oil viscosity NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 42 of 1833

MAINTENANCE

SECTION

MA

CONTENTS

PRE-DELIVERY INSPECTION ITEMS ............................3

GENERAL MAINTENANCE ............................................4

PERIODIC MAINTENANCE ............................................5

Maintenance Schedule for Diesel Engine Models

(annual mileage < 30,000 km/year) ............................5

Maintenance Schedule for Diesel Engine Models

(annual mileage > 30,000 km/year) ............................8

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) .......................... 11

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) ..........................14

RECOMMENDED FLUIDS AND LUBRICANTS ...........17

Fluids and Lubricants ................................................17

SAE Viscosity Number ..............................................18

Engine Coolant Mixture Ratio....................................19

TD

ENGINE MAINTENANCE ..............................................20

Retightening Manifold Bolts and Nuts .......................20

Adjusting Intake and Exhaust Valve Clearance ........20

Drive Belt Inspection..................................................20

Changing Engine Oil..................................................21

Changing Oil Filter .....................................................21

Changing Engine Coolant..........................................22

Checking Cooling System .........................................23

Checking and Replacing fuel filter and Draining

Water ........................................................................\

.23

Cleaning and Replacing Air Cleaner Filter (Dry

paper type).................................................................24

Checking Injection Nozzle .........................................25

Checking Idle Speed .................................................26

ZD

ENGINE MAINTENANCE ..............................................28

Checking Tightening Torque ......................................28

Adjusting Intake and Exhaust Valve Clearance ........28

Checking Drive Belt ...................................................28

Removal .....................................................................29 Installation ..................................................................29

Changing Engine Oil..................................................29

Changing Engine Oil Filter ........................................30

Changing Engine Coolant..........................................31

Checking Cooling System .........................................32

Checking and Replacing Fuel Filter and Draining

Water ........................................................................\

.33

Checking Fuel Lines ..................................................34

Cleaning and Replacing Air Cleaner Filter ................35

CHASSIS AND BODY MAINTENANCE .......................36

Checking Exhaust System.........................................36

Checking Clutch Operation........................................36

Checking Clutch Fluid Level and Leaks ....................36

Checking Clutch System ...........................................36

Checking M/T Oil .......................................................36

Changing M/T Oil.......................................................37

Checking Water Entry ................................................37

Checking Transfer Oil ................................................37

Changing Transfer Oil................................................38

Checking Propeller Shaft ...........................................38

Checking Differential Gear Oil ...................................38

Changing Differential Gear Oil ..................................39

Checking Front Wheel Bearing Grease ....................39

Repacking Front Wheel Bearing Grease ..................39

Checking Free-running Hub Grease .........................40

Checking Brake Fluid Level and Leaks.....................40

Checking Brake System ............................................40

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................40

Checking Disc Brake .................................................40

Checking Drum Brake ...............................................41

Checking Foot Brake Pedal Operation......................42

Checking Parking Brake ............................................42

Changing Brake Fluid ................................................43

Balancing Wheels ......................................................43

Tire Rotation ..............................................................43

Checking Steering Gear and Linkage .......................43

Checking Fluid Level and Leaks (Power steering) ...44

http://vnx.su/

Page 58 of 1833

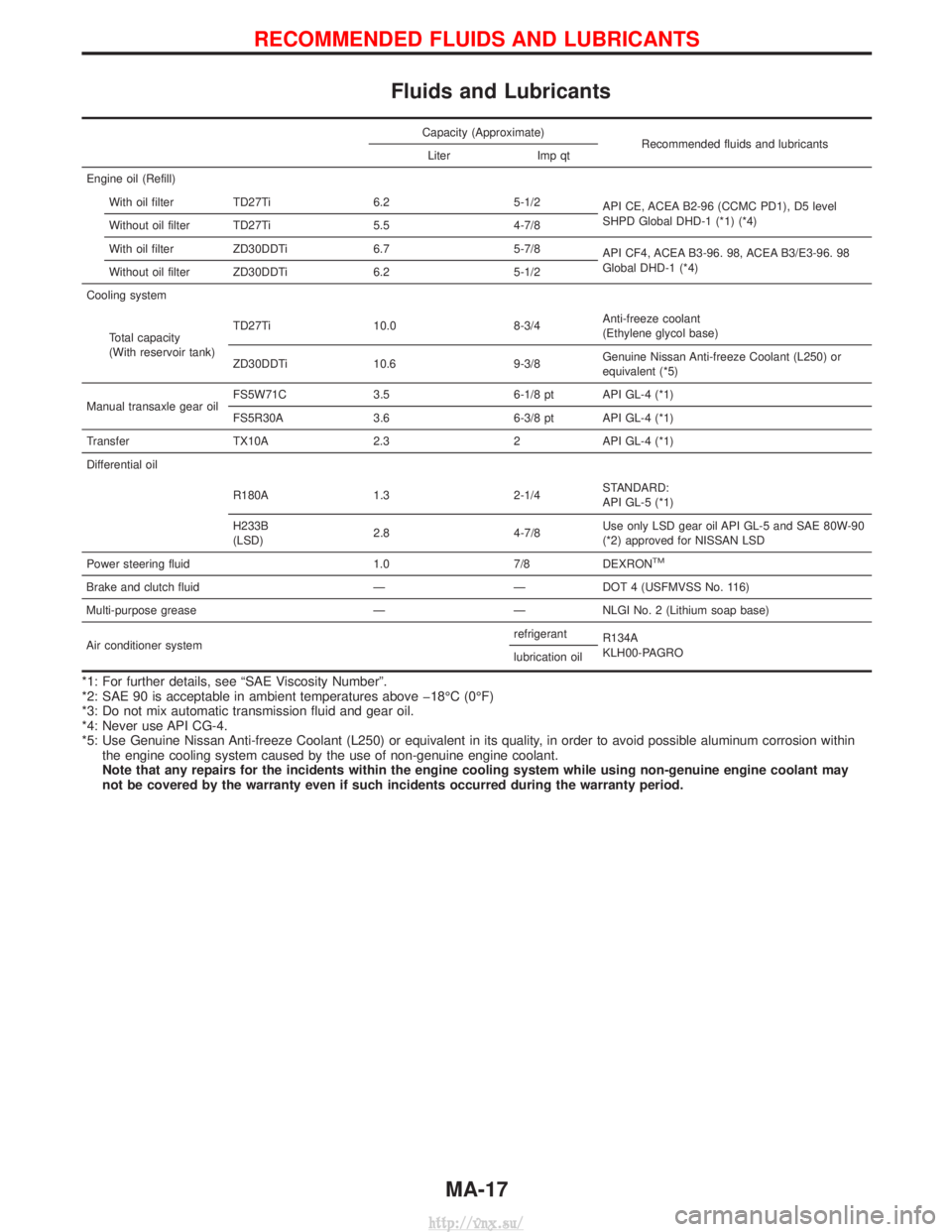

Fluids and Lubricants

Capacity (Approximate)Recommended fluids and lubricants

Liter Imp qt

Engine oil (Refill) With oil filter TD27Ti 6.2 5-1/2 API CE, ACEA B2-96 (CCMC PD1), D5 level

SHPD Global DHD-1 (*1) (*4)

Without oil filter TD27Ti 5.5 4-7/8

With oil filter ZD30DDTi 6.7 5-7/8 API CF4, ACEA B3-96. 98, ACEA B3/E3-96. 98

Global DHD-1 (*4)

Without oil filter ZD30DDTi 6.2 5-1/2

Cooling system

Total capacity

(With reservoir tank) TD27Ti 10.0 8-3/4

Anti-freeze coolant

(Ethylene glycol base)

ZD30DDTi 10.6 9-3/8 Genuine Nissan Anti-freeze Coolant (L250) or

equivalent (*5)

Manual transaxle gear oil FS5W71C 3.5 6-1/8 pt API GL-4 (*1)

FS5R30A 3.6 6-3/8 pt API GL-4 (*1)

Transfer TX10A 2.3 2 API GL-4 (*1)

Differential oil

R180A 1.3 2-1/4 STANDARD:

API GL-5 (*1)

H233B

(LSD) 2.8 4-7/8 Use only LSD gear oil API GL-5 and SAE 80W-90

(*2) approved for NISSAN LSD

Power steering fluid 1.0 7/8 DEXRON

TM

Brake and clutch fluid ÐÐDOT 4 (USFMVSS No. 116)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Air conditioner system refrigerant

R134A

KLH00-PAGRO

lubrication oil

*1: For further details, see ªSAE Viscosity Numberº.

*2: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF)

*3: Do not mix automatic transmission fluid and gear oil.

*4: Never use API CG-4.

*5: Use Genuine Nissan Anti-freeze Coolant (L250) or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may

not be covered by the warranty even if such incidents occurred during the warranty period.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

http://vnx.su/

Page 62 of 1833

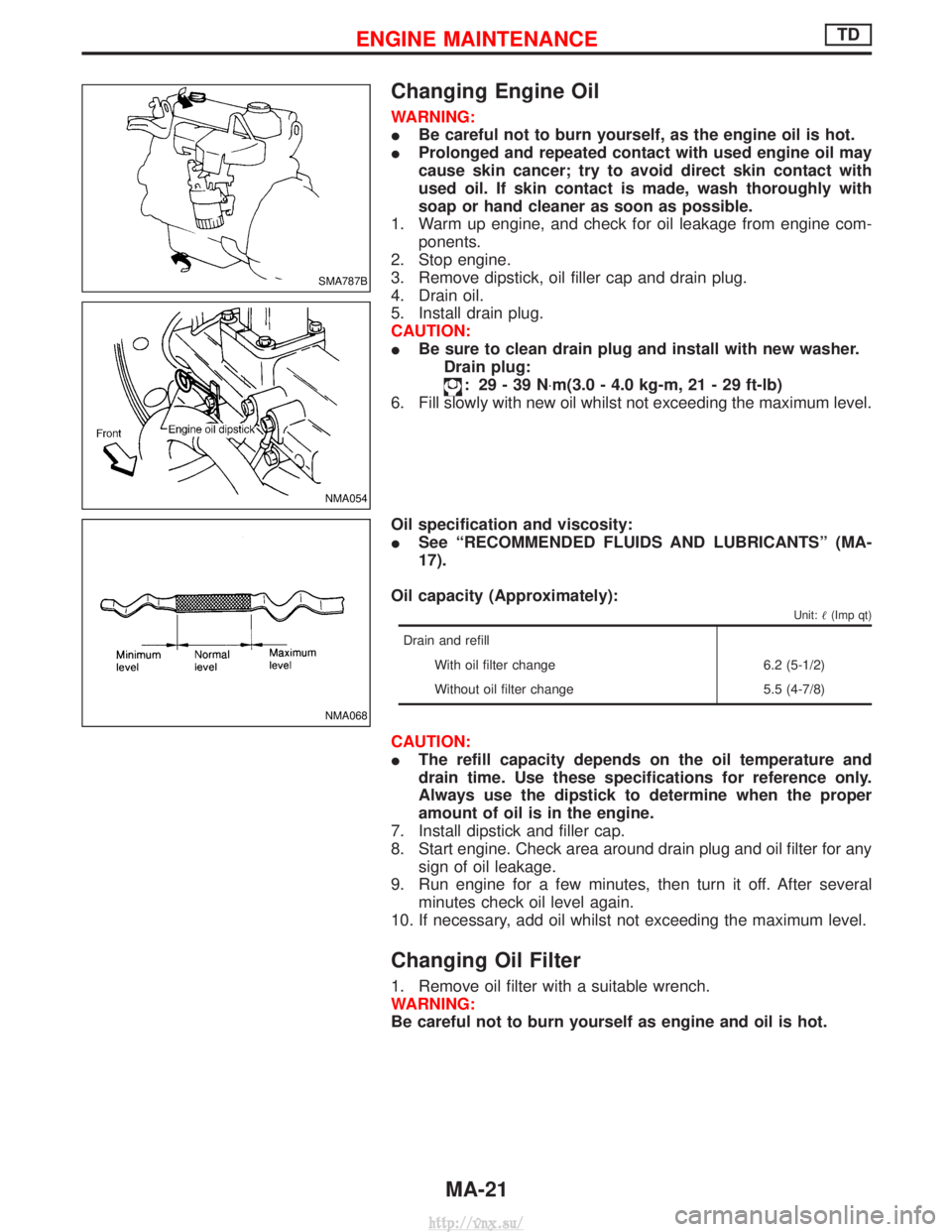

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

I Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com- ponents.

2. Stop engine.

3. Remove dipstick, oil filler cap and drain plug.

4. Drain oil.

5. Install drain plug.

CAUTION:

I Be sure to clean drain plug and install with new washer.

Drain plug:

: 29-39N ×m(3.0 - 4.0 kg-m, 21 - 29 ft-lb)

6. Fill slowly with new oil whilst not exceeding the maximum level.

Oil specification and viscosity:

I See ªRECOMMENDED FLUIDS AND LUBRICANTSº (MA-

17).

Oil capacity (Approximately):

Unit: (Imp qt)

Drain and refill

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

CAUTION:

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

7. Install dipstick and filler cap.

8. Start engine. Check area around drain plug and oil filter for any sign of oil leakage.

9. Run engine for a few minutes, then turn it off. After several minutes check oil level again.

10. If necessary, add oil whilst not exceeding the maximum level.

Changing Oil Filter

1. Remove oil filter with a suitable wrench.

WARNING:

Be careful not to burn yourself as engine and oil is hot.

SMA787B

NMA054

NMA068

ENGINE MAINTENANCETD

MA-21

http://vnx.su/

Page 71 of 1833

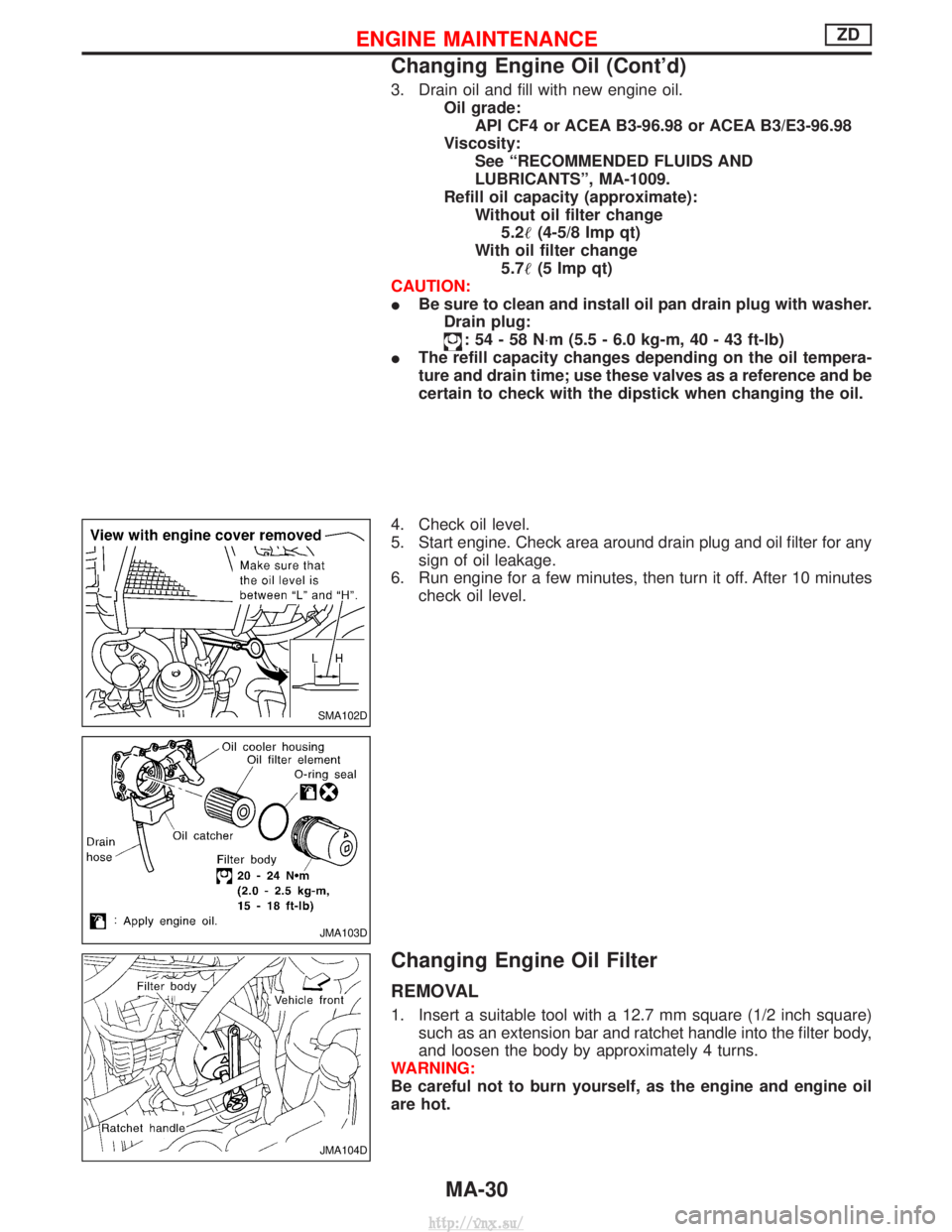

3. Drain oil and fill with new engine oil.Oil grade:API CF4 or ACEA B3-96.98 or ACEA B3/E3-96.98

Viscosity: See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate): Without oil filter change5.2 (4-5/8 Imp qt)

With oil filter change 5.7 (5 Imp qt)

CAUTION:

I Be sure to clean and install oil pan drain plug with washer.

Drain plug:

:54-58N ×m (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

I The refill capacity changes depending on the oil tempera-

ture and drain time; use these valves as a reference and be

certain to check with the dipstick when changing the oil.

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for any sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 minutes check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)such as an extension bar and ratchet handle into the filter body,

and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-30

http://vnx.su/

Page 1128 of 1833

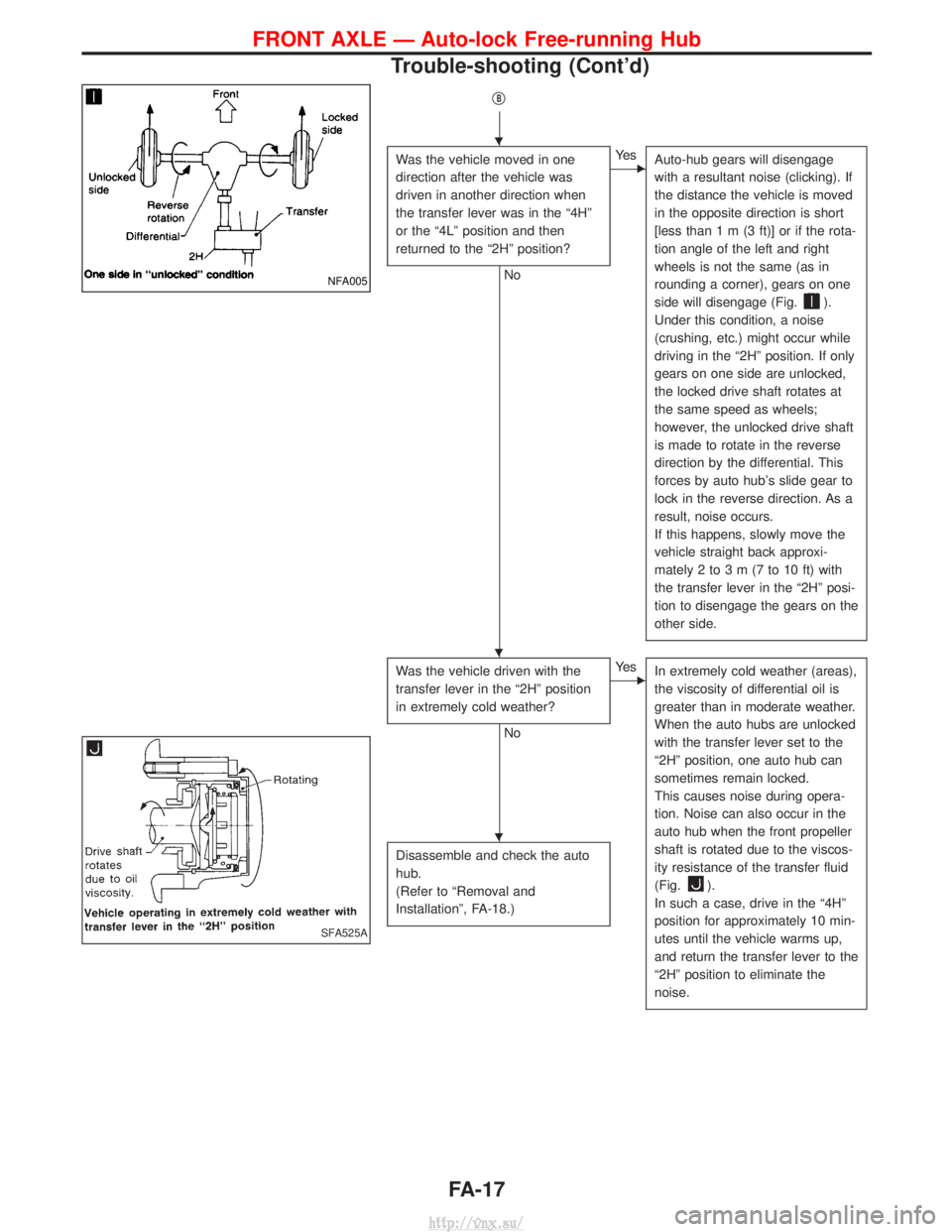

qB

Was the vehicle moved in one

direction after the vehicle was

driven in another direction when

the transfer lever was in the ª4Hº

or the ª4Lº position and then

returned to the ª2Hº position?

No

EYe sAuto-hub gears will disengage

with a resultant noise (clicking). If

the distance the vehicle is moved

in the opposite direction is short

[less than1m(3ft)] or if the rota-

tion angle of the left and right

wheels is not the same (as in

rounding a corner), gears on one

side will disengage (Fig.

).

Under this condition, a noise

(crushing, etc.) might occur while

driving in the ª2Hº position. If only

gears on one side are unlocked,

the locked drive shaft rotates at

the same speed as wheels;

however, the unlocked drive shaft

is made to rotate in the reverse

direction by the differential. This

forces by auto hub's slide gear to

lock in the reverse direction. As a

result, noise occurs.

If this happens, slowly move the

vehicle straight back approxi-

mately 2 to3m(7to10ft) with

the transfer lever in the ª2Hº posi-

tion to disengage the gears on the

other side.

Was the vehicle driven with the

transfer lever in the ª2Hº position

in extremely cold weather?

No

EYe s In extremely cold weather (areas),

the viscosity of differential oil is

greater than in moderate weather.

When the auto hubs are unlocked

with the transfer lever set to the

ª2Hº position, one auto hub can

sometimes remain locked.

This causes noise during opera-

tion. Noise can also occur in the

auto hub when the front propeller

shaft is rotated due to the viscos-

ity resistance of the transfer fluid

(Fig.

).

In such a case, drive in the ª4Hº

position for approximately 10 min-

utes until the vehicle warms up,

and return the transfer lever to the

ª2Hº position to eliminate the

noise.

Disassemble and check the auto

hub.

(Refer to ªRemoval and

Installationº, FA-18.)

NFA005

SFA525A

H

H

H

FRONT AXLE Ð Auto-lock Free-running Hub

Trouble-shooting (Cont'd)

FA-17

http://vnx.su/

Page 1832 of 1833

T

Tachometer .....................................................EL-86

Tail lamp ..........................................................EL-49

TAIL/L - Wiring diagram ..................................EL-49

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-173

Temperature control cable and linkageadjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-248

Theft warning system ...........EL-243, 244, 247, 264

Thermo control amp. ......................................HA-61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-458

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-458

Throttle position switch ...................................AT-62

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-37

Time control system .....................EL-216, 218, 220

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque converter clutch solenoid valve ..AT-74, 146

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-32

Towing point.....................................................GI-33

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time 4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-98

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-62

Turn signal lamp .......................................EL-61, 62

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33 V

Vacuum hose (brake system) ........................BR-20

Vacuum hose drawing (Engine

control)................................................EC-18, 327

Vacuum pump .............................EM-24, BR-24, 26

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control solenoid valve ...........................................EC-289

Vehicle identification number...........................GI-28

Vehicle speed sensor (VSS) ..................EC-99, 420

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-291

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram........................EL-100, 111

Warning chime ........................................EL-99, 111

Warning lamps ........................................EL-99, 100

Washer, front .................................................EL-112

Washer, rear ..................................................EL-114

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-86

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-39, 43

Wheel size .......................................................GI-30

WINDOW - Wiring diagram ..........................EL-159

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ................................EL-114

WIPER - Wiring diagram .......................EL-112, 118

Wiper and washer .................................EL-112, 116

Wiper, front ....................................................EL-112

Wiper, rear.....................................................EL-114

Wiring Diagram (Cell code) list .....................EL-326

ALPHABETICAL INDEX

IDX-7

http://vnx.su/