clock NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1002 of 1833

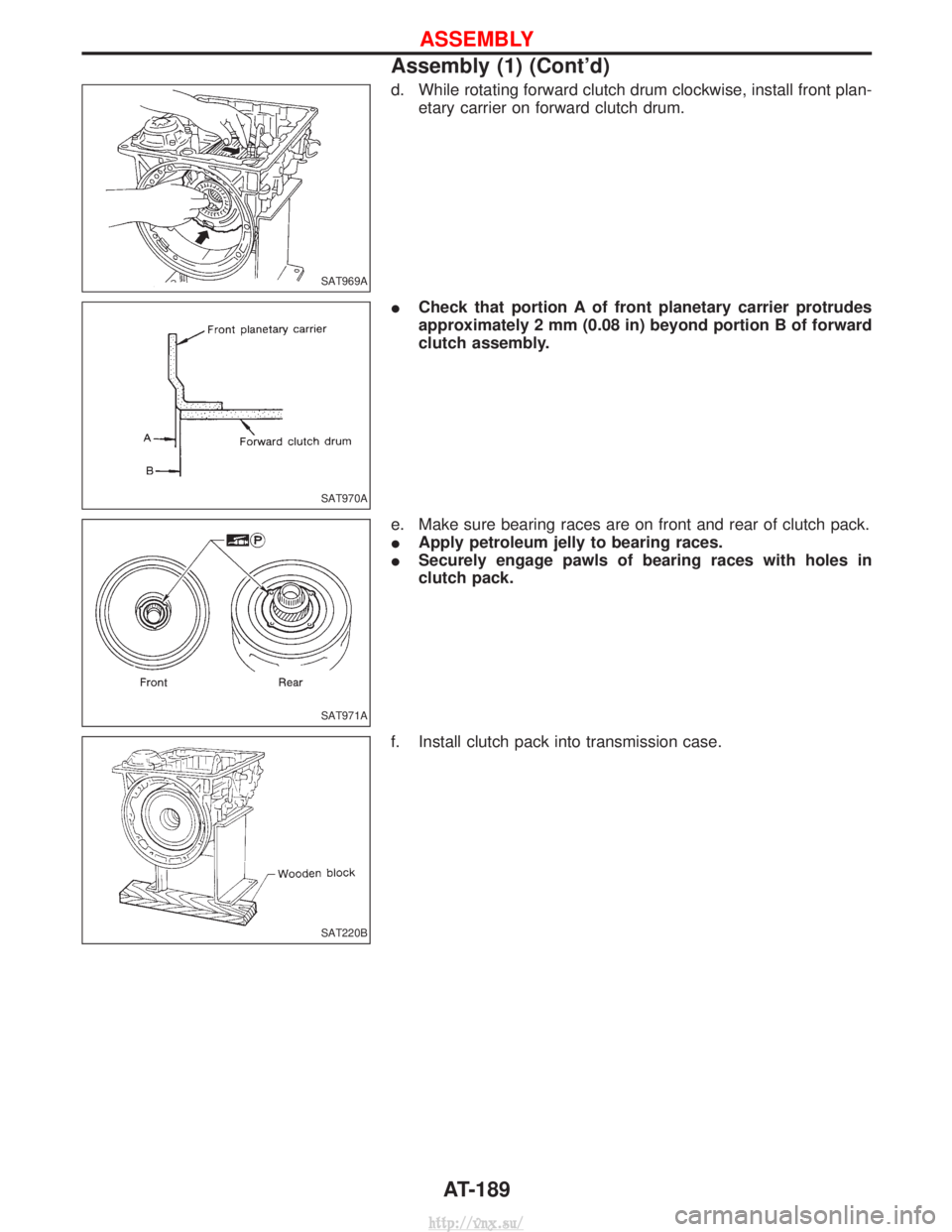

d. While rotating forward clutch drum clockwise, install front plan-etary carrier on forward clutch drum.

I Check that portion A of front planetary carrier protrudes

approximately 2 mm (0.08 in) beyond portion B of forward

clutch assembly.

e. Make sure bearing races are on front and rear of clutch pack.

I Apply petroleum jelly to bearing races.

I Securely engage pawls of bearing races with holes in

clutch pack.

f. Install clutch pack into transmission case.

SAT969A

SAT970A

SAT971A

SAT220B

ASSEMBLY

Assembly (1) (Cont'd)

AT-189

http://vnx.su/

Page 1191 of 1833

Removal and Installation

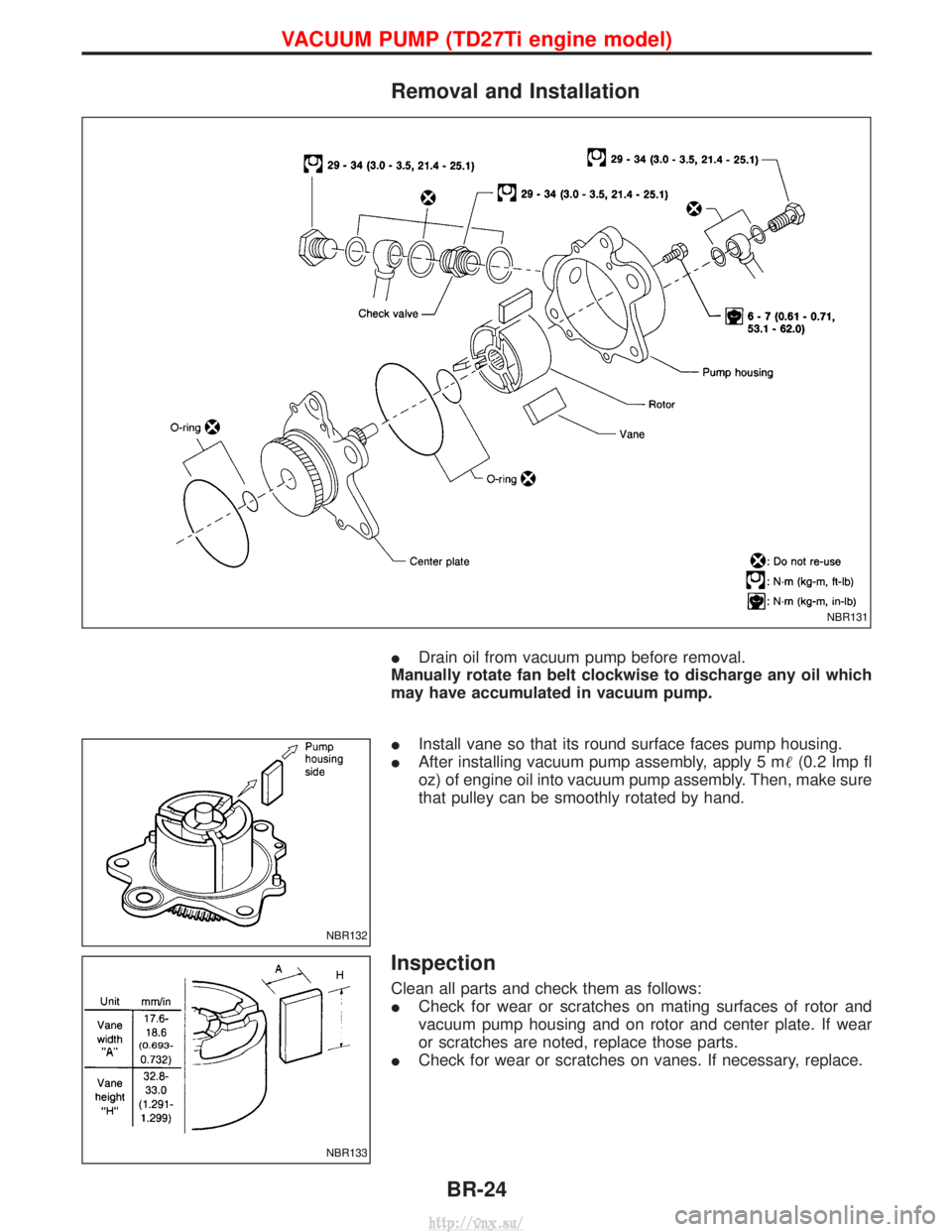

IDrain oil from vacuum pump before removal.

Manually rotate fan belt clockwise to discharge any oil which

may have accumulated in vacuum pump.

I Install vane so that its round surface faces pump housing.

I After installing vacuum pump assembly, apply 5 m (0.2 Imp fl

oz) of engine oil into vacuum pump assembly. Then, make sure

that pulley can be smoothly rotated by hand.

Inspection

Clean all parts and check them as follows:

I Check for wear or scratches on mating surfaces of rotor and

vacuum pump housing and on rotor and center plate. If wear

or scratches are noted, replace those parts.

I Check for wear or scratches on vanes. If necessary, replace.

NBR131

NBR132

NBR133

VACUUM PUMP (TD27Ti engine model)

BR-24

http://vnx.su/

Page 1268 of 1833

Inspection and Adjustment

STEERING GEAR PRELOAD

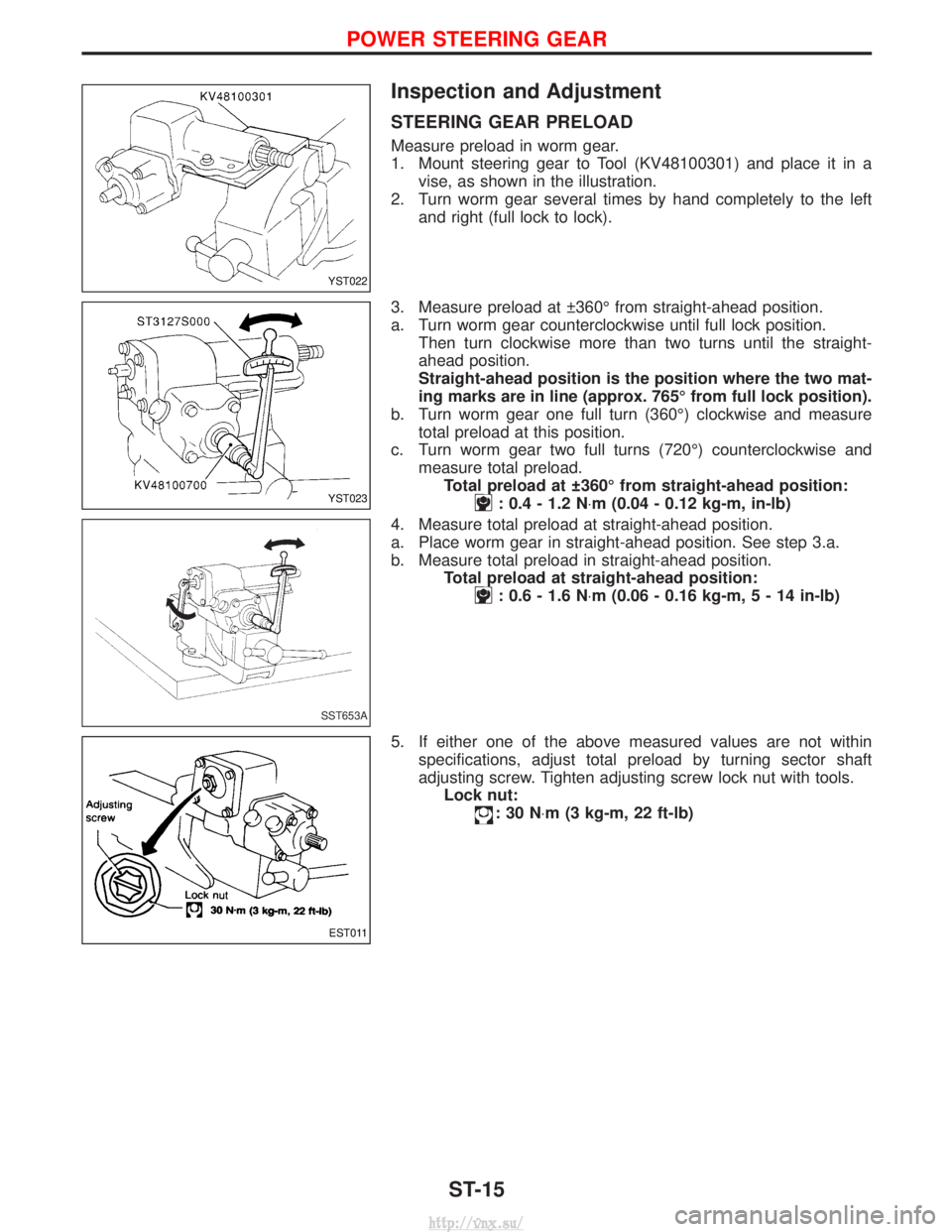

Measure preload in worm gear.

1. Mount steering gear to Tool (KV48100301) and place it in avise, as shown in the illustration.

2. Turn worm gear several times by hand completely to the left and right (full lock to lock).

3. Measure preload at 360É from straight-ahead position.

a. Turn worm gear counterclockwise until full lock position. Then turn clockwise more than two turns until the straight-

ahead position.

Straight-ahead position is the position where the two mat-

ing marks are in line (approx. 765É from full lock position).

b. Turn worm gear one full turn (360É) clockwise and measure total preload at this position.

c. Turn worm gear two full turns (720É) counterclockwise and measure total preload.Total preload at 360É from straight-ahead position:

: 0.4 - 1.2 N ×m (0.04 - 0.12 kg-m, in-lb)

4. Measure total preload at straight-ahead position.

a. Place worm gear in straight-ahead position. See step 3.a.

b. Measure total preload in straight-ahead position. Total preload at straight-ahead position:

: 0.6 - 1.6 N ×m (0.06 - 0.16 kg-m ,5-14in-lb)

5. If either one of the above measured values are not within specifications, adjust total preload by turning sector shaft

adjusting screw. Tighten adjusting screw lock nut with tools.Lock nut:

:30N ×m (3 kg-m, 22 ft-lb)

YST022

YST023

SST653A

EST011

POWER STEERING GEAR

ST-15

http://vnx.su/

Page 1293 of 1833

4. Set steering wheel in the neutral position.

5. Disconnect horn connector (or horn/audio connector) andremove nut.

6. Remove steering wheel.

CAUTION:

I Do not tap or bump the steering wheel.

7. Remove steering column cover.

8. Disconnect in order the air bag module connector and the (horn/audio steering switch) connector behind the spiral cable.

9. Remove spiral cable securing screws, and while pushing the upper plastic tab, remove the spiral cable.

CAUTION:

I Do not attempt to disassemble spiral cable.

I Do not apply lubricant to the spiral cable.

INSTALLATION

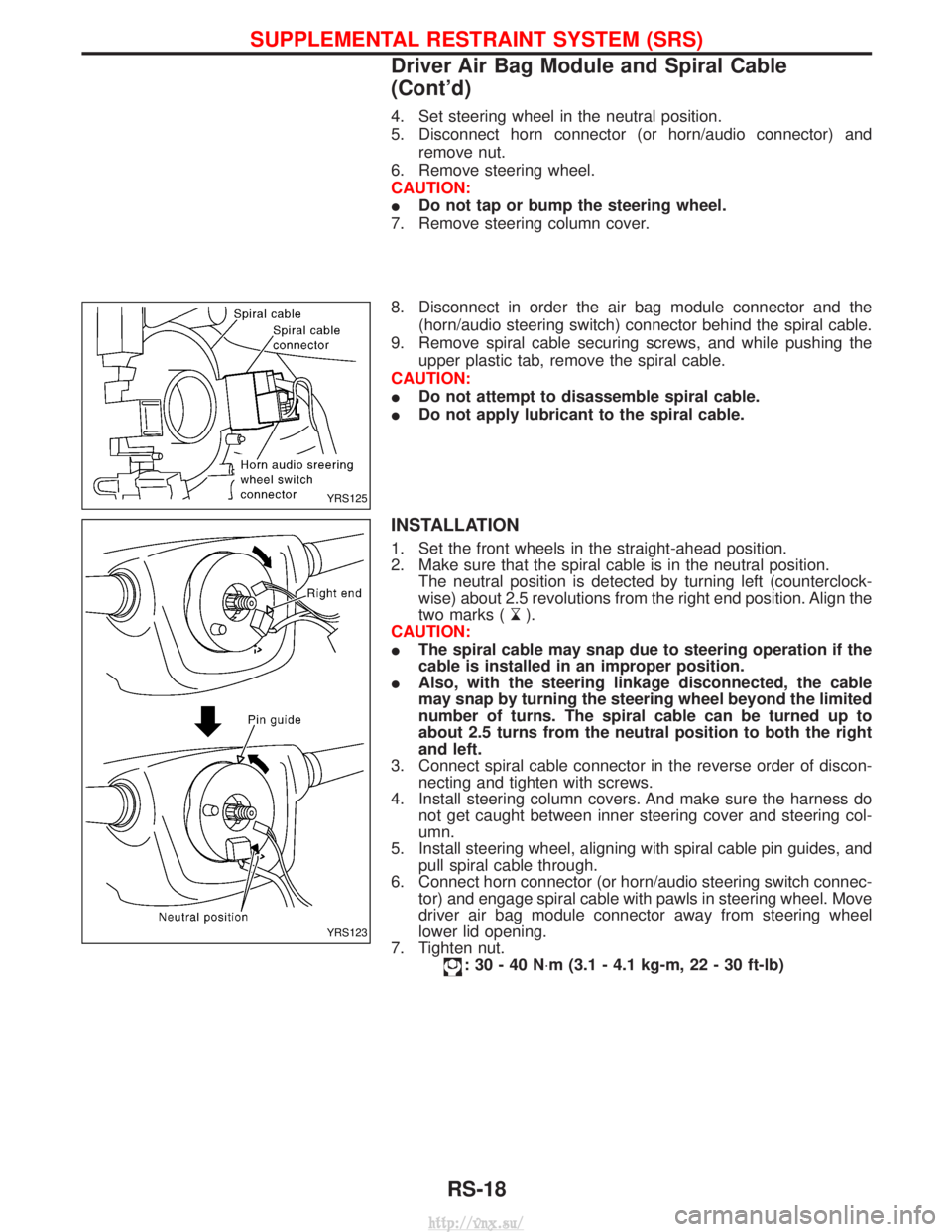

1. Set the front wheels in the straight-ahead position.

2. Make sure that the spiral cable is in the neutral position.

The neutral position is detected by turning left (counterclock-

wise) about 2.5 revolutions from the right end position. Align the

two marks (

).

CAUTION:

I The spiral cable may snap due to steering operation if the

cable is installed in an improper position.

I Also, with the steering linkage disconnected, the cable

may snap by turning the steering wheel beyond the limited

number of turns. The spiral cable can be turned up to

about 2.5 turns from the neutral position to both the right

and left.

3. Connect spiral cable connector in the reverse order of discon- necting and tighten with screws.

4. Install steering column covers. And make sure the harness do not get caught between inner steering cover and steering col-

umn.

5. Install steering wheel, aligning with spiral cable pin guides, and pull spiral cable through.

6. Connect horn connector (or horn/audio steering switch connec- tor) and engage spiral cable with pawls in steering wheel. Move

driver air bag module connector away from steering wheel

lower lid opening.

7. Tighten nut.

:30-40N ×m (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

YRS125

YRS123

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Driver Air Bag Module and Spiral Cable

(Cont'd)

RS-18

http://vnx.su/

Page 1412 of 1833

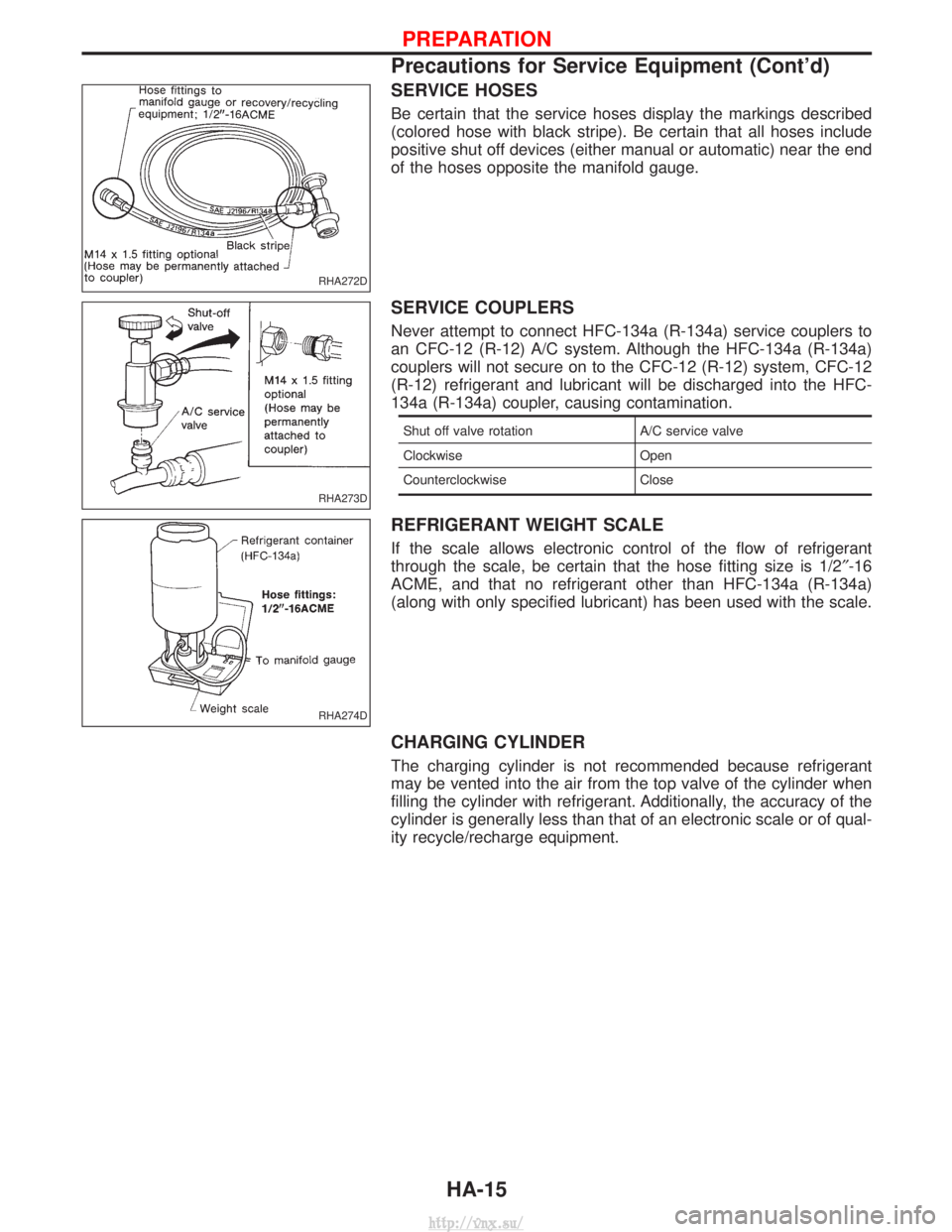

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). Be certain that all hoses include

positive shut off devices (either manual or automatic) near the end

of the hoses opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to

an CFC-12 (R-12) A/C system. Although the HFC-134a (R-134a)

couplers will not secure on to the CFC-12 (R-12) system, CFC-12

(R-12) refrigerant and lubricant will be discharged into the HFC-

134a (R-134a) coupler, causing contamination.

Shut off valve rotationA/C service valve

Clockwise Open

Counterclockwise Close

REFRIGERANT WEIGHT SCALE

If the scale allows electronic control of the flow of refrigerant

through the scale, be certain that the hose fitting size is 1/2 ²-16

ACME, and that no refrigerant other than HFC-134a (R-134a)

(along with only specified lubricant) has been used with the scale.

CHARGING CYLINDER

The charging cylinder is not recommended because refrigerant

may be vented into the air from the top valve of the cylinder when

filling the cylinder with refrigerant. Additionally, the accuracy of the

cylinder is generally less than that of an electronic scale or of qual-

ity recycle/recharge equipment.

RHA272D

RHA273D

RHA274D

PREPARATION

Precautions for Service Equipment (Cont'd)

HA-15

http://vnx.su/

Page 1422 of 1833

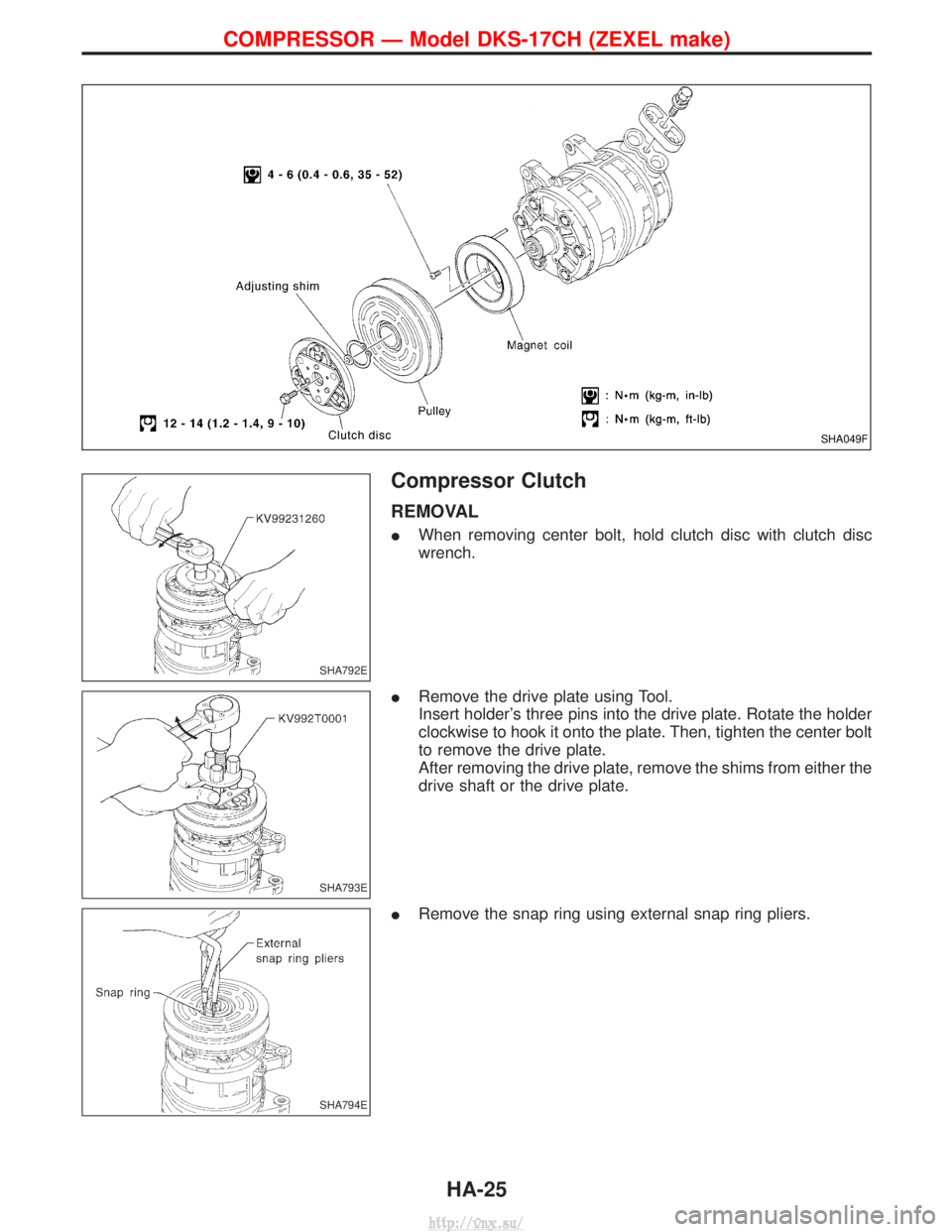

Compressor Clutch

REMOVAL

IWhen removing center bolt, hold clutch disc with clutch disc

wrench.

I Remove the drive plate using Tool.

Insert holder's three pins into the drive plate. Rotate the holder

clockwise to hook it onto the plate. Then, tighten the center bolt

to remove the drive plate.

After removing the drive plate, remove the shims from either the

drive shaft or the drive plate.

I Remove the snap ring using external snap ring pliers.

SHA049F

SHA792E

SHA793E

SHA794E

COMPRESSOR Ð Model DKS-17CH (ZEXEL make)

HA-25

http://vnx.su/

Page 1427 of 1833

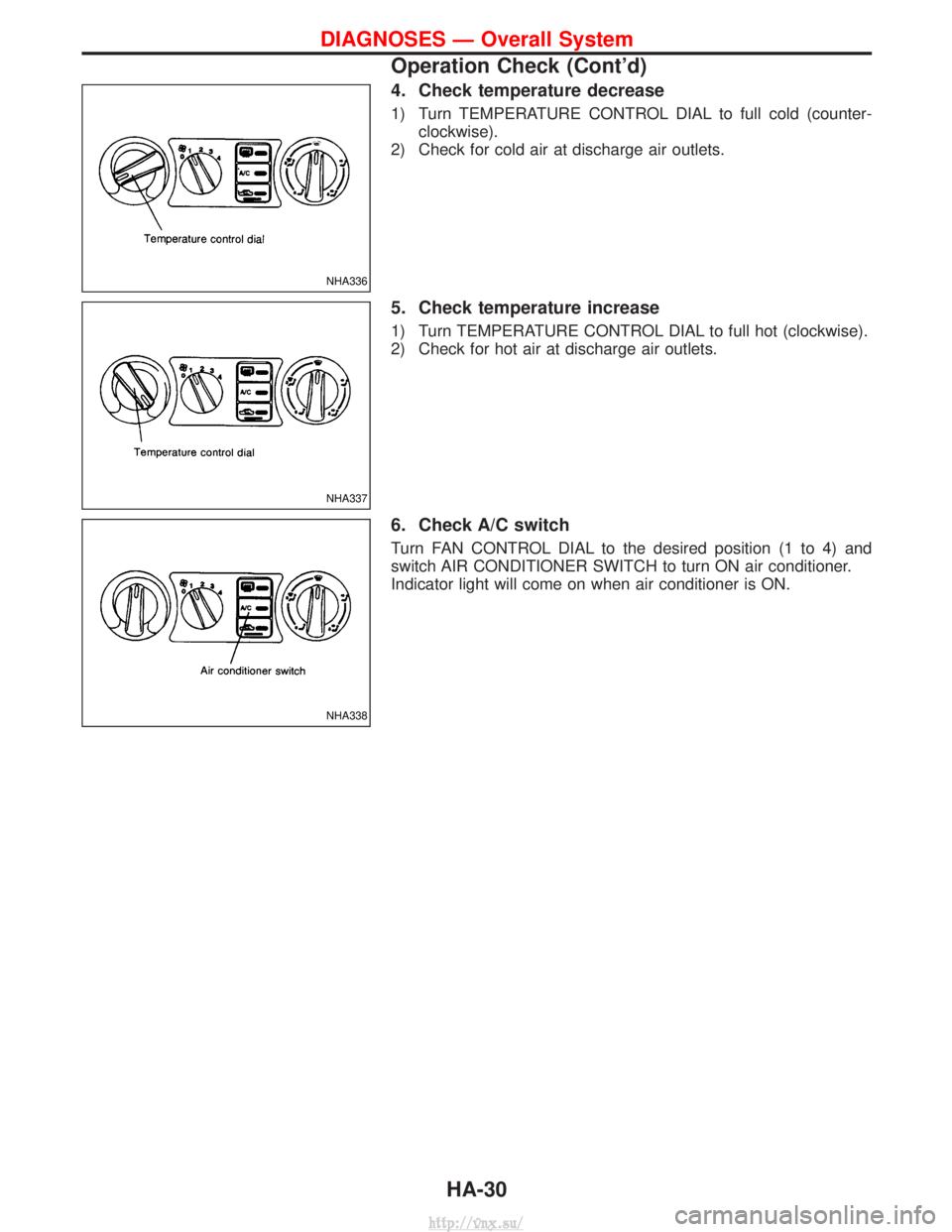

4. Check temperature decrease

1) Turn TEMPERATURE CONTROL DIAL to full cold (counter-clockwise).

2) Check for cold air at discharge air outlets.

5. Check temperature increase

1) Turn TEMPERATURE CONTROL DIAL to full hot (clockwise).

2) Check for hot air at discharge air outlets.

6. Check A/C switch

Turn FAN CONTROL DIAL to the desired position (1 to 4) and

switch AIR CONDITIONER SWITCH to turn ON air conditioner.

Indicator light will come on when air conditioner is ON.

NHA336

NHA337

NHA338

DIAGNOSES Ð Overall System

Operation Check (Cont'd)

HA-30

http://vnx.su/

Page 1462 of 1833

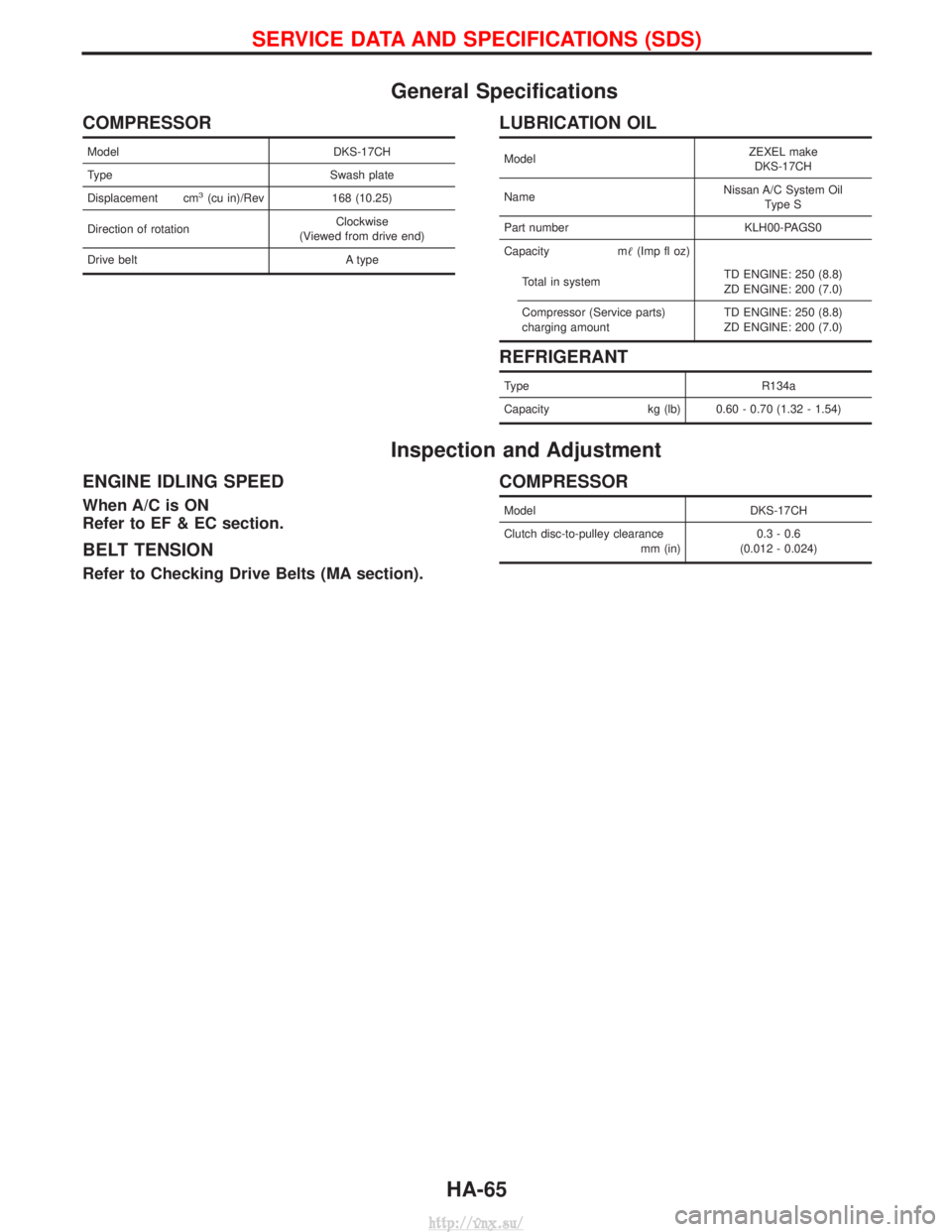

General Specifications

COMPRESSOR

ModelDKS-17CH

Type Swash plate

Displacement cm

3(cu in)/Rev 168 (10.25)

Direction of rotation Clockwise

(Viewed from drive end)

Drive belt A type

LUBRICATION OIL

ModelZEXEL make

DKS-17CH

Name Nissan A/C System Oil

Type S

Part number KLH00-PAGS0

Capacity m (Imp fl oz)

Total in system TD ENGINE: 250 (8.8)

ZD ENGINE: 200 (7.0)

Compressor (Service parts)

charging amount TD ENGINE: 250 (8.8)

ZD ENGINE: 200 (7.0)

REFRIGERANT

Type

R134a

Capacity kg (lb) 0.60 - 0.70 (1.32 - 1.54)

Inspection and Adjustment

ENGINE IDLING SPEED

When A/C is ON

Refer to EF & EC section.

BELT TENSION

Refer to Checking Drive Belts (MA section).

COMPRESSOR

Model DKS-17CH

Clutch disc-to-pulley clearance mm (in)0.3 - 0.6

(0.012 - 0.024)

SERVICE DATA AND SPECIFICATIONS (SDS)

HA-65

http://vnx.su/

Page 1495 of 1833

Oil Pressure Switch Check ...................................... 110

Wiring Diagram - CHIME - ...................................... 111

WIPER AND WASHER ................................................ 112

Wiring Diagram - WIPER - ...................................... 112

Wiring Diagram - WIP/R -........................................ 114

Installation ................................................................ 116

Washer Nozzle Adjustment ..................................... 117

Check Valve ............................................................. 117

Wiring Diagram - HLC - ........................................... 118

HORN, CIGARETTE LIGHTER AND CLOCK ............122

Wiring Diagram - HORN - .......................................122

Wiring Diagram - CIGAR -.......................................123

Wiring Diagram - CLOCK -......................................124

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER .................................................125

System Description ..................................................125

Wiring Diagram - DEF - ...........................................126

Trouble Diagnoses...................................................128

Filament Check ........................................................132

Filament Repair .......................................................133

AUDIO ........................................................................\

..134

System Description ..................................................134

Schematic ................................................................136

Wiring Diagram - AUDIO - .......................................138

Wiring Diagram - REMOTE -...................................145

Trouble Diagnoses...................................................147

Inspection.................................................................149

Location of Roof Mounted Antenna .........................150

HEATED SEAT ............................................................151

Wiring Diagram - HSEAT - ......................................151

SUNROOF ....................................................................153

Wiring Diagram - SROOF - .....................................153

DOOR MIRROR ...........................................................154

Wiring Diagram - MIRROR - ...................................154

POWER WINDOW .......................................................156

System Description ..................................................156

Schematic ................................................................158

Wiring Diagram - WINDOW - ..................................159

Trouble Diagnoses...................................................162

POWER DOOR LOCK .................................................163

System Description ..................................................163

Schematic ................................................................164

Wiring Diagram - D/LOCK -.....................................166

Trouble Diagnoses...................................................171

POWER DOOR LOCK - SUPER LOCK - ...................179

Component Parts Location ......................................179

System Description ..................................................180

Schematic ................................................................182 Wiring Diagram - S/LOCK - .....................................184

Trouble Diagnoses...................................................192

MULTI-REMOTE CONTROL SYSTEM .......................202

System Description ..................................................202

Schematic ................................................................204

Wiring Diagram - MULTI - .......................................205

Trouble Diagnoses...................................................213

ID Code Entry Procedure ........................................215

TIME CONTROL UNIT (TCU) .....................................216

System Description ..................................................216

Trouble Diagnosis ....................................................218

Schematic ................................................................220

NATS (Nissan Anti-Theft System) .............................222

System Description ..................................................222

System Composition ................................................223

Component Parts Location ......................................224

Wiring Diagram - NATS -.........................................225

CONSULT-II .............................................................229

Trouble Diagnoses...................................................231

How to Replace NATS IMMU ..................................242

THEFT WARNING SYSTEM .......................................243

Components Parts and Harness Connector

Location ...................................................................243

System Description ..................................................244

Theft Warning System/Schematic ...........................247

Wiring Diagram - THEFT -.......................................248

Trouble Diagnoses...................................................264

LOCATION OF ELECTRICAL UNITS .........................275

Engine Compartment ...............................................275

Passenger Compartment/LHD Models ....................276

Passenger Compartment/RHD Models ...................278

HARNESS LAYOUT ....................................................280

How to Read Harness Layout .................................280

Outline......................................................................281

Main Harness...........................................................282

EFC Harness ...........................................................298

Engine Harness .......................................................310

Body Harness ..........................................................312

Chassis Harness......................................................320

Room Lamp Harness...............................................321

Tailgate Harness ......................................................322

Door Harness (LH side)...........................................323

Door Harness (RH side) ..........................................324

BULB SPECIFICATIONS ............................................325

Headlamps ...............................................................325

Exterior Lamps.........................................................325

Interior Lamps ..........................................................325

WIRING DIAGRAM CODES (CELL CODES) .............326

CONTENTS(Cont'd)

EL-2

http://vnx.su/

Page 1512 of 1833

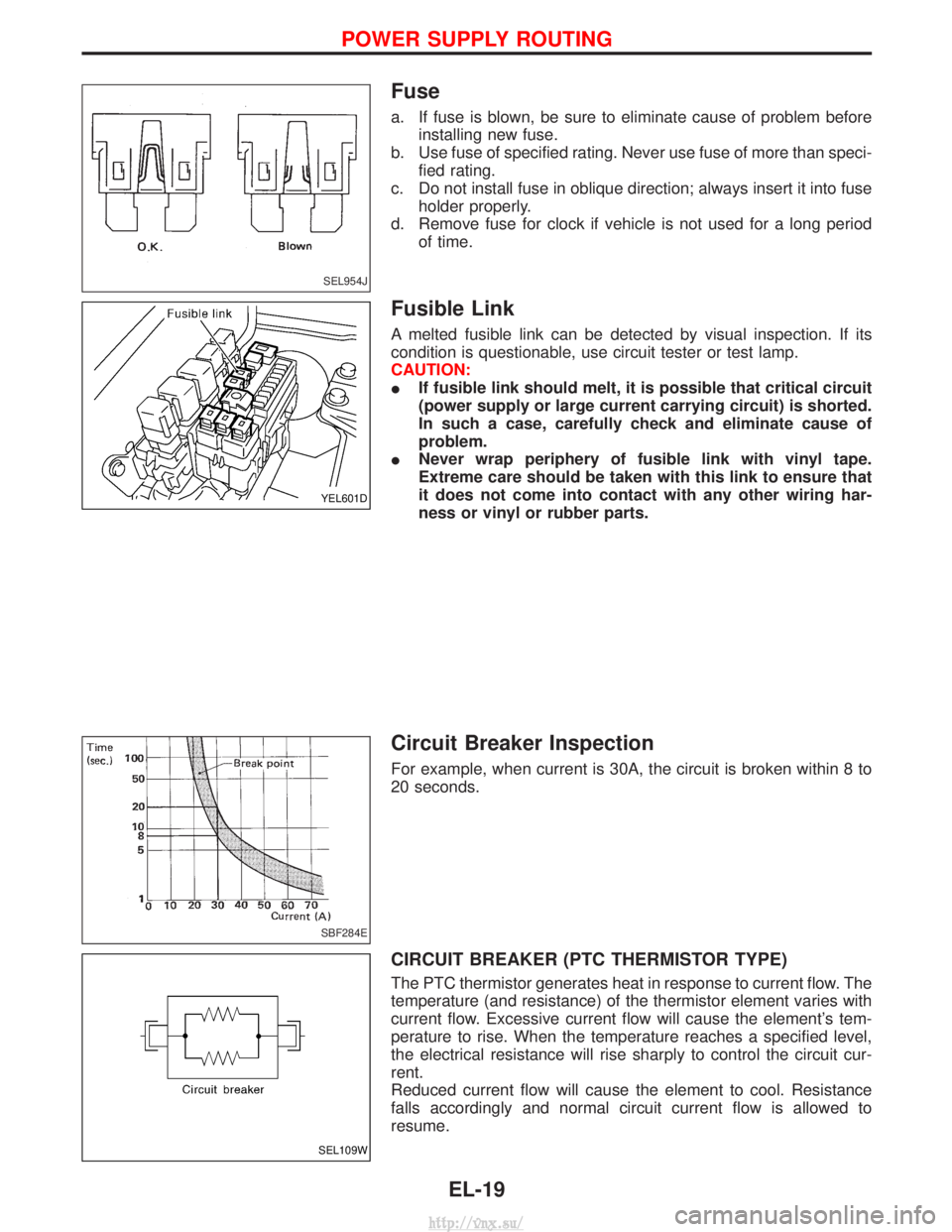

Fuse

a. If fuse is blown, be sure to eliminate cause of problem beforeinstalling new fuse.

b. Use fuse of specified rating. Never use fuse of more than speci- fied rating.

c. Do not install fuse in oblique direction; always insert it into fuse holder properly.

d. Remove fuse for clock if vehicle is not used for a long period of time.

Fusible Link

A melted fusible link can be detected by visual inspection. If its

condition is questionable, use circuit tester or test lamp.

CAUTION:

IIf fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

I Never wrap periphery of fusible link with vinyl tape.

Extreme care should be taken with this link to ensure that

it does not come into contact with any other wiring har-

ness or vinyl or rubber parts.

Circuit Breaker Inspection

For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

CIRCUIT BREAKER (PTC THERMISTOR TYPE)

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of the thermistor element varies with

current flow. Excessive current flow will cause the element's tem-

perature to rise. When the temperature reaches a specified level,

the electrical resistance will rise sharply to control the circuit cur-

rent.

Reduced current flow will cause the element to cool. Resistance

falls accordingly and normal circuit current flow is allowed to

resume.

SEL954J

YEL601D

SBF284E

SEL109W

POWER SUPPLY ROUTING

EL-19

http://vnx.su/