radiator NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 21 of 2771

PRECAUTIONS

AT-9

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to

Refer to .

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

MA-22, "

Changing A/T Fluid", MA-22, "Checking A/T Fluid".

Service Notice or PrecautionINFOID:0000000001703155

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Service Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to Refer to CO-11

.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engine coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-78, "

Diagnosis Procedure without CONSULT-III" for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-36, "

OBD-II Diagnostic Trouble Code

(DTC)" to complete the repair and avoid unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD-II, refer to AT- 3 6

.

•Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector.

For description and how to disconnect, refer to PG-65

.

Page 27 of 2771

A/T FLUID

AT-15

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

A/T FLUID

Checking A/T FluidINFOID:0000000001703158

1. Warm up engine.

2. Check for A/T fluid leakage.

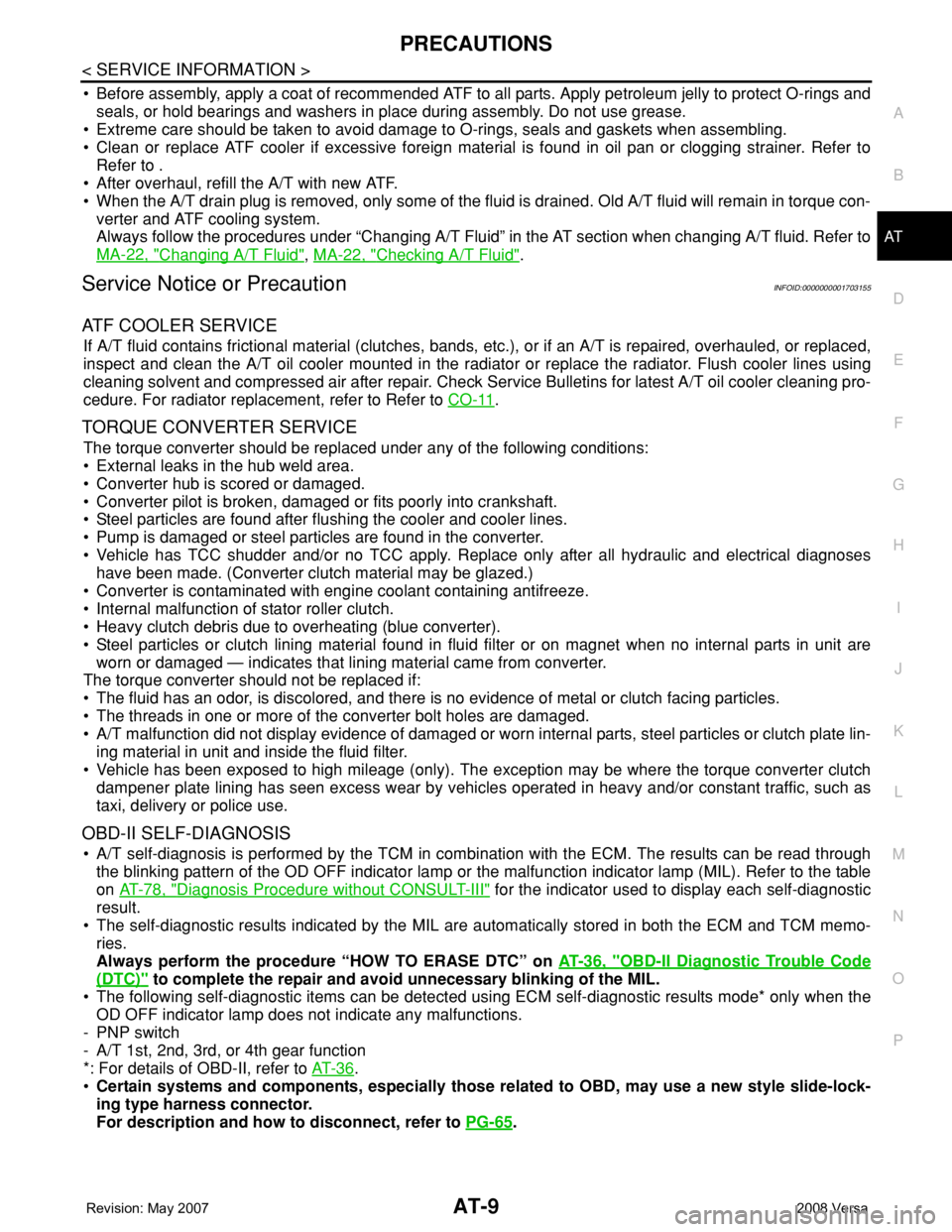

3. Before driving, A/T fluid level can be checked at A/T fluid tem-

peratures of 30 to 50°C (86 to 122°F) using the “COLD” range

on A/T fluid level gauge.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth.

CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

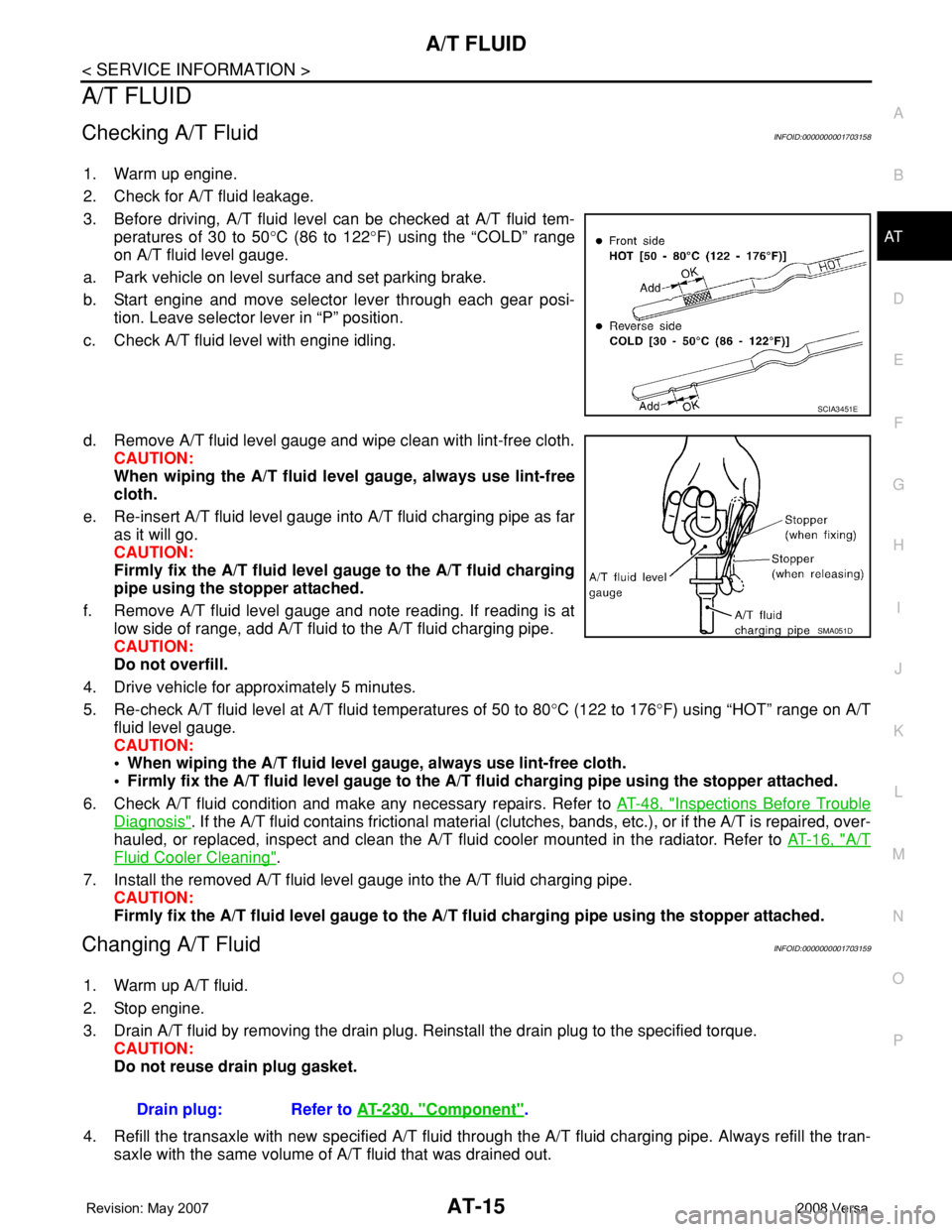

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far

as it will go.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at

low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on A/T

fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-48, "

Inspections Before Trouble

Diagnosis". If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired, over-

hauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-16, "

A/T

Fluid Cooler Cleaning".

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

Changing A/T FluidINFOID:0000000001703159

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Reinstall the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran-

saxle with the same volume of A/T fluid that was drained out.

SCIA3451E

SMA051D

Drain plug: Refer to AT-230, "Component".

Page 28 of 2771

AT-16

< SERVICE INFORMATION >

A/T FLUID

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to MA-22, "

Checking A/T Fluid".

A/T Fluid Cooler CleaningINFOID:0000000001703160

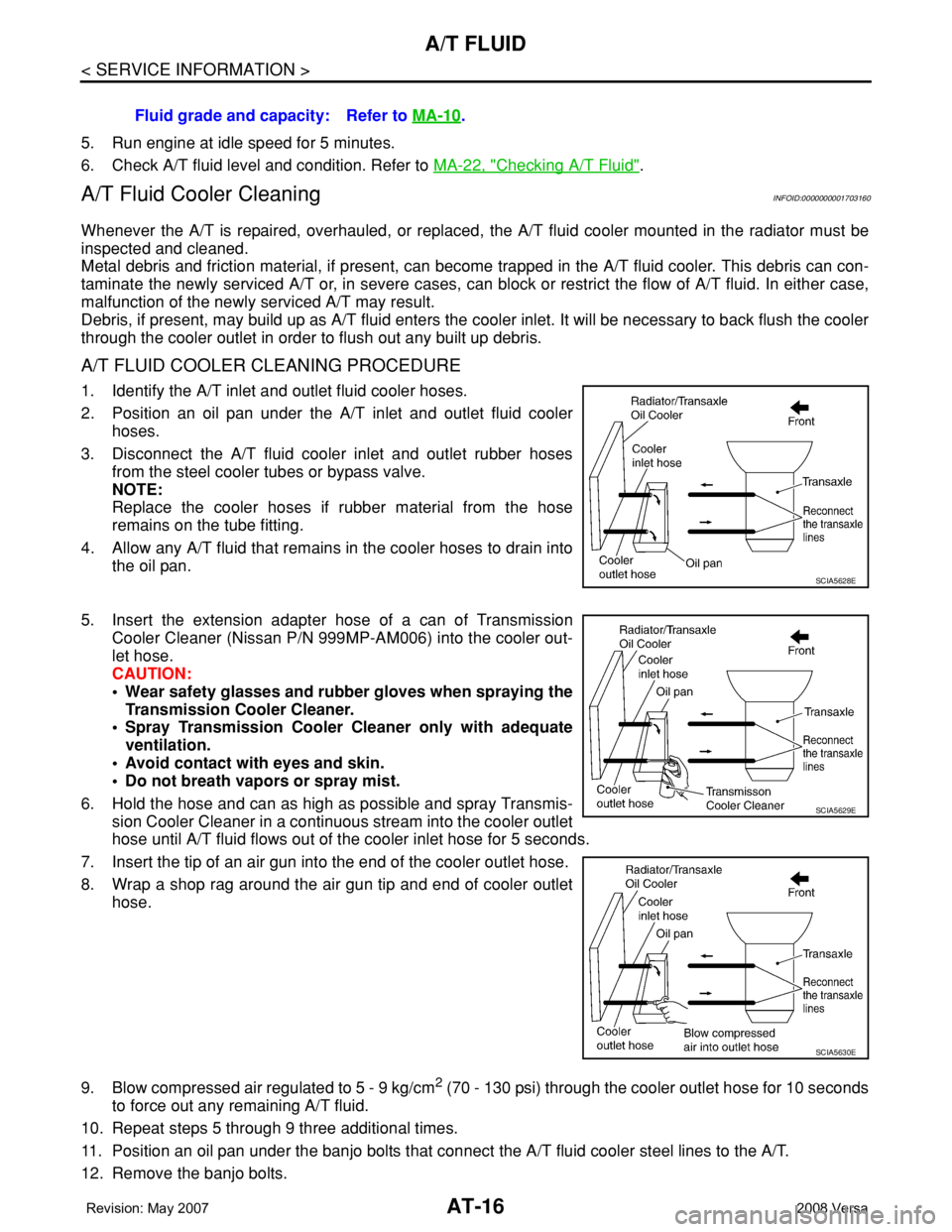

Whenever the A/T is repaired, overhauled, or replaced, the A/T fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can become trapped in the A/T fluid cooler. This debris can con-

taminate the newly serviced A/T or, in severe cases, can block or restrict the flow of A/T fluid. In either case,

malfunction of the newly serviced A/T may result.

Debris, if present, may build up as A/T fluid enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

1. Identify the A/T inlet and outlet fluid cooler hoses.

2. Position an oil pan under the A/T inlet and outlet fluid cooler

hoses.

3. Disconnect the A/T fluid cooler inlet and outlet rubber hoses

from the steel cooler tubes or bypass valve.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any A/T fluid that remains in the cooler hoses to drain into

the oil pan.

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis-

sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until A/T fluid flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the air gun tip and end of cooler outlet

hose.

9. Blow compressed air regulated to 5 - 9 kg/cm

2 (70 - 130 psi) through the cooler outlet hose for 10 seconds

to force out any remaining A/T fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the A/T fluid cooler steel lines to the A/T.

12. Remove the banjo bolts.Fluid grade and capacity: Refer to MA-10

.

SCIA5628E

SCIA5629E

SCIA5630E

Page 30 of 2771

AT-18

< SERVICE INFORMATION >

A/T FLUID

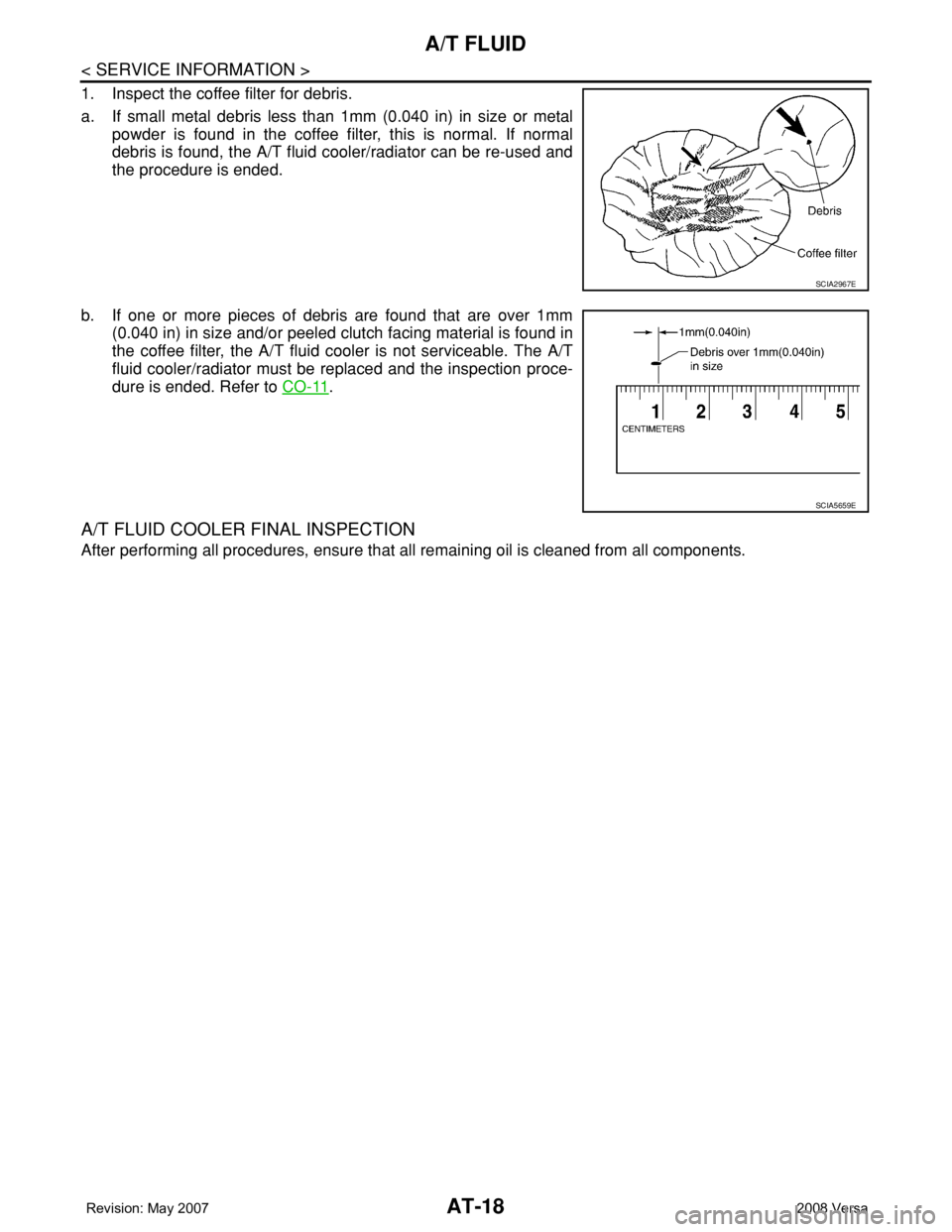

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1mm (0.040 in) in size or metal

powder is found in the coffee filter, this is normal. If normal

debris is found, the A/T fluid cooler/radiator can be re-used and

the procedure is ended.

b. If one or more pieces of debris are found that are over 1mm

(0.040 in) in size and/or peeled clutch facing material is found in

the coffee filter, the A/T fluid cooler is not serviceable. The A/T

fluid cooler/radiator must be replaced and the inspection proce-

dure is ended. Refer to CO-11

.

A/T FLUID COOLER FINAL INSPECTION

After performing all procedures, ensure that all remaining oil is cleaned from all components.

SCIA2967E

SCIA5659E

Page 228 of 2771

AT-216

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

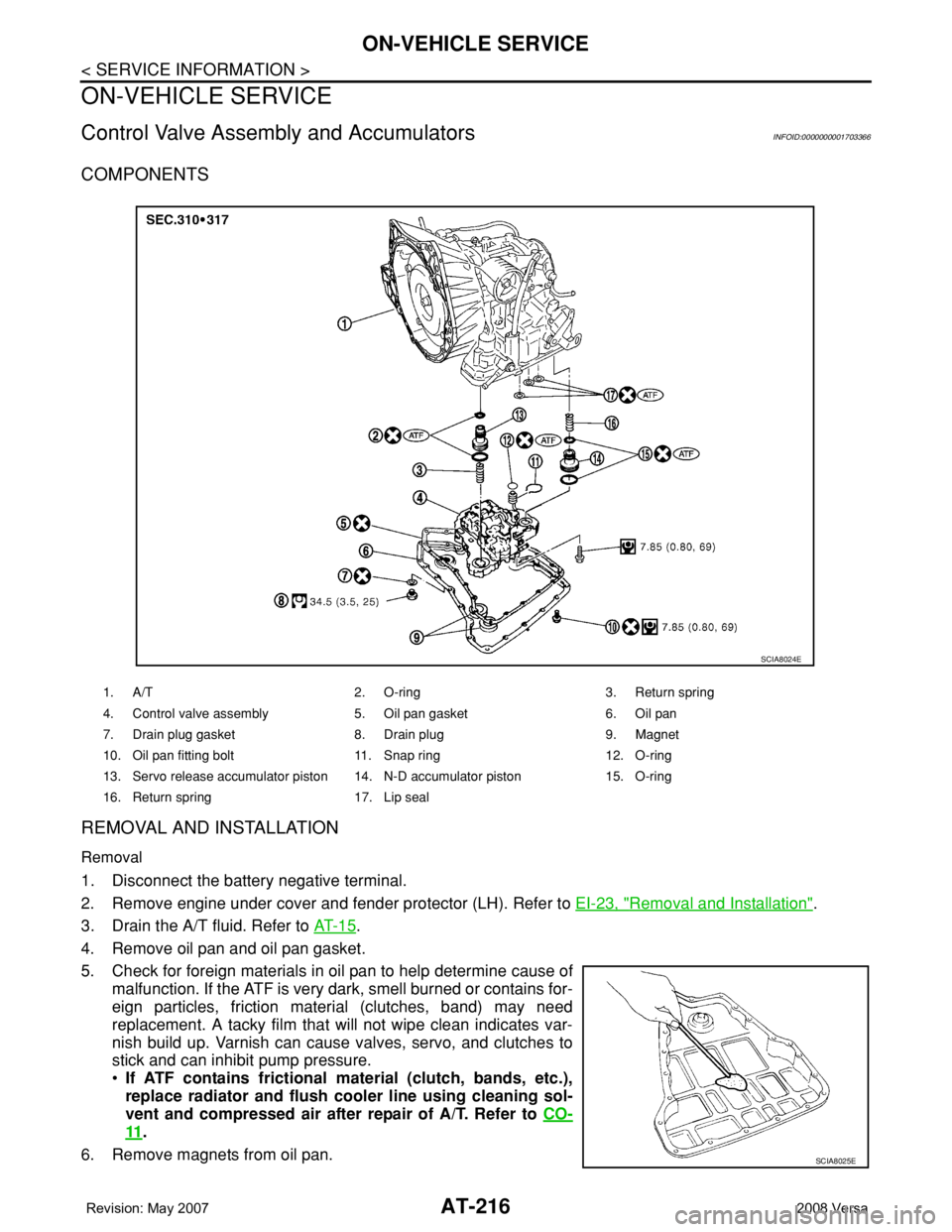

Control Valve Assembly and AccumulatorsINFOID:0000000001703366

COMPONENTS

REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery negative terminal.

2. Remove engine under cover and fender protector (LH). Refer to EI-23, "

Removal and Installation".

3. Drain the A/T fluid. Refer to AT- 1 5

.

4. Remove oil pan and oil pan gasket.

5. Check for foreign materials in oil pan to help determine cause of

malfunction. If the ATF is very dark, smell burned or contains for-

eign particles, friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

•If ATF contains frictional material (clutch, bands, etc.),

replace radiator and flush cooler line using cleaning sol-

vent and compressed air after repair of A/T. Refer to CO-

11.

6. Remove magnets from oil pan.

1. A/T 2. O-ring 3. Return spring

4. Control valve assembly 5. Oil pan gasket 6. Oil pan

7. Drain plug gasket 8. Drain plug 9. Magnet

10. Oil pan fitting bolt 11. Snap ring 12. O-ring

13. Servo release accumulator piston 14. N-D accumulator piston 15. O-ring

16. Return spring 17. Lip seal

SCIA8024E

SCIA8025E

Page 254 of 2771

AT-242

< SERVICE INFORMATION >

DISASSEMBLY

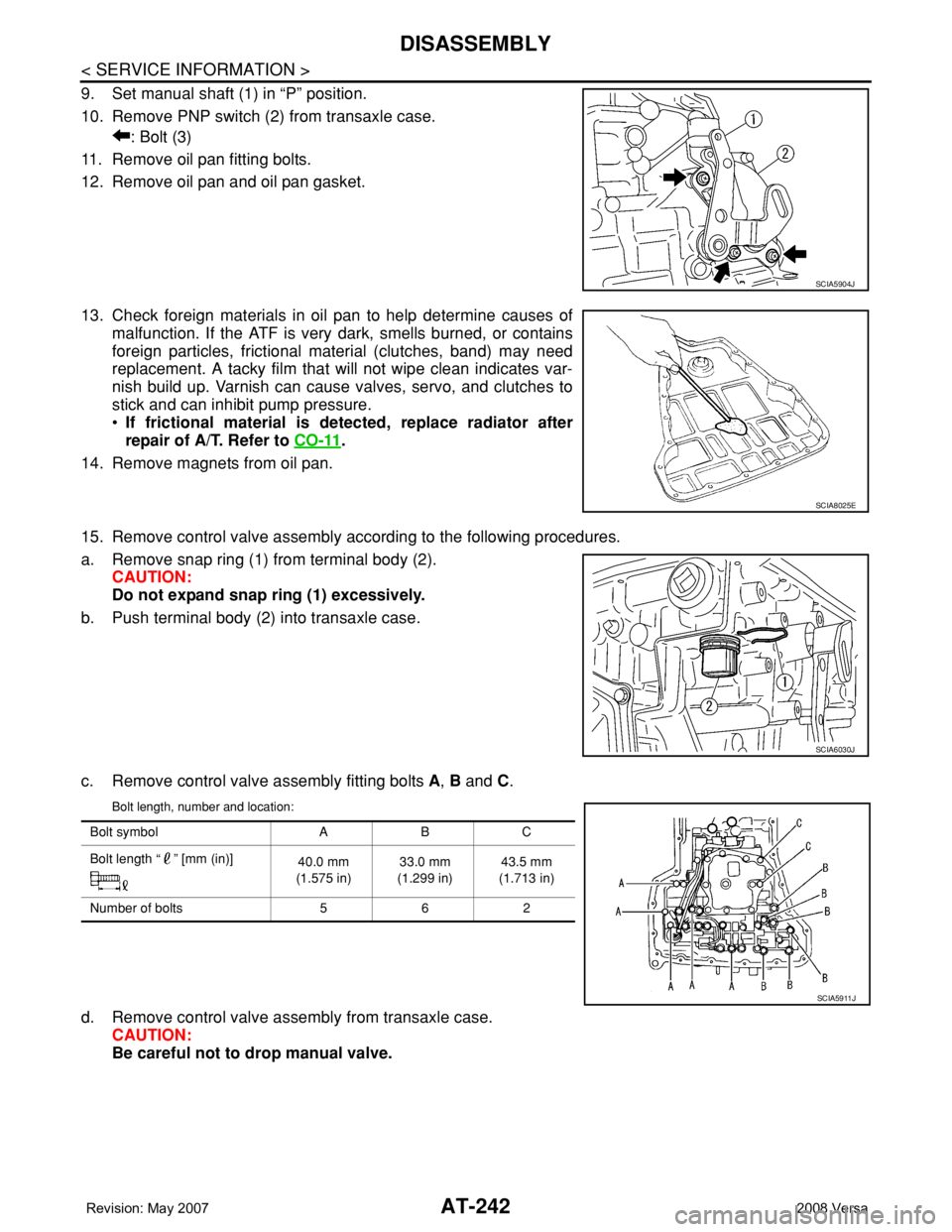

9. Set manual shaft (1) in “P” position.

10. Remove PNP switch (2) from transaxle case.

: Bolt (3)

11. Remove oil pan fitting bolts.

12. Remove oil pan and oil pan gasket.

13. Check foreign materials in oil pan to help determine causes of

malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, frictional material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

•If frictional material is detected, replace radiator after

repair of A/T. Refer to CO-11

.

14. Remove magnets from oil pan.

15. Remove control valve assembly according to the following procedures.

a. Remove snap ring (1) from terminal body (2).

CAUTION:

Do not expand snap ring (1) excessively.

b. Push terminal body (2) into transaxle case.

c. Remove control valve assembly fitting bolts A, B and C.

Bolt length, number and location:

d. Remove control valve assembly from transaxle case.

CAUTION:

Be careful not to drop manual valve.

SCIA5904J

SCIA8025E

SCIA6030J

Bolt symbol A B C

Bolt length “ ” [mm (in)]

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

SCIA5911J

Page 435 of 2771

BL-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

N

O

P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION ............................4

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ..................................................5

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

7

Work Flow .................................................................7

Generic Squeak and Rattle Troubleshooting ............9

Diagnostic Worksheet .............................................11

HOOD .................................................................13

Fitting Adjustment ...................................................13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control ......15

Hood Lock Control Inspection .................................17

RADIATOR CORE SUPPORT ...........................19

Removal and Installation .........................................19

FRONT FENDER ................................................21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM ........................22

Component Parts and Harness Connector Loca-

tion ..........................................................................

22

System Description .................................................22

CAN Communication System Description ...............24

Schematic ...............................................................25

Wiring Diagram - D/LOCK - .....................................26

Schematic ...............................................................30

Wiring Diagram - D/LOCK - .....................................31

Terminal and Reference Value for BCM ..................35

Work Flow ................................................................35

CONSULT-III Function (BCM) .................................36

Trouble Diagnosis Symptom Chart ..........................37

BCM Power Supply and Ground Circuit ..................37

Door Switch Check (Hatchback) ..............................37

Door Switch Check (Sedan) ....................................40

Key Switch (Insert) Check .......................................41

Door Lock and Unlock Switch Check ......................42

Front Door Lock Assembly LH (Actuator) Check .....45

Door Lock Actuator Check (Front RH and Rear

LH/RH) .....................................................................

46

Front Door Key Cylinder Switch LH Check ..............47

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ...............................................

48

REMOTE KEYLESS ENTRY SYSTEM .............51

Component Parts and Harness Connector Loca-

tion ...........................................................................

51

System Description ..................................................51

CAN Communication System Description ...............53

Schematic ................................................................54

Wiring Diagram - KEYLES - ....................................55

Terminal and Reference Value for BCM ..................57

How to Perform Trouble Diagnosis ..........................57

Preliminary Check ...................................................58

CONSULT-III Function (BCM) .................................58

Work Flow ................................................................59

Trouble Diagnosis Symptom Chart ..........................60

Keyfob Battery and Function Check ........................61

ACC Switch Check ..................................................62

Door Switch Check (Hatchback) ..............................62

Door Switch Check (Sedan) ....................................65

Key Switch (Insert) Check .......................................66

Hazard Function Check ...........................................67

Horn Function Check ...............................................67

Interior Lamp and Ignition Keyhole Illumination

Function Check ........................................................

68

Remote Keyless Entry Receiver Check ...................68

Keyfob Function (Lock) Check ................................71

Keyfob Function (Unlock) Check .............................71

Page 444 of 2771

BL-10

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 448 of 2771

BL-14

< SERVICE INFORMATION >

HOOD

5. After adjustment tighten lock bolts to the specified torque.

6. Install the front grille. Refer to EI-20

.

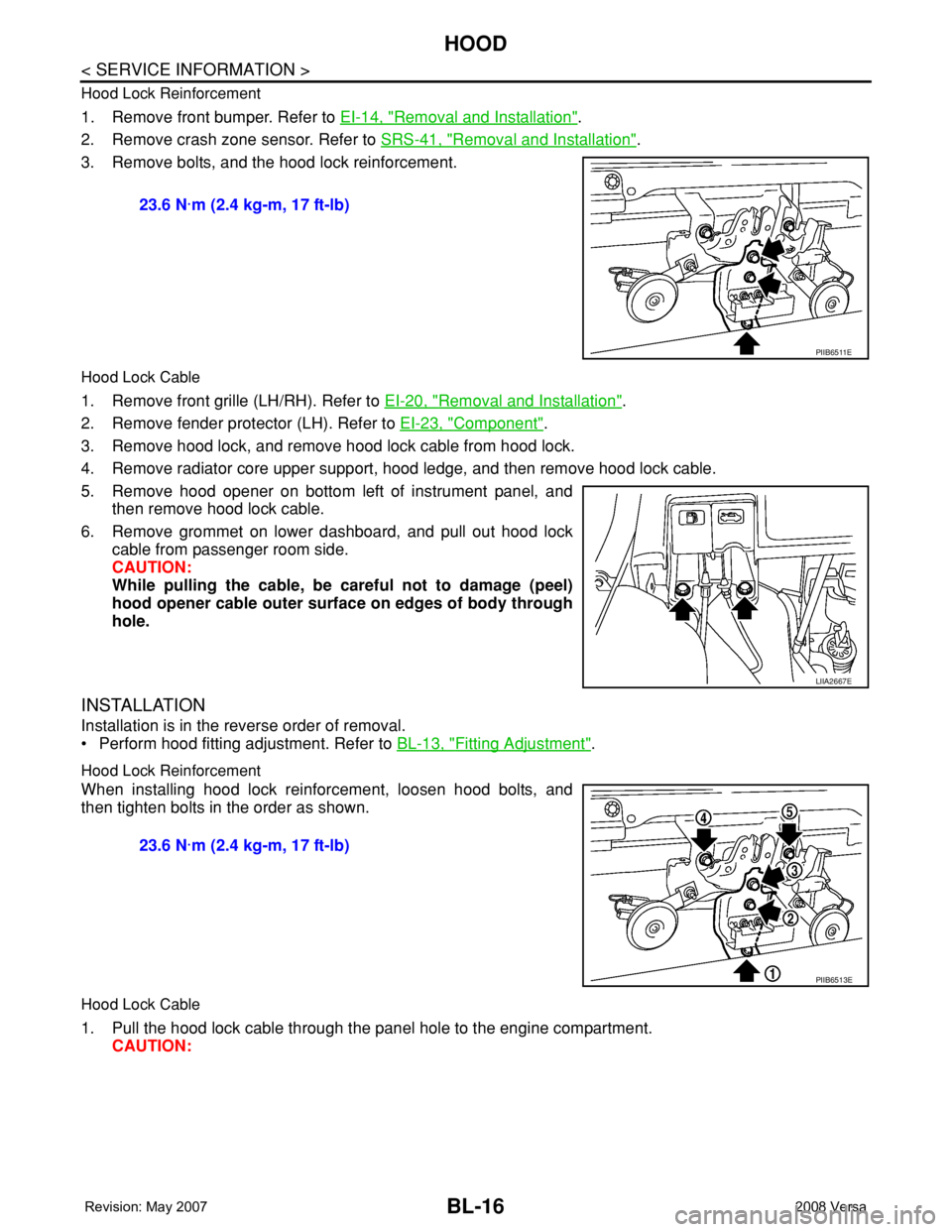

Removal and InstallationINFOID:0000000001703948

HOOD ASSEMBLY

Removal

1. Remove hinge nuts on hood and remove hood assembly.

CAUTION:

Two technicians should be used to avoid damaging the

hood during removal.

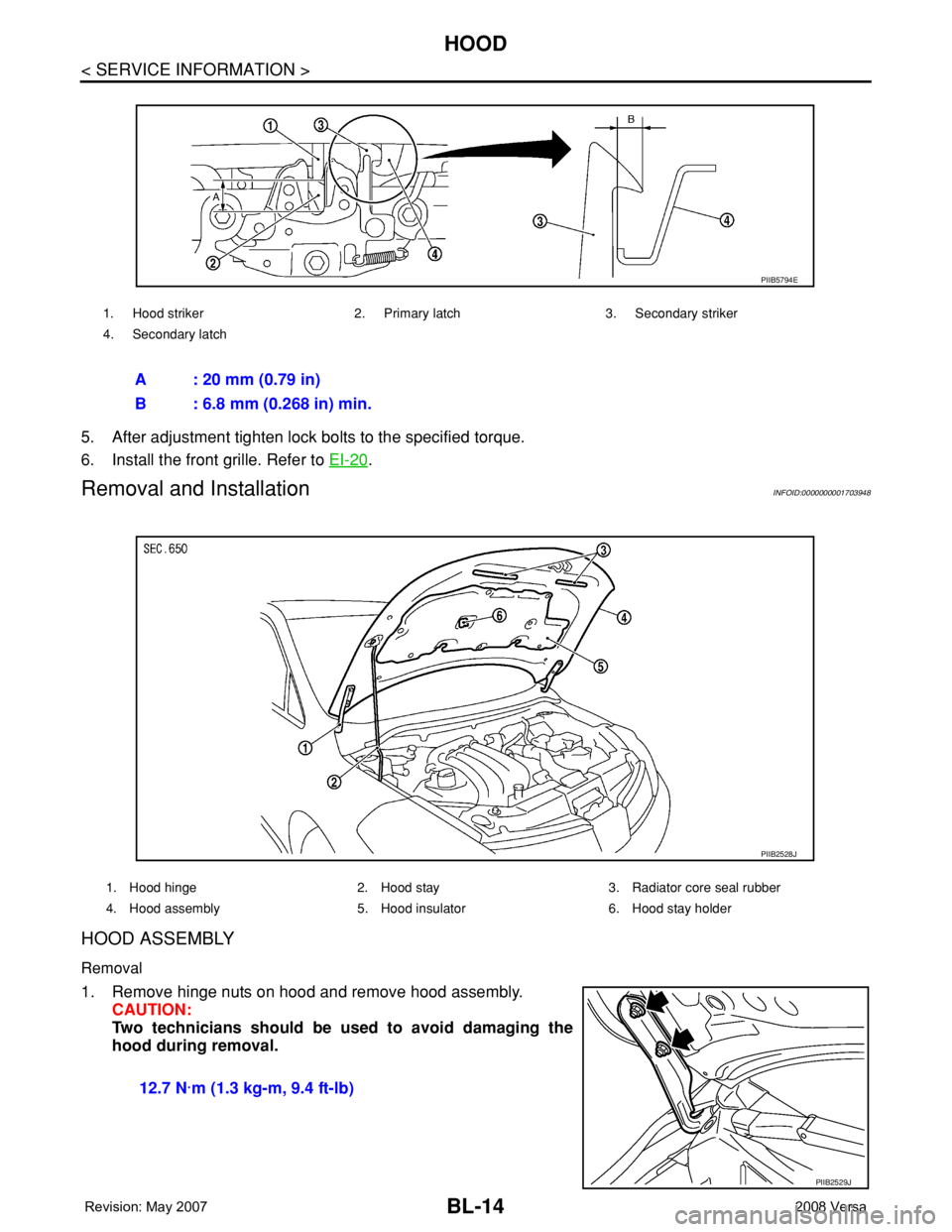

1. Hood striker 2. Primary latch 3. Secondary striker

4. Secondary latch

A : 20 mm (0.79 in)

B : 6.8 mm (0.268 in) min.

PIIB5794E

1. Hood hinge 2. Hood stay 3. Radiator core seal rubber

4. Hood assembly 5. Hood insulator 6. Hood stay holder

PIIB2528J

12.7 N·m (1.3 kg-m, 9.4 ft-lb)

PIIB2529J

Page 450 of 2771

BL-16

< SERVICE INFORMATION >

HOOD

Hood Lock Reinforcement

1. Remove front bumper. Refer to EI-14, "Removal and Installation".

2. Remove crash zone sensor. Refer to SRS-41, "

Removal and Installation".

3. Remove bolts, and the hood lock reinforcement.

Hood Lock Cable

1. Remove front grille (LH/RH). Refer to EI-20, "Removal and Installation".

2. Remove fender protector (LH). Refer to EI-23, "

Component".

3. Remove hood lock, and remove hood lock cable from hood lock.

4. Remove radiator core upper support, hood ledge, and then remove hood lock cable.

5. Remove hood opener on bottom left of instrument panel, and

then remove hood lock cable.

6. Remove grommet on lower dashboard, and pull out hood lock

cable from passenger room side.

CAUTION:

While pulling the cable, be careful not to damage (peel)

hood opener cable outer surface on edges of body through

hole.

INSTALLATION

Installation is in the reverse order of removal.

• Perform hood fitting adjustment. Refer to BL-13, "

Fitting Adjustment".

Hood Lock Reinforcement

When installing hood lock reinforcement, loosen hood bolts, and

then tighten bolts in the order as shown.

Hood Lock Cable

1. Pull the hood lock cable through the panel hole to the engine compartment.

CAUTION: 23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6511E

LIIA2667E

23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6513E