belt NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 3 of 1767

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

PREPARATION AND PRECAUTIONS............................3

Special Service Tools ..................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............4

Precautions ..................................................................4

Service Notice or Precautions .....................................5

OVERALL SYSTEM........................................................6

A/T Electrical Parts Location .......................................6

Wiring Diagram - A/T -.................................................7

Cross-sectional View ...................................................8

Hydraulic Control Circuits ............................................9

Shift Mechanism ........................................................10

Control System ..........................................................12

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................14

Self-diagnosis ............................................................14

Diagnosis by CONSULT-II .........................................20

TROUBLE DIAGNOSIS - Introduction........................22

Introduction ................................................................22

Diagnostic Worksheet ................................................23

Work Flow ..................................................................26

TROUBLE DIAGNOSIS - Basic Inspection................27

A/T Fluid Check .........................................................27

Stall Test ....................................................................27

Line Pressure Test .....................................................30

Road Test...................................................................32

TROUBLE DIAGNOSIS - General Description...........43

Symptom Chart ..........................................................43

TCM Terminals and Reference Value........................46

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×A/T.........................................................................49

Wiring Diagram - AT - VSSA/T ..................................49

Vehicle Speed Sensor×A/T (Revolution sensor) ........50

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×MTR.......................................................................52

Wiring Diagram - AT - VSSMTR ................................52

Vehicle Speed Sensor×MTR ......................................54TROUBLE DIAGNOSIS FOR THROTTLE POSI

SEN................................................................................56

Wiring Diagram - AT - TPS ........................................56

Throttle (Accelerator) Position Sensor ......................60

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

A.....................................................................................62

Wiring Diagram - AT - SSV/A ....................................62

Shift Solenoid Valve A ...............................................63

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

B.....................................................................................65

Wiring Diagram - AT - SSV/B ....................................65

Shift Solenoid Valve B ...............................................66

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH

S/V..................................................................................68

Wiring Diagram - AT - OVRCSV................................68

Overrun Clutch Solenoid Valve .................................69

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V.....71

Wiring Diagram - AT - TCV........................................71

Torque Converter Clutch Solenoid Valve ..................72

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP

SEN................................................................................75

Wiring Diagram - AT - BA/FTS ..................................75

A/T Fluid Temperature Sensor and TCM Power

Source........................................................................76

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG....79

Wiring Diagram - AT - ENGSS ..................................79

Engine Speed Signal .................................................80

TROUBLE DIAGNOSIS FOR LINE PRESSURE

S/V..................................................................................82

Wiring Diagram - AT - LPSV......................................82

Line Pressure Solenoid Valve ...................................84

TROUBLE DIAGNOSIS FOR NON-DETECTABLE

ITEMS.............................................................................87

Wiring Diagram - AT - PNP/SW.................................87

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches ...................88

DIAGNOSTIC PROCEDURES FOR SYMPTOMS........94

Page 6 of 1767

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL R20 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

IDisassembly should be done in a clean work area.

IUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

IPlace disassembled parts in order for easier and proper assembly.

IAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

IGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

IIt is very important to perform functional tests whenever they are indicated.

IThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

IProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

IExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

PREPARATION AND PRECAUTIONS

AT- 4

Page 203 of 1767

BRAKE SYSTEM

SECTION

BR

CONTENTS

PRECAUTIONS AND PREPARATION............................3

Supplement Restraint System (SRS)²AIR BAG²

and²SEAT BELT PRE-TENSIONER².........................3

Precautions ..................................................................3

Preparation ..................................................................4

CHECK AND ADJUSTMENT..........................................5

Checking Brake Fluid Level.........................................5

Checking Brake Line ...................................................5

Changing Brake Fluid ..................................................5

Brake Burnishing Procedure........................................5

BRAKE HYDRAULIC LINE.............................................6

Bleeding Brake System ...............................................8

Removal .......................................................................9

Inspection.....................................................................9

Installation ....................................................................9

LOAD SENSING VALVE...............................................10

Removal and Installation ...........................................10

Removal ..................................................................... 11

Installation .................................................................. 11

Inspection and Adjustment ........................................12

BRAKE PEDAL AND BRACKET..................................14

Removal and Installation ...........................................14

Inspection...................................................................15

Adjustment .................................................................15

MASTER CYLINDER.....................................................16

Removal .....................................................................16

Installation ..................................................................16

BRAKE BOOSTER........................................................17

Removal and Installation ...........................................17

Inspection...................................................................17

Installation ..................................................................18

VACUUM HOSE.............................................................19

Removal and Installation ...........................................19

Inspection...................................................................21

VACUUM PUMP (TD27Ti engine model)....................23

Removal and Installation ...........................................23

Inspection...................................................................23VACUUM PUMP (ZD30DDTi engine model)...............25

Removal and Installation ...........................................25

FRONT DISC BRAKE...................................................26

Pad Replacement ......................................................26

Removal .....................................................................27

Disassembly...............................................................27

Inspection...................................................................27

Assembly ...................................................................28

Inspection...................................................................28

Installation ..................................................................30

REAR DRUM BRAKE...................................................31

Removal .....................................................................32

Shoe Replacement ....................................................33

Inspection...................................................................33

Installation ..................................................................33

PARKING BRAKE CONTROL......................................35

Removal and Installation ...........................................35

Inspection...................................................................35

Adjustment .................................................................35

ANTI-LOCK BRAKE SYSTEM......................................37

Purpose......................................................................37

Operation ...................................................................37

ABS Hydraulic Circuit ................................................37

System Description ....................................................38

Removal and Installation ...........................................42

TROUBLE DIAGNOSES...............................................47

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................47

Component Parts and Harness Connector

Location .....................................................................48

Circuit Diagram for Quick Pinpoint Check.................49

Wiring Diagram - ABS - .............................................50

CONSULT-II ...............................................................58

CONSULT-II Inspection Procedure............................59

Preliminary Check......................................................65

Ground Circuit Check ................................................66

Diagnostic Procedure 1 (Not self-diagnostic item) ....67

Page 205 of 1767

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

ITo clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

INever use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

IUse flare nut wrench when removing and installing brake

tubes.

IAlways torque brake lines when installing.

IBurnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

IClean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

IAvoid prolonged and repeated skin contact with brake

fluid.

IWear protective clothing, including impervious gloves.

IWhere there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

Page 225 of 1767

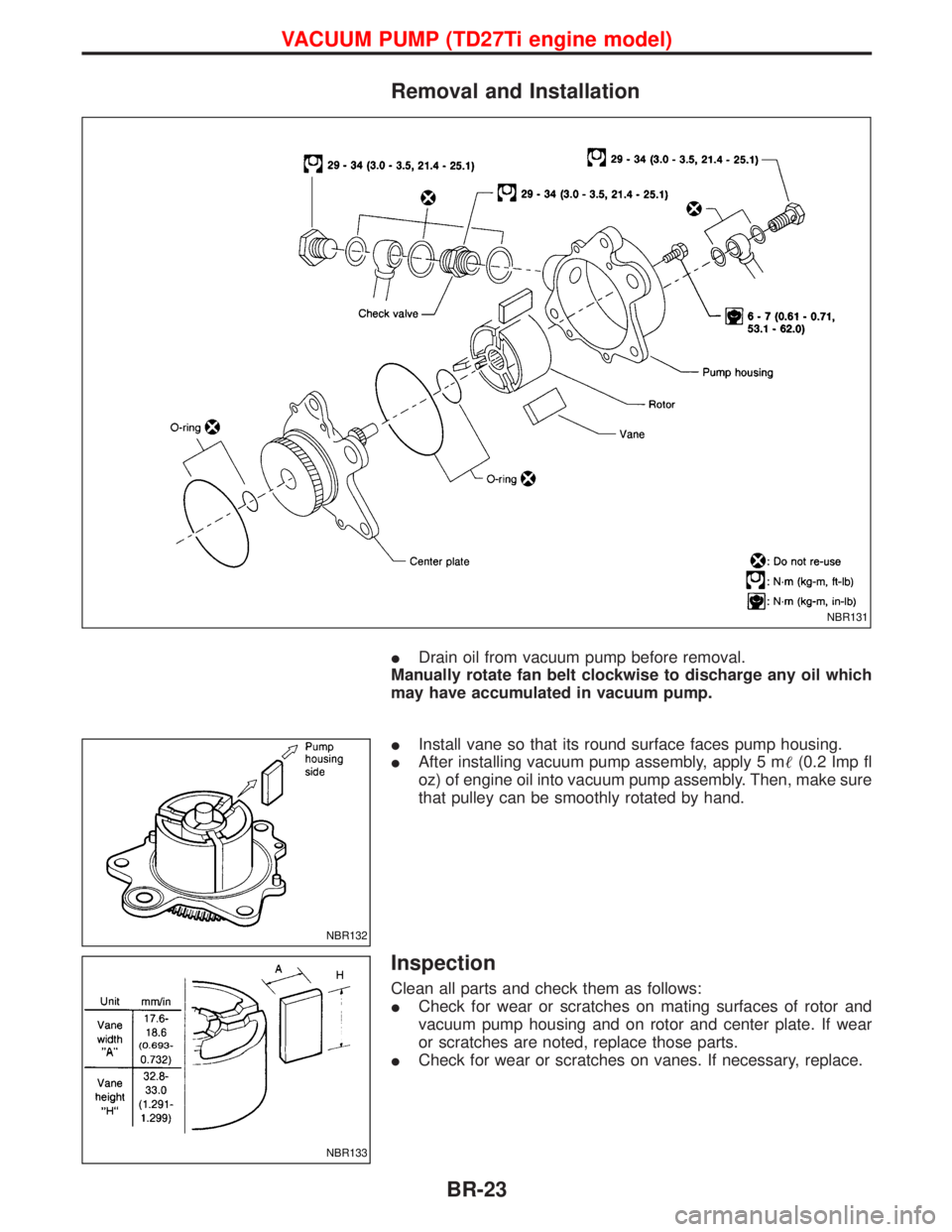

Removal and Installation

IDrain oil from vacuum pump before removal.

Manually rotate fan belt clockwise to discharge any oil which

may have accumulated in vacuum pump.

IInstall vane so that its round surface faces pump housing.

IAfter installing vacuum pump assembly, apply 5 m(0.2 Imp fl

oz) of engine oil into vacuum pump assembly. Then, make sure

that pulley can be smoothly rotated by hand.

Inspection

Clean all parts and check them as follows:

ICheck for wear or scratches on mating surfaces of rotor and

vacuum pump housing and on rotor and center plate. If wear

or scratches are noted, replace those parts.

ICheck for wear or scratches on vanes. If necessary, replace.

NBR131

NBR132

NBR133

VACUUM PUMP (TD27Ti engine model)

BR-23

Page 289 of 1767

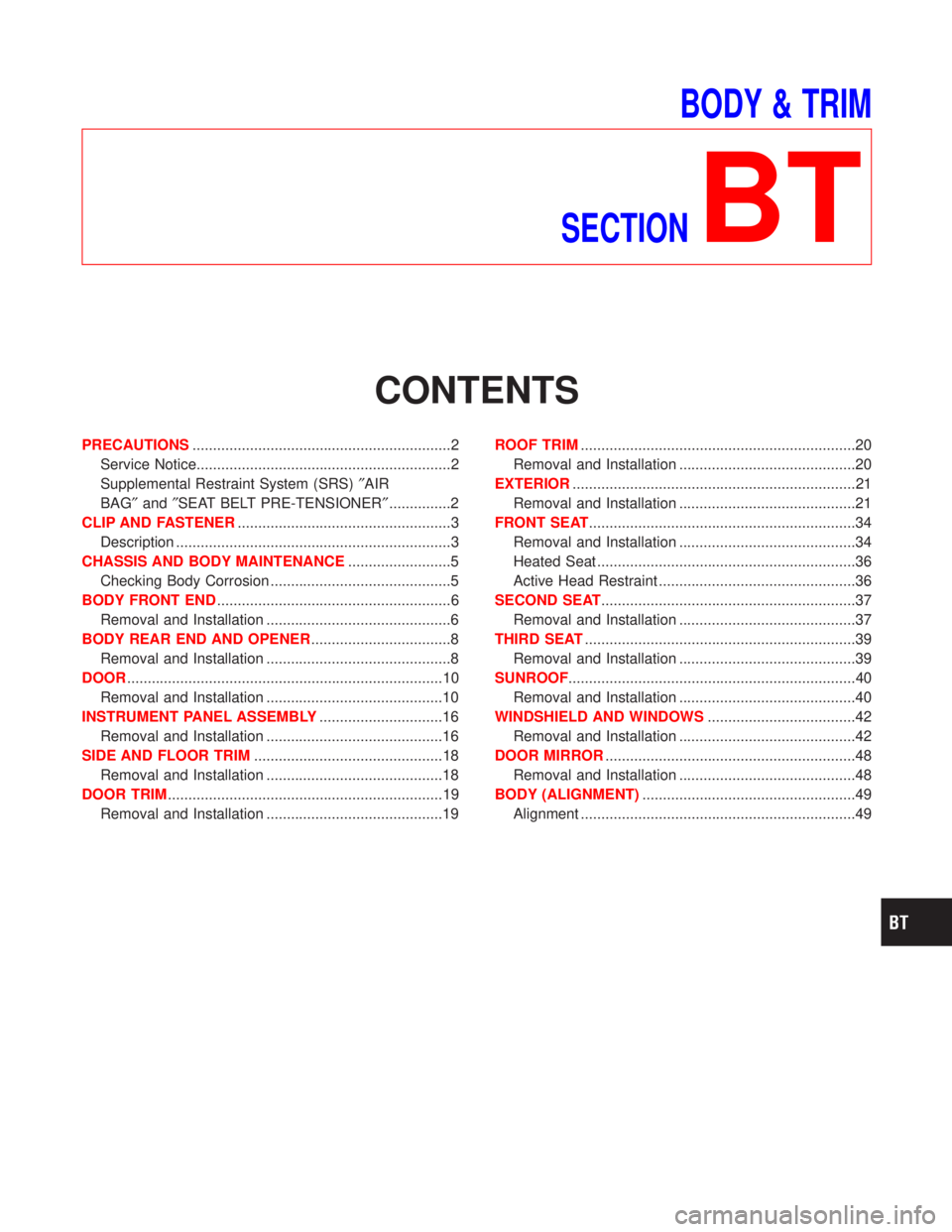

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS...............................................................2

Service Notice..............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

CLIP AND FASTENER....................................................3

Description ...................................................................3

CHASSIS AND BODY MAINTENANCE.........................5

Checking Body Corrosion ............................................5

BODY FRONT END.........................................................6

Removal and Installation .............................................6

BODY REAR END AND OPENER..................................8

Removal and Installation .............................................8

DOOR.............................................................................10

Removal and Installation ...........................................10

INSTRUMENT PANEL ASSEMBLY..............................16

Removal and Installation ...........................................16

SIDE AND FLOOR TRIM..............................................18

Removal and Installation ...........................................18

DOOR TRIM...................................................................19

Removal and Installation ...........................................19ROOF TRIM...................................................................20

Removal and Installation ...........................................20

EXTERIOR.....................................................................21

Removal and Installation ...........................................21

FRONT SEAT.................................................................34

Removal and Installation ...........................................34

Heated Seat ...............................................................36

Active Head Restraint ................................................36

SECOND SEAT..............................................................37

Removal and Installation ...........................................37

THIRD SEAT..................................................................39

Removal and Installation ...........................................39

SUNROOF......................................................................40

Removal and Installation ...........................................40

WINDSHIELD AND WINDOWS....................................42

Removal and Installation ...........................................42

DOOR MIRROR.............................................................48

Removal and Installation ...........................................48

BODY (ALIGNMENT)....................................................49

Alignment ...................................................................49

Page 290 of 1767

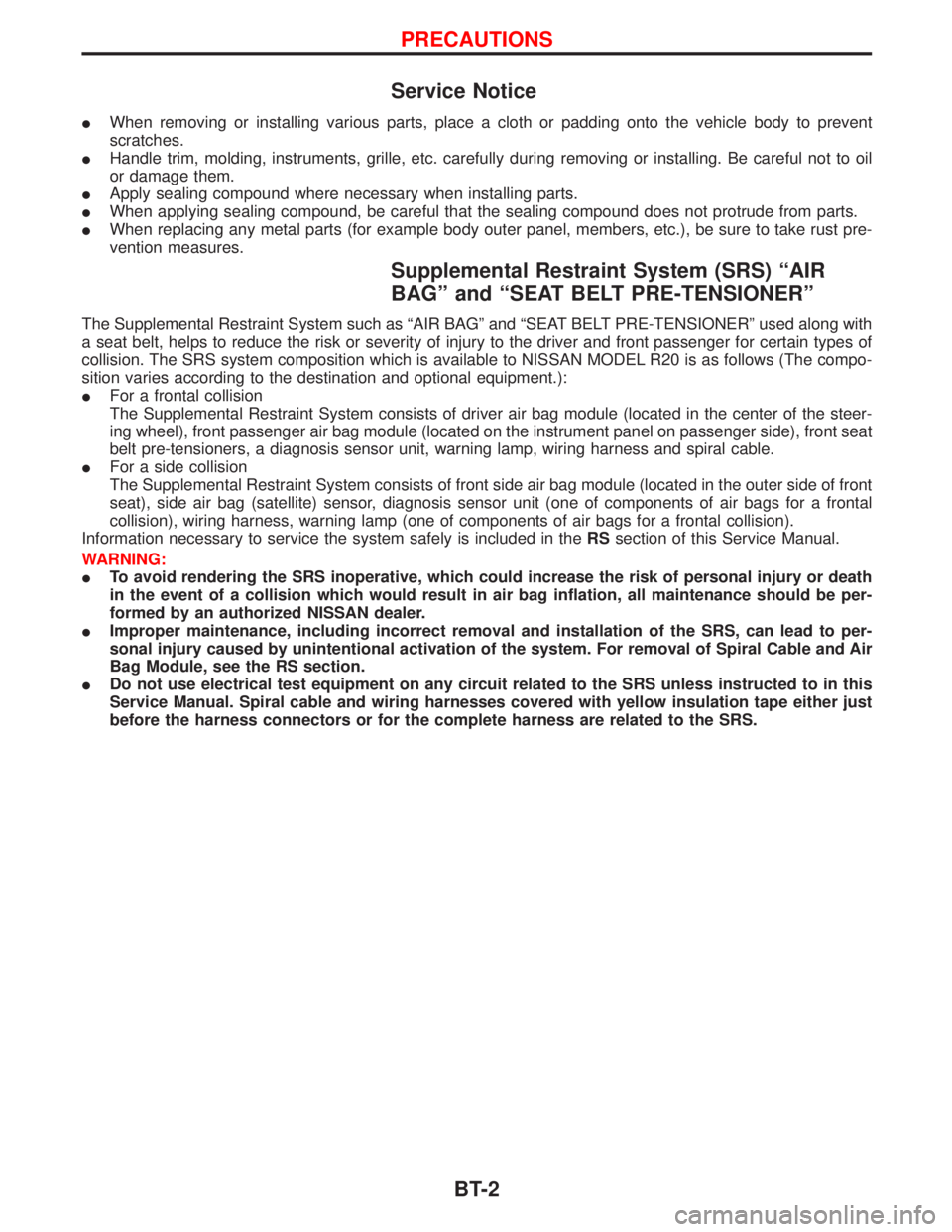

Service Notice

IWhen removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

IHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil

or damage them.

IApply sealing compound where necessary when installing parts.

IWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

IWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL R20 is as follows (The compo-

sition varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRSsection of this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

BT-2

Page 390 of 1767

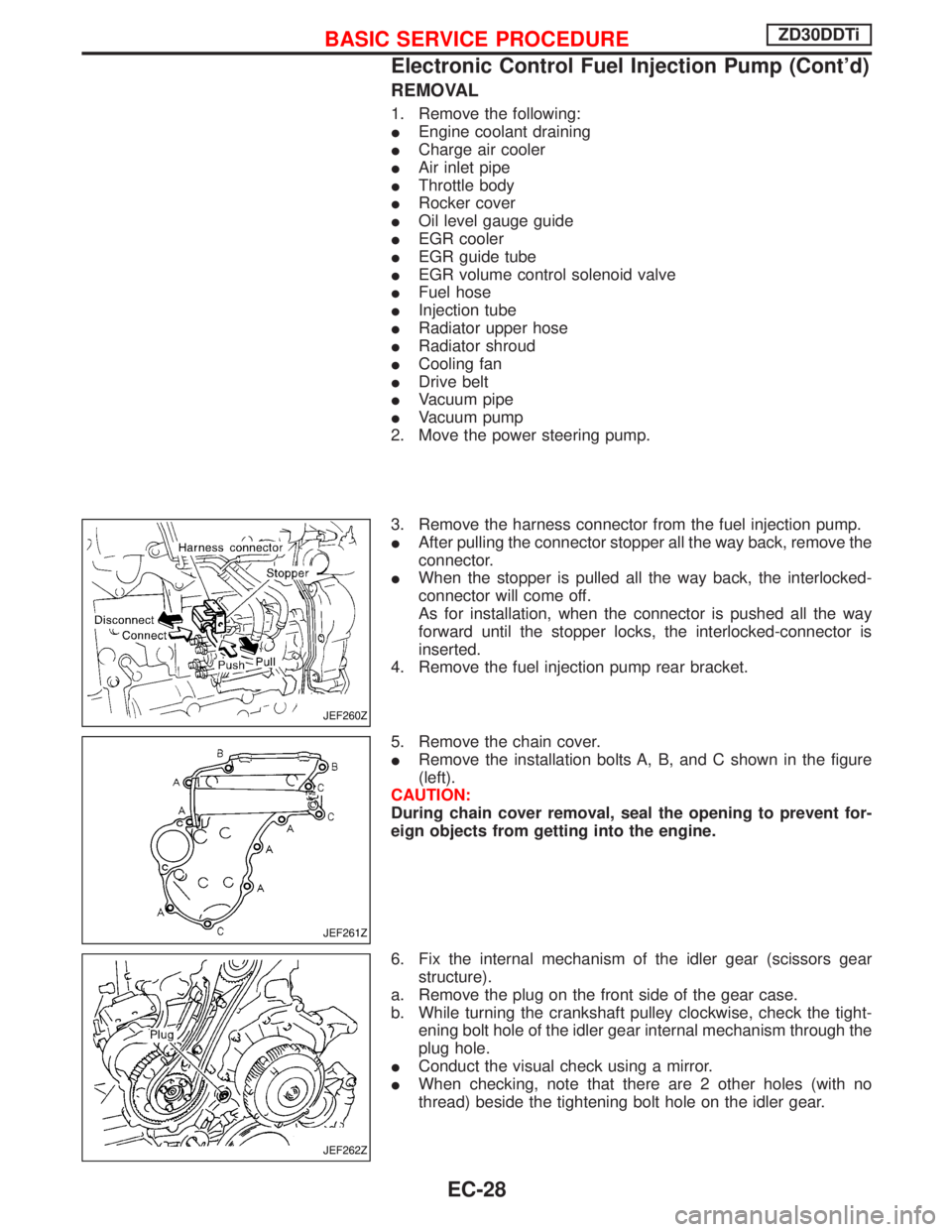

REMOVAL

1. Remove the following:

IEngine coolant draining

ICharge air cooler

IAir inlet pipe

IThrottle body

IRocker cover

IOil level gauge guide

IEGR cooler

IEGR guide tube

IEGR volume control solenoid valve

IFuel hose

IInjection tube

IRadiator upper hose

IRadiator shroud

ICooling fan

IDrive belt

IVacuum pipe

IVacuum pump

2. Move the power steering pump.

3. Remove the harness connector from the fuel injection pump.

IAfter pulling the connector stopper all the way back, remove the

connector.

IWhen the stopper is pulled all the way back, the interlocked-

connector will come off.

As for installation, when the connector is pushed all the way

forward until the stopper locks, the interlocked-connector is

inserted.

4. Remove the fuel injection pump rear bracket.

5. Remove the chain cover.

IRemove the installation bolts A, B, and C shown in the figure

(left).

CAUTION:

During chain cover removal, seal the opening to prevent for-

eign objects from getting into the engine.

6. Fix the internal mechanism of the idler gear (scissors gear

structure).

a. Remove the plug on the front side of the gear case.

b. While turning the crankshaft pulley clockwise, check the tight-

ening bolt hole of the idler gear internal mechanism through the

plug hole.

IConduct the visual check using a mirror.

IWhen checking, note that there are 2 other holes (with no

thread) beside the tightening bolt hole on the idler gear.

JEF260Z

JEF261Z

JEF262Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-28

Page 472 of 1767

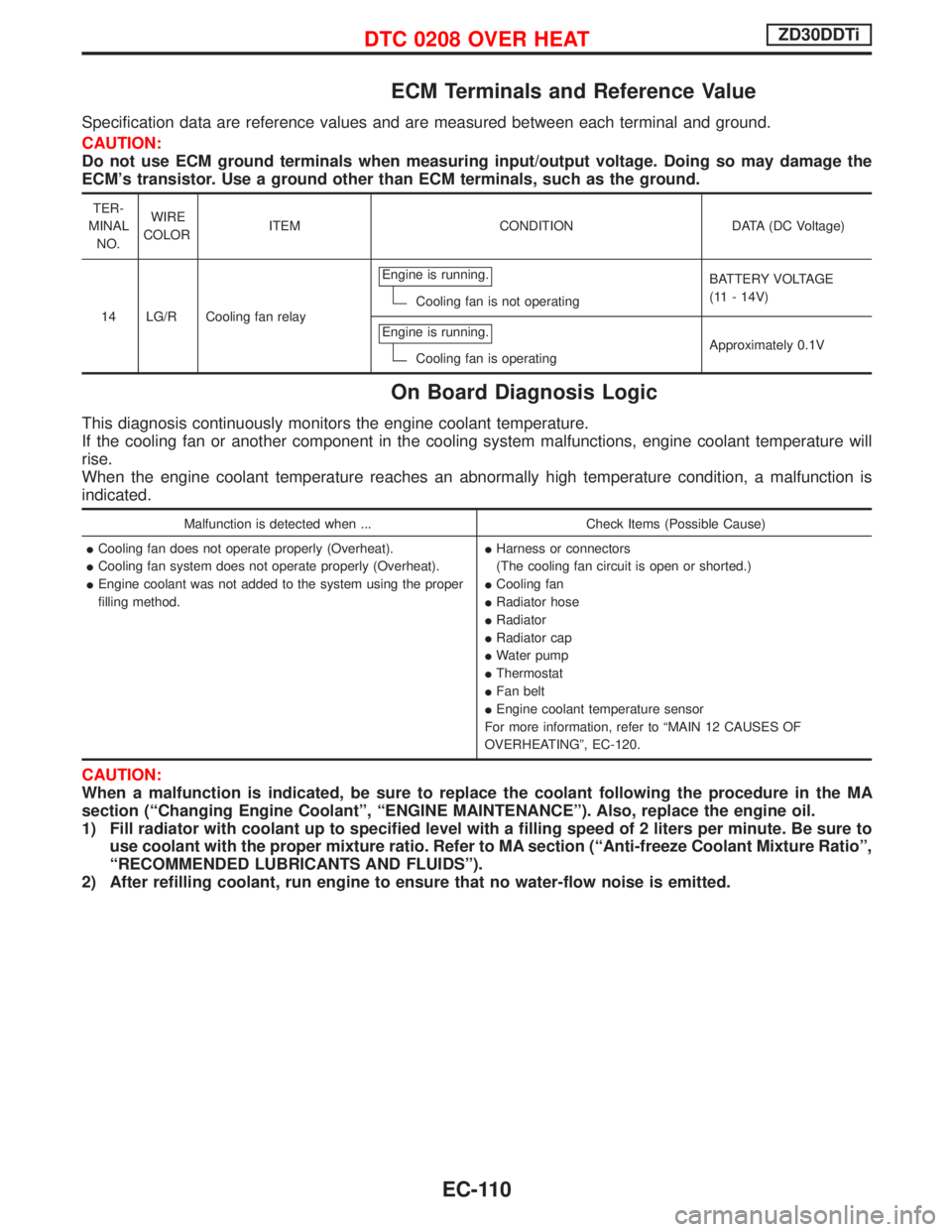

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 LG/R Cooling fan relayEngine is running.

Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operatingApproximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ... Check Items (Possible Cause)

ICooling fan does not operate properly (Overheat).

ICooling fan system does not operate properly (Overheat).

IEngine coolant was not added to the system using the proper

filling method.IHarness or connectors

(The cooling fan circuit is open or shorted.)

ICooling fan

IRadiator hose

IRadiator

IRadiator cap

IWater pump

IThermostat

IFan belt

IEngine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-120.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-110

Page 1117 of 1767

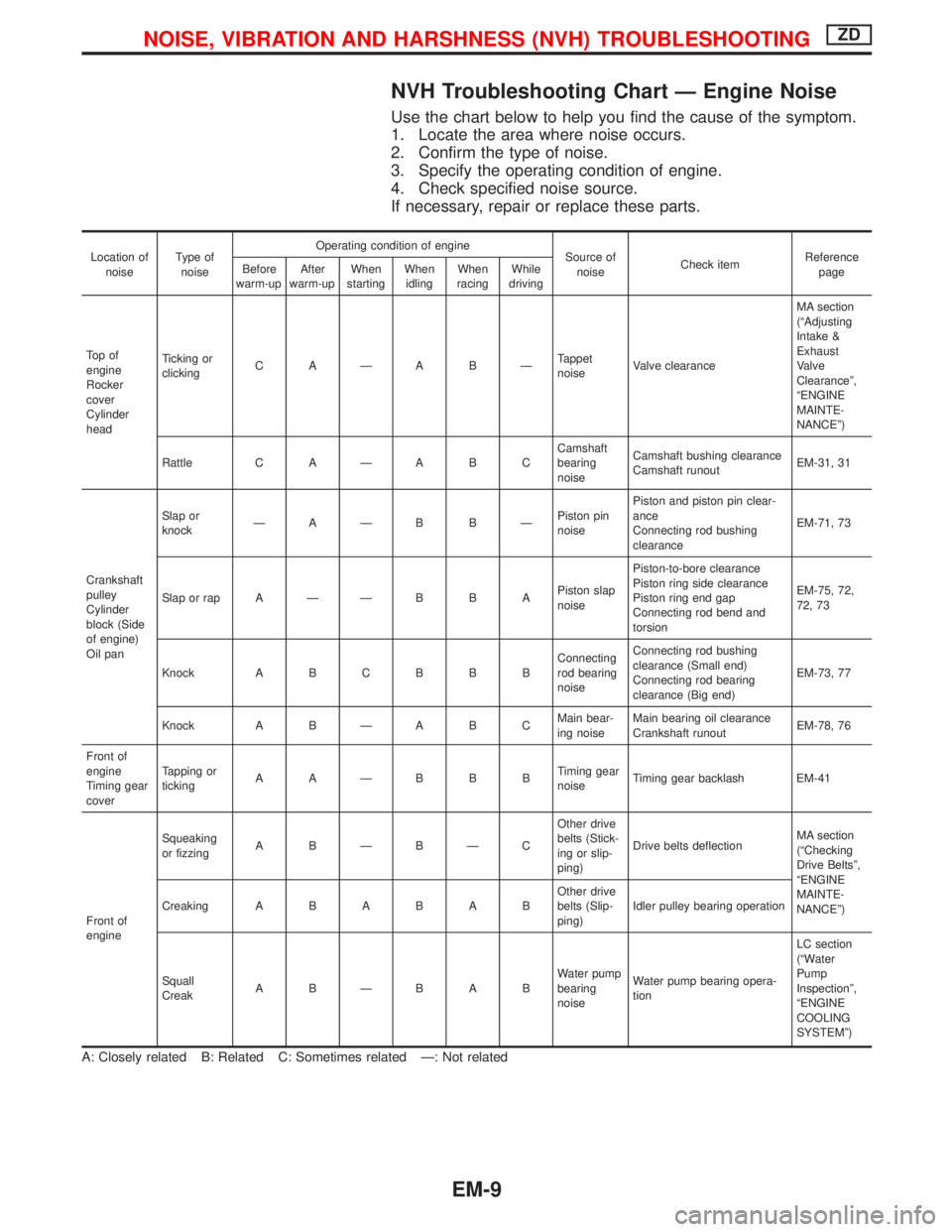

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingC AÐA BÐTappet

noiseValve clearanceMA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft bushing clearance

Camshaft runoutEM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-71, 73

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-75, 72,

72, 73

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-73, 77

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-78, 76

Front of

engine

Timing gear

coverTapping or

tickingAAÐBBBTiming gear

noiseTiming gear backlash EM-41

Front of

engineSqueaking

or fizzingA BÐBÐCOther drive

belts (Stick-

ing or slip-

ping)Drive belts deflectionMA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº) CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

bearing

noiseWater pump bearing opera-

tionLC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGZD

EM-9