tires NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 4 of 1833

GENERAL INFORMATIONSECTION

GI

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL ........................................8

HOW TO READ WIRING DIAGRAMS ..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL .......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT ........................................22 Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES ..................................................................25

CONSULT-II CHECKING SYSTEM ...............................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............26

Checking Equipment..................................................26

IDENTIFICATION INFORMATION .................................27

Model Variation ..........................................................27

Identification Number .................................................28

Dimensions ................................................................30

Wheels and Tires .......................................................30

LIFTING POINTS AND TOW TRUCK TOWING ...........31

Garage Jack and Safety Stand .................................31

Screw Jack ................................................................31

4-pole Lift ...................................................................32

Tow Truck Towing ......................................................32

ISO 15031-2 TERMINOLOGY LIST ..............................34

ISO 15031-2 Terminology List ...................................34

TIGHTENING TORQUE OF STANDARD BOLTS ........37

http://vnx.su/

Page 33 of 1833

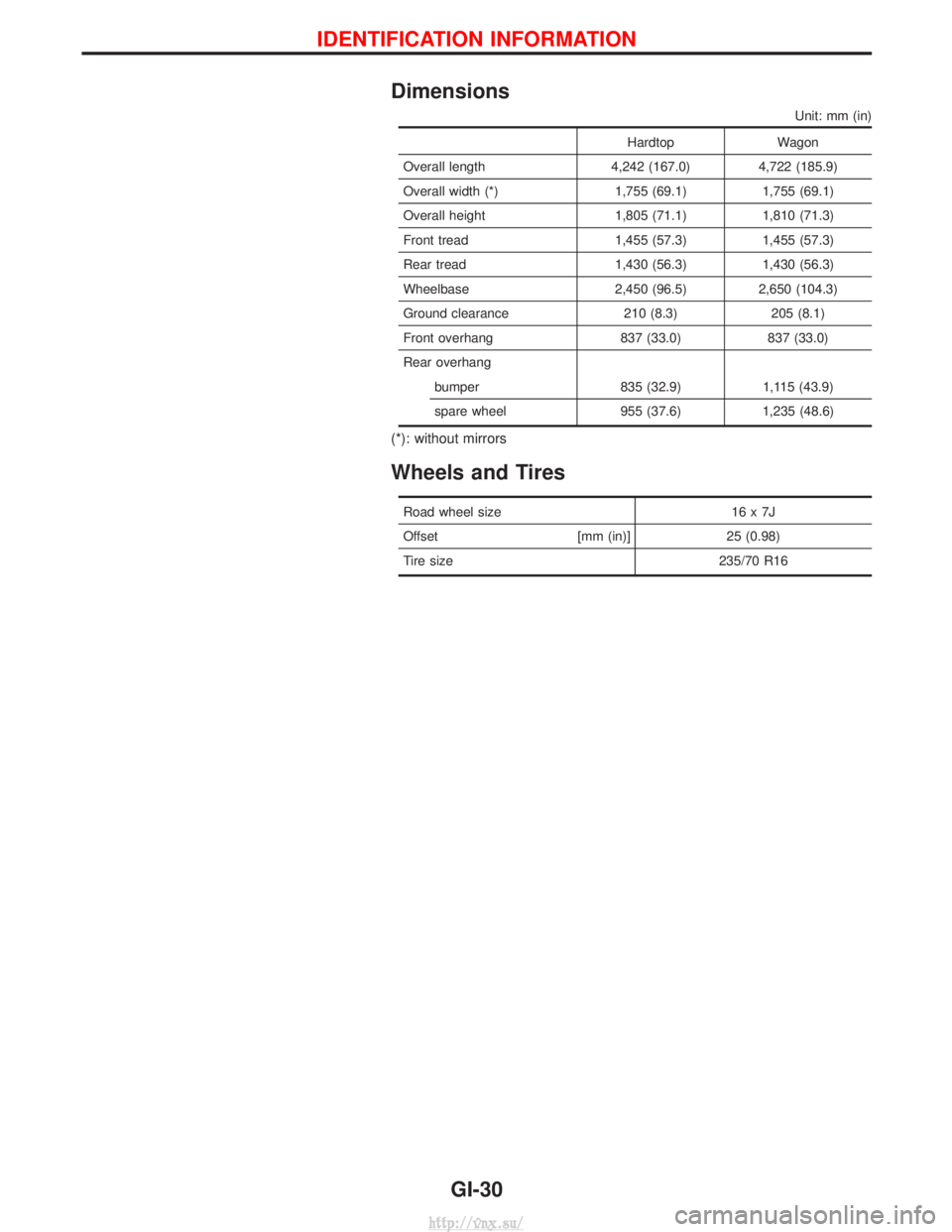

Dimensions

Unit: mm (in)

HardtopWagon

Overall length 4,242 (167.0) 4,722 (185.9)

Overall width (*) 1,755 (69.1) 1,755 (69.1)

Overall height 1,805 (71.1) 1,810 (71.3)

Front tread 1,455 (57.3) 1,455 (57.3)

Rear tread 1,430 (56.3) 1,430 (56.3)

Wheelbase 2,450 (96.5) 2,650 (104.3)

Ground clearance 210 (8.3) 205 (8.1)

Front overhang 837 (33.0) 837 (33.0)

Rear overhang bumper 835 (32.9) 1,115 (43.9)

spare wheel 955 (37.6) 1,235 (48.6)

(*): without mirrors

Wheels and Tires

Road wheel size 16 x 7J

Offset [mm (in)]25 (0.98)

Tire size 235/70 R16

IDENTIFICATION INFORMATION

GI-30

http://vnx.su/

Page 45 of 1833

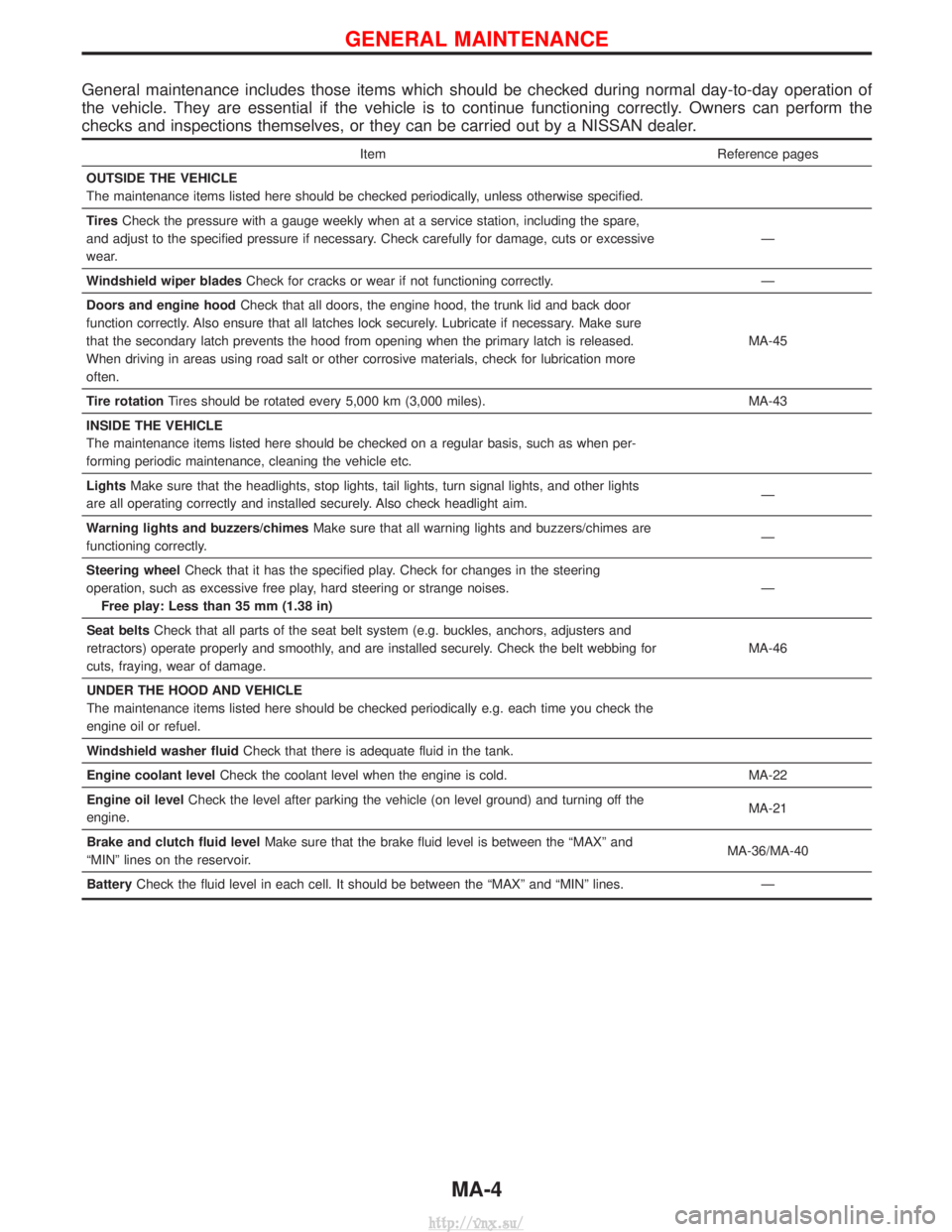

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 1113 of 1833

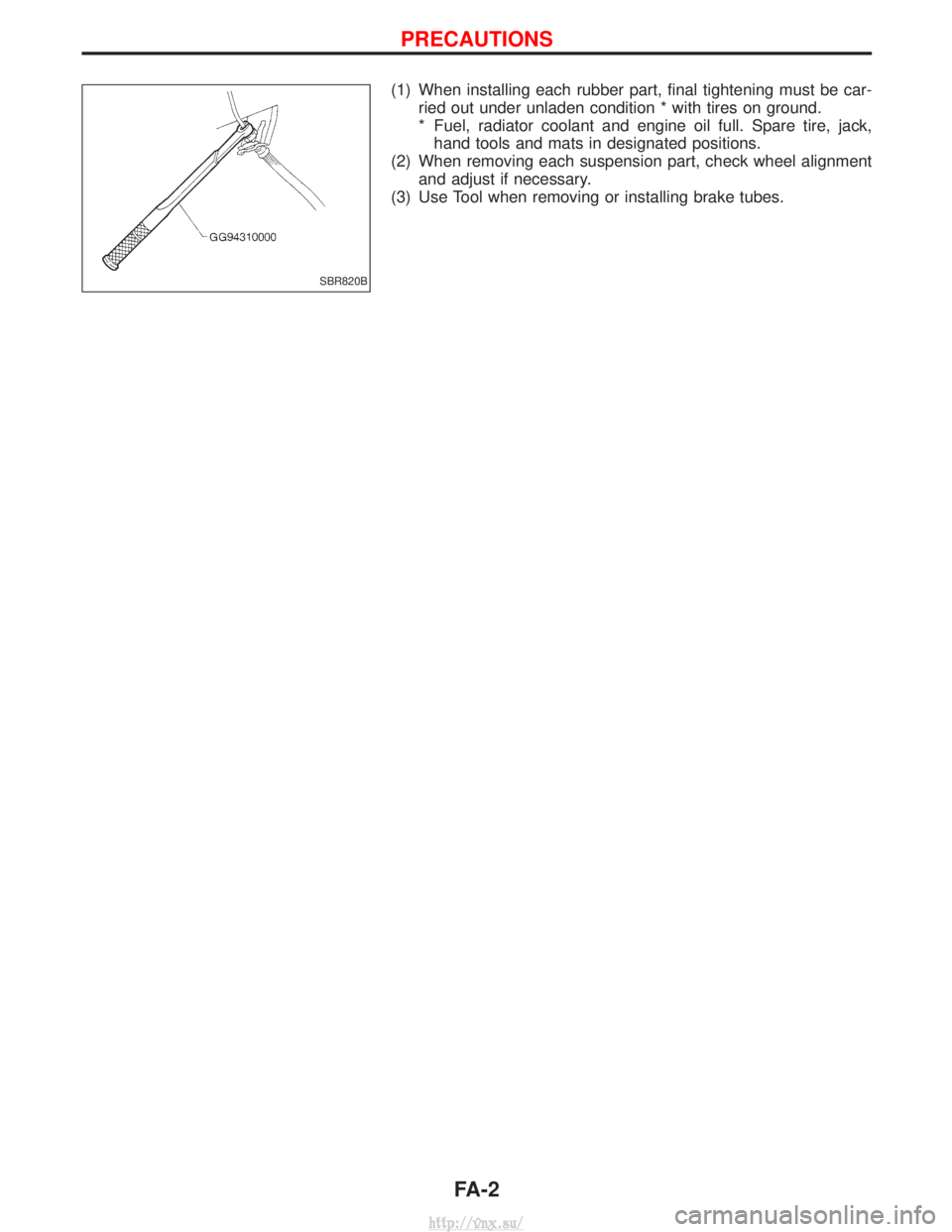

(1) When installing each rubber part, final tightening must be car-ried out under unladen condition * with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,hand tools and mats in designated positions.

(2) When removing each suspension part, check wheel alignment and adjust if necessary.

(3) Use Tool when removing or installing brake tubes.

SBR820B

PRECAUTIONS

FA-2

http://vnx.su/

Page 1119 of 1833

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a prelimi-

nary inspection.

PRELIMINARY INSPECTION

1. Check the tires for wear and proper inflation.

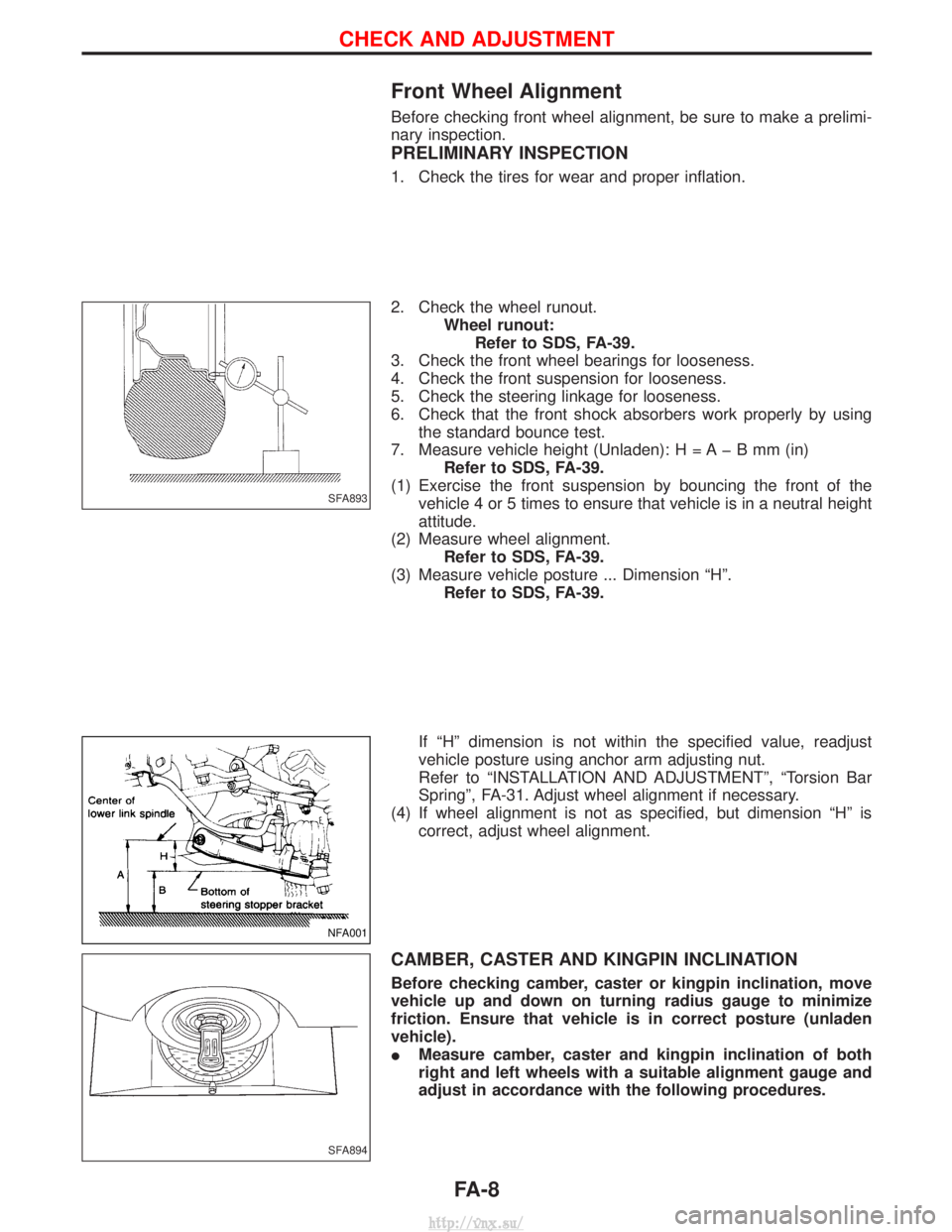

2. Check the wheel runout.Wheel runout:Refer to SDS, FA-39.

3. Check the front wheel bearings for looseness.

4. Check the front suspension for looseness.

5. Check the steering linkage for looseness.

6. Check that the front shock absorbers work properly by using the standard bounce test.

7. Measure vehicle height (Unladen): H = A þ B mm (in) Refer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the vehicle 4 or 5 times to ensure that vehicle is in a neutral height

attitude.

(2) Measure wheel alignment. Refer to SDS, FA-39.

(3) Measure vehicle posture ... Dimension ªHº. Refer to SDS, FA-39.

If ªHº dimension is not within the specified value, readjust

vehicle posture using anchor arm adjusting nut.

Refer to ªINSTALLATION AND ADJUSTMENTº, ªTorsion Bar

Springº, FA-31. Adjust wheel alignment if necessary.

(4) If wheel alignment is not as specified, but dimension ªHº is correct, adjust wheel alignment.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that vehicle is in correct posture (unladen

vehicle).

IMeasure camber, caster and kingpin inclination of both

right and left wheels with a suitable alignment gauge and

adjust in accordance with the following procedures.

SFA893

NFA001

SFA894

CHECK AND ADJUSTMENT

FA-8

http://vnx.su/

Page 1127 of 1833

qA

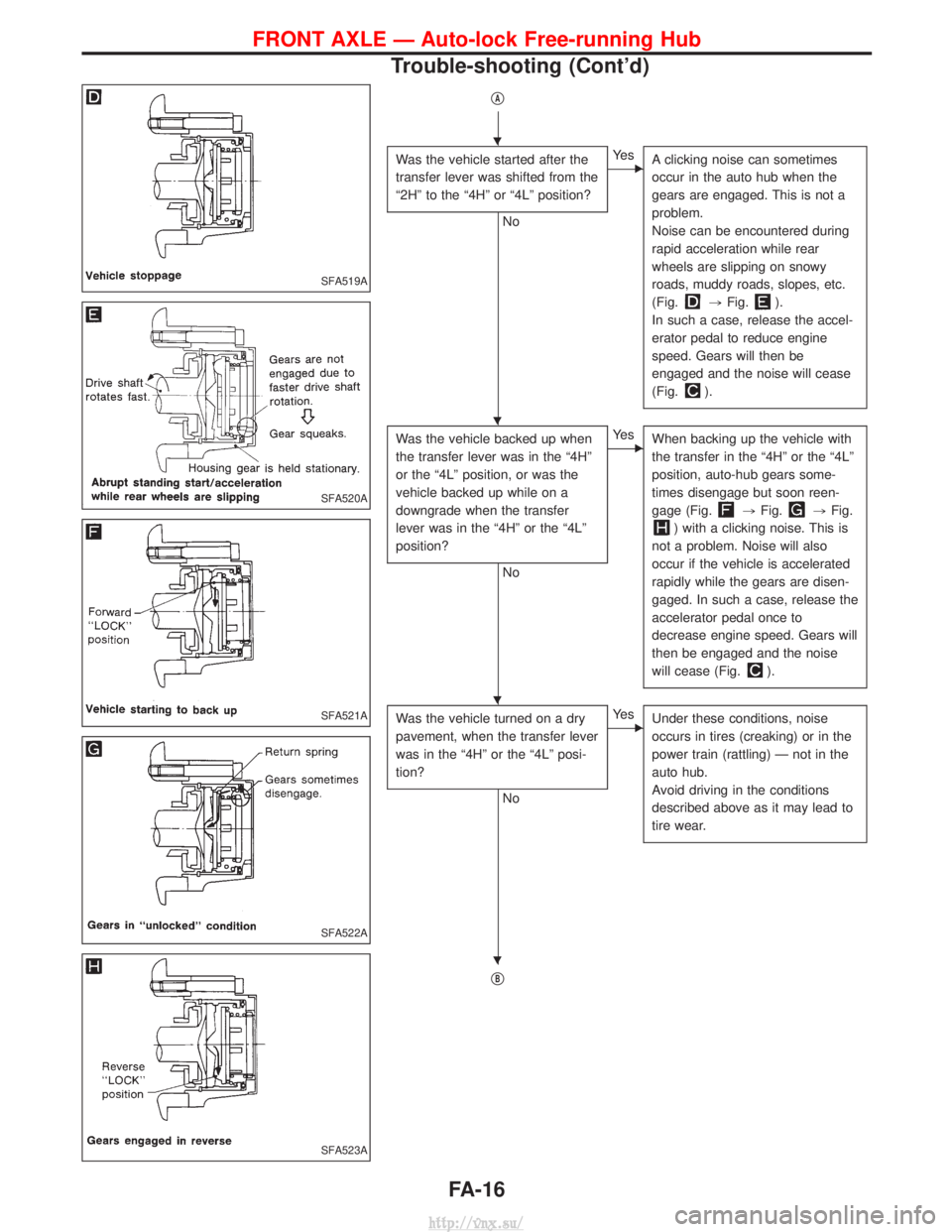

Was the vehicle started after the

transfer lever was shifted from the

ª2Hº to the ª4Hº or ª4Lº position?

No

EYe sA clicking noise can sometimes

occur in the auto hub when the

gears are engaged. This is not a

problem.

Noise can be encountered during

rapid acceleration while rear

wheels are slipping on snowy

roads, muddy roads, slopes, etc.

(Fig.

,Fig.).

In such a case, release the accel-

erator pedal to reduce engine

speed. Gears will then be

engaged and the noise will cease

(Fig.

).

Was the vehicle backed up when

the transfer lever was in the ª4Hº

or the ª4Lº position, or was the

vehicle backed up while on a

downgrade when the transfer

lever was in the ª4Hº or the ª4Lº

position?

No

EYe s When backing up the vehicle with

the transfer in the ª4Hº or the ª4Lº

position, auto-hub gears some-

times disengage but soon reen-

gage (Fig.

,Fig.,Fig.

) with a clicking noise. This is

not a problem. Noise will also

occur if the vehicle is accelerated

rapidly while the gears are disen-

gaged. In such a case, release the

accelerator pedal once to

decrease engine speed. Gears will

then be engaged and the noise

will cease (Fig.

).

Was the vehicle turned on a dry

pavement, when the transfer lever

was in the ª4Hº or the ª4Lº posi-

tion?

No

EYe s Under these conditions, noise

occurs in tires (creaking) or in the

power train (rattling) Ð not in the

auto hub.

Avoid driving in the conditions

described above as it may lead to

tire wear.

qB

SFA519A

SFA520A

SFA521A

SFA522A

SFA523A

H

H

H

H

FRONT AXLE Ð Auto-lock Free-running Hub

Trouble-shooting (Cont'd)

FA-16

http://vnx.su/

Page 1143 of 1833

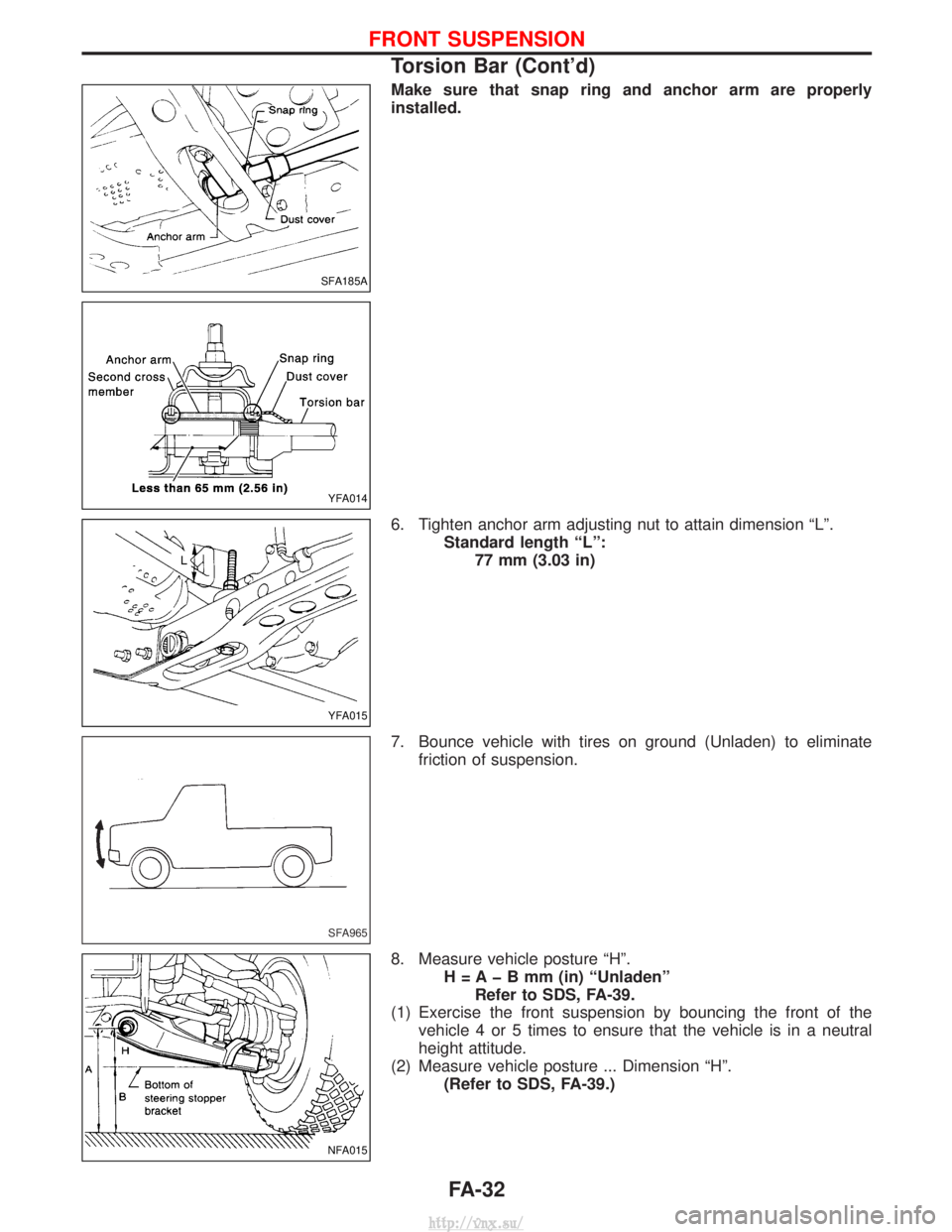

Make sure that snap ring and anchor arm are properly

installed.

6. Tighten anchor arm adjusting nut to attain dimension ªLº.Standard length ªLº:77 mm (3.03 in)

7. Bounce vehicle with tires on ground (Unladen) to eliminate friction of suspension.

8. Measure vehicle posture ªHº. H = A þ B mm (in) ªUnladenºRefer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the vehicle 4 or 5 times to ensure that the vehicle is in a neutral

height attitude.

(2) Measure vehicle posture ... Dimension ªHº. (Refer to SDS, FA-39.)

SFA185A

YFA014

YFA015

SFA965

NFA015

FRONT SUSPENSION

Torsion Bar (Cont'd)

FA-32

http://vnx.su/

Page 1145 of 1833

INSTALLATION

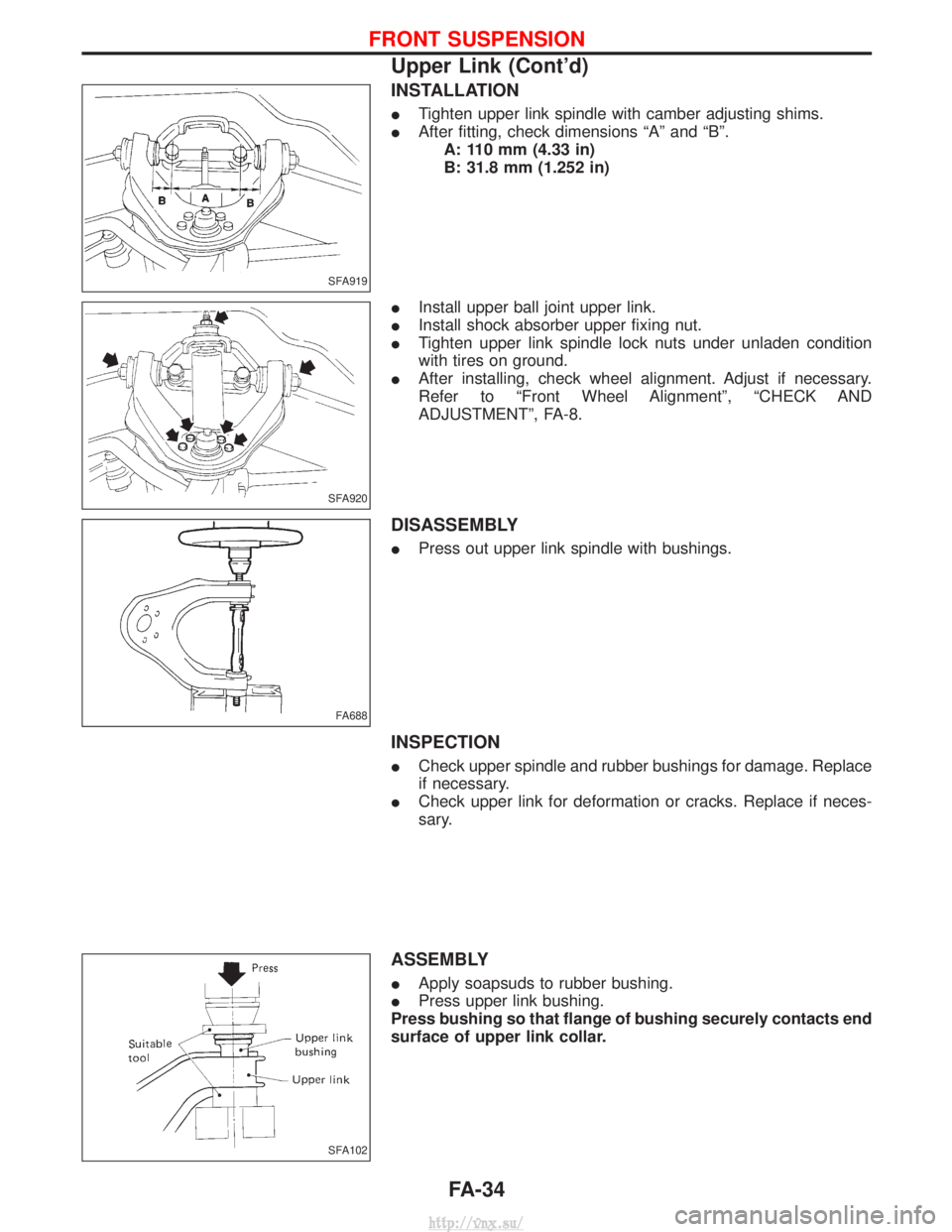

ITighten upper link spindle with camber adjusting shims.

I After fitting, check dimensions ªAº and ªBº.

A: 110 mm (4.33 in)

B: 31.8 mm (1.252 in)

I Install upper ball joint upper link.

I Install shock absorber upper fixing nut.

I Tighten upper link spindle lock nuts under unladen condition

with tires on ground.

I After installing, check wheel alignment. Adjust if necessary.

Refer to ªFront Wheel Alignmentº, ªCHECK AND

ADJUSTMENTº, FA-8.

DISASSEMBLY

IPress out upper link spindle with bushings.

INSPECTION

ICheck upper spindle and rubber bushings for damage. Replace

if necessary.

I Check upper link for deformation or cracks. Replace if neces-

sary.

ASSEMBLY

IApply soapsuds to rubber bushing.

I Press upper link bushing.

Press bushing so that flange of bushing securely contacts end

surface of upper link collar.

SFA919

SFA920

FA688

SFA102

FRONT SUSPENSION

Upper Link (Cont'd)

FA-34

http://vnx.su/

Page 1153 of 1833

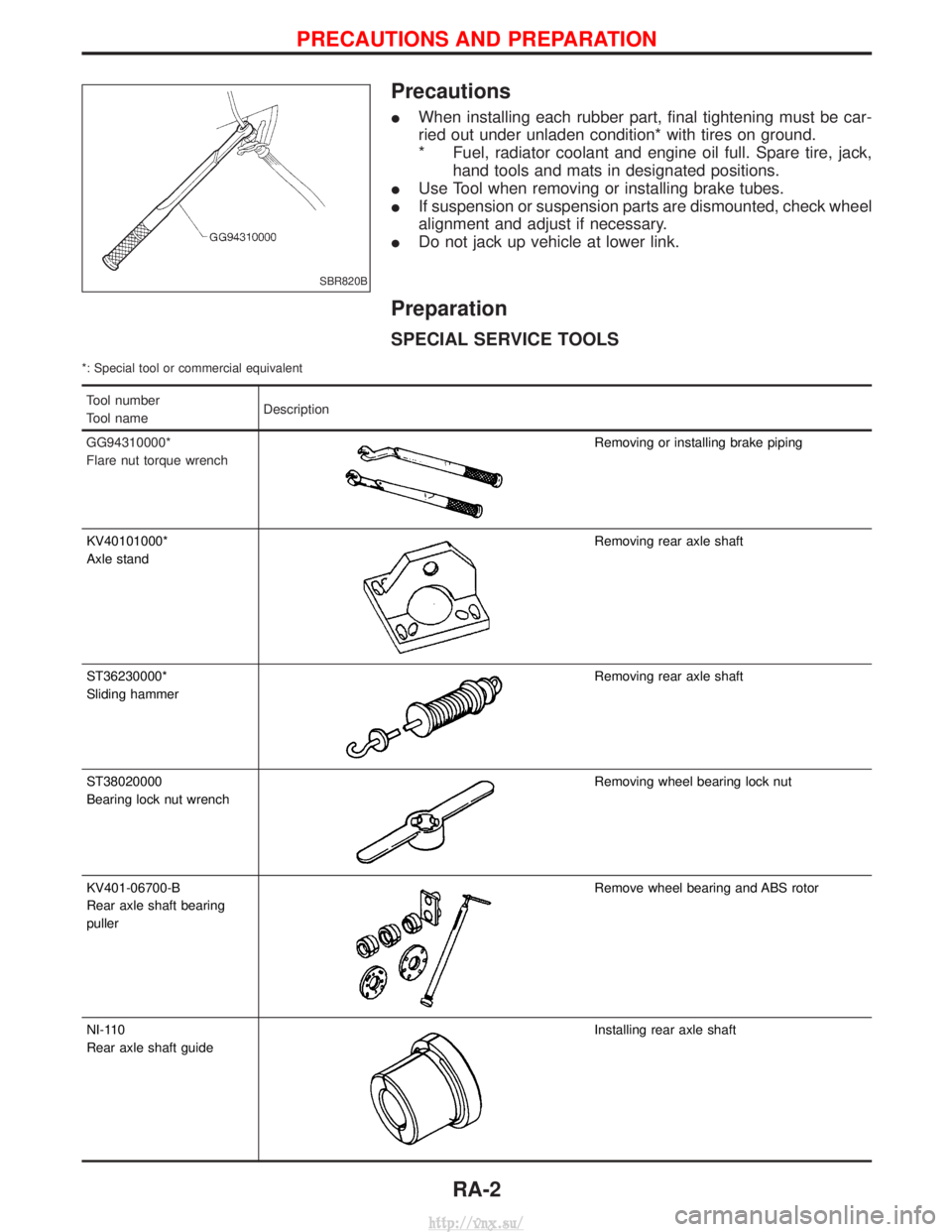

Precautions

IWhen installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

I Use Tool when removing or installing brake tubes.

I If suspension or suspension parts are dismounted, check wheel

alignment and adjust if necessary.

I Do not jack up vehicle at lower link.

Preparation

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool name Description

GG94310000*

Flare nut torque wrench

Removing or installing brake piping

KV40101000*

Axle stand

Removing rear axle shaft

ST36230000*

Sliding hammer

Removing rear axle shaft

ST38020000

Bearing lock nut wrench

Removing wheel bearing lock nut

KV401-06700-B

Rear axle shaft bearing

puller

Remove wheel bearing and ABS rotor

NI-110

Rear axle shaft guide

Installing rear axle shaft

SBR820B

PRECAUTIONS AND PREPARATION

RA-2

http://vnx.su/

Page 1163 of 1833

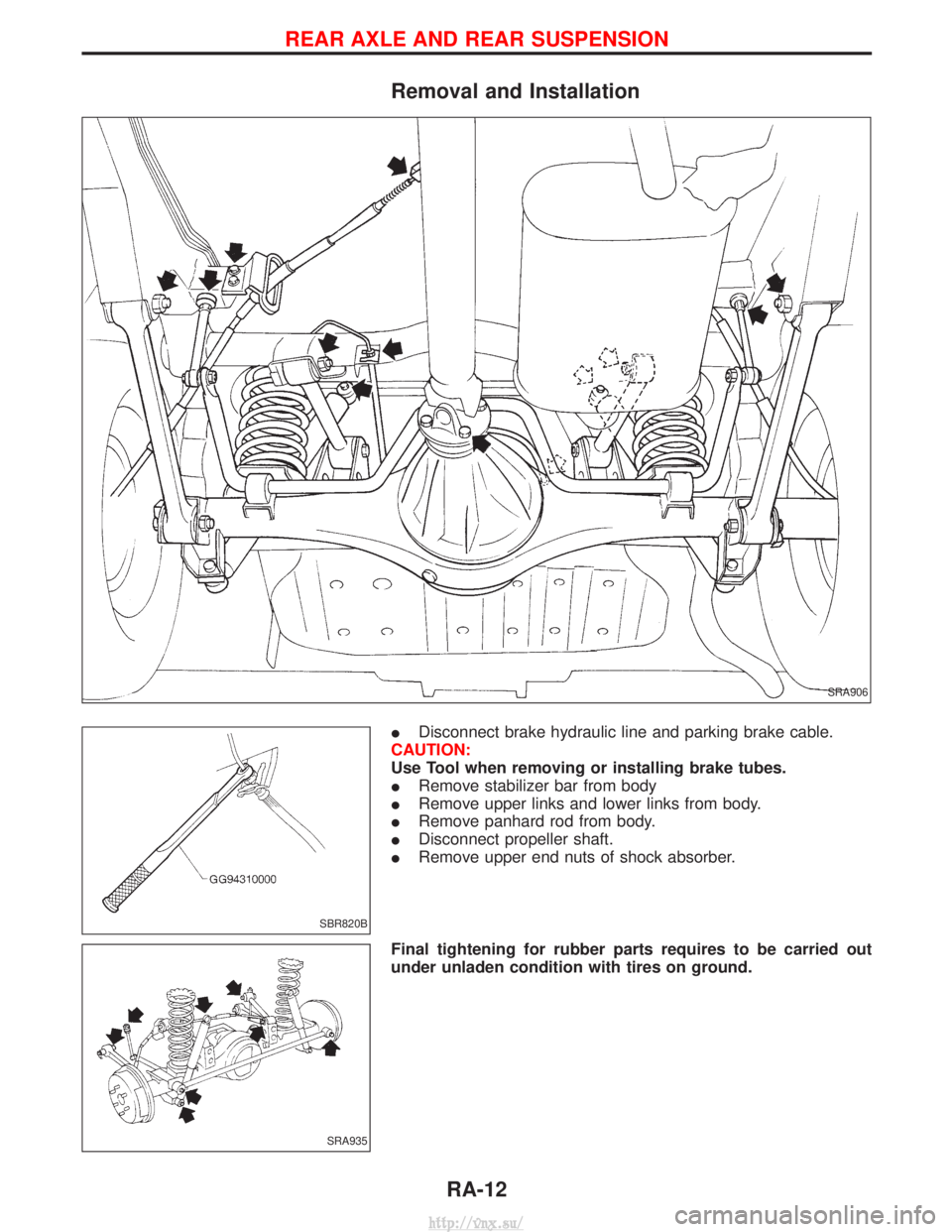

Removal and Installation

IDisconnect brake hydraulic line and parking brake cable.

CAUTION:

Use Tool when removing or installing brake tubes.

I Remove stabilizer bar from body

I Remove upper links and lower links from body.

I Remove panhard rod from body.

I Disconnect propeller shaft.

I Remove upper end nuts of shock absorber.

Final tightening for rubber parts requires to be carried out

under unladen condition with tires on ground.

SRA906

SBR820B

SRA935

REAR AXLE AND REAR SUSPENSION

RA-12

http://vnx.su/