fuse box NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 689 of 1767

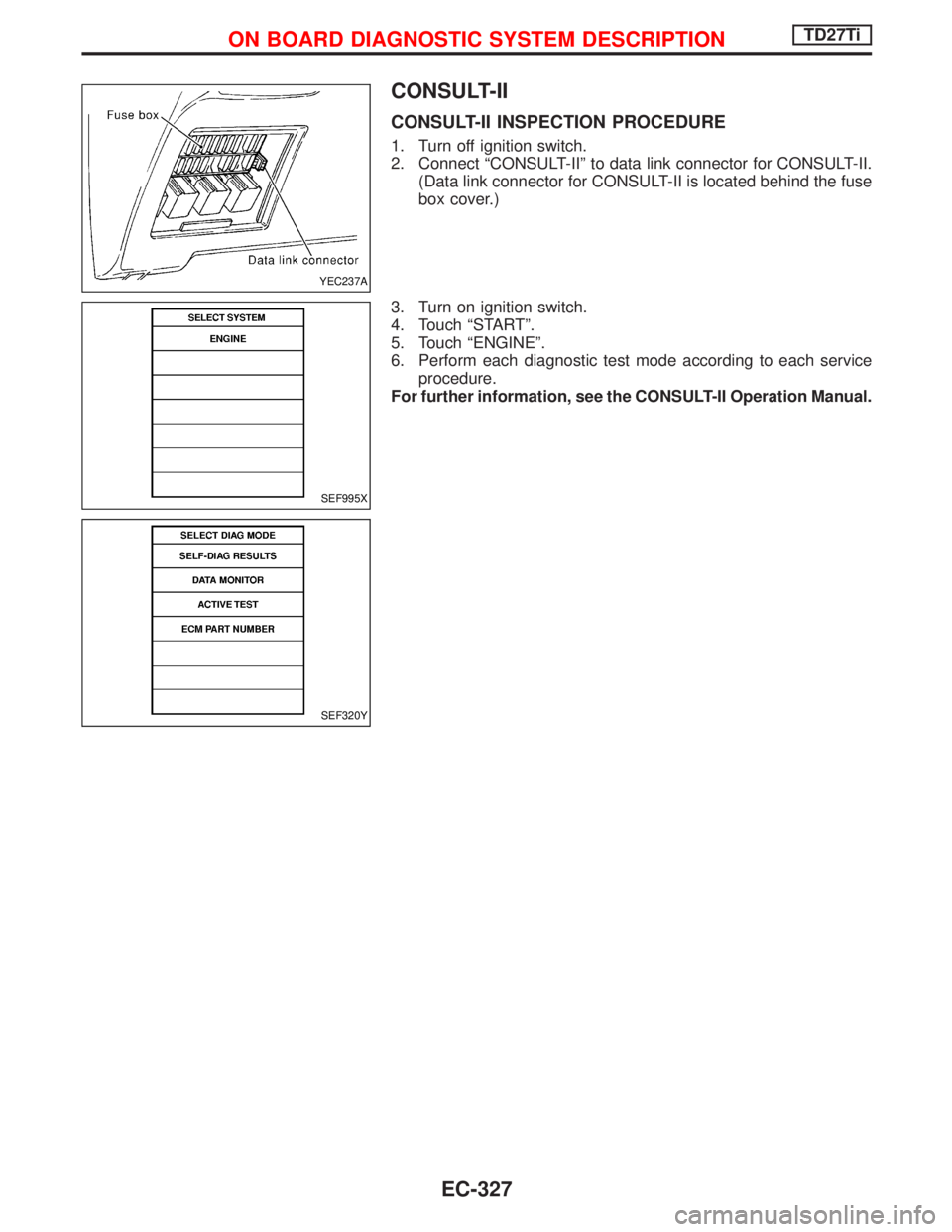

CONSULT-II

CONSULT-II INSPECTION PROCEDURE

1. Turn off ignition switch.

2. Connect ªCONSULT-IIº to data link connector for CONSULT-II.

(Data link connector for CONSULT-II is located behind the fuse

box cover.)

3. Turn on ignition switch.

4. Touch ªSTARTº.

5. Touch ªENGINEº.

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation Manual.

YEC237A

SEF995X

SEF320Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

EC-327

Page 716 of 1767

qA

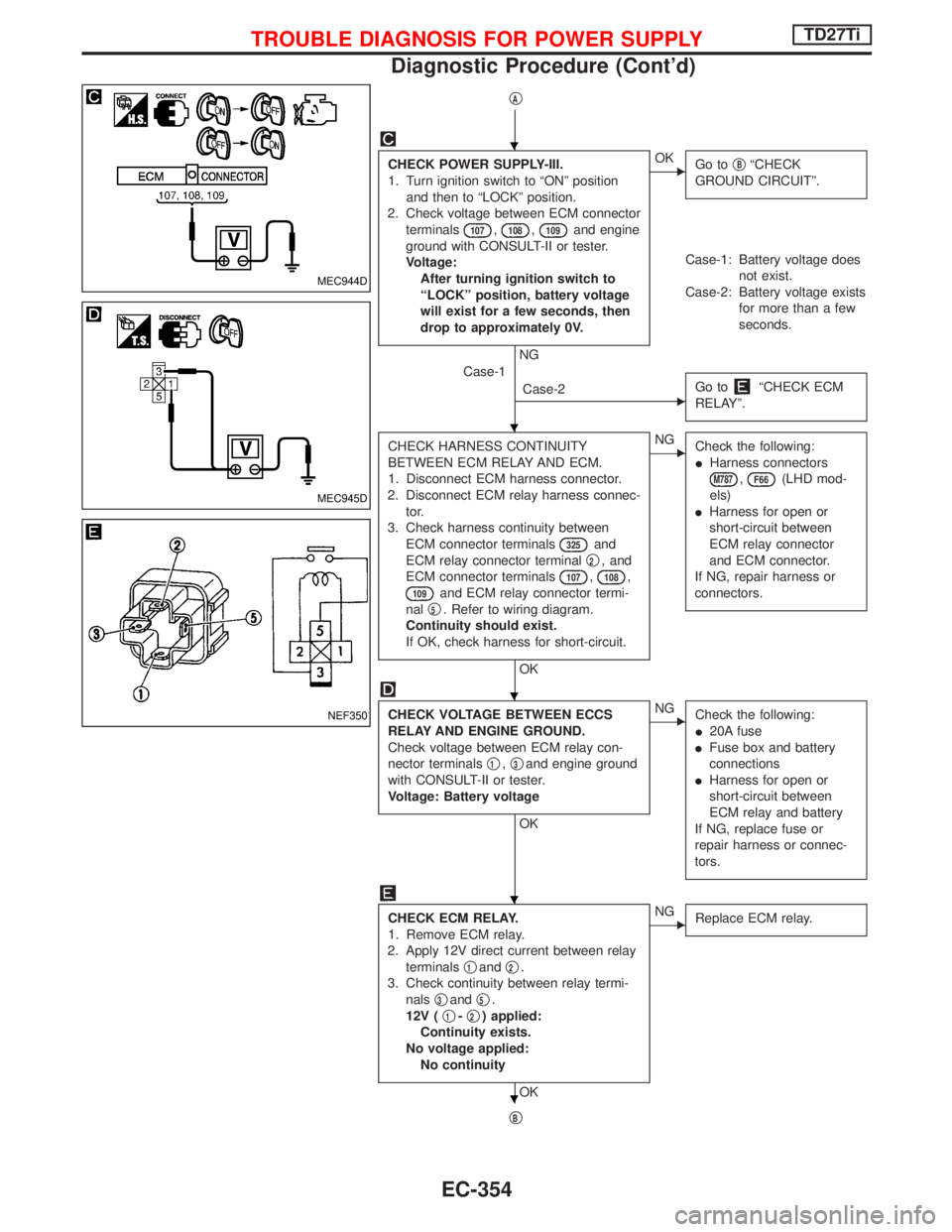

CHECK POWER SUPPLY-III.

1. Turn ignition switch to ªONº position

and then to ªLOCKº position.

2. Check voltage between ECM connector

terminals

107,108,109and engine

ground with CONSULT-II or tester.

Voltage:

After turning ignition switch to

ªLOCKº position, battery voltage

will exist for a few seconds, then

drop to approximately 0V.

NG

EOK

Go toqBªCHECK

GROUND CIRCUITº.

Case-1: Battery voltage does

not exist.

Case-2: Battery voltage exists

for more than a few

seconds.

Case-1

Case-2

EGo toªCHECK ECM

RELAYº.

CHECK HARNESS CONTINUITY

BETWEEN ECM RELAY AND ECM.

1. Disconnect ECM harness connector.

2. Disconnect ECM relay harness connec-

tor.

3. Check harness continuity between

ECM connector terminals

325and

ECM relay connector terminalq

2, and

ECM connector terminals

107,108,

109and ECM relay connector termi-

nalq

5. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness connectors

M787,F66(LHD mod-

els)

IHarness for open or

short-circuit between

ECM relay connector

and ECM connector.

If NG, repair harness or

connectors.

CHECK VOLTAGE BETWEEN ECCS

RELAY AND ENGINE GROUND.

Check voltage between ECM relay con-

nector terminalsq

1,q3and engine ground

with CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I20A fuse

IFuse box and battery

connections

IHarness for open or

short-circuit between

ECM relay and battery

If NG, replace fuse or

repair harness or connec-

tors.

CHECK ECM RELAY.

1. Remove ECM relay.

2. Apply 12V direct current between relay

terminalsq

1andq2.

3. Check continuity between relay termi-

nalsq

3andq5.

12V (q

1-q2) applied:

Continuity exists.

No voltage applied:

No continuity

OK

ENG

Replace ECM relay.

qB

MEC944D

MEC945D

NEF350

H

H

H

H

H

TROUBLE DIAGNOSIS FOR POWER SUPPLYTD27Ti

Diagnostic Procedure (Cont'd)

EC-354

Page 732 of 1767

qA

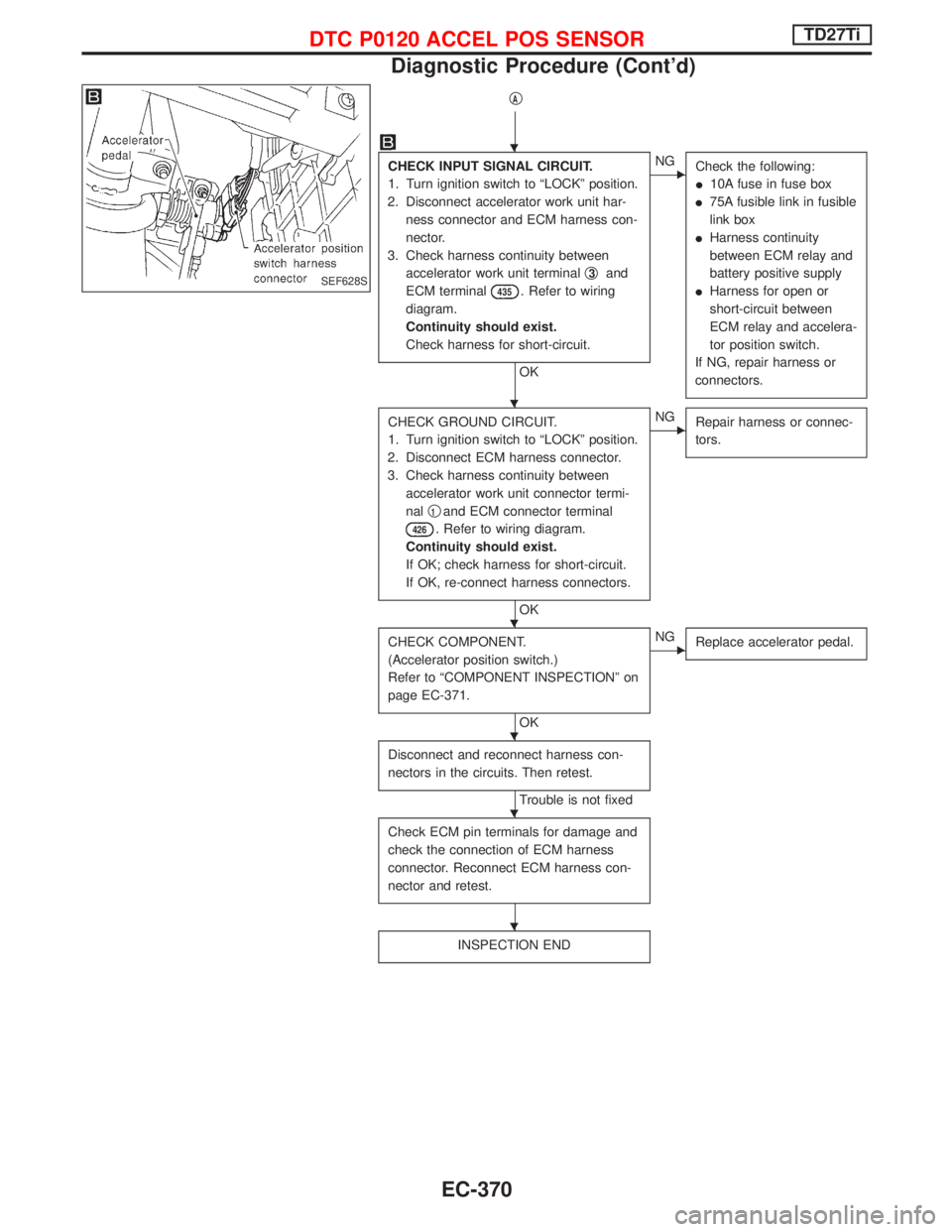

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect accelerator work unit har-

ness connector and ECM harness con-

nector.

3. Check harness continuity between

accelerator work unit terminalq

3and

ECM terminal

435. Refer to wiring

diagram.

Continuity should exist.

Check harness for short-circuit.

OK

ENG

Check the following:

I10A fuse in fuse box

I75A fusible link in fusible

link box

IHarness continuity

between ECM relay and

battery positive supply

IHarness for open or

short-circuit between

ECM relay and accelera-

tor position switch.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between

accelerator work unit connector termi-

nalq

1and ECM connector terminal

426. Refer to wiring diagram.

Continuity should exist.

If OK; check harness for short-circuit.

If OK, re-connect harness connectors.

OK

ENG

Repair harness or connec-

tors.

CHECK COMPONENT.

(Accelerator position switch.)

Refer to ªCOMPONENT INSPECTIONº on

page EC-371.

OK

ENG

Replace accelerator pedal.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF628S

H

H

H

H

H

H

DTC P0120 ACCEL POS SENSORTD27Ti

Diagnostic Procedure (Cont'd)

EC-370

Page 745 of 1767

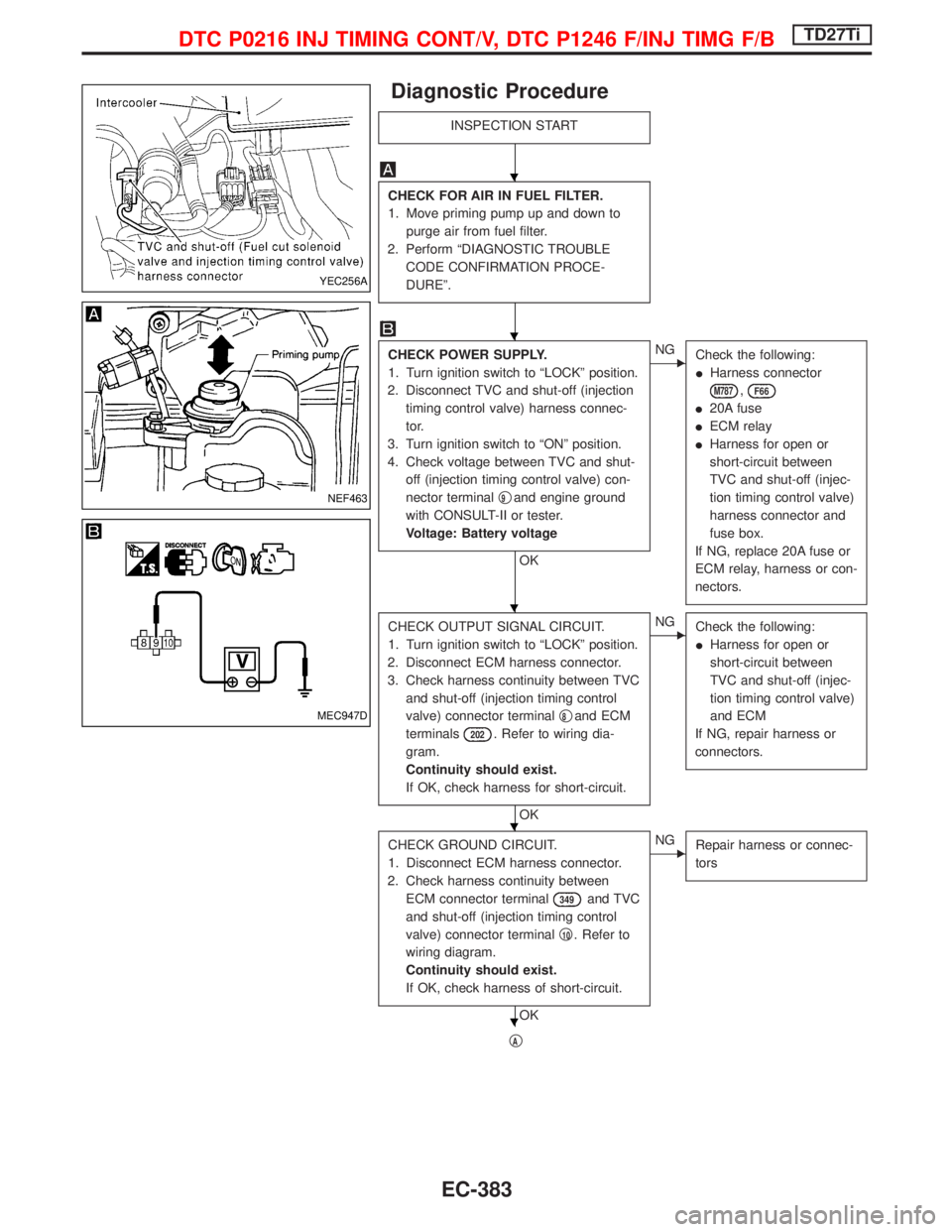

Diagnostic Procedure

INSPECTION START

CHECK FOR AIR IN FUEL FILTER.

1. Move priming pump up and down to

purge air from fuel filter.

2. Perform ªDIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCE-

DUREº.

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect TVC and shut-off (injection

timing control valve) harness connec-

tor.

3. Turn ignition switch to ªONº position.

4. Check voltage between TVC and shut-

off (injection timing control valve) con-

nector terminalq

9and engine ground

with CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG

Check the following:

IHarness connector

M787,F66

I20A fuse

IECM relay

IHarness for open or

short-circuit between

TVC and shut-off (injec-

tion timing control valve)

harness connector and

fuse box.

If NG, replace 20A fuse or

ECM relay, harness or con-

nectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between TVC

and shut-off (injection timing control

valve) connector terminalq

8and ECM

terminals

202. Refer to wiring dia-

gram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

TVC and shut-off (injec-

tion timing control valve)

and ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM connector terminal

349and TVC

and shut-off (injection timing control

valve) connector terminalq

10. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness of short-circuit.

OK

ENG

Repair harness or connec-

tors

qA

YEC256A

NEF463

MEC947D

H

H

H

H

H

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/INJ TIMG F/BTD27Ti

EC-383

Page 755 of 1767

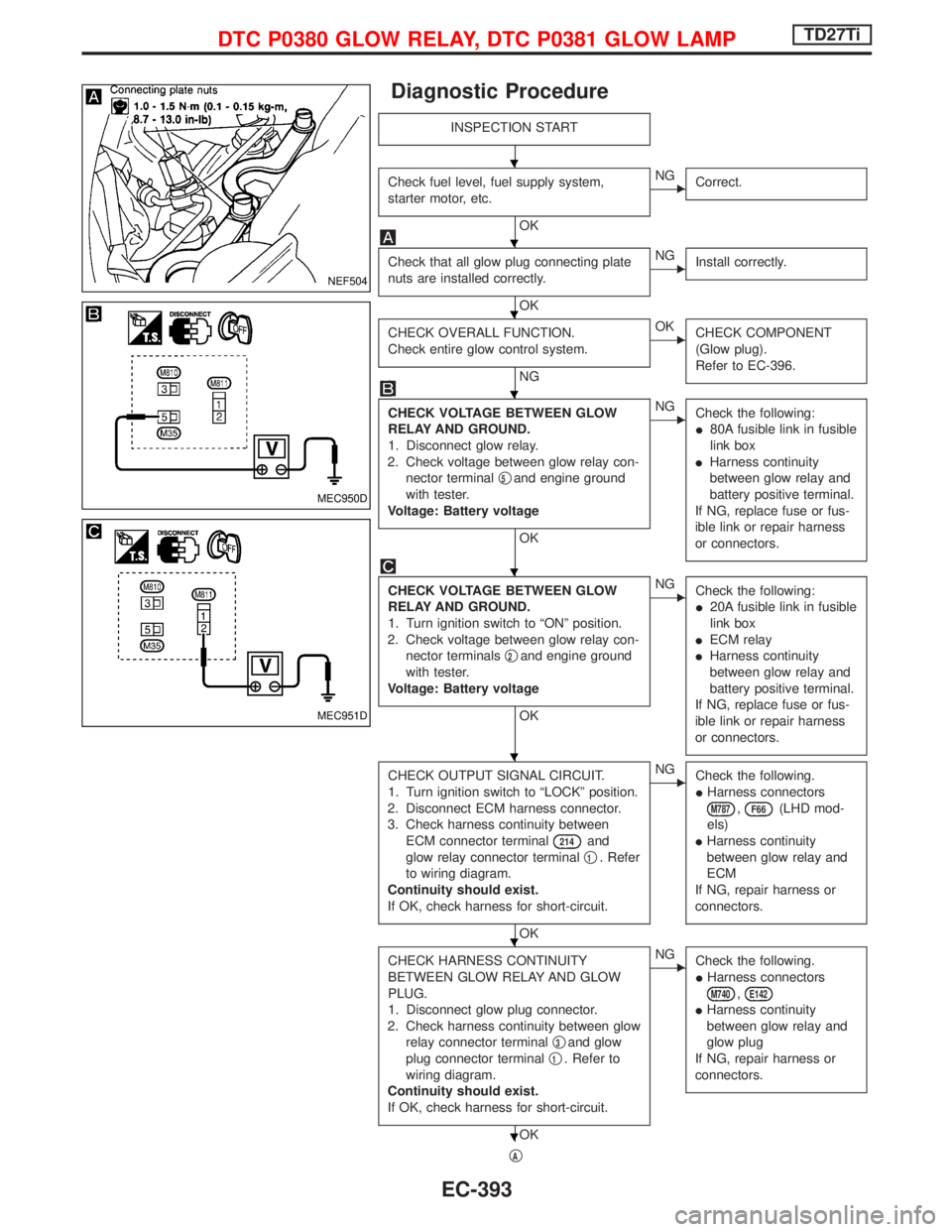

Diagnostic Procedure

INSPECTION START

Check fuel level, fuel supply system,

starter motor, etc.

OK

ENG

Correct.

Check that all glow plug connecting plate

nuts are installed correctly.

OK

ENG

Install correctly.

CHECK OVERALL FUNCTION.

Check entire glow control system.

NG

EOK

CHECK COMPONENT

(Glow plug).

Refer to EC-396.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Disconnect glow relay.

2. Check voltage between glow relay con-

nector terminalq

5and engine ground

with tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I80A fusible link in fusible

link box

IHarness continuity

between glow relay and

battery positive terminal.

If NG, replace fuse or fus-

ible link or repair harness

or connectors.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Turn ignition switch to ªONº position.

2. Check voltage between glow relay con-

nector terminalsq

2and engine ground

with tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I20A fusible link in fusible

link box

IECM relay

IHarness continuity

between glow relay and

battery positive terminal.

If NG, replace fuse or fus-

ible link or repair harness

or connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM connector terminal

214and

glow relay connector terminalq

1. Refer

to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

IHarness continuity

between glow relay and

ECM

If NG, repair harness or

connectors.

CHECK HARNESS CONTINUITY

BETWEEN GLOW RELAY AND GLOW

PLUG.

1. Disconnect glow plug connector.

2. Check harness continuity between glow

relay connector terminalq

3and glow

plug connector terminalq

1. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

M740,E142

IHarness continuity

between glow relay and

glow plug

If NG, repair harness or

connectors.

qA

NEF504

MEC950D

MEC951D

H

H

H

H

H

H

H

H

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-393

Page 836 of 1767

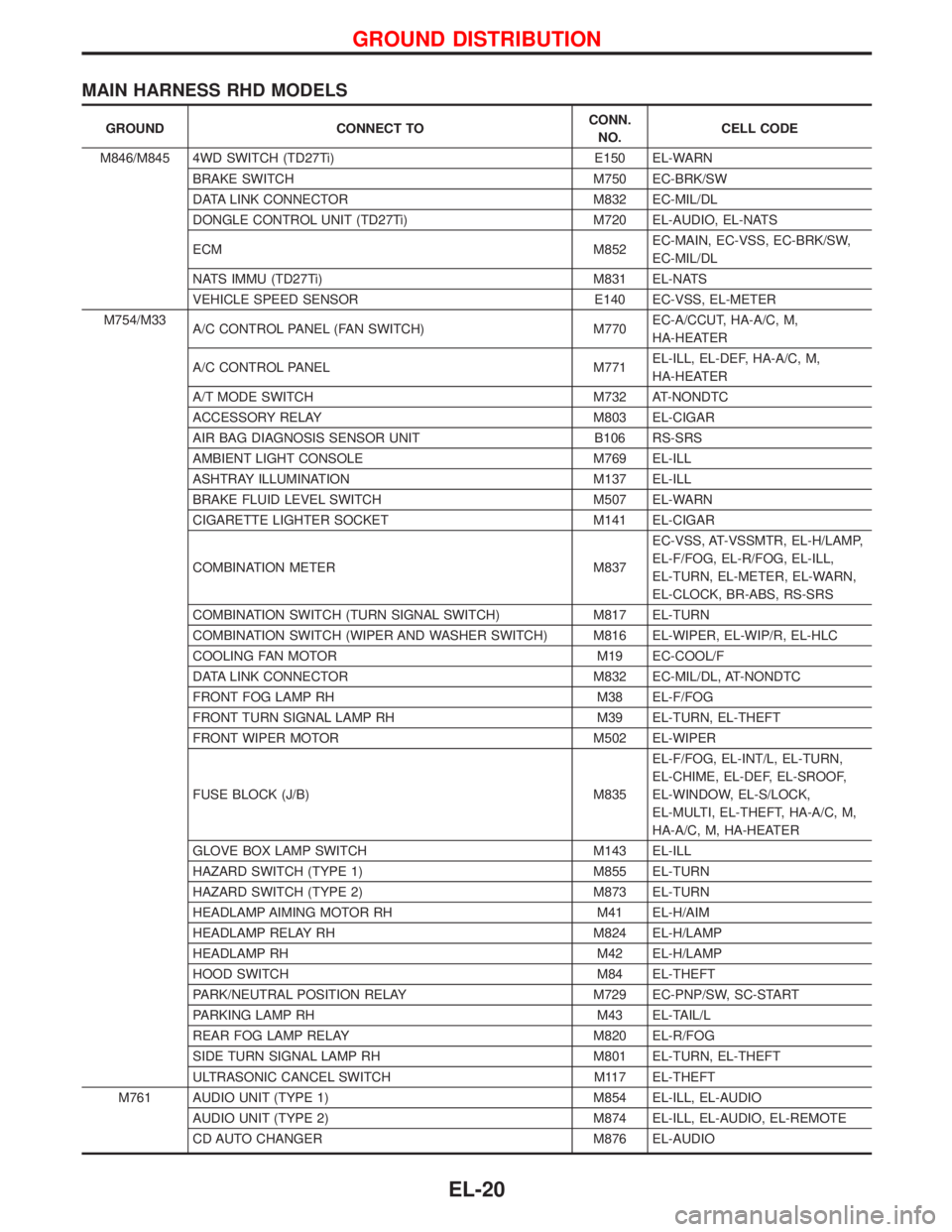

MAIN HARNESS RHD MODELS

GROUND CONNECT TOCONN.

NO.CELL CODE

M846/M845 4WD SWITCH (TD27Ti) E150 EL-WARN

BRAKE SWITCH M750 EC-BRK/SW

DATA LINK CONNECTOR M832 EC-MIL/DL

DONGLE CONTROL UNIT (TD27Ti) M720 EL-AUDIO, EL-NATS

ECM M852EC-MAIN, EC-VSS, EC-BRK/SW,

EC-MIL/DL

NATS IMMU (TD27Ti) M831 EL-NATS

VEHICLE SPEED SENSOR E140 EC-VSS, EL-METER

M754/M33

A/C CONTROL PANEL (FAN SWITCH) M770EC-A/CCUT, HA-A/C, M,

HA-HEATER

A/C CONTROL PANEL M771EL-ILL, EL-DEF, HA-A/C, M,

HA-HEATER

A/T MODE SWITCH M732 AT-NONDTC

ACCESSORY RELAY M803 EL-CIGAR

AIR BAG DIAGNOSIS SENSOR UNIT B106 RS-SRS

AMBIENT LIGHT CONSOLE M769 EL-ILL

ASHTRAY ILLUMINATION M137 EL-ILL

BRAKE FLUID LEVEL SWITCH M507 EL-WARN

CIGARETTE LIGHTER SOCKET M141 EL-CIGAR

COMBINATION METER M837EC-VSS, AT-VSSMTR, EL-H/LAMP,

EL-F/FOG, EL-R/FOG, EL-ILL,

EL-TURN, EL-METER, EL-WARN,

EL-CLOCK, BR-ABS, RS-SRS

COMBINATION SWITCH (TURN SIGNAL SWITCH) M817 EL-TURN

COMBINATION SWITCH (WIPER AND WASHER SWITCH) M816 EL-WIPER, EL-WIP/R, EL-HLC

COOLING FAN MOTOR M19 EC-COOL/F

DATA LINK CONNECTOR M832 EC-MIL/DL, AT-NONDTC

FRONT FOG LAMP RH M38 EL-F/FOG

FRONT TURN SIGNAL LAMP RH M39 EL-TURN, EL-THEFT

FRONT WIPER MOTOR M502 EL-WIPER

FUSE BLOCK (J/B) M835EL-F/FOG, EL-INT/L, EL-TURN,

EL-CHIME, EL-DEF, EL-SROOF,

EL-WINDOW, EL-S/LOCK,

EL-MULTI, EL-THEFT, HA-A/C, M,

HA-A/C, M, HA-HEATER

GLOVE BOX LAMP SWITCH M143 EL-ILL

HAZARD SWITCH (TYPE 1) M855 EL-TURN

HAZARD SWITCH (TYPE 2) M873 EL-TURN

HEADLAMP AIMING MOTOR RH M41 EL-H/AIM

HEADLAMP RELAY RH M824 EL-H/LAMP

HEADLAMP RH M42 EL-H/LAMP

HOOD SWITCH M84 EL-THEFT

PARK/NEUTRAL POSITION RELAY M729 EC-PNP/SW, SC-START

PARKING LAMP RH M43 EL-TAIL/L

REAR FOG LAMP RELAY M820 EL-R/FOG

SIDE TURN SIGNAL LAMP RH M801 EL-TURN, EL-THEFT

ULTRASONIC CANCEL SWITCH M117 EL-THEFT

M761 AUDIO UNIT (TYPE 1) M854 EL-ILL, EL-AUDIO

AUDIO UNIT (TYPE 2) M874 EL-ILL, EL-AUDIO, EL-REMOTE

CD AUTO CHANGER M876 EL-AUDIO

GROUND DISTRIBUTION

EL-20

Page 940 of 1767

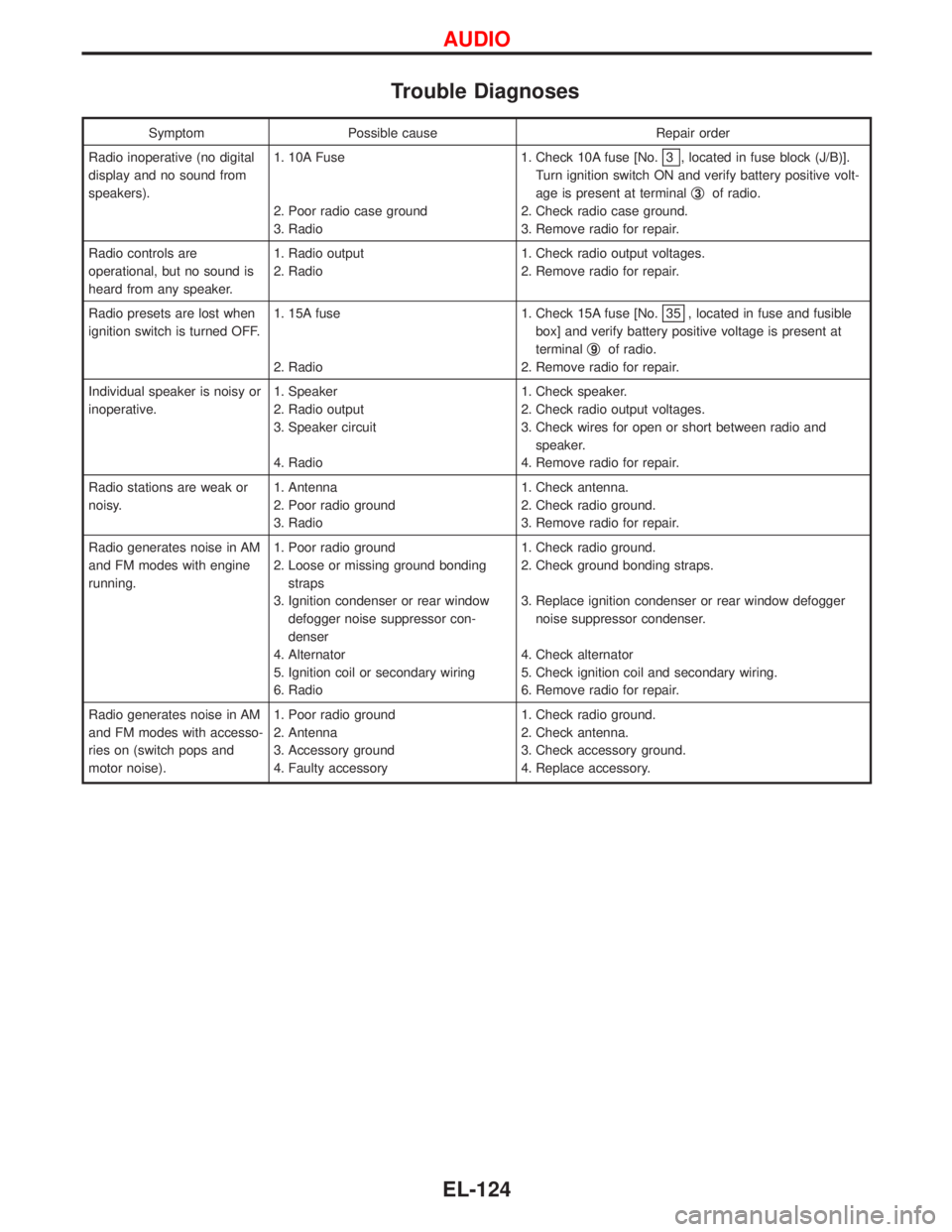

Trouble Diagnoses

Symptom Possible cause Repair order

Radio inoperative (no digital

display and no sound from

speakers).1. 10A Fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse [No.

3 , located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive volt-

age is present at terminalq

3of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are

operational, but no sound is

heard from any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 15A fuse

2. Radio1. Check 15A fuse [No.

35 , located in fuse and fusible

box] and verify battery positive voltage is present at

terminalq

9of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and

speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

Radio generates noise in AM

and FM modes with engine

running.1. Poor radio ground

2. Loose or missing ground bonding

straps

3. Ignition condenser or rear window

defogger noise suppressor con-

denser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger

noise suppressor condenser.

4. Check alternator

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates noise in AM

and FM modes with accesso-

ries on (switch pops and

motor noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

AUDIO

EL-124

Page 1055 of 1767

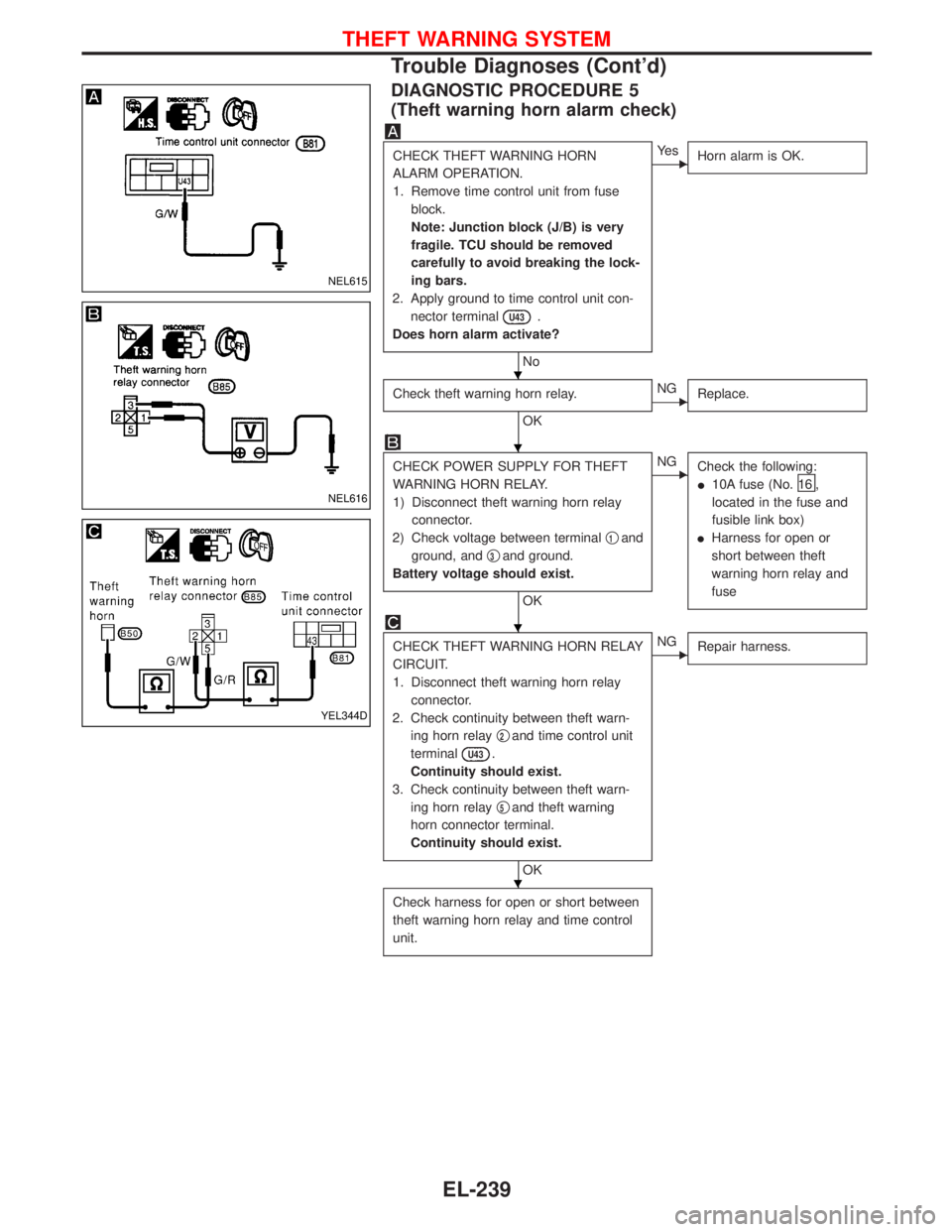

DIAGNOSTIC PROCEDURE 5

(Theft warning horn alarm check)

CHECK THEFT WARNING HORN

ALARM OPERATION.

1. Remove time control unit from fuse

block.

Note: Junction block (J/B) is very

fragile. TCU should be removed

carefully to avoid breaking the lock-

ing bars.

2. Apply ground to time control unit con-

nector terminal

U43.

Does horn alarm activate?

No

EYe s

Horn alarm is OK.

Check theft warning horn relay.

OK

ENG

Replace.

CHECK POWER SUPPLY FOR THEFT

WARNING HORN RELAY.

1) Disconnect theft warning horn relay

connector.

2) Check voltage between terminalq

1and

ground, andq

3and ground.

Battery voltage should exist.

OK

ENG

Check the following:

I10A fuse (No.

16 ,

located in the fuse and

fusible link box)

IHarness for open or

short between theft

warning horn relay and

fuse

CHECK THEFT WARNING HORN RELAY

CIRCUIT.

1. Disconnect theft warning horn relay

connector.

2. Check continuity between theft warn-

ing horn relayq

2and time control unit

terminal

U43.

Continuity should exist.

3. Check continuity between theft warn-

ing horn relayq

5and theft warning

horn connector terminal.

Continuity should exist.

OK

ENG

Repair harness.

Check harness for open or short between

theft warning horn relay and time control

unit.

NEL615

NEL616

YEL344D

H

H

H

H

THEFT WARNING SYSTEM

Trouble Diagnoses (Cont'd)

EL-239

Page 1118 of 1767

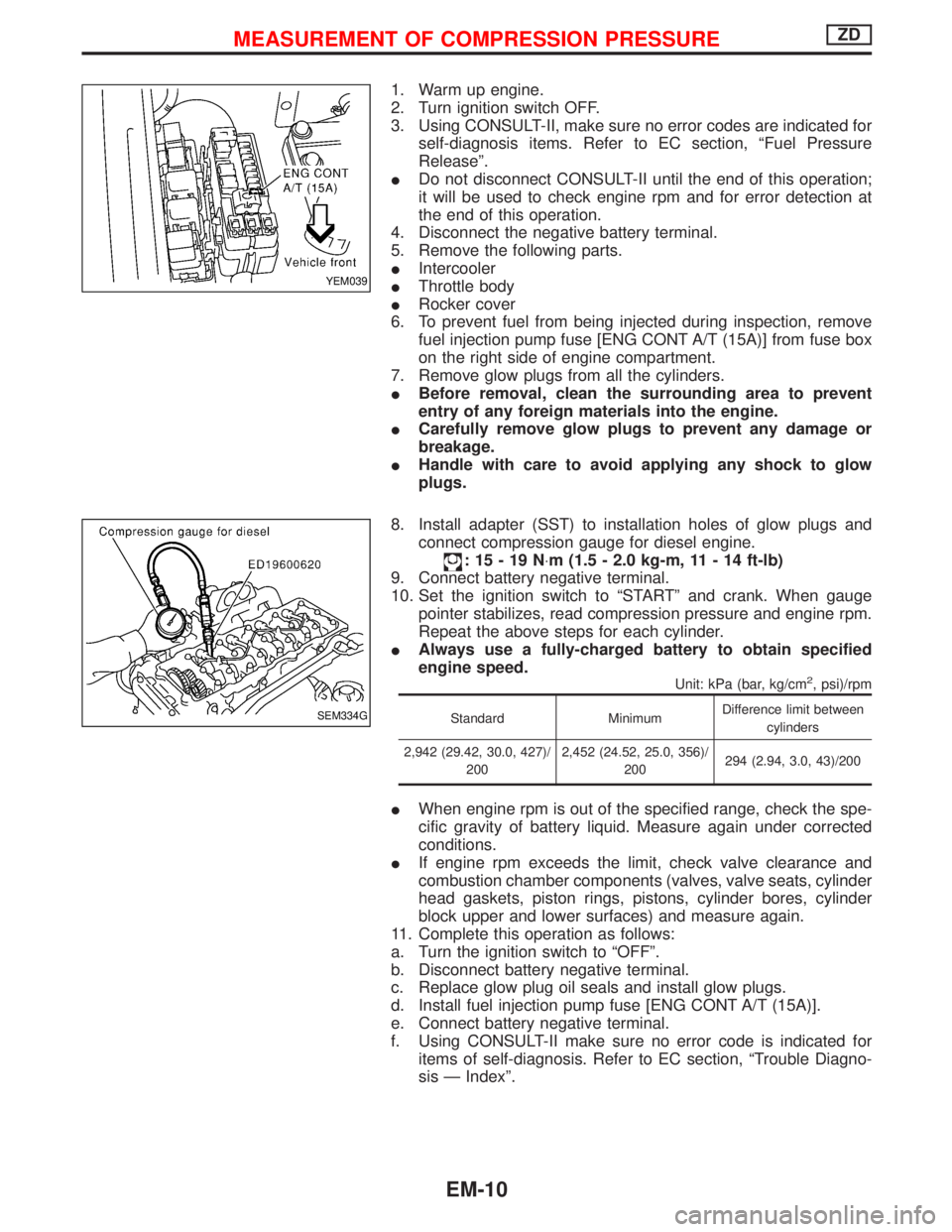

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

IDo not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

IIntercooler

IThrottle body

IRocker cover

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT A/T (15A)] from fuse box

on the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

IBefore removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

ICarefully remove glow plugs to prevent any damage or

breakage.

IHandle with care to avoid applying any shock to glow

plugs.

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:15-19N×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

IAlways use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/

2002,452 (24.52, 25.0, 356)/

200294 (2.94, 3.0, 43)/200

IWhen engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

IIf engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylinder

head gaskets, piston rings, pistons, cylinder bores, cylinder

block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT A/T (15A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, ªTrouble Diagno-

sis Ð Indexº.

YEM039

SEM334G

MEASUREMENT OF COMPRESSION PRESSUREZD

EM-10

Page 1313 of 1767

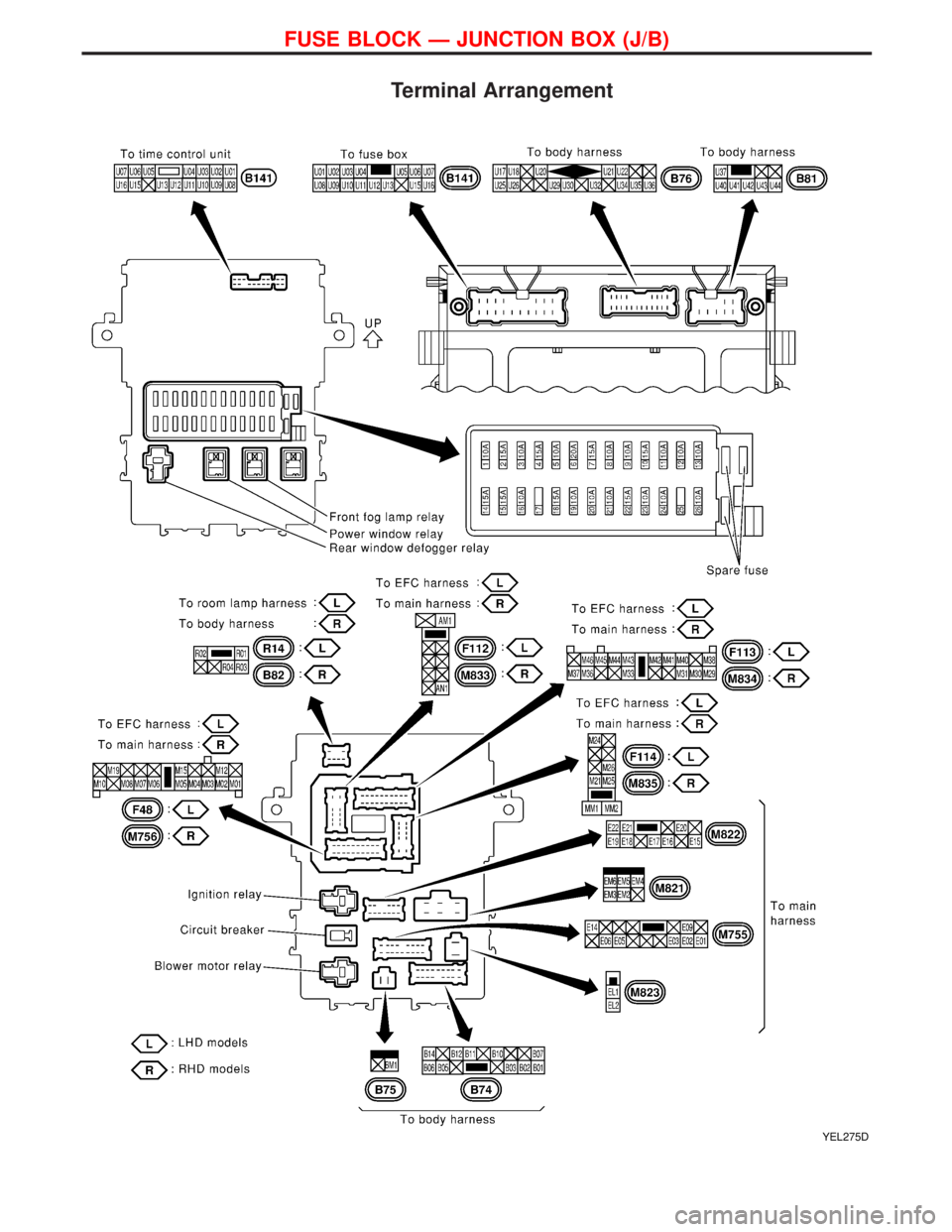

Terminal Arrangement

YEL275D

FUSE BLOCK Ð JUNCTION BOX (J/B)