alternator belt NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 61 of 1833

Retightening Manifold Bolts and Nuts

MANIFOLD BOLTS AND NUTS

Intake:

:17-23N×m (1.7 - 2.3 kg-m, 12 - 17 ft-lb)

Exhaust:

:31-38N ×m (3.2 - 3.9 kg-m, 22 - 28 ft-lb)

Retightening should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

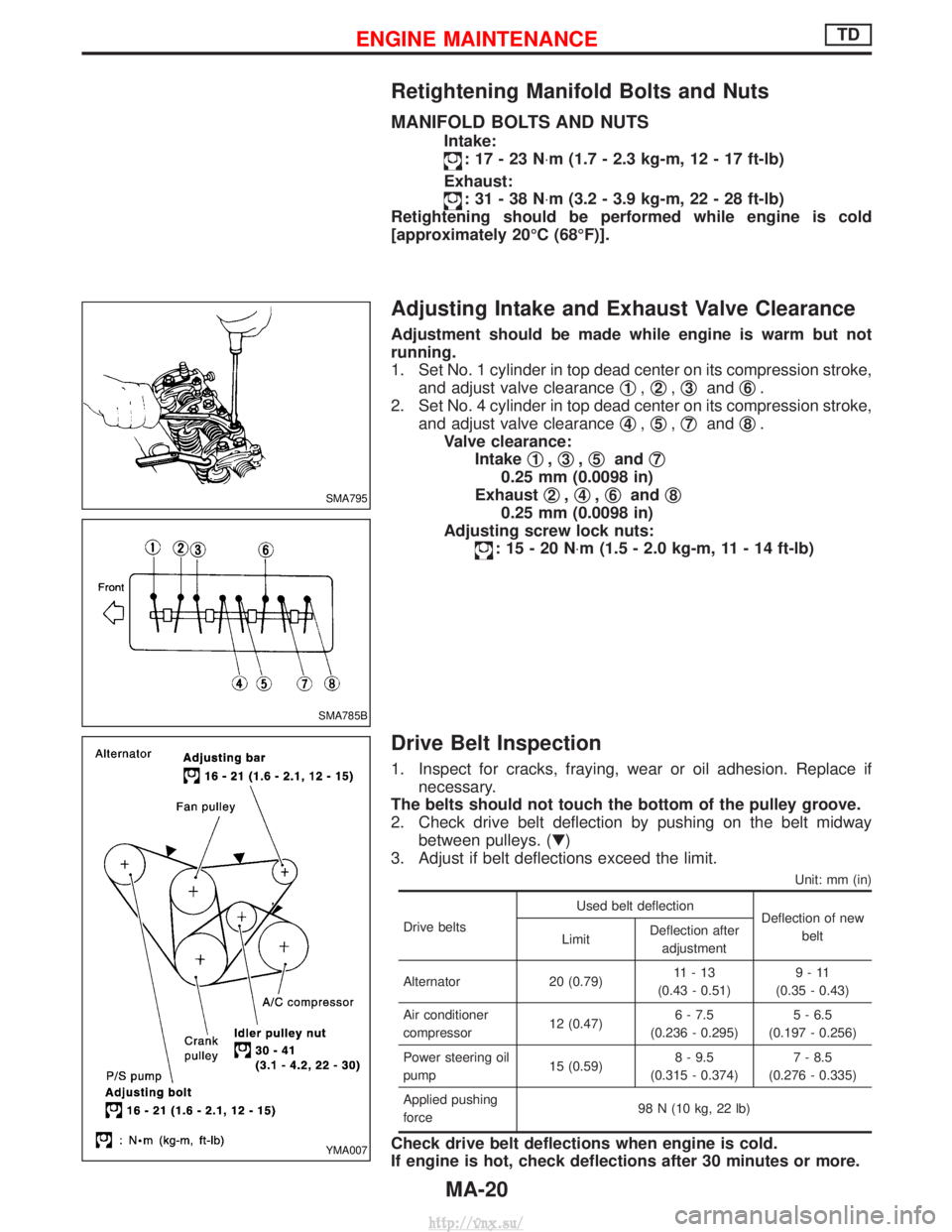

Adjusting Intake and Exhaust Valve Clearance

Adjustment should be made while engine is warm but not

running.

1. Set No. 1 cylinder in top dead center on its compression stroke, and adjust valve clearance q

1,q2,q3and q6.

2. Set No. 4 cylinder in top dead center on its compression stroke, and adjust valve clearance q

4,q5,q7and q8.

Valve clearance: Intake q

1,q3,q5and q7

0.25 mm (0.0098 in)

Exhaust q

2,q4,q6and q8

0.25 mm (0.0098 in)

Adjusting screw lock nuts:

:15-20N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

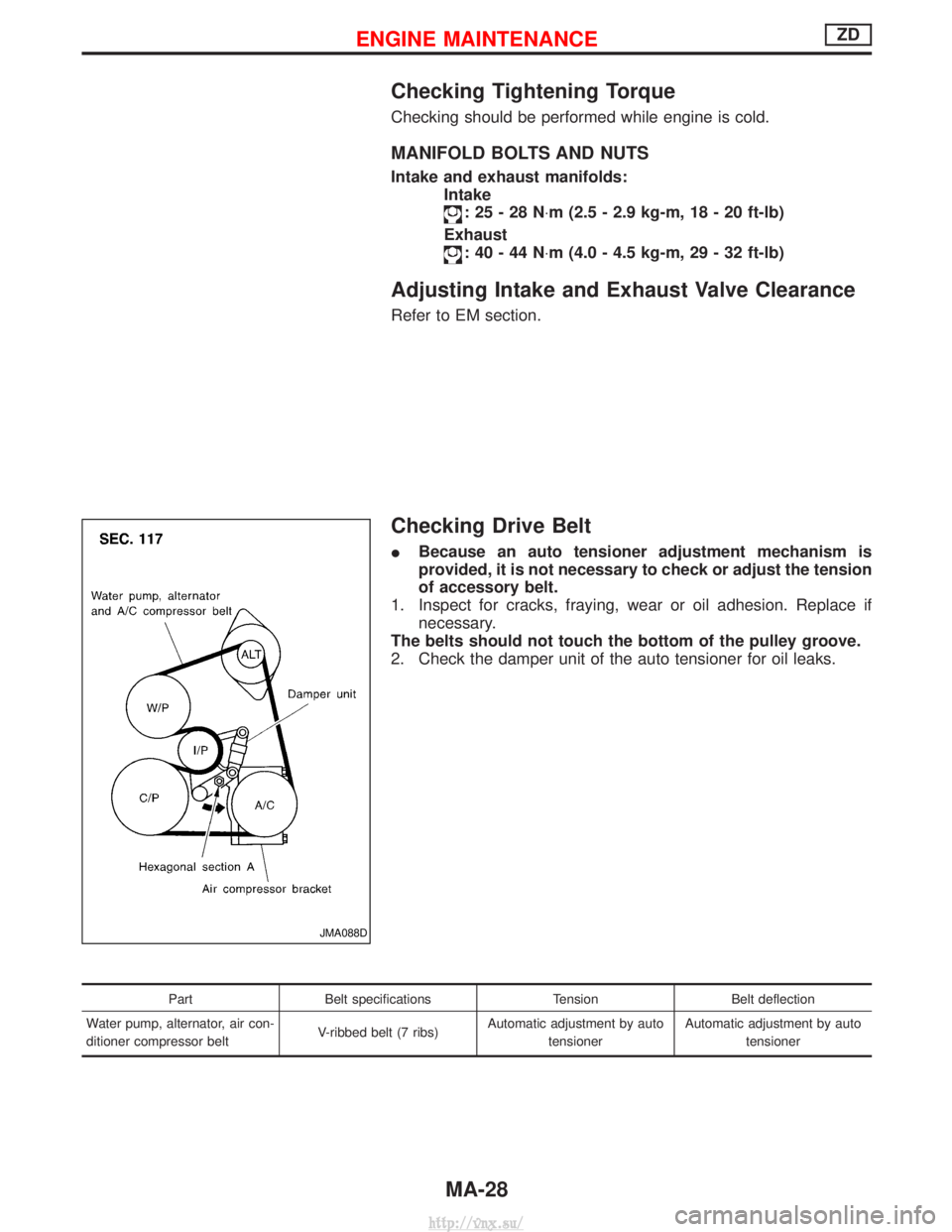

Drive Belt Inspection

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if

necessary.

The belts should not touch the bottom of the pulley groove.

2. Check drive belt deflection by pushing on the belt midway between pulleys. (H)

3. Adjust if belt deflections exceed the limit.

Unit: mm (in)

Drive belts Used belt deflection

Deflection of new

belt

Limit Deflection after

adjustment

Alternator 20 (0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner

compressor 12 (0.47)6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering oil

pump 15 (0.59)8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Check drive belt deflections when engine is cold.

If engine is hot, check deflections after 30 minutes or more.

SMA795

SMA785B

YMA007

ENGINE MAINTENANCETD

MA-20

http://vnx.su/

Page 69 of 1833

Checking Tightening Torque

Checking should be performed while engine is cold.

MANIFOLD BOLTS AND NUTS

Intake and exhaust manifolds:Intake

:25-28N ×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

Exhaust

:40-44N ×m (4.0 - 4.5 kg-m, 29 - 32 ft-lb)

Adjusting Intake and Exhaust Valve Clearance

Refer to EM section.

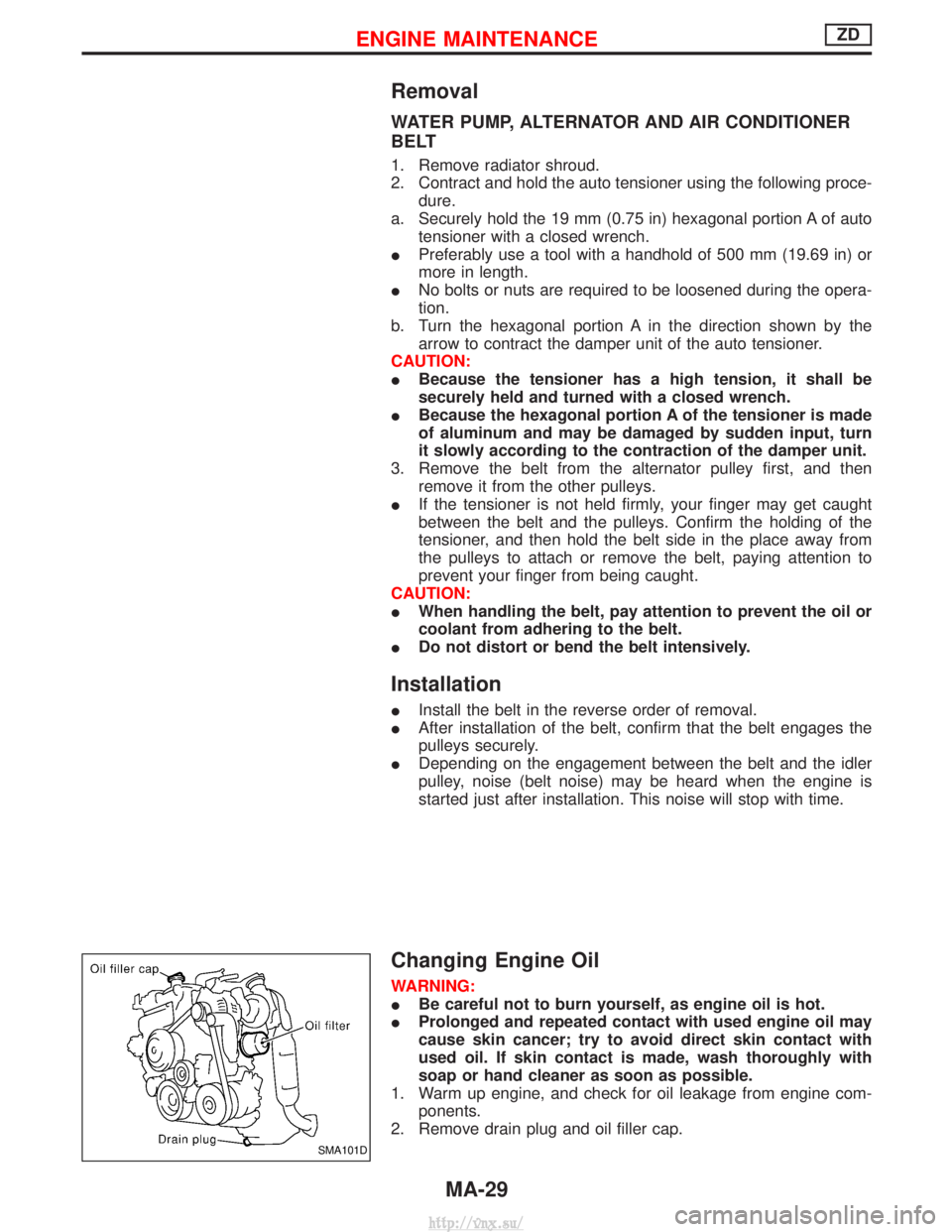

Checking Drive Belt

IBecause an auto tensioner adjustment mechanism is

provided, it is not necessary to check or adjust the tension

of accessory belt.

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if necessary.

The belts should not touch the bottom of the pulley groove.

2. Check the damper unit of the auto tensioner for oil leaks.

Part Belt specifications TensionBelt deflection

Water pump, alternator, air con-

ditioner compressor belt V-ribbed belt (7 ribs)Automatic adjustment by auto

tensioner Automatic adjustment by auto

tensioner

JMA088D

ENGINE MAINTENANCEZD

MA-28

http://vnx.su/

Page 70 of 1833

Removal

WATER PUMP, ALTERNATOR AND AIR CONDITIONER

BELT

1. Remove radiator shroud.

2. Contract and hold the auto tensioner using the following proce-dure.

a. Securely hold the 19 mm (0.75 in) hexagonal portion A of auto tensioner with a closed wrench.

I Preferably use a tool with a handhold of 500 mm (19.69 in) or

more in length.

I No bolts or nuts are required to be loosened during the opera-

tion.

b. Turn the hexagonal portion A in the direction shown by the arrow to contract the damper unit of the auto tensioner.

CAUTION:

I Because the tensioner has a high tension, it shall be

securely held and turned with a closed wrench.

I Because the hexagonal portion A of the tensioner is made

of aluminum and may be damaged by sudden input, turn

it slowly according to the contraction of the damper unit.

3. Remove the belt from the alternator pulley first, and then remove it from the other pulleys.

I If the tensioner is not held firmly, your finger may get caught

between the belt and the pulleys. Confirm the holding of the

tensioner, and then hold the belt side in the place away from

the pulleys to attach or remove the belt, paying attention to

prevent your finger from being caught.

CAUTION:

I When handling the belt, pay attention to prevent the oil or

coolant from adhering to the belt.

I Do not distort or bend the belt intensively.

Installation

IInstall the belt in the reverse order of removal.

I After installation of the belt, confirm that the belt engages the

pulleys securely.

I Depending on the engagement between the belt and the idler

pulley, noise (belt noise) may be heard when the engine is

started just after installation. This noise will stop with time.

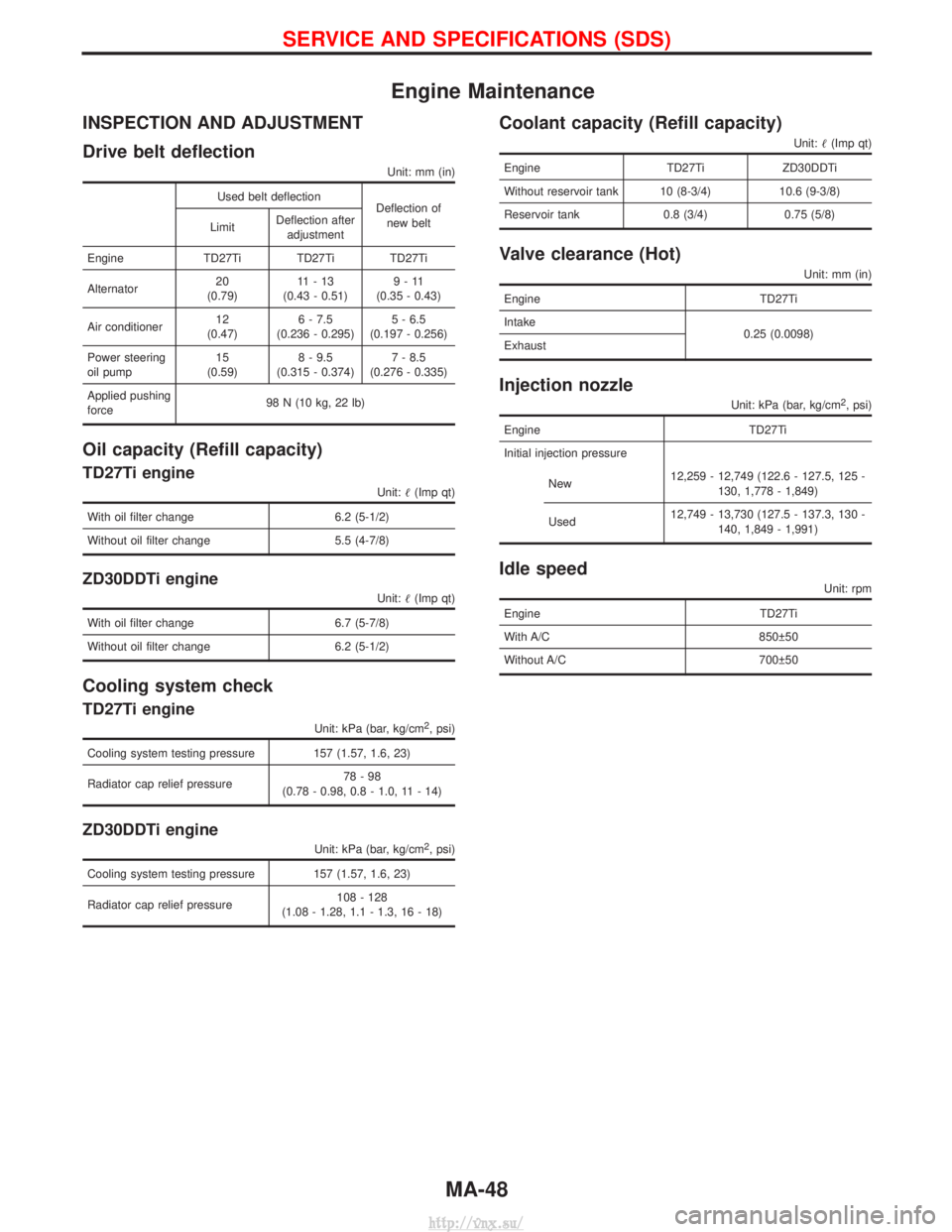

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as engine oil is hot.

I Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com- ponents.

2. Remove drain plug and oil filler cap.

SMA101D

ENGINE MAINTENANCEZD

MA-29

http://vnx.su/

Page 89 of 1833

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 1464 of 1833

STARTING & CHARGING SYSTEMSSECTION

SC

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY ........................................................................\

.3

How to Handle Battery ................................................3

Battery Test and Charging Chart .................................6

STARTING SYSTEM .....................................................13

System Description ....................................................13

Wiring Diagram - START -.........................................14

Trouble Diagnoses.....................................................16

Construction ...............................................................17

Magnetic Switch Check .............................................19

Pinion/Clutch Check ..................................................19

Brush Check ..............................................................20 Field Coil Check ........................................................20

Armature Check .........................................................21

Assembly ...................................................................22

CHARGING SYSTEM ....................................................23

System Description ....................................................23

Wiring Diagram - CHARGE -.....................................24

Trouble Diagnoses.....................................................26

Construction ...............................................................27

Disassembly...............................................................28

Inspection...................................................................28

Assembly ...................................................................29

SERVICE DATA AND SPECIFICATIONS (SDS) ..........30

Battery........................................................................\

30

Starter ........................................................................\

30

Alternator ...................................................................30

http://vnx.su/

Page 1829 of 1833

F

Fan switch ......................................................HA-60

F/FOG - Wiring diagram .................................EL-55

Final drive disassembly............................PD-15, 37

Final drive pre-inspection .........................PD-15, 37

Final drive removal and installation ...............PD-15

Finisher, interior - See Trim ............................BT-18

Finisher, rear panel .........................................BT-18

Floor trim .........................................................BT-18

Fluid temperature sensor (A/T) .....................AT-146

Fluids .............................................MA-5, 17, 20, 36

Flywheel (clutch) .......................................CL-11, 12

Flywheel runout..............................................EM-94

Fog lamp, front .........................................EL-55, 57

Fog lamp, rear ................................................EL-58

Fork rod (M/T) ................................................MT-13

Forward clutch...............................................AT-162

Front axle ....................................................FA-4, 13

Front bumper ....................................................BT-6

Front case (Transfer) ..................................TF-9, 23

Front combination lamp removal andinstallation .....................................................BT-6

Front disc brake .............................................BR-27

Front door .......................................................BT-10

Front Door Trim...............................................BT-19

Front drive shaft (Transfer) .........................TF-9, 19

Front final drive disassembly (4WD) ..............PD-14

Front final drive removal and installa- tion (4WD) ............................................PD-12, 13

Front fog lamp ..........................................EL-55, 57

Front passenger air bag .................................RS-19

Front seat ........................................................BT-34

Front seat belt ..................................................RS-4

Front seat belt pre-tensioner ..........................RS-14

Front side air bag ...........................................RS-20

Front suspension ........................................FA-4, 29

Fuel cut control (at no load & high engine speed).....................................EC-22, 334

Fuel cut solenoid valve ................................EC-399

Fuel cut system ............................................EC-237

Fuel filler lid.......................................................BT-8

Fuel filter replacement...................MA-5, 20, 23, 33

Fuel gauge..................................FE-3, 6, EL-86, 98

Fuel injection system .............................EC-20, 329

Fuel injection timing feed back (Elec- tronic Fuel Injection Pump) ......................EC-197

Fuel precautions ................................................GI-6

Fuel pump and gauge ..............................FE-3, 6, 7

Fuel system ..................................................FE-3, 6

Fuel tank .......................................................FE-3, 6

Fuel temperature sensor ......................EC-123, 395

Fuse ................................................................EL-19

Fuse and fusible link box .............................Foldout

Fuse block ....................................................Foldout

Fusible link ......................................................EL-19 GGarage jack and safety stand .........................GI-31

Gauges .....................................................EL-82, 85

Gear components (M/T) ........MT-11, 14, 16, 21, 23

Generator - See Alternator .............................SC-27

GLOW - Wiring diagram...............................EC-246

Glow control system ....................EC-244, 334, 412

Glow plug .............................................EC-244, 413

Glow relay ............................................EC-246, 419

Grease .........................................MA-17, 39, 40, 44

Ground distribution..........................................EL-20

H

Harness connector ............................................EL-5

Harness connector inspection .........................GI-19

Harness layout ....EL-280, 281, 282, 298, 310, 312,320, 321, 322, 323, 324

Hazard warning lamp................................EL-61, 62

Headlamp ......EL-28, 32, 33, 34, 41, 42, 43, 46, 47

Headlamp aiming control .............EL-41, 42, 43, 46

Headlamp washer .........................................EL-118

Headlining - See Roof trim .............................BT-20

Heat up switch..............................................EC-265

Heated seat .......................................BT-36, EL-151

HEATER - Wiring diagram .............................HA-41

HEATUP - Wiring diagram ...........................EC-266

Height (Dimensions) ........................................GI-10

HFC134a (R134a) system precaution .............HA-3

HFC134a (R134a) system service procedure....................................................HA-15

HFC134a (R134a) system service tools ........HA-11

High clutch ....................................................AT-160

H/LAMP - Wiring diagram ............EL-28, 34, 43, 62

Hood..................................................................BT-6

Hood lock system .............................................BT-6

Horn ..............................................................EL-122

HORN - Wiring diagram................................EL-122

How to erase DTC for OBD system ......EC-33, 344

HSEAT - Wiring diagram...............................EL-151

I

Identification .....................................................HA-2

Identification plate .....................................GI-28, 29

Idle speed...............................................EC-50, 361

Idle speed inspection ...............................MA-20, 26

ILL - Wiring diagram .......................................EL-68

Illumination ................................................EL-67, 68

Injection nozzle ......................................EC-24, 336

Injection nozzle inspection ..................MA-5, 20, 25

Injection timing control valve ........................EC-403

INJPMP - Wiring diagram ...EC-126, 169, 176, 183, 190, 200, 240

Instrument panel .............................................BT-16

INT/L - Wiring diagram....................................EL-74

ALPHABETICAL INDEX

IDX-4

http://vnx.su/