150 NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 15 of 2771

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

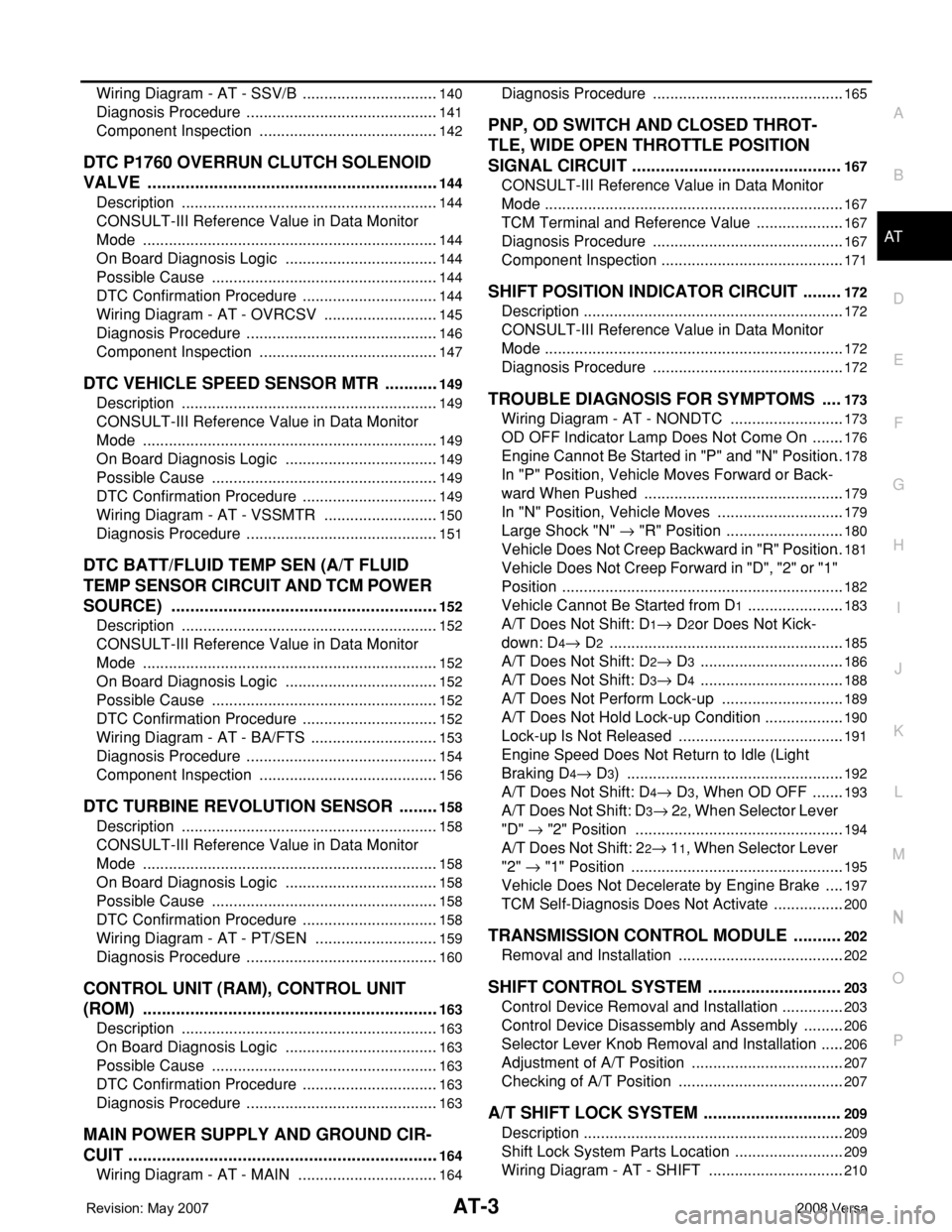

P N Wiring Diagram - AT - SSV/B ................................

140

Diagnosis Procedure .............................................141

Component Inspection ..........................................142

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE ..............................................................

144

Description ............................................................144

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

144

On Board Diagnosis Logic ....................................144

Possible Cause .....................................................144

DTC Confirmation Procedure ................................144

Wiring Diagram - AT - OVRCSV ...........................145

Diagnosis Procedure .............................................146

Component Inspection ..........................................147

DTC VEHICLE SPEED SENSOR MTR ............149

Description ............................................................149

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

149

On Board Diagnosis Logic ....................................149

Possible Cause .....................................................149

DTC Confirmation Procedure ................................149

Wiring Diagram - AT - VSSMTR ...........................150

Diagnosis Procedure .............................................151

DTC BATT/FLUID TEMP SEN (A/T FLUID

TEMP SENSOR CIRCUIT AND TCM POWER

SOURCE) .........................................................

152

Description ............................................................152

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

152

On Board Diagnosis Logic ....................................152

Possible Cause .....................................................152

DTC Confirmation Procedure ................................152

Wiring Diagram - AT - BA/FTS ..............................153

Diagnosis Procedure .............................................154

Component Inspection ..........................................156

DTC TURBINE REVOLUTION SENSOR .........158

Description ............................................................158

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

158

On Board Diagnosis Logic ....................................158

Possible Cause .....................................................158

DTC Confirmation Procedure ................................158

Wiring Diagram - AT - PT/SEN .............................159

Diagnosis Procedure .............................................160

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

163

Description ............................................................163

On Board Diagnosis Logic ....................................163

Possible Cause .....................................................163

DTC Confirmation Procedure ................................163

Diagnosis Procedure .............................................163

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

164

Wiring Diagram - AT - MAIN .................................164

Diagnosis Procedure .............................................165

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT ............................................

167

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

167

TCM Terminal and Reference Value .....................167

Diagnosis Procedure .............................................167

Component Inspection ...........................................171

SHIFT POSITION INDICATOR CIRCUIT ........172

Description .............................................................172

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

172

Diagnosis Procedure .............................................172

TROUBLE DIAGNOSIS FOR SYMPTOMS ....173

Wiring Diagram - AT - NONDTC ...........................173

OD OFF Indicator Lamp Does Not Come On ........176

Engine Cannot Be Started in "P" and "N" Position ..178

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

179

In "N" Position, Vehicle Moves ..............................179

Large Shock "N" → "R" Position ............................180

Vehicle Does Not Creep Backward in "R" Position ..181

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ..................................................................

182

Vehicle Cannot Be Started from D1 .......................183

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 .......................................................185

A/T Does Not Shift: D2→ D3 ..................................186

A/T Does Not Shift: D3→ D4 ..................................188

A/T Does Not Perform Lock-up .............................189

A/T Does Not Hold Lock-up Condition ...................190

Lock-up Is Not Released .......................................191

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................192

A/T Does Not Shift: D4→ D3, When OD OFF ........193

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

194

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

195

Vehicle Does Not Decelerate by Engine Brake .....197

TCM Self-Diagnosis Does Not Activate .................200

TRANSMISSION CONTROL MODULE ..........202

Removal and Installation .......................................202

SHIFT CONTROL SYSTEM ............................203

Control Device Removal and Installation ...............203

Control Device Disassembly and Assembly ..........206

Selector Lever Knob Removal and Installation ......206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................209

Description .............................................................209

Shift Lock System Parts Location ..........................209

Wiring Diagram - AT - SHIFT ................................210

Page 17 of 2771

INDEX FOR DTC

AT-5

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000001703149

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 3

.

*1: These numbers is prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.

DTC No. IndexINFOID:0000000001703150

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 3

.

Items

(CONSULT-III screen terms)DTC

Reference page

CONSULT-III or GST

*1

A/T 1ST GR FNCTN P0731AT-105

A/T 2ND GR FNCTN P0732AT-108

A/T 3RD GR FNCTN P0733AT- 111

A/T 4TH GR FNCTN P0734AT- 11 4

A/T TCC S/V FNCTN P0744AT-124

ATF TEMP SEN/CIRC P0710AT- 9 1

BATT/FLUID TEMP SEN —AT-152

CAN COMM CIRCUIT U1000AT- 8 3

CONTROL UNIT (RAM) —AT-163

CONTROL UNIT (ROM) —AT-163

ENGINE SPEED SIG P0725AT-101

LINE PRESSURE S/V P0745AT-129

OVERRUN CLUTCH S/V P1760AT-144

PNP SW/CIRC P0705AT- 8 6

SHIFT SOLENOID/V A*2P0750AT-134

SHIFT SOLENOID/V B*2P0755AT-139

T/C CLUTCH SOL/V P0740AT- 11 9

TURBINE SENSOR —AT-158

VHCL SPEED SEN-A/T*3P0720AT- 9 6

VHCL SPEED SEN-MTR —AT-149

DTC

Items

(CONSULT-III screen terms) Reference page

CONSULT-III or GST

*1

P0705 PNP SW/CIRCAT- 8 6

P0710 ATF TEMP SEN/CIRCAT- 9 1

P0720

VHCL SPEED SEN-A/T*3AT- 9 6

P0725 ENGINE SPEED SIGAT- 1 0 1

P0731 A/T 1ST GR FNCTNAT- 1 0 5

Page 73 of 2771

TROUBLE DIAGNOSIS

AT-61

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

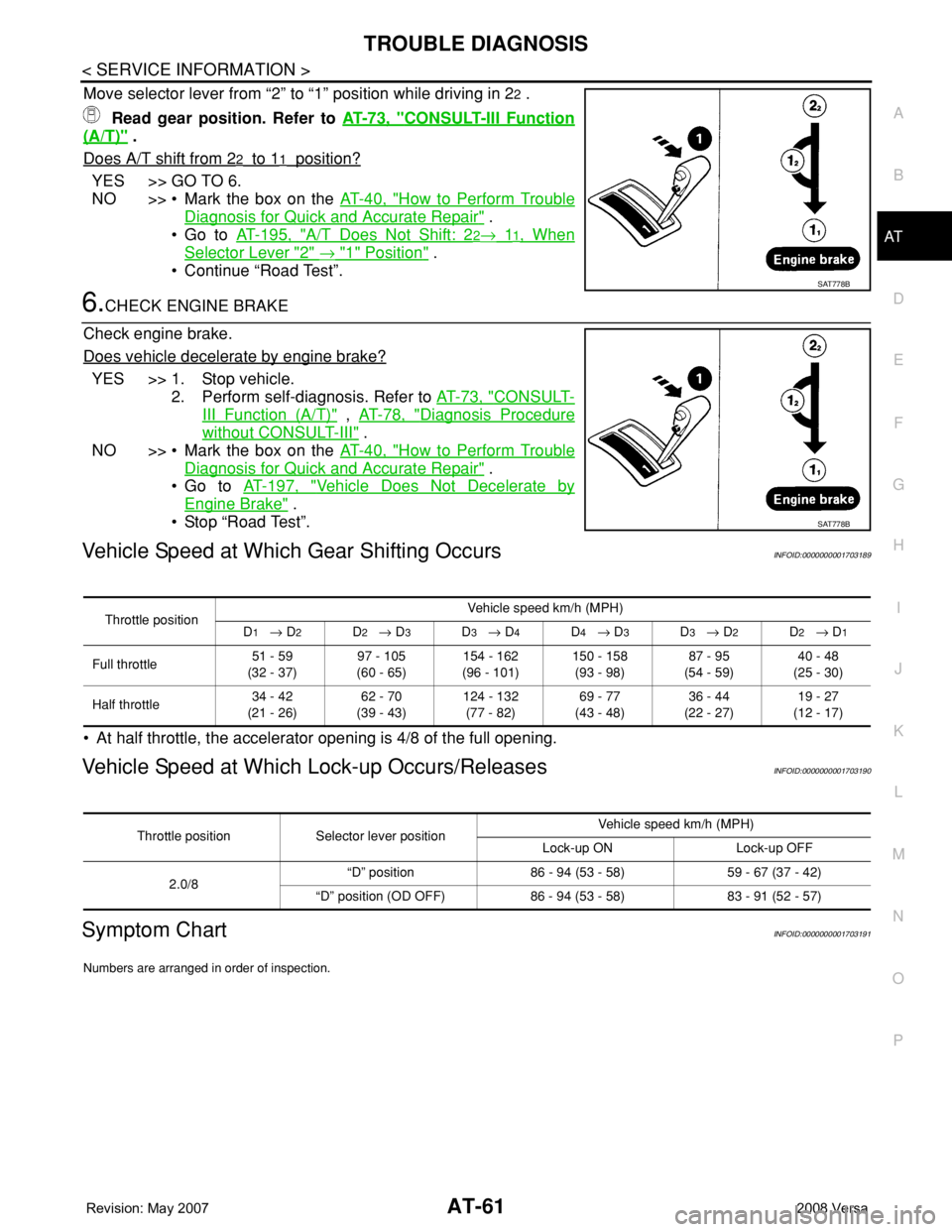

Move selector lever from “2” to “1” position while driving in 22 .

Read gear position. Refer to AT-73, "

CONSULT-III Function

(A/T)" .

Does A/T shift from 2

2 to 11 position?

YES >> GO TO 6.

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-195, "

A/T Does Not Shift: 22→ 11, When

Selector Lever "2" → "1" Position" .

• Continue “Road Test”.

6.CHECK ENGINE BRAKE

Check engine brake.

Does vehicle decelerate by engine brake?

YES >> 1. Stop vehicle.

2. Perform self-diagnosis. Refer to AT-73, "

CONSULT-

III Function (A/T)" , AT-78, "Diagnosis Procedure

without CONSULT-III" .

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-197, "

Vehicle Does Not Decelerate by

Engine Brake" .

• Stop “Road Test”.

Vehicle Speed at Which Gear Shifting OccursINFOID:0000000001703189

• At half throttle, the accelerator opening is 4/8 of the full opening.

Vehicle Speed at Which Lock-up Occurs/ReleasesINFOID:0000000001703190

Symptom ChartINFOID:0000000001703191

Numbers are arranged in order of inspection.

SAT778B

SAT778B

Throttle positionVehicle speed km/h (MPH)

D1 → D2D2 → D3D3 → D4D4 → D3D3 → D2D2 → D1

Full throttle51 - 59

(32 - 37)97 - 105

(60 - 65)154 - 162

(96 - 101)150 - 158

(93 - 98)87 - 95

(54 - 59)40 - 48

(25 - 30)

Half throttle34 - 42

(21 - 26)62 - 70

(39 - 43)124 - 132

(77 - 82)69 - 77

(43 - 48)36 - 44

(22 - 27)19 - 27

(12 - 17)

Throttle position Selector lever positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

2.0/8“D” position 86 - 94 (53 - 58) 59 - 67 (37 - 42)

“D” position (OD OFF) 86 - 94 (53 - 58) 83 - 91 (52 - 57)

Page 84 of 2771

AT-72

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

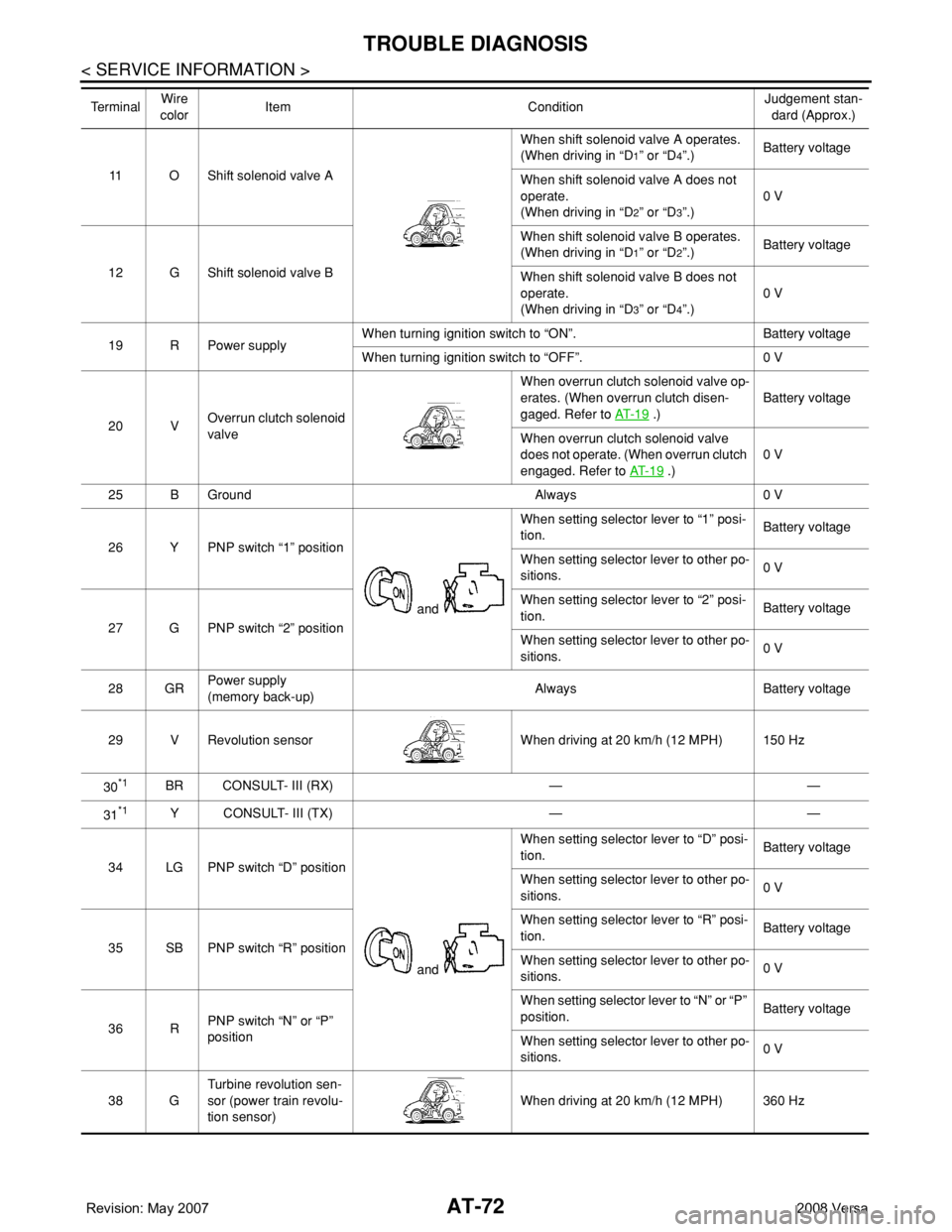

11 O Shift solenoid valve AWhen shift solenoid valve A operates.

(When driving in “D

1” or “D4”.)Battery voltage

When shift solenoid valve A does not

operate.

(When driving in “D

2” or “D3”.)0 V

12 G Shift solenoid valve BWhen shift solenoid valve B operates.

(When driving in “D

1” or “D2”.)Battery voltage

When shift solenoid valve B does not

operate.

(When driving in “D

3” or “D4”.)0 V

19 R Power supplyWhen turning ignition switch to “ON”. Battery voltage

When turning ignition switch to “OFF”. 0 V

20 VOverrun clutch solenoid

valveWhen overrun clutch solenoid valve op-

erates. (When overrun clutch disen-

gaged. Refer to AT- 1 9

.)Battery voltage

When overrun clutch solenoid valve

does not operate. (When overrun clutch

engaged. Refer to AT- 1 9

.)0 V

25 B Ground Always 0 V

26 Y PNP switch “1” position

and When setting selector lever to “1” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

27 G PNP switch “2” positionWhen setting selector lever to “2” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

28 GRPower supply

(memory back-up)Always Battery voltage

29 V Revolution sensor When driving at 20 km/h (12 MPH) 150 Hz

30

*1BR CONSULT- III (RX) — —

31

*1Y CONSULT- III (TX) — —

34 LG PNP switch “D” position

and When setting selector lever to “D” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

35 SB PNP switch “R” positionWhen setting selector lever to “R” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

36 RPNP switch “N” or “P”

positionWhen setting selector lever to “N” or “P”

position.Battery voltage

When setting selector lever to other po-

sitions.0 V

38 GTurbine revolution sen-

sor (power train revolu-

tion sensor)When driving at 20 km/h (12 MPH) 360 Hz Te r m i n a lWire

colorItem ConditionJudgement stan-

dard (Approx.)

Page 110 of 2771

AT-98

< SERVICE INFORMATION >

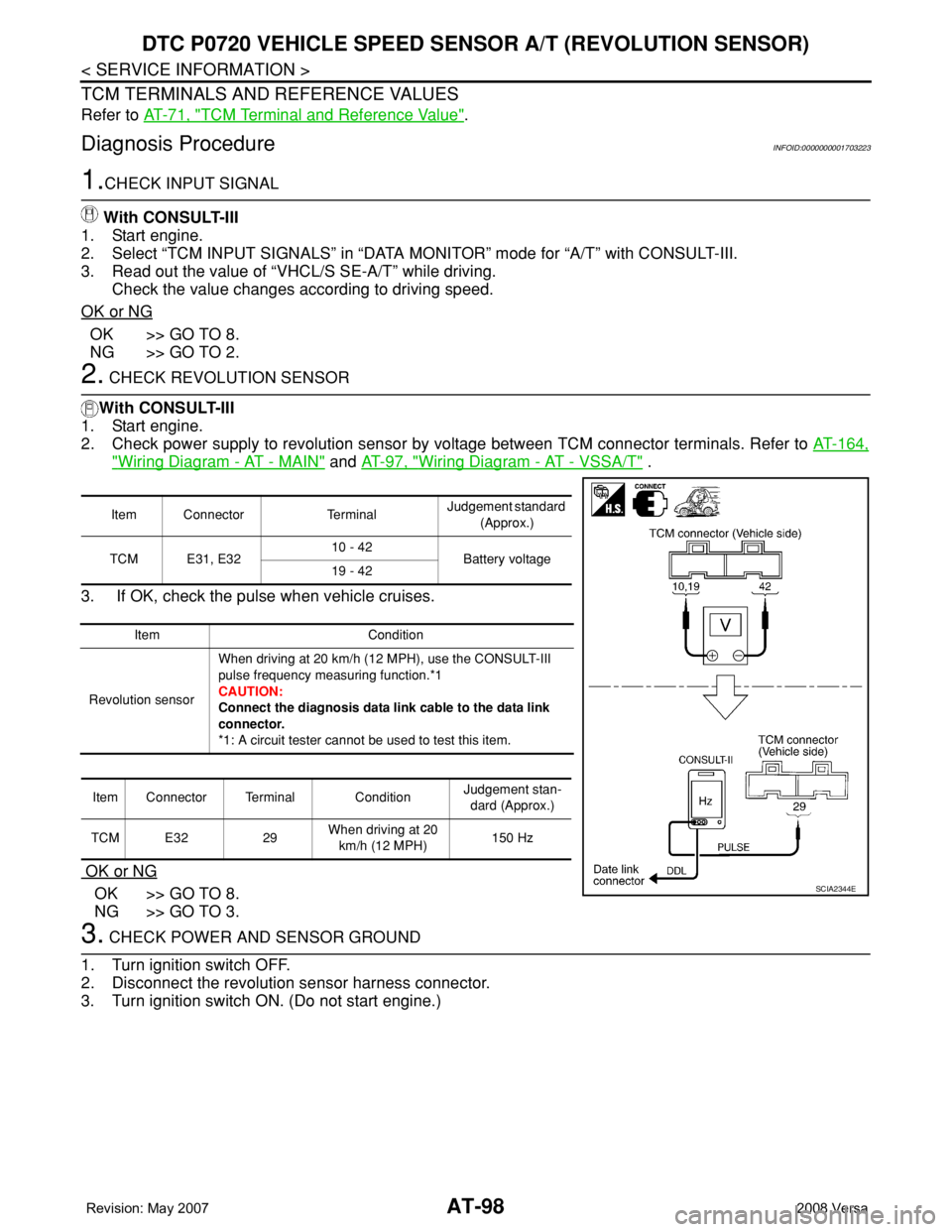

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-71, "TCM Terminal and Reference Value".

Diagnosis ProcedureINFOID:0000000001703223

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Read out the value of “VHCL/S SE-A/T” while driving.

Check the value changes according to driving speed.

OK or NG

OK >> GO TO 8.

NG >> GO TO 2.

2. CHECK REVOLUTION SENSOR

With CONSULT-III

1. Start engine.

2. Check power supply to revolution sensor by voltage between TCM connector terminals. Refer to AT-164,

"Wiring Diagram - AT - MAIN" and AT-97, "Wiring Diagram - AT - VSSA/T" .

3. If OK, check the pulse when vehicle cruises.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3. CHECK POWER AND SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect the revolution sensor harness connector.

3. Turn ignition switch ON. (Do not start engine.)

Item Connector TerminalJudgement standard

(Approx.)

TCM E31, E3210 - 42

Battery voltage

19 - 42

Item Condition

Revolution sensorWhen driving at 20 km/h (12 MPH), use the CONSULT-III

pulse frequency measuring function.*1

CAUTION:

Connect the diagnosis data link cable to the data link

connector.

*1: A circuit tester cannot be used to test this item.

Item Connector Terminal ConditionJudgement stan-

dard (Approx.)

TCM E32 29When driving at 20

km/h (12 MPH)150 Hz

SCIA2344E

Page 162 of 2771

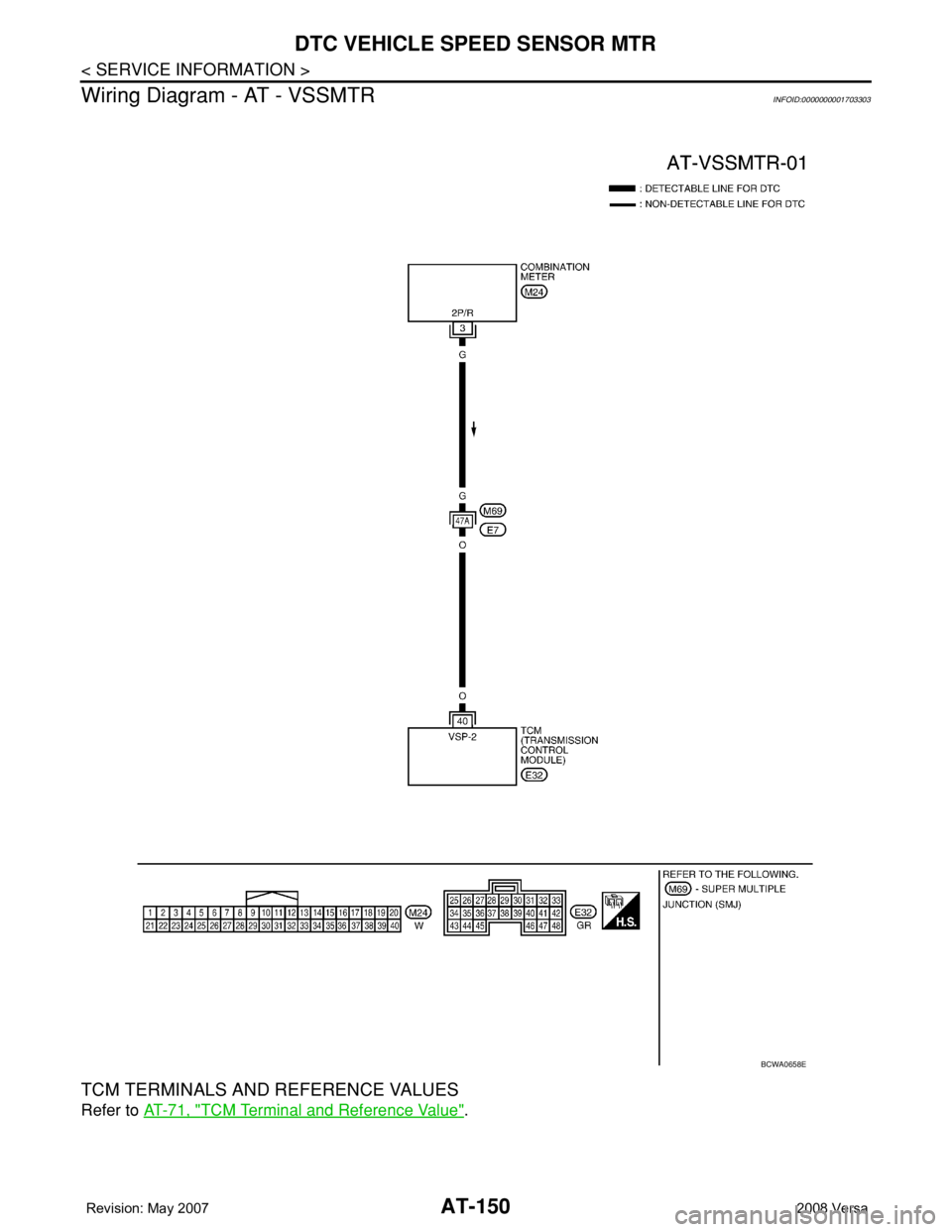

AT-150

< SERVICE INFORMATION >

DTC VEHICLE SPEED SENSOR MTR

Wiring Diagram - AT - VSSMTR

INFOID:0000000001703303

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-71, "TCM Terminal and Reference Value".

BCWA0658E

Page 229 of 2771

ON-VEHICLE SERVICE

AT-217

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

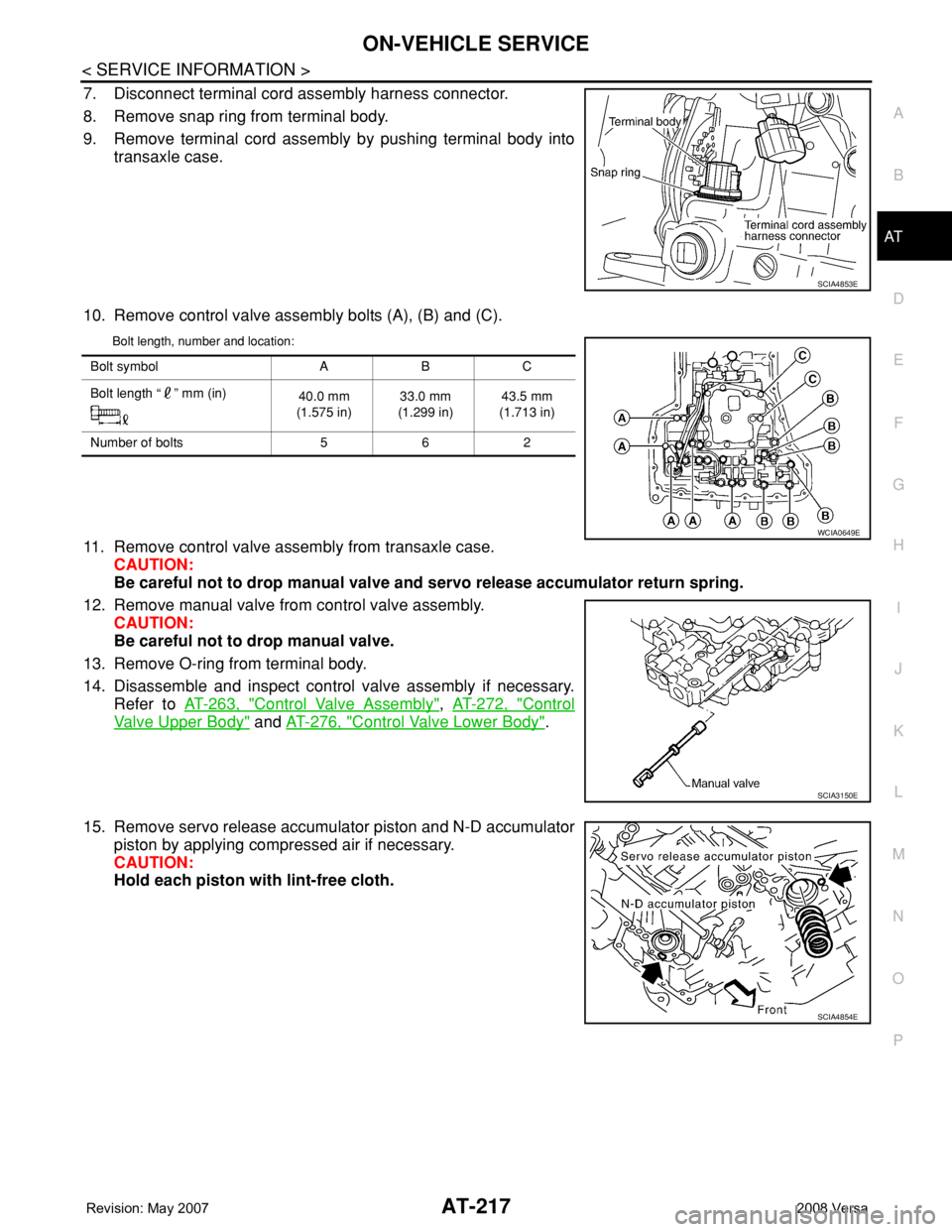

7. Disconnect terminal cord assembly harness connector.

8. Remove snap ring from terminal body.

9. Remove terminal cord assembly by pushing terminal body into

transaxle case.

10. Remove control valve assembly bolts (A), (B) and (C).

Bolt length, number and location:

11. Remove control valve assembly from transaxle case.

CAUTION:

Be careful not to drop manual valve and servo release accumulator return spring.

12. Remove manual valve from control valve assembly.

CAUTION:

Be careful not to drop manual valve.

13. Remove O-ring from terminal body.

14. Disassemble and inspect control valve assembly if necessary.

Refer to AT-263, "

Control Valve Assembly", AT-272, "Control

Valve Upper Body" and AT-276, "Control Valve Lower Body".

15. Remove servo release accumulator piston and N-D accumulator

piston by applying compressed air if necessary.

CAUTION:

Hold each piston with lint-free cloth.

SCIA4853E

Bolt symbol A B C

Bolt length “ ” mm (in)

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

WCIA0649E

SCIA3150E

SCIA4854E

Page 255 of 2771

DISASSEMBLY

AT-243

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

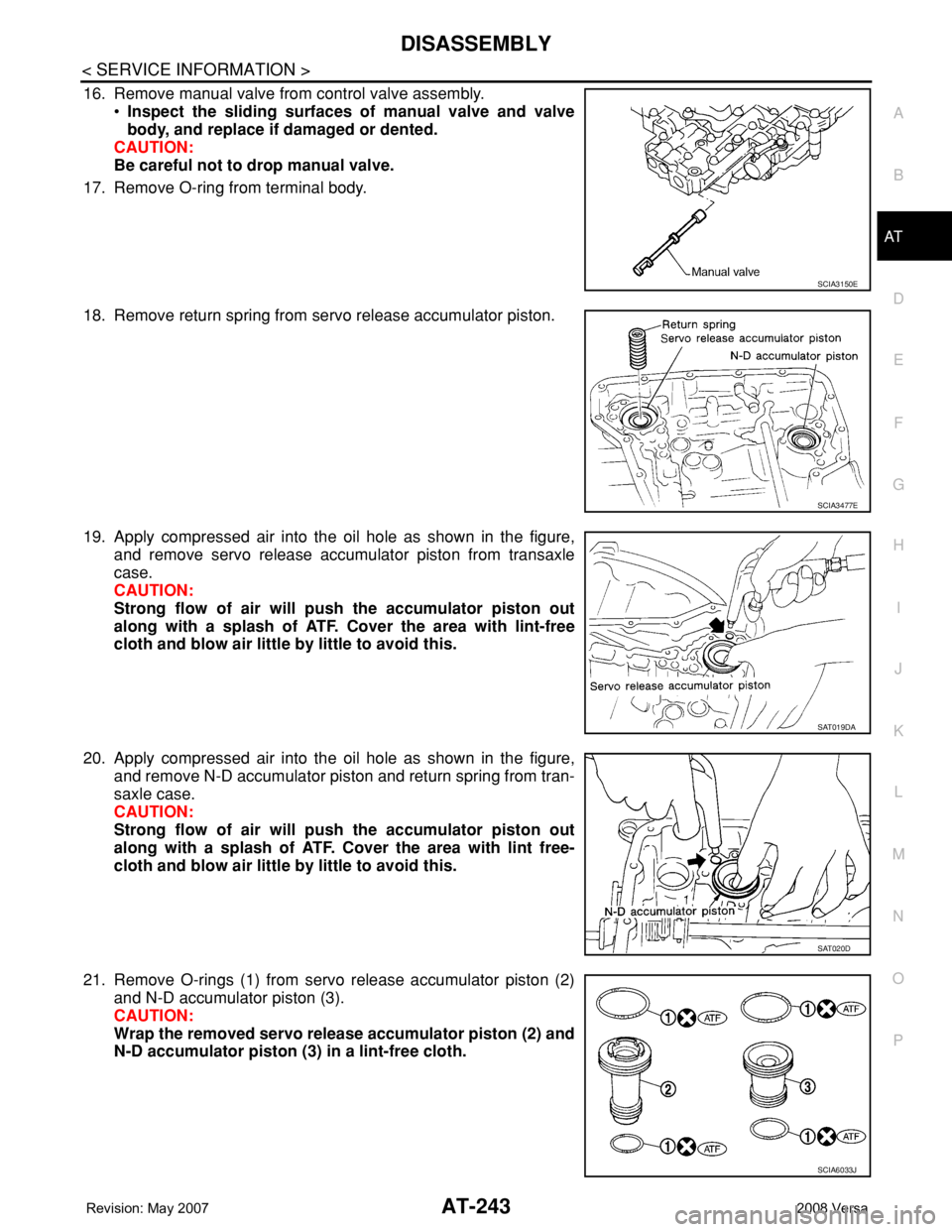

16. Remove manual valve from control valve assembly.

•Inspect the sliding surfaces of manual valve and valve

body, and replace if damaged or dented.

CAUTION:

Be careful not to drop manual valve.

17. Remove O-ring from terminal body.

18. Remove return spring from servo release accumulator piston.

19. Apply compressed air into the oil hole as shown in the figure,

and remove servo release accumulator piston from transaxle

case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. Cover the area with lint-free

cloth and blow air little by little to avoid this.

20. Apply compressed air into the oil hole as shown in the figure,

and remove N-D accumulator piston and return spring from tran-

saxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. Cover the area with lint free-

cloth and blow air little by little to avoid this.

21. Remove O-rings (1) from servo release accumulator piston (2)

and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo release accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth.

SCIA3150E

SCIA3477E

SAT019DA

SAT020D

SCIA6033J

Page 353 of 2771

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-341

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000001703396

*: Refer to MA-10.

Vehicle Speed at Which Gear Shifting OccursINFOID:0000000001703397

• At half throttle, the accelerator opening is 4/8 of the full opening.

Vehicle Speed at When Lock-up Occurs/ReleasesINFOID:0000000001703398

Stall SpeedINFOID:0000000001703399

Line PressureINFOID:0000000001703400

Adjusting shims, Needle Bearings, Thrust Washers and Snap RingsINFOID:0000000001703401

NOTE:

EngineMR18DE

Automatic transaxle model RE4F03B

Automatic transaxle assembly Model code number 3CX0D

Transaxle gear ratio1st 2.861

2nd 1.562

3rd 1.000

4th 0.697

Reverse 2.310

Final drive 4.072

Recommended fluidGenuine NISSAN Matic D ATF (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid*

Fluid capacity [ (US qt, Imp qt)]7.9 (8-3/8, 7)

Throttle positionVehicle speed km/h (MPH)

D1 → D2D2 → D3D3 → D4D4 → D3D3 → D2D2 → D1

Full throttle51 - 59

(32 - 37)97 - 105

(60 - 65)154 - 162

(96 - 101)150 - 158

(93 - 98)87 - 95

(54 - 59)40 - 48

(25 - 30)

Half throttle34 - 42

(21 - 26)62 - 70

(39 - 43)124 - 132

(77 - 82)69 - 77

(43 - 48)36 - 44

(22 - 27)19 - 27

(12 - 17)

Throttle position Selector lever positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

2.0/8“D” position 86 - 94 (53 - 58) 59 - 67 (37 - 42)

“D” position (OD OFF) 86 - 94 (53 - 58) 83 - 91 (52 - 57)

Stall revolution (rpm)2,310 - 2,770

Engine speedLine pressure kPa (kg/cm2, psi)

“D”, “2” and “1” positions “R” position

Idle speed 500 (5.1, 73) 778 (7.9, 113)

Stall speed 1,173 (12.0, 170) 1,825 (18.6, 265)

Page 359 of 2771

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-347

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

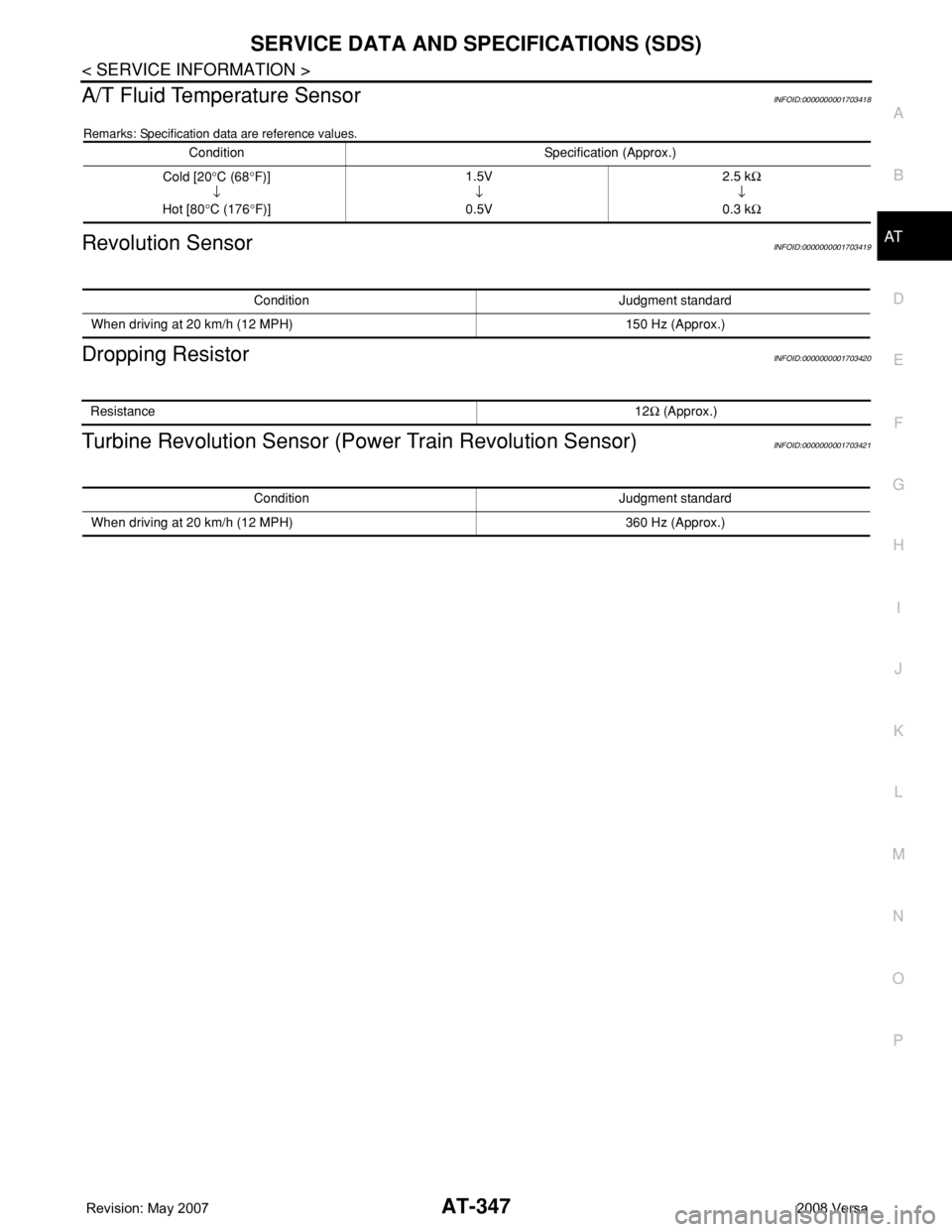

A/T Fluid Temperature SensorINFOID:0000000001703418

Remarks: Specification data are reference values.

Revolution SensorINFOID:0000000001703419

Dropping ResistorINFOID:0000000001703420

Turbine Revolution Sensor (Power Train Revolution Sensor)INFOID:0000000001703421

Condition Specification (Approx.)

Cold [20°C (68°F)]

↓

Hot [80°C (176°F)]1.5V

↓

0.5V2.5 kΩ

↓

0.3 kΩ

Condition Judgment standard

When driving at 20 km/h (12 MPH) 150 Hz (Approx.)

Resistance12Ω (Approx.)

Condition Judgment standard

When driving at 20 km/h (12 MPH) 360 Hz (Approx.)