door lock NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 1297 of 1833

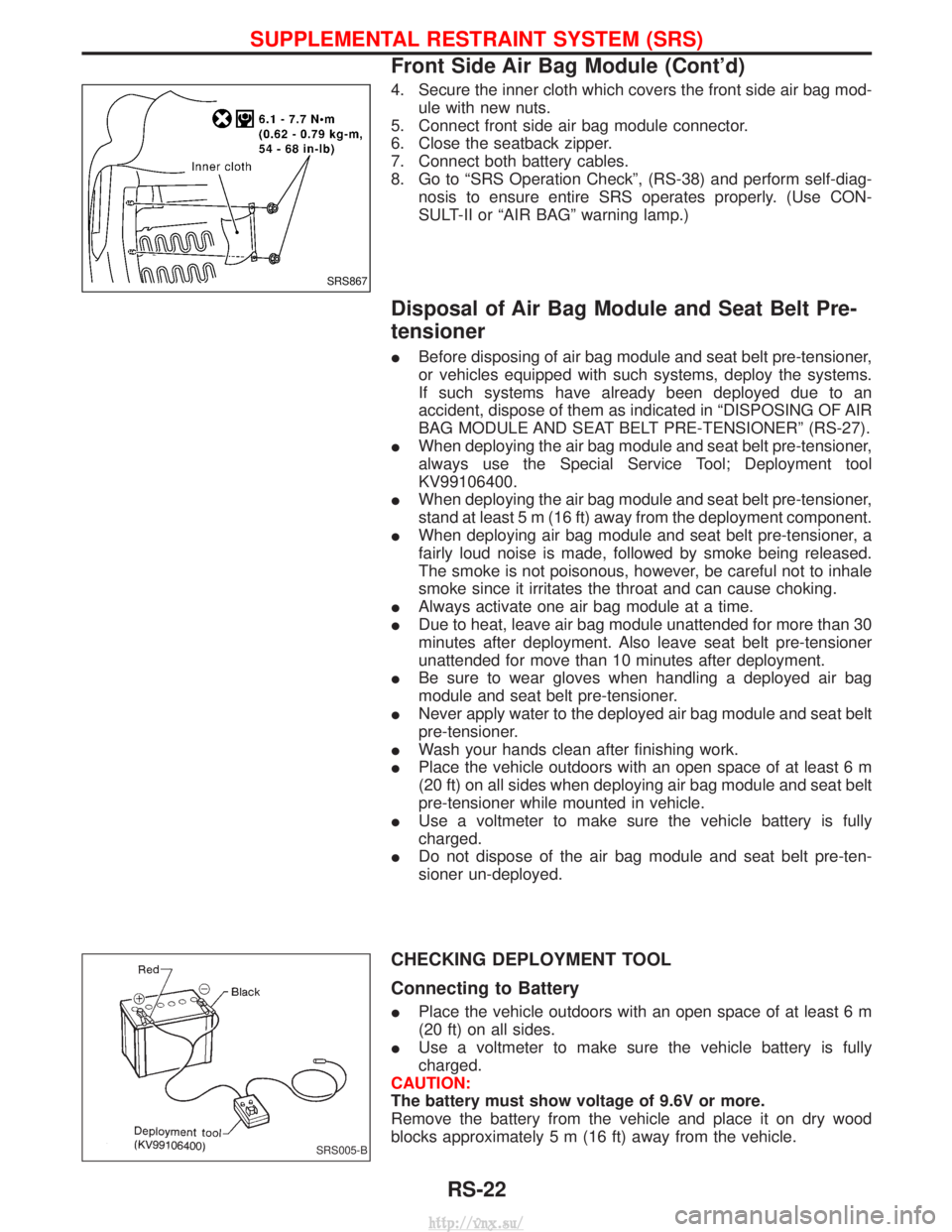

4. Secure the inner cloth which covers the front side air bag mod-ule with new nuts.

5. Connect front side air bag module connector.

6. Close the seatback zipper.

7. Connect both battery cables.

8. Go to ªSRS Operation Checkº, (RS-38) and perform self-diag- nosis to ensure entire SRS operates properly. (Use CON-

SULT-II or ªAIR BAGº warning lamp.)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner

IBefore disposing of air bag module and seat belt pre-tensioner,

or vehicles equipped with such systems, deploy the systems.

If such systems have already been deployed due to an

accident, dispose of them as indicated in ªDISPOSING OF AIR

BAG MODULE AND SEAT BELT PRE-TENSIONERº (RS-27).

I When deploying the air bag module and seat belt pre-tensioner,

always use the Special Service Tool; Deployment tool

KV99106400.

I When deploying the air bag module and seat belt pre-tensioner,

stand at least 5 m (16 ft) away from the deployment component.

I When deploying air bag module and seat belt pre-tensioner, a

fairly loud noise is made, followed by smoke being released.

The smoke is not poisonous, however, be careful not to inhale

smoke since it irritates the throat and can cause choking.

I Always activate one air bag module at a time.

I Due to heat, leave air bag module unattended for more than 30

minutes after deployment. Also leave seat belt pre-tensioner

unattended for move than 10 minutes after deployment.

I Be sure to wear gloves when handling a deployed air bag

module and seat belt pre-tensioner.

I Never apply water to the deployed air bag module and seat belt

pre-tensioner.

I Wash your hands clean after finishing work.

I Place the vehicle outdoors with an open space of at least 6 m

(20 ft) on all sides when deploying air bag module and seat belt

pre-tensioner while mounted in vehicle.

I Use a voltmeter to make sure the vehicle battery is fully

charged.

I Do not dispose of the air bag module and seat belt pre-ten-

sioner un-deployed.

CHECKING DEPLOYMENT TOOL

Connecting to Battery

IPlace the vehicle outdoors with an open space of at least 6 m

(20 ft) on all sides.

I Use a voltmeter to make sure the vehicle battery is fully

charged.

CAUTION:

The battery must show voltage of 9.6V or more.

Remove the battery from the vehicle and place it on dry wood

blocks approximately 5 m (16 ft) away from the vehicle.

SRS867

SRS005-B

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Side Air Bag Module (Cont'd)

RS-22

http://vnx.su/

Page 1345 of 1833

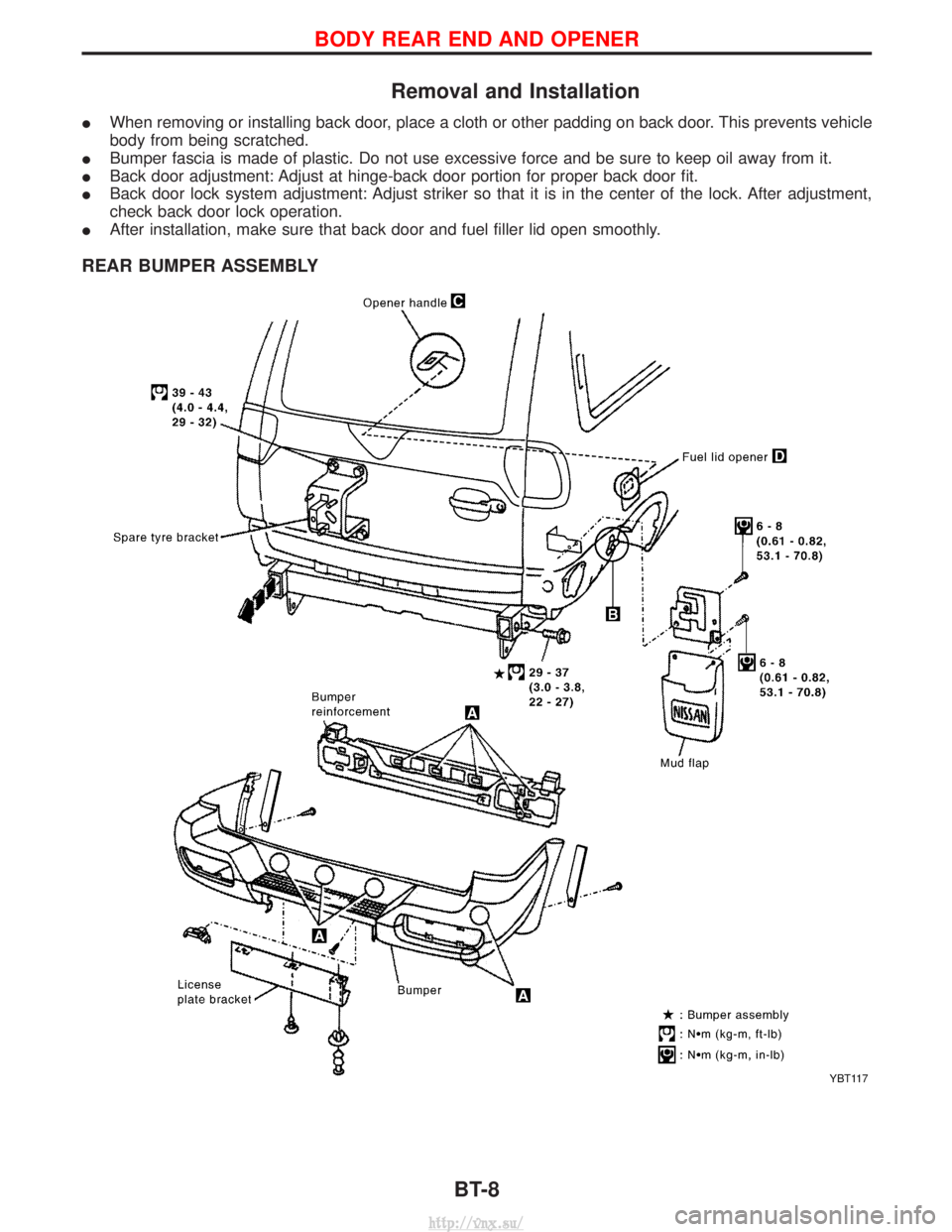

Removal and Installation

IWhen removing or installing back door, place a cloth or other padding on back door. This prevents vehicle

body from being scratched.

I Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

I Back door adjustment: Adjust at hinge-back door portion for proper back door fit.

I Back door lock system adjustment: Adjust striker so that it is in the center of the lock. After adjustment,

check back door lock operation.

I After installation, make sure that back door and fuel filler lid open smoothly.

REAR BUMPER ASSEMBLY

YBT117

BODY REAR END AND OPENER

BT-8

http://vnx.su/

Page 1347 of 1833

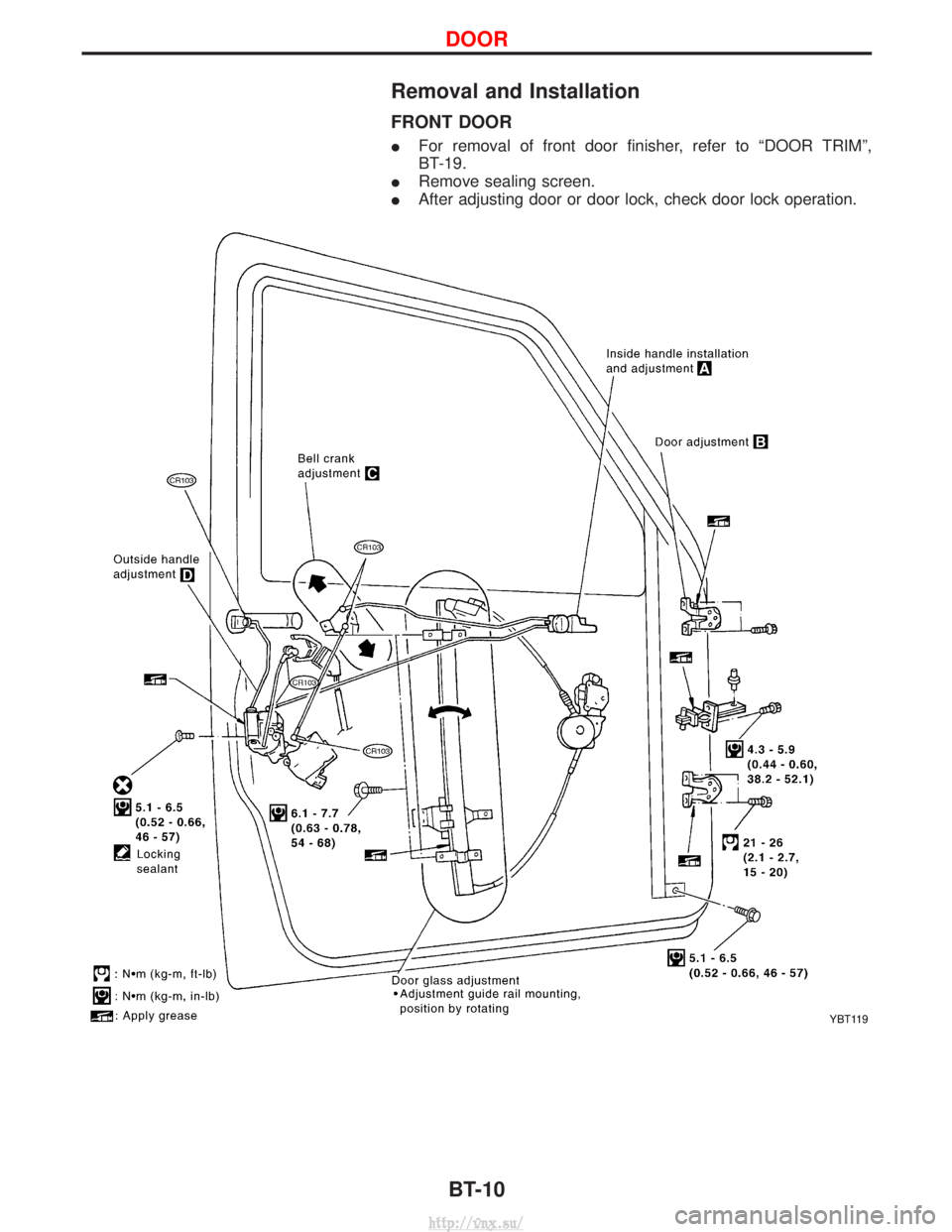

Removal and Installation

FRONT DOOR

IFor removal of front door finisher, refer to ªDOOR TRIMº,

BT-19.

I Remove sealing screen.

I After adjusting door or door lock, check door lock operation.

YBT119

DOOR

BT-10

http://vnx.su/

Page 1349 of 1833

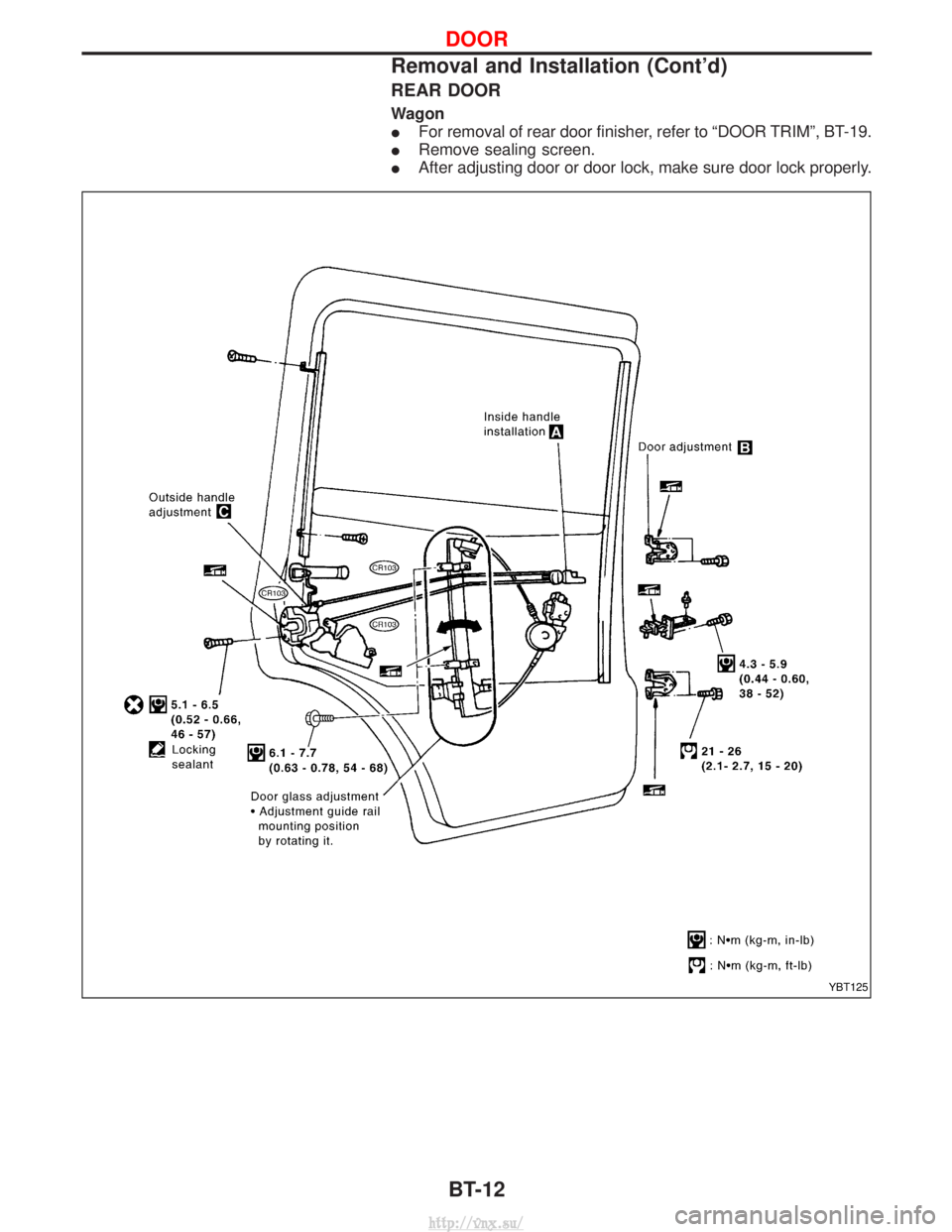

REAR DOOR

Wagon

IFor removal of rear door finisher, refer to ªDOOR TRIMº, BT-19.

I Remove sealing screen.

I After adjusting door or door lock, make sure door lock properly.

YBT125

DOOR

Removal and Installation (Cont'd)

BT-12

http://vnx.su/

Page 1351 of 1833

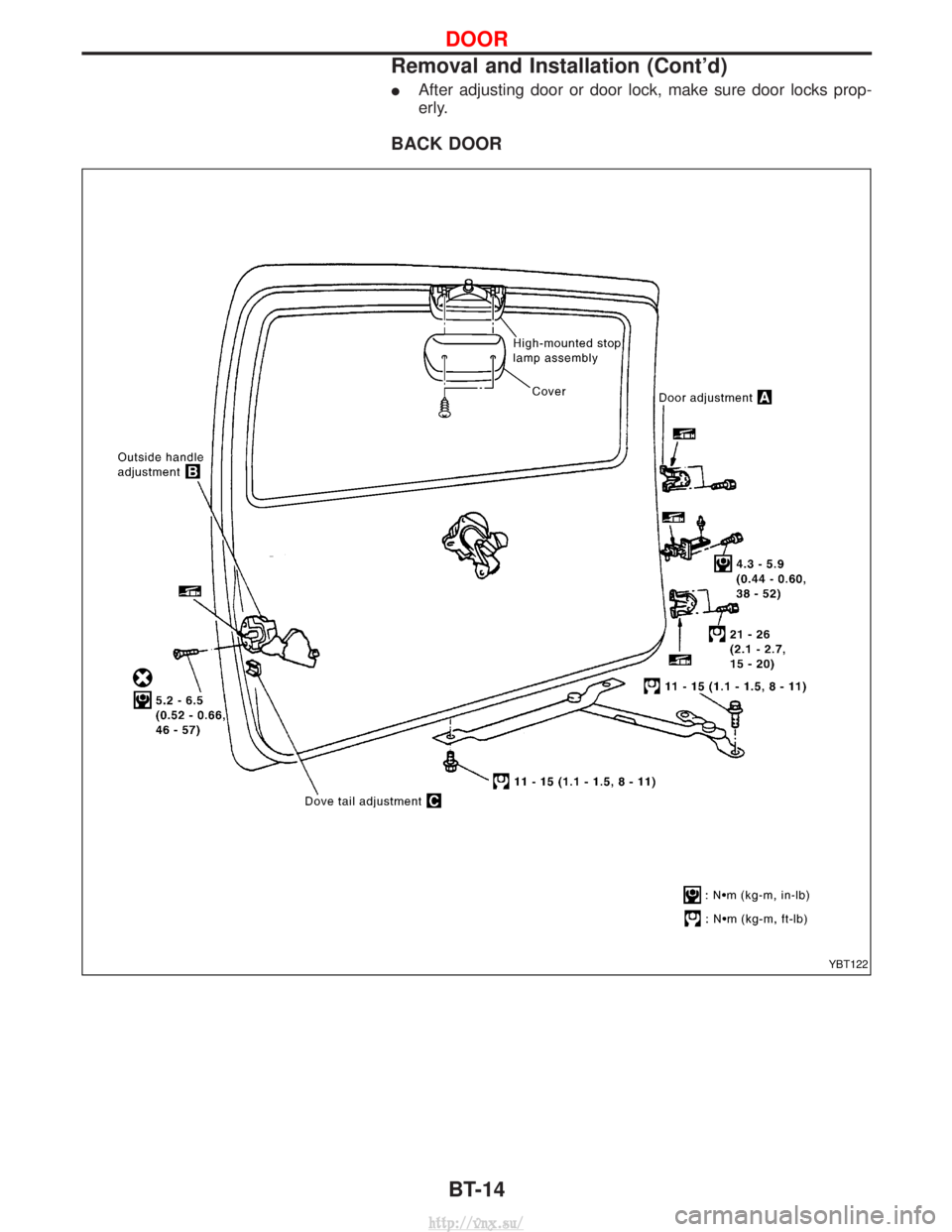

IAfter adjusting door or door lock, make sure door locks prop-

erly.

BACK DOOR

YBT122

DOOR

Removal and Installation (Cont'd)

BT-14

http://vnx.su/

Page 1495 of 1833

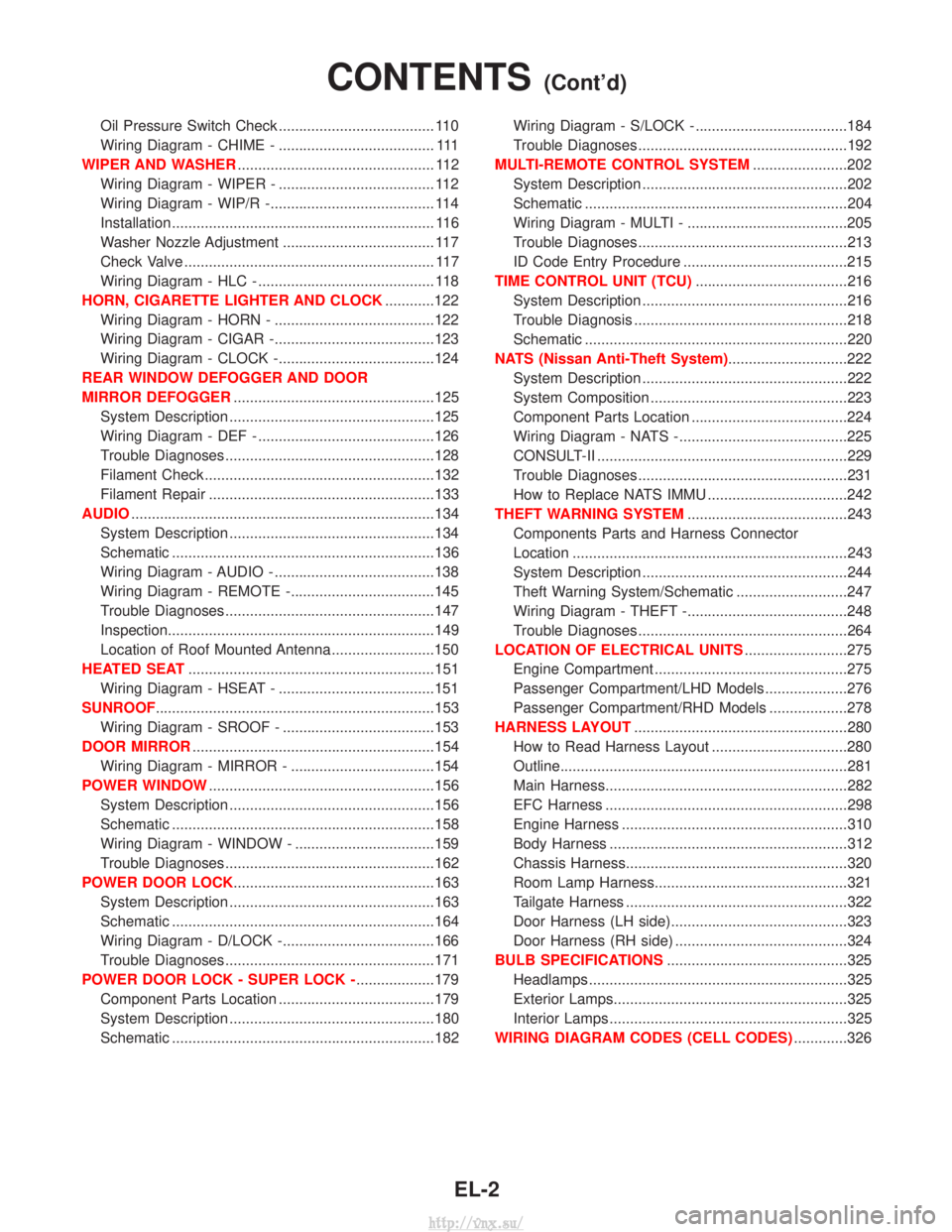

Oil Pressure Switch Check ...................................... 110

Wiring Diagram - CHIME - ...................................... 111

WIPER AND WASHER ................................................ 112

Wiring Diagram - WIPER - ...................................... 112

Wiring Diagram - WIP/R -........................................ 114

Installation ................................................................ 116

Washer Nozzle Adjustment ..................................... 117

Check Valve ............................................................. 117

Wiring Diagram - HLC - ........................................... 118

HORN, CIGARETTE LIGHTER AND CLOCK ............122

Wiring Diagram - HORN - .......................................122

Wiring Diagram - CIGAR -.......................................123

Wiring Diagram - CLOCK -......................................124

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER .................................................125

System Description ..................................................125

Wiring Diagram - DEF - ...........................................126

Trouble Diagnoses...................................................128

Filament Check ........................................................132

Filament Repair .......................................................133

AUDIO ........................................................................\

..134

System Description ..................................................134

Schematic ................................................................136

Wiring Diagram - AUDIO - .......................................138

Wiring Diagram - REMOTE -...................................145

Trouble Diagnoses...................................................147

Inspection.................................................................149

Location of Roof Mounted Antenna .........................150

HEATED SEAT ............................................................151

Wiring Diagram - HSEAT - ......................................151

SUNROOF ....................................................................153

Wiring Diagram - SROOF - .....................................153

DOOR MIRROR ...........................................................154

Wiring Diagram - MIRROR - ...................................154

POWER WINDOW .......................................................156

System Description ..................................................156

Schematic ................................................................158

Wiring Diagram - WINDOW - ..................................159

Trouble Diagnoses...................................................162

POWER DOOR LOCK .................................................163

System Description ..................................................163

Schematic ................................................................164

Wiring Diagram - D/LOCK -.....................................166

Trouble Diagnoses...................................................171

POWER DOOR LOCK - SUPER LOCK - ...................179

Component Parts Location ......................................179

System Description ..................................................180

Schematic ................................................................182 Wiring Diagram - S/LOCK - .....................................184

Trouble Diagnoses...................................................192

MULTI-REMOTE CONTROL SYSTEM .......................202

System Description ..................................................202

Schematic ................................................................204

Wiring Diagram - MULTI - .......................................205

Trouble Diagnoses...................................................213

ID Code Entry Procedure ........................................215

TIME CONTROL UNIT (TCU) .....................................216

System Description ..................................................216

Trouble Diagnosis ....................................................218

Schematic ................................................................220

NATS (Nissan Anti-Theft System) .............................222

System Description ..................................................222

System Composition ................................................223

Component Parts Location ......................................224

Wiring Diagram - NATS -.........................................225

CONSULT-II .............................................................229

Trouble Diagnoses...................................................231

How to Replace NATS IMMU ..................................242

THEFT WARNING SYSTEM .......................................243

Components Parts and Harness Connector

Location ...................................................................243

System Description ..................................................244

Theft Warning System/Schematic ...........................247

Wiring Diagram - THEFT -.......................................248

Trouble Diagnoses...................................................264

LOCATION OF ELECTRICAL UNITS .........................275

Engine Compartment ...............................................275

Passenger Compartment/LHD Models ....................276

Passenger Compartment/RHD Models ...................278

HARNESS LAYOUT ....................................................280

How to Read Harness Layout .................................280

Outline......................................................................281

Main Harness...........................................................282

EFC Harness ...........................................................298

Engine Harness .......................................................310

Body Harness ..........................................................312

Chassis Harness......................................................320

Room Lamp Harness...............................................321

Tailgate Harness ......................................................322

Door Harness (LH side)...........................................323

Door Harness (RH side) ..........................................324

BULB SPECIFICATIONS ............................................325

Headlamps ...............................................................325

Exterior Lamps.........................................................325

Interior Lamps ..........................................................325

WIRING DIAGRAM CODES (CELL CODES) .............326

CONTENTS(Cont'd)

EL-2

http://vnx.su/

Page 1517 of 1833

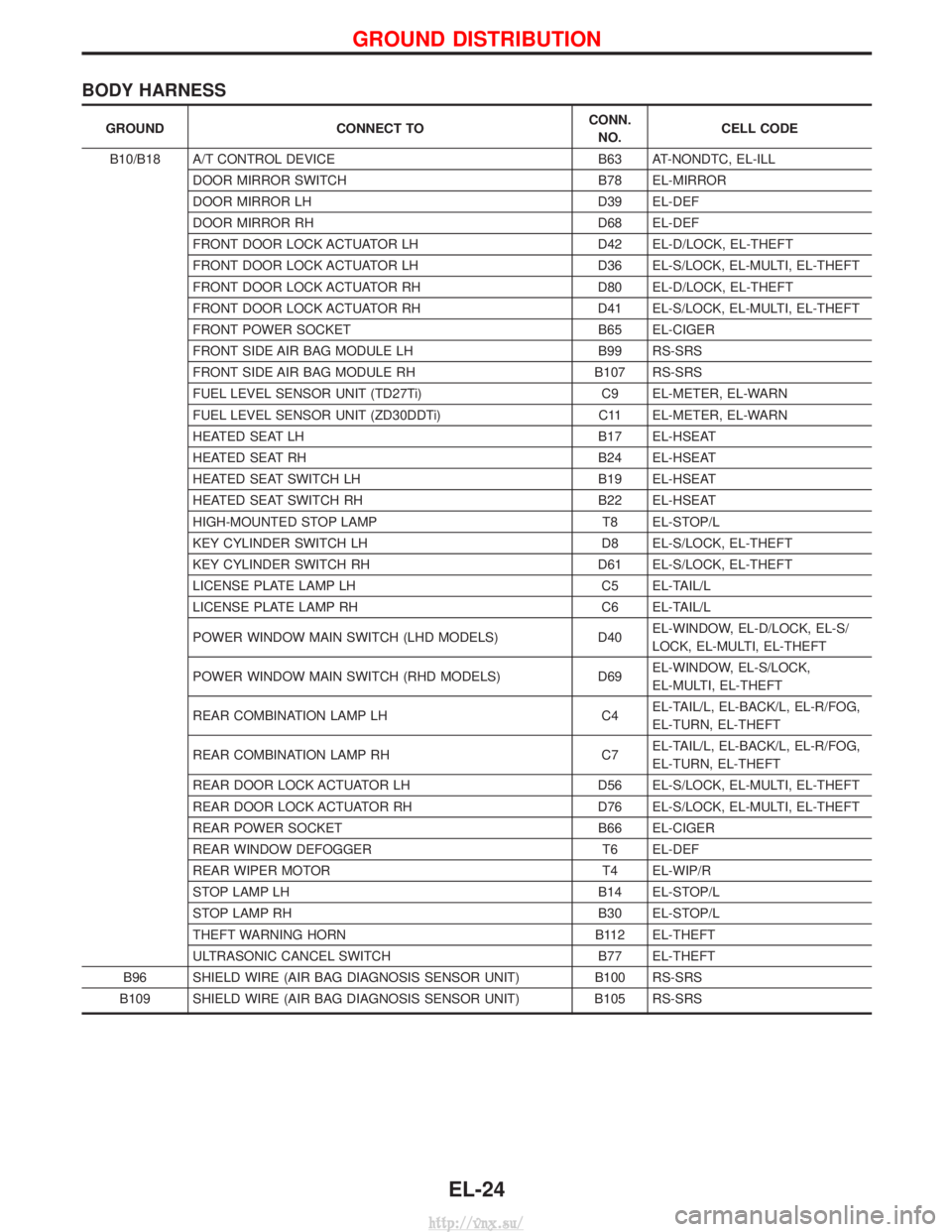

BODY HARNESS

GROUNDCONNECT TO CONN.

NO. CELL CODE

B10/B18 A/T CONTROL DEVICE B63 AT-NONDTC, EL-ILL

DOOR MIRROR SWITCH B78 EL-MIRROR

DOOR MIRROR LH D39 EL-DEF

DOOR MIRROR RH D68 EL-DEF

FRONT DOOR LOCK ACTUATOR LH D42 EL-D/LOCK, EL-THEFT

FRONT DOOR LOCK ACTUATOR LH D36 EL-S/LOCK, EL-MULTI, EL-THEFT

FRONT DOOR LOCK ACTUATOR RH D80 EL-D/LOCK, EL-THEFT

FRONT DOOR LOCK ACTUATOR RH D41 EL-S/LOCK, EL-MULTI, EL-THEFT

FRONT POWER SOCKET B65 EL-CIGER

FRONT SIDE AIR BAG MODULE LH B99 RS-SRS

FRONT SIDE AIR BAG MODULE RH B107 RS-SRS

FUEL LEVEL SENSOR UNIT (TD27Ti) C9 EL-METER, EL-WARN

FUEL LEVEL SENSOR UNIT (ZD30DDTi) C11 EL-METER, EL-WARN

HEATED SEAT LH B17 EL-HSEAT

HEATED SEAT RH B24 EL-HSEAT

HEATED SEAT SWITCH LH B19 EL-HSEAT

HEATED SEAT SWITCH RH B22 EL-HSEAT

HIGH-MOUNTED STOP LAMP T8 EL-STOP/L

KEY CYLINDER SWITCH LH D8 EL-S/LOCK, EL-THEFT

KEY CYLINDER SWITCH RH D61 EL-S/LOCK, EL-THEFT

LICENSE PLATE LAMP LH C5 EL-TAIL/L

LICENSE PLATE LAMP RH C6 EL-TAIL/L

POWER WINDOW MAIN SWITCH (LHD MODELS) D40EL-WINDOW, EL-D/LOCK, EL-S/

LOCK, EL-MULTI, EL-THEFT

POWER WINDOW MAIN SWITCH (RHD MODELS) D69EL-WINDOW, EL-S/LOCK,

EL-MULTI, EL-THEFT

REAR COMBINATION LAMP LH C4EL-TAIL/L, EL-BACK/L, EL-R/FOG,

EL-TURN, EL-THEFT

REAR COMBINATION LAMP RH C7EL-TAIL/L, EL-BACK/L, EL-R/FOG,

EL-TURN, EL-THEFT

REAR DOOR LOCK ACTUATOR LH D56 EL-S/LOCK, EL-MULTI, EL-THEFT

REAR DOOR LOCK ACTUATOR RH D76 EL-S/LOCK, EL-MULTI, EL-THEFT

REAR POWER SOCKET B66 EL-CIGER

REAR WINDOW DEFOGGER T6 EL-DEF

REAR WIPER MOTOR T4 EL-WIP/R

STOP LAMP LH B14 EL-STOP/L

STOP LAMP RH B30 EL-STOP/L

THEFT WARNING HORN B112 EL-THEFT

ULTRASONIC CANCEL SWITCH B77 EL-THEFT

B96 SHIELD WIRE (AIR BAG DIAGNOSIS SENSOR UNIT) B100 RS-SRS

B109 SHIELD WIRE (AIR BAG DIAGNOSIS SENSOR UNIT) B105 RS-SRS

GROUND DISTRIBUTION

EL-24

http://vnx.su/

Page 1553 of 1833

or M33, M754 (RHD models).

Ground is supplied to terminal 4 of each rear combination lamp through body grounds B10 and B18.

With power and ground supplied, the time control unit controls the flashing of the hazard warning lamps, and

time control unit supplies power to combination meter terminals 7 or 33, to flash hazard warning indicator.

HAZARD REMINDER OPERATION FOR MULTI-REMOTE CONTROL SYSTEM

When the doors are locked or unlocked by multi-remote controller, time control unit controls turn lamps haz-

ard reminder flashes as follows.

ILocked operation: Flash once

I Unlock operation: Flash twice

EXTERIOR LAMP

System Description (Cont'd)

EL-60

http://vnx.su/