coolant NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 215 of 1767

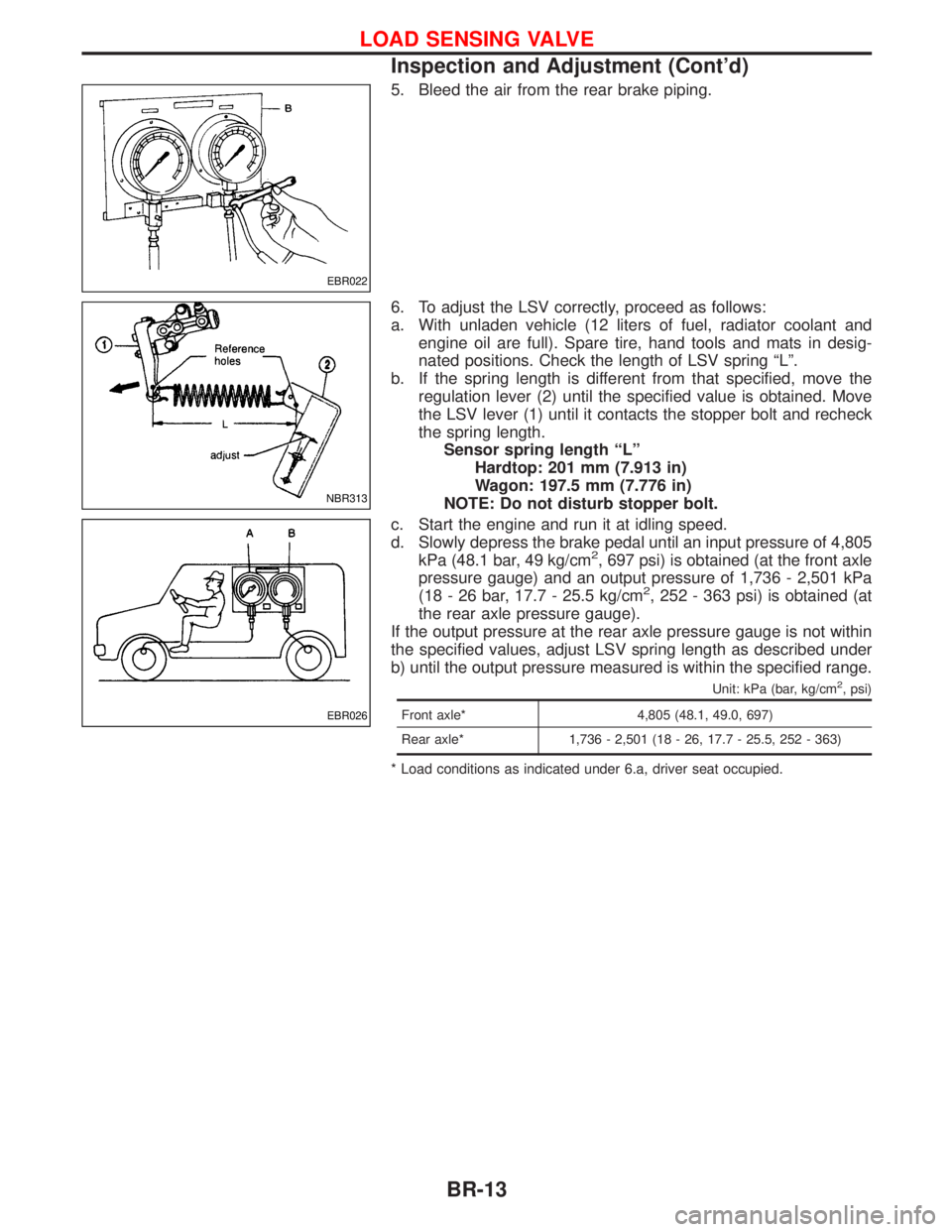

5. Bleed the air from the rear brake piping.

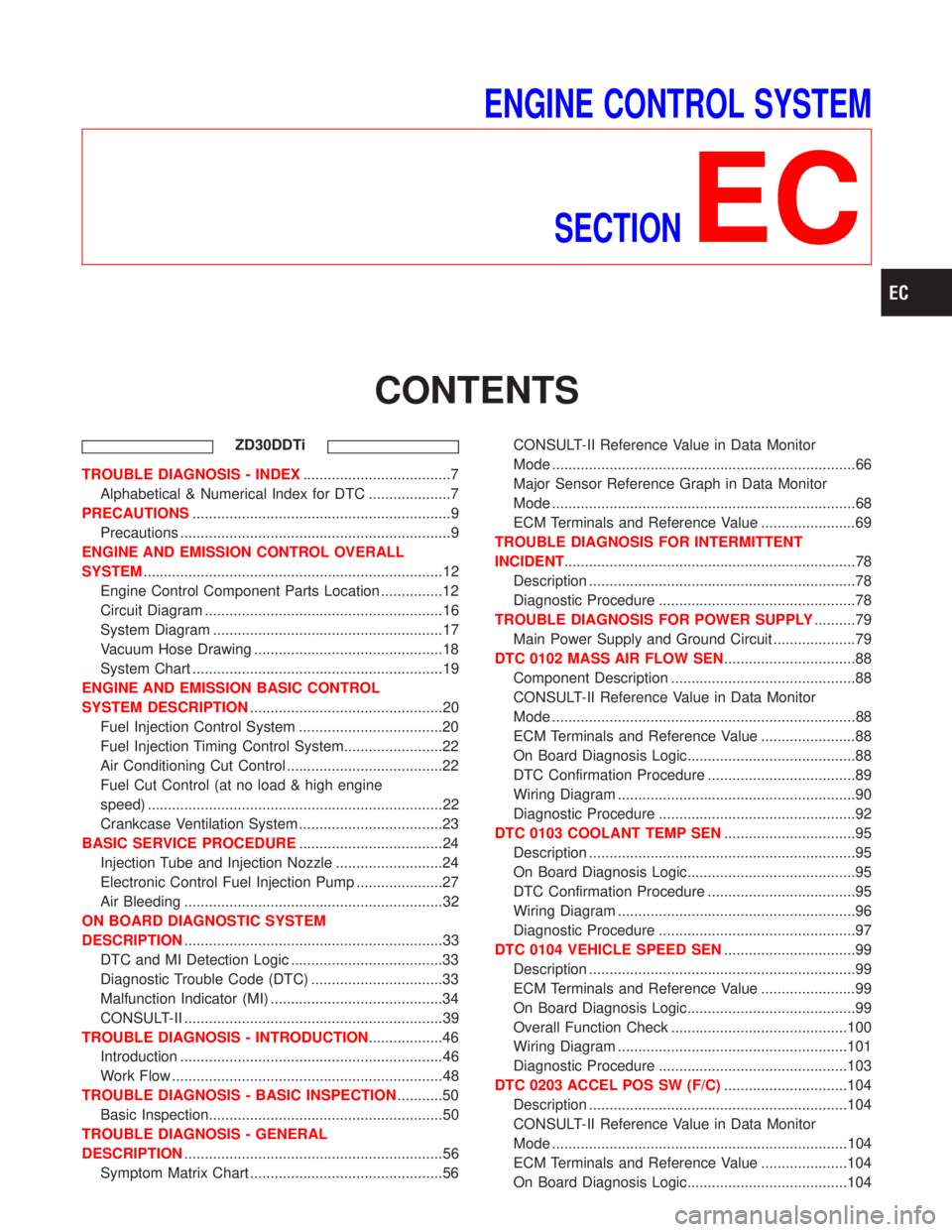

6. To adjust the LSV correctly, proceed as follows:

a. With unladen vehicle (12 liters of fuel, radiator coolant and

engine oil are full). Spare tire, hand tools and mats in desig-

nated positions. Check the length of LSV spring ªLº.

b. If the spring length is different from that specified, move the

regulation lever (2) until the specified value is obtained. Move

the LSV lever (1) until it contacts the stopper bolt and recheck

the spring length.

Sensor spring length ªLº

Hardtop: 201 mm (7.913 in)

Wagon: 197.5 mm (7.776 in)

NOTE: Do not disturb stopper bolt.

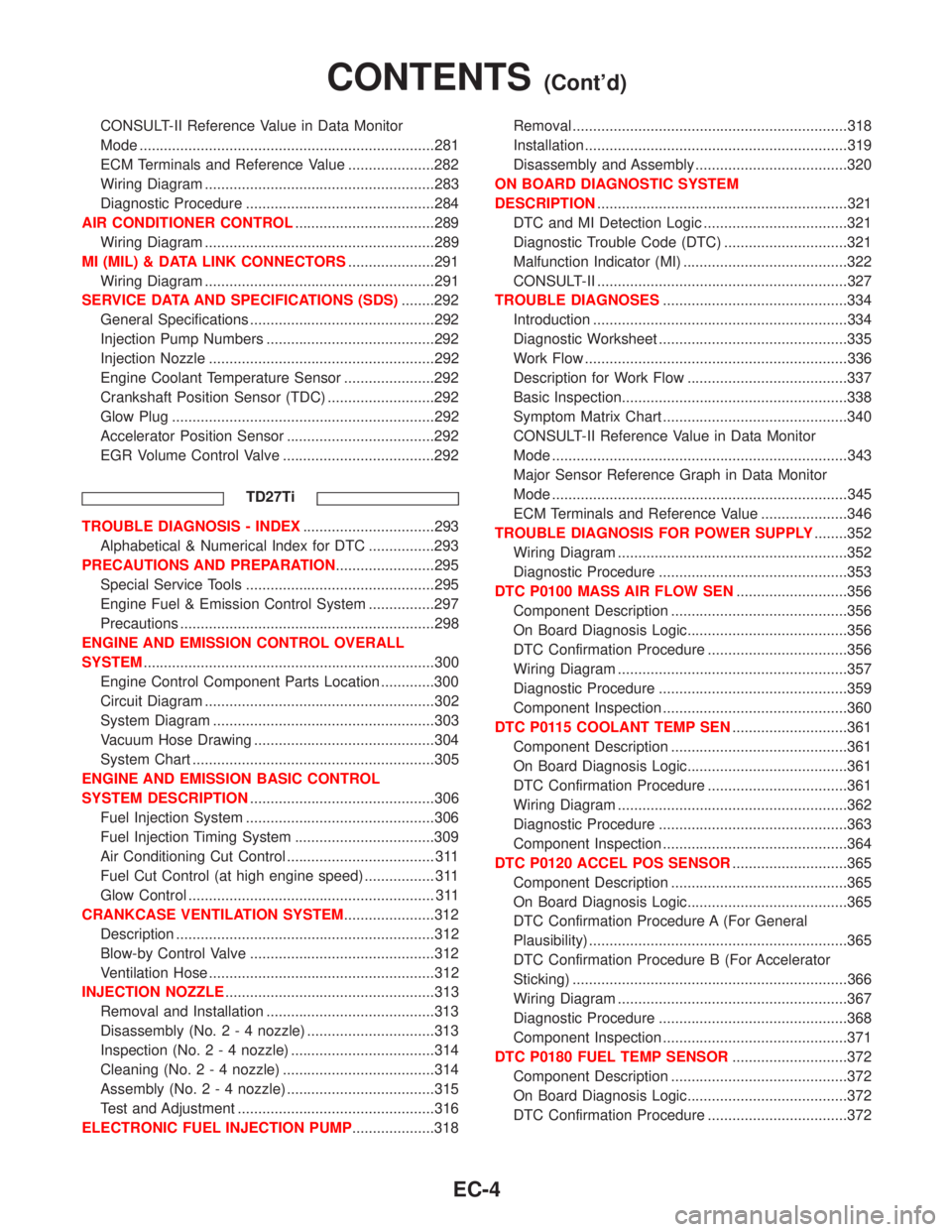

c. Start the engine and run it at idling speed.

d. Slowly depress the brake pedal until an input pressure of 4,805

kPa (48.1 bar, 49 kg/cm

2, 697 psi) is obtained (at the front axle

pressure gauge) and an output pressure of 1,736 - 2,501 kPa

(18 - 26 bar, 17.7 - 25.5 kg/cm

2, 252 - 363 psi) is obtained (at

the rear axle pressure gauge).

If the output pressure at the rear axle pressure gauge is not within

the specified values, adjust LSV spring length as described under

b) until the output pressure measured is within the specified range.

Unit: kPa (bar, kg/cm2, psi)

Front axle* 4,805 (48.1, 49.0, 697)

Rear axle* 1,736 - 2,501 (18 - 26, 17.7 - 25.5, 252 - 363)

* Load conditions as indicated under 6.a, driver seat occupied.

EBR022

NBR313

EBR026

LOAD SENSING VALVE

Inspection and Adjustment (Cont'd)

BR-13

Page 363 of 1767

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

ZD30DDTi

TROUBLE DIAGNOSIS - INDEX....................................7

Alphabetical & Numerical Index for DTC ....................7

PRECAUTIONS...............................................................9

Precautions ..................................................................9

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................12

Engine Control Component Parts Location ...............12

Circuit Diagram ..........................................................16

System Diagram ........................................................17

Vacuum Hose Drawing ..............................................18

System Chart .............................................................19

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................20

Fuel Injection Control System ...................................20

Fuel Injection Timing Control System........................22

Air Conditioning Cut Control ......................................22

Fuel Cut Control (at no load & high engine

speed) ........................................................................22

Crankcase Ventilation System ...................................23

BASIC SERVICE PROCEDURE...................................24

Injection Tube and Injection Nozzle ..........................24

Electronic Control Fuel Injection Pump .....................27

Air Bleeding ...............................................................32

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................33

DTC and MI Detection Logic .....................................33

Diagnostic Trouble Code (DTC) ................................33

Malfunction Indicator (MI) ..........................................34

CONSULT-II ...............................................................39

TROUBLE DIAGNOSIS - INTRODUCTION..................46

Introduction ................................................................46

Work Flow ..................................................................48

TROUBLE DIAGNOSIS - BASIC INSPECTION...........50

Basic Inspection.........................................................50

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................56

Symptom Matrix Chart ...............................................56CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................66

Major Sensor Reference Graph in Data Monitor

Mode ..........................................................................68

ECM Terminals and Reference Value .......................69

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.......................................................................78

Description .................................................................78

Diagnostic Procedure ................................................78

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........79

Main Power Supply and Ground Circuit ....................79

DTC 0102 MASS AIR FLOW SEN................................88

Component Description .............................................88

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................88

ECM Terminals and Reference Value .......................88

On Board Diagnosis Logic.........................................88

DTC Confirmation Procedure ....................................89

Wiring Diagram ..........................................................90

Diagnostic Procedure ................................................92

DTC 0103 COOLANT TEMP SEN................................95

Description .................................................................95

On Board Diagnosis Logic.........................................95

DTC Confirmation Procedure ....................................95

Wiring Diagram ..........................................................96

Diagnostic Procedure ................................................97

DTC 0104 VEHICLE SPEED SEN................................99

Description .................................................................99

ECM Terminals and Reference Value .......................99

On Board Diagnosis Logic.........................................99

Overall Function Check ...........................................100

Wiring Diagram ........................................................101

Diagnostic Procedure ..............................................103

DTC 0203 ACCEL POS SW (F/C)..............................104

Description ...............................................................104

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................104

ECM Terminals and Reference Value .....................104

On Board Diagnosis Logic.......................................104

Page 366 of 1767

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................281

ECM Terminals and Reference Value .....................282

Wiring Diagram ........................................................283

Diagnostic Procedure ..............................................284

AIR CONDITIONER CONTROL..................................289

Wiring Diagram ........................................................289

MI (MIL) & DATA LINK CONNECTORS.....................291

Wiring Diagram ........................................................291

SERVICE DATA AND SPECIFICATIONS (SDS)........292

General Specifications .............................................292

Injection Pump Numbers .........................................292

Injection Nozzle .......................................................292

Engine Coolant Temperature Sensor ......................292

Crankshaft Position Sensor (TDC) ..........................292

Glow Plug ................................................................292

Accelerator Position Sensor ....................................292

EGR Volume Control Valve .....................................292

TD27Ti

TROUBLE DIAGNOSIS - INDEX................................293

Alphabetical & Numerical Index for DTC ................293

PRECAUTIONS AND PREPARATION........................295

Special Service Tools ..............................................295

Engine Fuel & Emission Control System ................297

Precautions ..............................................................298

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.......................................................................300

Engine Control Component Parts Location .............300

Circuit Diagram ........................................................302

System Diagram ......................................................303

Vacuum Hose Drawing ............................................304

System Chart ...........................................................305

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION.............................................306

Fuel Injection System ..............................................306

Fuel Injection Timing System ..................................309

Air Conditioning Cut Control .................................... 311

Fuel Cut Control (at high engine speed) ................. 311

Glow Control ............................................................ 311

CRANKCASE VENTILATION SYSTEM......................312

Description ...............................................................312

Blow-by Control Valve .............................................312

Ventilation Hose .......................................................312

INJECTION NOZZLE...................................................313

Removal and Installation .........................................313

Disassembly (No.2-4nozzle) ...............................313

Inspection (No.2-4nozzle) ...................................314

Cleaning (No.2-4nozzle) .....................................314

Assembly (No.2-4nozzle) ....................................315

Test and Adjustment ................................................316

ELECTRONIC FUEL INJECTION PUMP....................318Removal ...................................................................318

Installation ................................................................319

Disassembly and Assembly .....................................320

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION.............................................................321

DTC and MI Detection Logic ...................................321

Diagnostic Trouble Code (DTC) ..............................321

Malfunction Indicator (MI) ........................................322

CONSULT-II .............................................................327

TROUBLE DIAGNOSES.............................................334

Introduction ..............................................................334

Diagnostic Worksheet ..............................................335

Work Flow ................................................................336

Description for Work Flow .......................................337

Basic Inspection.......................................................338

Symptom Matrix Chart .............................................340

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................343

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................345

ECM Terminals and Reference Value .....................346

TROUBLE DIAGNOSIS FOR POWER SUPPLY........352

Wiring Diagram ........................................................352

Diagnostic Procedure ..............................................353

DTC P0100 MASS AIR FLOW SEN...........................356

Component Description ...........................................356

On Board Diagnosis Logic.......................................356

DTC Confirmation Procedure ..................................356

Wiring Diagram ........................................................357

Diagnostic Procedure ..............................................359

Component Inspection .............................................360

DTC P0115 COOLANT TEMP SEN............................361

Component Description ...........................................361

On Board Diagnosis Logic.......................................361

DTC Confirmation Procedure ..................................361

Wiring Diagram ........................................................362

Diagnostic Procedure ..............................................363

Component Inspection .............................................364

DTC P0120 ACCEL POS SENSOR............................365

Component Description ...........................................365

On Board Diagnosis Logic.......................................365

DTC Confirmation Procedure A (For General

Plausibility) ...............................................................365

DTC Confirmation Procedure B (For Accelerator

Sticking) ...................................................................366

Wiring Diagram ........................................................367

Diagnostic Procedure ..............................................368

Component Inspection .............................................371

DTC P0180 FUEL TEMP SENSOR............................372

Component Description ...........................................372

On Board Diagnosis Logic.......................................372

DTC Confirmation Procedure ..................................372

CONTENTS(Cont'd)

EC-4

Page 369 of 1767

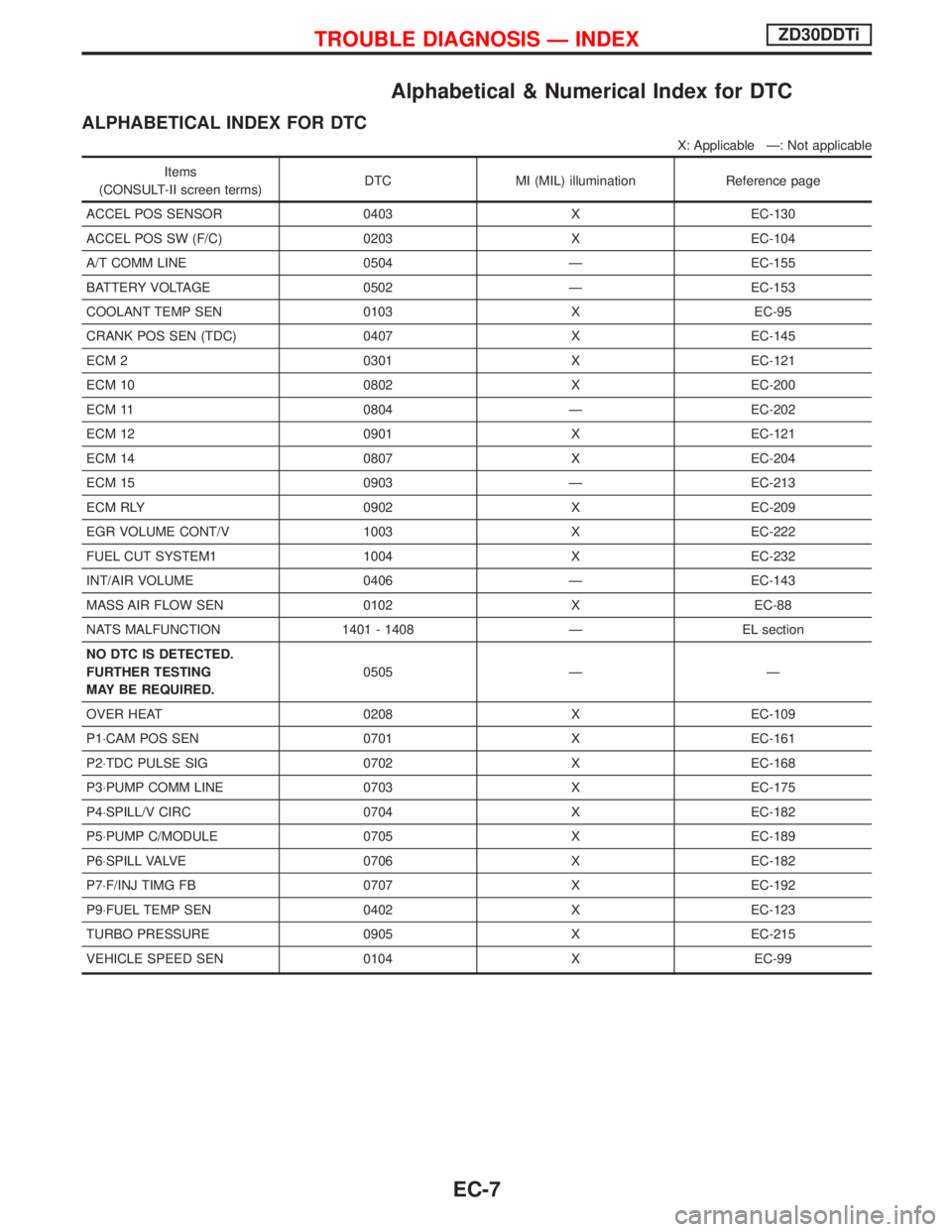

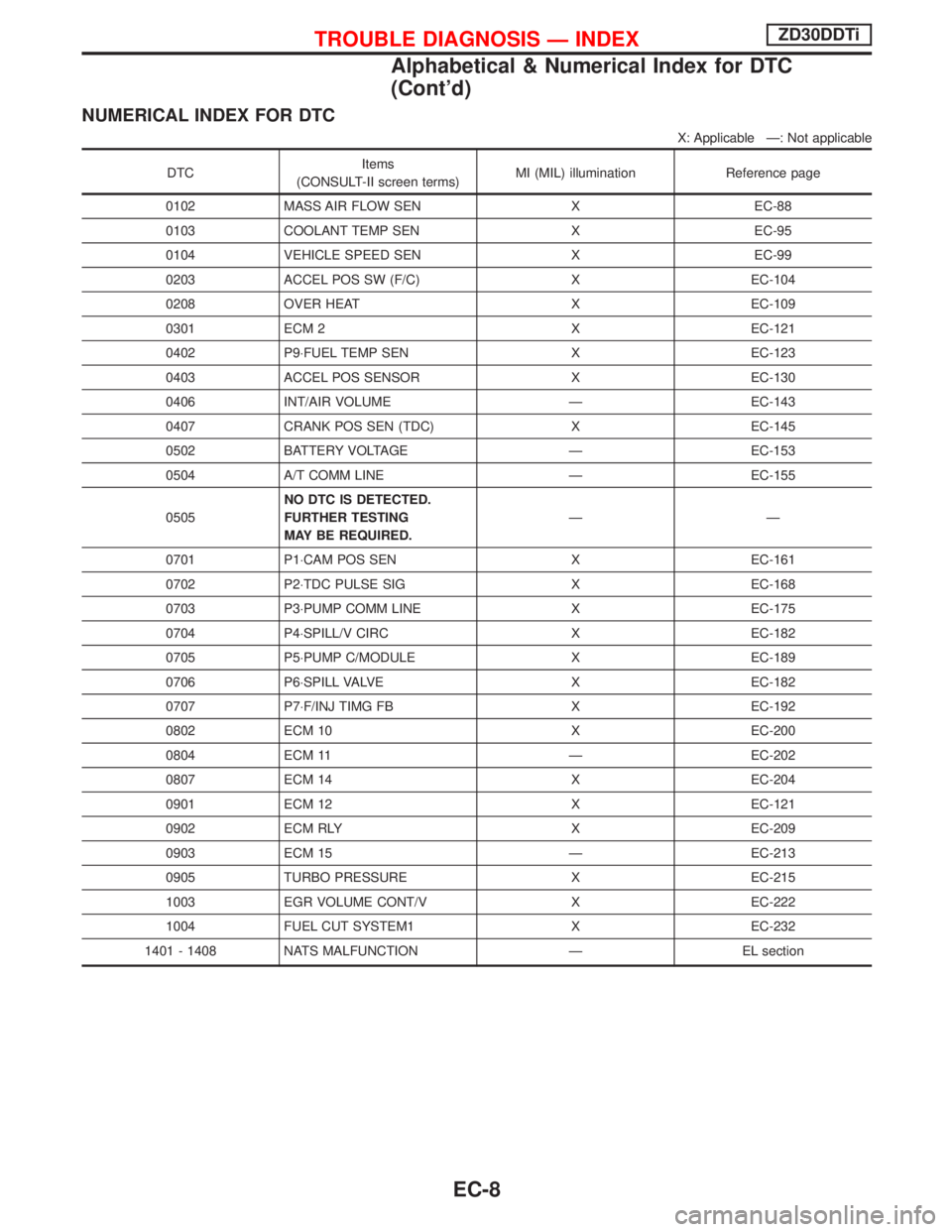

Alphabetical & Numerical Index for DTC

ALPHABETICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC MI (MIL) illumination Reference page

ACCEL POS SENSOR 0403 X EC-130

ACCEL POS SW (F/C) 0203 X EC-104

A/T COMM LINE 0504 Ð EC-155

BATTERY VOLTAGE 0502 Ð EC-153

COOLANT TEMP SEN 0103 X EC-95

CRANK POS SEN (TDC) 0407 X EC-145

ECM 2 0301 X EC-121

ECM 10 0802 X EC-200

ECM 11 0804 Ð EC-202

ECM 12 0901 X EC-121

ECM 14 0807 X EC-204

ECM 15 0903 Ð EC-213

ECM RLY 0902 X EC-209

EGR VOLUME CONT/V 1003 X EC-222

FUEL CUT SYSTEM1 1004 X EC-232

INT/AIR VOLUME 0406 Ð EC-143

MASS AIR FLOW SEN 0102 X EC-88

NATS MALFUNCTION 1401 - 1408 Ð EL section

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.0505 Ð Ð

OVER HEAT 0208 X EC-109

P1×CAM POS SEN 0701 X EC-161

P2×TDC PULSE SIG 0702 X EC-168

P3×PUMP COMM LINE 0703 X EC-175

P4×SPILL/V CIRC 0704 X EC-182

P5×PUMP C/MODULE 0705 X EC-189

P6×SPILL VALVE 0706 X EC-182

P7×F/INJ TIMG FB 0707 X EC-192

P9×FUEL TEMP SEN 0402 X EC-123

TURBO PRESSURE 0905 X EC-215

VEHICLE SPEED SEN 0104 X EC-99

TROUBLE DIAGNOSIS Ð INDEXZD30DDTi

EC-7

Page 370 of 1767

NUMERICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

DTCItems

(CONSULT-II screen terms)MI (MIL) illumination Reference page

0102 MASS AIR FLOW SEN X EC-88

0103 COOLANT TEMP SEN X EC-95

0104 VEHICLE SPEED SEN X EC-99

0203 ACCEL POS SW (F/C) X EC-104

0208 OVER HEAT X EC-109

0301 ECM 2 X EC-121

0402 P9×FUEL TEMP SEN X EC-123

0403 ACCEL POS SENSOR X EC-130

0406 INT/AIR VOLUME Ð EC-143

0407 CRANK POS SEN (TDC) X EC-145

0502 BATTERY VOLTAGE Ð EC-153

0504 A/T COMM LINE Ð EC-155

0505NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.ÐÐ

0701 P1×CAM POS SEN X EC-161

0702 P2×TDC PULSE SIG X EC-168

0703 P3×PUMP COMM LINE X EC-175

0704 P4×SPILL/V CIRC X EC-182

0705 P5×PUMP C/MODULE X EC-189

0706 P6×SPILL VALVE X EC-182

0707 P7×F/INJ TIMG FB X EC-192

0802 ECM 10 X EC-200

0804 ECM 11 Ð EC-202

0807 ECM 14 X EC-204

0901 ECM 12 X EC-121

0902 ECM RLY X EC-209

0903 ECM 15 Ð EC-213

0905 TURBO PRESSURE X EC-215

1003 EGR VOLUME CONT/V X EC-222

1004 FUEL CUT SYSTEM1 X EC-232

1401 - 1408 NATS MALFUNCTION Ð EL section

TROUBLE DIAGNOSIS Ð INDEXZD30DDTi

Alphabetical & Numerical Index for DTC

(Cont'd)

EC-8

Page 381 of 1767

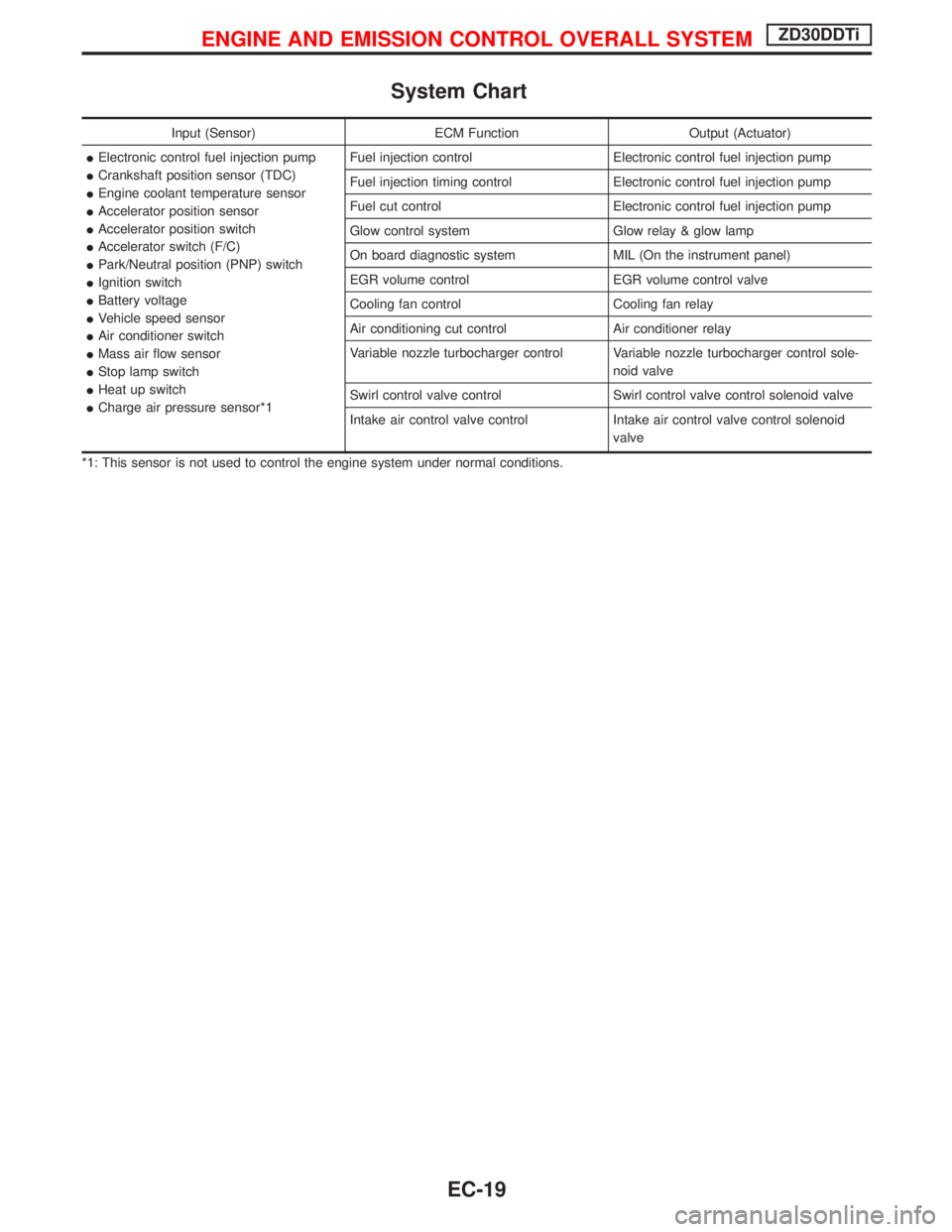

System Chart

Input (Sensor) ECM Function Output (Actuator)

IElectronic control fuel injection pump

ICrankshaft position sensor (TDC)

IEngine coolant temperature sensor

IAccelerator position sensor

IAccelerator position switch

IAccelerator switch (F/C)

IPark/Neutral position (PNP) switch

IIgnition switch

IBattery voltage

IVehicle speed sensor

IAir conditioner switch

IMass air flow sensor

IStop lamp switch

IHeat up switch

ICharge air pressure sensor*1Fuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole-

noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

*1: This sensor is not used to control the engine system under normal conditions.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-19

Page 382 of 1767

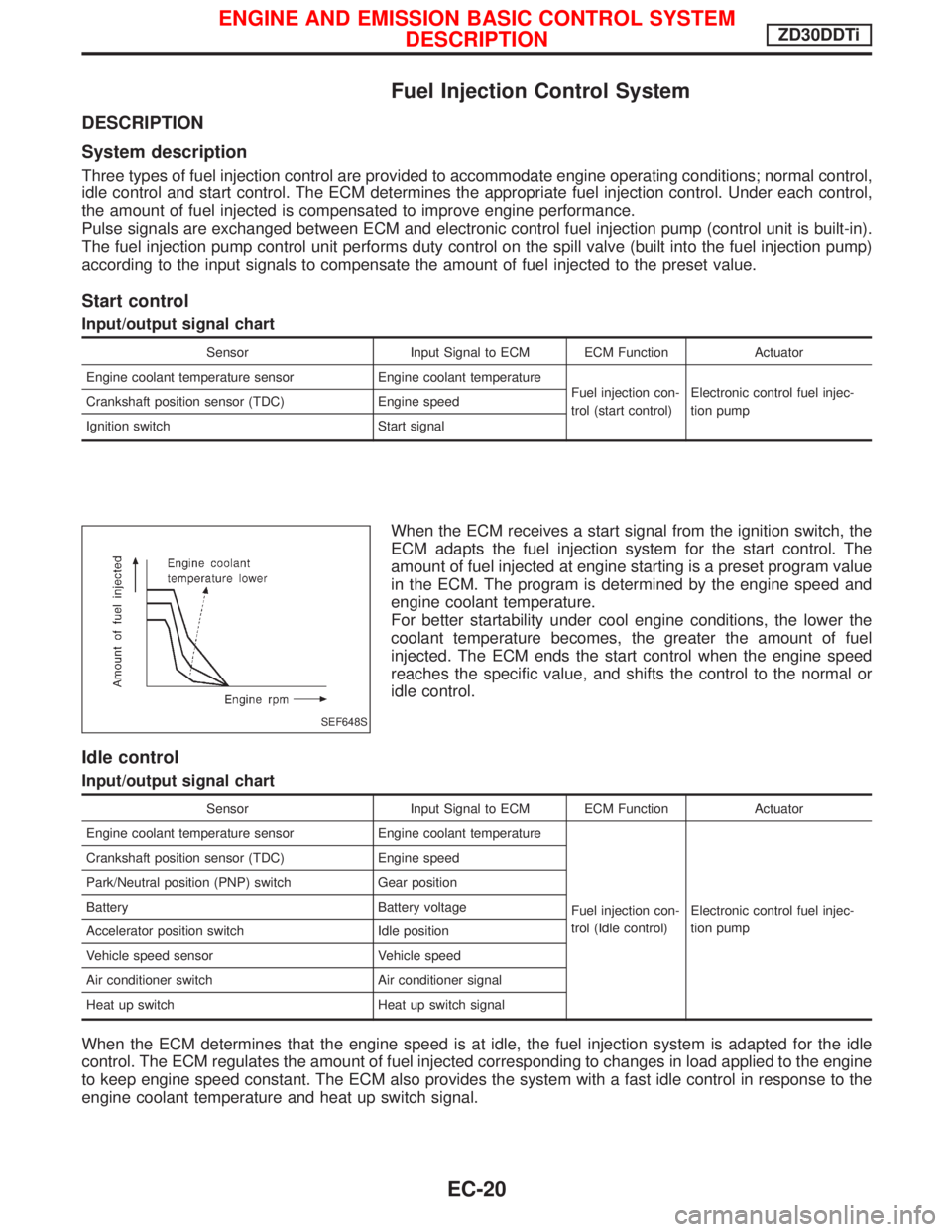

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-in).

The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection pump)

according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Ignition switch Start signal

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or

idle control.

Idle control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Heat up switch Heat up switch signal

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-20

Page 383 of 1767

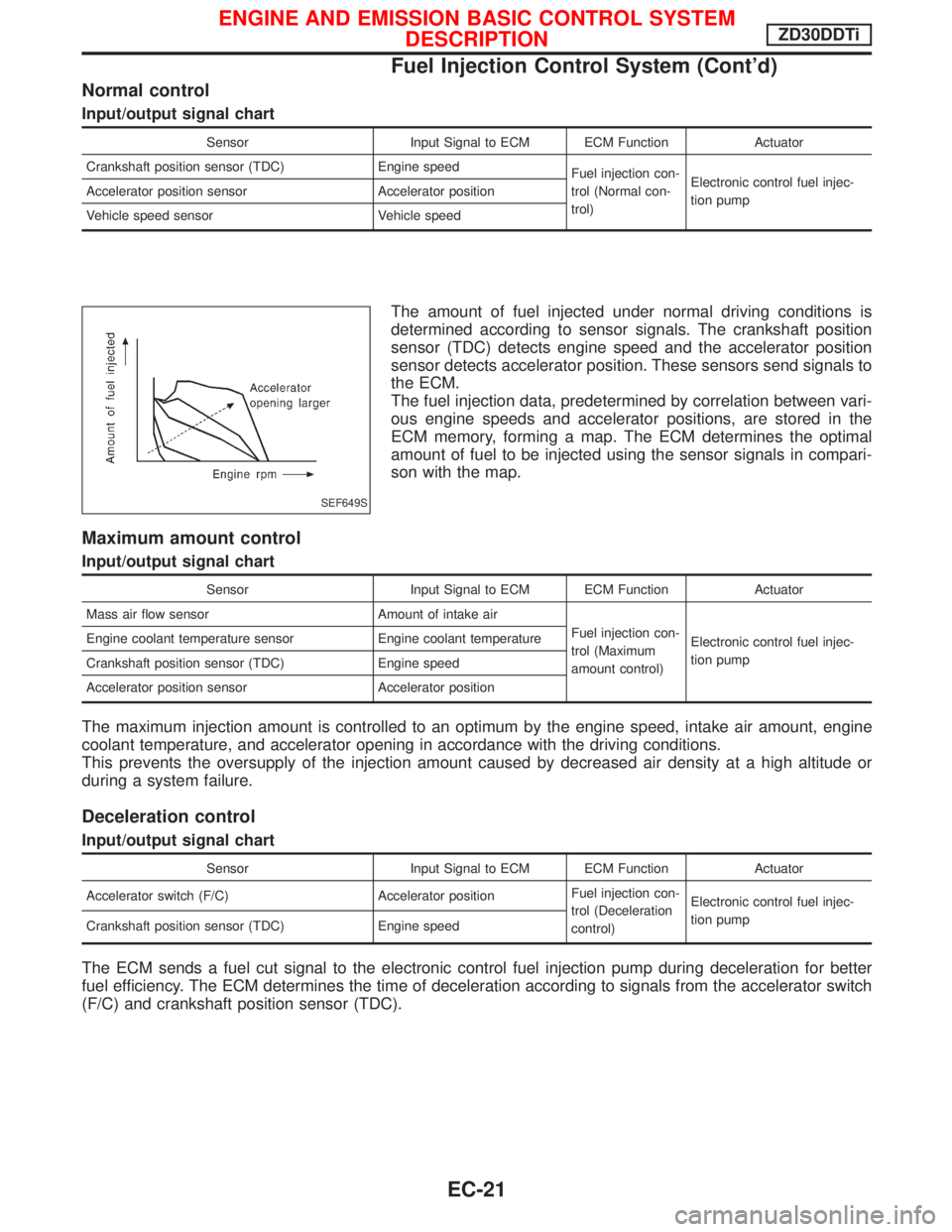

Normal control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Fuel injection con-

trol (Normal con-

trol)Electronic control fuel injec-

tion pump Accelerator position sensor Accelerator position

Vehicle speed sensor Vehicle speed

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals to

the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds and accelerator positions, are stored in the

ECM memory, forming a map. The ECM determines the optimal

amount of fuel to be injected using the sensor signals in compari-

son with the map.

Maximum amount control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Mass air flow sensor Amount of intake air

Fuel injection con-

trol (Maximum

amount control)Electronic control fuel injec-

tion pump Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

Accelerator position sensor Accelerator position

The maximum injection amount is controlled to an optimum by the engine speed, intake air amount, engine

coolant temperature, and accelerator opening in accordance with the driving conditions.

This prevents the oversupply of the injection amount caused by decreased air density at a high altitude or

during a system failure.

Deceleration control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Accelerator switch (F/C) Accelerator positionFuel injection con-

trol (Deceleration

control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC) Engine speed

The ECM sends a fuel cut signal to the electronic control fuel injection pump during deceleration for better

fuel efficiency. The ECM determines the time of deceleration according to signals from the accelerator switch

(F/C) and crankshaft position sensor (TDC).

SEF649S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

Fuel Injection Control System (Cont'd)

EC-21

Page 384 of 1767

Fuel Injection Timing Control System

DESCRIPTION

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are recorded

as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals and per-

form feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay Accelerator position sensorAccelerator valve opening

angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump Park/Neutral position (PNP) switch Neutral position

Accelerator position switch or Accelerator

switch (F/C)Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº, EC-20.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-22

Page 390 of 1767

REMOVAL

1. Remove the following:

IEngine coolant draining

ICharge air cooler

IAir inlet pipe

IThrottle body

IRocker cover

IOil level gauge guide

IEGR cooler

IEGR guide tube

IEGR volume control solenoid valve

IFuel hose

IInjection tube

IRadiator upper hose

IRadiator shroud

ICooling fan

IDrive belt

IVacuum pipe

IVacuum pump

2. Move the power steering pump.

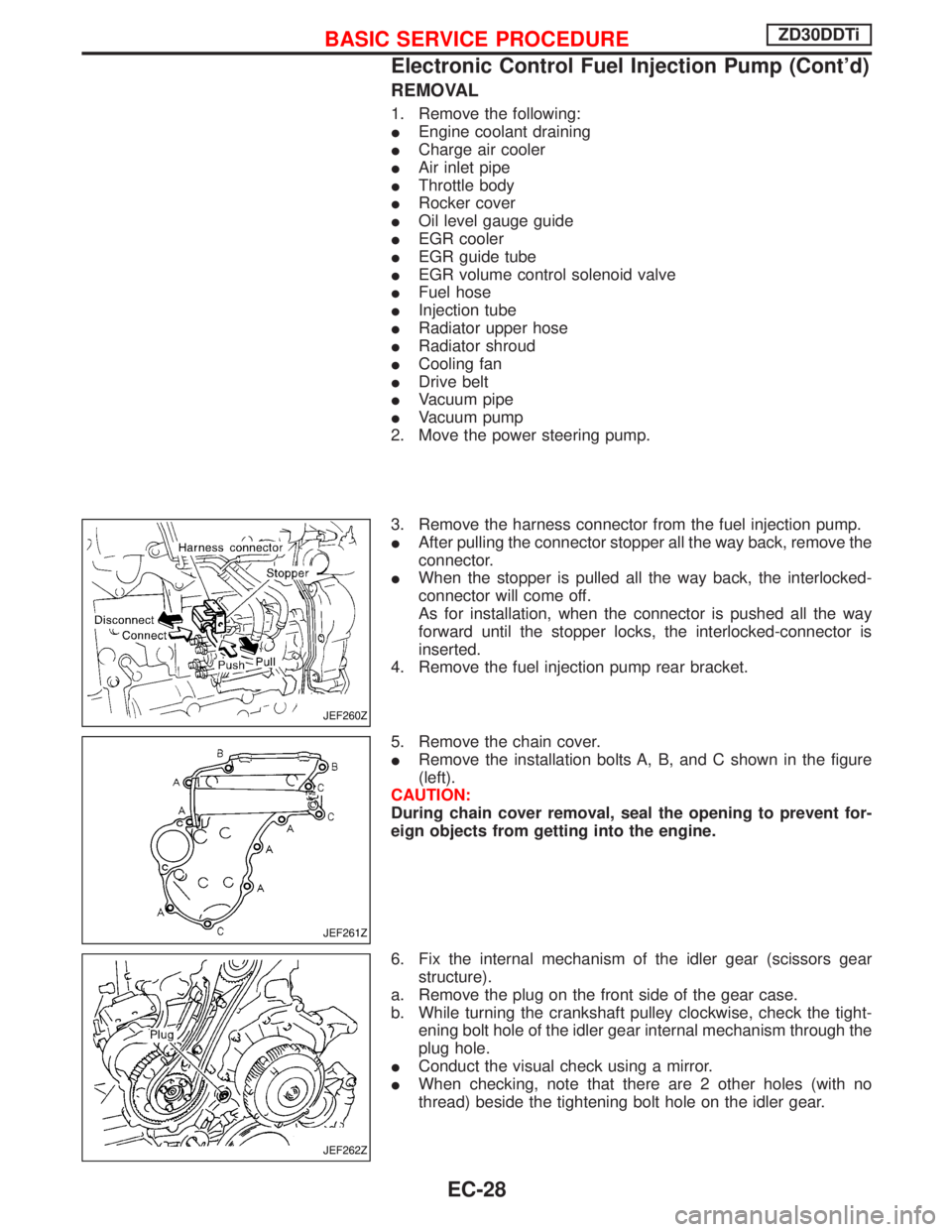

3. Remove the harness connector from the fuel injection pump.

IAfter pulling the connector stopper all the way back, remove the

connector.

IWhen the stopper is pulled all the way back, the interlocked-

connector will come off.

As for installation, when the connector is pushed all the way

forward until the stopper locks, the interlocked-connector is

inserted.

4. Remove the fuel injection pump rear bracket.

5. Remove the chain cover.

IRemove the installation bolts A, B, and C shown in the figure

(left).

CAUTION:

During chain cover removal, seal the opening to prevent for-

eign objects from getting into the engine.

6. Fix the internal mechanism of the idler gear (scissors gear

structure).

a. Remove the plug on the front side of the gear case.

b. While turning the crankshaft pulley clockwise, check the tight-

ening bolt hole of the idler gear internal mechanism through the

plug hole.

IConduct the visual check using a mirror.

IWhen checking, note that there are 2 other holes (with no

thread) beside the tightening bolt hole on the idler gear.

JEF260Z

JEF261Z

JEF262Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-28