roof rack NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 416 of 2771

TELEPHONE

AV-57

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

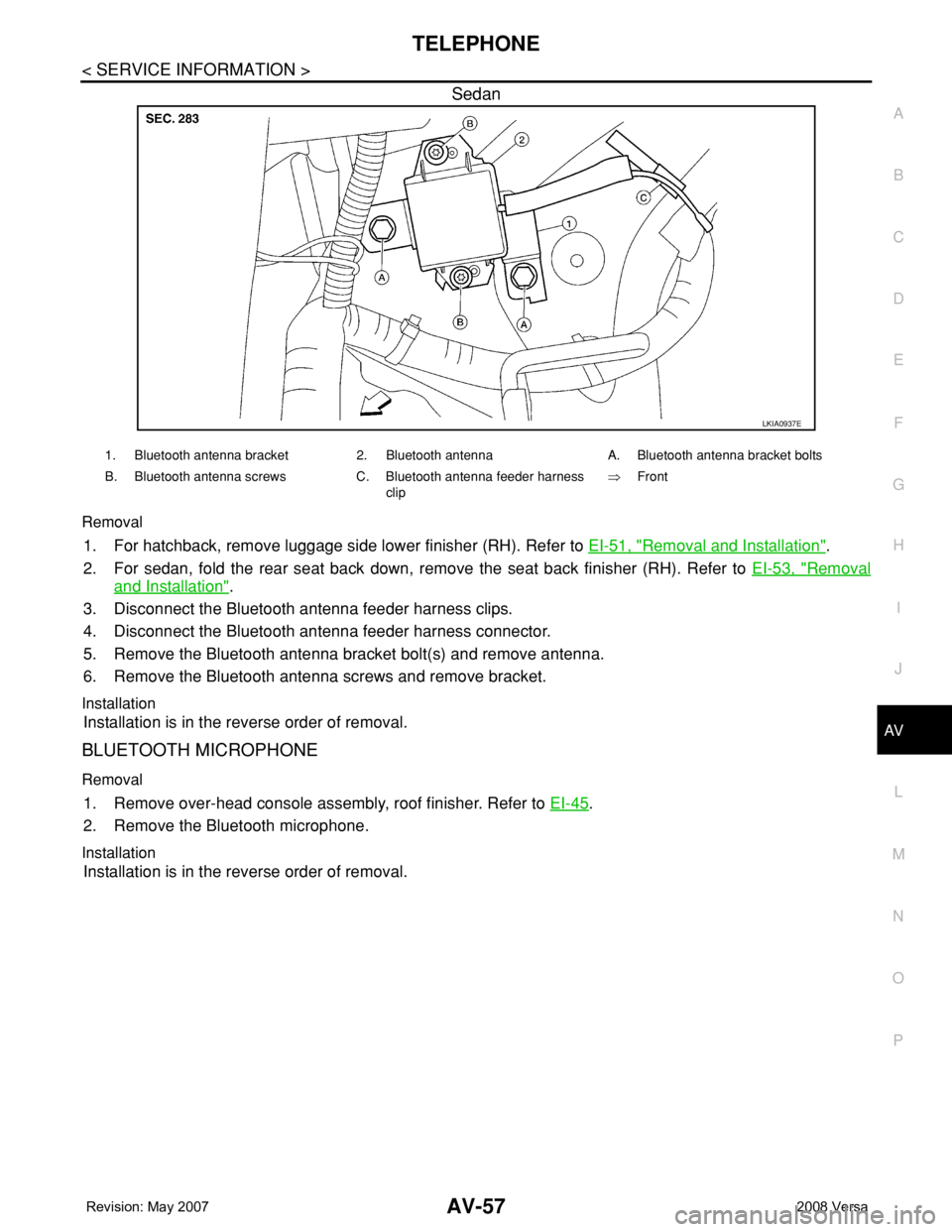

Sedan

Removal

1. For hatchback, remove luggage side lower finisher (RH). Refer to EI-51, "Removal and Installation".

2. For sedan, fold the rear seat back down, remove the seat back finisher (RH). Refer to EI-53, "

Removal

and Installation".

3. Disconnect the Bluetooth antenna feeder harness clips.

4. Disconnect the Bluetooth antenna feeder harness connector.

5. Remove the Bluetooth antenna bracket bolt(s) and remove antenna.

6. Remove the Bluetooth antenna screws and remove bracket.

Installation

Installation is in the reverse order of removal.

BLUETOOTH MICROPHONE

Removal

1. Remove over-head console assembly, roof finisher. Refer to EI-45.

2. Remove the Bluetooth microphone.

Installation

Installation is in the reverse order of removal.

LKIA0937E

1. Bluetooth antenna bracket 2. Bluetooth antenna A. Bluetooth antenna bracket bolts

B. Bluetooth antenna screws C. Bluetooth antenna feeder harness

clip⇒Front

Page 444 of 2771

BL-10

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 664 of 2771

BL-230

< SERVICE INFORMATION >

BODY REPAIR

6. 1st roof rail assembly

7. Front roof rail assembly

8. Sun roof assembly

9. Front roof rail assembly (if equipped with sunroof)

10. Roof side rail reinforcement (RH & LH)

11. Inner center pillar (RH & LH)

12. Hood assembly

13. Center pillar reinforcement (RH & LH)

14. Front pillar inner (RH & LH)

15. Front pillar upper reinforcement (RH & LH)

16. Front pillar lower reinforcement (RH & LH)

17. Fender (RH & LH)

18. Side body (RH & LH)

19. Side body assembly (RH & LH)

20. Outer sill (RH & LH)

21. Outer sill reinforcement (RH & LH)

22. Front door assembly (RH & LH)

23. Outer front door panel (RH & LH)

24. Outer rear door panel (RH & LH)

25. Rear door assembly (RH & LH)

26. Rear fender (RH & LH)

27. Rear fender assembly (RH & LH)

28. Rear fender corner (RH & LH)

29. Rear fender extension (RH & LH)

30. Rear combination lamp base (RH & LH)

31. Rear pillar inner reinforcement (RH & LH)

32. Rear wheel housing outer (RH & LH)

33. Rear wheel housing inner (RH & LH)

34. Rear spring base assembly (RH & LH)

35. Rear seatback hinge bracket (RH & LH)

36. Rear seatback catch bracket (RH & LH)

37. Rear pillar inner (RH & LH)

38. Rear roof rail reinforcement (RH & LH)

39. Rear roof rail brace (RH & LH)

40. Rear panel

41. Rear bumper fascia lower bracket

42. Rear bumper fascia upper bracket

43. Rear bumper fascia center bracket

44. Rear panel assembly

45. Back door assembly

Page 666 of 2771

BL-232

< SERVICE INFORMATION >

BODY REPAIR

7. Front roof rail assembly

8. Sun roof assembly

9. Front roof rail assembly (if equipped with sunroof)

10. Roof side rail reinforcement (RH & LH)

11. Inner center pillar (RH & LH)

12. Hood assembly

13. Center pillar reinforcement (RH & LH)

14. Front pillar inner (RH & LH)

15. Front pillar upper reinforcement (RH & LH)

16. Front pillar lower reinforcement (RH & LH)

17. Fender (RH & LH)

18. Side body (RH & LH)

19. Side body assembly (RH & LH)

20. Outer sill (RH & LH)

21. Outer sill reinforcement (RH & LH)

22. Front door assembly (RH & LH)

23. Outer front door panel (RH & LH)

24. Outer rear door panel (RH & LH)

25. Rear door assembly (RH & LH)

26. Rear fender (RH & LH)

27. Rear fender corner (RH & LH)

28. Rear combination lamp base (RH & LH)

29. Rear wheel housing front extension (RH & LH)

30. Rear wheel housing outer (RH & LH)

31. Rear pillar inner reinforcement (RH & LH)

32. Rear body side inner (RH & LH)

33. Rear wheel housing inner (RH & LH)

34. Rear panel assembly

35. Rear bumper fascia upper bracket

36. Rear bumper fascia center bracket

37. Trunk lid assembly

38. Parcel shelf side (RH & LH)

39. Parcel shelf assembly

40. Rear waist panel

41. Rear bumper fascia lower bracket

Corrosion ProtectionINFOID:0000000001704120

DESCRIPTION

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

Page 1631 of 2771

EI-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1824 of 2771

FL-4

< SERVICE INFORMATION >

FUEL SYSTEM

FUEL SYSTEM

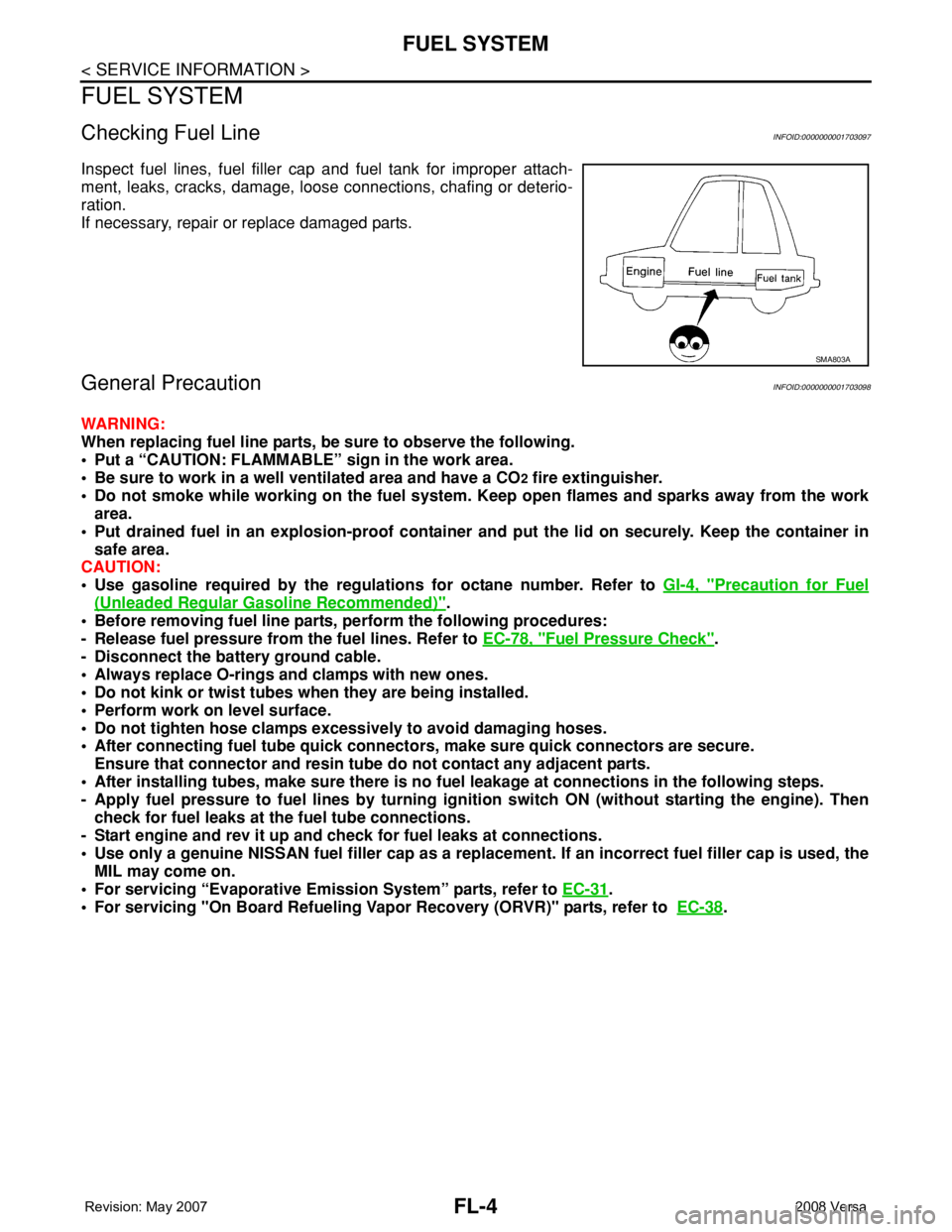

Checking Fuel LineINFOID:0000000001703097

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General PrecautionINFOID:0000000001703098

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the work area.

• Be sure to work in a well ventilated area and have a CO

2 fire extinguisher.

• Do not smoke while working on the fuel system. Keep open flames and sparks away from the work

area.

• Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

CAUTION:

• Use gasoline required by the regulations for octane number. Refer to GI-4, "

Precaution for Fuel

(Unleaded Regular Gasoline Recommended)".

• Before removing fuel line parts, perform the following procedures:

- Release fuel pressure from the fuel lines. Refer to EC-78, "

Fuel Pressure Check".

- Disconnect the battery ground cable.

• Always replace O-rings and clamps with new ones.

• Do not kink or twist tubes when they are being installed.

• Perform work on level surface.

• Do not tighten hose clamps excessively to avoid damaging hoses.

• After connecting fuel tube quick connectors, make sure quick connectors are secure.

Ensure that connector and resin tube do not contact any adjacent parts.

• After installing tubes, make sure there is no fuel leakage at connections in the following steps.

- Apply fuel pressure to fuel lines by turning ignition switch ON (without starting the engine). Then

check for fuel leaks at the fuel tube connections.

- Start engine and rev it up and check for fuel leaks at connections.

• Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the

MIL may come on.

• For servicing “Evaporative Emission System” parts, refer to EC-31

.

• For servicing "On Board Refueling Vapor Recovery (ORVR)" parts, refer to EC-38

.

SMA803A

Page 1909 of 2771

GW-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1917 of 2771

GW-16

< SERVICE INFORMATION >

REAR WINDOW GLASS AND MOLDING

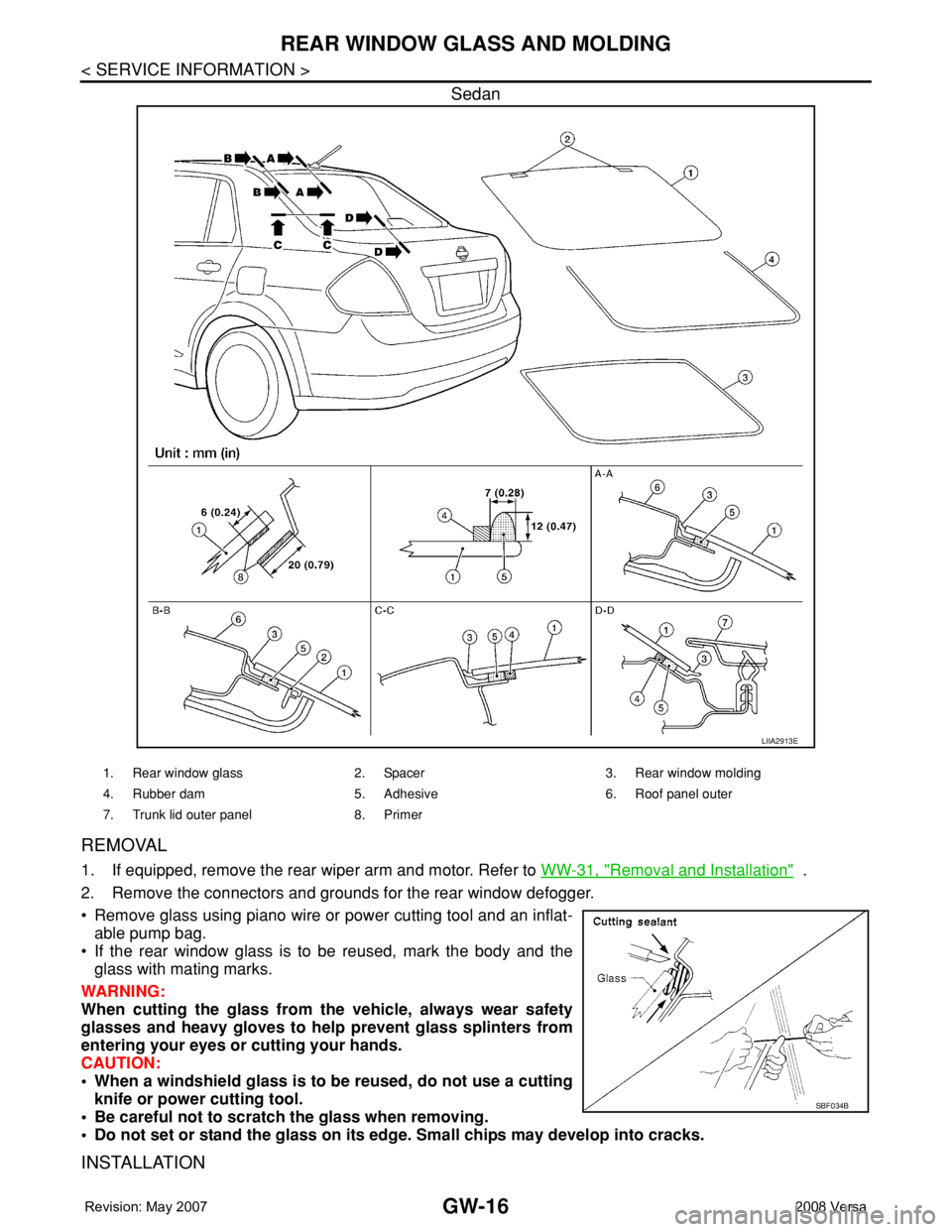

Sedan

REMOVAL

1. If equipped, remove the rear wiper arm and motor. Refer to WW-31, "Removal and Installation" .

2. Remove the connectors and grounds for the rear window defogger.

• Remove glass using piano wire or power cutting tool and an inflat-

able pump bag.

• If the rear window glass is to be reused, mark the body and the

glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

• When a windshield glass is to be reused, do not use a cutting

knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

LIIA2913E

1. Rear window glass 2. Spacer 3. Rear window molding

4. Rubber dam 5. Adhesive 6. Roof panel outer

7. Trunk lid outer panel 8. Primer

SBF034B

Page 1973 of 2771

SQUEAK AND RATTLE TROUBLE DIAGNOSES

IP-7

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2537 of 2771

SQUEAK AND RATTLE TROUBLE DIAGNOSES

RF-7

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

RF

N

O

P

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.