water pump NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 472 of 1767

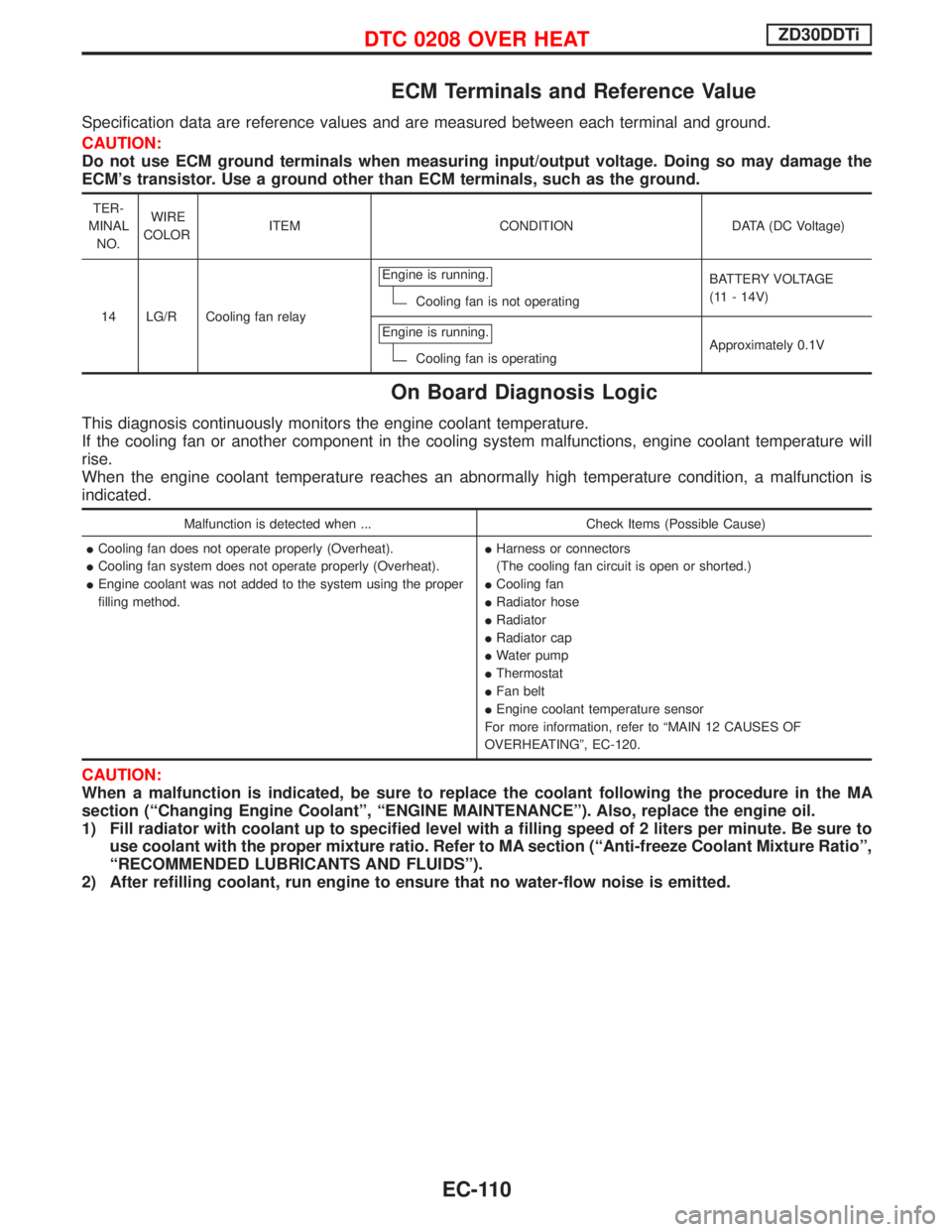

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 LG/R Cooling fan relayEngine is running.

Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operatingApproximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ... Check Items (Possible Cause)

ICooling fan does not operate properly (Overheat).

ICooling fan system does not operate properly (Overheat).

IEngine coolant was not added to the system using the proper

filling method.IHarness or connectors

(The cooling fan circuit is open or shorted.)

ICooling fan

IRadiator hose

IRadiator

IRadiator cap

IWater pump

IThermostat

IFan belt

IEngine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-120.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-110

Page 480 of 1767

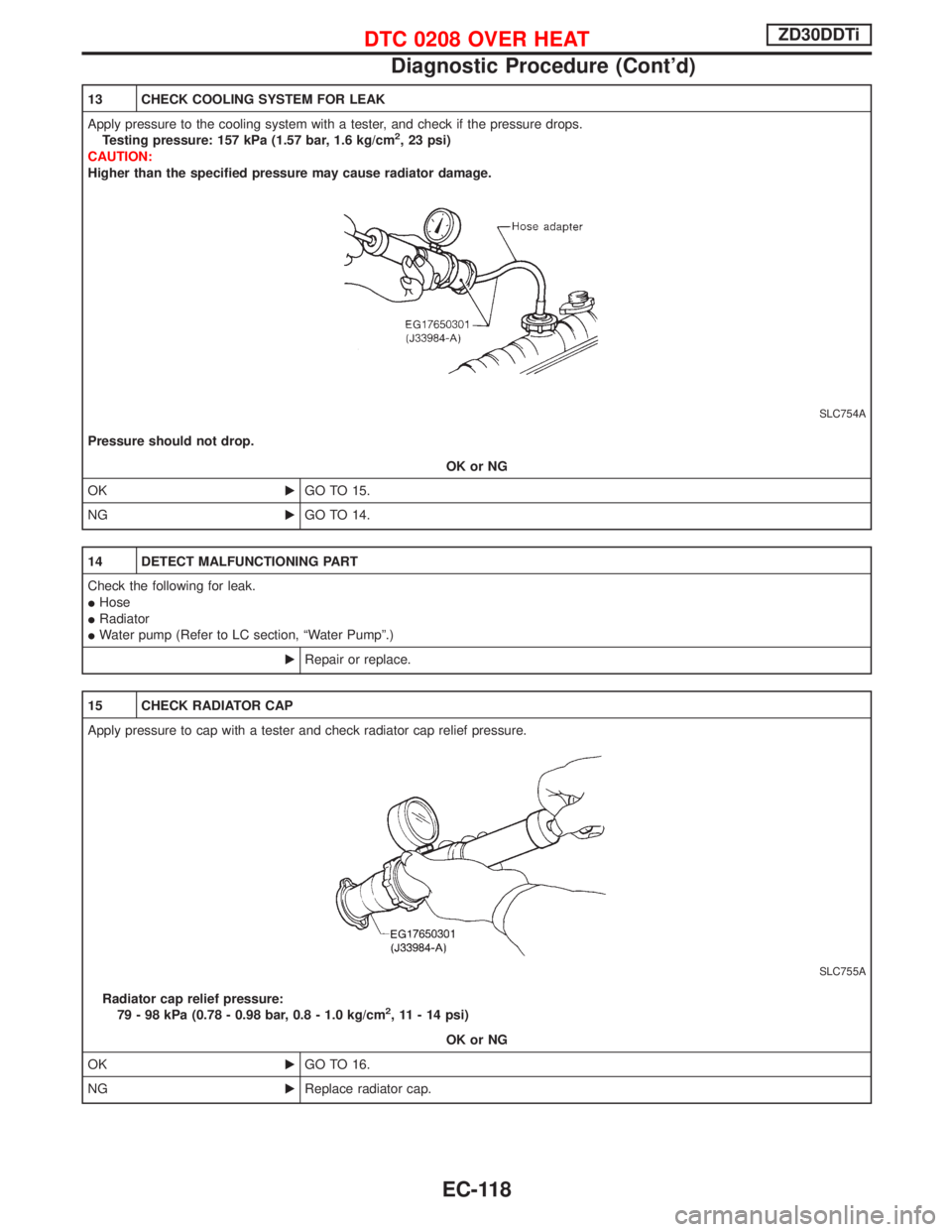

13 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OKEGO TO 15.

NGEGO TO 14.

14 DETECT MALFUNCTIONING PART

Check the following for leak.

IHose

IRadiator

IWater pump (Refer to LC section, ªWater Pumpº.)

ERepair or replace.

15 CHECK RADIATOR CAP

Apply pressure to cap with a tester and check radiator cap relief pressure.

SLC755A

Radiator cap relief pressure:

79 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0 kg/cm2, 11 - 14 psi)

OK or NG

OKEGO TO 16.

NGEReplace radiator cap.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-118

Page 559 of 1767

Diagnostic Procedure

1 INSPECTION START

1. Turn ignition switch ªOFFº.

2. Perform ªAir Bleedingº, EC-32, and ªDRAINING WATERº in MA section.

EGO TO 2.

2 PERFORM DTC CONFIRMATION PROCEDURE AGAIN

Perform ªDTC Confirmation Procedureº, EC-194 again.

OK or NG

OKEINSPECTION END

NGEGO TO 3.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0707 P7×F/INJ TIMG FBZD30DDTi

EC-197

Page 780 of 1767

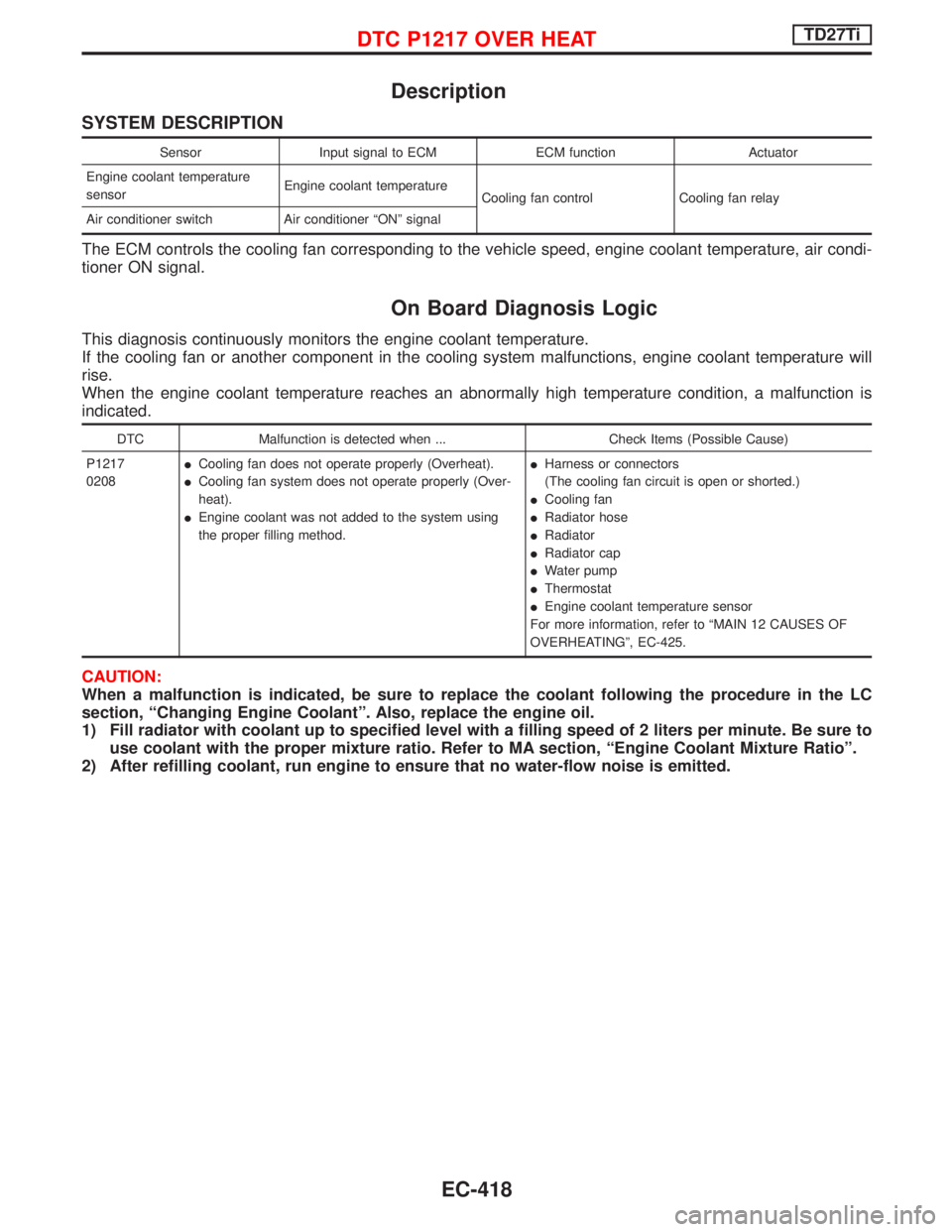

Description

SYSTEM DESCRIPTION

Sensor Input signal to ECM ECM function Actuator

Engine coolant temperature

sensorEngine coolant temperature

Cooling fan control Cooling fan relay

Air conditioner switch Air conditioner ªONº signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, air condi-

tioner ON signal.

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1217

0208ICooling fan does not operate properly (Overheat).

ICooling fan system does not operate properly (Over-

heat).

IEngine coolant was not added to the system using

the proper filling method.IHarness or connectors

(The cooling fan circuit is open or shorted.)

ICooling fan

IRadiator hose

IRadiator

IRadiator cap

IWater pump

IThermostat

IEngine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-425.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the LC

section, ªChanging Engine Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA section, ªEngine Coolant Mixture Ratioº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVER HEATTD27Ti

EC-418

Page 786 of 1767

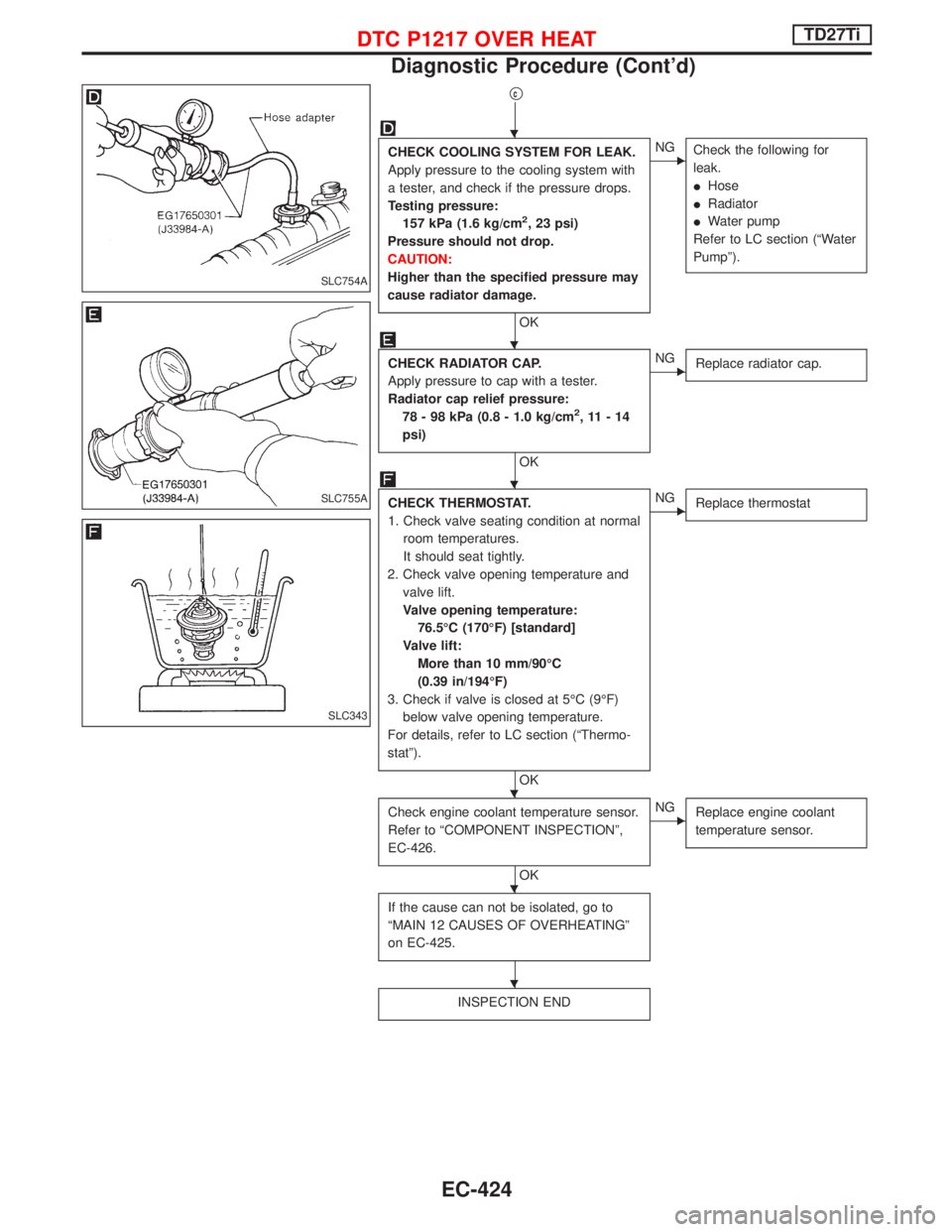

qc

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with

a tester, and check if the pressure drops.

Testing pressure:

157 kPa (1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

ENG

Check the following for

leak.

IHose

IRadiator

IWater pump

Refer to LC section (ªWater

Pumpº).

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

78 - 98 kPa (0.8 - 1.0 kg/cm

2,11-14

psi)

OK

ENG

Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and

valve lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 10 mm/90ÉC

(0.39 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF)

below valve opening temperature.

For details, refer to LC section (ªThermo-

statº).

OK

ENG

Replace thermostat

Check engine coolant temperature sensor.

Refer to ªCOMPONENT INSPECTIONº,

EC-426.

OK

ENG

Replace engine coolant

temperature sensor.

If the cause can not be isolated, go to

ªMAIN 12 CAUSES OF OVERHEATINGº

on EC-425.

INSPECTION END

SLC754A

SLC755A

SLC343

H

H

H

H

H

H

DTC P1217 OVER HEATTD27Ti

Diagnostic Procedure (Cont'd)

EC-424

Page 1117 of 1767

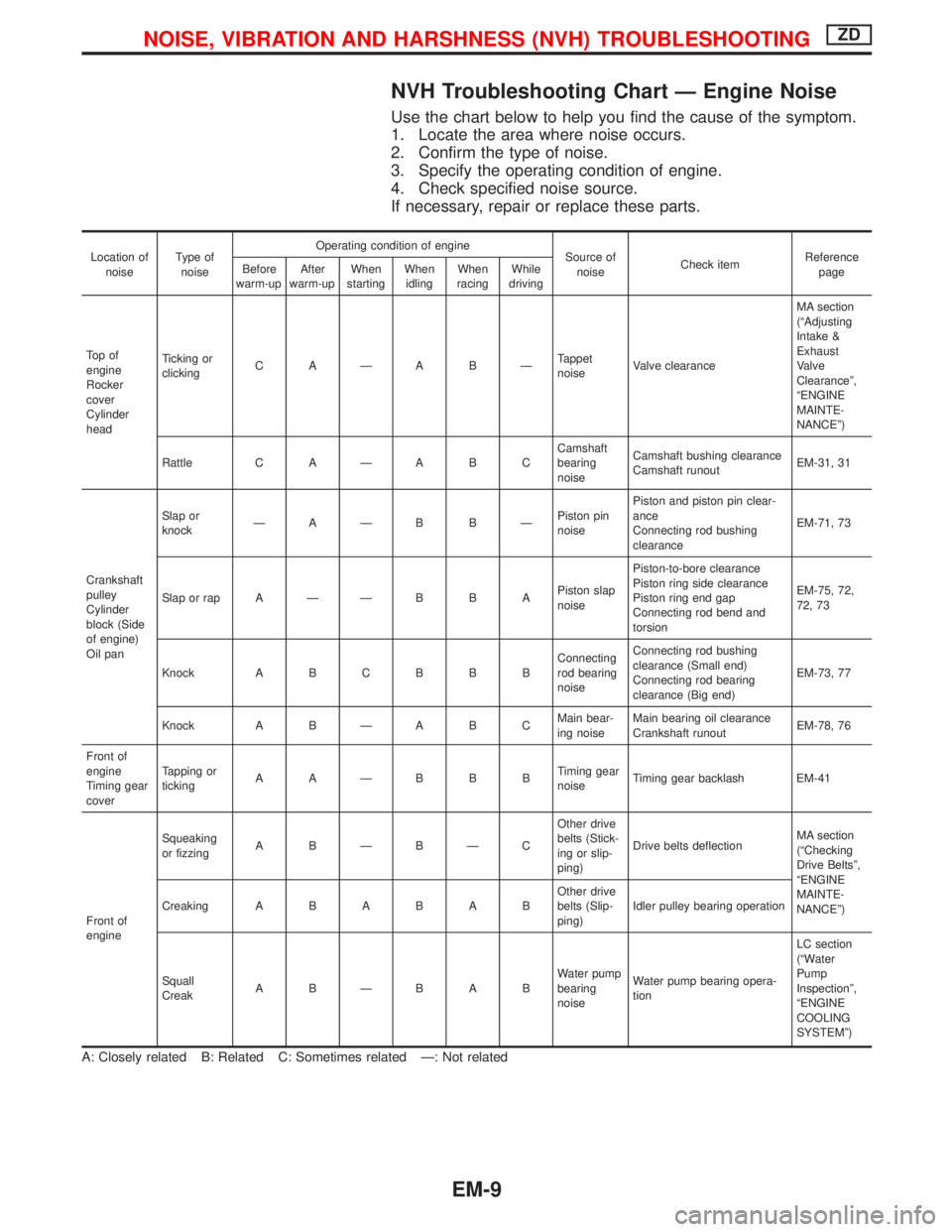

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingC AÐA BÐTappet

noiseValve clearanceMA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft bushing clearance

Camshaft runoutEM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-71, 73

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-75, 72,

72, 73

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-73, 77

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-78, 76

Front of

engine

Timing gear

coverTapping or

tickingAAÐBBBTiming gear

noiseTiming gear backlash EM-41

Front of

engineSqueaking

or fizzingA BÐBÐCOther drive

belts (Stick-

ing or slip-

ping)Drive belts deflectionMA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº) CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

bearing

noiseWater pump bearing opera-

tionLC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGZD

EM-9

Page 1134 of 1767

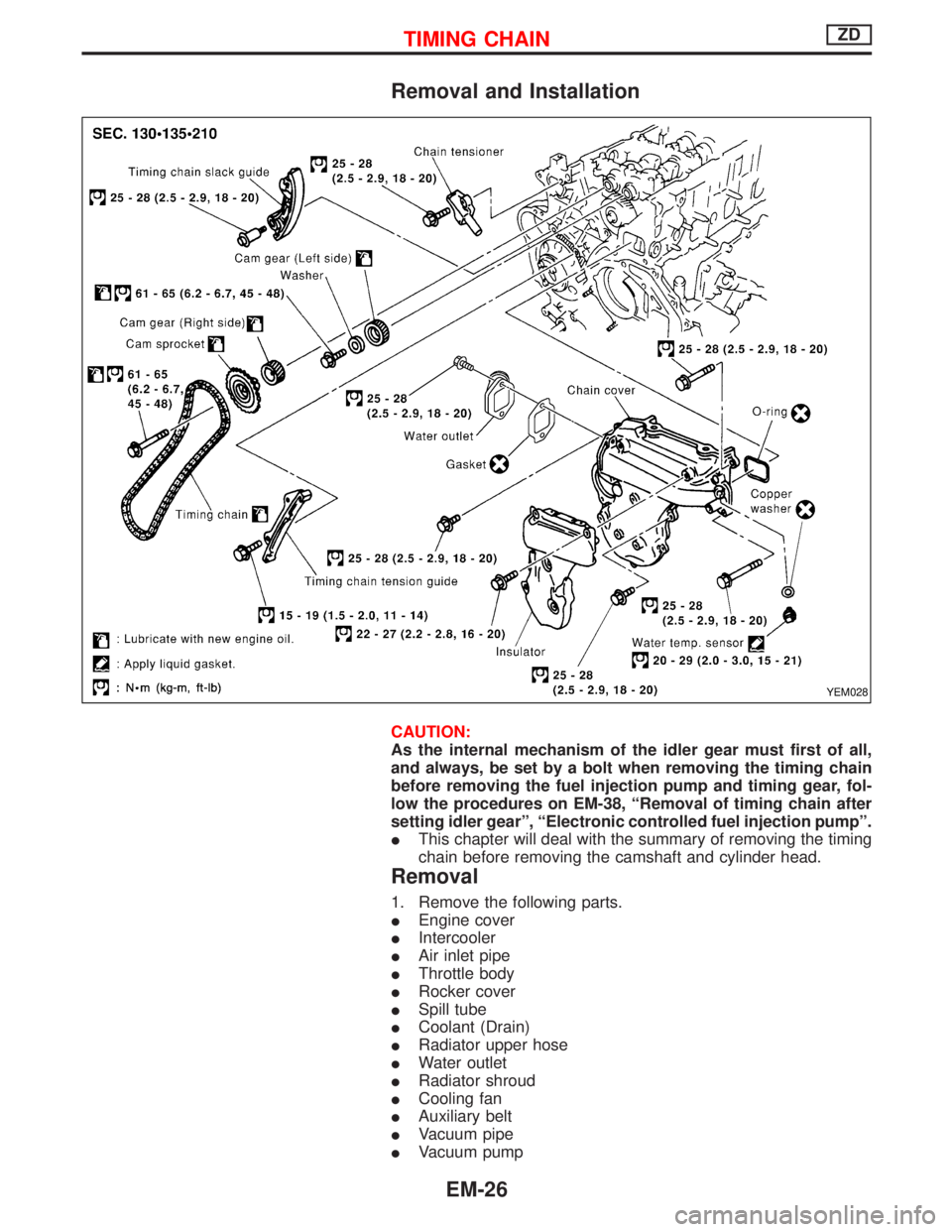

Removal and Installation

CAUTION:

As the internal mechanism of the idler gear must first of all,

and always, be set by a bolt when removing the timing chain

before removing the fuel injection pump and timing gear, fol-

low the procedures on EM-38, ªRemoval of timing chain after

setting idler gearº, ªElectronic controlled fuel injection pumpº.

IThis chapter will deal with the summary of removing the timing

chain before removing the camshaft and cylinder head.

Removal

1. Remove the following parts.

IEngine cover

IIntercooler

IAir inlet pipe

IThrottle body

IRocker cover

ISpill tube

ICoolant (Drain)

IRadiator upper hose

IWater outlet

IRadiator shroud

ICooling fan

IAuxiliary belt

IVacuum pipe

IVacuum pump

YEM028

TIMING CHAINZD

EM-26

Page 1147 of 1767

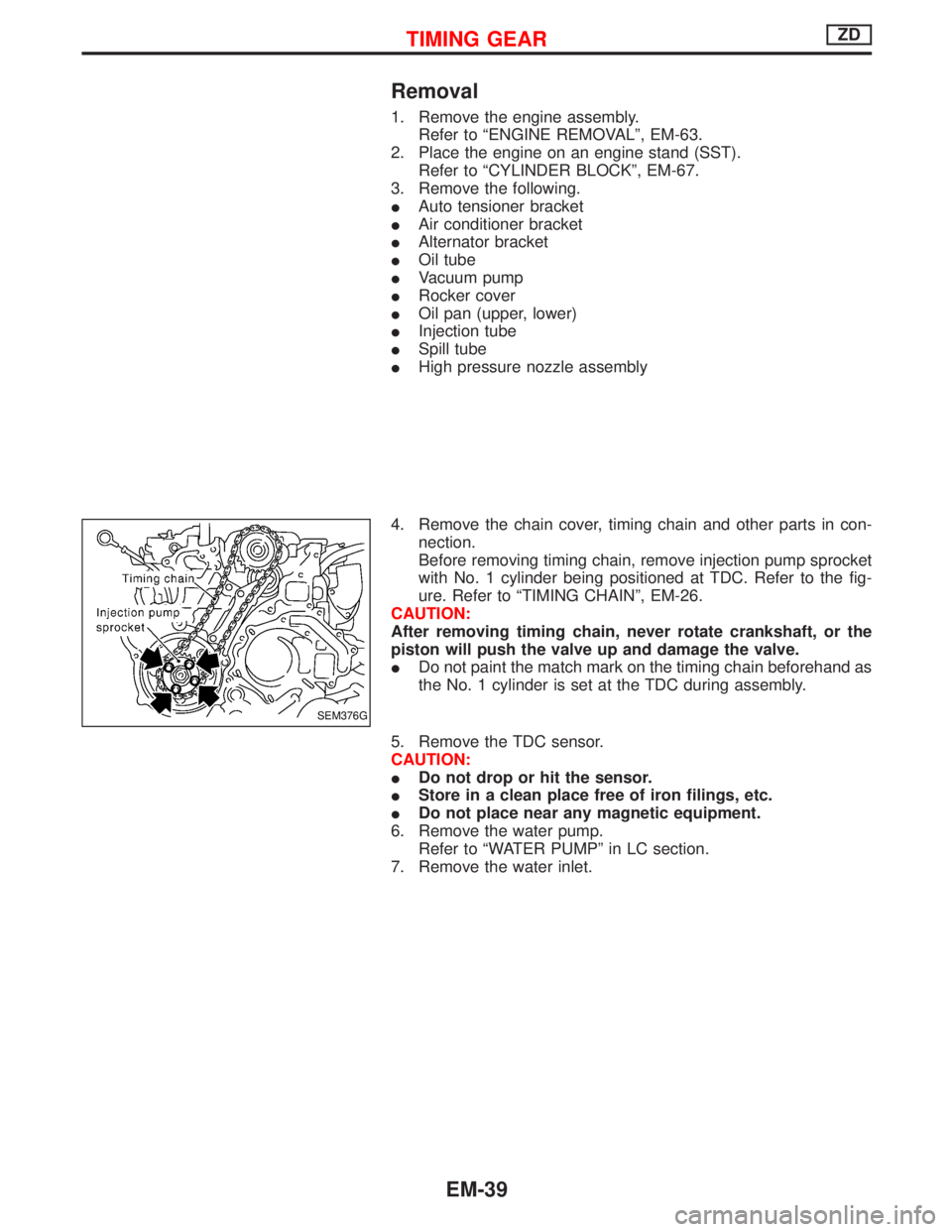

Removal

1. Remove the engine assembly.

Refer to ªENGINE REMOVALº, EM-63.

2. Place the engine on an engine stand (SST).

Refer to ªCYLINDER BLOCKº, EM-67.

3. Remove the following.

IAuto tensioner bracket

IAir conditioner bracket

IAlternator bracket

IOil tube

IVacuum pump

IRocker cover

IOil pan (upper, lower)

IInjection tube

ISpill tube

IHigh pressure nozzle assembly

4. Remove the chain cover, timing chain and other parts in con-

nection.

Before removing timing chain, remove injection pump sprocket

with No. 1 cylinder being positioned at TDC. Refer to the fig-

ure. Refer to ªTIMING CHAINº, EM-26.

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

IDo not paint the match mark on the timing chain beforehand as

the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

IDo not drop or hit the sensor.

IStore in a clean place free of iron filings, etc.

IDo not place near any magnetic equipment.

6. Remove the water pump.

Refer to ªWATER PUMPº in LC section.

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-39

Page 1156 of 1767

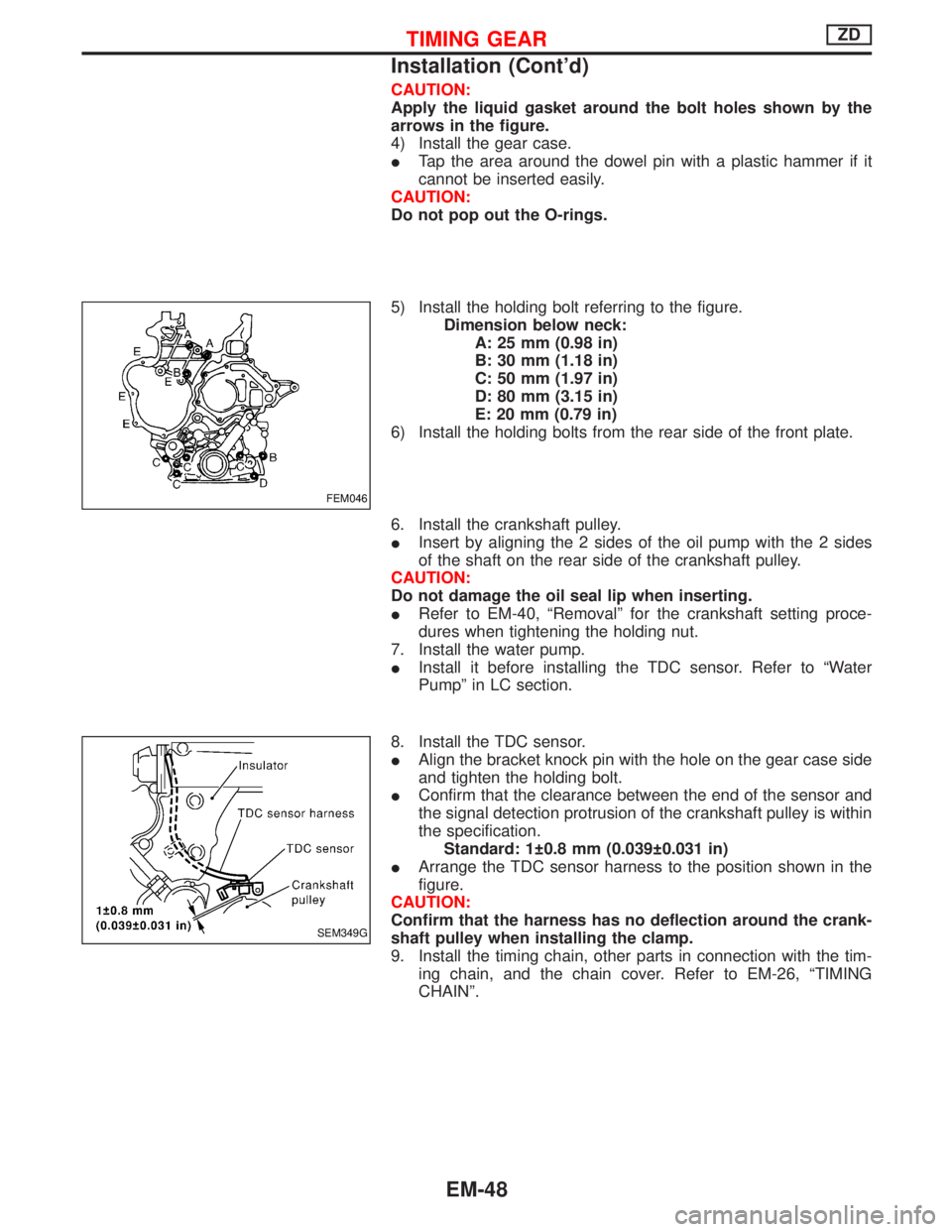

CAUTION:

Apply the liquid gasket around the bolt holes shown by the

arrows in the figure.

4) Install the gear case.

ITap the area around the dowel pin with a plastic hammer if it

cannot be inserted easily.

CAUTION:

Do not pop out the O-rings.

5) Install the holding bolt referring to the figure.

Dimension below neck:

A: 25 mm (0.98 in)

B: 30 mm (1.18 in)

C: 50 mm (1.97 in)

D: 80 mm (3.15 in)

E: 20 mm (0.79 in)

6) Install the holding bolts from the rear side of the front plate.

6. Install the crankshaft pulley.

IInsert by aligning the 2 sides of the oil pump with the 2 sides

of the shaft on the rear side of the crankshaft pulley.

CAUTION:

Do not damage the oil seal lip when inserting.

IRefer to EM-40, ªRemovalº for the crankshaft setting proce-

dures when tightening the holding nut.

7. Install the water pump.

IInstall it before installing the TDC sensor. Refer to ªWater

Pumpº in LC section.

8. Install the TDC sensor.

IAlign the bracket knock pin with the hole on the gear case side

and tighten the holding bolt.

IConfirm that the clearance between the end of the sensor and

the signal detection protrusion of the crankshaft pulley is within

the specification.

Standard: 1 0.8 mm (0.039 0.031 in)

IArrange the TDC sensor harness to the position shown in the

figure.

CAUTION:

Confirm that the harness has no deflection around the crank-

shaft pulley when installing the clamp.

9. Install the timing chain, other parts in connection with the tim-

ing chain, and the chain cover. Refer to EM-26, ªTIMING

CHAINº.

FEM046

SEM349G

TIMING GEARZD

Installation (Cont'd)

EM-48

Page 1160 of 1767

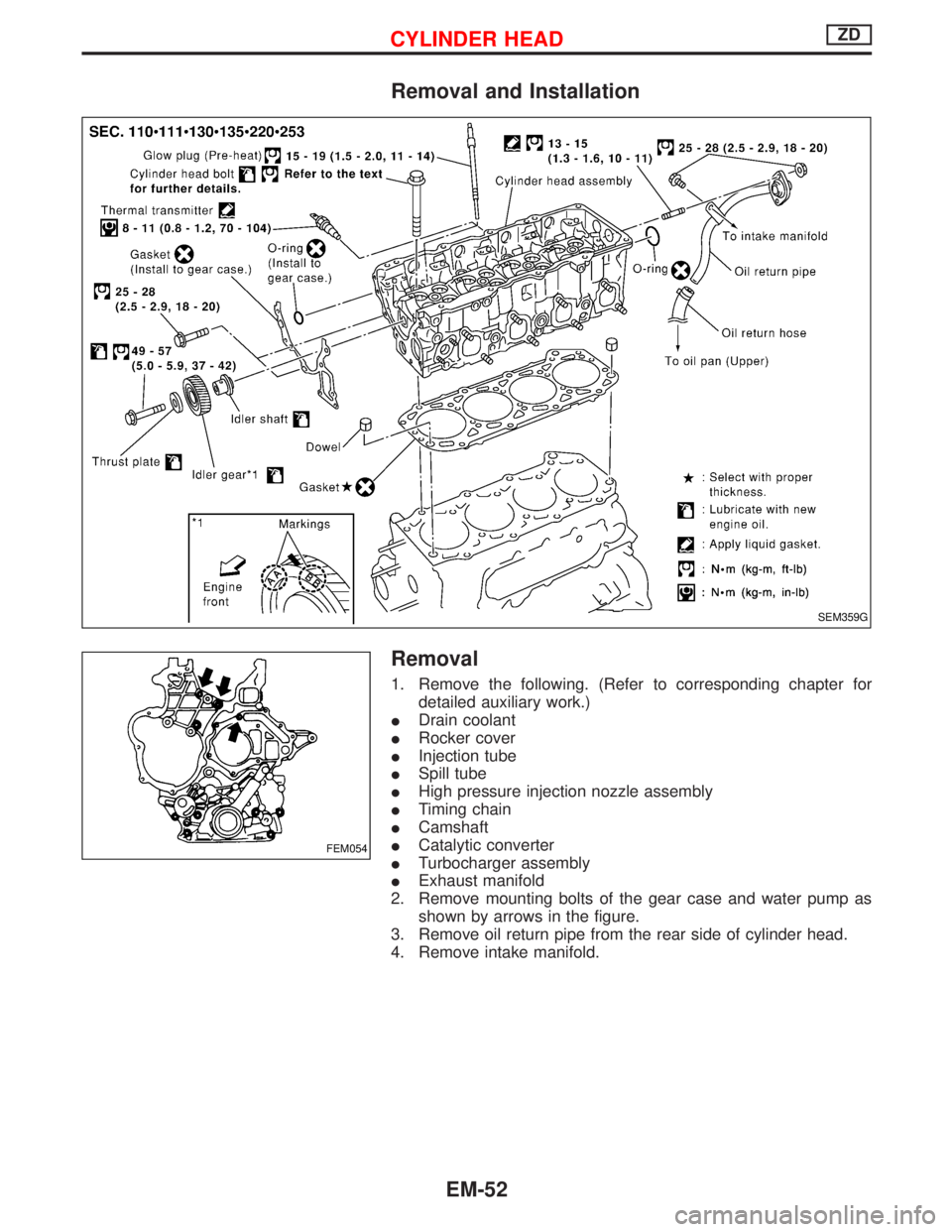

Removal and Installation

Removal

1. Remove the following. (Refer to corresponding chapter for

detailed auxiliary work.)

IDrain coolant

IRocker cover

IInjection tube

ISpill tube

IHigh pressure injection nozzle assembly

ITiming chain

ICamshaft

ICatalytic converter

ITurbocharger assembly

IExhaust manifold

2. Remove mounting bolts of the gear case and water pump as

shown by arrows in the figure.

3. Remove oil return pipe from the rear side of cylinder head.

4. Remove intake manifold.

SEM359G

FEM054

CYLINDER HEADZD

EM-52