ESP NISSAN TIIDA 2008 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1001 of 2771

CVT-162

< SERVICE INFORMATION >

CVT SHIFT LOCK SYSTEM

CVT SHIFT LOCK SYSTEM

DescriptionINFOID:0000000001703675

• The mechanical key interlock mechanism also operates as a shift lock:

With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside key cylinder, respectively.

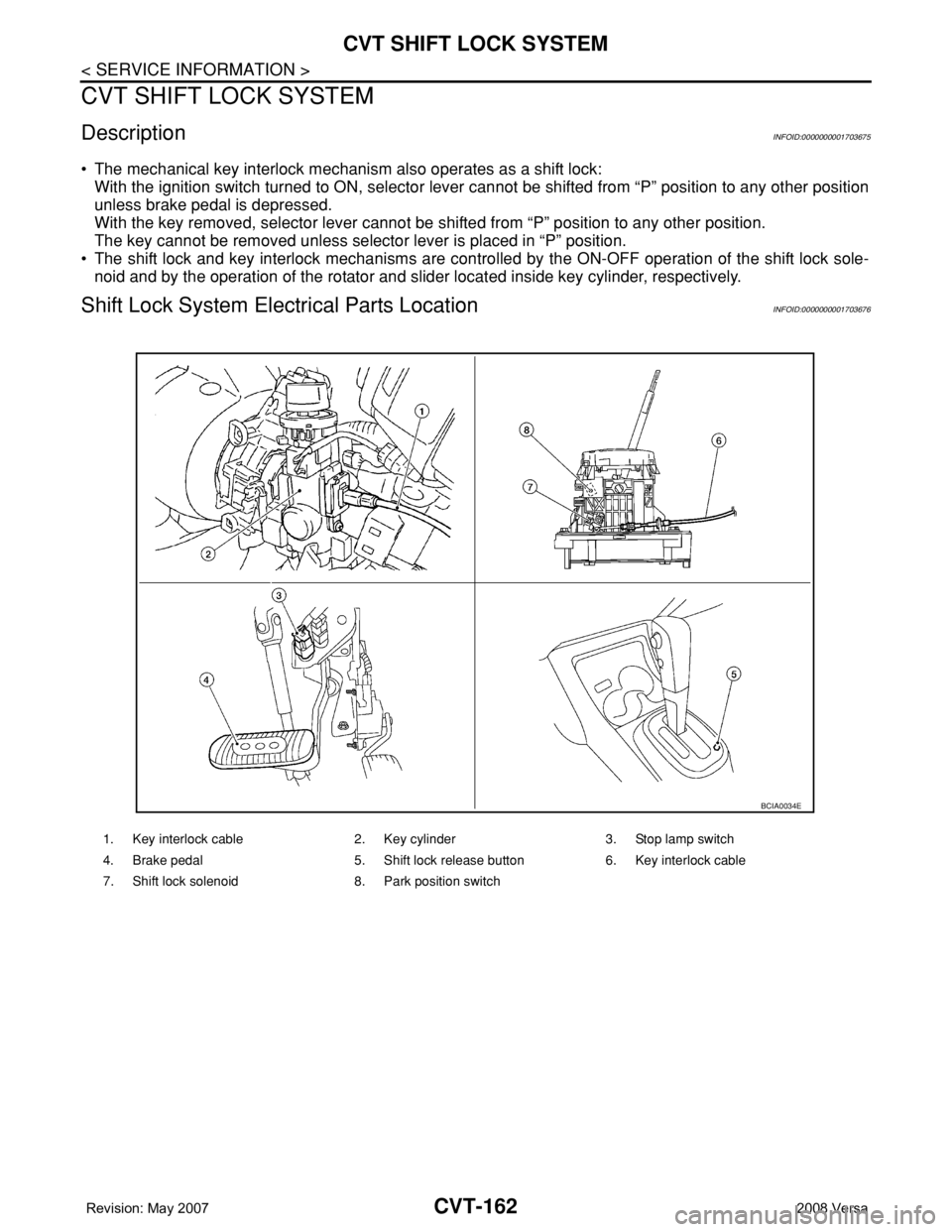

Shift Lock System Electrical Parts LocationINFOID:0000000001703676

1. Key interlock cable 2. Key cylinder 3. Stop lamp switch

4. Brake pedal 5. Shift lock release button 6. Key interlock cable

7. Shift lock solenoid 8. Park position switch

BCIA0034E

Page 1068 of 2771

WARNING CHIME

DI-47

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

1.CHECK BCM

Perform self-diagnosis of BCM. Refer to DI-45, "

CONSULT-III Function (BCM)".

Self

-diagnostic results content

No malfunction detected>>GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK COMBINATION METER

Perform self-diagnosis of combination meter. Refer to DI-13, "

CONSULT-III Function (METER/M&A)".

Self

-diagnostic results content

No malfunction detected>> Inspection End.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

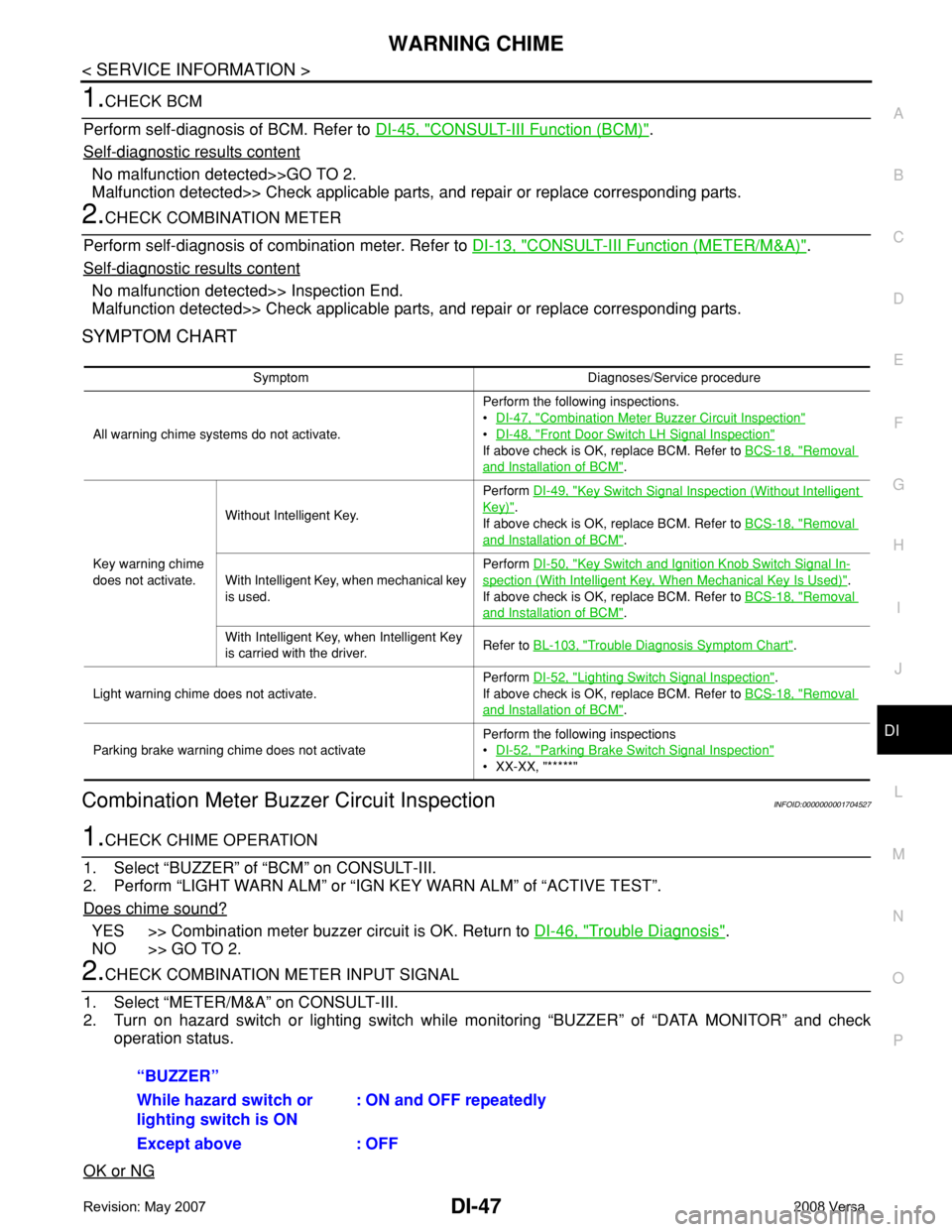

SYMPTOM CHART

Combination Meter Buzzer Circuit InspectionINFOID:0000000001704527

1.CHECK CHIME OPERATION

1. Select “BUZZER” of “BCM” on CONSULT-III.

2. Perform “LIGHT WARN ALM” or “IGN KEY WARN ALM” of “ACTIVE TEST”.

Does chime sound?

YES >> Combination meter buzzer circuit is OK. Return to DI-46, "Trouble Diagnosis".

NO >> GO TO 2.

2.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Turn on hazard switch or lighting switch while monitoring “BUZZER” of “DATA MONITOR” and check

operation status.

OK or NG

Symptom Diagnoses/Service procedure

All warning chime systems do not activate.Perform the following inspections.

•DI-47, "

Combination Meter Buzzer Circuit Inspection"

•DI-48, "Front Door Switch LH Signal Inspection"

If above check is OK, replace BCM. Refer to BCS-18, "Removal

and Installation of BCM".

Key warning chime

does not activate.Without Intelligent Key.Perform DI-49, "

Key Switch Signal Inspection (Without Intelligent

Key)".

If above check is OK, replace BCM. Refer to BCS-18, "

Removal

and Installation of BCM".

With Intelligent Key, when mechanical key

is used.Perform DI-50, "

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical Key Is Used)".

If above check is OK, replace BCM. Refer to BCS-18, "

Removal

and Installation of BCM".

With Intelligent Key, when Intelligent Key

is carried with the driver.Refer to BL-103, "

Trouble Diagnosis Symptom Chart".

Light warning chime does not activate.Perform DI-52, "

Lighting Switch Signal Inspection".

If above check is OK, replace BCM. Refer to BCS-18, "

Removal

and Installation of BCM".

Parking brake warning chime does not activatePerform the following inspections

•DI-52, "

Parking Brake Switch Signal Inspection"

• XX-XX, "*****"

“BUZZER”

While hazard switch or

lighting switch is ON : ON and OFF repeatedly

Except above : OFF

Page 1090 of 2771

EC-16

< SERVICE INFORMATION >

PRECAUTIONS

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001702548

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

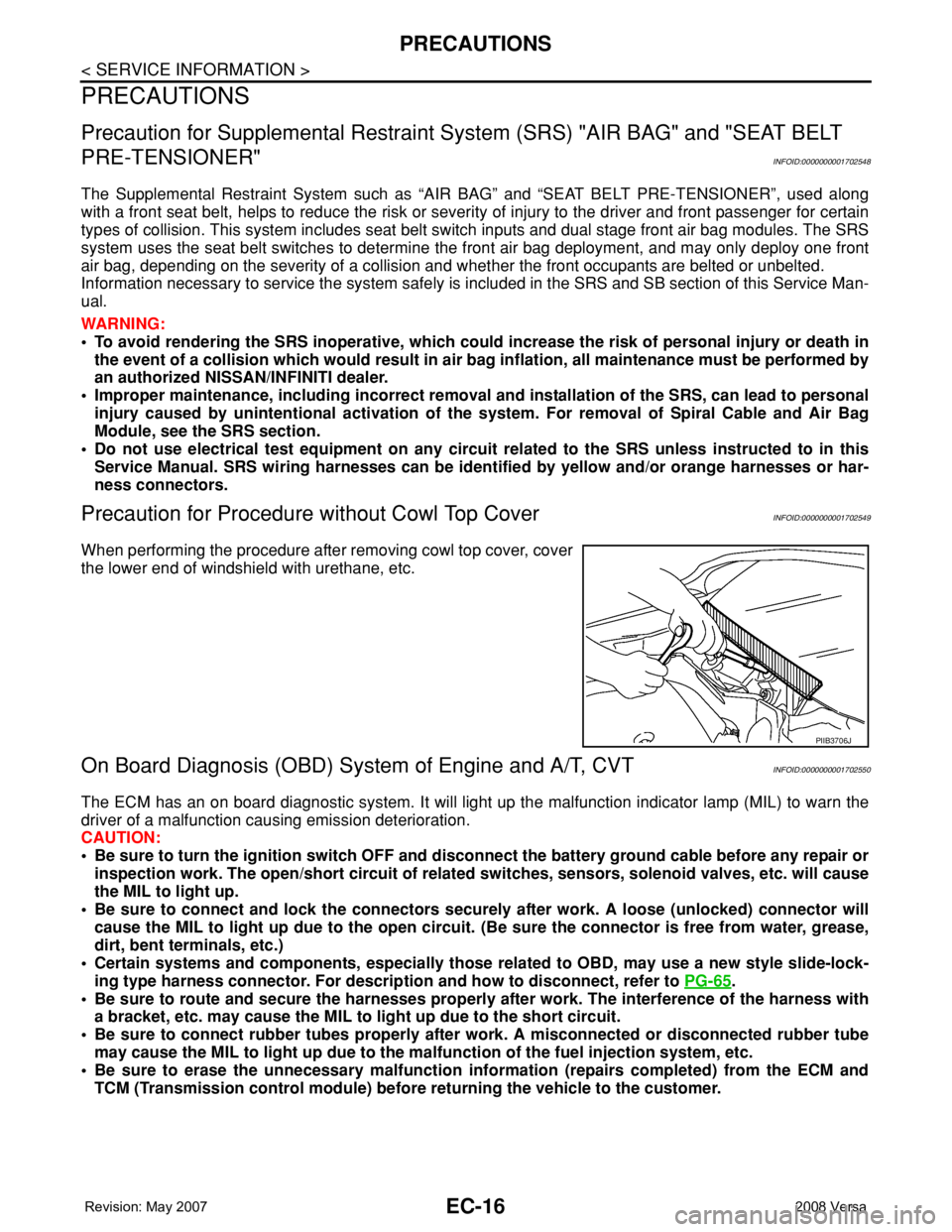

Precaution for Procedure without Cowl Top CoverINFOID:0000000001702549

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnosis (OBD) System of Engine and A/T, CVTINFOID:0000000001702550

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the battery ground cable before any repair or

inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will cause

the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-65

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to light up due to the short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PIIB3706J

Page 1126 of 2771

EC-52

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indicates “CMPLT” for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT indicates “INCMP” for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If MIL is ON during the state emissions inspection, the vehicle is also returned to the customer untested even

though the SRT indicates “CMPLT” for all test items. Therefore, it is important to check SRT (“CMPLT”) and

DTC (No DTCs) before the inspection.

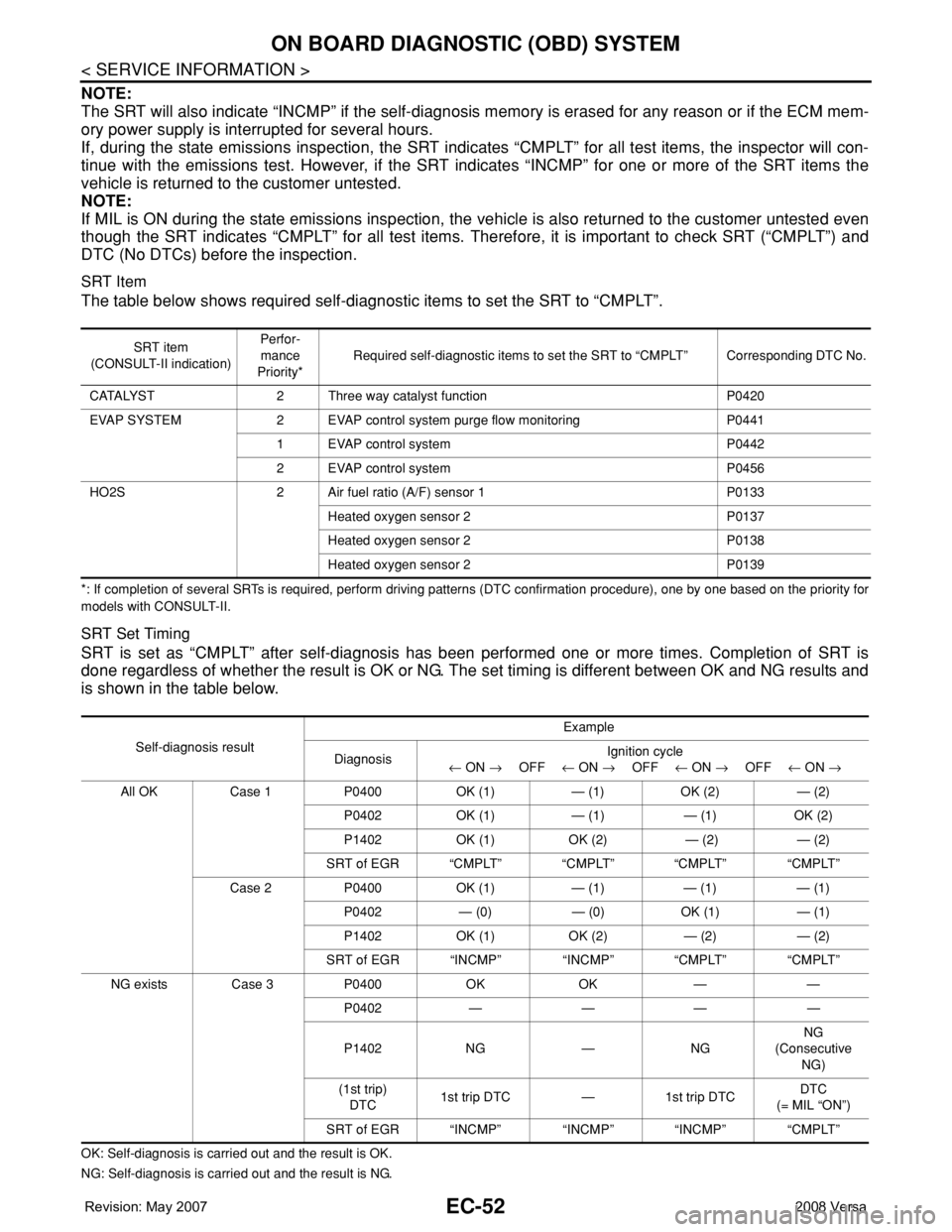

SRT Item

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

*: If completion of several SRTs is required, perform driving patterns (DTC confirmation procedure), one by one based on the priority for

models with CONSULT-II.

SRT Set Timing

SRT is set as “CMPLT” after self-diagnosis has been performed one or more times. Completion of SRT is

done regardless of whether the result is OK or NG. The set timing is different between OK and NG results and

is shown in the table below.

OK: Self-diagnosis is carried out and the result is OK.

NG: Self-diagnosis is carried out and the result is NG.SRT item

(CONSULT-II indication)Perfor-

mance

Priority*Required self-diagnostic items to set the SRT to “CMPLT” Corresponding DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 P0133

Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139

Self-diagnosis resultExample

DiagnosisIgnition cycle

← ON → OFF ← ON → OFF ← ON → OFF ← ON →

All OK Case 1 P0400 OK (1) — (1) OK (2) — (2)

P0402 OK (1) — (1) — (1) OK (2)

P1402 OK (1) OK (2) — (2) — (2)

SRT of EGR “CMPLT” “CMPLT” “CMPLT” “CMPLT”

Case 2 P0400 OK (1) — (1) — (1) — (1)

P0402 — (0) — (0) OK (1) — (1)

P1402 OK (1) OK (2) — (2) — (2)

SRT of EGR “INCMP” “INCMP” “CMPLT” “CMPLT”

NG exists Case 3 P0400 OK OK — —

P0402 — — — —

P1402 NG — NGNG

(Consecutive

NG)

(1st trip)

DTC1st trip DTC — 1st trip DTCDTC

(= MIL “ON”)

SRT of EGR “INCMP” “INCMP” “INCMP” “CMPLT”

Page 1127 of 2771

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-53

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

—: Self-diagnosis is not carried out.

When all SRT related self-diagnoses showed OK results in a single cycle (Ignition OFF-ON-OFF), the SRT will

indicate “CMPLT”. → Case 1 above

When all SRT related self-diagnoses showed OK results through several different cycles, the SRT will indicate

“CMPLT” at the time the respective self-diagnoses have at least one OK result. → Case 2 above

If one or more SRT related self-diagnoses showed NG results in 2 consecutive cycles, the SRT will also indi-

cate “CMPLT”. → Case 3 above

The table above shows that the minimum number of cycles for setting SRT as “INCMP” is one (1) for each

self-diagnosis (Case 1 & 2) or two (2) for one of self-diagnoses (Case 3). However, in preparation for the state

emissions inspection, it is unnecessary for each self-diagnosis to be executed twice (Case 3) for the following

reasons:

• The SRT will indicate “CMPLT” at the time the respective self-diagnoses have one (1) OK result.

• The emissions inspection requires “CMPLT” of the SRT only with OK self-diagnosis results.

• When, during SRT driving pattern, 1st trip DTC (NG) is detected prior to “CMPLT” of SRT, the self-diagnosis

memory must be erased from ECM after repair.

• If the 1st trip DTC is erased, all the SRT will indicate “INCMP”.

NOTE:

SRT can be set as “CMPLT” together with the DTC(s). Therefore, DTC check must always be carried out

prior to the state emission inspection even though the SRT indicates “CMPLT”.

SRT Service Procedure

If a vehicle has failed the state emissions inspection due to one or more SRT items indicating “INCMP”, review

the flowchart diagnostic sequence on the next page.

Page 1129 of 2771

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-55

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

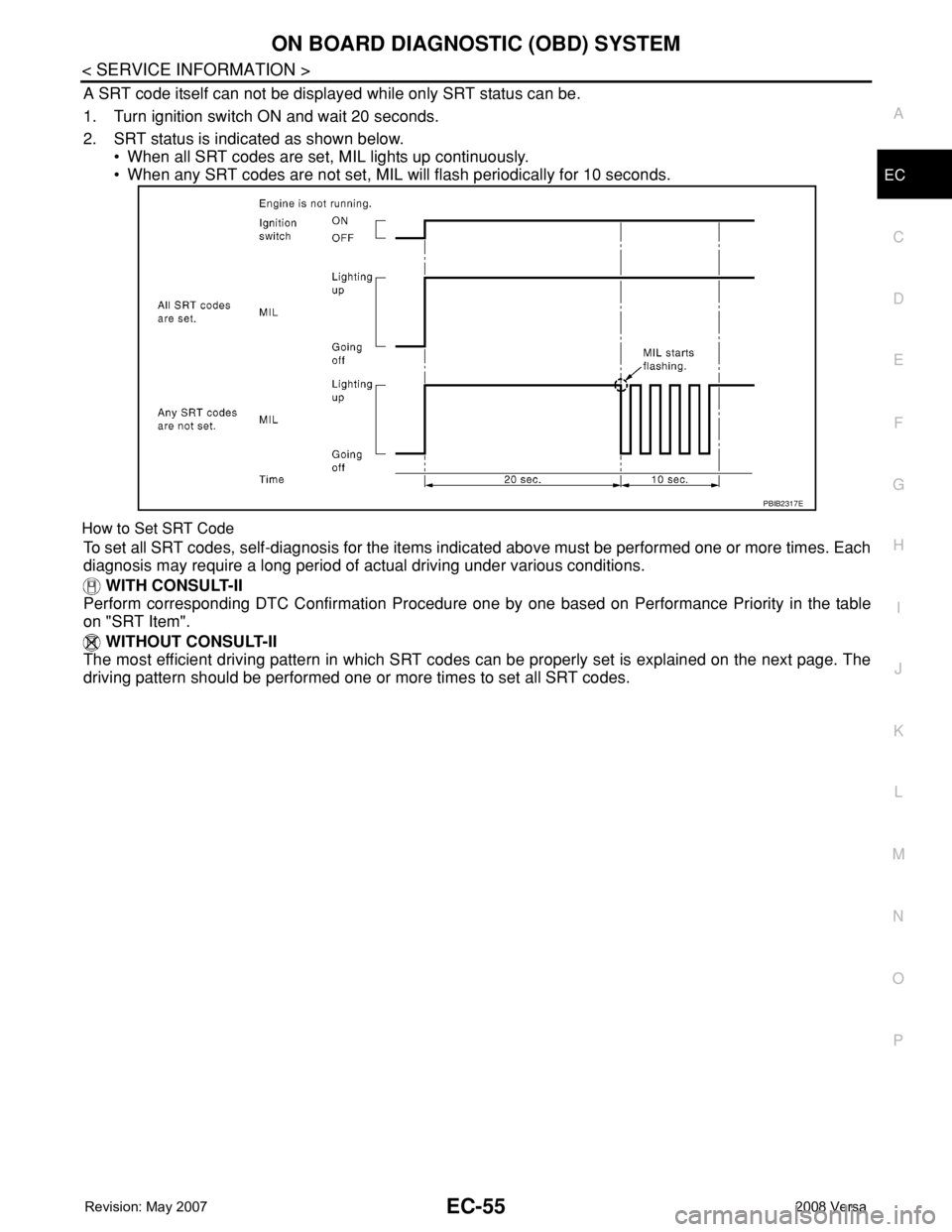

A SRT code itself can not be displayed while only SRT status can be.

1. Turn ignition switch ON and wait 20 seconds.

2. SRT status is indicated as shown below.

• When all SRT codes are set, MIL lights up continuously.

• When any SRT codes are not set, MIL will flash periodically for 10 seconds.

How to Set SRT Code

To set all SRT codes, self-diagnosis for the items indicated above must be performed one or more times. Each

diagnosis may require a long period of actual driving under various conditions.

WITH CONSULT-II

Perform corresponding DTC Confirmation Procedure one by one based on Performance Priority in the table

on "SRT Item".

WITHOUT CONSULT-II

The most efficient driving pattern in which SRT codes can be properly set is explained on the next page. The

driving pattern should be performed one or more times to set all SRT codes.

PBIB2317E

Page 1143 of 2771

BASIC SERVICE PROCEDURE

EC-69

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

BASIC SERVICE PROCEDURE

Basic InspectionINFOID:0000000001702578

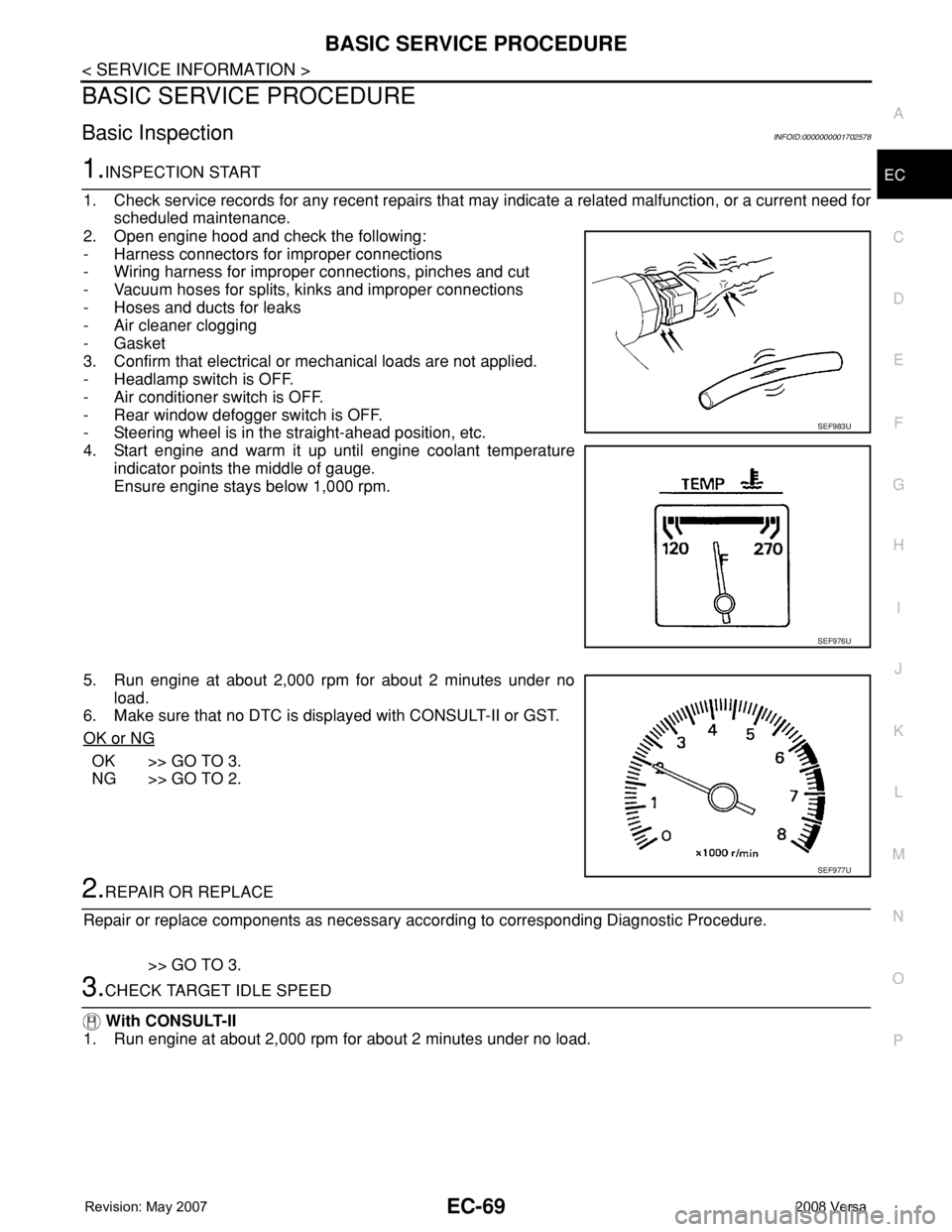

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.CHECK TARGET IDLE SPEED

With CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Page 1155 of 2771

TROUBLE DIAGNOSIS

EC-81

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

TROUBLE DIAGNOSIS

Trouble Diagnosis IntroductionINFOID:0000000001702586

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the incidents. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on "WORK FLOW".

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Diagnostic Worksheet like the example

on "Worksheet Sample" should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

WORK FLOW

MEF036D

SEF233G

SEF234G

Page 1192 of 2771

EC-118

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-II while engine is running may cause the engine to overheat.

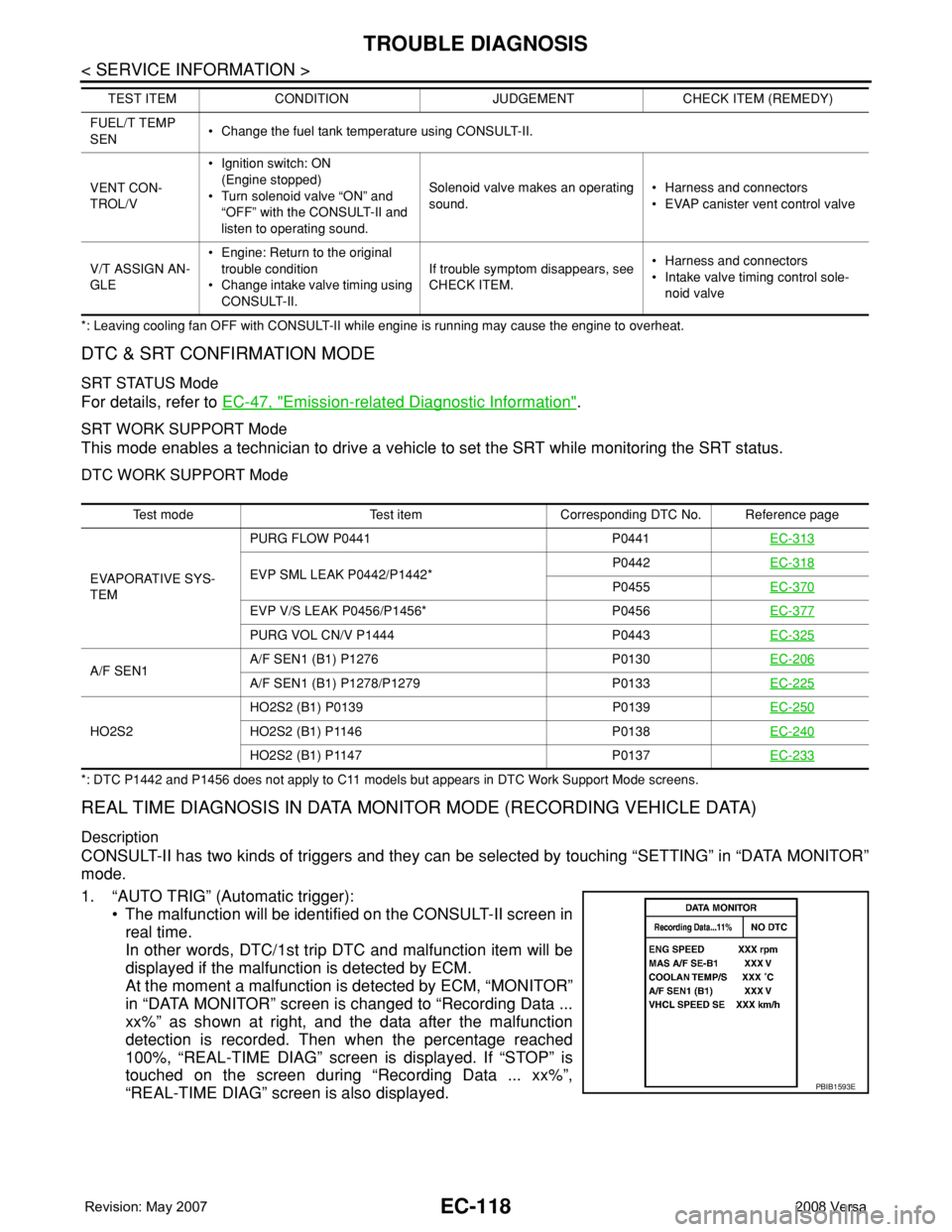

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to EC-47, "Emission-related Diagnostic Information".

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 models but appears in DTC Work Support Mode screens.

REAL TIME DIAGNOSIS IN DATA MONITOR MODE (RECORDING VEHICLE DATA)

Description

CONSULT-II has two kinds of triggers and they can be selected by touching “SETTING” in “DATA MONITOR”

mode.

1. “AUTO TRIG” (Automatic trigger):

• The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC/1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, “MONITOR”

in “DATA MONITOR” screen is changed to “Recording Data ...

xx%” as shown at right, and the data after the malfunction

detection is recorded. Then when the percentage reached

100%, “REAL-TIME DIAG” screen is displayed. If “STOP” is

touched on the screen during “Recording Data ... xx%”,

“REAL-TIME DIAG” screen is also displayed.

FUEL/T TEMP

SEN• Change the fuel tank temperature using CONSULT-II.

VENT CON-

TROL/V•Ignition switch: ON

(Engine stopped)

• Turn solenoid valve “ON” and

“OFF” with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.• Harness and connectors

• EVAP canister vent control valve

V/T ASSIGN AN-

GLE• Engine: Return to the original

trouble condition

• Change intake valve timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Intake valve timing control sole-

noid valve TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

Test mode Test item Corresponding DTC No. Reference page

EVAPORATIVE SYS-

TEMPURG FLOW P0441 P0441EC-313

EVP SML LEAK P0442/P1442*P0442EC-318P0455EC-370

EVP V/S LEAK P0456/P1456* P0456EC-377

PURG VOL CN/V P1444 P0443EC-325

A/F SEN1A/F SEN1 (B1) P1276 P0130EC-206A/F SEN1 (B1) P1278/P1279 P0133EC-225

HO2S2HO2S2 (B1) P0139 P0139EC-250HO2S2 (B1) P1146 P0138EC-240

HO2S2 (B1) P1147 P0137EC-233

PBIB1593E

Page 1193 of 2771

TROUBLE DIAGNOSIS

EC-119

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

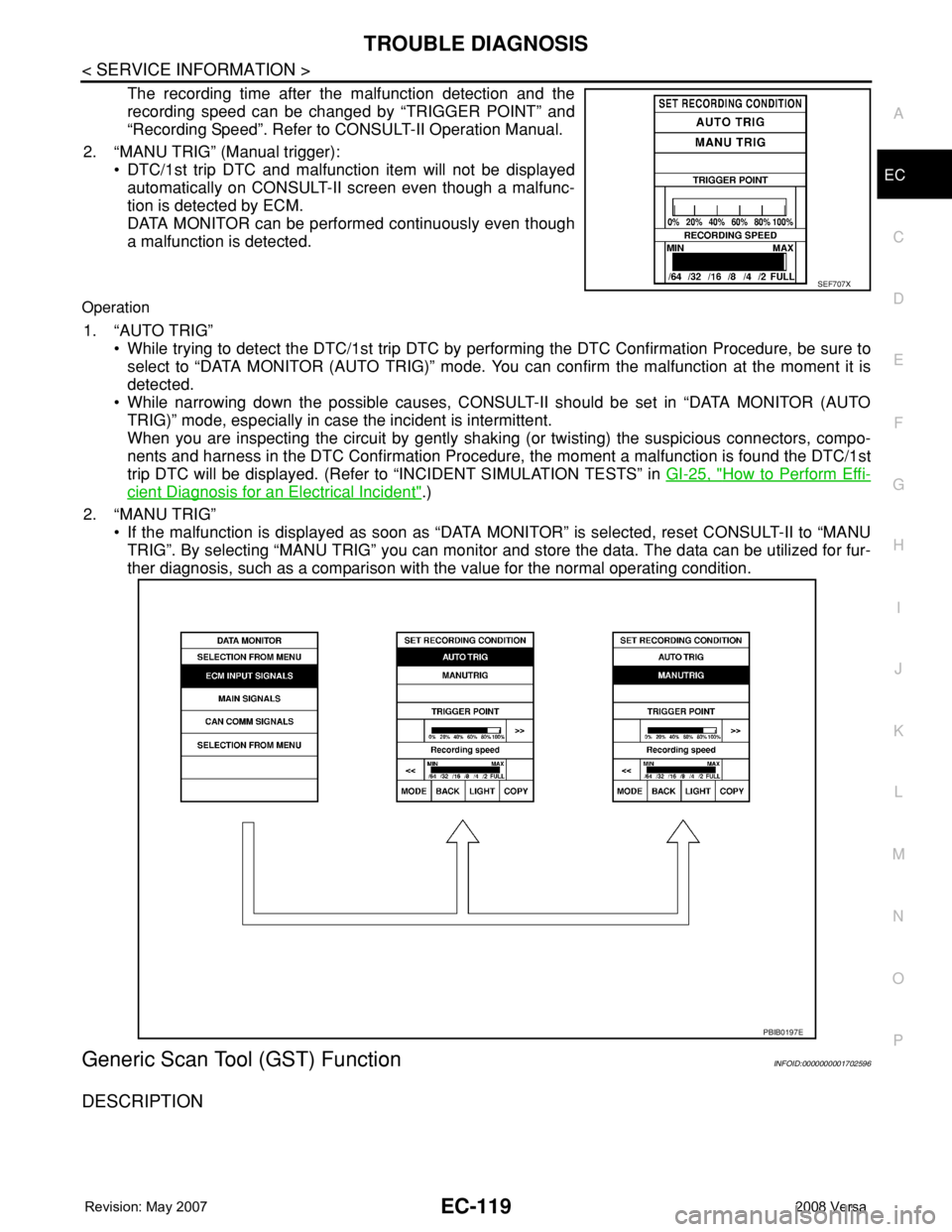

The recording time after the malfunction detection and the

recording speed can be changed by “TRIGGER POINT” and

“Recording Speed”. Refer to CONSULT-II Operation Manual.

2. “MANU TRIG” (Manual trigger):

• DTC/1st trip DTC and malfunction item will not be displayed

automatically on CONSULT-II screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though

a malfunction is detected.

Operation

1. “AUTO TRIG”

• While trying to detect the DTC/1st trip DTC by performing the DTC Confirmation Procedure, be sure to

select to “DATA MONITOR (AUTO TRIG)” mode. You can confirm the malfunction at the moment it is

detected.

• While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, compo-

nents and harness in the DTC Confirmation Procedure, the moment a malfunction is found the DTC/1st

trip DTC will be displayed. (Refer to “INCIDENT SIMULATION TESTS” in GI-25, "

How to Perform Effi-

cient Diagnosis for an Electrical Incident".)

2. “MANU TRIG”

• If the malfunction is displayed as soon as “DATA MONITOR” is selected, reset CONSULT-II to “MANU

TRIG”. By selecting “MANU TRIG” you can monitor and store the data. The data can be utilized for fur-

ther diagnosis, such as a comparison with the value for the normal operating condition.

Generic Scan Tool (GST) FunctionINFOID:0000000001702596

DESCRIPTION

SEF707X

PBIB0197E