fuel pressure NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 42 of 2771

AT-30

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

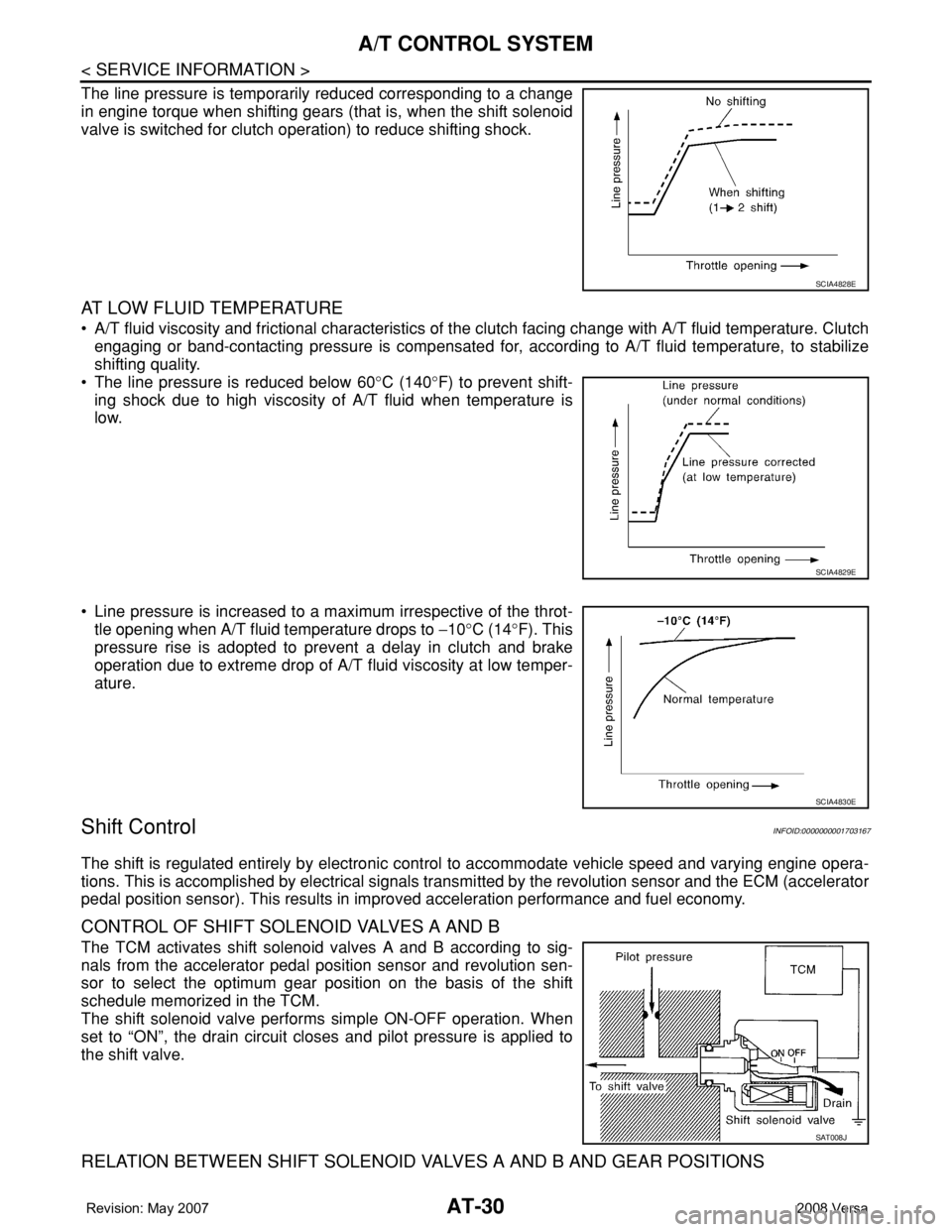

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE

• A/T fluid viscosity and frictional characteristics of the clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

• The line pressure is reduced below 60°C (140°F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

• Line pressure is increased to a maximum irrespective of the throt-

tle opening when A/T fluid temperature drops to −10°C (14°F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift ControlINFOID:0000000001703167

The shift is regulated entirely by electronic control to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals transmitted by the revolution sensor and the ECM (accelerator

pedal position sensor). This results in improved acceleration performance and fuel economy.

CONTROL OF SHIFT SOLENOID VALVES A AND B

The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and revolution sen-

sor to select the optimum gear position on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS

SCIA4828E

SCIA4829E

SCIA4830E

SAT008J

Page 1022 of 2771

DI-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION DI

A

B

DI

N

O

P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION ............................2

PRECAUTION .....................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Commercial Service Tool ..........................................3

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ............................................................................

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ............11

CONSULT-III Function (METER/M&A) ...................13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit .............19

Electrical Component Inspection .............................19

Removal and Installation .........................................20

WARNING LAMPS .............................................21

Schematic ................................................................21

Wiring Diagram - WARN - .......................................22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) ..............................................................

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ..........................................

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Wiring Diagram - CVTIND - .....................................38

CVT Indicator Does Not Illuminate ..........................39

WARNING CHIME .............................................41

Component Parts and Harness Connector Loca-

tion ...........................................................................

41

System Description ..................................................41

Wiring Diagram - CHIME - .......................................44

Terminal and Reference Value for BCM ..................45

CONSULT-III Function (BCM) .................................45

Trouble Diagnosis ....................................................46

Combination Meter Buzzer Circuit Inspection .........47

Front Door Switch LH Signal Inspection ..................48

Key Switch Signal Inspection (Without Intelligent

Key) .........................................................................

49

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ............................................................

50

Lighting Switch Signal Inspection ............................52

Parking Brake Switch Signal Inspection ..................52

Electrical Component Inspection .............................53

Page 1034 of 2771

COMBINATION METERS

DI-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

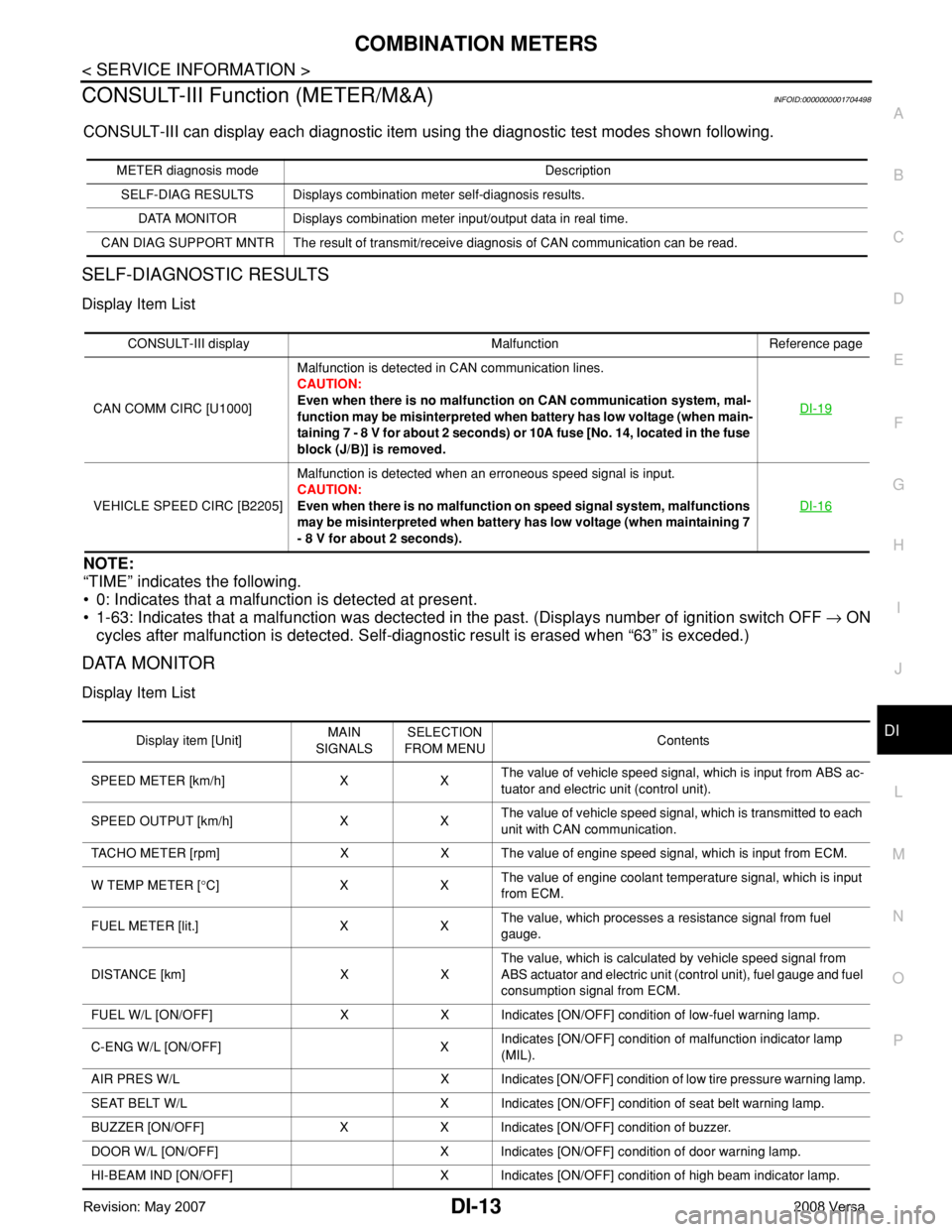

CONSULT-III Function (METER/M&A)INFOID:0000000001704498

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List

NOTE:

“TIME” indicates the following.

• 0: Indicates that a malfunction is detected at present.

• 1-63: Indicates that a malfunction was dectected in the past. (Displays number of ignition switch OFF → ON

cycles after malfunction is detected. Self-diagnostic result is erased when “63” is exceded.)

DATA MONITOR

Display Item List

METER diagnosis mode Description

SELF-DIAG RESULTS Displays combination meter self-diagnosis results.

DATA MONITOR Displays combination meter input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

CONSULT-III display Malfunction Reference page

CAN COMM CIRC [U1000]Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunction on CAN communication system, mal-

function may be misinterpreted when battery has low voltage (when main-

taining 7 - 8 V for about 2 seconds) or 10A fuse [No. 14, located in the fuse

block (J/B)] is removed.DI-19

VEHICLE SPEED CIRC [B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunctions

may be misinterpreted when battery has low voltage (when maintaining 7

- 8 V for about 2 seconds).DI-16

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUContents

SPEED METER [km/h] X XThe value of vehicle speed signal, which is input from ABS ac-

tuator and electric unit (control unit).

SPEED OUTPUT [km/h] X XThe value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] X X The value of engine speed signal, which is input from ECM.

W TEMP METER [°C] X XThe value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] X XThe value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] X XThe value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and fuel

consumption signal from ECM.

FUEL W/L [ON/OFF] X X Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] XIndicates [ON/OFF] condition of malfunction indicator lamp

(MIL).

AIR PRES W/L X Indicates [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Indicates [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicates [ON/OFF] condition of high beam indicator lamp.

Page 1075 of 2771

EC-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

N

O

P

CONTENTS

ENGINE CONTROL SYSTEM

SERVICE INFORMATION ............................9

INDEX FOR DTC .................................................9

DTC No. Index ..........................................................9

Alphabetical Index ...................................................12

PRECAUTIONS ..................................................16

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

16

Precaution for Procedure without Cowl Top Cover ....16

On Board Diagnosis (OBD) System of Engine and

A/T, CVT .................................................................

16

Precaution ...............................................................17

PREPARATION ..................................................20

Special Service Tool ...............................................20

Commercial Service Tool ........................................21

ENGINE CONTROL SYSTEM ............................22

Schematic ...............................................................22

Multiport Fuel Injection (MFI) System .....................22

Electronic Ignition (EI) System ................................25

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

25

AIR CONDITIONING CUT CONTROL ...............27

Input/Output Signal Chart ........................................27

System Description .................................................27

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

28

System Description .................................................28

Component Description ...........................................29

CAN COMMUNICATION ....................................30

System Description .................................................30

EVAPORATIVE EMISSION SYSTEM ................31

Description ..............................................................31

Component Inspection ............................................33

Removal and Installation .........................................35

How to Detect Fuel Vapor Leakage .........................35

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

38

System Description ..................................................38

Diagnosis Procedure ...............................................38

Component Inspection .............................................40

POSITIVE CRANKCASE VENTILATION .........43

Description ...............................................................43

Component Inspection .............................................43

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

45

Description ...............................................................45

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....46

Introduction ..............................................................46

Two Trip Detection Logic .........................................46

Emission-related Diagnostic Information .................47

Malfunction Indicator Lamp (MIL) ............................60

OBD System Operation Chart .................................63

BASIC SERVICE PROCEDURE .......................69

Basic Inspection ......................................................69

Idle Speed and Ignition Timing Check .....................73

Procedure After Replacing ECM .............................75

VIN Registration ......................................................75

Accelerator Pedal Released Position Learning .......76

Throttle Valve Closed Position Learning .................76

Idle Air Volume Learning .........................................76

Fuel Pressure Check ...............................................78

TROUBLE DIAGNOSIS ....................................81

Trouble Diagnosis Introduction ................................81

DTC Inspection Priority Chart ..................................86

Fail-Safe Chart ........................................................87

Symptom Matrix Chart .............................................88

Engine Control Component Parts Location .............93

Vacuum Hose Drawing ............................................99

Circuit Diagram ......................................................100

ECM Harness Connector Terminal Layout ............102

Page 1079 of 2771

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA

N

O

P Component Description .........................................

338

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

338

On Board Diagnosis Logic ....................................338

DTC Confirmation Procedure ................................338

Wiring Diagram .....................................................340

Diagnosis Procedure .............................................341

Component Inspection ..........................................343

DTC P0448 EVAP CANISTER VENT CON-

TROL VALVE ...................................................

345

Component Description .........................................345

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

345

On Board Diagnosis Logic ....................................345

DTC Confirmation Procedure ................................345

Wiring Diagram .....................................................347

Diagnosis Procedure .............................................348

Component Inspection ..........................................349

DTC P0451 EVAP CONTROL SYSTEM

PRESSURE SENSOR ......................................

351

Component Description .........................................351

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

351

On Board Diagnosis Logic ....................................351

DTC Confirmation Procedure ................................351

Diagnosis Procedure .............................................352

Component Inspection ..........................................353

DTC P0452 EVAP CONTROL SYSTEM

PRESSURE SENSOR ......................................

355

Component Description .........................................355

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

355

On Board Diagnosis Logic ....................................355

DTC Confirmation Procedure ................................355

Wiring Diagram .....................................................357

Diagnosis Procedure .............................................358

Component Inspection ..........................................361

DTC P0453 EVAP CONTROL SYSTEM

PRESSURE SENSOR ......................................

362

Component Description .........................................362

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

362

On Board Diagnosis Logic ....................................362

DTC Confirmation Procedure ................................362

Wiring Diagram .....................................................364

Diagnosis Procedure .............................................365

Component Inspection ..........................................369

DTC P0455 EVAP CONTROL SYSTEM ..........370

On Board Diagnosis Logic ....................................370

DTC Confirmation Procedure ................................370

Diagnosis Procedure .............................................372

DTC P0456 EVAP CONTROL SYSTEM ..........377

On Board Diagnosis Logic ....................................377

DTC Confirmation Procedure ................................378

Overall Function Check .........................................378

Diagnosis Procedure .............................................379

DTC P0460 FUEL LEVEL SENSOR ...............385

Component Description .........................................385

On Board Diagnosis Logic .....................................385

DTC Confirmation Procedure ................................385

Diagnosis Procedure .............................................386

Removal and Installation .......................................386

DTC P0461 FUEL LEVEL SENSOR ...............387

Component Description .........................................387

On Board Diagnosis Logic .....................................387

Overall Function Check .........................................387

Diagnosis Procedure .............................................388

Removal and Installation .......................................388

DTC P0462, P0463 FUEL LEVEL SENSOR ..389

Component Description .........................................389

On Board Diagnosis Logic .....................................389

DTC Confirmation Procedure ................................389

Diagnosis Procedure .............................................390

Removal and Installation .......................................390

DTC P0500 VSS ..............................................391

Description .............................................................391

On Board Diagnosis Logic .....................................391

DTC Confirmation Procedure ................................391

Overall Function Check .........................................392

Diagnosis Procedure .............................................392

DTC P0506 ISC SYSTEM ...............................393

Description .............................................................393

On Board Diagnosis Logic .....................................393

DTC Confirmation Procedure ................................393

Diagnosis Procedure .............................................393

DTC P0507 ISC SYSTEM ...............................395

Description .............................................................395

On Board Diagnosis Logic .....................................395

DTC Confirmation Procedure ................................395

Diagnosis Procedure .............................................395

DTC P0605 ECM .............................................397

Component Description .........................................397

On Board Diagnosis Logic .....................................397

DTC Confirmation Procedure ................................397

Diagnosis Procedure .............................................398

DTC P0643 SENSOR POWER SUPPLY ........400

On Board Diagnosis Logic .....................................400

DTC Confirmation Procedure ................................400

Wiring Diagram ......................................................401

Diagnosis Procedure .............................................402

DTC P0850 PNP SWITCH ..............................405

Component Description .........................................405

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

405

On Board Diagnosis Logic .....................................405

DTC Confirmation Procedure ................................405

Page 1081 of 2771

EC-7

C

D

E

F

G

H

I

J

K

L

M

ECA

N

O

P

DTC P2119 ELECTRIC THROTTLE CON-

TROL ACTUATOR ...........................................

472

Component Description .........................................472

On Board Diagnosis Logic ....................................472

DTC Confirmation Procedure ................................472

Diagnosis Procedure .............................................473

DTC P2122, P2123 APP SENSOR ..................474

Component Description .........................................474

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

474

On Board Diagnosis Logic ....................................474

DTC Confirmation Procedure ................................474

Wiring Diagram .....................................................476

Diagnosis Procedure .............................................477

Component Inspection ..........................................479

Removal and Installation .......................................479

DTC P2127, P2128 APP SENSOR ..................480

Component Description .........................................480

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

480

On Board Diagnosis Logic ....................................480

DTC Confirmation Procedure ................................481

Wiring Diagram .....................................................482

Diagnosis Procedure .............................................483

Component Inspection ..........................................485

Removal and Installation .......................................486

DTC P2135 TP SENSOR .................................487

Component Description .........................................487

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

487

On Board Diagnosis Logic ....................................487

DTC Confirmation Procedure ................................487

Wiring Diagram .....................................................489

Diagnosis Procedure .............................................490

Component Inspection ..........................................492

Removal and Installation .......................................492

DTC P2138 APP SENSOR ...............................493

Component Description .........................................493

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

493

On Board Diagnosis Logic ....................................493

DTC Confirmation Procedure ................................494

Wiring Diagram .....................................................495

Diagnosis Procedure .............................................496

Component Inspection ..........................................499

Removal and Installation .......................................499

DTC P2A00 A/F SENSOR 1 .............................500

Component Description .........................................500

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

500

On Board Diagnosis Logic ....................................500

DTC Confirmation Procedure ................................500

Wiring Diagram .....................................................502

Diagnosis Procedure .............................................503

Removal and Installation .......................................507

ASCD BRAKE SWITCH ..................................508

Component Description .........................................508

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

508

Wiring Diagram ......................................................509

Diagnosis Procedure .............................................510

Component Inspection ...........................................514

ASCD INDICATOR ..........................................516

Component Description .........................................516

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

516

Wiring Diagram ......................................................517

Diagnosis Procedure .............................................517

ELECTRICAL LOAD SIGNAL ........................519

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

519

Diagnosis Procedure .............................................519

FUEL INJECTOR ............................................521

Component Description .........................................521

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

521

Wiring Diagram ......................................................522

Diagnosis Procedure .............................................523

Component Inspection ...........................................525

Removal and Installation .......................................525

FUEL PUMP ....................................................526

Description .............................................................526

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

526

Wiring Diagram ......................................................527

Diagnosis Procedure .............................................528

Component Inspection ...........................................530

Removal and Installation .......................................530

IGNITION SIGNAL ..........................................531

Component Description .........................................531

Wiring Diagram ......................................................532

Diagnosis Procedure .............................................535

Component Inspection ...........................................538

Removal and Installation .......................................540

REFRIGERANT PRESSURE SENSOR ..........541

Component Description .........................................541

Wiring Diagram ......................................................542

Diagnosis Procedure .............................................543

Removal and Installation .......................................545

MIL AND DATA LINK CONNECTOR .............546

Wiring Diagram ......................................................546

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

548

Fuel Pressure ........................................................548

Idle Speed and Ignition Timing ..............................548

Calculated Load Value ..........................................548

Mass Air Flow Sensor ............................................548

Intake Air Temperature Sensor .............................548

Page 1092 of 2771

EC-18

< SERVICE INFORMATION >

PRECAUTIONS

•Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspection and make sure ECM functions prop-

erly. Refer to EC-102, "

ECM Terminal and Reference Value".

•Handle mass air flow sensor carefully to avoid damage.

•Do not disassemble mass air flow sensor.

•Do not clean mass air flow sensor with any type of detergent.

•Do not disassemble electric throttle control actuator.

•Even a slight leak in the air intake system can cause serious

incidents.

•Do not shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

•After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displayed in the DTC Confirmation

Procedure if the repair is completed. The Overall Function

Check should be a good result if the repair is completed.

•When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

•Do not use ECM ground terminals when measuring input/out-

put voltage. Doing so may result in damage to the ECM's tran-

sistor. Use a ground other than ECM terminals, such as the

ground.

•Do not operate fuel pump when there is no fuel in lines.

•Tighten fuel hose clamps to the specified torque.

-Fuel level sensor unit and fuel pump (1)

-Fuel pressure regulator (2)

-Fuel level sensor (3)

-Fuel tank temperature sensor (4)

MEF040D

SEF217U

SEF348N

BBIA0704E

Page 1094 of 2771

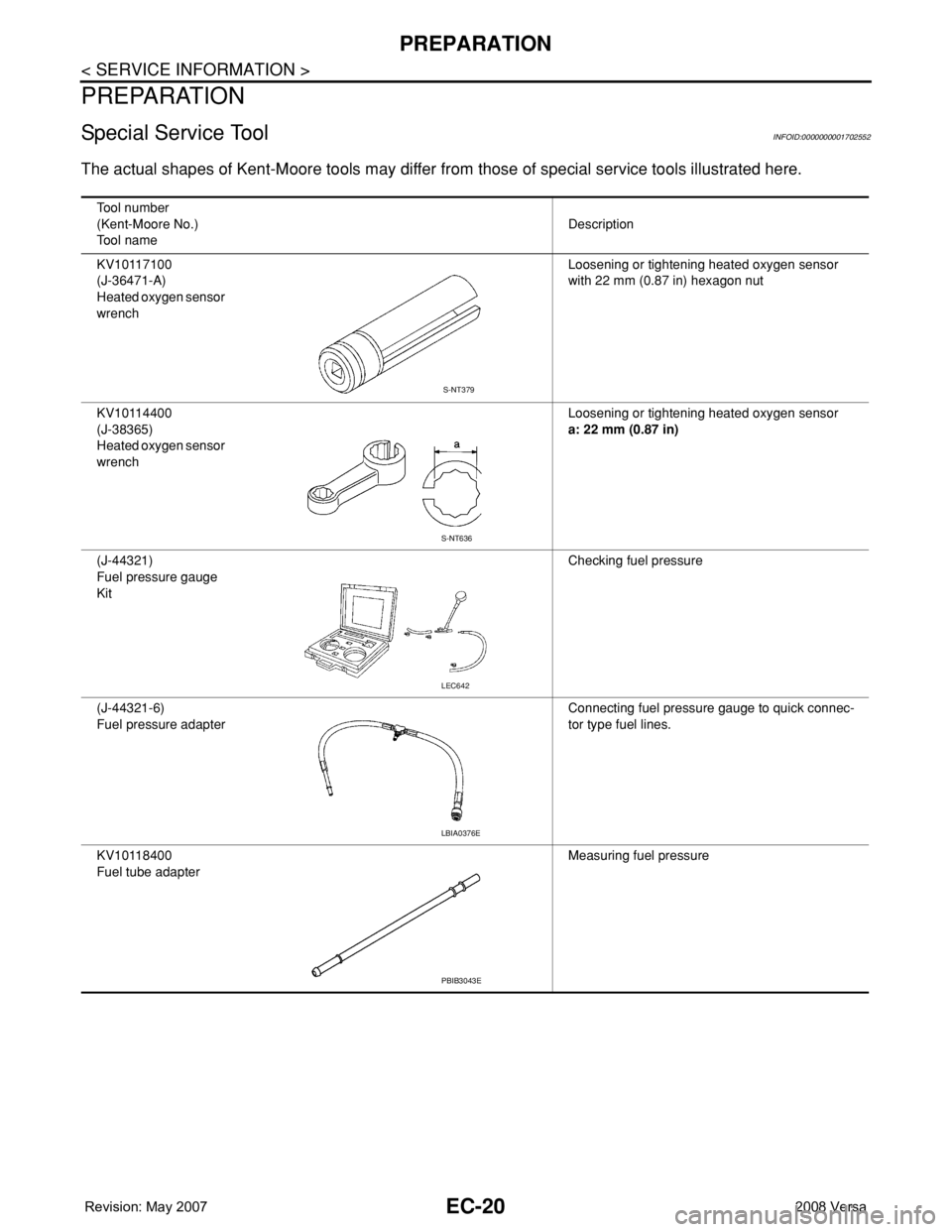

EC-20

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000001702552

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV10117100

(J-36471-A)

Heated oxygen sensor

wrenchLoosening or tightening heated oxygen sensor

with 22 mm (0.87 in) hexagon nut

KV10114400

(J-38365)

Heated oxygen sensor

wrenchLoosening or tightening heated oxygen sensor

a: 22 mm (0.87 in)

(J-44321)

Fuel pressure gauge

KitChecking fuel pressure

(J-44321-6)

Fuel pressure adapterConnecting fuel pressure gauge to quick connec-

tor type fuel lines.

KV10118400

Fuel tube adapterMeasuring fuel pressure

S-NT379

S-NT636

LEC642

LBIA0376E

PBIB3043E

Page 1095 of 2771

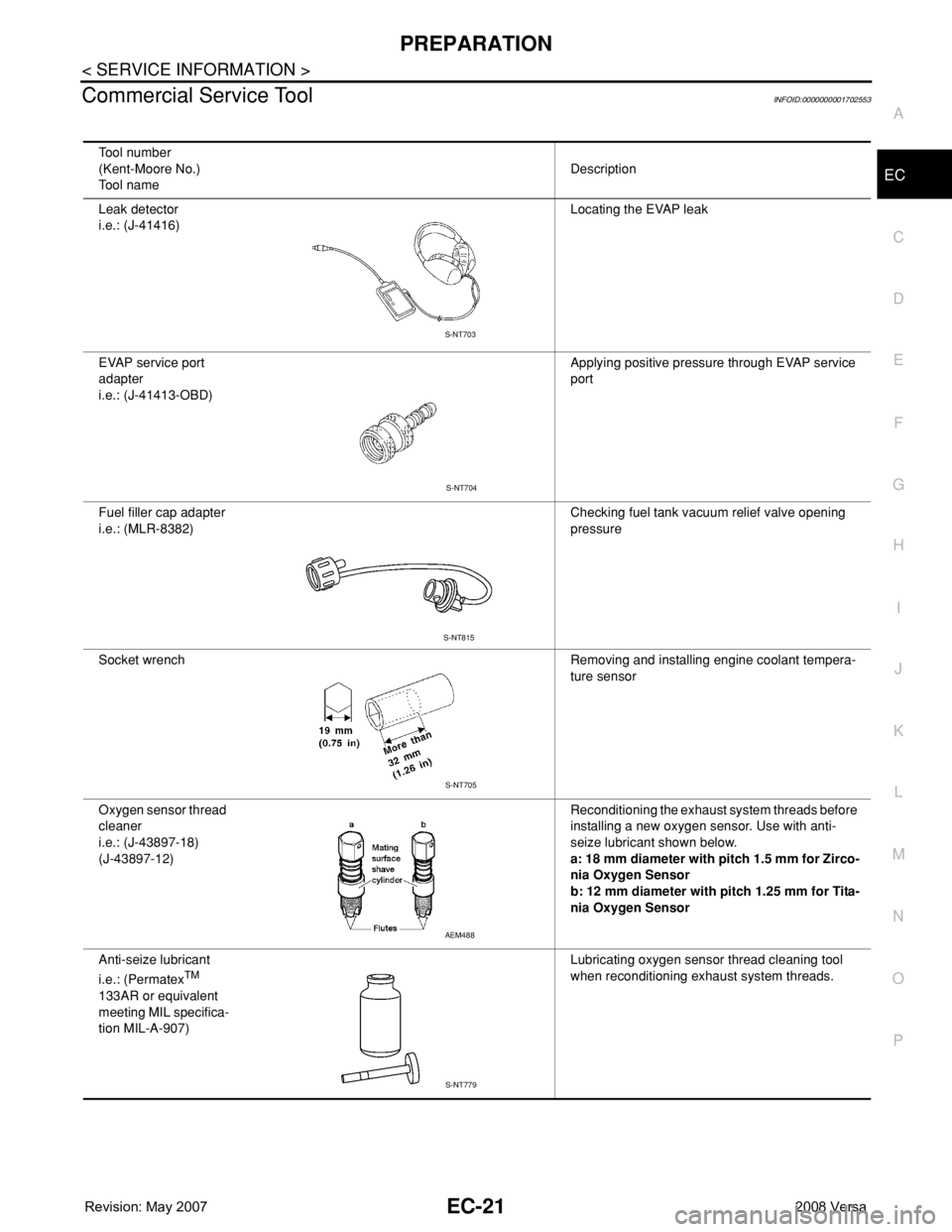

PREPARATION

EC-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Commercial Service ToolINFOID:0000000001702553

Tool number

(Kent-Moore No.)

Tool nameDescription

Leak detector

i.e.: (J-41416)Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD)Applying positive pressure through EVAP service

port

Fuel filler cap adapter

i.e.: (MLR-8382)Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coolant tempera-

ture sensor

Oxygen sensor thread

cleaner

i.e.: (J-43897-18)

(J-43897-12)Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for Zirco-

nia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for Tita-

nia Oxygen Sensor

Anti-seize lubricant

i.e.: (Permatex

TM

133AR or equivalent

meeting MIL specifica-

tion MIL-A-907)Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

S-NT703

S-NT704

S-NT815

S-NT705

AEM488

S-NT779

Page 1108 of 2771

EC-34

< SERVICE INFORMATION >

EVAPORATIVE EMISSION SYSTEM

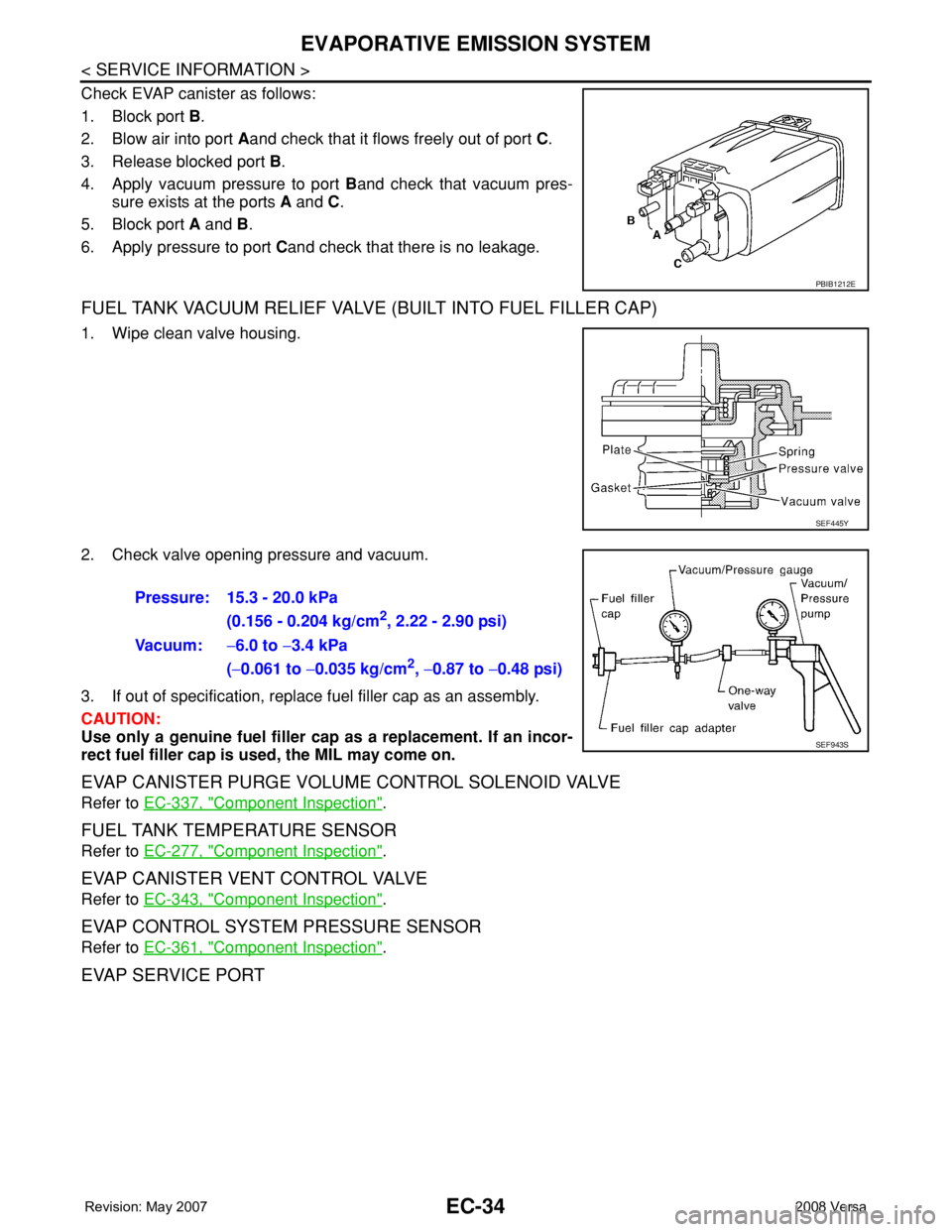

Check EVAP canister as follows:

1. Block port B.

2. Blow air into port Aand check that it flows freely out of port C.

3. Release blocked port B.

4. Apply vacuum pressure to port Band check that vacuum pres-

sure exists at the ports A and C.

5. Block port A and B.

6. Apply pressure to port Cand check that there is no leakage.

FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FILLER CAP)

1. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

3. If out of specification, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may come on.

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to EC-337, "Component Inspection".

FUEL TANK TEMPERATURE SENSOR

Refer to EC-277, "Component Inspection".

EVAP CANISTER VENT CONTROL VALVE

Refer to EC-343, "Component Inspection".

EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-361, "Component Inspection".

EVAP SERVICE PORT

PBIB1212E

SEF445Y

Pressure: 15.3 - 20.0 kPa

(0.156 - 0.204 kg/cm

2, 2.22 - 2.90 psi)

Vacuum:−6.0 to −3.4 kPa

(−0.061 to −0.035 kg/cm

2, −0.87 to −0.48 psi)

SEF943S