air filter NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 101 of 1767

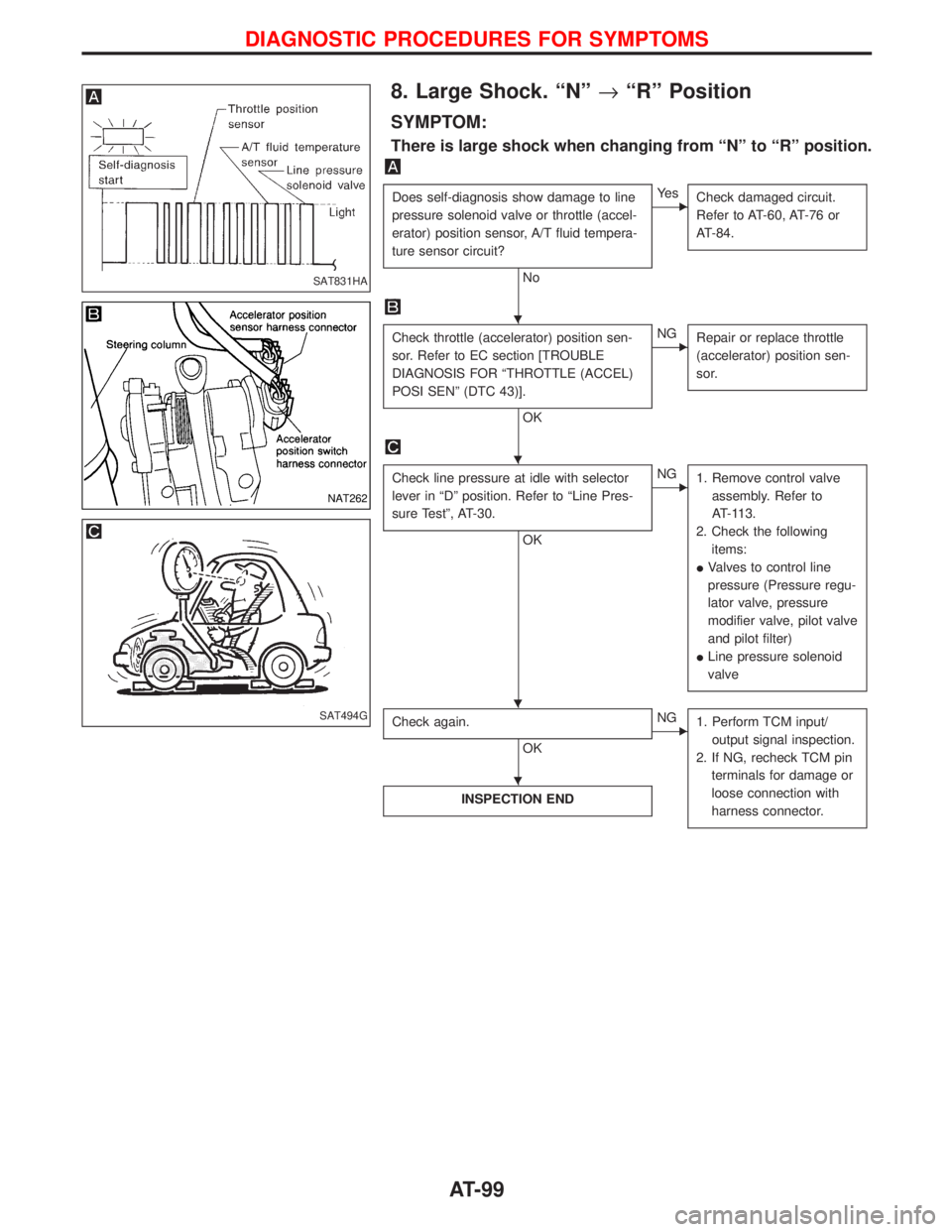

8. Large Shock. ªNº®ªRº Position

SYMPTOM:

There is large shock when changing from ªNº to ªRº position.

Does self-diagnosis show damage to line

pressure solenoid valve or throttle (accel-

erator) position sensor, A/T fluid tempera-

ture sensor circuit?

No

EYe s

Check damaged circuit.

Refer to AT-60, AT-76 or

AT-84.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº (DTC 43)].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pres-

sure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IValves to control line

pressure (Pressure regu-

lator valve, pressure

modifier valve, pilot valve

and pilot filter)

ILine pressure solenoid

valve

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT831HA

NAT262

SAT494G

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-99

Page 104 of 1767

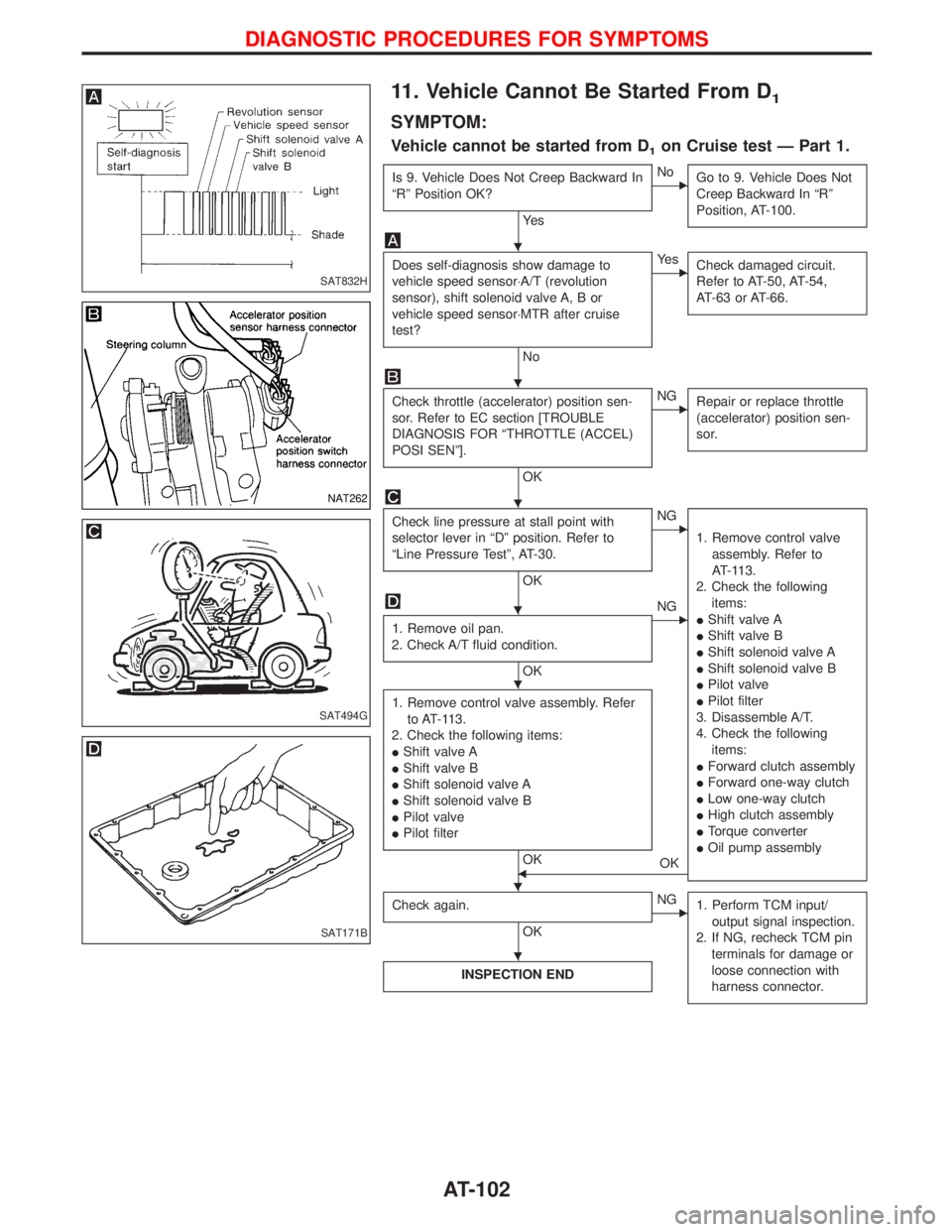

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward In

ªRº Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-100.

Does self-diagnosis show damage to

vehicle speed sensor×A/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensor×MTR after cruise

test?

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63 or AT-66.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

IHigh clutch assembly

ITorque converter

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

NAT262

SAT494G

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-102

Page 105 of 1767

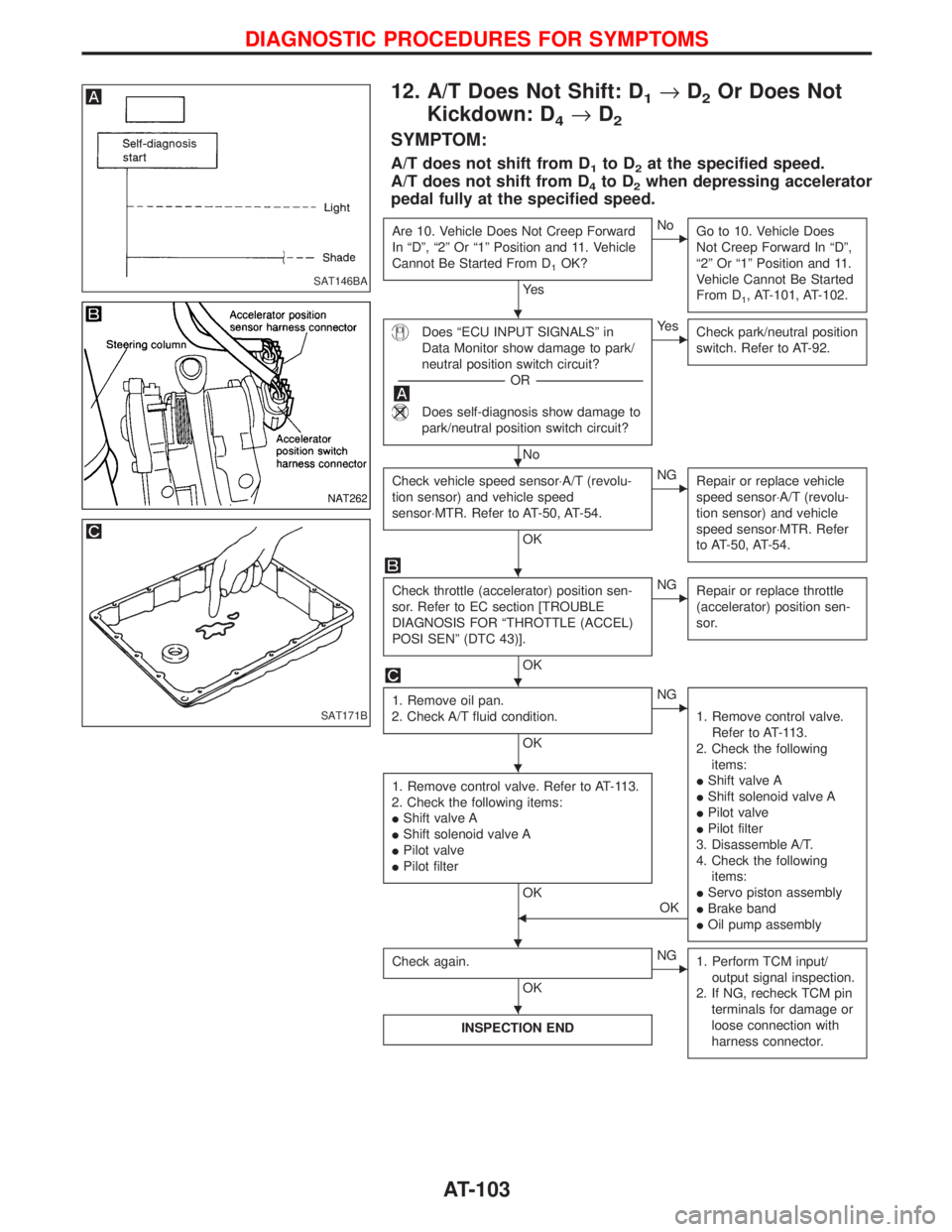

12. A/T Does Not Shift: D1®D2Or Does Not

Kickdown: D

4®D2

SYMPTOM:

A/T does not shift from D1to D2at the specified speed.

A/T does not shift from D

4to D2when depressing accelerator

pedal fully at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check vehicle speed sensor×A/T (revolu-

tion sensor) and vehicle speed

sensor×MTR. Refer to AT-50, AT-54.

OK

ENG

Repair or replace vehicle

speed sensor×A/T (revolu-

tion sensor) and vehicle

speed sensor×MTR. Refer

to AT-50, AT-54.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº (DTC 43)].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve.

Refer to AT-113.

2. Check the following

items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

IOil pump assembly

1. Remove control valve. Refer to AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-103

Page 106 of 1767

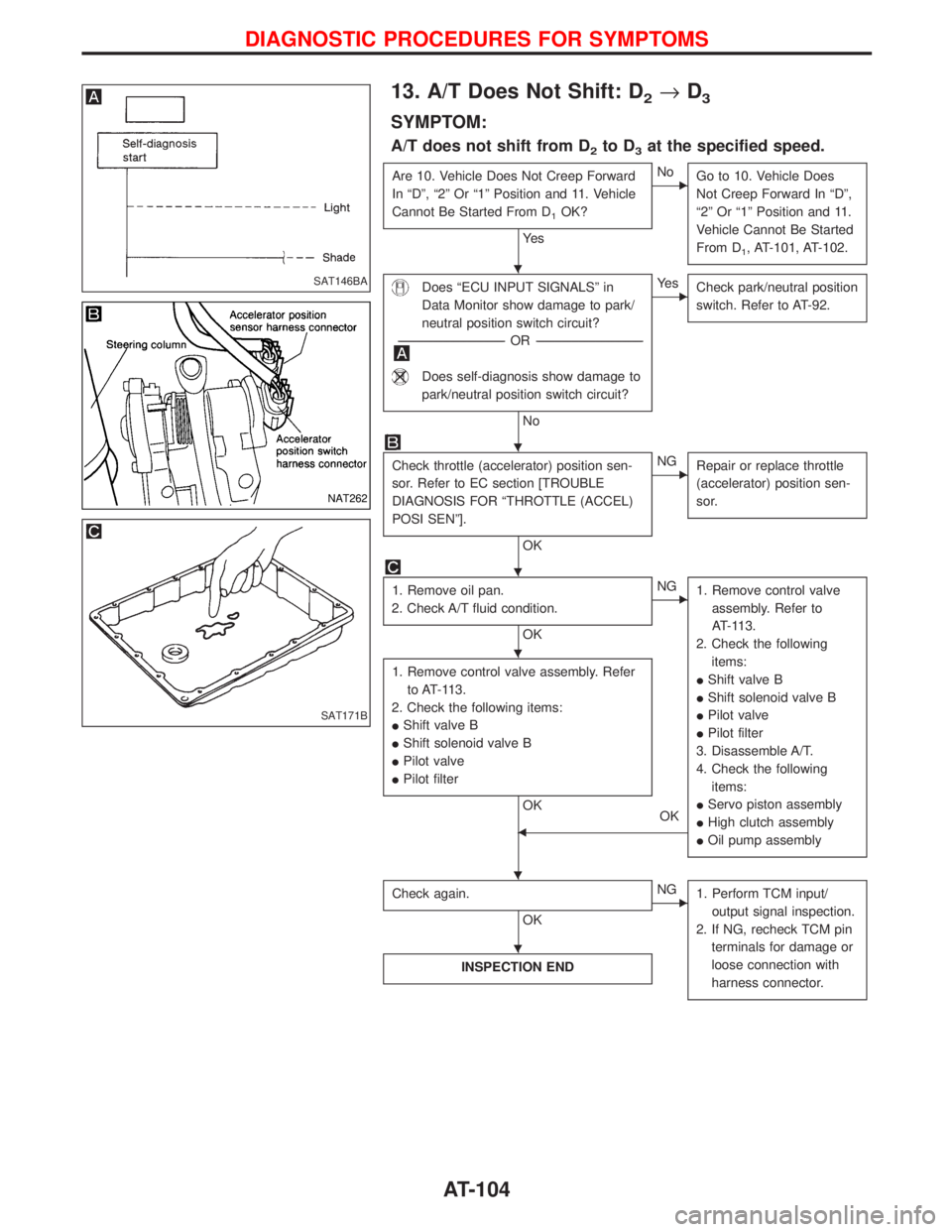

13. A/T Does Not Shift: D2®D3

SYMPTOM:

A/T does not shift from D2to D3at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IHigh clutch assembly

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

OK

OK

F

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-104

Page 107 of 1767

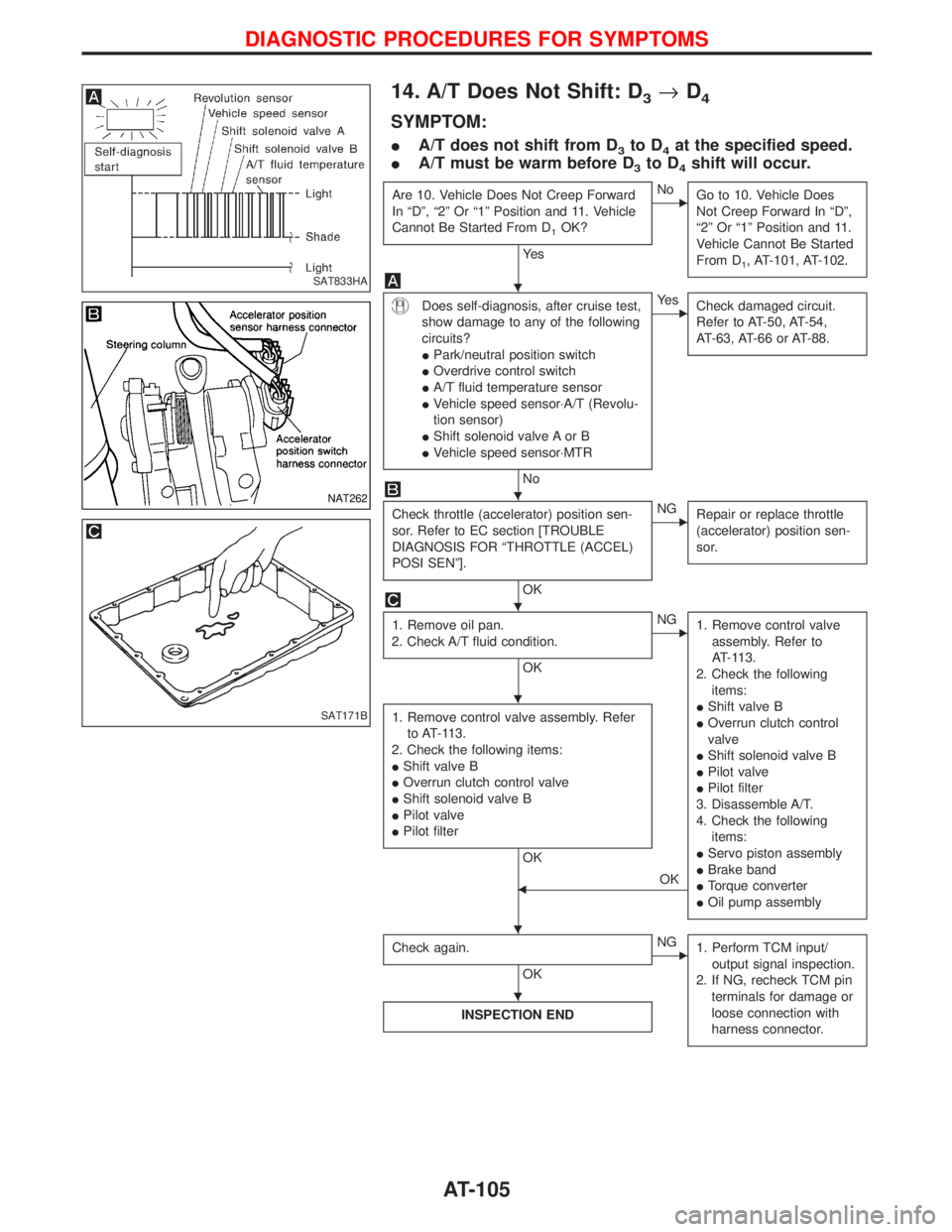

14. A/T Does Not Shift: D3®D4

SYMPTOM:

IA/T does not shift from D3to D4at the specified speed.

IA/T must be warm before D

3to D4shift will occur.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does self-diagnosis, after cruise test,

show damage to any of the following

circuits?

IPark/neutral position switch

IOverdrive control switch

IA/T fluid temperature sensor

IVehicle speed sensor×A/T (Revolu-

tion sensor)

IShift solenoid valve A or B

IVehicle speed sensor×MTR

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63, AT-66 or AT-88.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IOverrun clutch control

valve

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

ITorque converter

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IOverrun clutch control valve

IShift solenoid valve B

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT833HA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-105

Page 108 of 1767

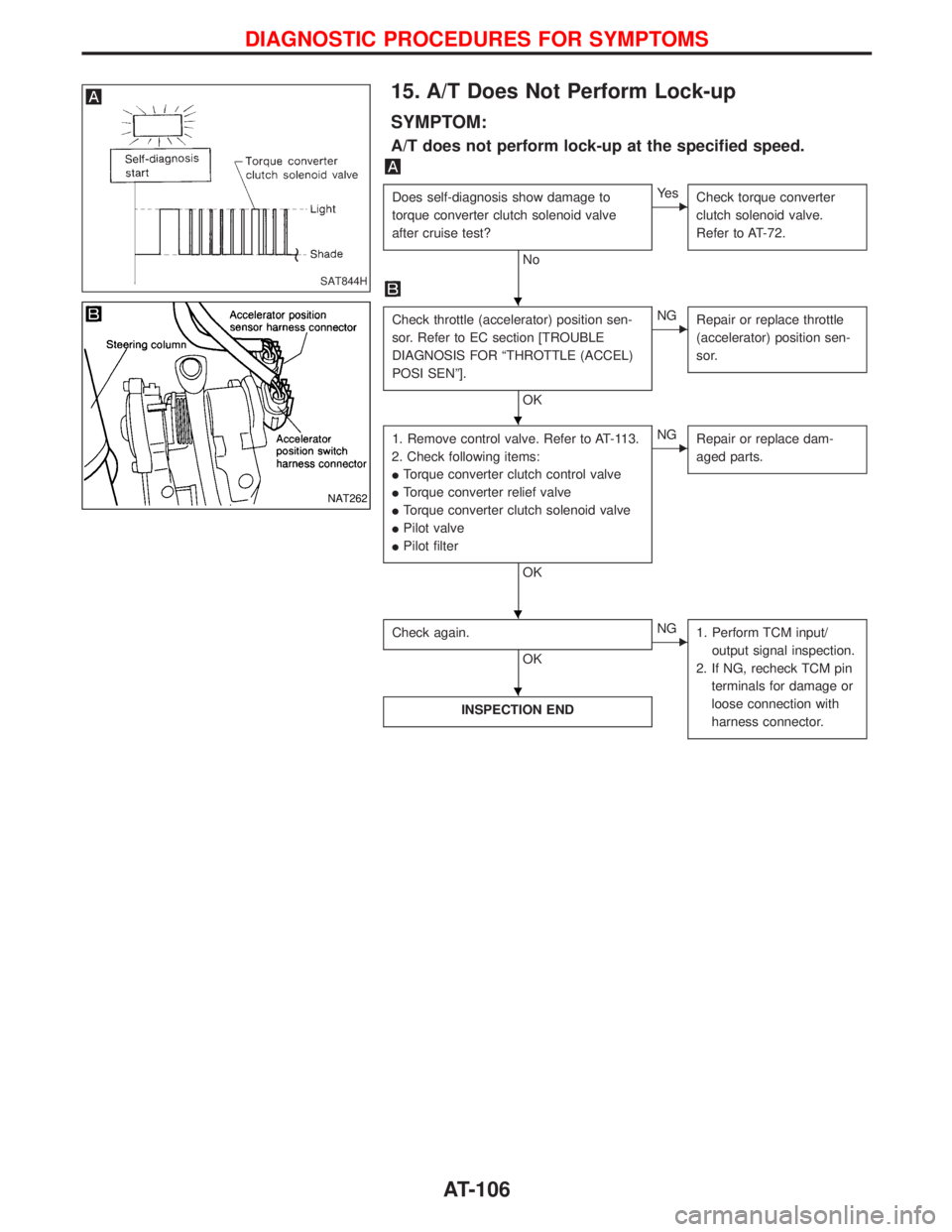

15. A/T Does Not Perform Lock-up

SYMPTOM:

A/T does not perform lock-up at the specified speed.

Does self-diagnosis show damage to

torque converter clutch solenoid valve

after cruise test?

No

EYe s

Check torque converter

clutch solenoid valve.

Refer to AT-72.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove control valve. Refer to AT-113.

2. Check following items:

ITorque converter clutch control valve

ITorque converter relief valve

ITorque converter clutch solenoid valve

IPilot valve

IPilot filter

OK

ENG

Repair or replace dam-

aged parts.

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT844H

NAT262

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-106

Page 112 of 1767

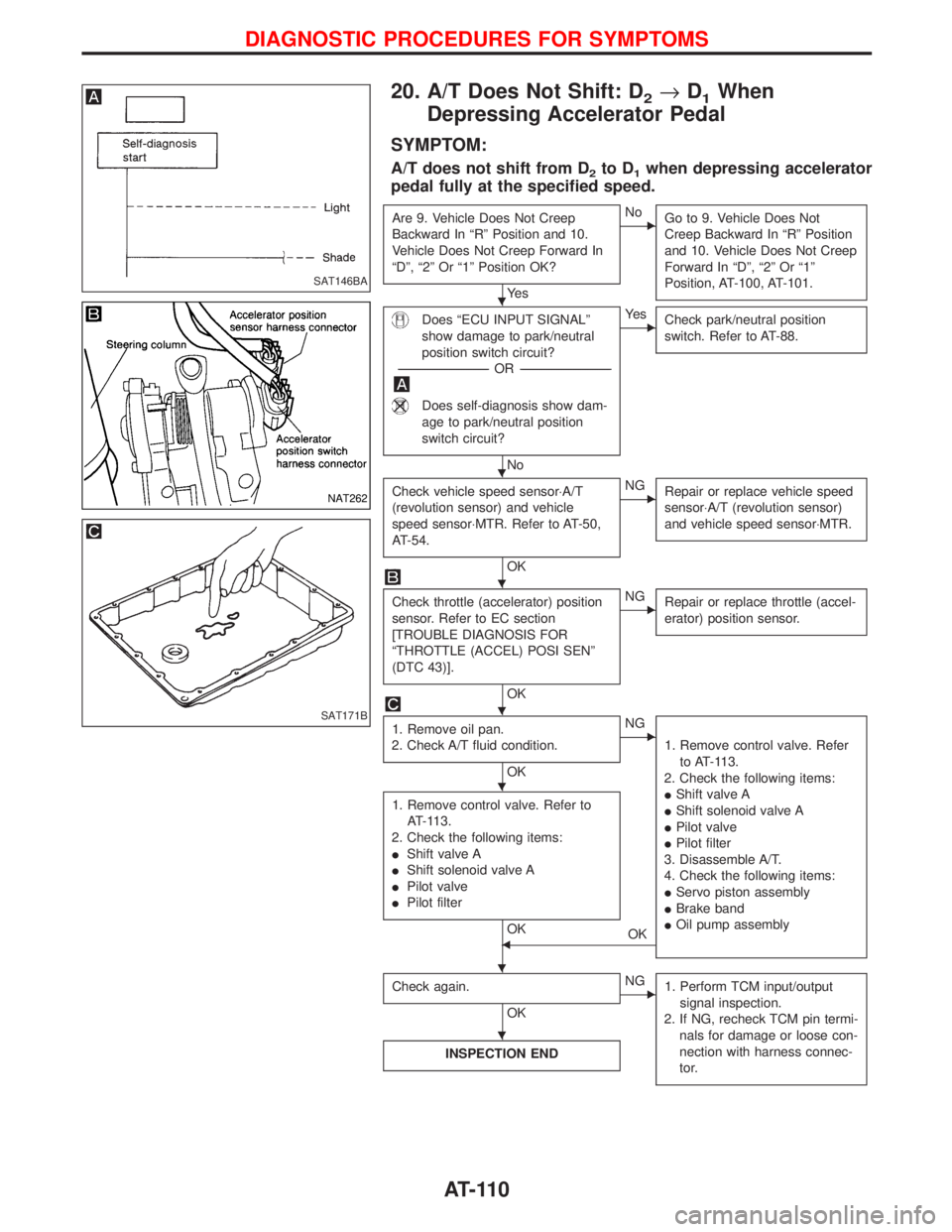

20. A/T Does Not Shift: D2®D1When

Depressing Accelerator Pedal

SYMPTOM:

A/T does not shift from D2to D1when depressing accelerator

pedal fully at the specified speed.

Are 9. Vehicle Does Not Creep

Backward In ªRº Position and 10.

Vehicle Does Not Creep Forward In

ªDº, ª2º Or ª1º Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº Position

and 10. Vehicle Does Not Creep

Forward In ªDº, ª2º Or ª1º

Position, AT-100, AT-101.

Does ªECU INPUT SIGNALº

show damage to park/neutral

position switch circuit?

-----------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------

Does self-diagnosis show dam-

age to park/neutral position

switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-88.

Check vehicle speed sensor×A/T

(revolution sensor) and vehicle

speed sensor×MTR. Refer to AT-50,

AT-54.

OK

ENG

Repair or replace vehicle speed

sensor×A/T (revolution sensor)

and vehicle speed sensor×MTR.

Check throttle (accelerator) position

sensor. Refer to EC section

[TROUBLE DIAGNOSIS FOR

ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

ENG

Repair or replace throttle (accel-

erator) position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following items:

IServo piston assembly

IBrake band

IOil pump assembly

1. Remove control valve. Refer to

AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin termi-

nals for damage or loose con-

nection with harness connec-

tor.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-110

Page 141 of 1767

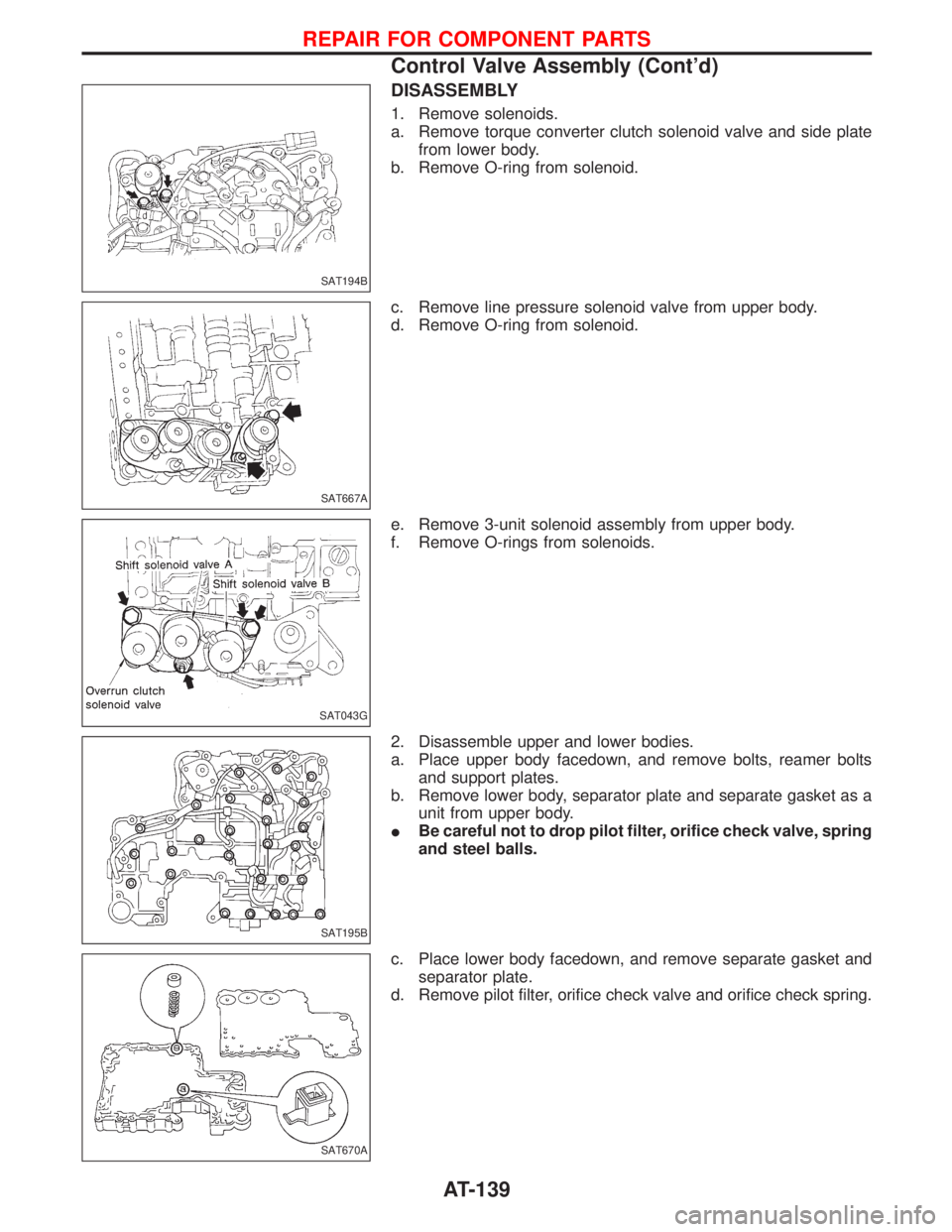

DISASSEMBLY

1. Remove solenoids.

a. Remove torque converter clutch solenoid valve and side plate

from lower body.

b. Remove O-ring from solenoid.

c. Remove line pressure solenoid valve from upper body.

d. Remove O-ring from solenoid.

e. Remove 3-unit solenoid assembly from upper body.

f. Remove O-rings from solenoids.

2. Disassemble upper and lower bodies.

a. Place upper body facedown, and remove bolts, reamer bolts

and support plates.

b. Remove lower body, separator plate and separate gasket as a

unit from upper body.

IBe careful not to drop pilot filter, orifice check valve, spring

and steel balls.

c. Place lower body facedown, and remove separate gasket and

separator plate.

d. Remove pilot filter, orifice check valve and orifice check spring.

SAT194B

SAT667A

SAT043G

SAT195B

SAT670A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-139

Page 143 of 1767

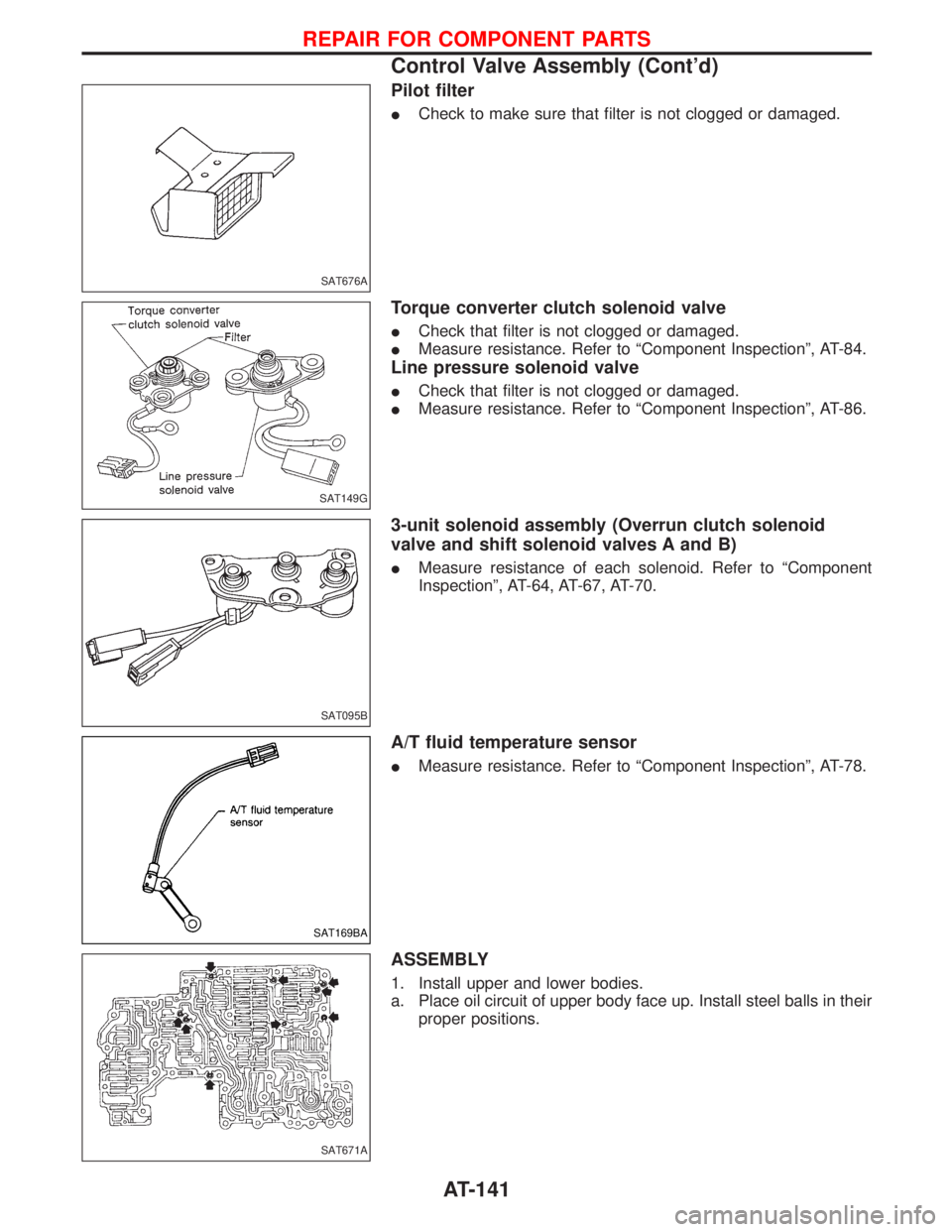

Pilot filter

ICheck to make sure that filter is not clogged or damaged.

Torque converter clutch solenoid valve

ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-84.

Line pressure solenoid valve

ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-86.

3-unit solenoid assembly (Overrun clutch solenoid

valve and shift solenoid valves A and B)

IMeasure resistance of each solenoid. Refer to ªComponent

Inspectionº, AT-64, AT-67, AT-70.

A/T fluid temperature sensor

IMeasure resistance. Refer to ªComponent Inspectionº, AT-78.

ASSEMBLY

1. Install upper and lower bodies.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

SAT676A

SAT149G

SAT095B

SAT169BA

SAT671A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-141

Page 144 of 1767

b. Install reamer bolts from bottom of upper body and install sepa-

rate gaskets.

c. Place oil circuit of lower body face up. Install orifice check

spring, orifice check valve and pilot filter.

d. Install lower separate gaskets and separator plates on lower

body.

e. Install and temporarily tighten support plates, fluid temperature

sensor and tube brackets.

f. Temporarily assemble lower and upper bodies, using reamer

bolt as a guide.

IBe careful not to dislocate or drop steel balls, orifice check

spring, orifice check valve and pilot filter.

SAT681A

SAT682A

SAT197B

SAT198B

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-142