torque NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 114 of 1833

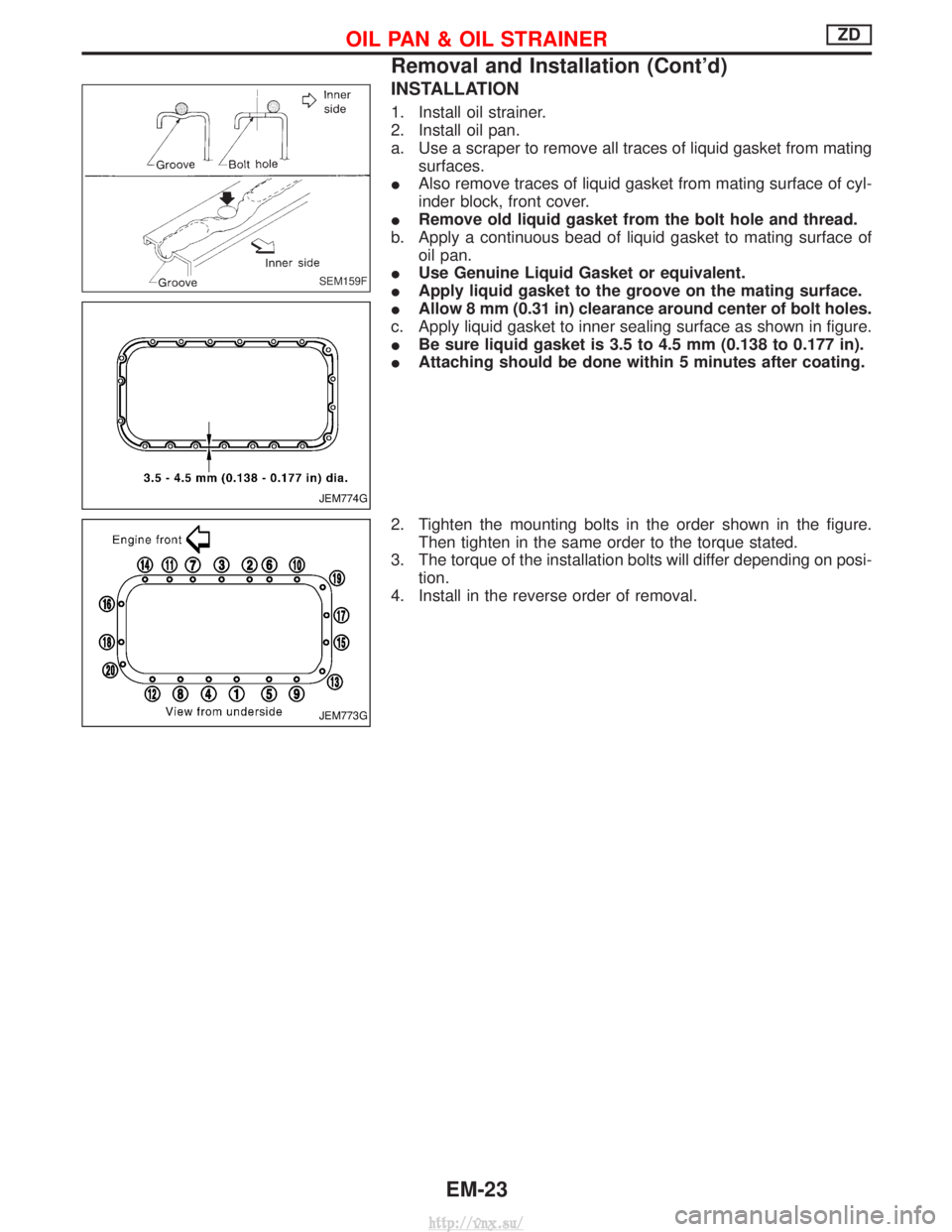

INSTALLATION

1. Install oil strainer.

2. Install oil pan.

a. Use a scraper to remove all traces of liquid gasket from matingsurfaces.

I Also remove traces of liquid gasket from mating surface of cyl-

inder block, front cover.

I Remove old liquid gasket from the bolt hole and thread.

b. Apply a continuous bead of liquid gasket to mating surface of oil pan.

I Use Genuine Liquid Gasket or equivalent.

I Apply liquid gasket to the groove on the mating surface.

I Allow 8 mm (0.31 in) clearance around center of bolt holes.

c. Apply liquid gasket to inner sealing surface as shown in figure.

I Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in).

I Attaching should be done within 5 minutes after coating.

2. Tighten the mounting bolts in the order shown in the figure. Then tighten in the same order to the torque stated.

3. The torque of the installation bolts will differ depending on posi- tion.

4. Install in the reverse order of removal.

SEM159F

JEM774G

JEM773G

OIL PAN & OIL STRAINERZD

Removal and Installation (Cont'd)

EM-23

http://vnx.su/

Page 119 of 1833

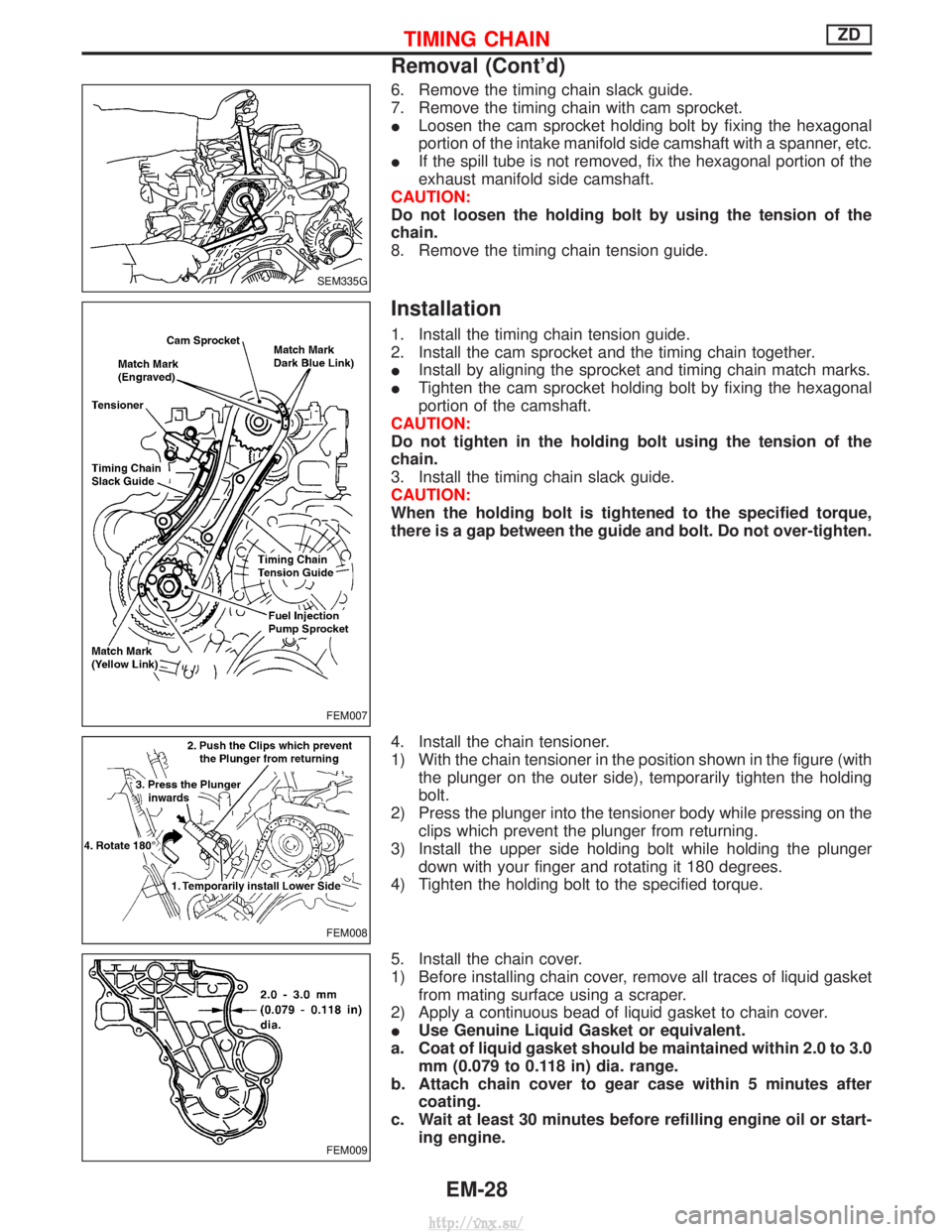

6. Remove the timing chain slack guide.

7. Remove the timing chain with cam sprocket.

ILoosen the cam sprocket holding bolt by fixing the hexagonal

portion of the intake manifold side camshaft with a spanner, etc.

I If the spill tube is not removed, fix the hexagonal portion of the

exhaust manifold side camshaft.

CAUTION:

Do not loosen the holding bolt by using the tension of the

chain.

8. Remove the timing chain tension guide.

Installation

1. Install the timing chain tension guide.

2. Install the cam sprocket and the timing chain together.

I Install by aligning the sprocket and timing chain match marks.

I Tighten the cam sprocket holding bolt by fixing the hexagonal

portion of the camshaft.

CAUTION:

Do not tighten in the holding bolt using the tension of the

chain.

3. Install the timing chain slack guide.

CAUTION:

When the holding bolt is tightened to the specified torque,

there is a gap between the guide and bolt. Do not over-tighten.

4. Install the chain tensioner.

1) With the chain tensioner in the position shown in the figure (with the plunger on the outer side), temporarily tighten the holding

bolt.

2) Press the plunger into the tensioner body while pressing on the clips which prevent the plunger from returning.

3) Install the upper side holding bolt while holding the plunger down with your finger and rotating it 180 degrees.

4) Tighten the holding bolt to the specified torque.

5. Install the chain cover.

1) Before installing chain cover, remove all traces of liquid gasket from mating surface using a scraper.

2) Apply a continuous bead of liquid gasket to chain cover.

I Use Genuine Liquid Gasket or equivalent.

a. Coat of liquid gasket should be maintained within 2.0 to 3.0 mm (0.079 to 0.118 in) dia. range.

b. Attach chain cover to gear case within 5 minutes after coating.

c. Wait at least 30 minutes before refilling engine oil or start- ing engine.

SEM335G

FEM007

FEM008

FEM009

TIMING CHAINZD

Removal (Cont'd)

EM-28

http://vnx.su/

Page 123 of 1833

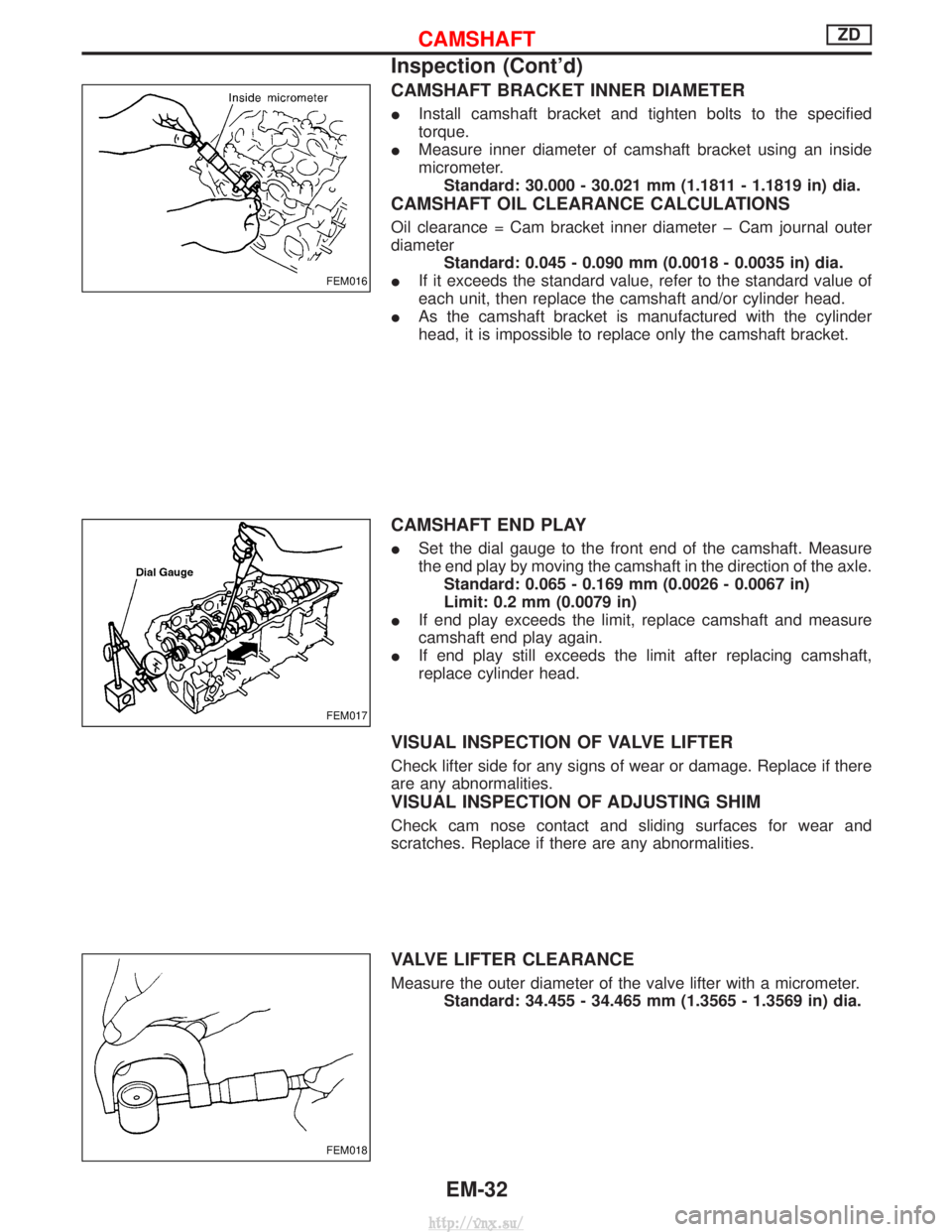

CAMSHAFT BRACKET INNER DIAMETER

IInstall camshaft bracket and tighten bolts to the specified

torque.

I Measure inner diameter of camshaft bracket using an inside

micrometer.

Standard: 30.000 - 30.021 mm (1.1811 - 1.1819 in) dia.

CAMSHAFT OIL CLEARANCE CALCULATIONS

Oil clearance = Cam bracket inner diameter þ Cam journal outer

diameter Standard: 0.045 - 0.090 mm (0.0018 - 0.0035 in) dia.

I If it exceeds the standard value, refer to the standard value of

each unit, then replace the camshaft and/or cylinder head.

I As the camshaft bracket is manufactured with the cylinder

head, it is impossible to replace only the camshaft bracket.

CAMSHAFT END PLAY

ISet the dial gauge to the front end of the camshaft. Measure

the end play by moving the camshaft in the direction of the axle.

Standard: 0.065 - 0.169 mm (0.0026 - 0.0067 in)

Limit: 0.2 mm (0.0079 in)

I If end play exceeds the limit, replace camshaft and measure

camshaft end play again.

I If end play still exceeds the limit after replacing camshaft,

replace cylinder head.

VISUAL INSPECTION OF VALVE LIFTER

Check lifter side for any signs of wear or damage. Replace if there

are any abnormalities.

VISUAL INSPECTION OF ADJUSTING SHIM

Check cam nose contact and sliding surfaces for wear and

scratches. Replace if there are any abnormalities.

VALVE LIFTER CLEARANCE

Measure the outer diameter of the valve lifter with a micrometer.

Standard: 34.455 - 34.465 mm (1.3565 - 1.3569 in) dia.

FEM016

FEM017

FEM018

CAMSHAFTZD

Inspection (Cont'd)

EM-32

http://vnx.su/

Page 144 of 1833

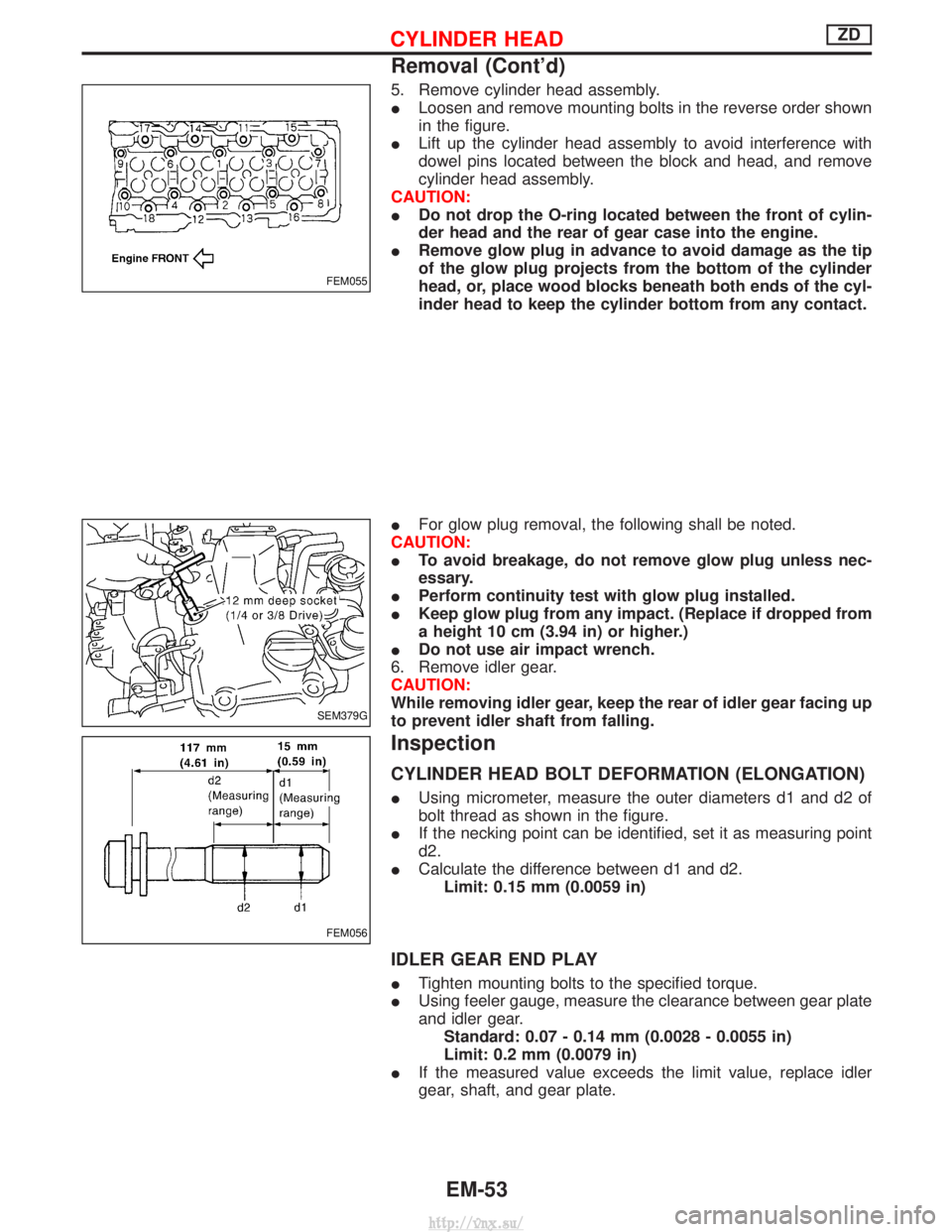

5. Remove cylinder head assembly.

ILoosen and remove mounting bolts in the reverse order shown

in the figure.

I Lift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

I Do not drop the O-ring located between the front of cylin-

der head and the rear of gear case into the engine.

I Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylinder

head, or, place wood blocks beneath both ends of the cyl-

inder head to keep the cylinder bottom from any contact.

I For glow plug removal, the following shall be noted.

CAUTION:

I To avoid breakage, do not remove glow plug unless nec-

essary.

I Perform continuity test with glow plug installed.

I Keep glow plug from any impact. (Replace if dropped from

a height 10 cm (3.94 in) or higher.)

I Do not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing up

to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION (ELONGATION)

I Using micrometer, measure the outer diameters d1 and d2 of

bolt thread as shown in the figure.

I If the necking point can be identified, set it as measuring point

d2.

I Calculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

I Tighten mounting bolts to the specified torque.

I Using feeler gauge, measure the clearance between gear plate

and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

I If the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-53

http://vnx.su/

Page 146 of 1833

Unit: mm (in)

GradePiston crown

depression Gasket thick-

ness*1 No. of notches

1 Less than þ0.078

(þ0.0031)*2 0.65 (0.0256) 1

2 More than þ0.078

(þ0.0031)*3 0.70 (0.0276) 2

*1: Thickness of gasket tightened with head bolts

*2: Indicates values such as þ0.080 mm (þ0.0031 in).

*3: Indicates values such as þ0.075 mm (þ0.0030 in).

2. Install idler gear and idler shaft.

I

Check that the counter marks with cam gear, ªAAº and ªBBº, are

located on the front side of the engine.

Refer to EM-52.

CAUTION:

Since idler gear cannot be installed or removed with cylinder

head assembly mounted on the engine because of interfer-

ence with gear case, make sure that there are no reverse

installations or uninstalled parts.

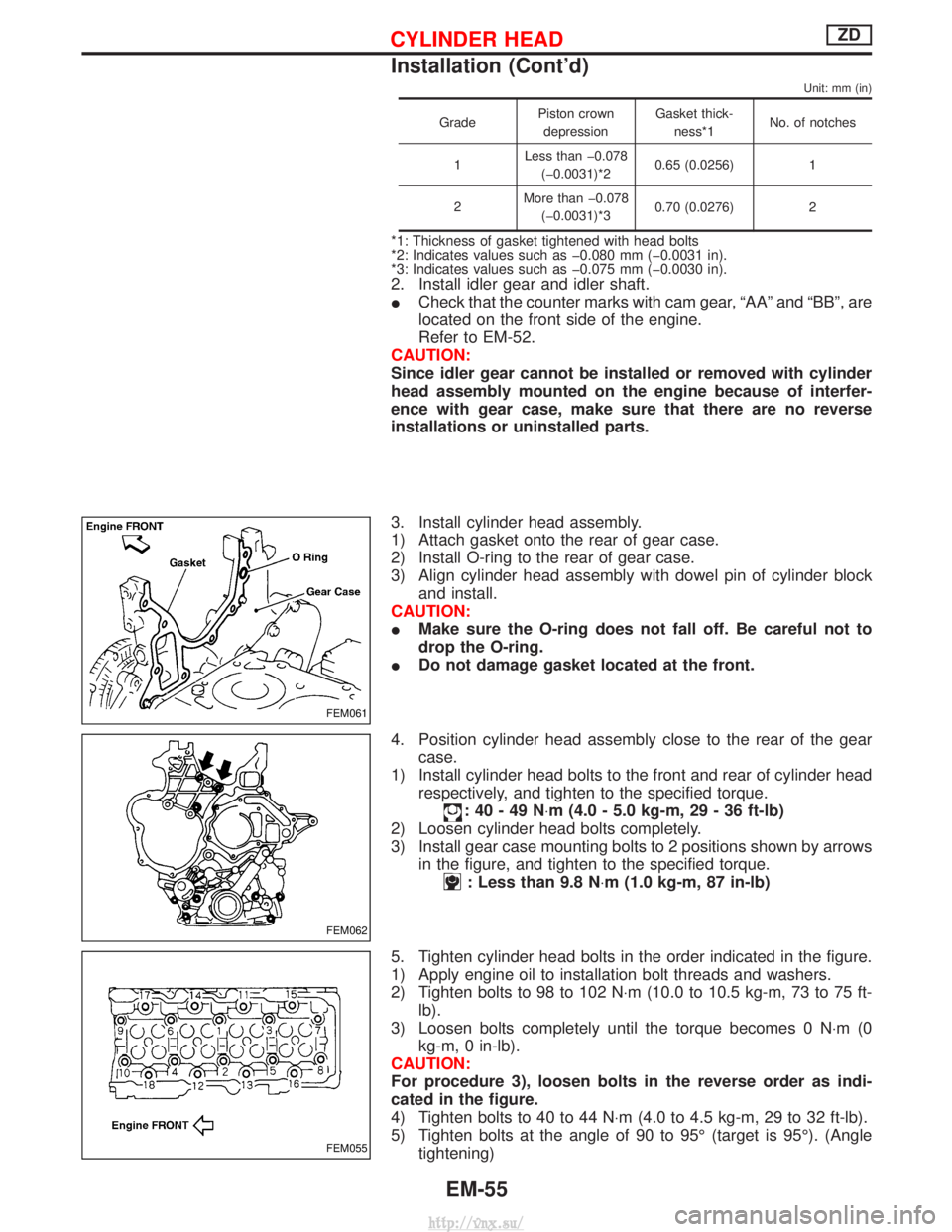

3. Install cylinder head assembly.

1) Attach gasket onto the rear of gear case.

2) Install O-ring to the rear of gear case.

3) Align cylinder head assembly with dowel pin of cylinder block and install.

CAUTION:

I Make sure the O-ring does not fall off. Be careful not to

drop the O-ring.

I Do not damage gasket located at the front.

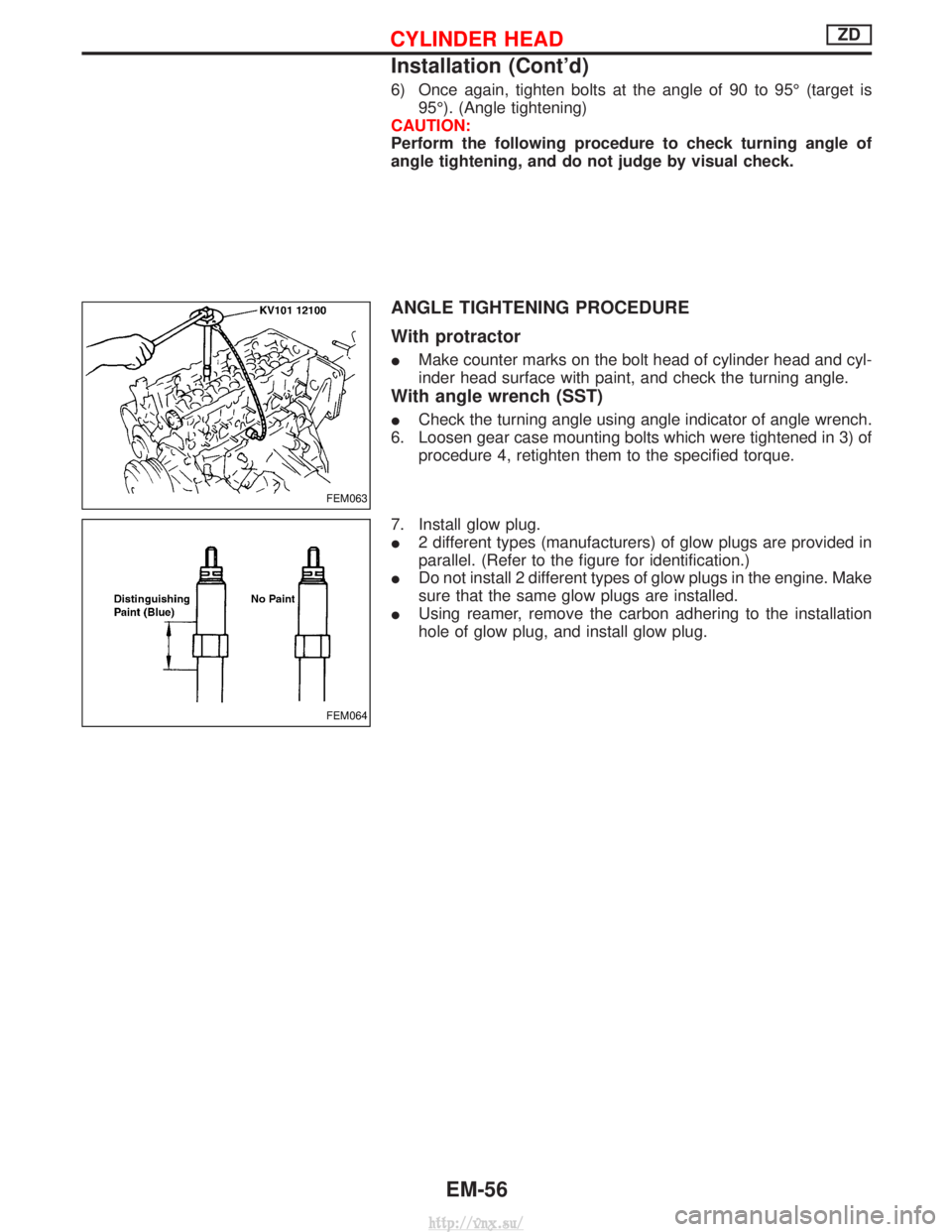

4. Position cylinder head assembly close to the rear of the gear case.

1) Install cylinder head bolts to the front and rear of cylinder head respectively, and tighten to the specified torque.

:40-49N ×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

2) Loosen cylinder head bolts completely.

3) Install gear case mounting bolts to 2 positions shown by arrows in the figure, and tighten to the specified torque.

: Less than 9.8 N ×m (1.0 kg-m, 87 in-lb)

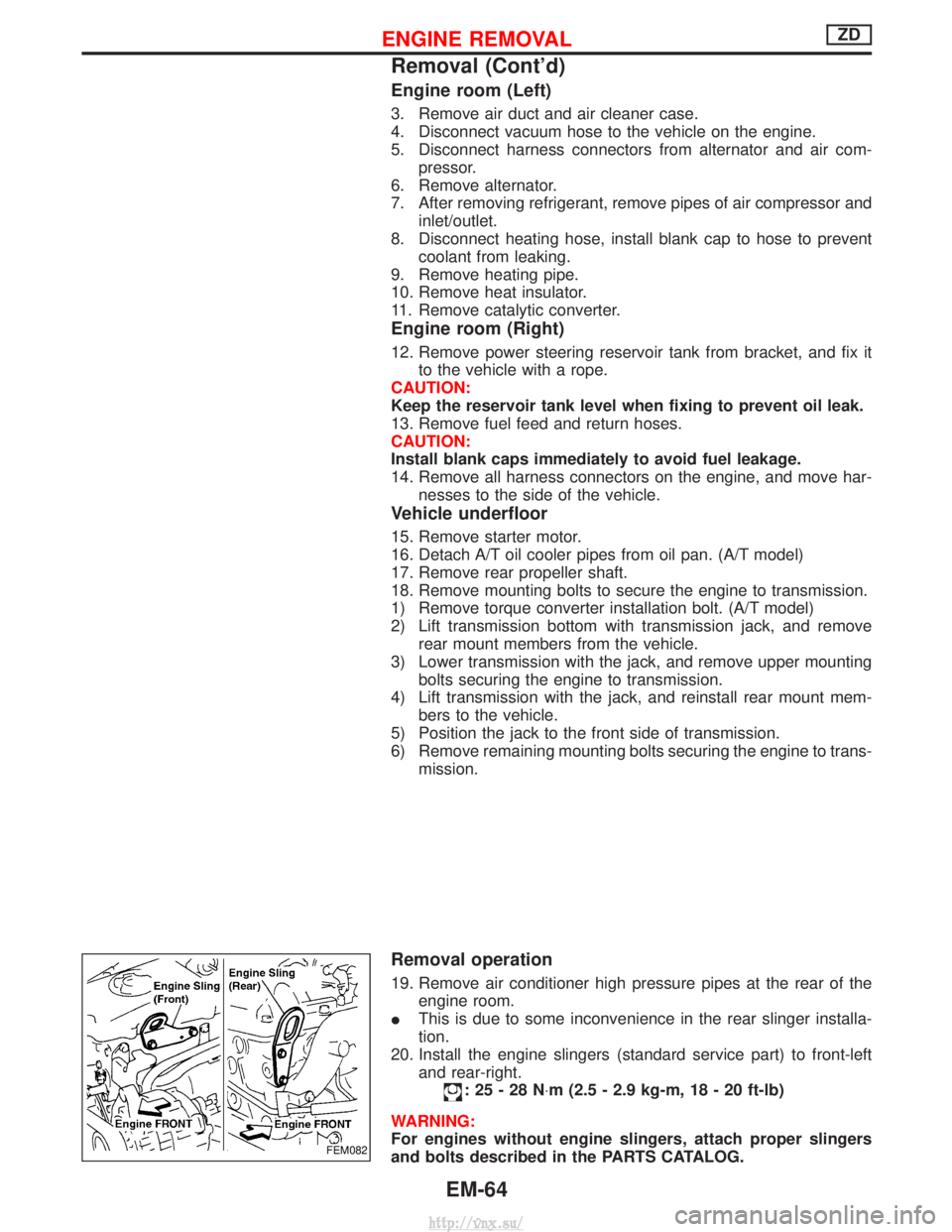

5. Tighten cylinder head bolts in the order indicated in the figure.

1) Apply engine oil to installation bolt threads and washers.

2) Tighten bolts to 98 to 102 N×m (10.0 to 10.5 kg-m, 73 to 75 ft- lb).

3) Loosen bolts completely until the torque becomes 0 N ×m(0

kg-m, 0 in-lb).

CAUTION:

For procedure 3), loosen bolts in the reverse order as indi-

cated in the figure.

4) Tighten bolts to 40 to 44 N ×m (4.0 to 4.5 kg-m, 29 to 32 ft-lb).

5) Tighten bolts at the angle of 90 to 95É (target is 95É). (Angle tightening)

FEM061

FEM062

FEM055

CYLINDER HEADZD

Installation (Cont'd)

EM-55

http://vnx.su/

Page 147 of 1833

6) Once again, tighten bolts at the angle of 90 to 95É (target is95É). (Angle tightening)

CAUTION:

Perform the following procedure to check turning angle of

angle tightening, and do not judge by visual check.

ANGLE TIGHTENING PROCEDURE

With protractor

I Make counter marks on the bolt head of cylinder head and cyl-

inder head surface with paint, and check the turning angle.

With angle wrench (SST)

ICheck the turning angle using angle indicator of angle wrench.

6. Loosen gear case mounting bolts which were tightened in 3) of procedure 4, retighten them to the specified torque.

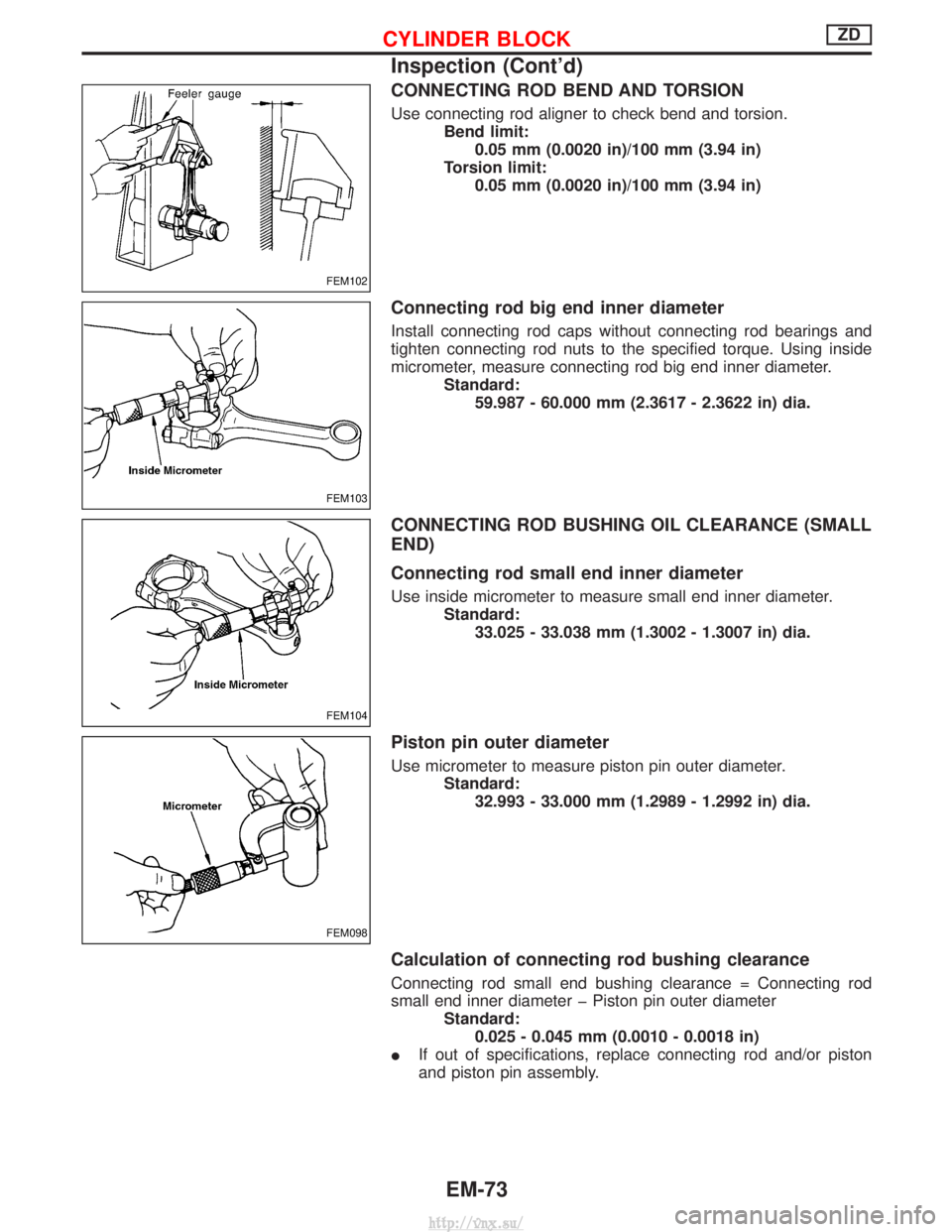

7. Install glow plug.

I 2 different types (manufacturers) of glow plugs are provided in

parallel. (Refer to the figure for identification.)

I Do not install 2 different types of glow plugs in the engine. Make

sure that the same glow plugs are installed.

I Using reamer, remove the carbon adhering to the installation

hole of glow plug, and install glow plug.

FEM063

FEM064

CYLINDER HEADZD

Installation (Cont'd)

EM-56

http://vnx.su/

Page 155 of 1833

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

5. Disconnect harness connectors from alternator and air com-pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move har- nesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and removerear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mounting bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem- bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to trans- mission.

Removal operation

19. Remove air conditioner high pressure pipes at the rear of theengine room.

I This is due to some inconvenience in the rear slinger installa-

tion.

20. Install the engine slingers (standard service part) to front-left and rear-right.

:25-28N ×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-64

http://vnx.su/

Page 164 of 1833

CONNECTING ROD BEND AND TORSION

Use connecting rod aligner to check bend and torsion.Bend limit:0.05 mm (0.0020 in)/100 mm (3.94 in)

Torsion limit: 0.05 mm (0.0020 in)/100 mm (3.94 in)

Connecting rod big end inner diameter

Install connecting rod caps without connecting rod bearings and

tighten connecting rod nuts to the specified torque. Using inside

micrometer, measure connecting rod big end inner diameter. Standard:59.987 - 60.000 mm (2.3617 - 2.3622 in) dia.

CONNECTING ROD BUSHING OIL CLEARANCE (SMALL

END)

Connecting rod small end inner diameter

Use inside micrometer to measure small end inner diameter. Standard:33.025 - 33.038 mm (1.3002 - 1.3007 in) dia.

Piston pin outer diameter

Use micrometer to measure piston pin outer diameter. Standard:32.993 - 33.000 mm (1.2989 - 1.2992 in) dia.

Calculation of connecting rod bushing clearance

Connecting rod small end bushing clearance = Connecting rod

small end inner diameter þ Piston pin outer diameter Standard:0.025 - 0.045 mm (0.0010 - 0.0018 in)

I If out of specifications, replace connecting rod and/or piston

and piston pin assembly.

FEM102

FEM103

FEM104

FEM098

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-73

http://vnx.su/

Page 165 of 1833

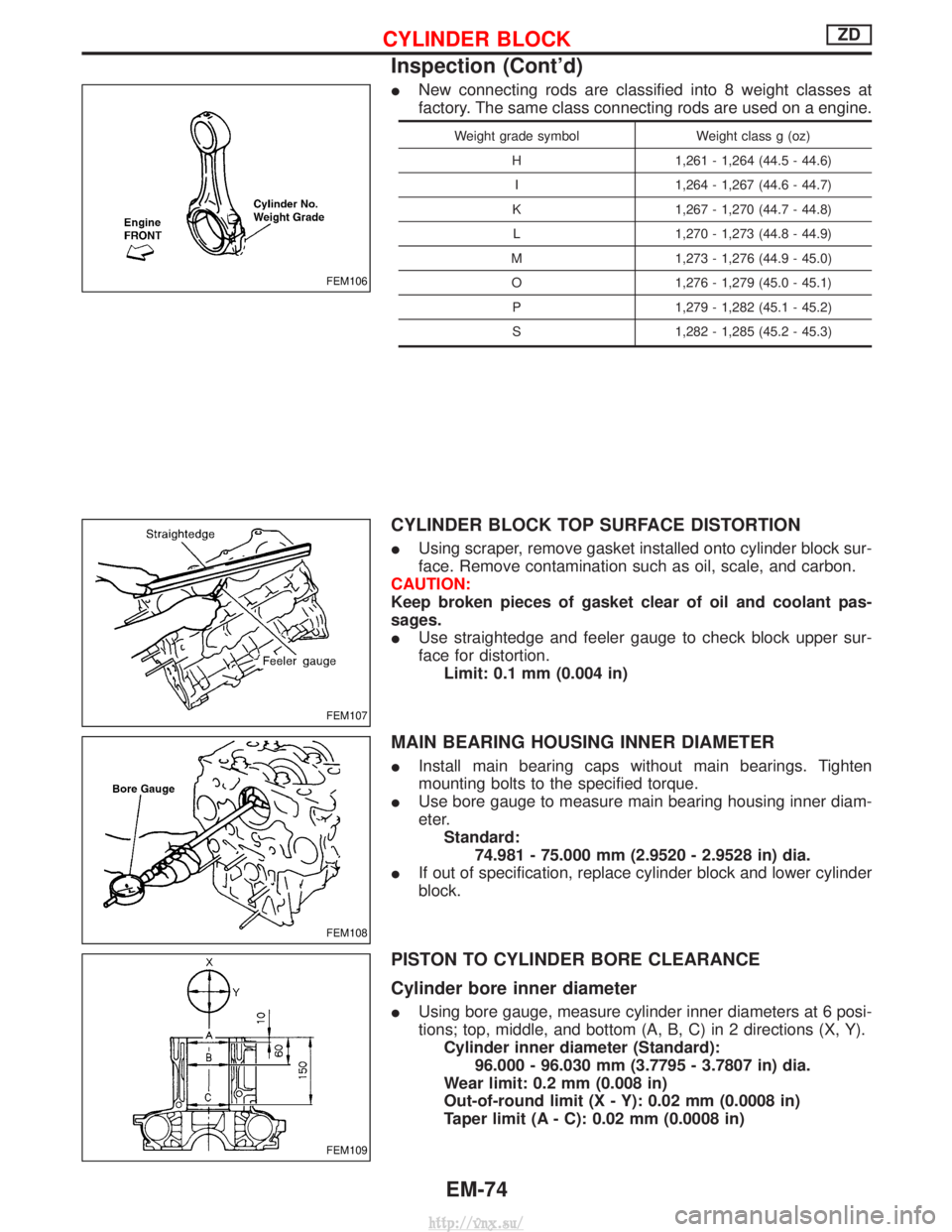

INew connecting rods are classified into 8 weight classes at

factory. The same class connecting rods are used on a engine.

Weight grade symbol Weight class g (oz)

H 1,261 - 1,264 (44.5 - 44.6) I 1,264 - 1,267 (44.6 - 44.7)

K 1,267 - 1,270 (44.7 - 44.8) L 1,270 - 1,273 (44.8 - 44.9)

M 1,273 - 1,276 (44.9 - 45.0) O 1,276 - 1,279 (45.0 - 45.1) P 1,279 - 1,282 (45.1 - 45.2)

S 1,282 - 1,285 (45.2 - 45.3)

CYLINDER BLOCK TOP SURFACE DISTORTION

I Using scraper, remove gasket installed onto cylinder block sur-

face. Remove contamination such as oil, scale, and carbon.

CAUTION:

Keep broken pieces of gasket clear of oil and coolant pas-

sages.

I Use straightedge and feeler gauge to check block upper sur-

face for distortion.

Limit: 0.1 mm (0.004 in)

MAIN BEARING HOUSING INNER DIAMETER

I Install main bearing caps without main bearings. Tighten

mounting bolts to the specified torque.

I Use bore gauge to measure main bearing housing inner diam-

eter.

Standard: 74.981 - 75.000 mm (2.9520 - 2.9528 in) dia.

I If out of specification, replace cylinder block and lower cylinder

block.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder bore inner diameter

IUsing bore gauge, measure cylinder inner diameters at 6 posi-

tions; top, middle, and bottom (A, B, C) in 2 directions (X, Y).

Cylinder inner diameter (Standard): 96.000 - 96.030 mm (3.7795 - 3.7807 in) dia.

Wear limit: 0.2 mm (0.008 in)

Out-of-round limit (X - Y): 0.02 mm (0.0008 in)

Taper limit (A - C): 0.02 mm (0.0008 in)

FEM106

FEM107

FEM108

FEM109

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-74

http://vnx.su/

Page 168 of 1833

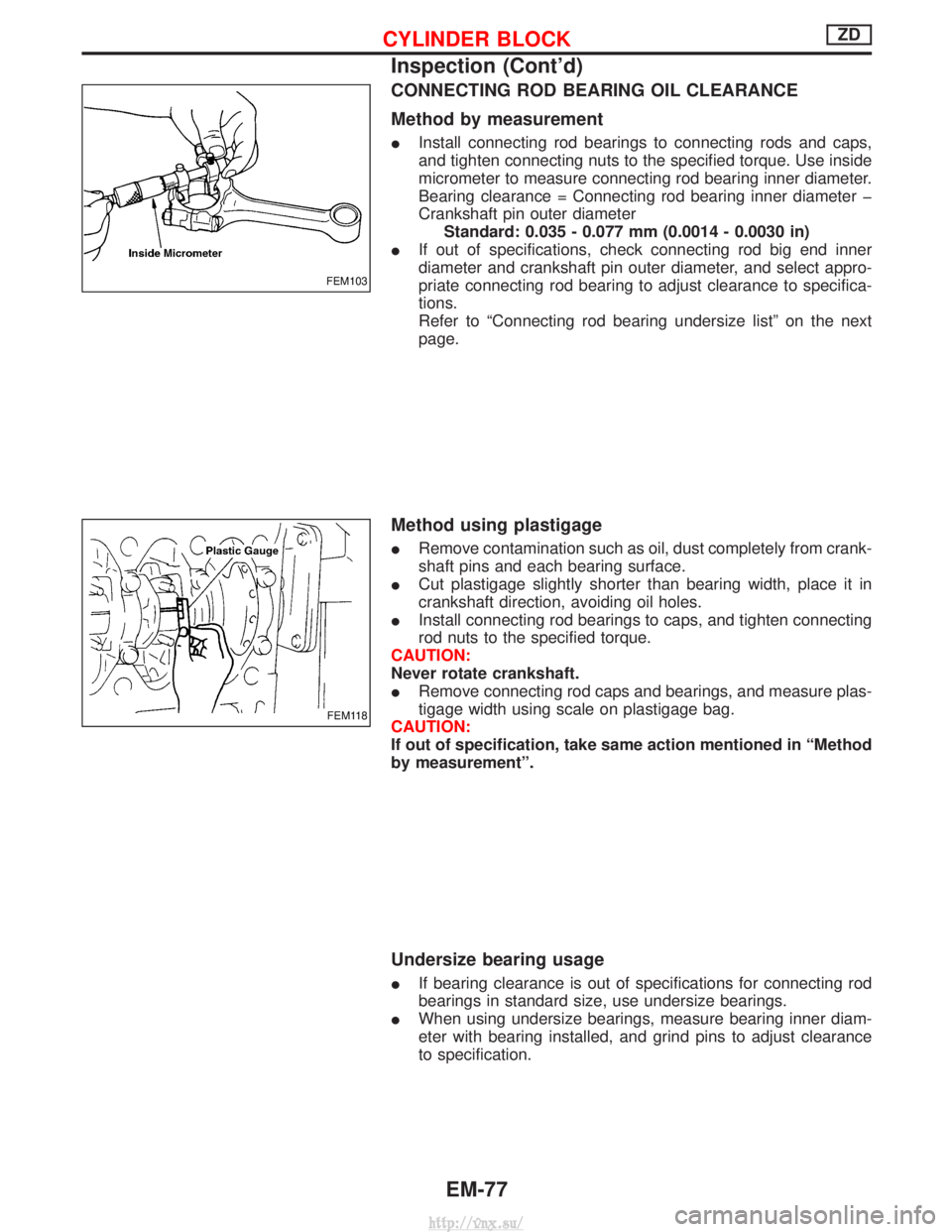

CONNECTING ROD BEARING OIL CLEARANCE

Method by measurement

IInstall connecting rod bearings to connecting rods and caps,

and tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

Bearing clearance = Connecting rod bearing inner diameter þ

Crankshaft pin outer diameter

Standard: 0.035 - 0.077 mm (0.0014 - 0.0030 in)

I If out of specifications, check connecting rod big end inner

diameter and crankshaft pin outer diameter, and select appro-

priate connecting rod bearing to adjust clearance to specifica-

tions.

Refer to ªConnecting rod bearing undersize listº on the next

page.

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft pins and each bearing surface.

I Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

I Install connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

I Remove connecting rod caps and bearings, and measure plas-

tigage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

I If bearing clearance is out of specifications for connecting rod

bearings in standard size, use undersize bearings.

I When using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind pins to adjust clearance

to specification.

FEM103

FEM118

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-77

http://vnx.su/