meter NISSAN TIIDA 2008 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 281 of 2771

REPAIR FOR COMPONENT PARTS

AT-269

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

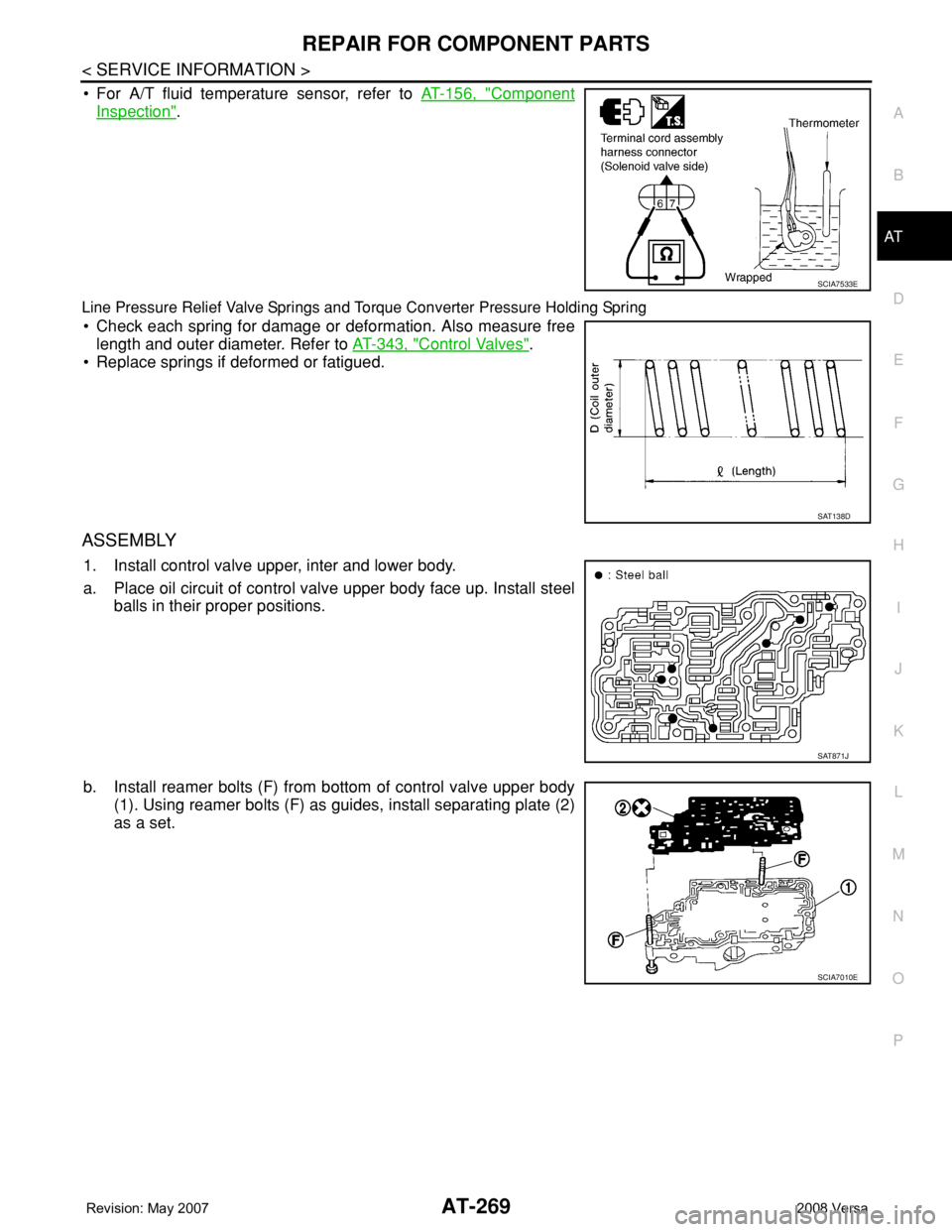

• For A/T fluid temperature sensor, refer to AT-156, "Component

Inspection".

Line Pressure Relief Valve Springs and Torque Converter Pressure Holding Spring

• Check each spring for damage or deformation. Also measure free

length and outer diameter. Refer to AT-343, "

Control Valves".

• Replace springs if deformed or fatigued.

ASSEMBLY

1. Install control valve upper, inter and lower body.

a. Place oil circuit of control valve upper body face up. Install steel

balls in their proper positions.

b. Install reamer bolts (F) from bottom of control valve upper body

(1). Using reamer bolts (F) as guides, install separating plate (2)

as a set.

SCIA7533E

SAT138D

SAT871J

SCIA7010E

Page 287 of 2771

REPAIR FOR COMPONENT PARTS

AT-275

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

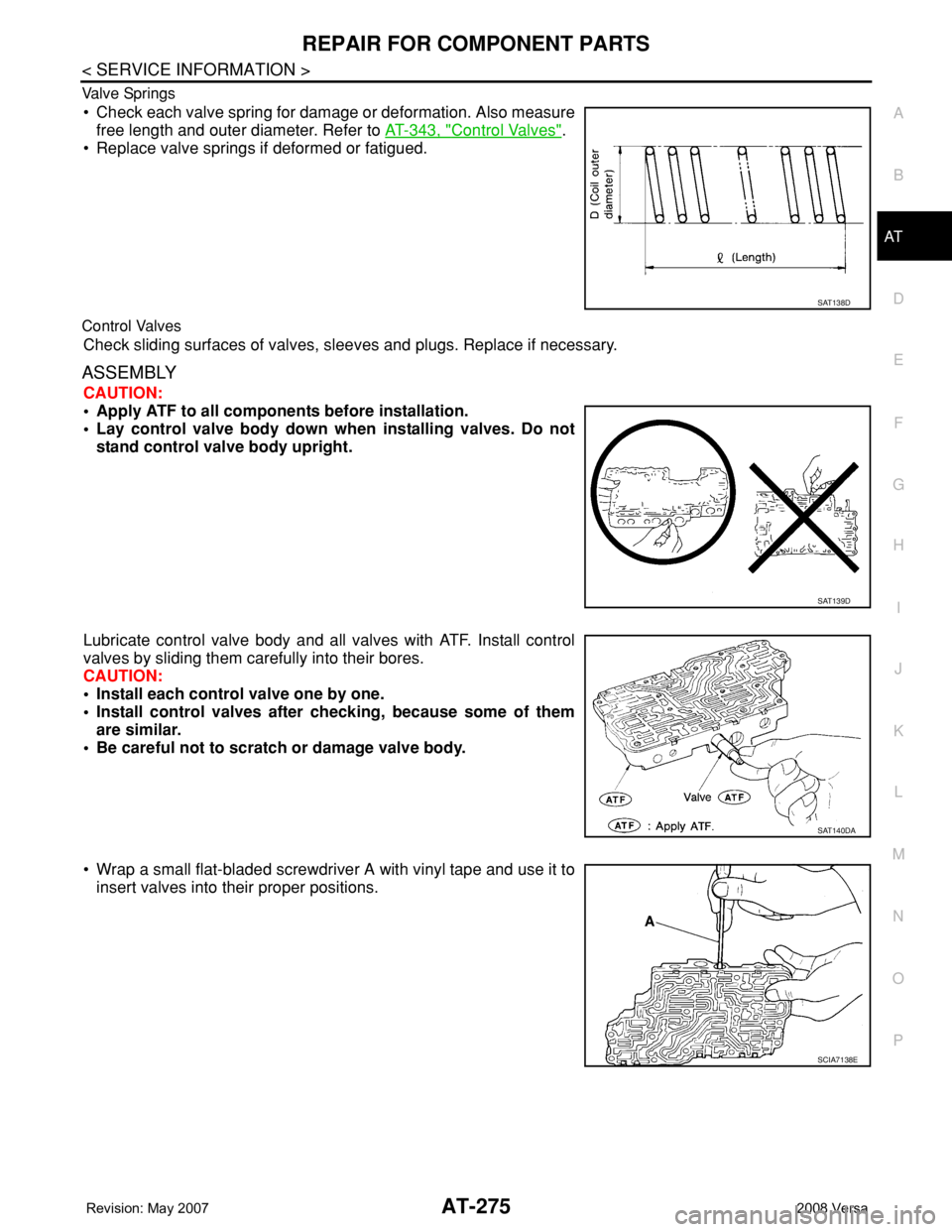

P Va l v e Sp r i n g s

• Check each valve spring for damage or deformation. Also measure

free length and outer diameter. Refer to AT-343, "

Control Valves".

• Replace valve springs if deformed or fatigued.

Control Valves

Check sliding surfaces of valves, sleeves and plugs. Replace if necessary.

ASSEMBLY

CAUTION:

• Apply ATF to all components before installation.

• Lay control valve body down when installing valves. Do not

stand control valve body upright.

Lubricate control valve body and all valves with ATF. Install control

valves by sliding them carefully into their bores.

CAUTION:

• Install each control valve one by one.

• Install control valves after checking, because some of them

are similar.

• Be careful not to scratch or damage valve body.

• Wrap a small flat-bladed screwdriver A with vinyl tape and use it to

insert valves into their proper positions.

SAT138D

SAT139D

SAT140DA

SCIA7138E

Page 290 of 2771

AT-278

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

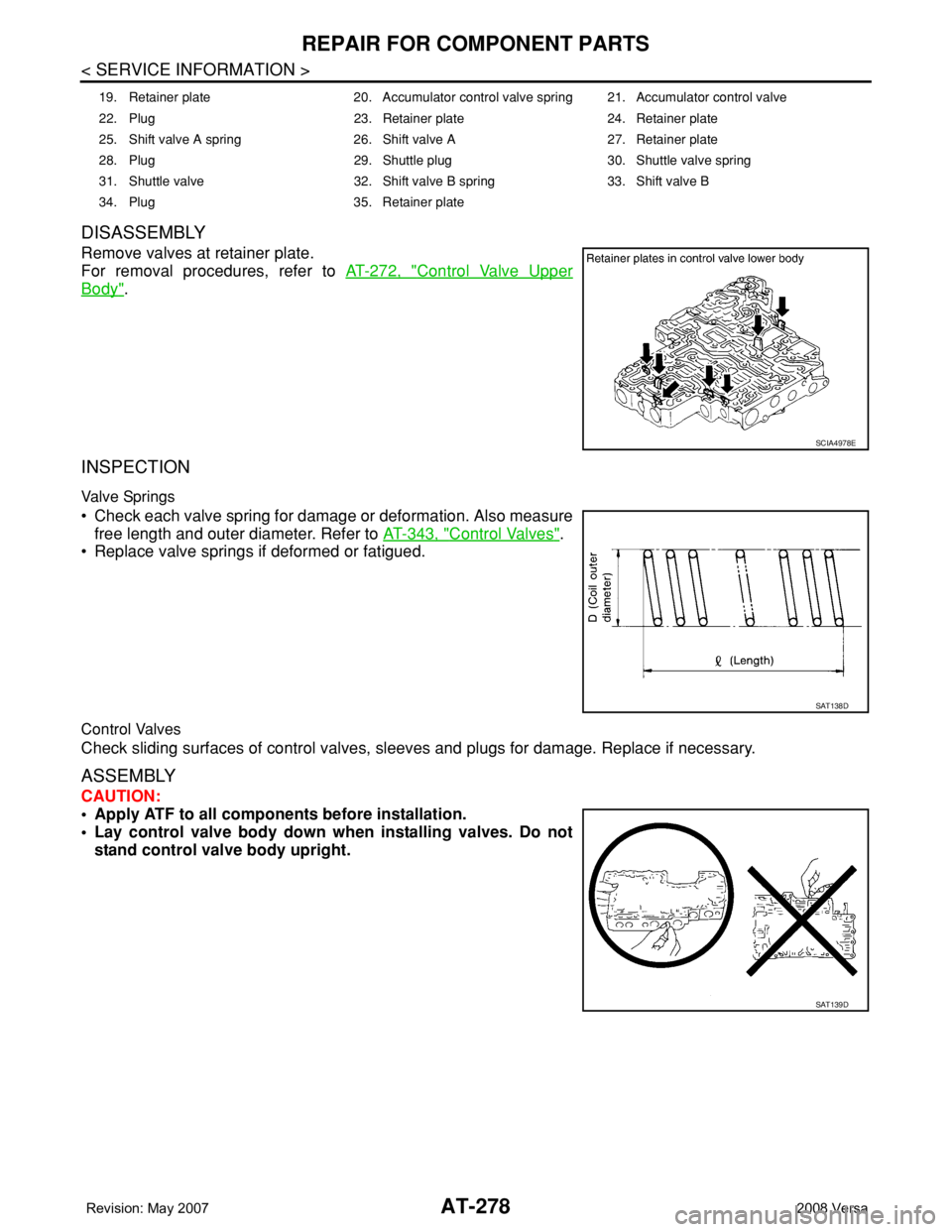

DISASSEMBLY

Remove valves at retainer plate.

For removal procedures, refer to AT-272, "

Control Valve Upper

Body".

INSPECTION

Valve Springs

• Check each valve spring for damage or deformation. Also measure

free length and outer diameter. Refer to AT-343, "

Control Valves".

• Replace valve springs if deformed or fatigued.

Control Valves

Check sliding surfaces of control valves, sleeves and plugs for damage. Replace if necessary.

ASSEMBLY

CAUTION:

• Apply ATF to all components before installation.

• Lay control valve body down when installing valves. Do not

stand control valve body upright.

19. Retainer plate 20. Accumulator control valve spring 21. Accumulator control valve

22. Plug 23. Retainer plate 24. Retainer plate

25. Shift valve A spring 26. Shift valve A 27. Retainer plate

28. Plug 29. Shuttle plug 30. Shuttle valve spring

31. Shuttle valve 32. Shift valve B spring 33. Shift valve B

34. Plug 35. Retainer plate

SCIA4978E

SAT138D

SAT139D

Page 321 of 2771

REPAIR FOR COMPONENT PARTS

AT-309

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

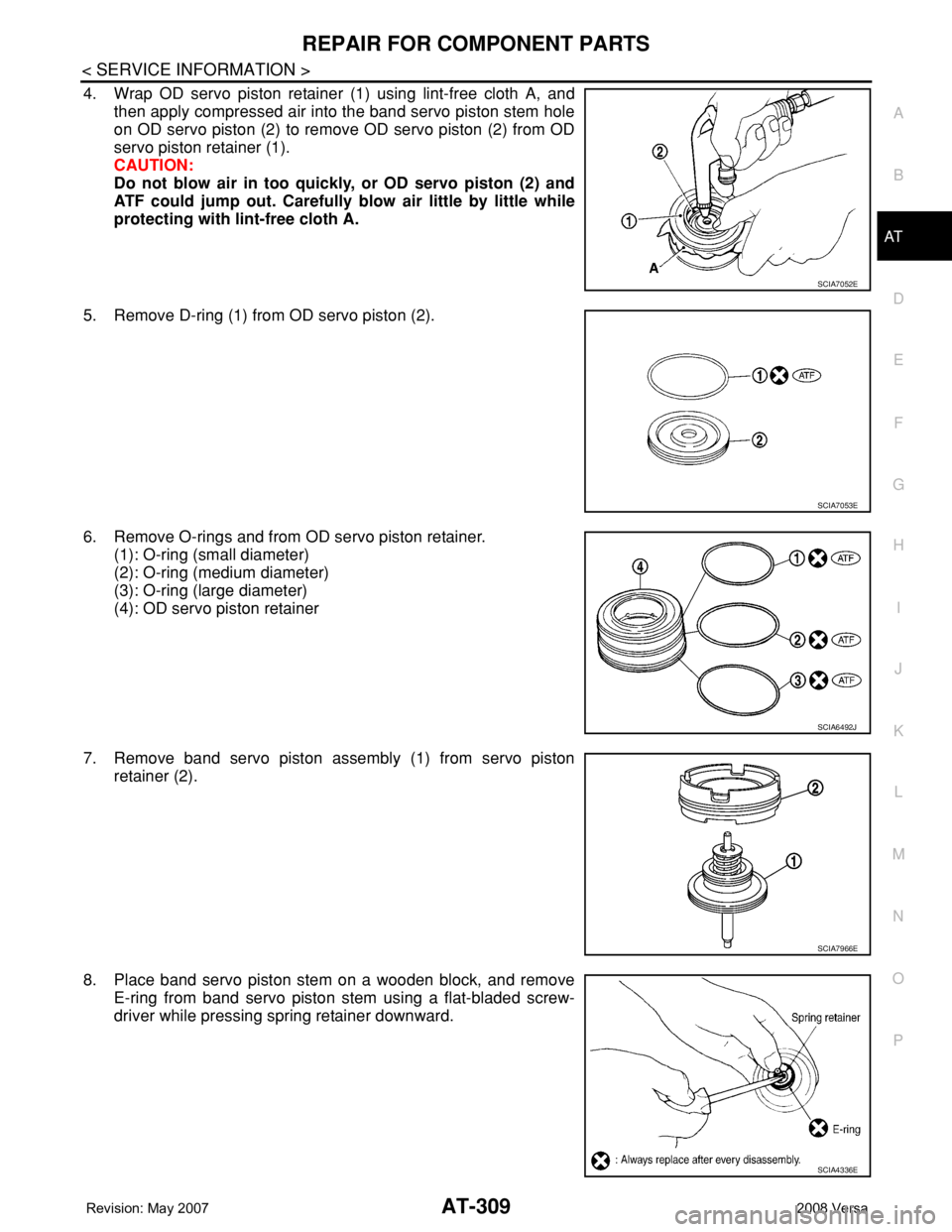

4. Wrap OD servo piston retainer (1) using lint-free cloth A, and

then apply compressed air into the band servo piston stem hole

on OD servo piston (2) to remove OD servo piston (2) from OD

servo piston retainer (1).

CAUTION:

Do not blow air in too quickly, or OD servo piston (2) and

ATF could jump out. Carefully blow air little by little while

protecting with lint-free cloth A.

5. Remove D-ring (1) from OD servo piston (2).

6. Remove O-rings and from OD servo piston retainer.

(1): O-ring (small diameter)

(2): O-ring (medium diameter)

(3): O-ring (large diameter)

(4): OD servo piston retainer

7. Remove band servo piston assembly (1) from servo piston

retainer (2).

8. Place band servo piston stem on a wooden block, and remove

E-ring from band servo piston stem using a flat-bladed screw-

driver while pressing spring retainer downward.

SCIA7052E

SCIA7053E

SCIA6492J

SCIA7966E

SCIA4336E

Page 324 of 2771

AT-312

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

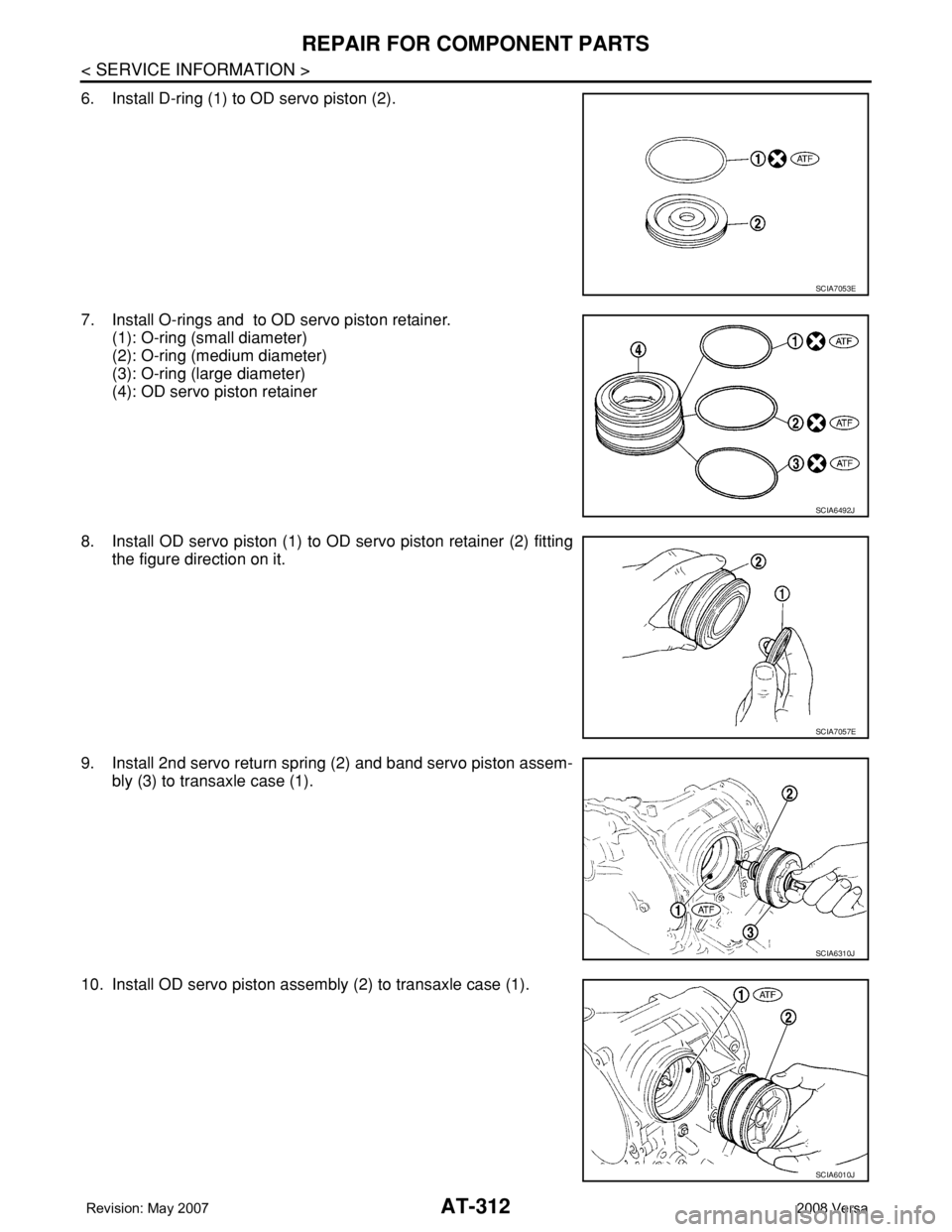

6. Install D-ring (1) to OD servo piston (2).

7. Install O-rings and to OD servo piston retainer.

(1): O-ring (small diameter)

(2): O-ring (medium diameter)

(3): O-ring (large diameter)

(4): OD servo piston retainer

8. Install OD servo piston (1) to OD servo piston retainer (2) fitting

the figure direction on it.

9. Install 2nd servo return spring (2) and band servo piston assem-

bly (3) to transaxle case (1).

10. Install OD servo piston assembly (2) to transaxle case (1).

SCIA7053E

SCIA6492J

SCIA7057E

SCIA6310J

SCIA6010J

Page 325 of 2771

REPAIR FOR COMPONENT PARTS

AT-313

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

11. Push in OD servo piston assembly using a puller A (commercial

service tool) and a suitable drift B, and install snap ring (1) to

transaxle case using a flat-bladed screwdriver C.

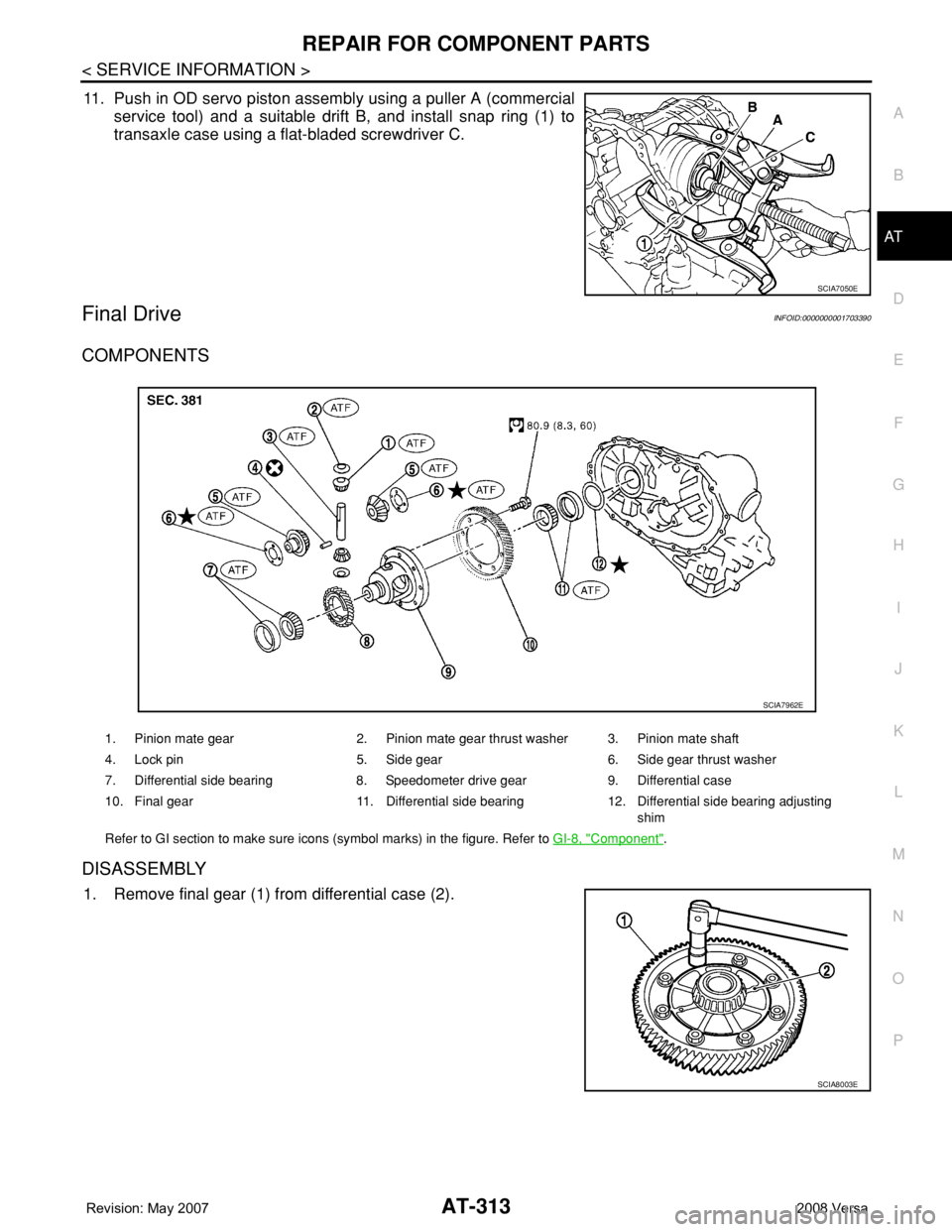

Final DriveINFOID:0000000001703390

COMPONENTS

DISASSEMBLY

1. Remove final gear (1) from differential case (2).

SCIA7050E

1. Pinion mate gear 2. Pinion mate gear thrust washer 3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing 12. Differential side bearing adjusting

shim

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA7962E

SCIA8003E

Page 326 of 2771

AT-314

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

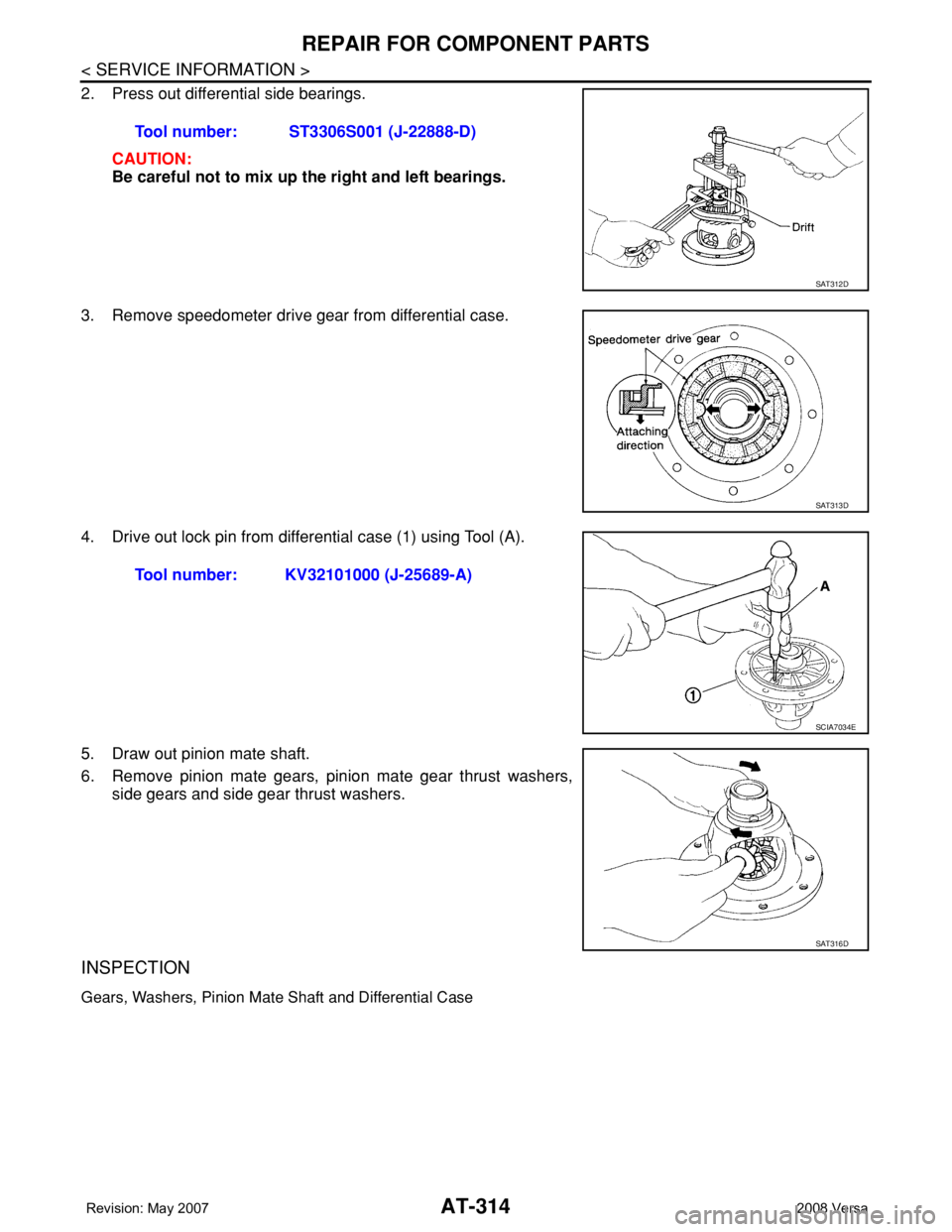

2. Press out differential side bearings.

CAUTION:

Be careful not to mix up the right and left bearings.

3. Remove speedometer drive gear from differential case.

4. Drive out lock pin from differential case (1) using Tool (A).

5. Draw out pinion mate shaft.

6. Remove pinion mate gears, pinion mate gear thrust washers,

side gears and side gear thrust washers.

INSPECTION

Gears, Washers, Pinion Mate Shaft and Differential Case

Tool number: ST3306S001 (J-22888-D)

SAT312D

SAT313D

Tool number: KV32101000 (J-25689-A)

SCIA7034E

SAT316D

Page 328 of 2771

AT-316

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

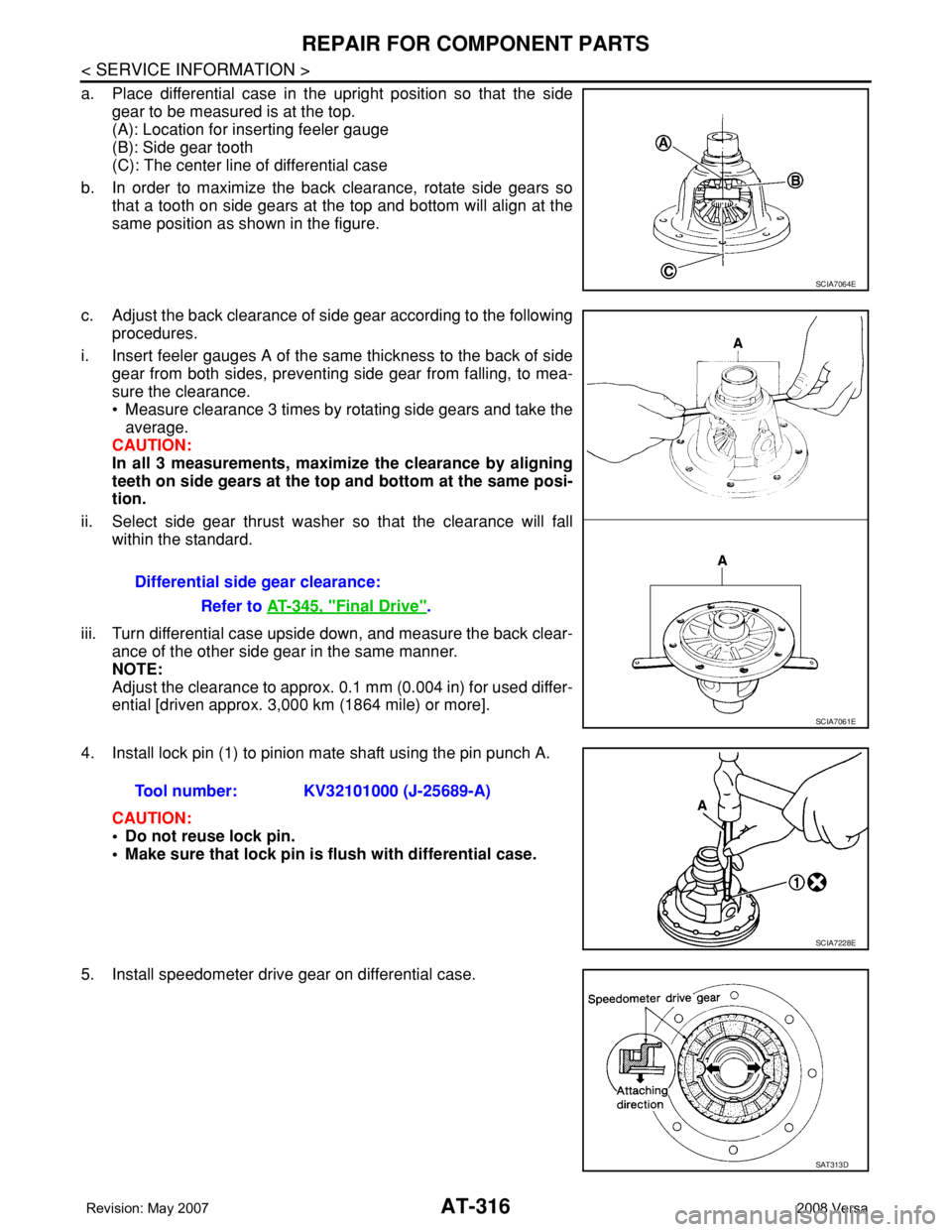

a. Place differential case in the upright position so that the side

gear to be measured is at the top.

(A): Location for inserting feeler gauge

(B): Side gear tooth

(C): The center line of differential case

b. In order to maximize the back clearance, rotate side gears so

that a tooth on side gears at the top and bottom will align at the

same position as shown in the figure.

c. Adjust the back clearance of side gear according to the following

procedures.

i. Insert feeler gauges A of the same thickness to the back of side

gear from both sides, preventing side gear from falling, to mea-

sure the clearance.

• Measure clearance 3 times by rotating side gears and take the

average.

CAUTION:

In all 3 measurements, maximize the clearance by aligning

teeth on side gears at the top and bottom at the same posi-

tion.

ii. Select side gear thrust washer so that the clearance will fall

within the standard.

iii. Turn differential case upside down, and measure the back clear-

ance of the other side gear in the same manner.

NOTE:

Adjust the clearance to approx. 0.1 mm (0.004 in) for used differ-

ential [driven approx. 3,000 km (1864 mile) or more].

4. Install lock pin (1) to pinion mate shaft using the pin punch A.

CAUTION:

• Do not reuse lock pin.

• Make sure that lock pin is flush with differential case.

5. Install speedometer drive gear on differential case.

SCIA7064E

Differential side gear clearance:

Refer to AT-345, "

Final Drive".

SCIA7061E

Tool number: KV32101000 (J-25689-A)

SCIA7228E

SAT313D

Page 330 of 2771

AT-318

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001703391

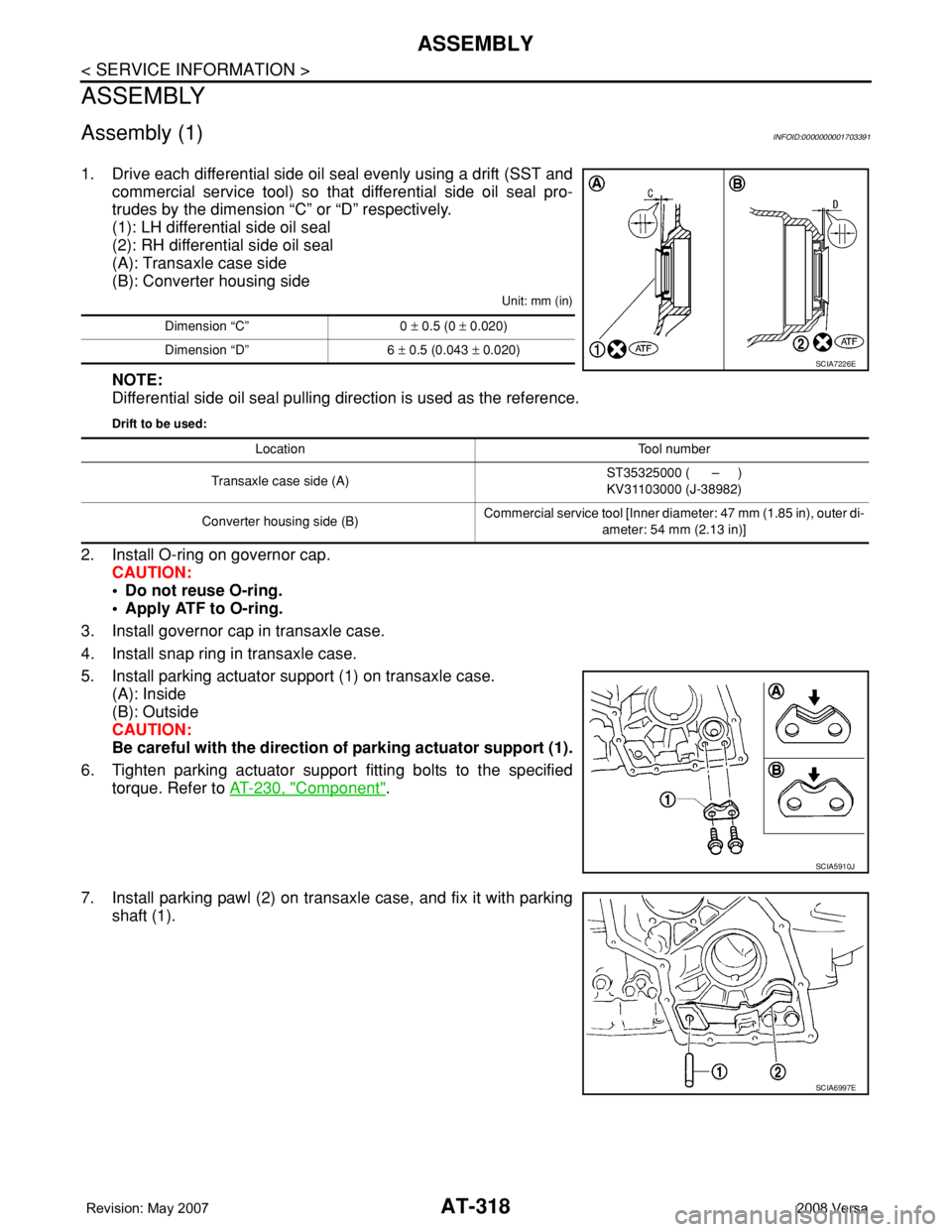

1. Drive each differential side oil seal evenly using a drift (SST and

commercial service tool) so that differential side oil seal pro-

trudes by the dimension “C” or “D” respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

Differential side oil seal pulling direction is used as the reference.

Drift to be used:

2. Install O-ring on governor cap.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case.

(A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support fitting bolts to the specified

torque. Refer to AT-230, "

Component".

7. Install parking pawl (2) on transaxle case, and fix it with parking

shaft (1).

Dimension “C” 0 ± 0.5 (0 ± 0.020)

Dimension “D” 6 ± 0.5 (0.043 ± 0.020)

SCIA7226E

Location Tool number

Transaxle case side (A)ST35325000 ( – )

KV31103000 (J-38982)

Converter housing side (B)Commercial service tool [Inner diameter: 47 mm (1.85 in), outer di-

ameter: 54 mm (2.13 in)]

SCIA5910J

SCIA6997E

Page 348 of 2771

AT-336

< SERVICE INFORMATION >

ASSEMBLY

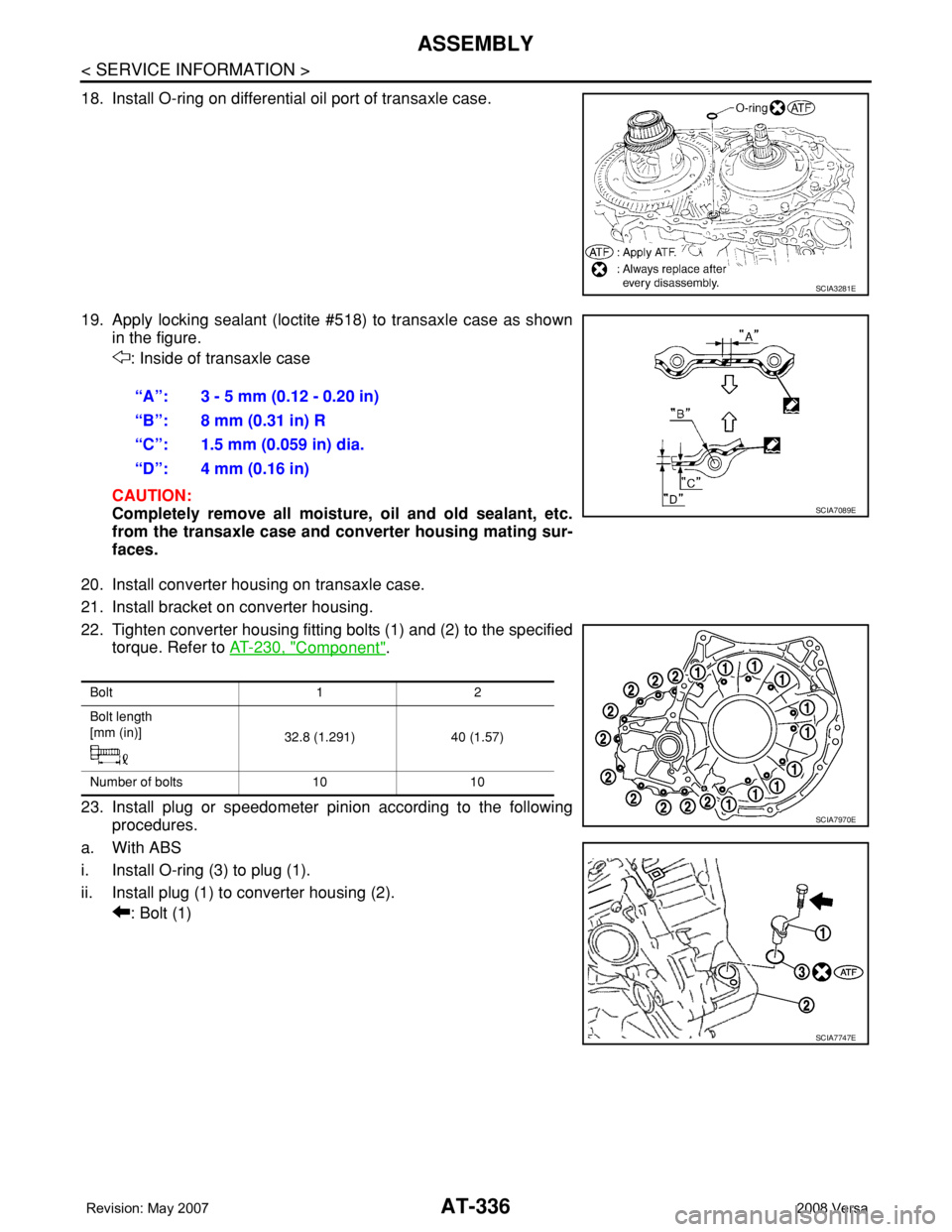

18. Install O-ring on differential oil port of transaxle case.

19. Apply locking sealant (loctite #518) to transaxle case as shown

in the figure.

: Inside of transaxle case

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transaxle case and converter housing mating sur-

faces.

20. Install converter housing on transaxle case.

21. Install bracket on converter housing.

22. Tighten converter housing fitting bolts (1) and (2) to the specified

torque. Refer to AT-230, "

Component".

23. Install plug or speedometer pinion according to the following

procedures.

a. With ABS

i. Install O-ring (3) to plug (1).

ii. Install plug (1) to converter housing (2).

: Bolt (1)

SCIA3281E

“A”: 3 - 5 mm (0.12 - 0.20 in)

“B”: 8 mm (0.31 in) R

“C”: 1.5 mm (0.059 in) dia.

“D”: 4 mm (0.16 in)

SCIA7089E

Bolt 1 2

Bolt length

[mm (in)]

32.8 (1.291) 40 (1.57)

Number of bolts 10 10

SCIA7970E

SCIA7747E