air flow NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 3 of 1767

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

PREPARATION AND PRECAUTIONS............................3

Special Service Tools ..................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............4

Precautions ..................................................................4

Service Notice or Precautions .....................................5

OVERALL SYSTEM........................................................6

A/T Electrical Parts Location .......................................6

Wiring Diagram - A/T -.................................................7

Cross-sectional View ...................................................8

Hydraulic Control Circuits ............................................9

Shift Mechanism ........................................................10

Control System ..........................................................12

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................14

Self-diagnosis ............................................................14

Diagnosis by CONSULT-II .........................................20

TROUBLE DIAGNOSIS - Introduction........................22

Introduction ................................................................22

Diagnostic Worksheet ................................................23

Work Flow ..................................................................26

TROUBLE DIAGNOSIS - Basic Inspection................27

A/T Fluid Check .........................................................27

Stall Test ....................................................................27

Line Pressure Test .....................................................30

Road Test...................................................................32

TROUBLE DIAGNOSIS - General Description...........43

Symptom Chart ..........................................................43

TCM Terminals and Reference Value........................46

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×A/T.........................................................................49

Wiring Diagram - AT - VSSA/T ..................................49

Vehicle Speed Sensor×A/T (Revolution sensor) ........50

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×MTR.......................................................................52

Wiring Diagram - AT - VSSMTR ................................52

Vehicle Speed Sensor×MTR ......................................54TROUBLE DIAGNOSIS FOR THROTTLE POSI

SEN................................................................................56

Wiring Diagram - AT - TPS ........................................56

Throttle (Accelerator) Position Sensor ......................60

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

A.....................................................................................62

Wiring Diagram - AT - SSV/A ....................................62

Shift Solenoid Valve A ...............................................63

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

B.....................................................................................65

Wiring Diagram - AT - SSV/B ....................................65

Shift Solenoid Valve B ...............................................66

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH

S/V..................................................................................68

Wiring Diagram - AT - OVRCSV................................68

Overrun Clutch Solenoid Valve .................................69

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V.....71

Wiring Diagram - AT - TCV........................................71

Torque Converter Clutch Solenoid Valve ..................72

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP

SEN................................................................................75

Wiring Diagram - AT - BA/FTS ..................................75

A/T Fluid Temperature Sensor and TCM Power

Source........................................................................76

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG....79

Wiring Diagram - AT - ENGSS ..................................79

Engine Speed Signal .................................................80

TROUBLE DIAGNOSIS FOR LINE PRESSURE

S/V..................................................................................82

Wiring Diagram - AT - LPSV......................................82

Line Pressure Solenoid Valve ...................................84

TROUBLE DIAGNOSIS FOR NON-DETECTABLE

ITEMS.............................................................................87

Wiring Diagram - AT - PNP/SW.................................87

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches ...................88

DIAGNOSTIC PROCEDURES FOR SYMPTOMS........94

Page 4 of 1767

1. SPORT Indicator Lamp Does Not Come On ........94

2. SPORT or SNOW Indicator Lamp Does Not

Come On...................................................................95

3. O/D OFF Indicator Lamp Does Not Come On......95

4. SPORT Indicator Lamp Does Not Come On ........96

5. Engine Cannot Be Started In²P²and²N²

Position......................................................................97

6. In²P²Position, Vehicle Moves Forward Or

Backward When Pushed...........................................97

7. In²N²Position, Vehicle Moves .............................98

8. Large Shock.²N²->²R²Position .........................99

9. Vehicle Does Not Creep Backward In²R²

Position....................................................................100

10. Vehicle Does Not Creep Forward In²D²,²2²

Or²1²Position.........................................................101

11. Vehicle Cannot Be Started From D

1.................102

12. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................103

13. A/T Does Not Shift: D

2-> D3............................104

14. A/T Does Not Shift: D

3-> D4.............................105

15. A/T Does Not Perform Lock-up .........................106

16. A/T Does Not Hold Lock-up Condition ..............107

17. Lock-up Is Not Released ...................................107

18. Engine Speed Does Not Return To Idle (Light

Braking D

4-> D3) .....................................................108

19. Vehicle Does Not Start From D

1.......................109

20. A/T Does Not Shift: D

2-> D1When

Depressing Accelerator Pedal................................. 110

21. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch²ON²->²OFF²............... 111

22. A/T Does Not Shift: D

3-> 22, When Selector

Lever²D²->²2²Position......................................... 111

23. A/T Does Not Shift: 2

2-> 11, When Selector

Lever²2²->²1²Position ......................................... 112

24. Vehicle Does Not Decelerate By Engine

Brake........................................................................ 112

ON-VEHICLE SERVICE.............................................. 113Control Valve Assembly and Accumulators ............. 113

Revolution Sensor Replacement ............................. 114

Rear Oil Seal Replacement ..................................... 114

Parking Components Inspection.............................. 114

Park/neutral Position Switch Adjustment ................. 114

Manual Control Linkage Adjustment........................ 115

REMOVAL AND INSTALLATION................................ 116

Removal ................................................................... 116

Installation ................................................................ 117

MAJOR OVERHAUL................................................... 119

Oil Channel ..............................................................121

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................122

DISASSEMBLY............................................................123

Disassembly.............................................................123

REPAIR FOR COMPONENT PARTS..........................134

Oil Pump ..................................................................134

Control Valve Assembly ...........................................138

Control Valve Upper Body .......................................144

Control Valve Lower Body .......................................149

Reverse Clutch ........................................................151

High Clutch ..............................................................155

Forward and Overrun Clutches ...............................157

Low & Reverse Brake..............................................161

Forward Clutch Drum Assembly ..............................165

Rear Internal Gear and Forward Clutch Hub ..........168

Band Servo Piston Assembly ..................................171

Parking Pawl Components ......................................175

ASSEMBLY..................................................................177

Assembly (1) ............................................................177

Adjustment ...............................................................185

Assembly (2) ............................................................188

A/T FLUID COOLER SYSTEM...................................195

A/T Fluid Cooler.......................................................195

SERVICE DATA AND SPECIFICATIONS (SDS)........196

General Specifications .............................................196

Specifications and Adjustment.................................196

When you read wiring diagrams:

IRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

ISee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENTº.

CONTENTS(Cont'd)

AT- 2

Page 28 of 1767

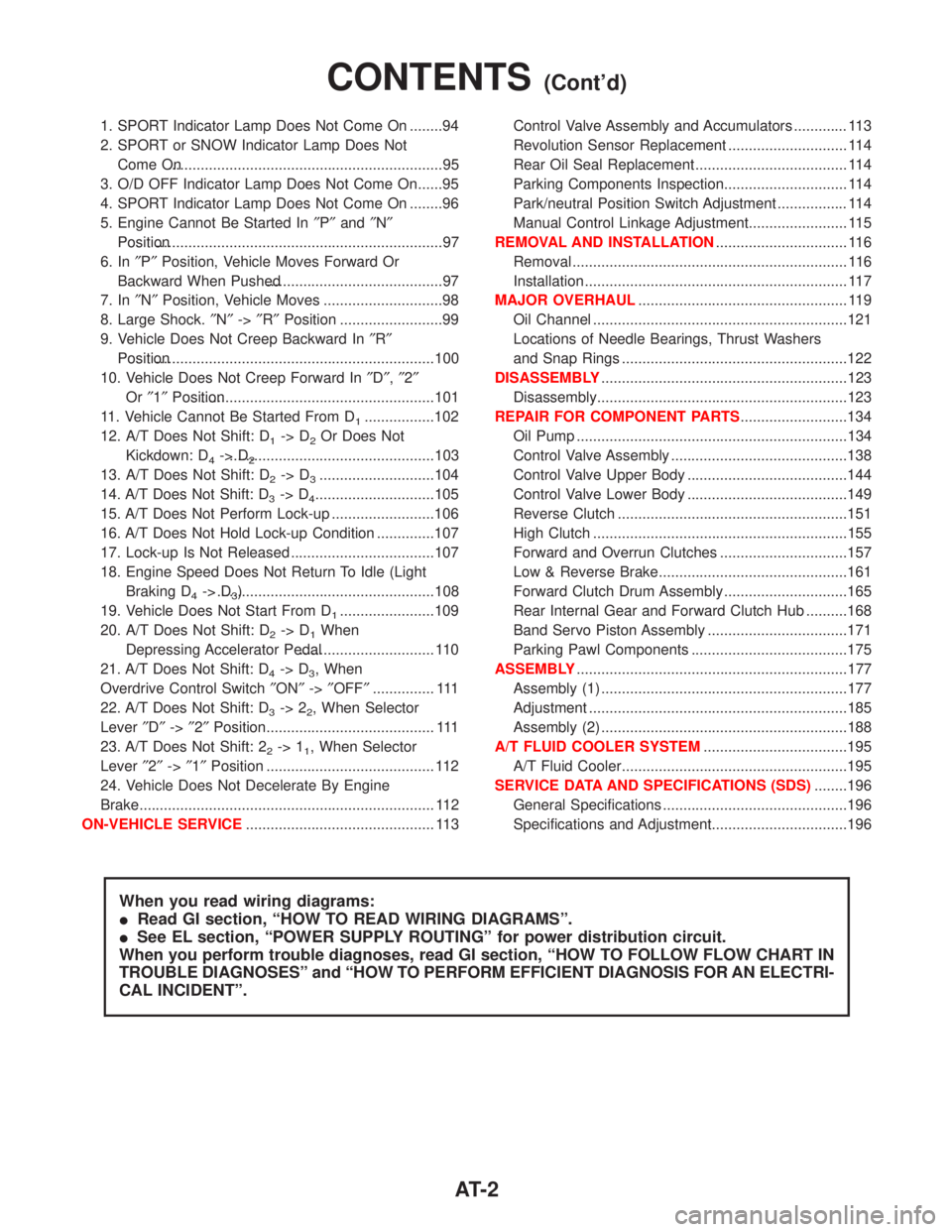

Work Flow

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is important to fully understand the symptoms

or conditions for a customer complaint.

Make good use of the two sheets provided, ªINFORMATION FROM CUSTOMERº and ªDIAGNOSTIC

WORKSHEETº, to perform the best troubleshooting possible.

CHECK IN

LISTEN TO CUSTOMER COMPLAINTS AND FILL OUT

ªINFORMATION FROM CUSTOMERº, AT-23.

Check for any Service Bulletins.FRefer to FAIL-SAFE Service Notice or Precautions, AT-5.

CHECK A/T FLUID LEVEL AND CONDITION. IF NG, PLACE

CHECK ON THE DIAGNOSTIC WORKSHEET, AT-24.FRefer to A/T Fluid Check, AT-27.

PERFORM STALL TEST AND LINE PRESSURE TEST.FRefer to Stall Test and Line Pressure Test, AT-27, AT-30.

PERFORM ROAD TEST WITH SELF-DIAGNOSIS AND

PLACE CHECKS FOR NG ITEMS ON THE DIAGNOSTIC

WORKSHEET.

NG items including

self-diagnostic item

FFollow ROAD TEST procedure, AT-32.

IFOR SELF-DIAGNOSIS NG ITEMS:

-INSPECT EACH COMPONENT.

-REPAIR/REPLACE.

IPERFORM ROAD TEST AND PLACE CHECKS FOR NG

ITEMS ON THE DIAGNOSTIC WORKSHEET AGAIN.FIRefer to self-diagnosis, AT-14.

IPerform ROAD TEST for all items.

IFOR ALL REMAINING MALFUNCTIONS:

-INSPECT EACH COMPONENT.

-REPAIR/REPLACE.

IPERFORM ROAD TEST AND CONFIRM ALL MALFUNC-

TIONS ARE ELIMINATED.FRefer to

ION BOARD DIAGNOSTIC SYSTEM DESCRIPTION,

AT-14, AT-20.

ITROUBLE DIAGNOSIS FOR SELF-DIAGNOSIS CODE,

AT-50, AT-88.

IDIAGNOSTIC PROCEDURES FOR SYMPTOMS, AT-26,

AT-112.

ISymptom Chart, AT-43.

ERASE SELF-DIAGNOSIS CODE FROM TCM MEMORIES.FRefer to HOW TO ERASE SELF-DIAGNOSIS RESULTS,

AT-19.

PERFORM FINAL CHECK

OK

FRefer to SELF-DIAGNOSIS CONFIRMATION PROCEDURE,

AT-50 - AT-84.

CHECK OUT

H

H

H

H

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Introduction

AT-26

Page 354 of 1767

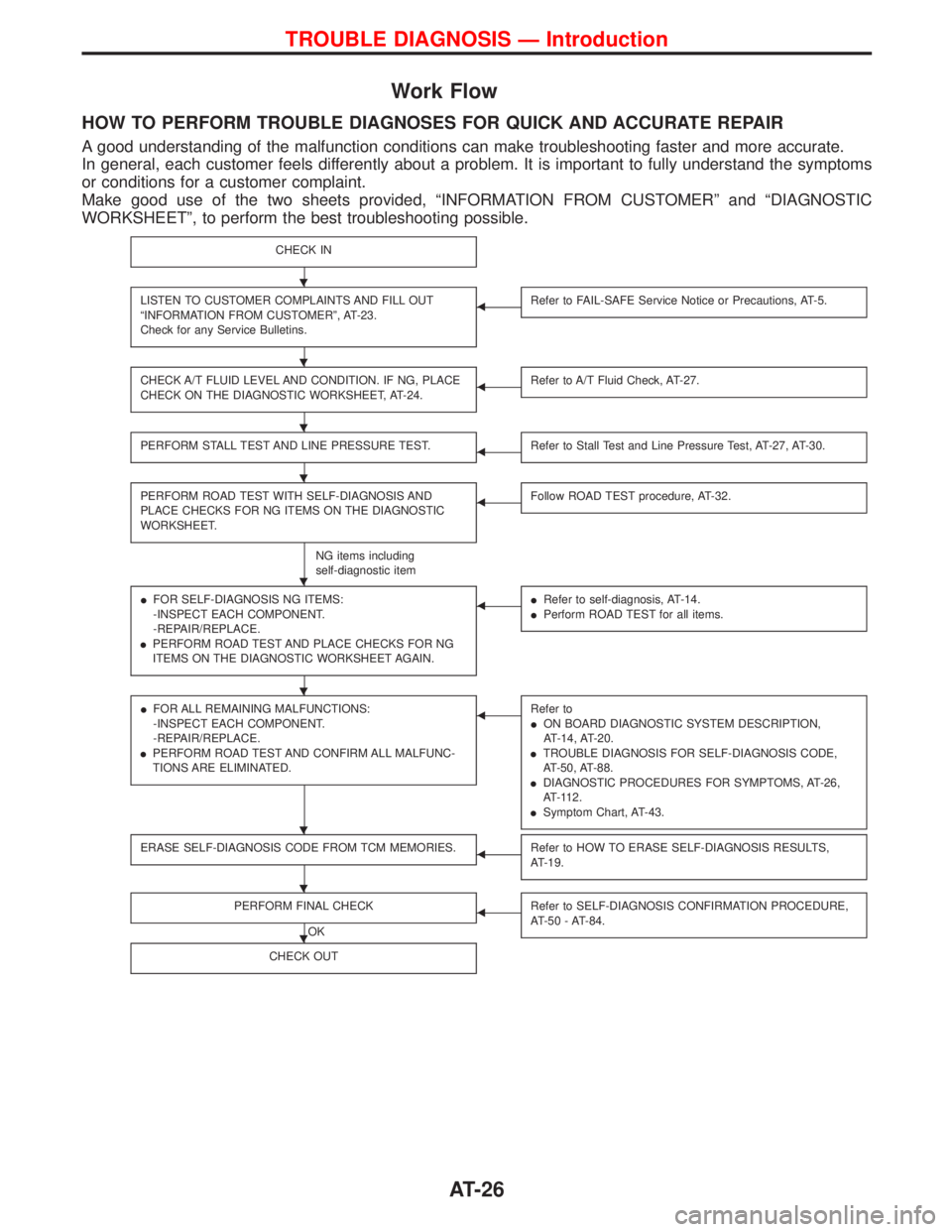

Bleeding Procedure

1. Bleed air from clutch operating cylinder according to the follow-

ing procedure.

Carefully monitor fluid level at master cylinder during bleeding

operation.

a. Top up reservoir with recommended brake fluid.

b. Connect a transparent vinyl tube to air bleeder valve of clutch

damper.

c. Fully depress clutch pedal several times.

d. With clutch pedal depressed, open bleeder valve to release air.

e. Close bleeder valve.

f. Repeat steps (c) through (e) above until brake fluid flows from

air bleeder valve without air bubbles.

2. Bleed air from clutch operating cylinder according to the above

procedure.

3. Repeat the above bleeding procedures 1 and 2 several times.

NCL025

INSPECTION AND ADJUSTMENT

CL-6

Page 363 of 1767

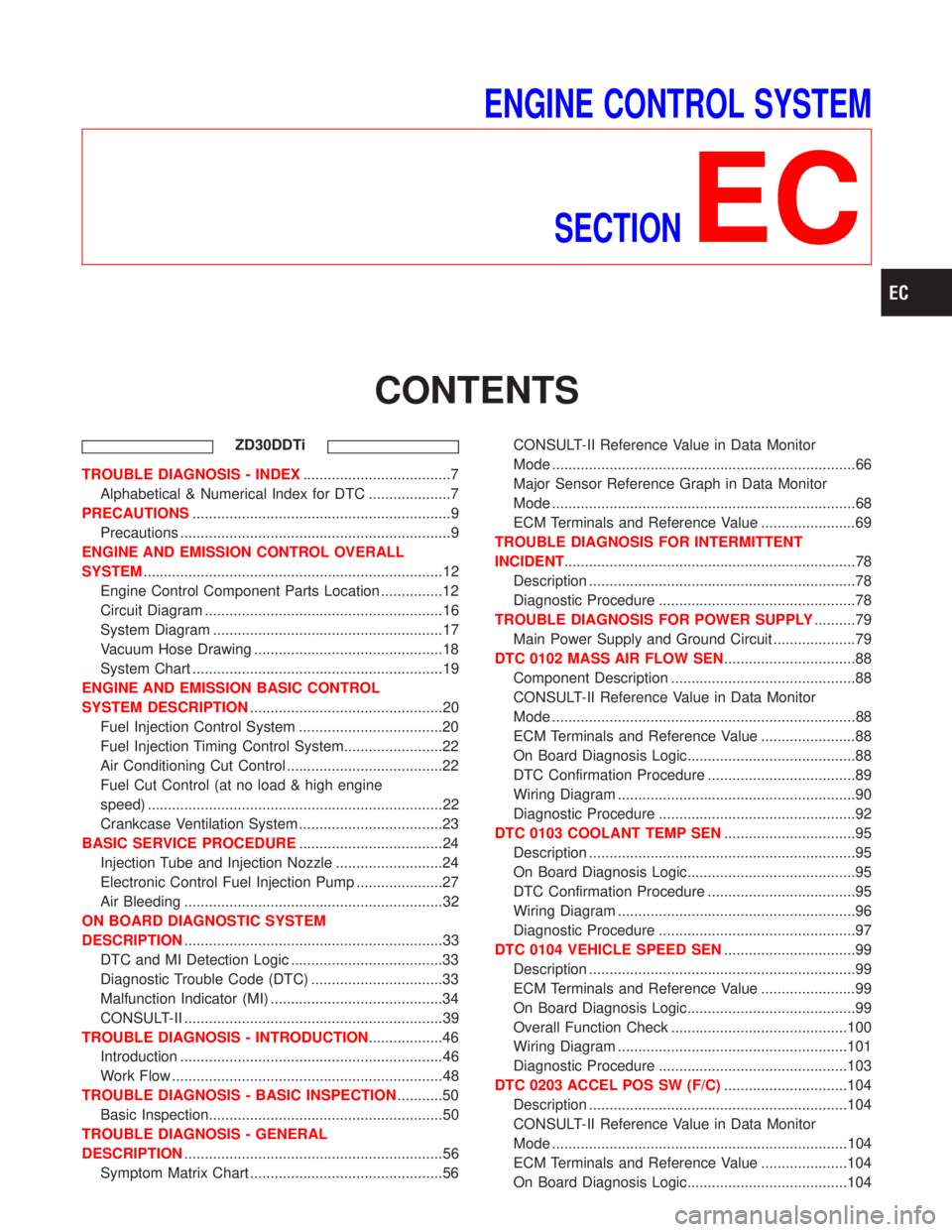

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

ZD30DDTi

TROUBLE DIAGNOSIS - INDEX....................................7

Alphabetical & Numerical Index for DTC ....................7

PRECAUTIONS...............................................................9

Precautions ..................................................................9

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................12

Engine Control Component Parts Location ...............12

Circuit Diagram ..........................................................16

System Diagram ........................................................17

Vacuum Hose Drawing ..............................................18

System Chart .............................................................19

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................20

Fuel Injection Control System ...................................20

Fuel Injection Timing Control System........................22

Air Conditioning Cut Control ......................................22

Fuel Cut Control (at no load & high engine

speed) ........................................................................22

Crankcase Ventilation System ...................................23

BASIC SERVICE PROCEDURE...................................24

Injection Tube and Injection Nozzle ..........................24

Electronic Control Fuel Injection Pump .....................27

Air Bleeding ...............................................................32

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................33

DTC and MI Detection Logic .....................................33

Diagnostic Trouble Code (DTC) ................................33

Malfunction Indicator (MI) ..........................................34

CONSULT-II ...............................................................39

TROUBLE DIAGNOSIS - INTRODUCTION..................46

Introduction ................................................................46

Work Flow ..................................................................48

TROUBLE DIAGNOSIS - BASIC INSPECTION...........50

Basic Inspection.........................................................50

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................56

Symptom Matrix Chart ...............................................56CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................66

Major Sensor Reference Graph in Data Monitor

Mode ..........................................................................68

ECM Terminals and Reference Value .......................69

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.......................................................................78

Description .................................................................78

Diagnostic Procedure ................................................78

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........79

Main Power Supply and Ground Circuit ....................79

DTC 0102 MASS AIR FLOW SEN................................88

Component Description .............................................88

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................88

ECM Terminals and Reference Value .......................88

On Board Diagnosis Logic.........................................88

DTC Confirmation Procedure ....................................89

Wiring Diagram ..........................................................90

Diagnostic Procedure ................................................92

DTC 0103 COOLANT TEMP SEN................................95

Description .................................................................95

On Board Diagnosis Logic.........................................95

DTC Confirmation Procedure ....................................95

Wiring Diagram ..........................................................96

Diagnostic Procedure ................................................97

DTC 0104 VEHICLE SPEED SEN................................99

Description .................................................................99

ECM Terminals and Reference Value .......................99

On Board Diagnosis Logic.........................................99

Overall Function Check ...........................................100

Wiring Diagram ........................................................101

Diagnostic Procedure ..............................................103

DTC 0203 ACCEL POS SW (F/C)..............................104

Description ...............................................................104

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................104

ECM Terminals and Reference Value .....................104

On Board Diagnosis Logic.......................................104

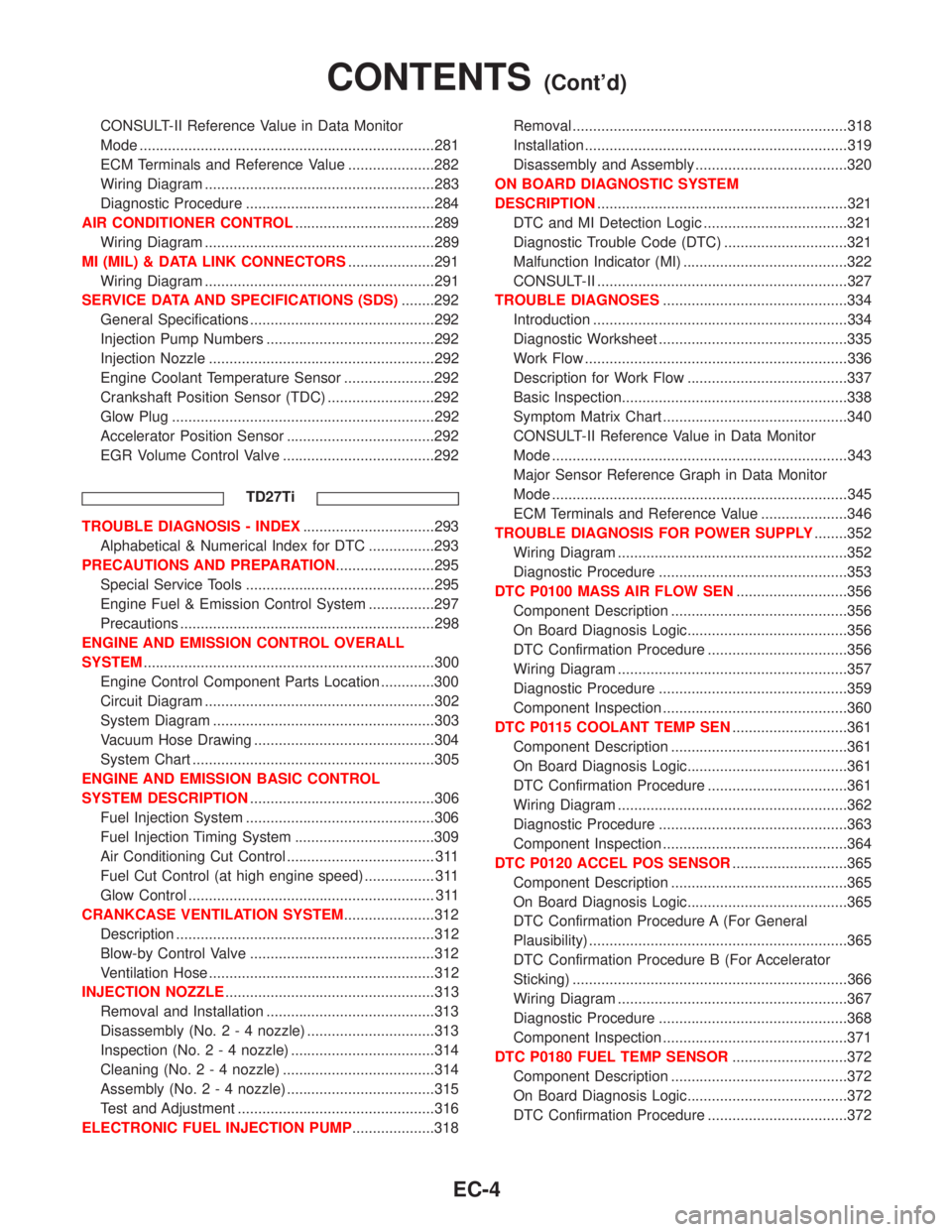

Page 366 of 1767

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................281

ECM Terminals and Reference Value .....................282

Wiring Diagram ........................................................283

Diagnostic Procedure ..............................................284

AIR CONDITIONER CONTROL..................................289

Wiring Diagram ........................................................289

MI (MIL) & DATA LINK CONNECTORS.....................291

Wiring Diagram ........................................................291

SERVICE DATA AND SPECIFICATIONS (SDS)........292

General Specifications .............................................292

Injection Pump Numbers .........................................292

Injection Nozzle .......................................................292

Engine Coolant Temperature Sensor ......................292

Crankshaft Position Sensor (TDC) ..........................292

Glow Plug ................................................................292

Accelerator Position Sensor ....................................292

EGR Volume Control Valve .....................................292

TD27Ti

TROUBLE DIAGNOSIS - INDEX................................293

Alphabetical & Numerical Index for DTC ................293

PRECAUTIONS AND PREPARATION........................295

Special Service Tools ..............................................295

Engine Fuel & Emission Control System ................297

Precautions ..............................................................298

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.......................................................................300

Engine Control Component Parts Location .............300

Circuit Diagram ........................................................302

System Diagram ......................................................303

Vacuum Hose Drawing ............................................304

System Chart ...........................................................305

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION.............................................306

Fuel Injection System ..............................................306

Fuel Injection Timing System ..................................309

Air Conditioning Cut Control .................................... 311

Fuel Cut Control (at high engine speed) ................. 311

Glow Control ............................................................ 311

CRANKCASE VENTILATION SYSTEM......................312

Description ...............................................................312

Blow-by Control Valve .............................................312

Ventilation Hose .......................................................312

INJECTION NOZZLE...................................................313

Removal and Installation .........................................313

Disassembly (No.2-4nozzle) ...............................313

Inspection (No.2-4nozzle) ...................................314

Cleaning (No.2-4nozzle) .....................................314

Assembly (No.2-4nozzle) ....................................315

Test and Adjustment ................................................316

ELECTRONIC FUEL INJECTION PUMP....................318Removal ...................................................................318

Installation ................................................................319

Disassembly and Assembly .....................................320

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION.............................................................321

DTC and MI Detection Logic ...................................321

Diagnostic Trouble Code (DTC) ..............................321

Malfunction Indicator (MI) ........................................322

CONSULT-II .............................................................327

TROUBLE DIAGNOSES.............................................334

Introduction ..............................................................334

Diagnostic Worksheet ..............................................335

Work Flow ................................................................336

Description for Work Flow .......................................337

Basic Inspection.......................................................338

Symptom Matrix Chart .............................................340

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................343

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................345

ECM Terminals and Reference Value .....................346

TROUBLE DIAGNOSIS FOR POWER SUPPLY........352

Wiring Diagram ........................................................352

Diagnostic Procedure ..............................................353

DTC P0100 MASS AIR FLOW SEN...........................356

Component Description ...........................................356

On Board Diagnosis Logic.......................................356

DTC Confirmation Procedure ..................................356

Wiring Diagram ........................................................357

Diagnostic Procedure ..............................................359

Component Inspection .............................................360

DTC P0115 COOLANT TEMP SEN............................361

Component Description ...........................................361

On Board Diagnosis Logic.......................................361

DTC Confirmation Procedure ..................................361

Wiring Diagram ........................................................362

Diagnostic Procedure ..............................................363

Component Inspection .............................................364

DTC P0120 ACCEL POS SENSOR............................365

Component Description ...........................................365

On Board Diagnosis Logic.......................................365

DTC Confirmation Procedure A (For General

Plausibility) ...............................................................365

DTC Confirmation Procedure B (For Accelerator

Sticking) ...................................................................366

Wiring Diagram ........................................................367

Diagnostic Procedure ..............................................368

Component Inspection .............................................371

DTC P0180 FUEL TEMP SENSOR............................372

Component Description ...........................................372

On Board Diagnosis Logic.......................................372

DTC Confirmation Procedure ..................................372

CONTENTS(Cont'd)

EC-4

Page 369 of 1767

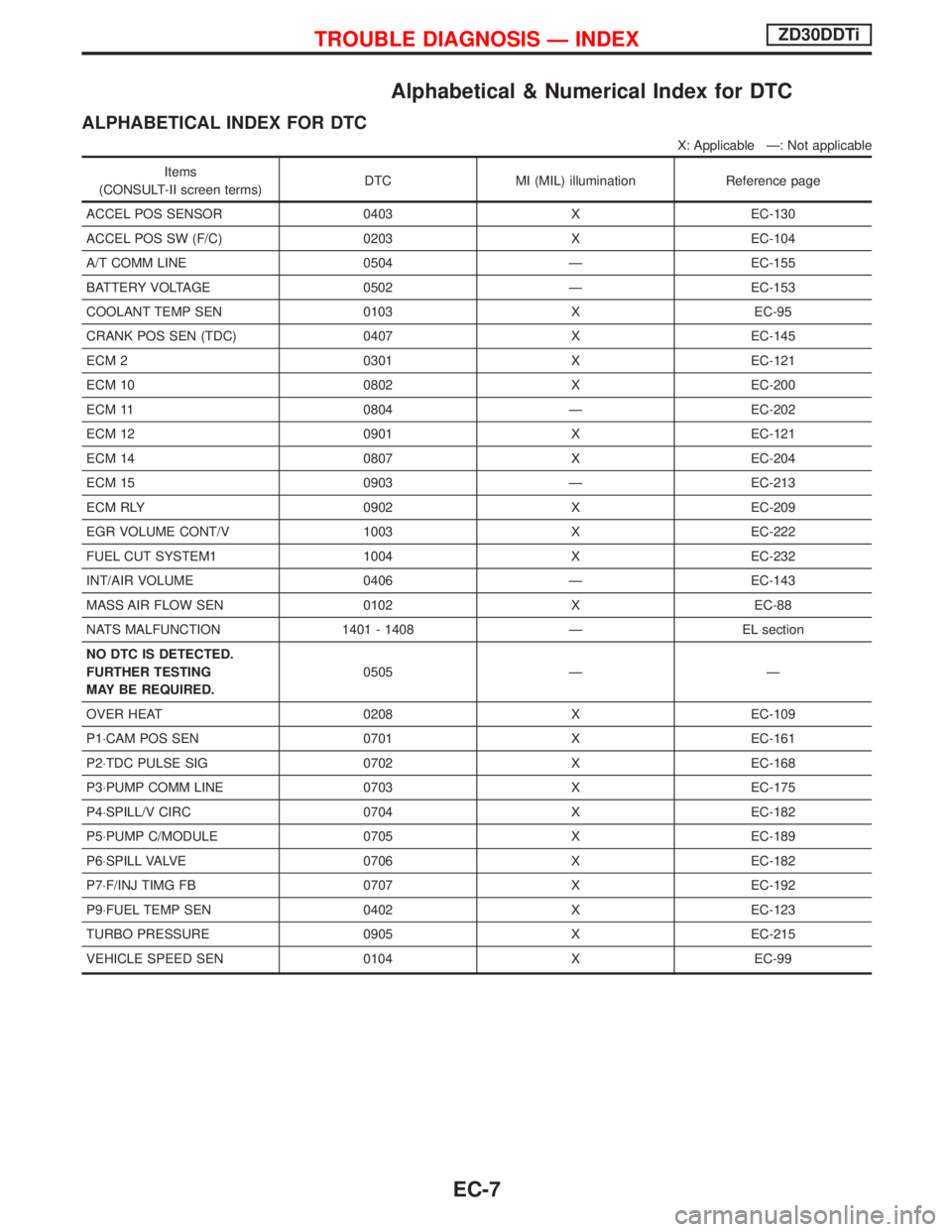

Alphabetical & Numerical Index for DTC

ALPHABETICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC MI (MIL) illumination Reference page

ACCEL POS SENSOR 0403 X EC-130

ACCEL POS SW (F/C) 0203 X EC-104

A/T COMM LINE 0504 Ð EC-155

BATTERY VOLTAGE 0502 Ð EC-153

COOLANT TEMP SEN 0103 X EC-95

CRANK POS SEN (TDC) 0407 X EC-145

ECM 2 0301 X EC-121

ECM 10 0802 X EC-200

ECM 11 0804 Ð EC-202

ECM 12 0901 X EC-121

ECM 14 0807 X EC-204

ECM 15 0903 Ð EC-213

ECM RLY 0902 X EC-209

EGR VOLUME CONT/V 1003 X EC-222

FUEL CUT SYSTEM1 1004 X EC-232

INT/AIR VOLUME 0406 Ð EC-143

MASS AIR FLOW SEN 0102 X EC-88

NATS MALFUNCTION 1401 - 1408 Ð EL section

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.0505 Ð Ð

OVER HEAT 0208 X EC-109

P1×CAM POS SEN 0701 X EC-161

P2×TDC PULSE SIG 0702 X EC-168

P3×PUMP COMM LINE 0703 X EC-175

P4×SPILL/V CIRC 0704 X EC-182

P5×PUMP C/MODULE 0705 X EC-189

P6×SPILL VALVE 0706 X EC-182

P7×F/INJ TIMG FB 0707 X EC-192

P9×FUEL TEMP SEN 0402 X EC-123

TURBO PRESSURE 0905 X EC-215

VEHICLE SPEED SEN 0104 X EC-99

TROUBLE DIAGNOSIS Ð INDEXZD30DDTi

EC-7

Page 370 of 1767

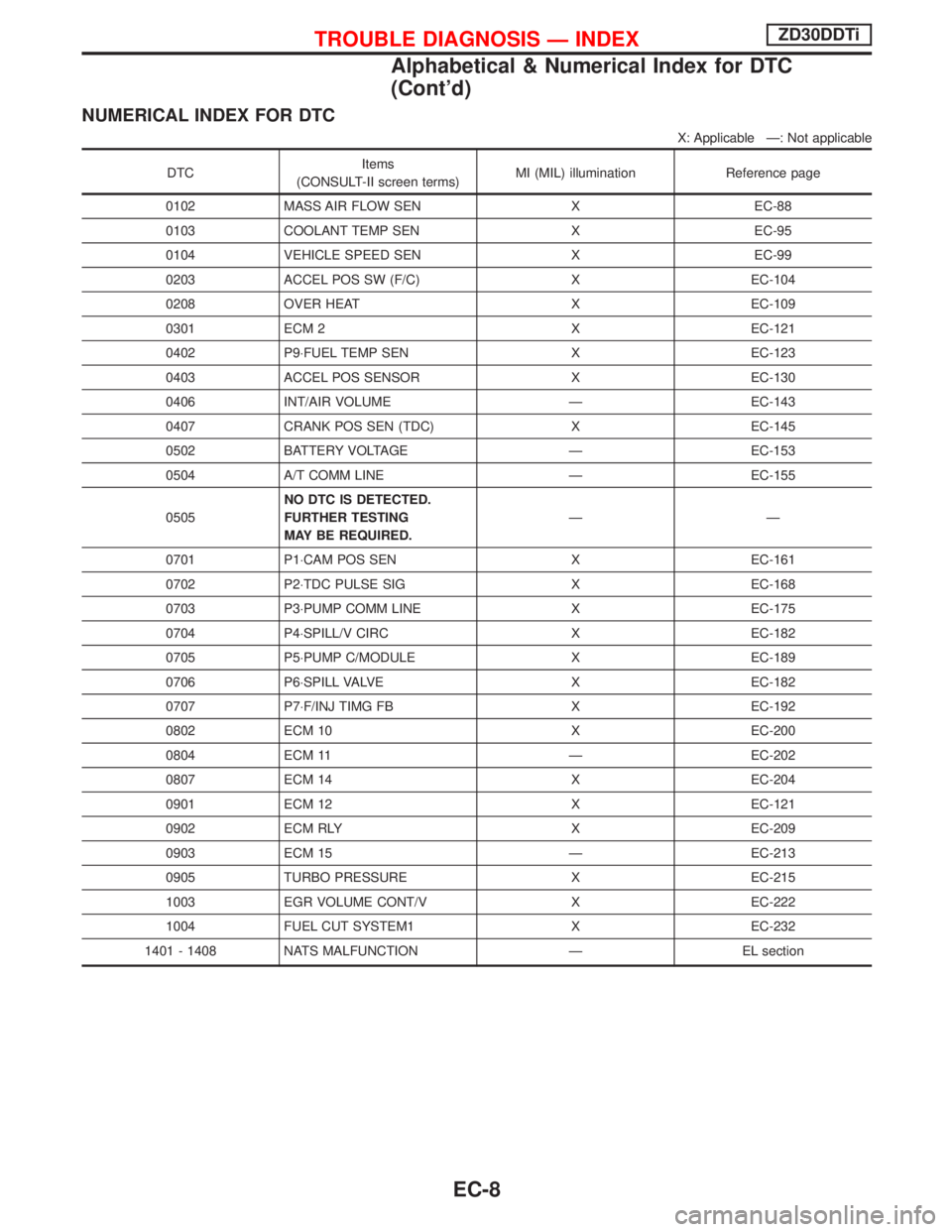

NUMERICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

DTCItems

(CONSULT-II screen terms)MI (MIL) illumination Reference page

0102 MASS AIR FLOW SEN X EC-88

0103 COOLANT TEMP SEN X EC-95

0104 VEHICLE SPEED SEN X EC-99

0203 ACCEL POS SW (F/C) X EC-104

0208 OVER HEAT X EC-109

0301 ECM 2 X EC-121

0402 P9×FUEL TEMP SEN X EC-123

0403 ACCEL POS SENSOR X EC-130

0406 INT/AIR VOLUME Ð EC-143

0407 CRANK POS SEN (TDC) X EC-145

0502 BATTERY VOLTAGE Ð EC-153

0504 A/T COMM LINE Ð EC-155

0505NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.ÐÐ

0701 P1×CAM POS SEN X EC-161

0702 P2×TDC PULSE SIG X EC-168

0703 P3×PUMP COMM LINE X EC-175

0704 P4×SPILL/V CIRC X EC-182

0705 P5×PUMP C/MODULE X EC-189

0706 P6×SPILL VALVE X EC-182

0707 P7×F/INJ TIMG FB X EC-192

0802 ECM 10 X EC-200

0804 ECM 11 Ð EC-202

0807 ECM 14 X EC-204

0901 ECM 12 X EC-121

0902 ECM RLY X EC-209

0903 ECM 15 Ð EC-213

0905 TURBO PRESSURE X EC-215

1003 EGR VOLUME CONT/V X EC-222

1004 FUEL CUT SYSTEM1 X EC-232

1401 - 1408 NATS MALFUNCTION Ð EL section

TROUBLE DIAGNOSIS Ð INDEXZD30DDTi

Alphabetical & Numerical Index for DTC

(Cont'd)

EC-8

Page 381 of 1767

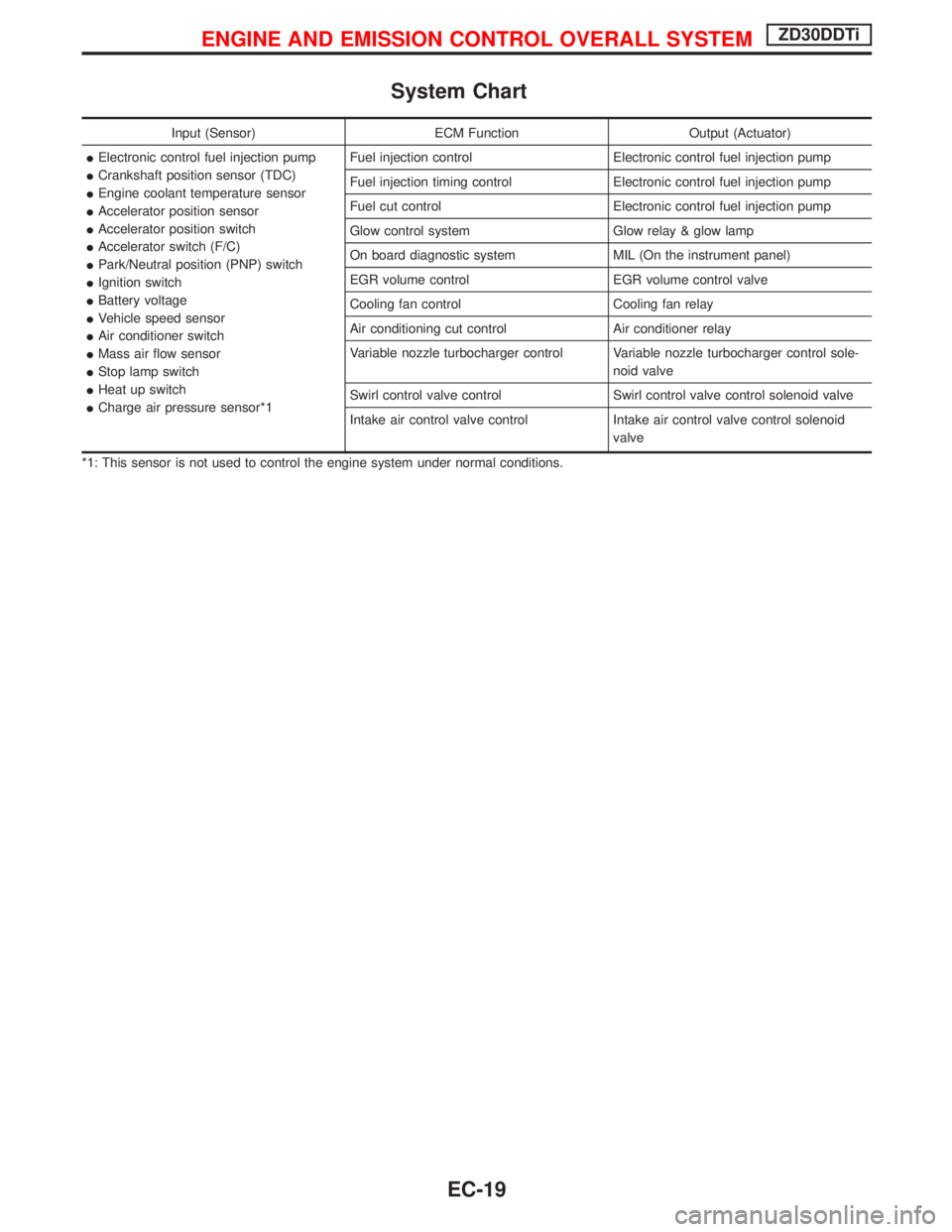

System Chart

Input (Sensor) ECM Function Output (Actuator)

IElectronic control fuel injection pump

ICrankshaft position sensor (TDC)

IEngine coolant temperature sensor

IAccelerator position sensor

IAccelerator position switch

IAccelerator switch (F/C)

IPark/Neutral position (PNP) switch

IIgnition switch

IBattery voltage

IVehicle speed sensor

IAir conditioner switch

IMass air flow sensor

IStop lamp switch

IHeat up switch

ICharge air pressure sensor*1Fuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole-

noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

*1: This sensor is not used to control the engine system under normal conditions.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-19

Page 383 of 1767

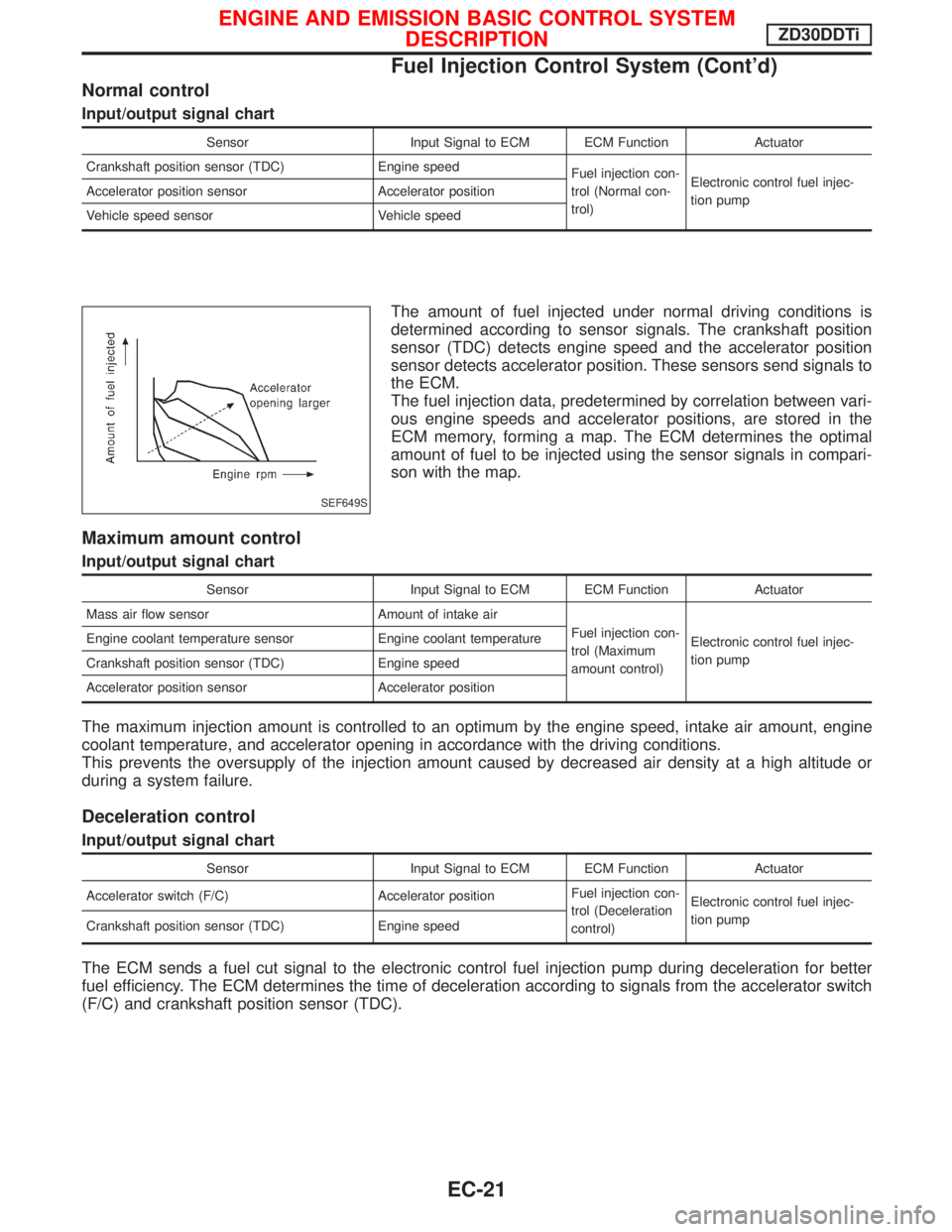

Normal control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Fuel injection con-

trol (Normal con-

trol)Electronic control fuel injec-

tion pump Accelerator position sensor Accelerator position

Vehicle speed sensor Vehicle speed

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals to

the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds and accelerator positions, are stored in the

ECM memory, forming a map. The ECM determines the optimal

amount of fuel to be injected using the sensor signals in compari-

son with the map.

Maximum amount control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Mass air flow sensor Amount of intake air

Fuel injection con-

trol (Maximum

amount control)Electronic control fuel injec-

tion pump Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

Accelerator position sensor Accelerator position

The maximum injection amount is controlled to an optimum by the engine speed, intake air amount, engine

coolant temperature, and accelerator opening in accordance with the driving conditions.

This prevents the oversupply of the injection amount caused by decreased air density at a high altitude or

during a system failure.

Deceleration control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Accelerator switch (F/C) Accelerator positionFuel injection con-

trol (Deceleration

control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC) Engine speed

The ECM sends a fuel cut signal to the electronic control fuel injection pump during deceleration for better

fuel efficiency. The ECM determines the time of deceleration according to signals from the accelerator switch

(F/C) and crankshaft position sensor (TDC).

SEF649S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

Fuel Injection Control System (Cont'd)

EC-21