meter NISSAN TIIDA 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 163 of 2771

DTC VEHICLE SPEED SENSOR MTR

AT-151

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Diagnosis ProcedureINFOID:0000000001703304

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Read out the value of “VHCL/S SE-MTR” while driving. Check the value changes according to driving

speed.

Without CONSULT-III

1. Start engine.

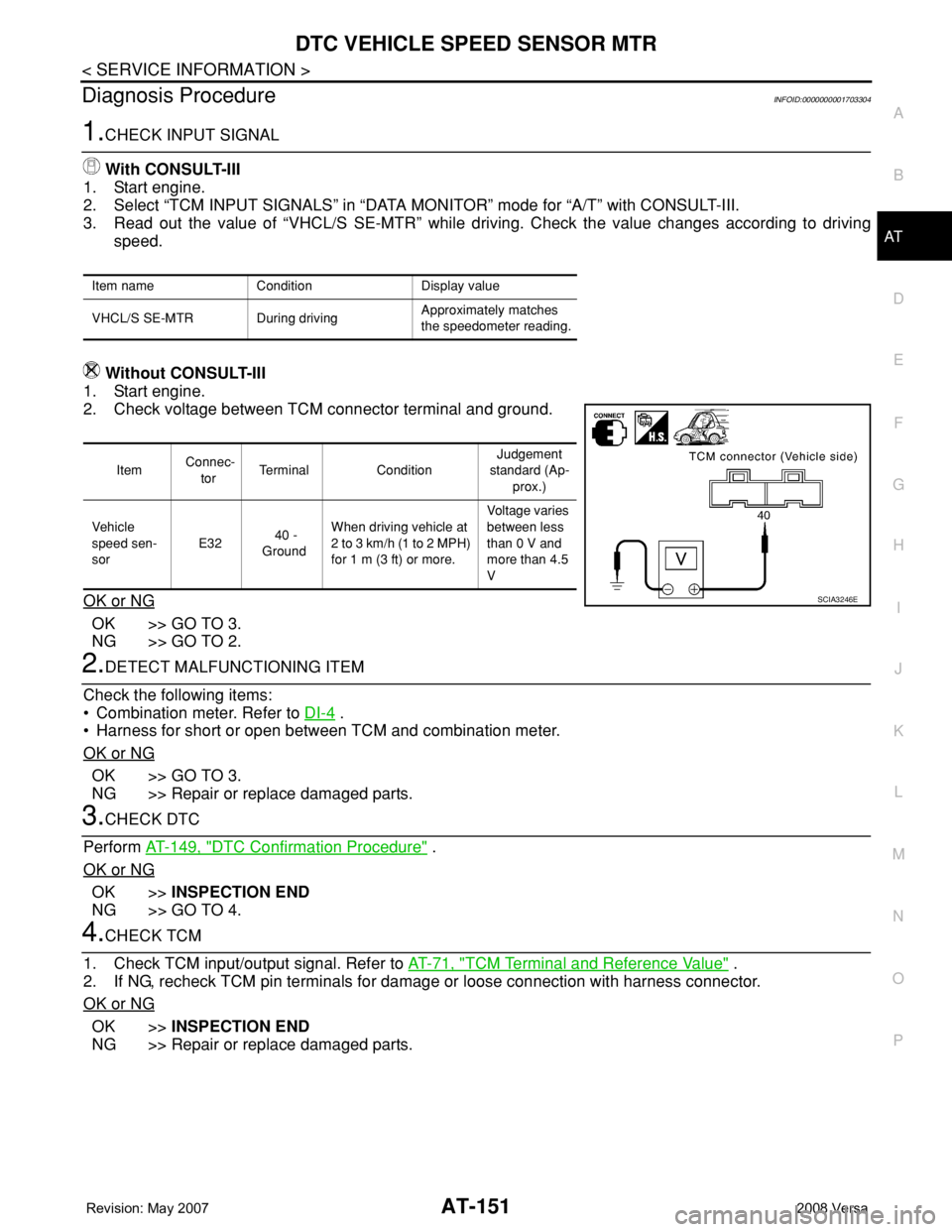

2. Check voltage between TCM connector terminal and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEM

Check the following items:

• Combination meter. Refer to DI-4

.

• Harness for short or open between TCM and combination meter.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK DTC

Perform AT-149, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.CHECK TCM

1. Check TCM input/output signal. Refer to AT-71, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Item name Condition Display value

VHCL/S SE-MTR During drivingApproximately matches

the speedometer reading.

Item Connec-

torTerminal ConditionJudgement

standard (Ap-

prox.)

Vehicle

speed sen-

sor E32 40 -

GroundWhen driving vehicle at

2 to 3 km/h (1 to 2 MPH)

for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5

V

SCIA3246E

Page 170 of 2771

AT-158

< SERVICE INFORMATION >

DTC TURBINE REVOLUTION SENSOR

DTC TURBINE REVOLUTION SENSOR

DescriptionINFOID:0000000001703313

The turbine revolution sensor (power train revolution sensor) detects forward clutch drum rpm (revolutions per

minute). It is located on the input side of the automatic transaxle. The vehicle speed sensor A/T (Revolution

sensor) is located on the output side of the automatic transaxle. With the two sensors, input and output rpms

are accurately detected. As a result, optimal shift timing during deceleration and shift quality can be improved.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703314

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703315

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “TURBINE SENSOR” with CONSULT-III or 10th judgement flicker without CON-

SULT-III is detected when TCM does not receive the proper voltage signal from the sensor.

Possible CauseINFOID:0000000001703316

• Harness or connector

(The sensor circuit is open or shorted.)

• Turbine revolution sensor (power train revolution sensor)

DTC Confirmation ProcedureINFOID:0000000001703317

CAUTION:

• Always drive vehicle at a safe speed.

• Be careful not to rev engine into the red zone on the tachometer.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine.

2. Select “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Touch “START”.

4. Drive vehicle under the following conditions for more than 5 seconds.

SLCT LVR POSI: “D” position

VEHICLE SPEED: Higher than 40 km/h (25 MPH)

ENGINE SPEED: Higher than 1,500 rpm

THROTTLE POSI: Greater than 1.0/8 of the full throttle position

5. If the check result is NG, go to AT-160, "

Diagnosis Procedure" .

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle under the following conditions for more than 5 seconds.

Selector lever position: “D” position

Vehicle speed: Higher than 40 km/h (25 MPH)

Engine speed: Higher than 1,500 rpm

Throttle position: 1.0/8 of the full throttle position

3. Perform self-diagnosis. Refer to AT-78, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-160, "

Diagnosis Procedure" .

Item name Condition Display value

TURBINE REV During driving (lock-up ON) Approximately matches the engine speed.

Page 181 of 2771

PNP, OD SWITCH AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSI-

TION SIGNAL CIRCUIT

AT-169

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

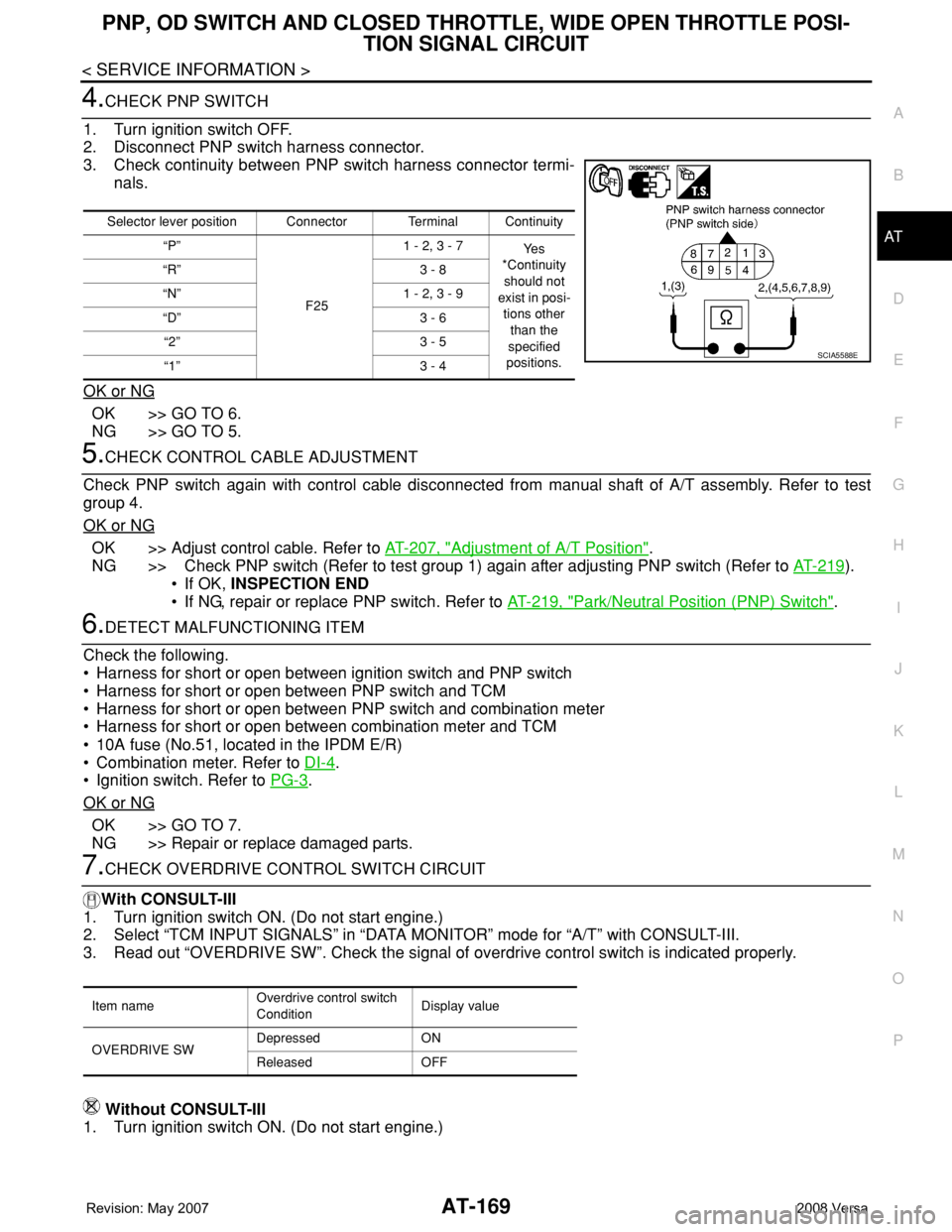

4.CHECK PNP SWITCH

1. Turn ignition switch OFF.

2. Disconnect PNP switch harness connector.

3. Check continuity between PNP switch harness connector termi-

nals.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK CONTROL CABLE ADJUSTMENT

Check PNP switch again with control cable disconnected from manual shaft of A/T assembly. Refer to test

group 4.

OK or NG

OK >> Adjust control cable. Refer to AT-207, "Adjustment of A/T Position".

NG >> Check PNP switch (Refer to test group 1) again after adjusting PNP switch (Refer to AT-219

).

• If OK, INSPECTION END

• If NG, repair or replace PNP switch. Refer to AT-219, "

Park/Neutral Position (PNP) Switch".

6.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and PNP switch

• Harness for short or open between PNP switch and TCM

• Harness for short or open between PNP switch and combination meter

• Harness for short or open between combination meter and TCM

• 10A fuse (No.51, located in the IPDM E/R)

• Combination meter. Refer to DI-4

.

• Ignition switch. Refer to PG-3

.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Read out “OVERDRIVE SW”. Check the signal of overdrive control switch is indicated properly.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

Selector lever position Connector Terminal Continuity

“P”

F251 - 2, 3 - 7

Ye s

*Continuity

should not

exist in posi-

tions other

than the

specified

positions. “R” 3 - 8

“N” 1 - 2, 3 - 9

“D” 3 - 6

“2” 3 - 5

“1” 3 - 4

SCIA5588E

Item nameOverdrive control switch

ConditionDisplay value

OVERDRIVE SWDepressed ON

Released OFF

Page 182 of 2771

AT-170

< SERVICE INFORMATION >

PNP, OD SWITCH AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSI-

TION SIGNAL CIRCUIT

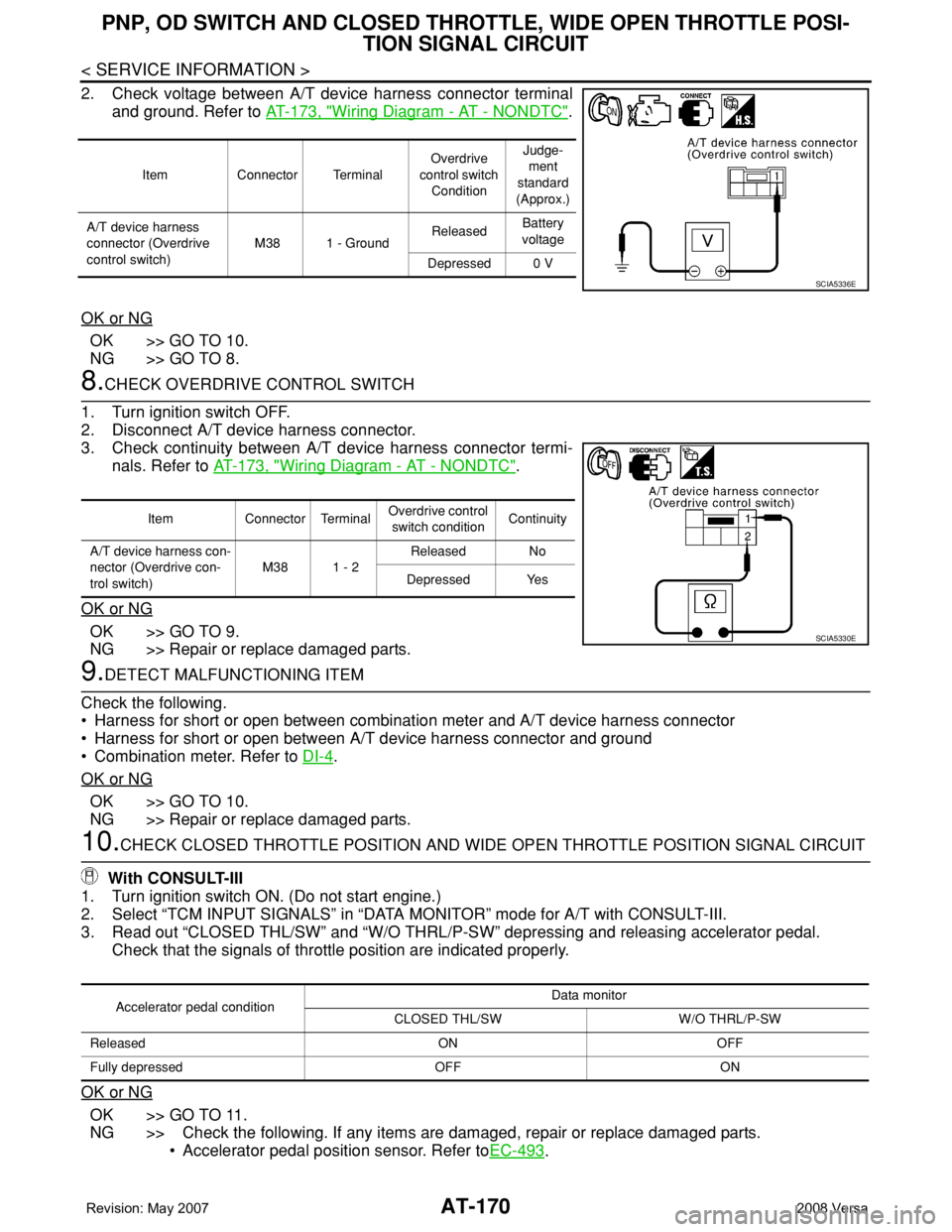

2. Check voltage between A/T device harness connector terminal

and ground. Refer to AT-173, "

Wiring Diagram - AT - NONDTC".

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8.CHECK OVERDRIVE CONTROL SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness connector termi-

nals. Refer to AT-173, "

Wiring Diagram - AT - NONDTC".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between combination meter and A/T device harness connector

• Harness for short or open between A/T device harness connector and ground

• Combination meter. Refer to DI-4

.

OK or NG

OK >> GO TO 10.

NG >> Repair or replace damaged parts.

10.CHECK CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION SIGNAL CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for A/T with CONSULT-III.

3. Read out “CLOSED THL/SW” and “W/O THRL/P-SW” depressing and releasing accelerator pedal.

Check that the signals of throttle position are indicated properly.

OK or NG

OK >> GO TO 11.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

• Accelerator pedal position sensor. Refer toEC-493

.

Item Connector TerminalOverdrive

control switch

ConditionJudge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch)M38 1 - GroundReleasedBattery

voltage

Depressed 0 V

SCIA5336E

Item Connector TerminalOverdrive control

switch conditionContinuity

A/T device harness con-

nector (Overdrive con-

trol switch)M38 1 - 2Released No

Depressed Yes

SCIA5330E

Accelerator pedal conditionData monitor

CLOSED THL/SW W/O THRL/P-SW

Released ON OFF

Fully depressed OFF ON

Page 184 of 2771

AT-172

< SERVICE INFORMATION >

SHIFT POSITION INDICATOR CIRCUIT

SHIFT POSITION INDICATOR CIRCUIT

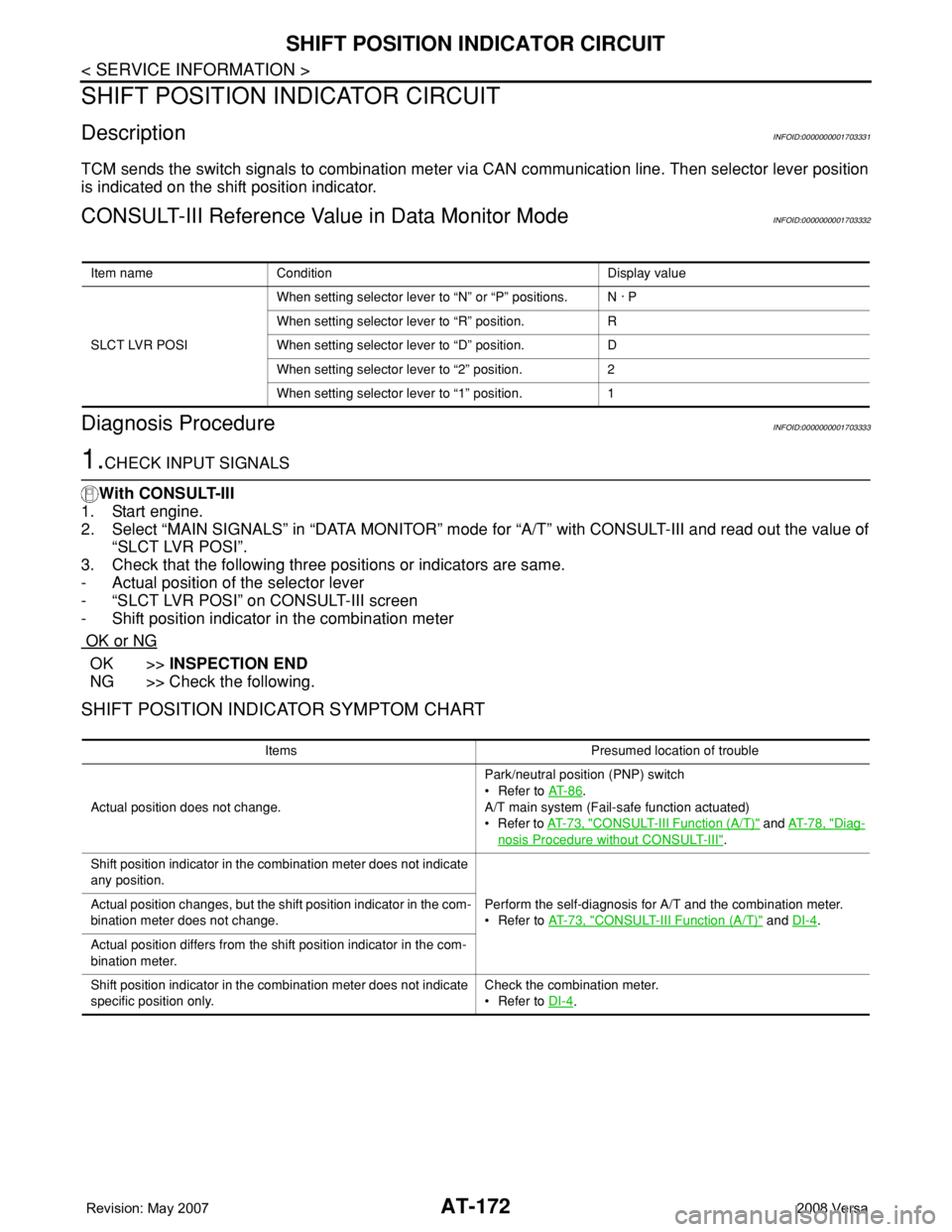

DescriptionINFOID:0000000001703331

TCM sends the switch signals to combination meter via CAN communication line. Then selector lever position

is indicated on the shift position indicator.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703332

Diagnosis ProcedureINFOID:0000000001703333

1.CHECK INPUT SIGNALS

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III and read out the value of

“SLCT LVR POSI”.

3. Check that the following three positions or indicators are same.

- Actual position of the selector lever

- “SLCT LVR POSI” on CONSULT-III screen

- Shift position indicator in the combination meter

OK or NG

OK >>INSPECTION END

NG >> Check the following.

SHIFT POSITION INDICATOR SYMPTOM CHART

Item name Condition Display value

SLCT LVR POSIWhen setting selector lever to “N” or “P” positions. N · P

When setting selector lever to “R” position. R

When setting selector lever to “D” position. D

When setting selector lever to “2” position. 2

When setting selector lever to “1” position. 1

Items Presumed location of trouble

Actual position does not change.Park/neutral position (PNP) switch

• Refer to AT- 8 6

.

A/T main system (Fail-safe function actuated)

•Refer to AT- 7 3 , "

CONSULT-III Function (A/T)" and AT- 7 8 , "Diag-

nosis Procedure without CONSULT-III".

Shift position indicator in the combination meter does not indicate

any position.

Perform the self-diagnosis for A/T and the combination meter.

• Refer to AT- 7 3 , "

CONSULT-III Function (A/T)" and DI-4. Actual position changes, but the shift position indicator in the com-

bination meter does not change.

Actual position differs from the shift position indicator in the com-

bination meter.

Shift position indicator in the combination meter does not indicate

specific position only.Check the combination meter.

• Refer to DI-4

.

Page 190 of 2771

AT-178

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

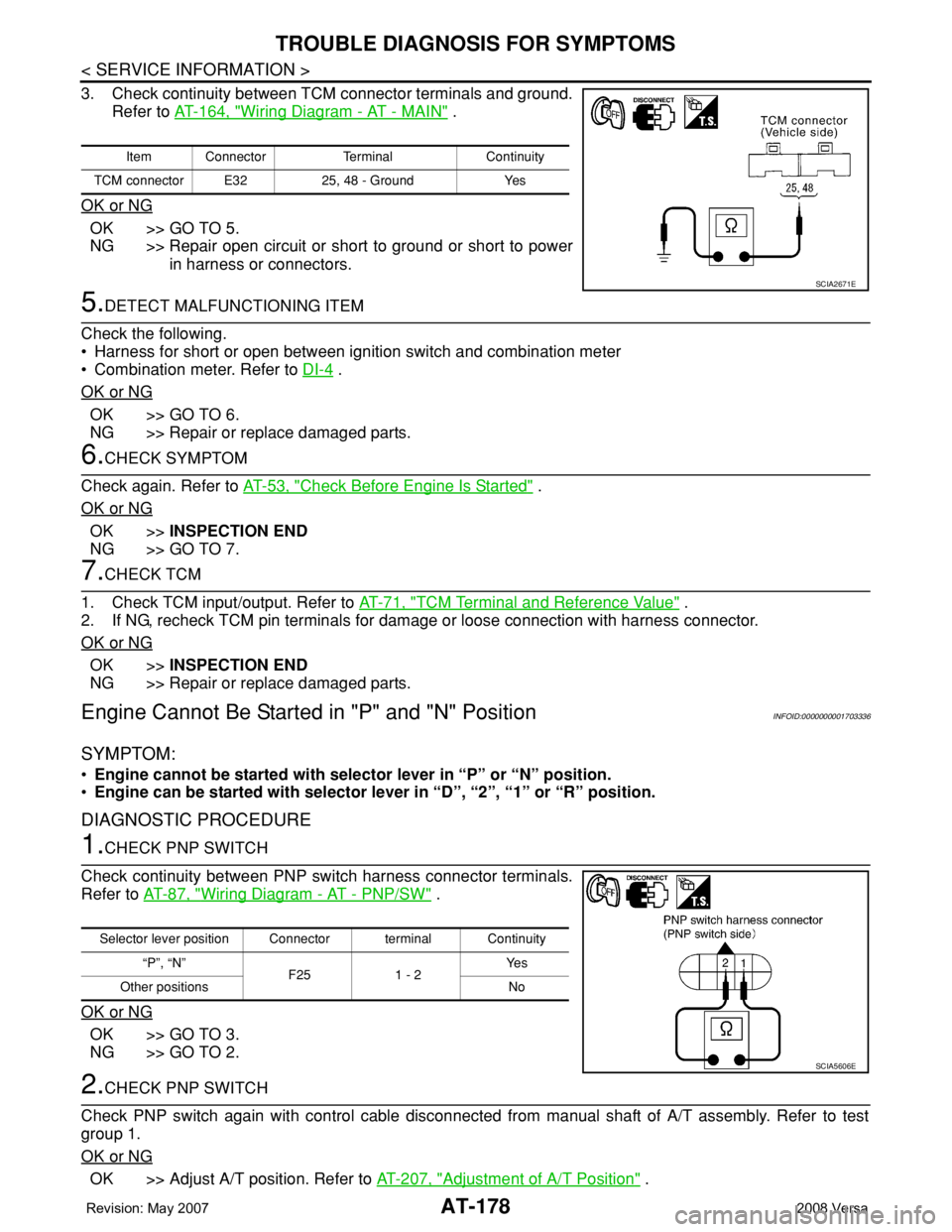

3. Check continuity between TCM connector terminals and ground.

Refer to AT-164, "

Wiring Diagram - AT - MAIN" .

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

5.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and combination meter

• Combination meter. Refer to DI-4

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again. Refer to AT-53, "

Check Before Engine Is Started" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output. Refer to AT-71, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in "P" and "N" PositionINFOID:0000000001703336

SYMPTOM:

•Engine cannot be started with selector lever in “P” or “N” position.

•Engine can be started with selector lever in “D”, “2”, “1” or “R” position.

DIAGNOSTIC PROCEDURE

1.CHECK PNP SWITCH

Check continuity between PNP switch harness connector terminals.

Refer to AT-87, "

Wiring Diagram - AT - PNP/SW" .

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK PNP SWITCH

Check PNP switch again with control cable disconnected from manual shaft of A/T assembly. Refer to test

group 1.

OK or NG

OK >> Adjust A/T position. Refer to AT-207, "Adjustment of A/T Position" .

Item Connector Terminal Continuity

TCM connector E32 25, 48 - Ground Yes

SCIA2671E

Selector lever position Connector terminal Continuity

“P”, “N”

F25 1 - 2Ye s

Other positions No

SCIA5606E

Page 236 of 2771

AT-224

< SERVICE INFORMATION >

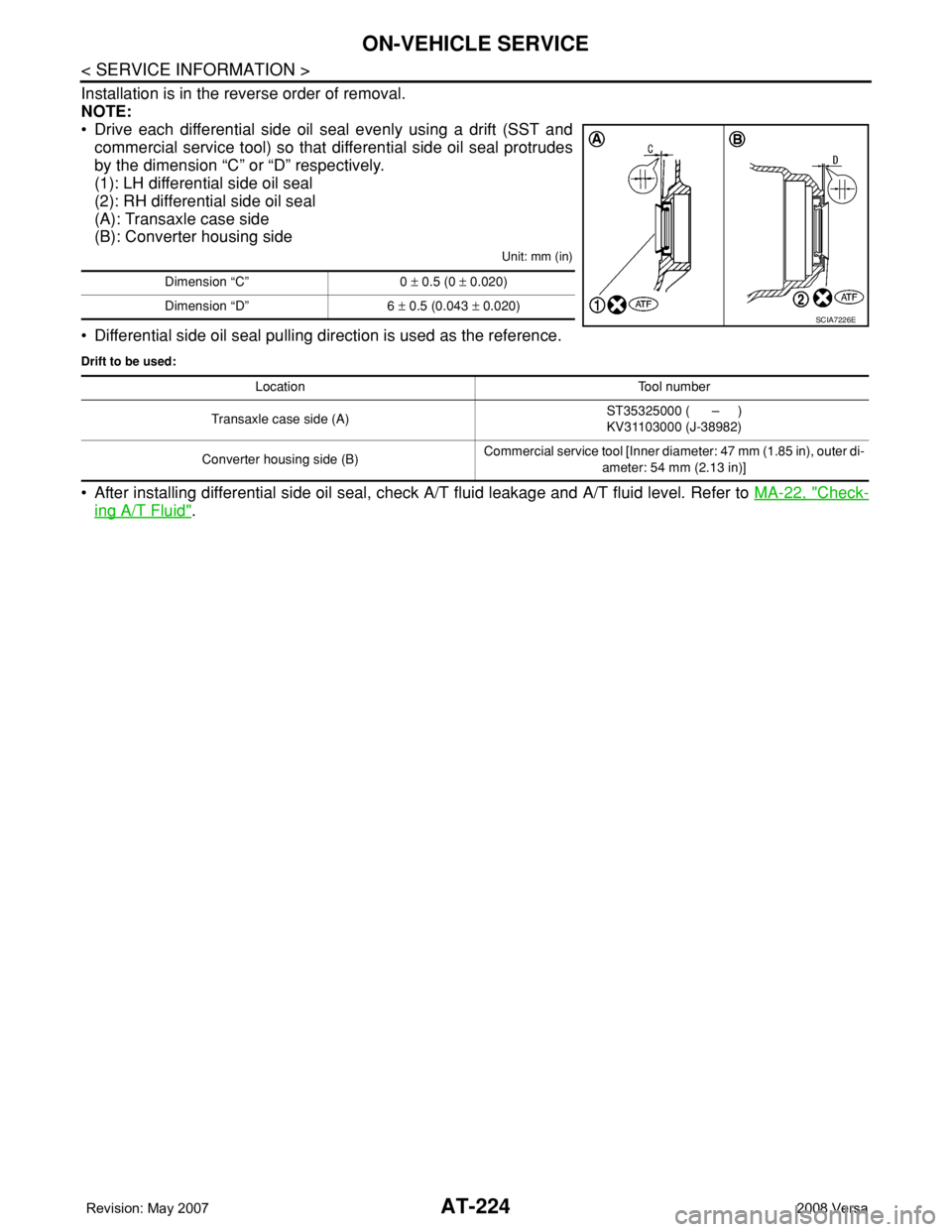

ON-VEHICLE SERVICE

Installation is in the reverse order of removal.

NOTE:

• Drive each differential side oil seal evenly using a drift (SST and

commercial service tool) so that differential side oil seal protrudes

by the dimension “C” or “D” respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

• Differential side oil seal pulling direction is used as the reference.

Drift to be used:

• After installing differential side oil seal, check A/T fluid leakage and A/T fluid level. Refer to MA-22, "Check-

ing A/T Fluid".

Dimension “C” 0 ± 0.5 (0 ± 0.020)

Dimension “D” 6 ± 0.5 (0.043 ± 0.020)

SCIA7226E

Location Tool number

Transaxle case side (A)ST35325000 ( – )

KV31103000 (J-38982)

Converter housing side (B)Commercial service tool [Inner diameter: 47 mm (1.85 in), outer di-

ameter: 54 mm (2.13 in)]

Page 242 of 2771

AT-230

< SERVICE INFORMATION >

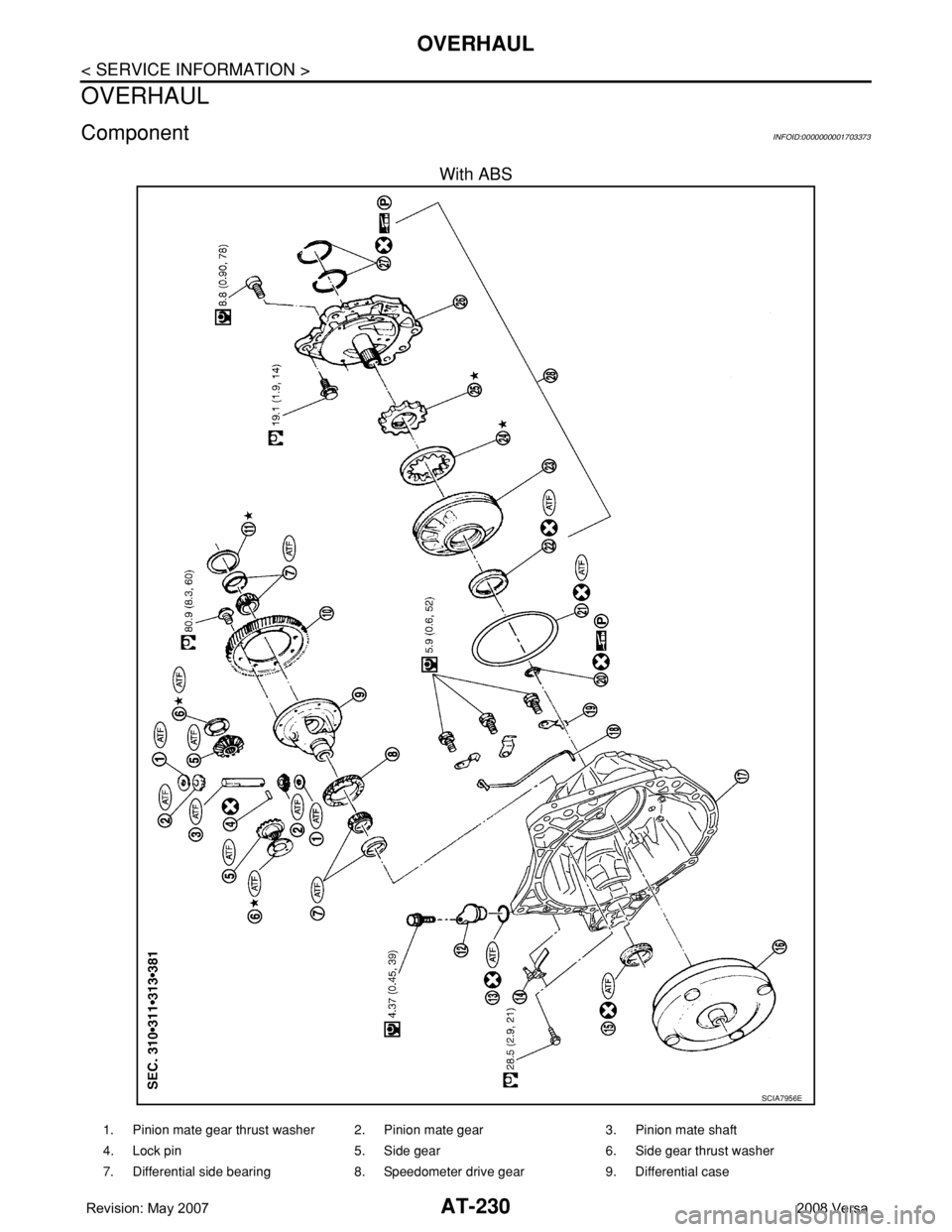

OVERHAUL

OVERHAUL

ComponentINFOID:0000000001703373

With ABS

SCIA7956E

1. Pinion mate gear thrust washer 2. Pinion mate gear 3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

Page 244 of 2771

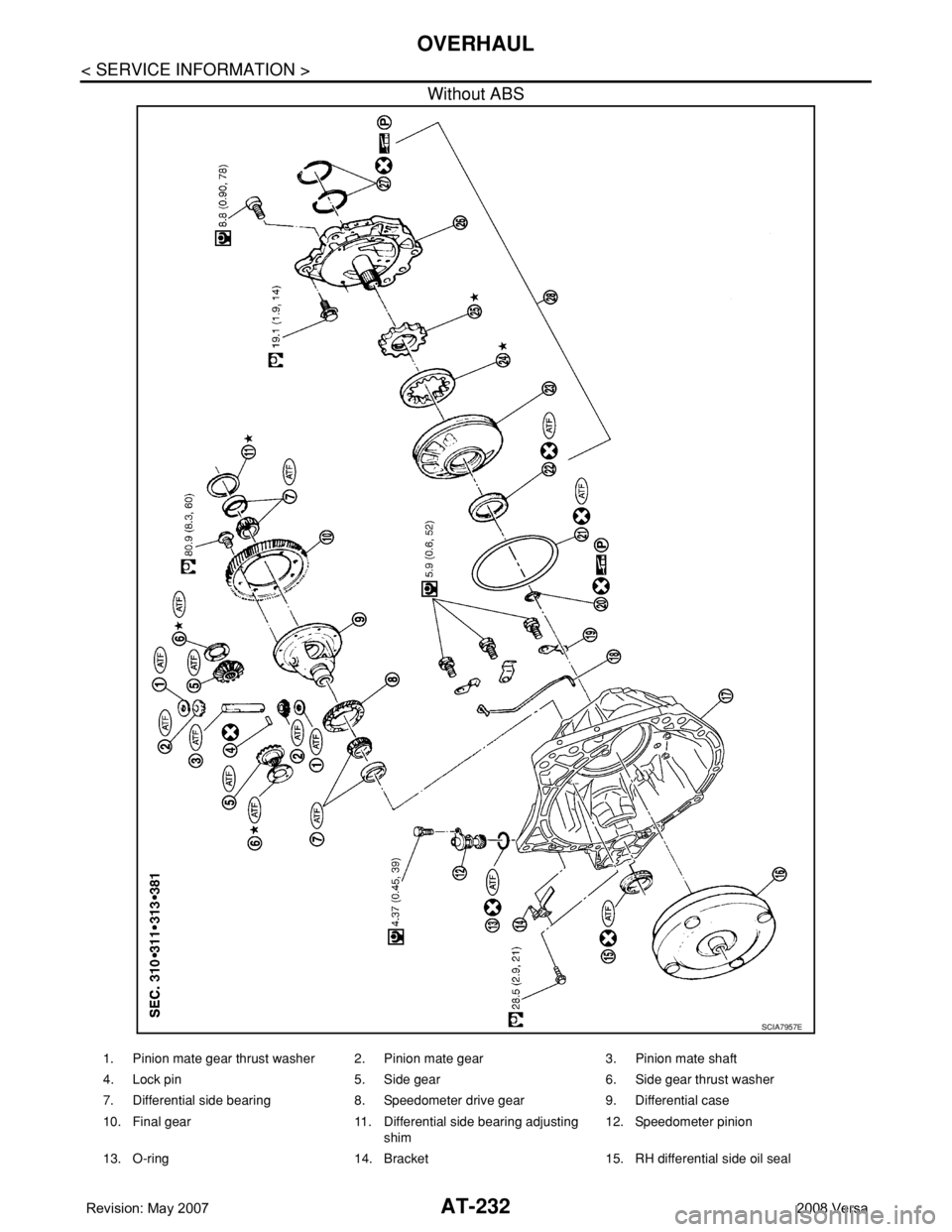

AT-232

< SERVICE INFORMATION >

OVERHAUL

Without ABS

SCIA7957E

1. Pinion mate gear thrust washer 2. Pinion mate gear 3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing adjusting

shim12. Speedometer pinion

13. O-ring 14. Bracket 15. RH differential side oil seal

Page 253 of 2771

DISASSEMBLY

AT-241

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

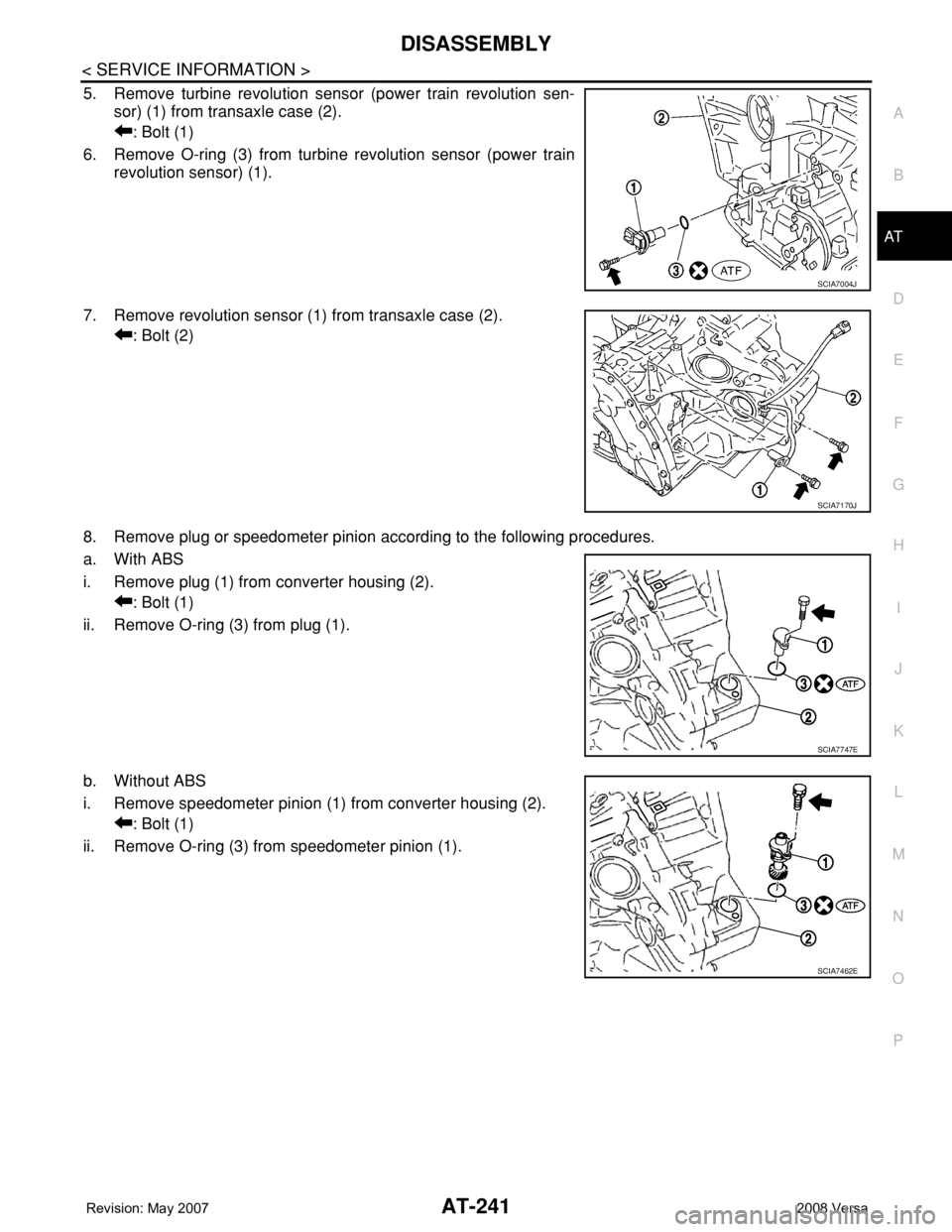

5. Remove turbine revolution sensor (power train revolution sen-

sor) (1) from transaxle case (2).

: Bolt (1)

6. Remove O-ring (3) from turbine revolution sensor (power train

revolution sensor) (1).

7. Remove revolution sensor (1) from transaxle case (2).

: Bolt (2)

8. Remove plug or speedometer pinion according to the following procedures.

a. With ABS

i. Remove plug (1) from converter housing (2).

: Bolt (1)

ii. Remove O-ring (3) from plug (1).

b. Without ABS

i. Remove speedometer pinion (1) from converter housing (2).

: Bolt (1)

ii. Remove O-ring (3) from speedometer pinion (1).

SCIA7004J

SCIA7170J

SCIA7747E

SCIA7462E