check oil NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 5 of 1767

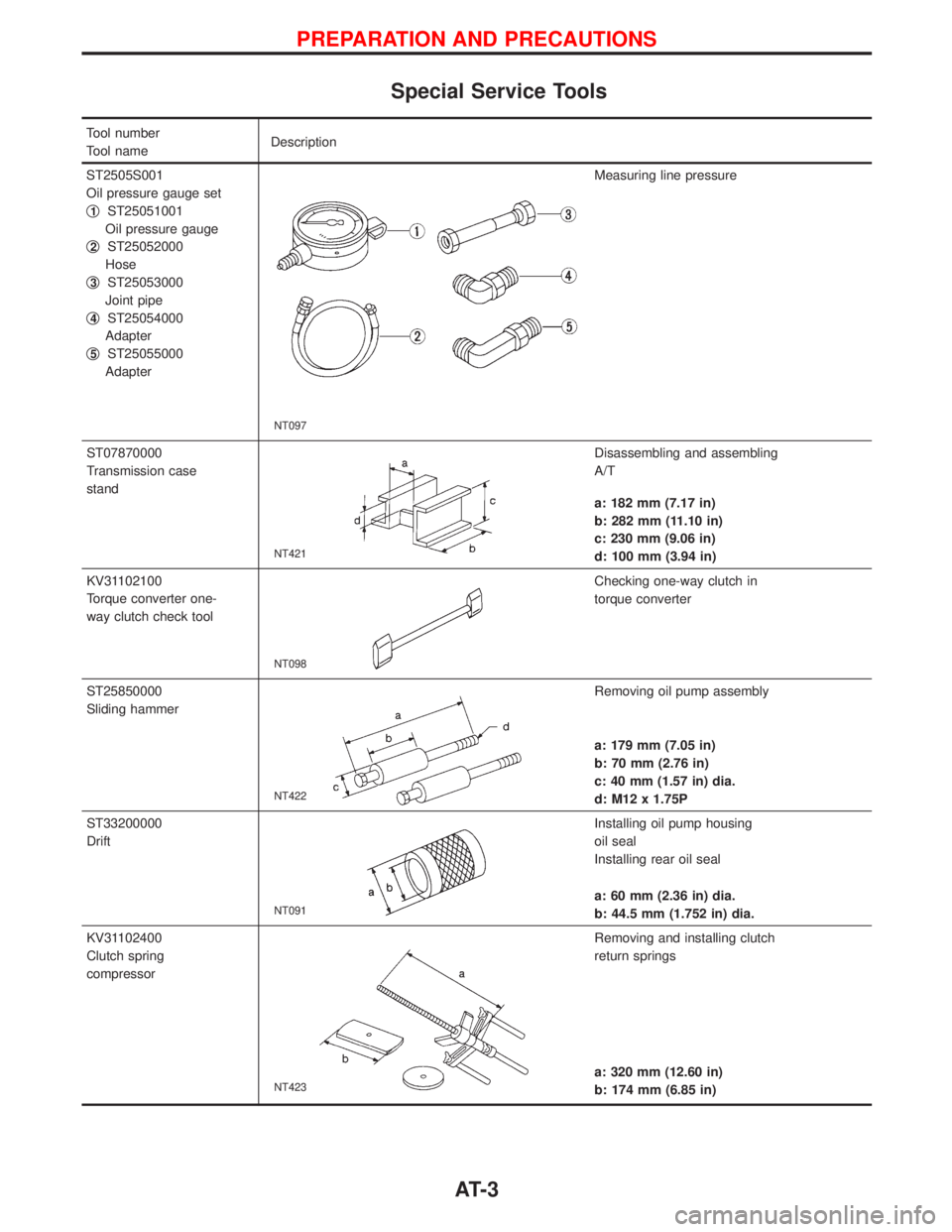

Special Service Tools

Tool number

Tool nameDescription

ST2505S001

Oil pressure gauge set

q

1ST25051001

Oil pressure gauge

q

2ST25052000

Hose

q

3ST25053000

Joint pipe

q

4ST25054000

Adapter

q

5ST25055000

Adapter

NT097

Measuring line pressure

ST07870000

Transmission case

stand

NT421

Disassembling and assembling

A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in

torque converter

ST25850000

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

ST33200000

Drift

NT091

Installing oil pump housing

oil seal

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

KV31102400

Clutch spring

compressor

NT423

Removing and installing clutch

return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

PREPARATION AND PRECAUTIONS

AT- 3

Page 29 of 1767

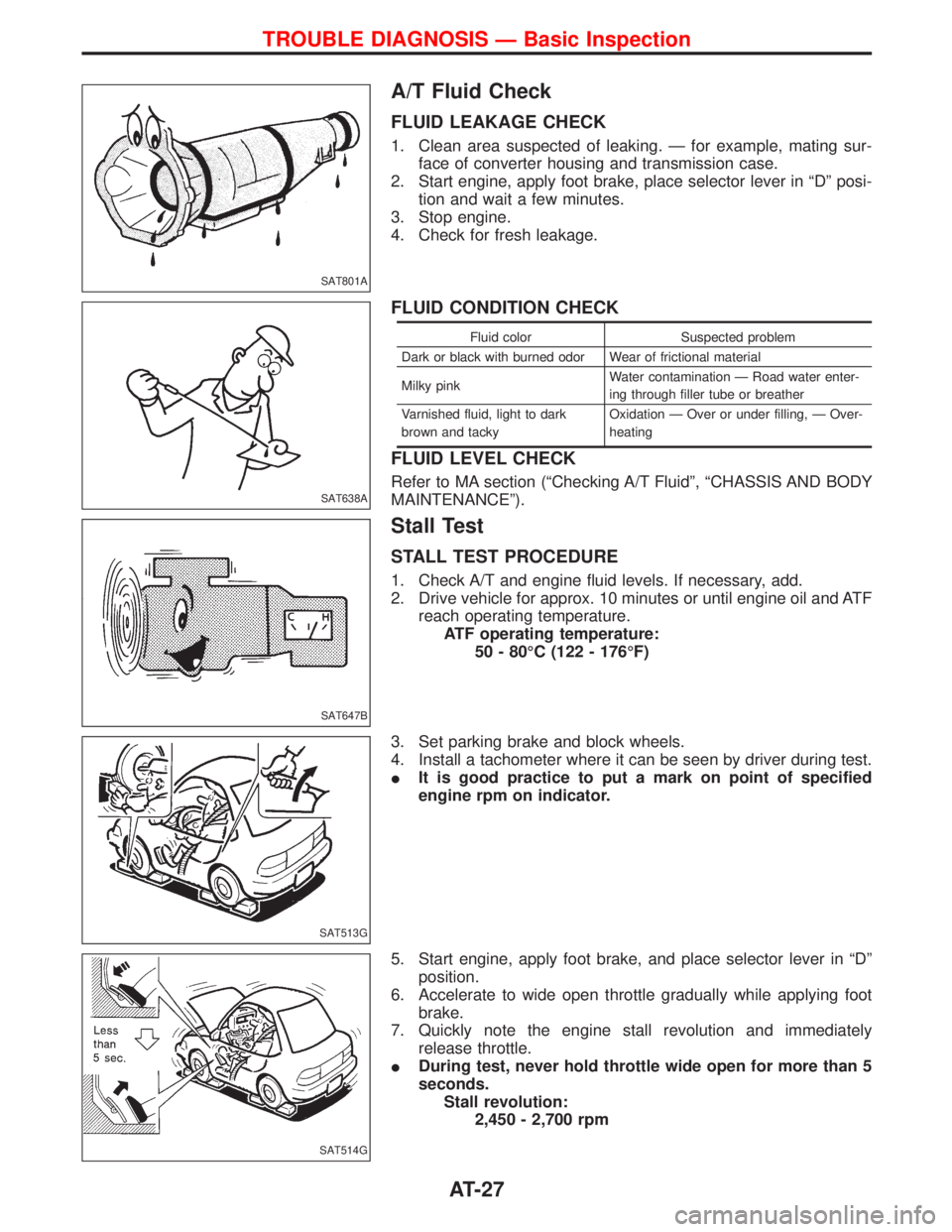

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water enter-

ing through filler tube or breather

Varnished fluid, light to dark

brown and tackyOxidation Ð Over or under filling, Ð Over-

heating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND BODY

MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

IIt is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

IDuring test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

2,450 - 2,700 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-27

Page 32 of 1767

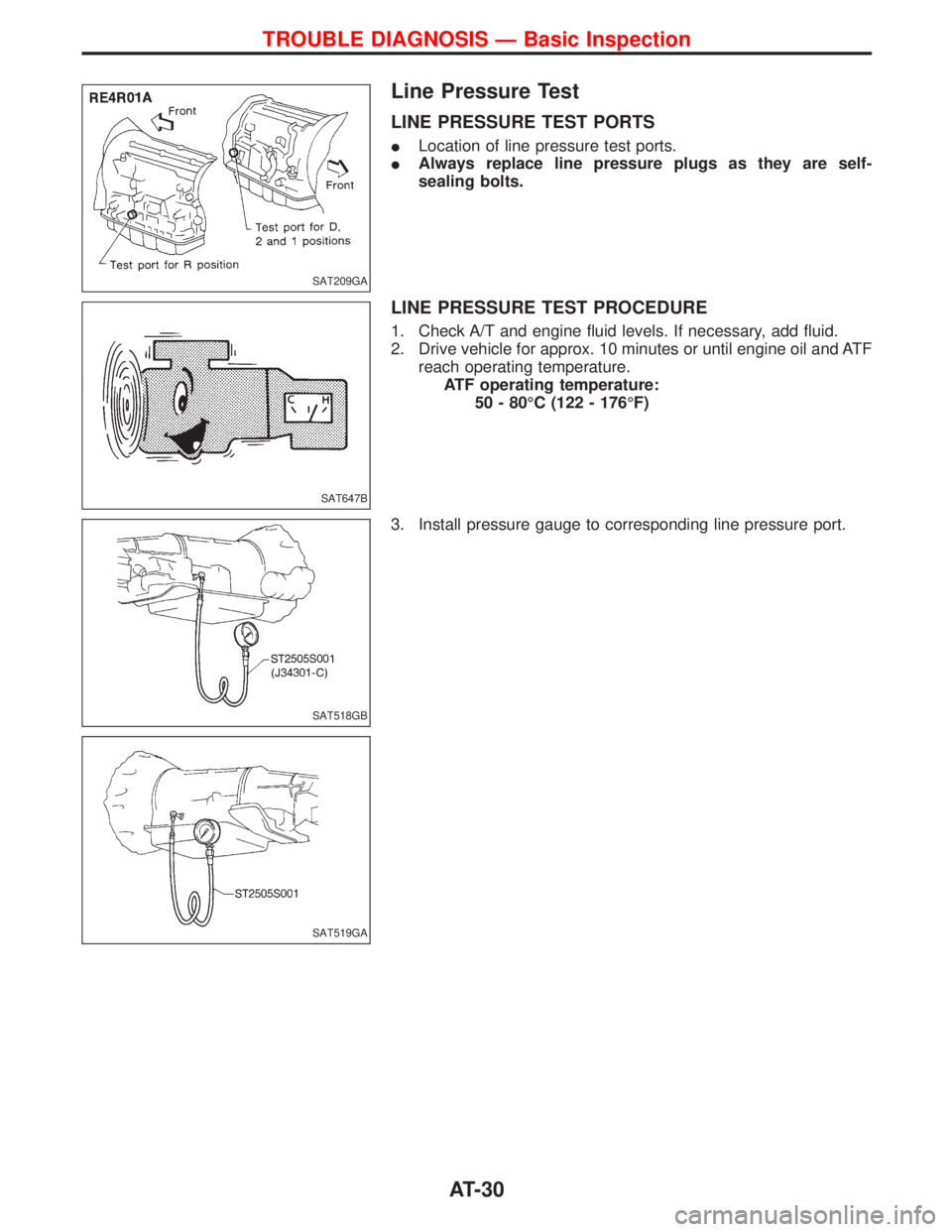

Line Pressure Test

LINE PRESSURE TEST PORTS

ILocation of line pressure test ports.

IAlways replace line pressure plugs as they are self-

sealing bolts.

LINE PRESSURE TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add fluid.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Install pressure gauge to corresponding line pressure port.

SAT209GA

SAT647B

SAT518GB

SAT519GA

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-30

Page 75 of 1767

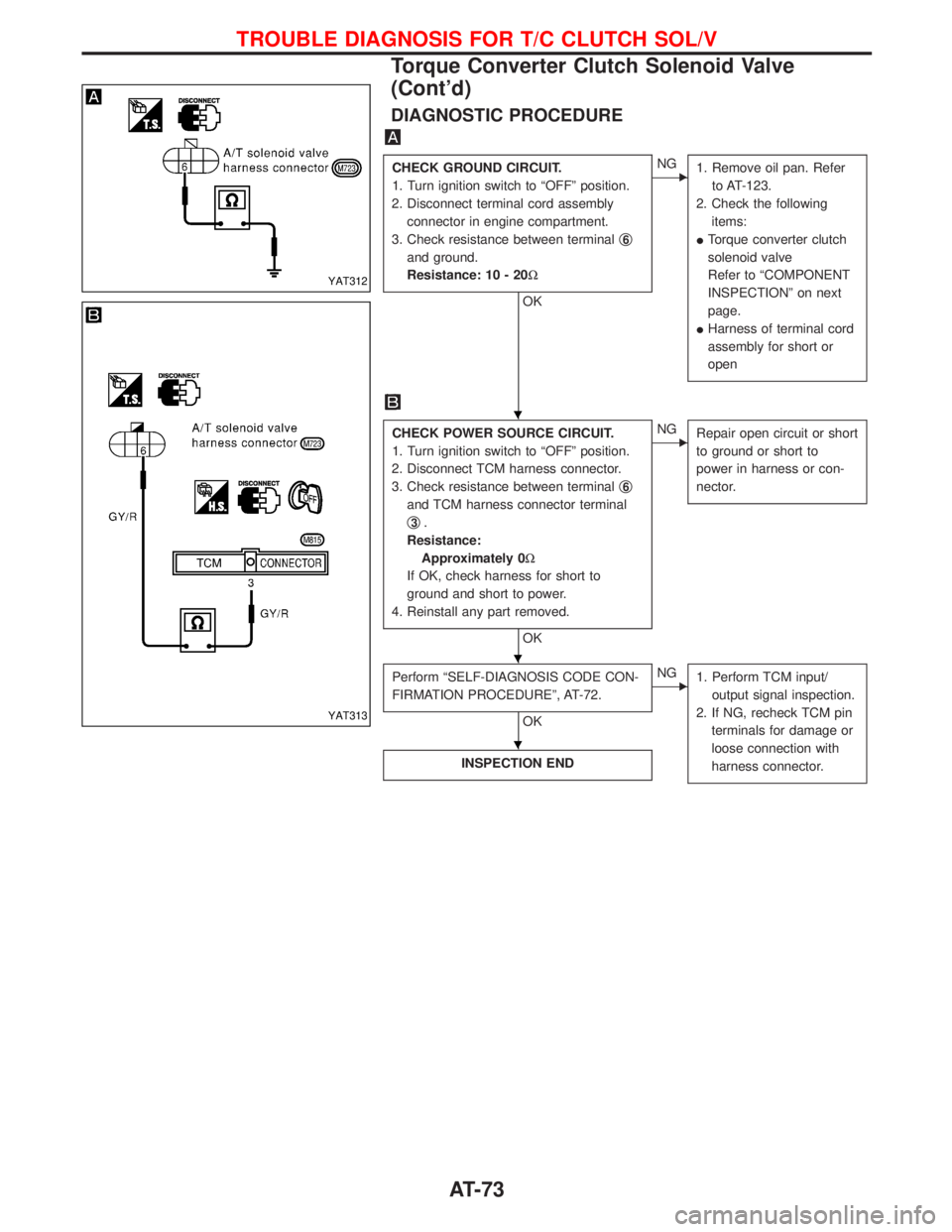

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalq

6

and ground.

Resistance: 10 - 20W

OK

ENG

1. Remove oil pan. Refer

to AT-123.

2. Check the following

items:

ITorque converter clutch

solenoid valve

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

6

and TCM harness connector terminal

q

3.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-72.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT312

YAT313

H

H

H

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-73

Page 79 of 1767

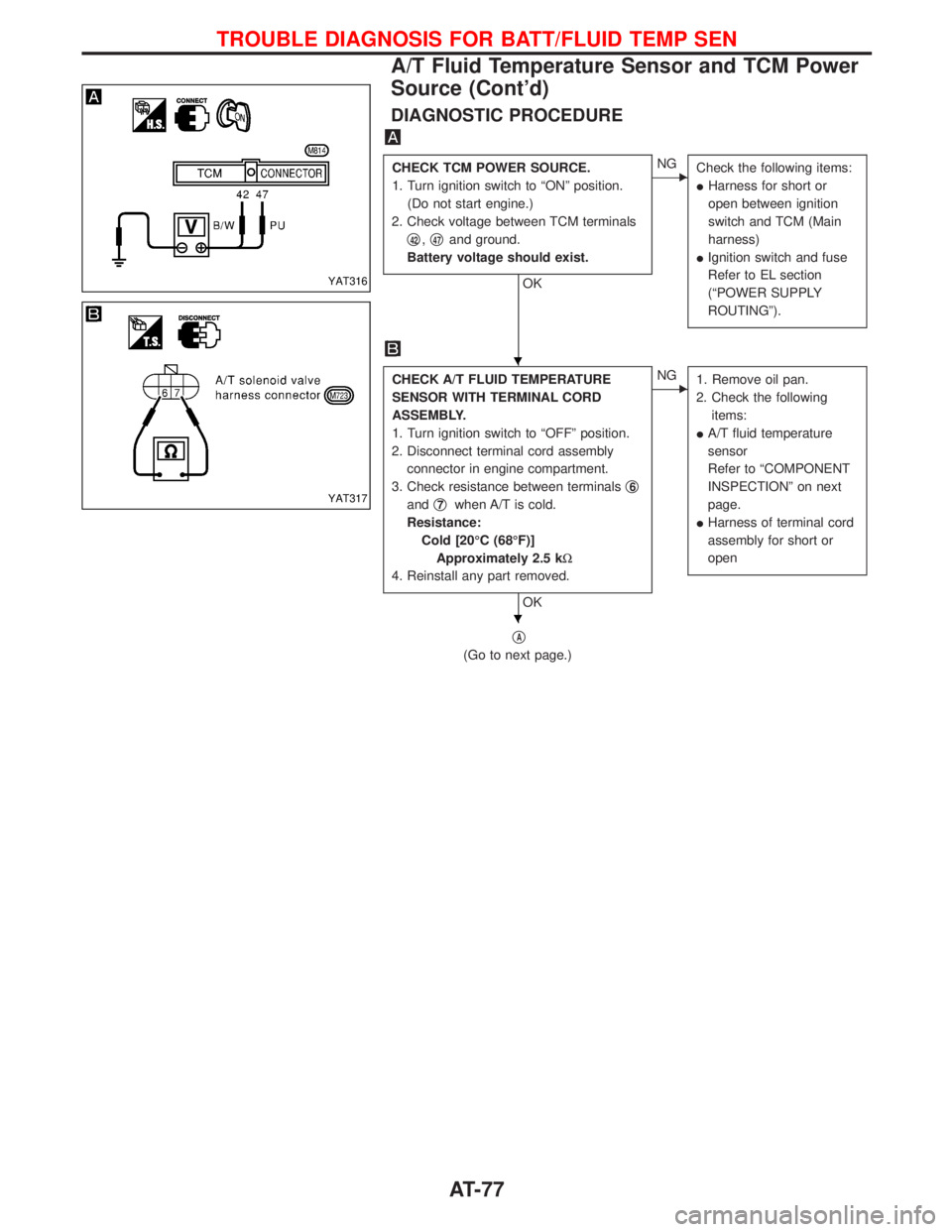

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

42,q47and ground.

Battery voltage should exist.

OK

ENG

Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

IIgnition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalsq

6

andq7when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

ENG

1. Remove oil pan.

2. Check the following

items:

IA/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness of terminal cord

assembly for short or

open

qA

(Go to next page.)

YAT316

YAT317

H

H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM Power

Source (Cont'd)

AT-77

Page 86 of 1767

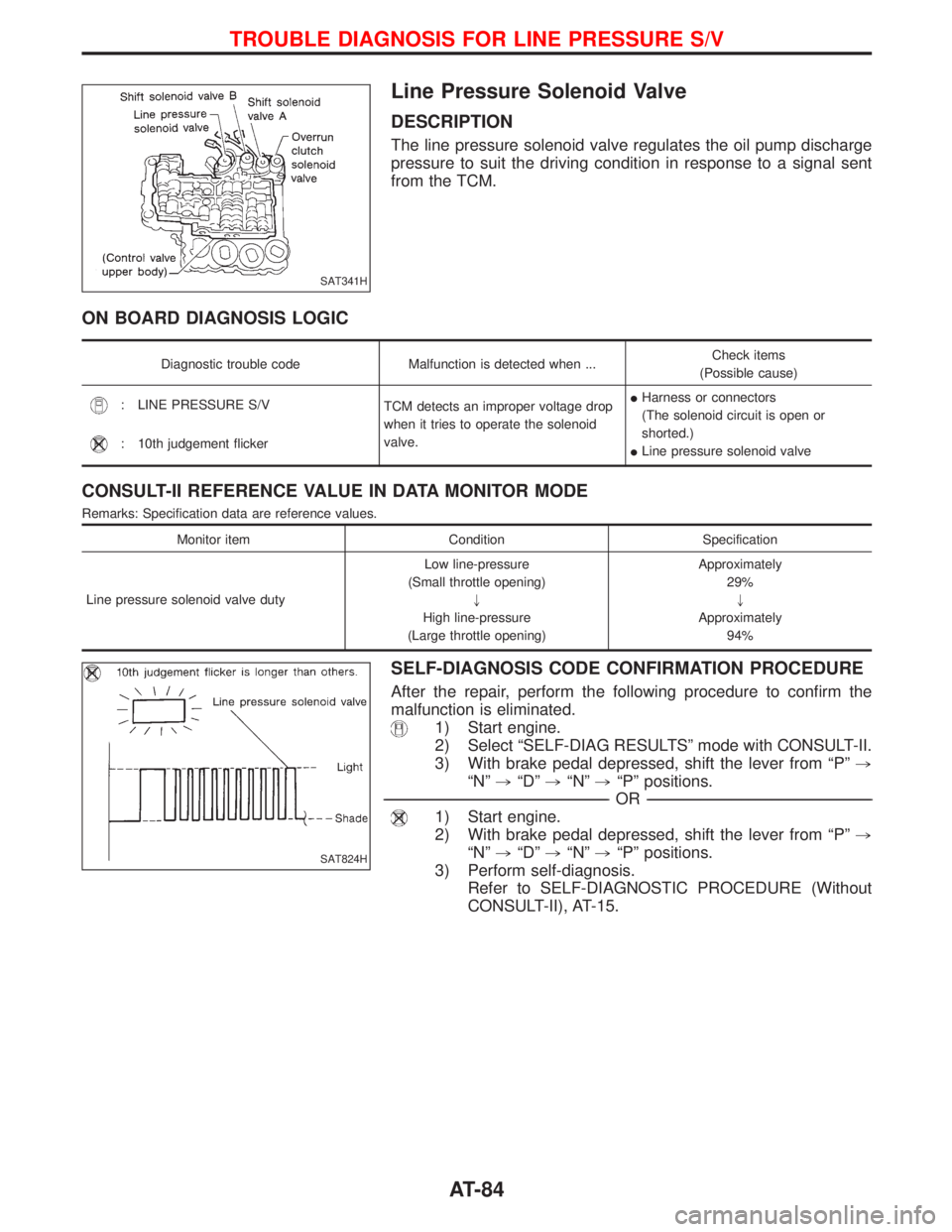

Line Pressure Solenoid Valve

DESCRIPTION

The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: LINE PRESSURE S/V

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or

shorted.)

ILine pressure solenoid valve

: 10th judgement flicker

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutyLow line-pressure

(Small throttle opening)

"

High line-pressure

(Large throttle opening)Approximately

29%

"

Approximately

94%

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

3) With brake pedal depressed, shift the lever from ªPº,

ªNº,ªDº,ªNº,ªPº positions.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) With brake pedal depressed, shift the lever from ªPº,

ªNº,ªDº,ªNº,ªPº positions.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-15.

SAT341H

SAT824H

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

AT-84

Page 100 of 1767

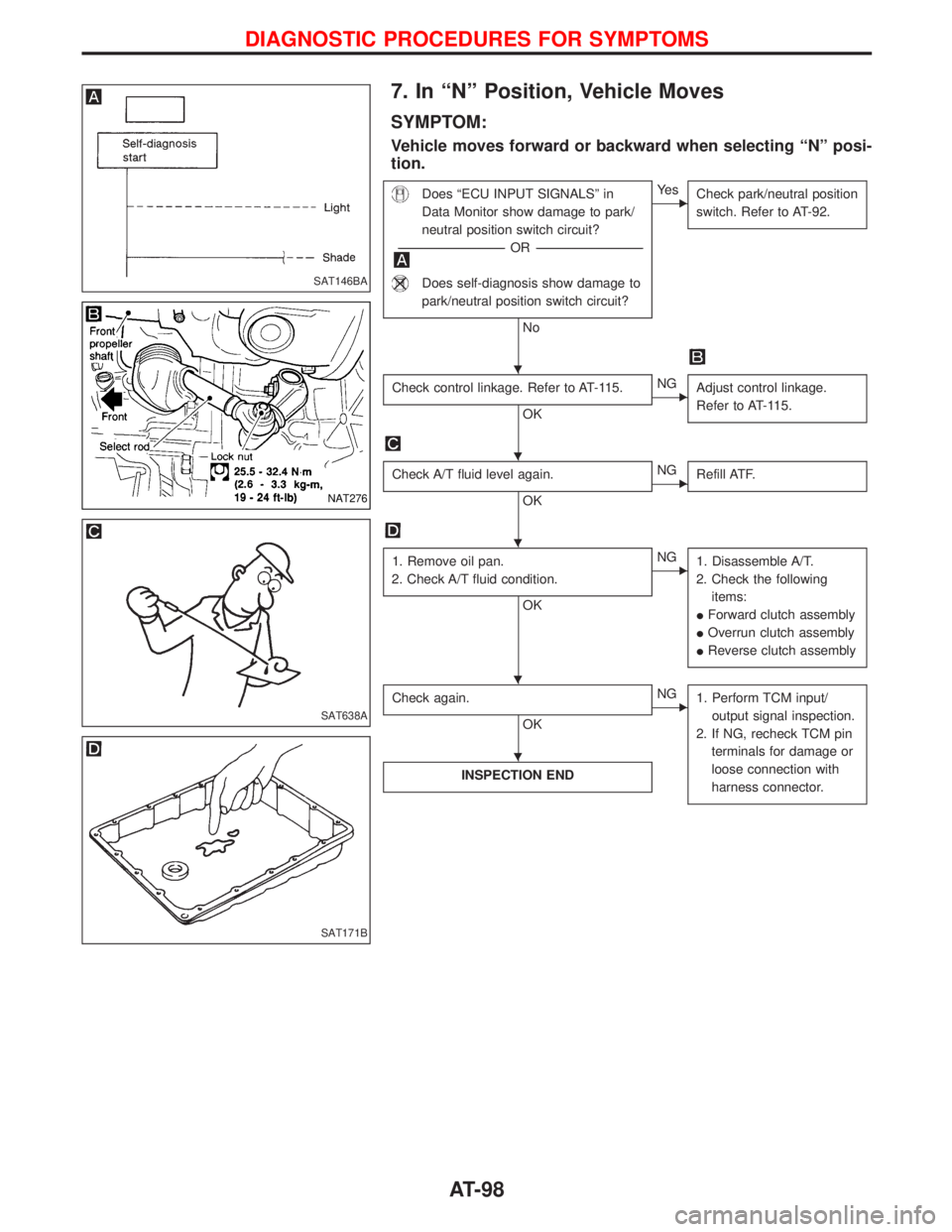

7. In ªNº Position, Vehicle Moves

SYMPTOM:

Vehicle moves forward or backward when selecting ªNº posi-

tion.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check control linkage. Refer to AT-115.

OK

ENG

Adjust control linkage.

Refer to AT-115.

Check A/T fluid level again.

OK

ENG

Refill ATF.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Disassemble A/T.

2. Check the following

items:

IForward clutch assembly

IOverrun clutch assembly

IReverse clutch assembly

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT276

SAT638A

SAT171B

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-98

Page 102 of 1767

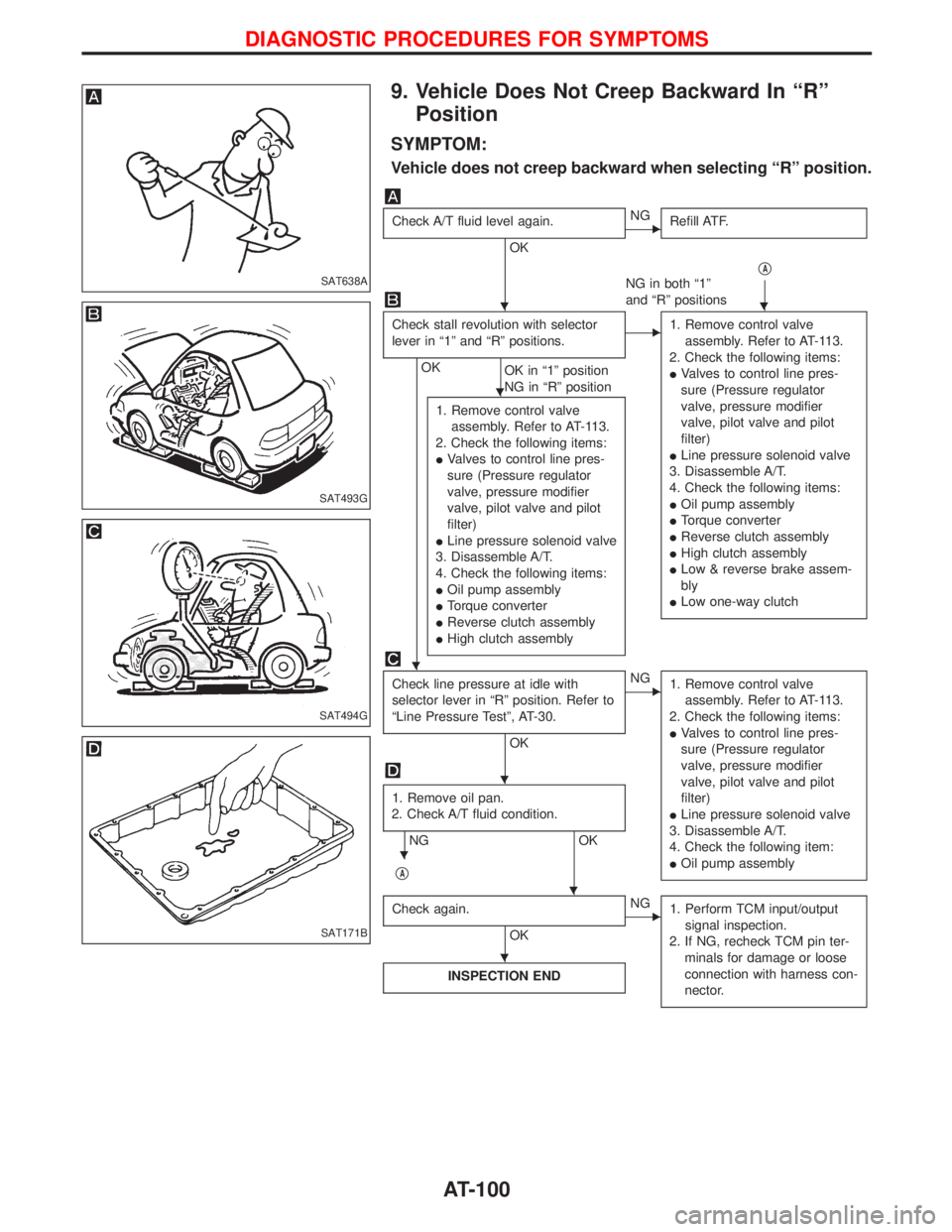

9. Vehicle Does Not Creep Backward In ªRº

Position

SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

Check A/T fluid level again.

OK

ENG

Refill ATF.

qA

NG in both ª1º

and ªRº positions

Check stall revolution with selector

lever in ª1º and ªRº positions.

OK

OK in ª1º position

NG in ªRº position

E1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

ILow & reverse brake assem-

bly

ILow one-way clutch

1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

Check line pressure at idle with

selector lever in ªRº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

NG OK

q

A

Check again.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin ter-

minals for damage or loose

connection with harness con-

nector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

HH

H

H

H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-100

Page 103 of 1767

10. Vehicle Does Not Creep Forward In ªDº, ª2º

Or ª1º Position

SYMPTOM:

Vehicle does not creep forward when selecting ªDº, ª2º or ª1º

position.

Check A/T fluid level again.

OK

ENG

Refill ATF.

qA

Check stall revolution with selector lever in

ªDº position. Refer to ªSTALL TESTº, AT-27.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IValves to control line

pressure (Pressure

regulator valve, pres-

sure modifier valve,

pilot valve and pilot

filter)

ILine pressure sole-

noid valve

3. Disassemble A/T.

4. Check the following

items:

IOil pump assembly

IForward clutch

assembly

IForward one-way

clutch

ILow one-way clutch

ILow & reverse brake

assembly

ITorque converter

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pressure

Testº, AT-30.

OK NG

1. Remove control valve assembly.

Refer to AT-113.

2. Check the following items:

IValves to control line pressure

(Pressure regulator valve, pressure

modifier valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

qA

Check again.

OK

ENG

1. Perform TCM input/

output signal inspec-

tion.

2. If NG, recheck TCM

pin terminals for

damage or loose

connection with har-

ness connector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

HH

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-101

Page 104 of 1767

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward In

ªRº Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-100.

Does self-diagnosis show damage to

vehicle speed sensor×A/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensor×MTR after cruise

test?

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63 or AT-66.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

IHigh clutch assembly

ITorque converter

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

NAT262

SAT494G

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-102