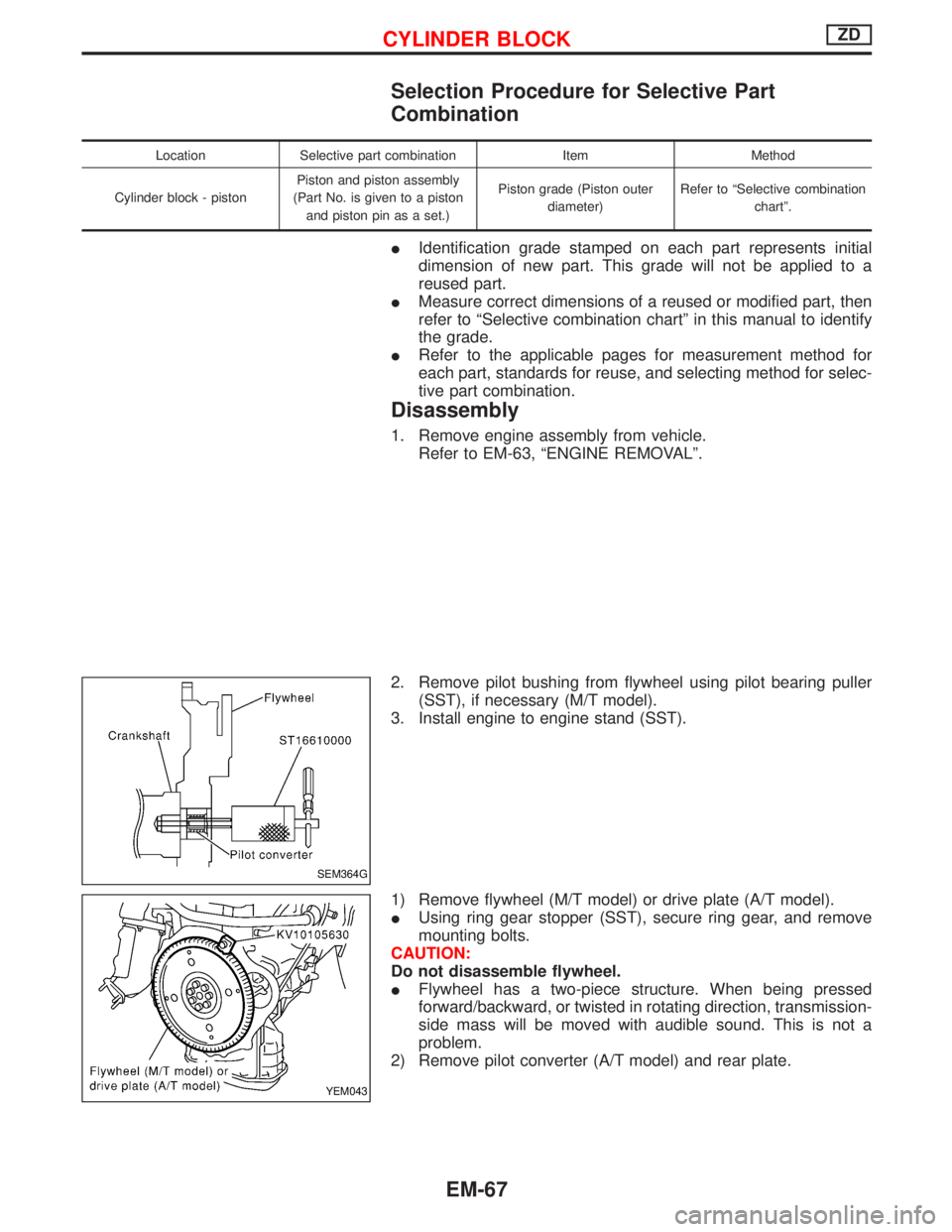

Disassembly

1. Remove engine assembly from vehicle.

Refer to EM-63, ªENGINE REMOVALº.

2. Remove pilot bushing from flywheel using pilot bearing puller

(SST), if necessary (M/T model).

3. Install engine to engine stand (SST).

1) Remove flywheel (M/T model) or drive plate (A/T model).

IUsing ring gear stopper (SST), secure ring gear, and remove

mounting bolts.

CAUTION:

Do not disassemble flywheel.

IFlywheel has a two-piece structure. When being pressed

forward/backward, or twisted in rotating direction, transmission-

side mass will be moved with audible sound. This is not a

problem.

2) Remove pilot converter (A/T model) and rear plate.

SEM364G

YEM043

CYLINDER BLOCKZD

EM-67