relay NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 15 of 1833

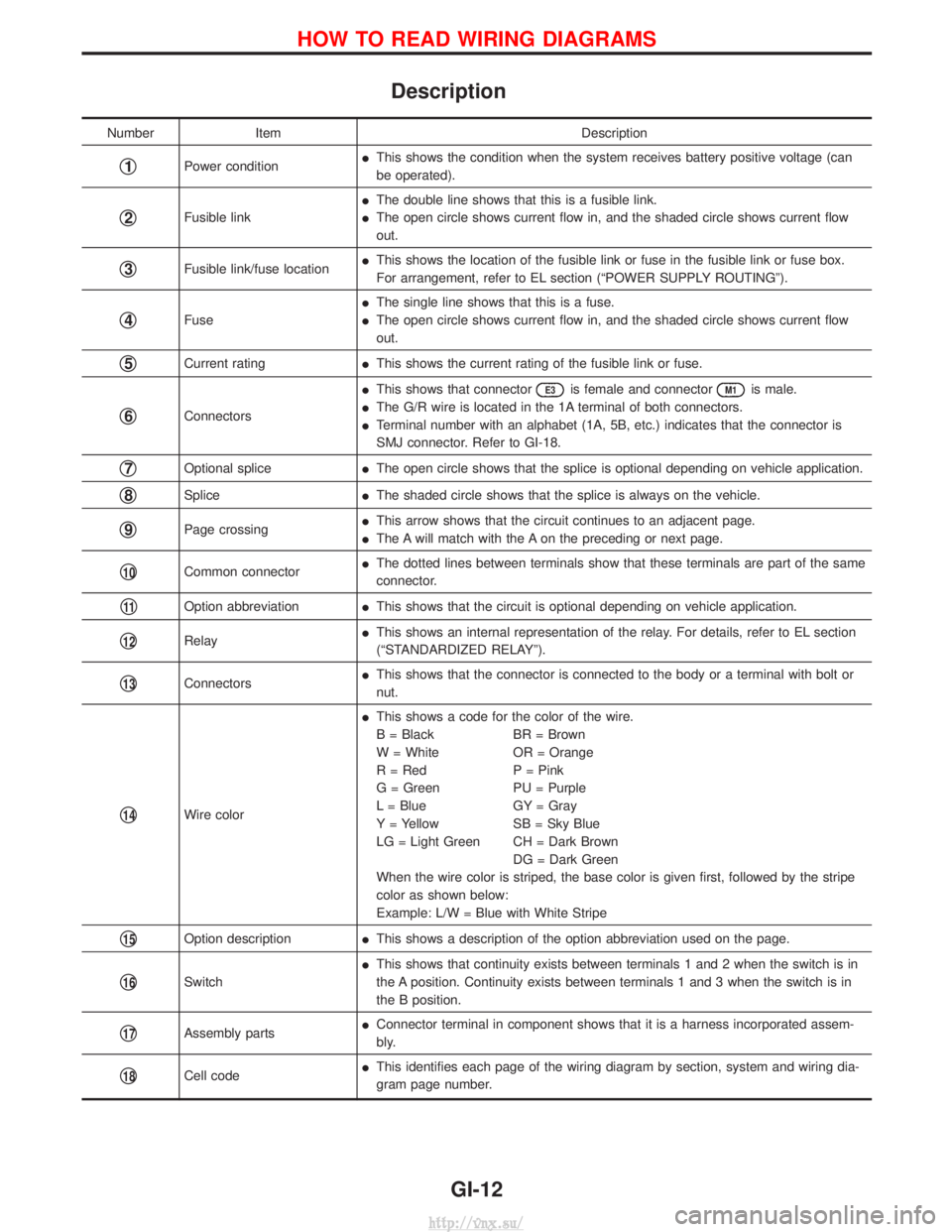

Description

NumberItem Description

q1Power conditionI

This shows the condition when the system receives battery positive voltage (can

be operated).

q2Fusible link I

The double line shows that this is a fusible link.

I The open circle shows current flow in, and the shaded circle shows current flow

out.

q3Fusible link/fuse location I

This shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (ªPOWER SUPPLY ROUTINGº).

q4Fuse I

The single line shows that this is a fuse.

I The open circle shows current flow in, and the shaded circle shows current flow

out.

q5Current rating IThis shows the current rating of the fusible link or fuse.

q6Connectors I

This shows that connector

E3is female and connectorM1is male.

I The G/R wire is located in the 1A terminal of both connectors.

I Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-18.

q7Optional splice IThe open circle shows that the splice is optional depending on vehicle application.

q8Splice IThe shaded circle shows that the splice is always on the vehicle.

q9Page crossing I

This arrow shows that the circuit continues to an adjacent page.

I The A will match with the A on the preceding or next page.

q10Common connector I

The dotted lines between terminals show that these terminals are part of the same

connector.

q11Option abbreviation IThis shows that the circuit is optional depending on vehicle application.

q12Relay I

This shows an internal representation of the relay. For details, refer to EL section

(ªSTANDARDIZED RELAYº).

q13Connectors I

This shows that the connector is connected to the body or a terminal with bolt or

nut.

q14Wire color I

This shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

q15Option description IThis shows a description of the option abbreviation used on the page.

q16Switch I

This shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

q17Assembly parts I

Connector terminal in component shows that it is a harness incorporated assem-

bly.

q18Cell code I

This identifies each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-12

http://vnx.su/

Page 26 of 1833

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

I Heat sensitive

I Freezing

I Water intrusion

I Electrical load

I Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

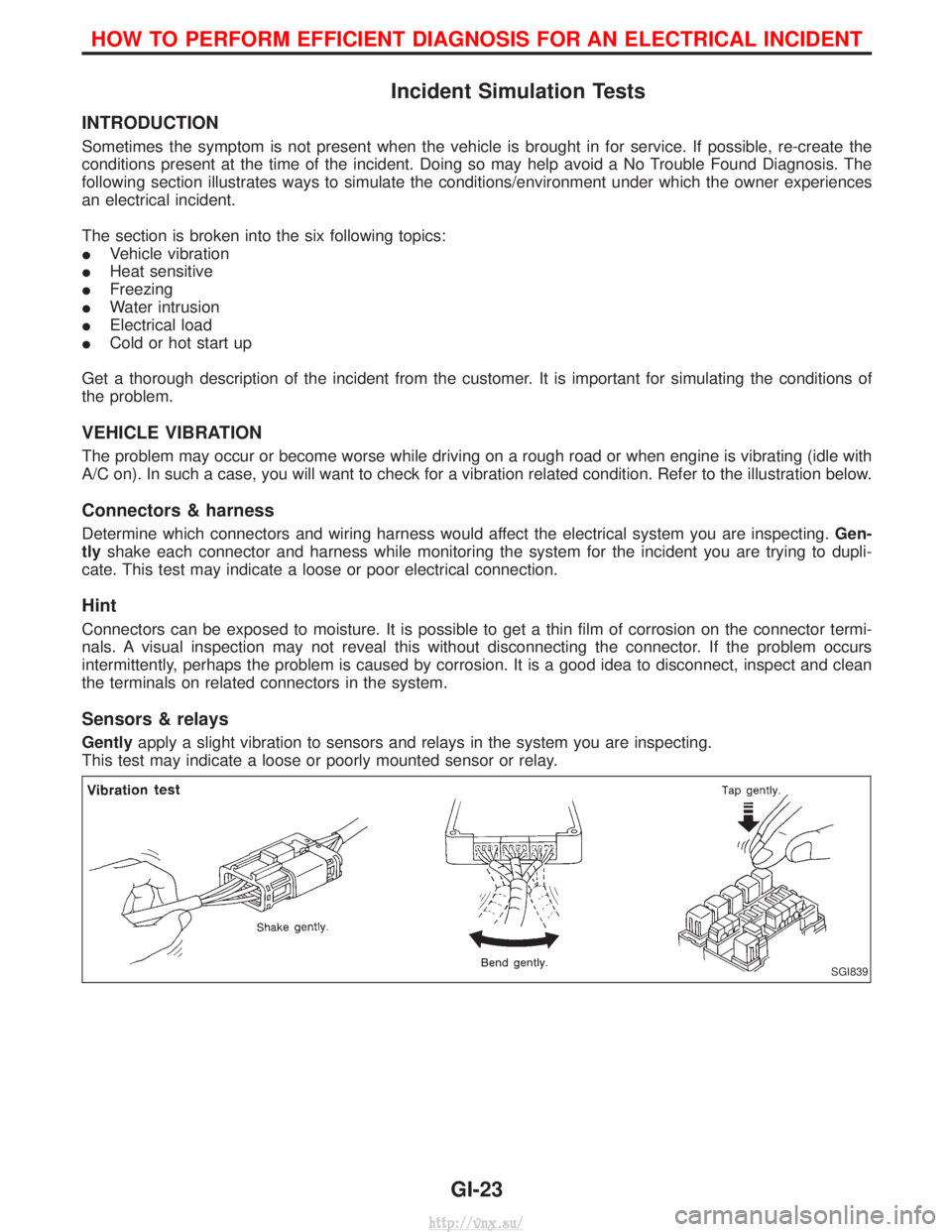

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gen-

tly shake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23

http://vnx.su/

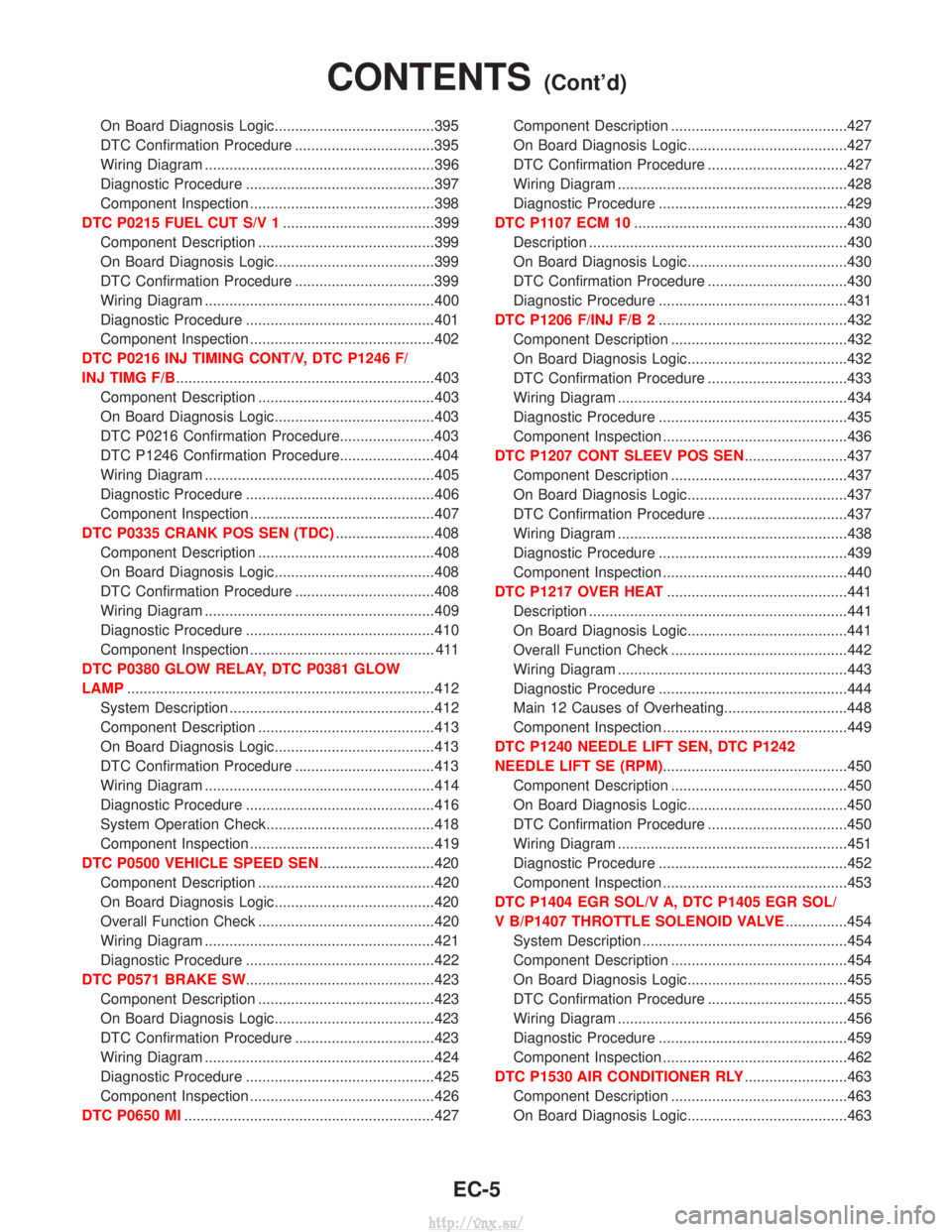

Page 280 of 1833

On Board Diagnosis Logic.......................................395

DTC Confirmation Procedure ..................................395

Wiring Diagram ........................................................396

Diagnostic Procedure ..............................................397

Component Inspection .............................................398

DTC P0215 FUEL CUT S/V 1 .....................................399

Component Description ...........................................399

On Board Diagnosis Logic.......................................399

DTC Confirmation Procedure ..................................399

Wiring Diagram ........................................................400

Diagnostic Procedure ..............................................401

Component Inspection .............................................402

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/

INJ TIMG F/B ...............................................................403

Component Description ...........................................403

On Board Diagnosis Logic.......................................403

DTC P0216 Confirmation Procedure.......................403

DTC P1246 Confirmation Procedure.......................404

Wiring Diagram ........................................................405

Diagnostic Procedure ..............................................406

Component Inspection .............................................407

DTC P0335 CRANK POS SEN (TDC) ........................408

Component Description ...........................................408

On Board Diagnosis Logic.......................................408

DTC Confirmation Procedure ..................................408

Wiring Diagram ........................................................409

Diagnostic Procedure ..............................................410

Component Inspection ............................................. 411

DTC P0380 GLOW RELAY, DTC P0381 GLOW

LAMP ........................................................................\

...412

System Description ..................................................412

Component Description ...........................................413

On Board Diagnosis Logic.......................................413

DTC Confirmation Procedure ..................................413

Wiring Diagram ........................................................414

Diagnostic Procedure ..............................................416

System Operation Check.........................................418

Component Inspection .............................................419

DTC P0500 VEHICLE SPEED SEN ............................420

Component Description ...........................................420

On Board Diagnosis Logic.......................................420

Overall Function Check ...........................................420

Wiring Diagram ........................................................421

Diagnostic Procedure ..............................................422

DTC P0571 BRAKE SW ..............................................423

Component Description ...........................................423

On Board Diagnosis Logic.......................................423

DTC Confirmation Procedure ..................................423

Wiring Diagram ........................................................424

Diagnostic Procedure ..............................................425

Component Inspection .............................................426

DTC P0650 MI .............................................................427 Component Description ...........................................427

On Board Diagnosis Logic.......................................427

DTC Confirmation Procedure ..................................427

Wiring Diagram ........................................................428

Diagnostic Procedure ..............................................429

DTC P1107 ECM 10 ....................................................430

Description ...............................................................430

On Board Diagnosis Logic.......................................430

DTC Confirmation Procedure ..................................430

Diagnostic Procedure ..............................................431

DTC P1206 F/INJ F/B 2 ..............................................432

Component Description ...........................................432

On Board Diagnosis Logic.......................................432

DTC Confirmation Procedure ..................................433

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................435

Component Inspection .............................................436

DTC P1207 CONT SLEEV POS SEN .........................437

Component Description ...........................................437

On Board Diagnosis Logic.......................................437

DTC Confirmation Procedure ..................................437

Wiring Diagram ........................................................438

Diagnostic Procedure ..............................................439

Component Inspection .............................................440

DTC P1217 OVER HEAT ............................................441

Description ...............................................................441

On Board Diagnosis Logic.......................................441

Overall Function Check ...........................................442

Wiring Diagram ........................................................443

Diagnostic Procedure ..............................................444

Main 12 Causes of Overheating..............................448

Component Inspection .............................................449

DTC P1240 NEEDLE LIFT SEN, DTC P1242

NEEDLE LIFT SE (RPM) .............................................450

Component Description ...........................................450

On Board Diagnosis Logic.......................................450

DTC Confirmation Procedure ..................................450

Wiring Diagram ........................................................451

Diagnostic Procedure ..............................................452

Component Inspection .............................................453

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/

V B/P1407 THROTTLE SOLENOID VALVE ...............454

System Description ..................................................454

Component Description ...........................................454

On Board Diagnosis Logic.......................................455

DTC Confirmation Procedure ..................................455

Wiring Diagram ........................................................456

Diagnostic Procedure ..............................................459

Component Inspection .............................................462

DTC P1530 AIR CONDITIONER RLY .........................463

Component Description ...........................................463

On Board Diagnosis Logic.......................................463

CONTENTS(Cont'd)

EC-5

http://vnx.su/

Page 294 of 1833

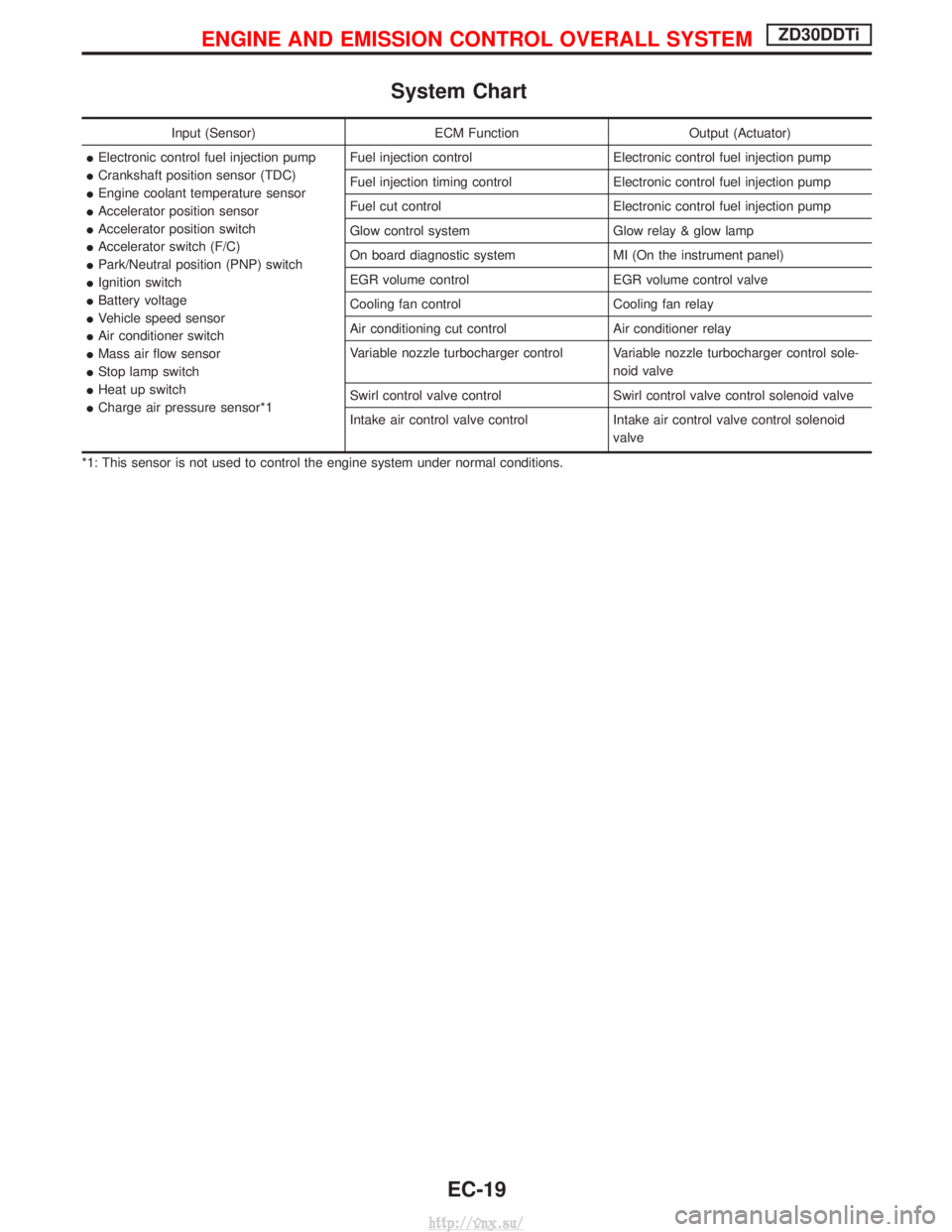

System Chart

Input (Sensor)ECM FunctionOutput (Actuator)

I Electronic control fuel injection pump

I Crankshaft position sensor (TDC)

I Engine coolant temperature sensor

I Accelerator position sensor

I Accelerator position switch

I Accelerator switch (F/C)

I Park/Neutral position (PNP) switch

I Ignition switch

I Battery voltage

I Vehicle speed sensor

I Air conditioner switch

I Mass air flow sensor

I Stop lamp switch

I Heat up switch

I Charge air pressure sensor*1 Fuel injection control

Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MI (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole- noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

*1: This sensor is not used to control the engine system under normal conditions.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-19

http://vnx.su/

Page 297 of 1833

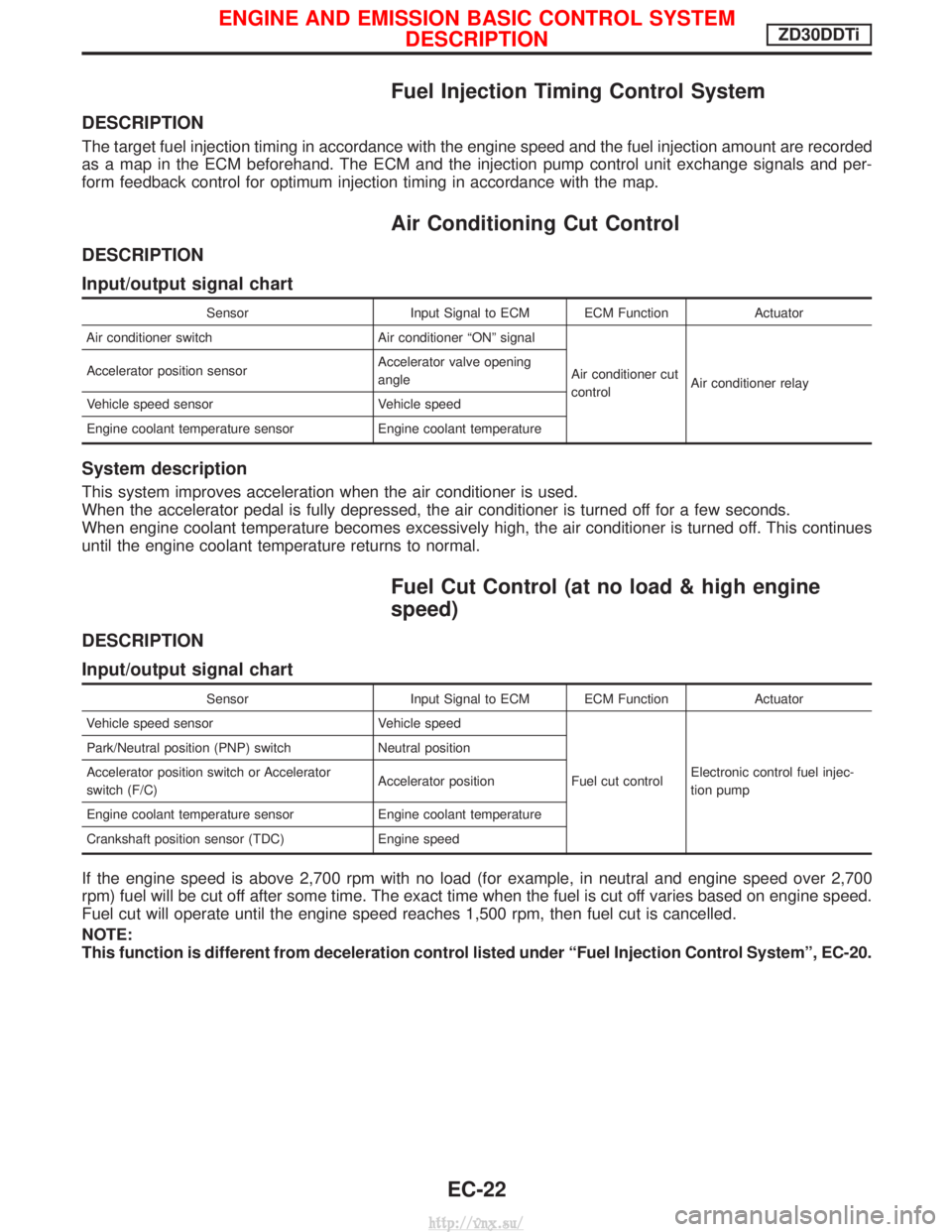

Fuel Injection Timing Control System

DESCRIPTION

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are recorded

as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals and per-

form feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay

Accelerator position sensor

Accelerator valve opening

angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump

Park/Neutral position (PNP) switch

Neutral position

Accelerator position switch or Accelerator

switch (F/C) Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº, EC-20.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-22

http://vnx.su/

Page 315 of 1833

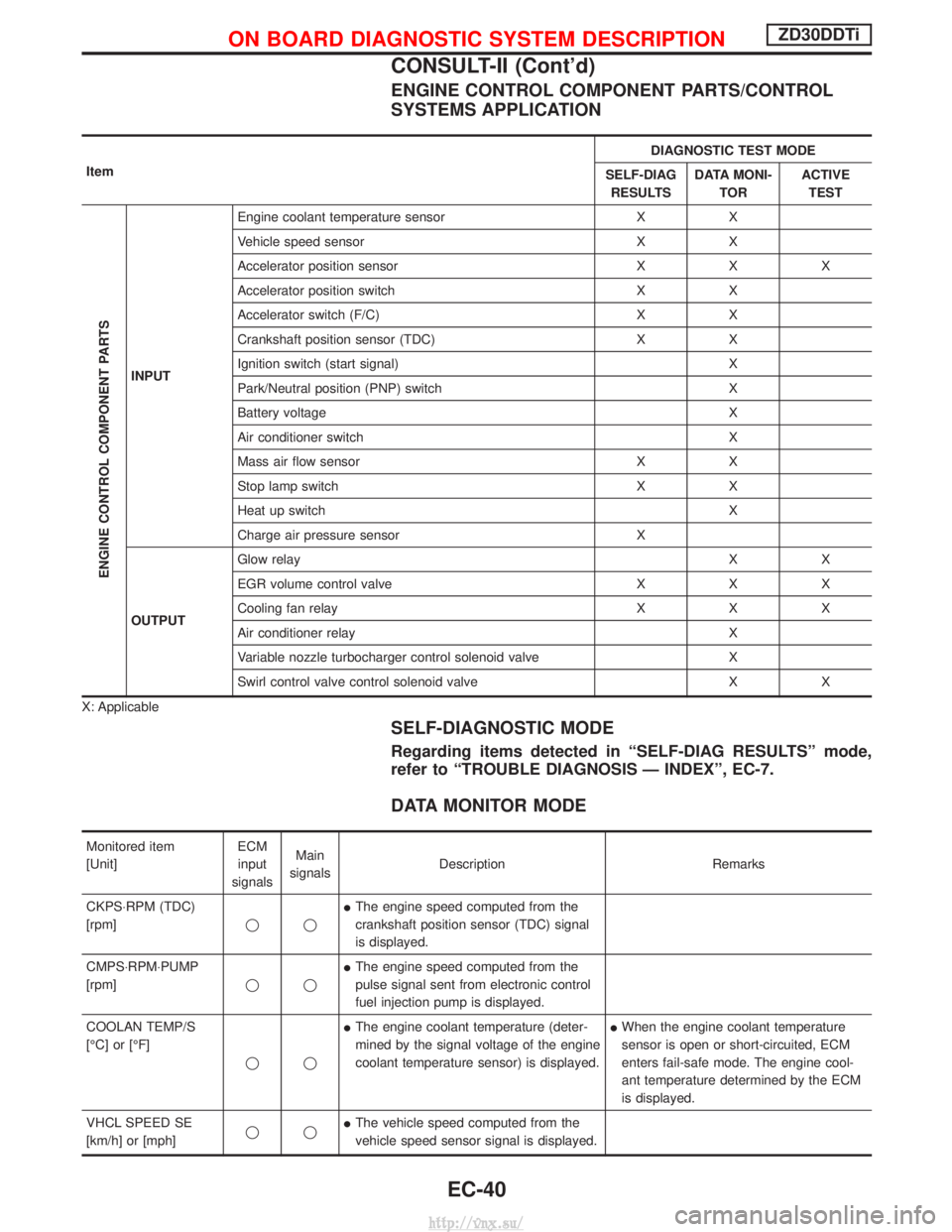

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG RESULTS DATA MONI-

TOR ACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUT Engine coolant temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X X

Accelerator position switch X X

Accelerator switch (F/C) X X

Crankshaft position sensor (TDC) X X

Ignition switch (start signal) X

Park/Neutral position (PNP) switch X

Battery voltage X

Air conditioner switch X

Mass air flow sensor X X

Stop lamp switch X X

Heat up switch X

Charge air pressure sensor X

OUTPUT Glow relay

XX

EGR volume control valve X X X

Cooling fan relay X X X

Air conditioner relay X

Variable nozzle turbocharger control solenoid valve X

Swirl control valve control solenoid valve X X

X: Applicable

SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

DATA MONITOR MODE

Monitored item

[Unit] ECM

input

signals Main

signals Description Remarks

CKPS×RPM (TDC)

[rpm] qqI

The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPS×RPM×PUMP

[rpm] qqI

The engine speed computed from the

pulse signal sent from electronic control

fuel injection pump is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF] qqI

The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed. I

When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

VHCL SPEED SE

[km/h] or [mph] qqI

The vehicle speed computed from the

vehicle speed sensor signal is displayed.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-40

http://vnx.su/

Page 316 of 1833

![NISSAN TERRANO 2004 Service Repair Manual Monitored item

[Unit]ECM

input

signals Main

signals Description Remarks

FUEL TEMP SEN

[ÉC] or [ÉF] qqI

The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL NISSAN TERRANO 2004 Service Repair Manual Monitored item

[Unit]ECM

input

signals Main

signals Description Remarks

FUEL TEMP SEN

[ÉC] or [ÉF] qqI

The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL](/img/5/57394/w960_57394-315.png)

Monitored item

[Unit]ECM

input

signals Main

signals Description Remarks

FUEL TEMP SEN

[ÉC] or [ÉF] qqI

The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS SEN [V] qqI

The accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE] qqI

Indicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

accelerator position switch signal.

SPILL/V [ÉCA] qI

The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V] qqI

The power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

starter signal. I

After starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF] qqI

Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW [ON/OFF] qqI

Indicates [ON/OFF] condition from the

stop lamp switch signal.

IGN SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from igni-

tion switch signal.

WARM UP SW

[ON/OFF] qI

Indicates [ON/OFF] condition from the

heat up switch signal.

MAS AIR/FL SE [V] qqI

The signal voltage of the mass air flow

sensor is displayed. I

When the engine is stopped, a certain

value is indicated.

DECELER F/CUT

[ON/OFF] qI

The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

INJ TIMG C/V [%] qI

The duty ratio of fuel injection timing

control valve (sent from electronic control

fuel injection pump) is displayed.

AIR COND RLY

[ON/OFF] qI

Indicates the control condition of the air

conditioner relay (determined by ECM

according to the input signals).

GLOW RLY [ON/OFF] qI

The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[ON/OFF] qI

Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

I ON ... Operates.

OFF ... Stopped.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-41

http://vnx.su/

Page 318 of 1833

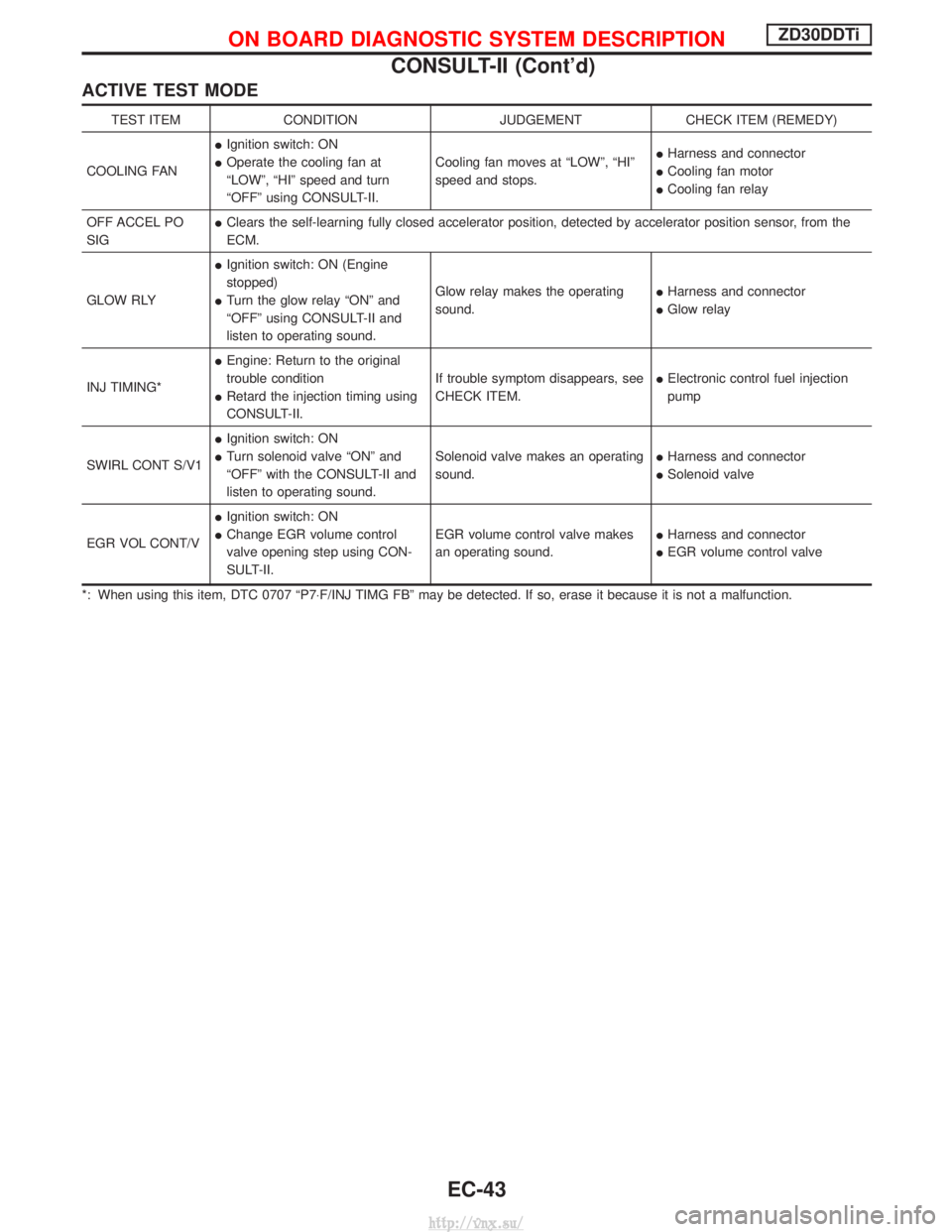

ACTIVE TEST MODE

TEST ITEMCONDITION JUDGEMENTCHECK ITEM (REMEDY)

COOLING FAN I

Ignition switch: ON

I Operate the cooling fan at

ªLOWº, ªHIº speed and turn

ªOFFº using CONSULT-II. Cooling fan moves at ªLOWº, ªHIº

speed and stops.

I

Harness and connector

I Cooling fan motor

I Cooling fan relay

OFF ACCEL PO

SIG I

Clears the self-learning fully closed accelerator position, detected by accelerator position sensor, from the

ECM.

GLOW RLY I

Ignition switch: ON (Engine

stopped)

I Turn the glow relay ªONº and

ªOFFº using CONSULT-II and

listen to operating sound. Glow relay makes the operating

sound.

I

Harness and connector

I Glow relay

INJ TIMING* I

Engine: Return to the original

trouble condition

I Retard the injection timing using

CONSULT-II. If trouble symptom disappears, see

CHECK ITEM.

I

Electronic control fuel injection

pump

SWIRL CONT S/V1 I

Ignition switch: ON

I Turn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound. Solenoid valve makes an operating

sound.

I

Harness and connector

I Solenoid valve

EGR VOL CONT/V I

Ignition switch: ON

I Change EGR volume control

valve opening step using CON-

SULT-II. EGR volume control valve makes

an operating sound.

I

Harness and connector

I EGR volume control valve

*: When using this item, DTC 0707 ªP7 ×F/INJ TIMG FBº may be detected. If so, erase it because it is not a malfunction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-43

http://vnx.su/

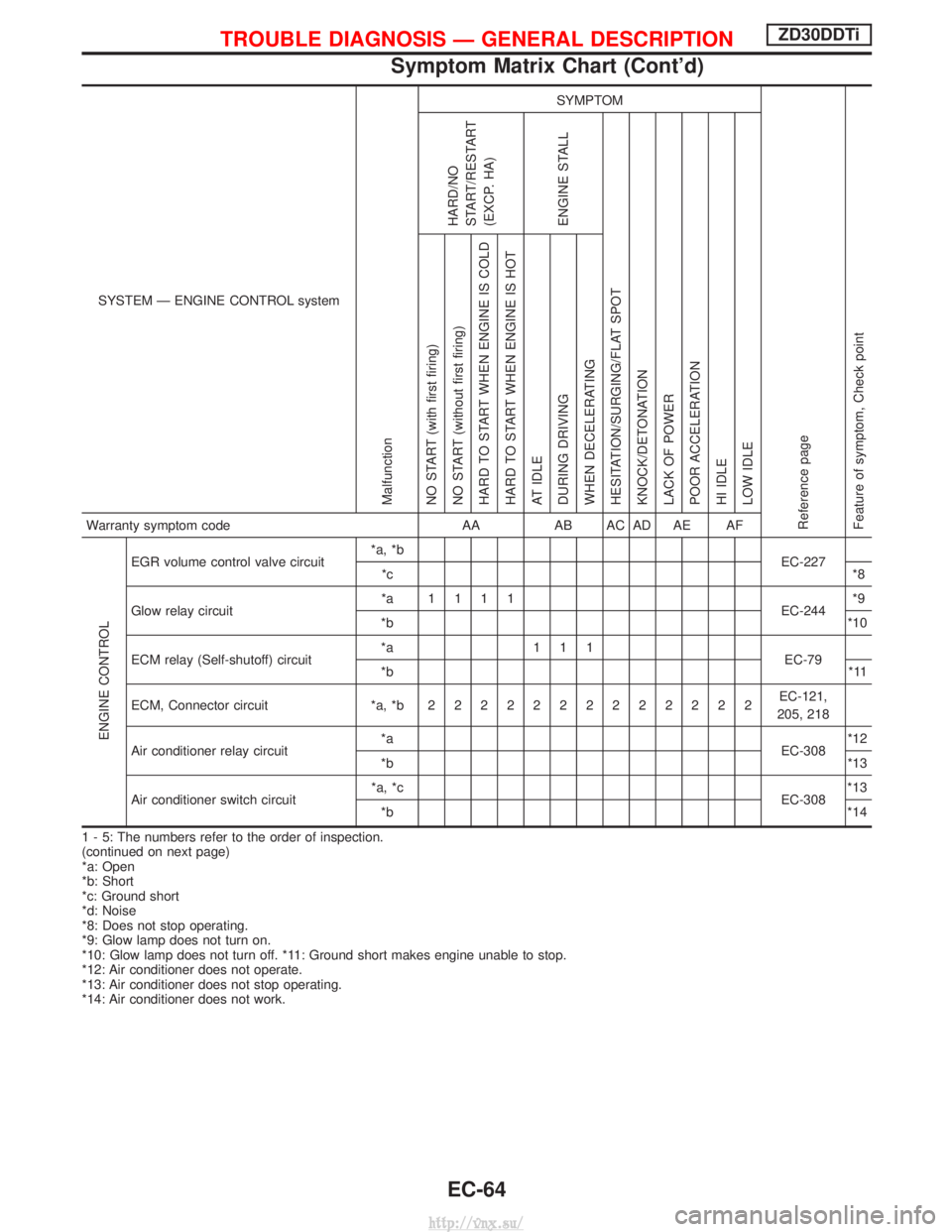

Page 339 of 1833

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO

START/RESTART

(EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGWarranty symptom code AAAB AC AD AE AF

ENGINE CONTROL

EGR volume control valve circuit *a, *b

EC-227

*c *8

Glow relay circuit *a 1111

EC-244*9

*b *10

ECM relay (Self-shutoff) circuit *a 111

EC-79

*b *11

ECM, Connector circuit *a, *b 2222222222222 EC-121,

205, 218

Air conditioner relay circuit *a

EC-308*12

*b *13

Air conditioner switch circuit *a, *c

EC-308*13

*b *14

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*8: Does not stop operating.

*9: Glow lamp does not turn on.

*10: Glow lamp does not turn off. *11: Ground short makes engine unable to stop.

*12: Air conditioner does not operate.

*13: Air conditioner does not stop operating.

*14: Air conditioner does not work.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-64

http://vnx.su/

Page 340 of 1833

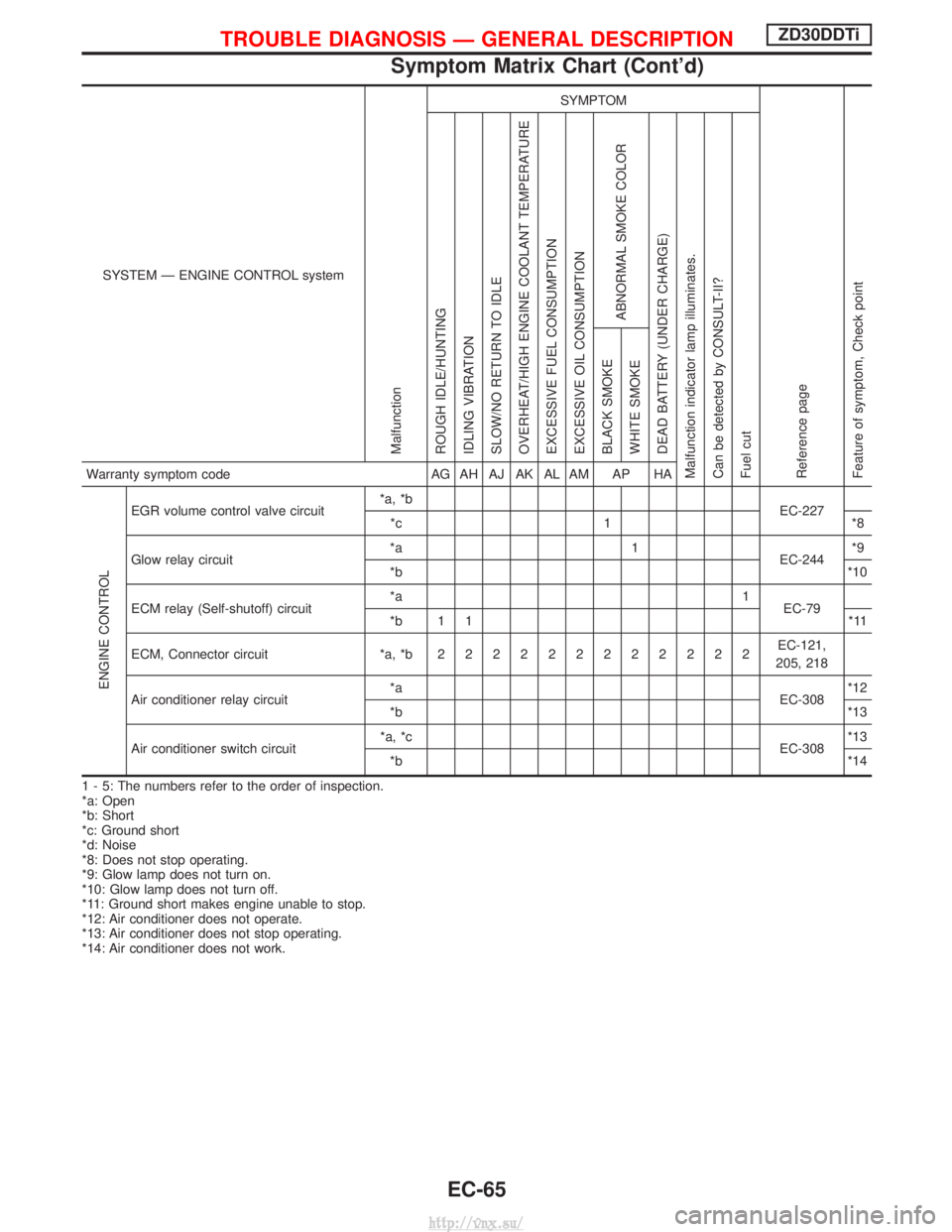

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

ENGINE CONTROL

EGR volume control valve circuit*a, *b

EC-227

*c 1 *8

Glow relay circuit *a 1

EC-244*9

*b *10

ECM relay (Self-shutoff) circuit *a 1

EC-79

*b 1 1 *11

ECM, Connector circuit *a, *b 222222222222 EC-121,

205, 218

Air conditioner relay circuit *a

EC-308*12

*b *13

Air conditioner switch circuit *a, *c

EC-308*13

*b *14

1 - 5: The numbers refer to the order of inspection.

*a: Open

*b: Short

*c: Ground short

*d: Noise

*8: Does not stop operating.

*9: Glow lamp does not turn on.

*10: Glow lamp does not turn off.

*11: Ground short makes engine unable to stop.

*12: Air conditioner does not operate.

*13: Air conditioner does not stop operating.

*14: Air conditioner does not work.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-65

http://vnx.su/