compression ratio NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 8 of 1833

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector forthe multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriouslydamage the catalytic converter.

2. When checking for ignition spark or measuring engine compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam- mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions forproper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start- ing.

3. If engine had been operating at high rpm for an extended period of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

http://vnx.su/

Page 92 of 1833

ENGINE MECHANICAL

SECTION

EM

CONTENTS

ZD

PRECAUTIONS ...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION ................................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .....................................................8

NVH Troubleshooting Chart - Engine Noise ...............9

MEASUREMENT OF COMPRESSION PRESSURE ....10

INTERCOOLER ............................................................. 11

Removal and Installation ........................................... 11

INTAKE MANIFOLD ......................................................12

Removal and Installation ...........................................12

Inspection...................................................................13

CATALYST AND TURBOCHARGER ............................14

Removal and Installation ...........................................14

Inspection...................................................................15

EXHAUST MANIFOLD ..................................................18

Removal and Installation ...........................................18

Inspection...................................................................19

ROCKER COVER ..........................................................20

Removal and Installation ...........................................20

OIL PAN & OIL STRAINER ...........................................22

Removal and Installation ...........................................22

VACUUM PUMP ............................................................24

Removal and Installation ...........................................24

TIMING CHAIN ..............................................................26

Removal and Installation ...........................................26

Removal .....................................................................26

Installation ..................................................................28

CAMSHAFT ...................................................................30

Removal and Installation ...........................................30

Removal .....................................................................30

Inspection...................................................................31

Installation ..................................................................33 VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS

.............................................................35

Inspection...................................................................35

Adjustments ...............................................................36

TIMING GEAR ...............................................................38

Removal and Installation ...........................................38

Removal .....................................................................39

Inspection...................................................................41

Installation ..................................................................46

OIL SEAL REPLACEMENT ..........................................50

CYLINDER HEAD ..........................................................52

Removal and Installation ...........................................52

Removal .....................................................................52

Inspection...................................................................53

Installation ..................................................................54

Disassembly...............................................................57

Inspection...................................................................58

Assembly ...................................................................61

ENGINE REMOVAL .......................................................63

Precautions ................................................................63

Removal .....................................................................63

Installation ..................................................................65

Inspection...................................................................65

CYLINDER BLOCK .......................................................66

Selection Procedure for Selective Part

Combination ...............................................................67

Disassembly...............................................................67

Inspection...................................................................71

Assembly ...................................................................80

SERVICE DATA AND SPECIFICATIONS (SDS) ..........84

General Specifications ...............................................84

Compression Pressure ..............................................84

Cylinder Head ............................................................84

Valve ........................................................................\

..84

Valve Seat..................................................................87

Camshaft and Camshaft Bearing ..............................89

Cylinder Block ............................................................90

Piston, Piston Ring and Piston Pin ...........................90

http://vnx.su/

Page 93 of 1833

Connecting Rod .........................................................91

Crankshaft..................................................................92

Available Main Bearing ..............................................92

Available Connecting Rod Bearing............................93

Miscellaneous Components.......................................94TD27Ti

PRECAUTIONS.............................................................95

Parts Requiring Angular Tightening ...........................95

Liquid Gasket Application Procedure ........................95

PREPARATION ..............................................................96

Special Service Tools ................................................96

Commercial Service Tools .........................................99

ENGINE COMPONENTS - Outer Parts .....................100

ENGINE COMPONENTS - Internal Parts ..................102

COMPRESSION PRESSURE......................................103 Measurement of Compression Pressure .................103

CYLINDER HEAD ........................................................104 Removal ...................................................................105

Disassembly.............................................................106

Inspection.................................................................107

Assembly ................................................................. 113

Installation ................................................................ 114

OIL SEAL REPLACEMENT ........................................ 117

TURBOCHARGER ....................................................... 119

Removal and Installation ......................................... 119

Inspection................................................................. 119

ENGINE REMOVAL .....................................................123

ENGINE OVERHAUL ..................................................125

Disassembly.............................................................125

Inspection.................................................................127

Assembly .................................................................138

SERVICE DATA AND SPECIFICATIONS (SDS) ........143

General Specifications .............................................143

Inspection and Adjustment ......................................144

CONTENTS(Cont'd)

EM-2

http://vnx.su/

Page 96 of 1833

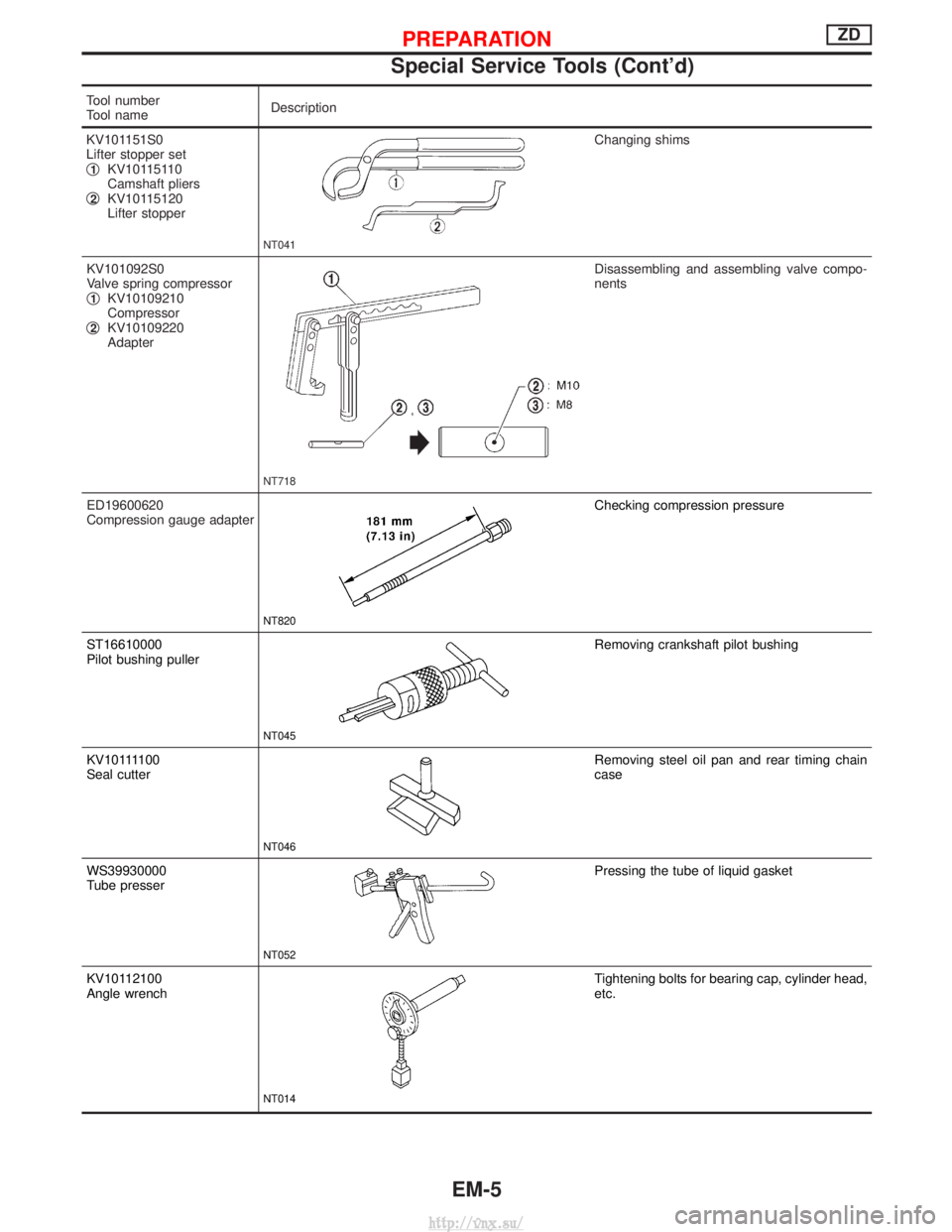

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

q

1KV10115110

Camshaft pliers

q

2KV10115120

Lifter stopper

NT041

Changing shims

KV101092S0

Valve spring compressor

q

1KV10109210

Compressor

q

2KV10109220

Adapter

NT718

Disassembling and assembling valve compo-

nents

ED19600620

Compression gauge adapter

NT820

Checking compression pressure

ST16610000

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV101111 0 0

Seal cutter

NT046

Removing steel oil pan and rear timing chain

case

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head,

etc.

PREPARATIONZD

Special Service Tools (Cont'd)

EM-5

http://vnx.su/

Page 101 of 1833

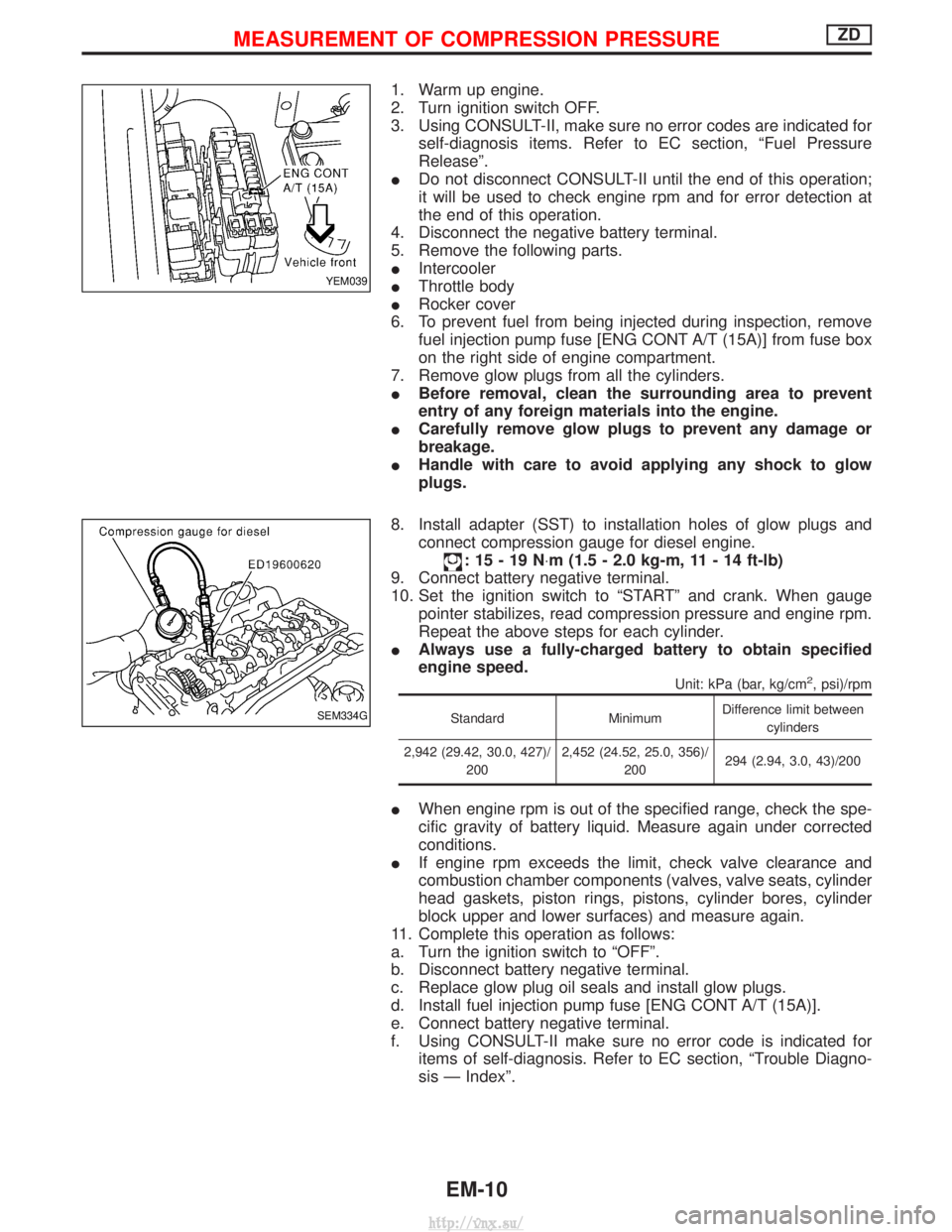

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated forself-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

I Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

I Intercooler

I Throttle body

I Rocker cover

6. To prevent fuel from being injected during inspection, remove fuel injection pump fuse [ENG CONT A/T (15A)] from fuse box

on the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

I Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

I Carefully remove glow plugs to prevent any damage or

breakage.

I Handle with care to avoid applying any shock to glow

plugs.

8. Install adapter (SST) to installation holes of glow plugs and connect compression gauge for diesel engine.

:15-19N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

I Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/ 200 2,452 (24.52, 25.0, 356)/

200 294 (2.94, 3.0, 43)/200

I

When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

I If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylinder

head gaskets, piston rings, pistons, cylinder bores, cylinder

block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT A/T (15A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for items of self-diagnosis. Refer to EC section, ªTrouble Diagno-

sis Ð Indexº.

YEM039

SEM334G

MEASUREMENT OF COMPRESSION PRESSUREZD

EM-10

http://vnx.su/

Page 175 of 1833

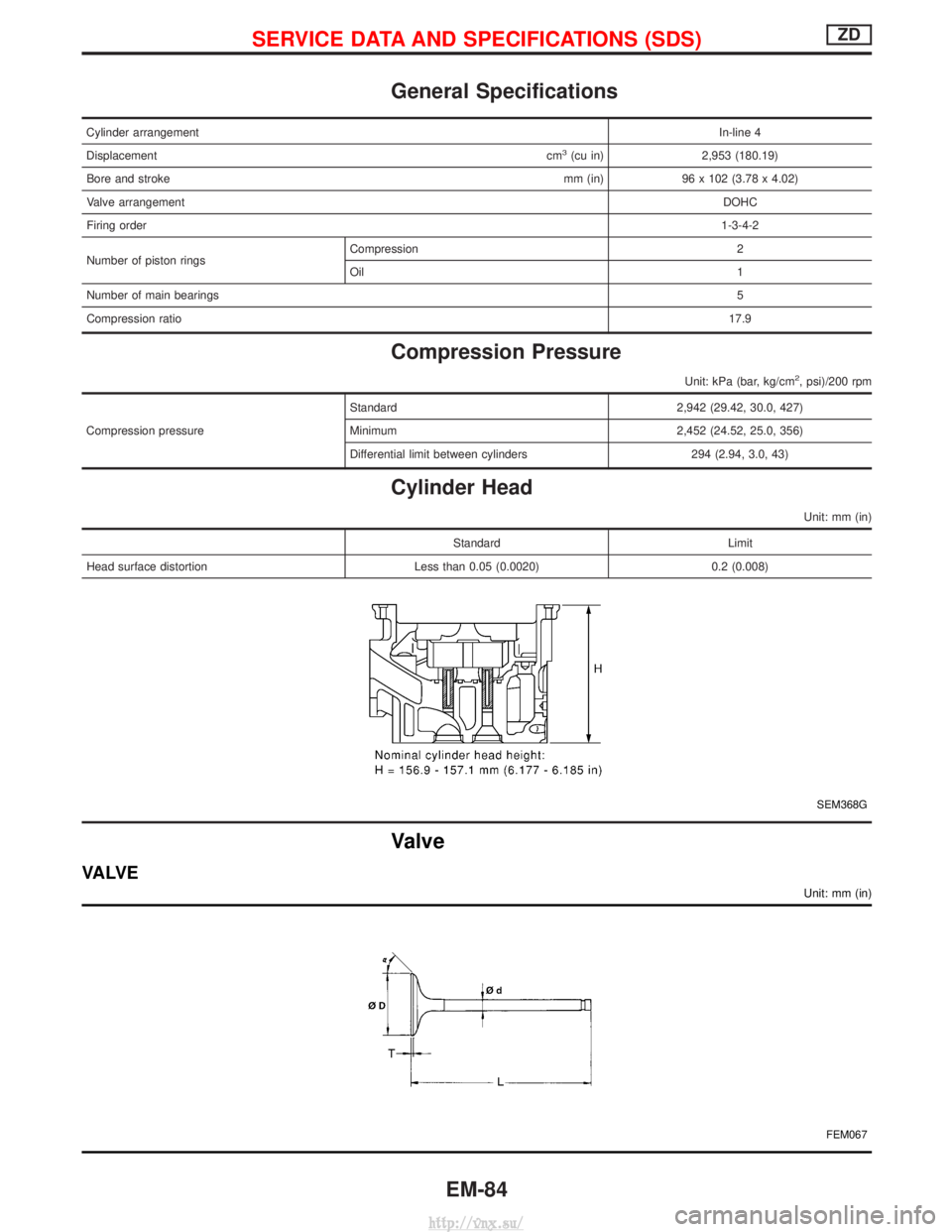

General Specifications

Cylinder arrangementIn-line 4

Displacement cm

3(cu in)2,953 (180.19)

Bore and stroke mm (in) 96 x 102 (3.78 x 4.02)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression 2

Oil

1

Number of main bearings 5

Compression ratio 17.9

Compression Pressure

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressureStandard 2,942 (29.42, 30.0, 427)

Minimum 2,452 (24.52, 25.0, 356)

Differential limit between cylinders 294 (2.94, 3.0, 43)

Cylinder Head

Unit: mm (in)

Standard

Limit

Head surface distortion Less than 0.05 (0.0020) 0.2 (0.008)

SEM368G

Valve

VA LV E

Unit: mm (in)

FEM067

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

EM-84

http://vnx.su/

Page 189 of 1833

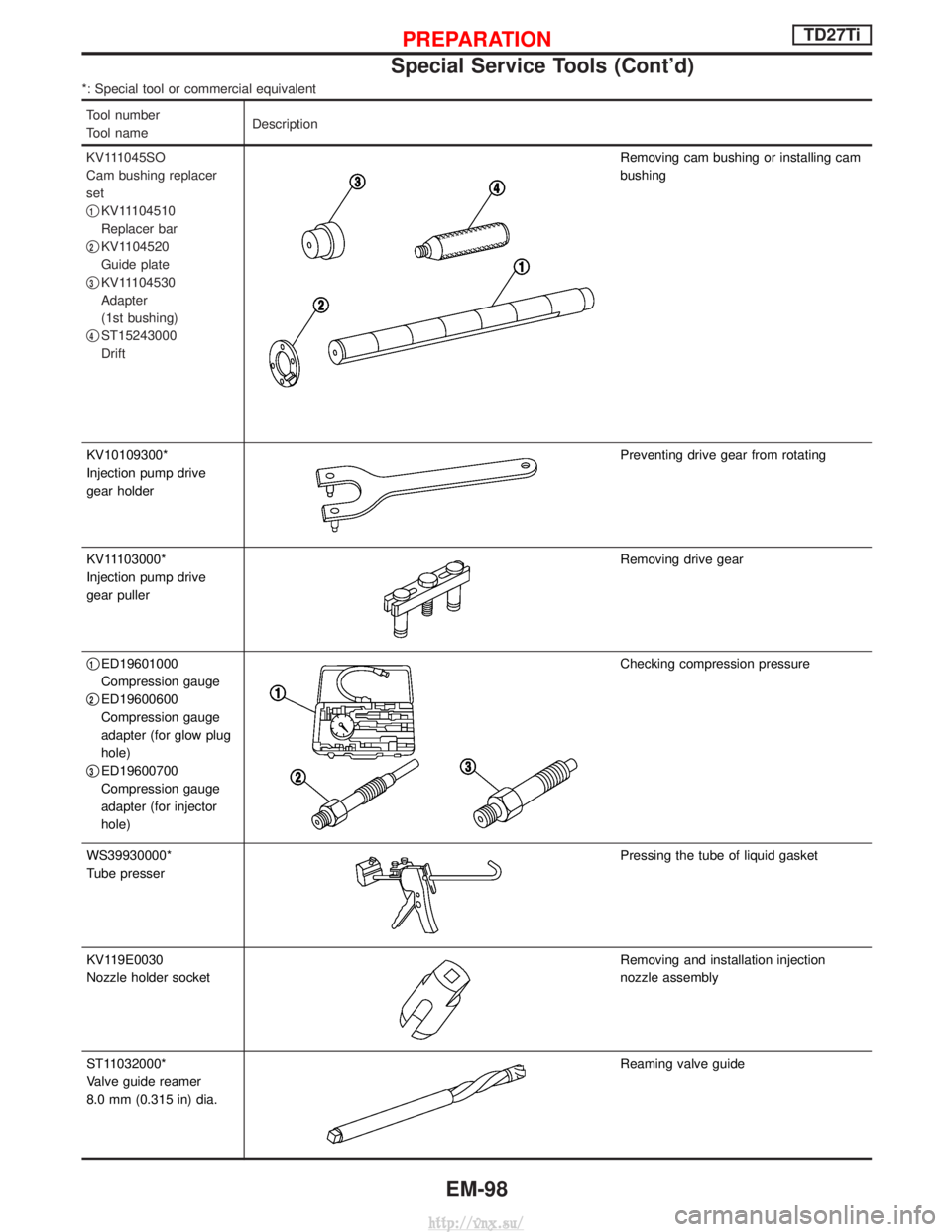

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

KV111045SO

Cam bushing replacer

set

q

1KV11104510

Replacer bar

q

2KV1104520

Guide plate

q

3KV11104530

Adapter

(1st bushing)

q

4ST15243000

Drift

Removing cam bushing or installing cam

bushing

KV10109300*

Injection pump drive

gear holder

Preventing drive gear from rotating

KV11103000*

Injection pump drive

gear puller

Removing drive gear

q

1ED19601000

Compression gauge

q

2ED19600600

Compression gauge

adapter (for glow plug

hole)

q

3ED19600700

Compression gauge

adapter (for injector

hole)

Checking compression pressure

WS39930000*

Tube presser

Pressing the tube of liquid gasket

KV119E0030

Nozzle holder socket

Removing and installation injection

nozzle assembly

ST11032000*

Valve guide reamer

8.0 mm (0.315 in) dia.

Reaming valve guide

PREPARATIONTD27Ti

Special Service Tools (Cont'd)

EM-98

http://vnx.su/

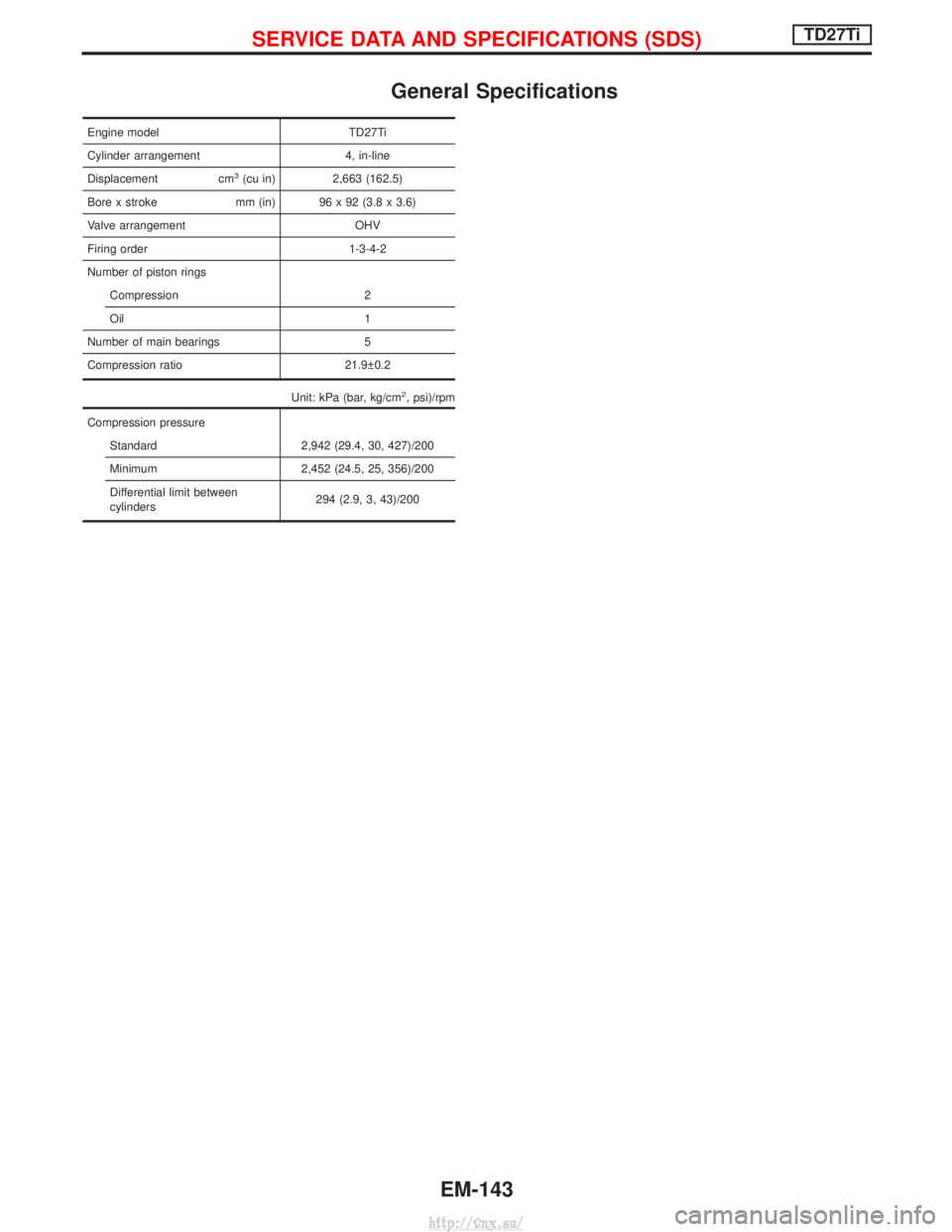

Page 234 of 1833

General Specifications

Engine modelTD27Ti

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,663 (162.5)

Bore x stroke mm (in) 96 x 92 (3.8 x 3.6)

Valve arrangement OHV

Firing order 1-3-4-2

Number of piston rings Compression 2

Oil 1

Number of main bearings 5

Compression ratio 21.9 0.2

Unit: kPa (bar, kg/cm

2, psi)/rpm

Compression pressureStandard 2,942 (29.4, 30, 427)/200

Minimum 2,452 (24.5, 25, 356)/200

Differential limit between

cylinders 294 (2.9, 3, 43)/200

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-143

http://vnx.su/

Page 331 of 1833

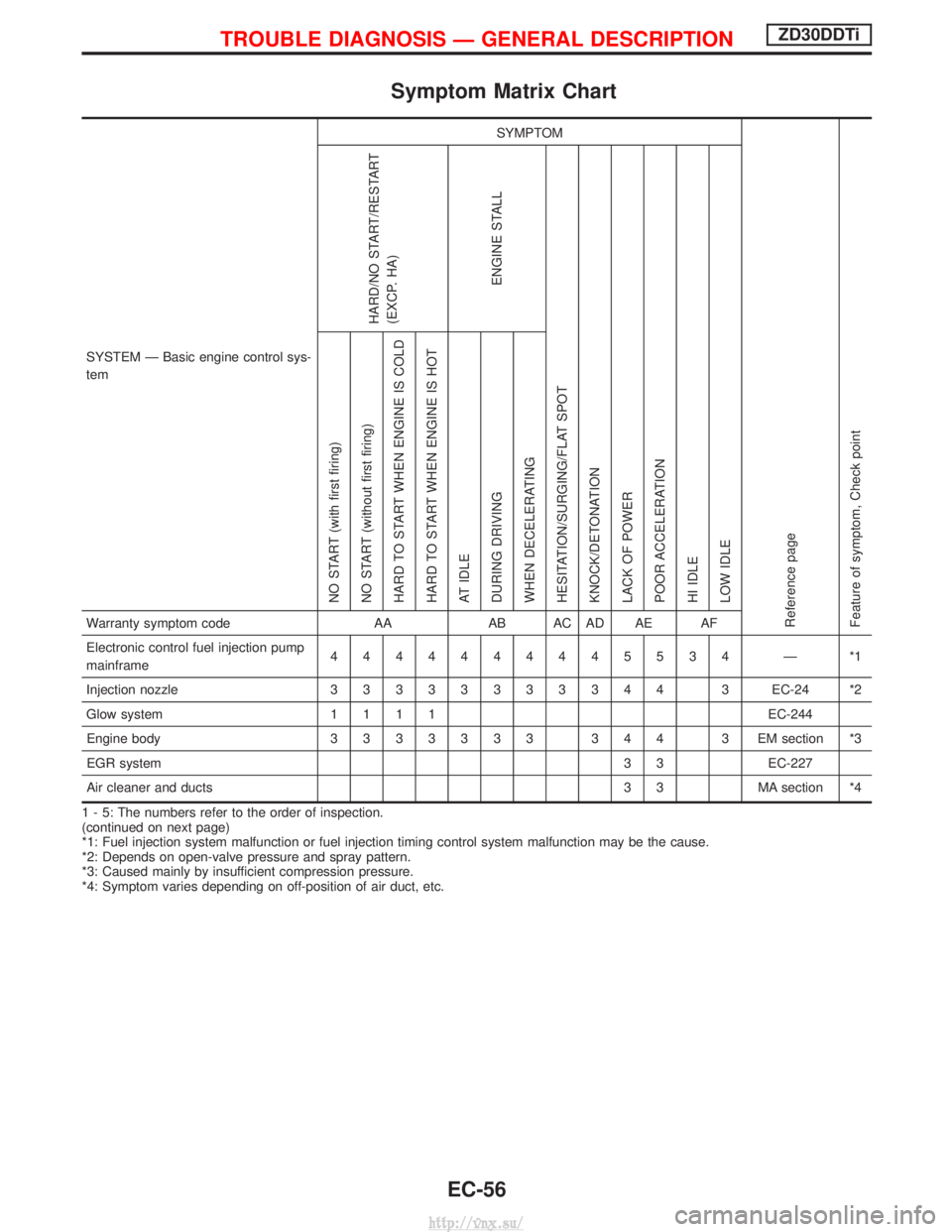

Symptom Matrix Chart

SYSTEM Ð Basic engine control sys-

temSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART

(EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGWarranty symptom code AAAB AC AD AE AF

Electronic control fuel injection pump

mainframe 4444444445534 Ð *1

Injection nozzle 33333333344 3 EC-24 *2

Glow system 1111 EC-244

Engine body 3333333 344 3 EM section *3

EGR system 3 3 EC-227

Air cleaner and ducts 3 3 MA section *4

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*1: Fuel injection system malfunction or fuel injection timing control system malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-56

http://vnx.su/

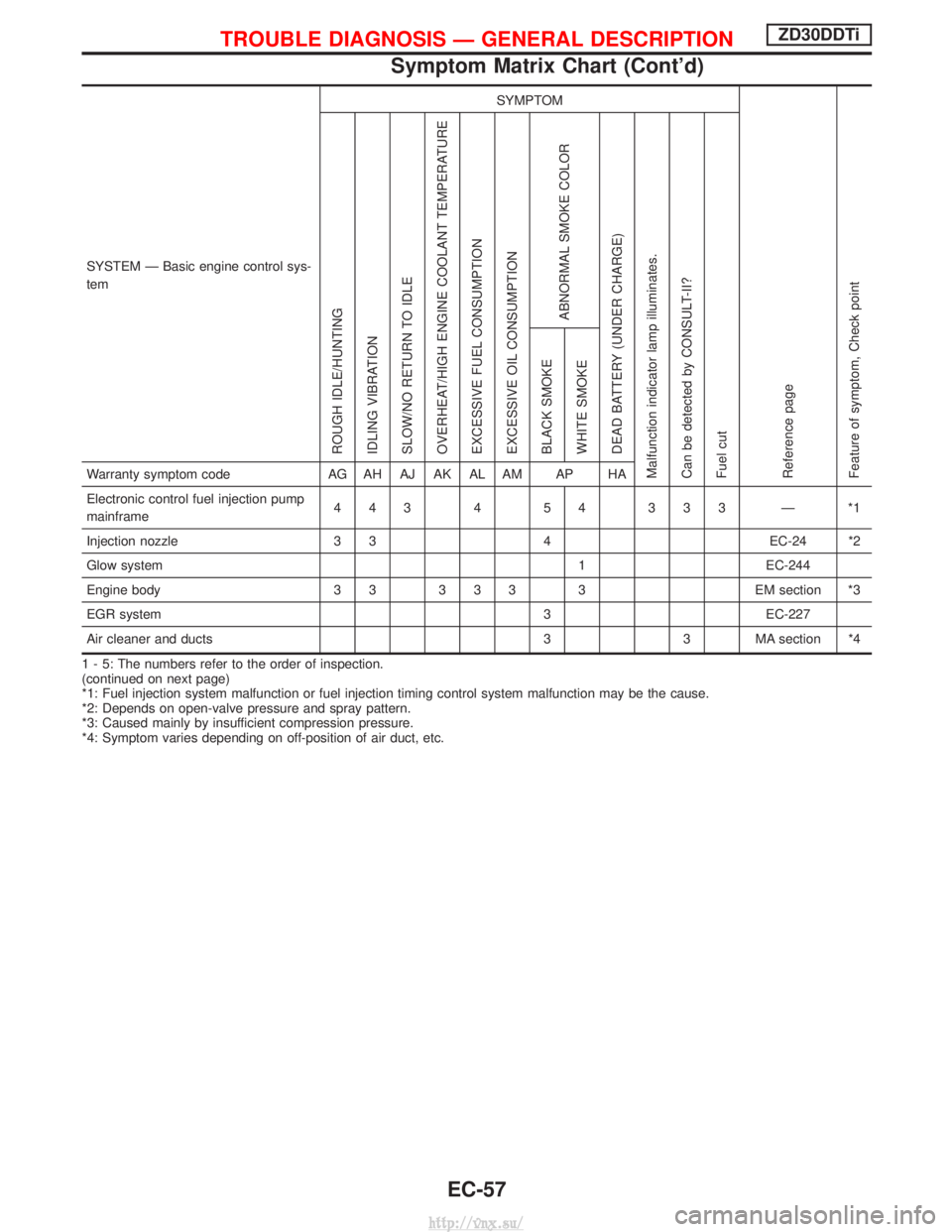

Page 332 of 1833

SYSTEM Ð Basic engine control sys-

temSYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

Electronic control fuel injection pump

mainframe 443 4 54 333 Ð *1

Injection nozzle 3 34 EC-24 *2

Glow system 1 EC-244

Engine body 3 3 3 3 3 3 EM section *3

EGR system 3 EC-227

Air cleaner and ducts 3 3 MA section *4

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*1: Fuel injection system malfunction or fuel injection timing control system malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-57

http://vnx.su/