ignition NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 4282 of 4331

WT

N

O P

NOTE:

Before performing the self-diagnosis, be sure to register the ID or else the actual malfunction location may be different from that dis-

played on CONSULT-III.

Data Monitor Mode

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or the actual malfunction location may be different from that displayed on

CONSULT-III.

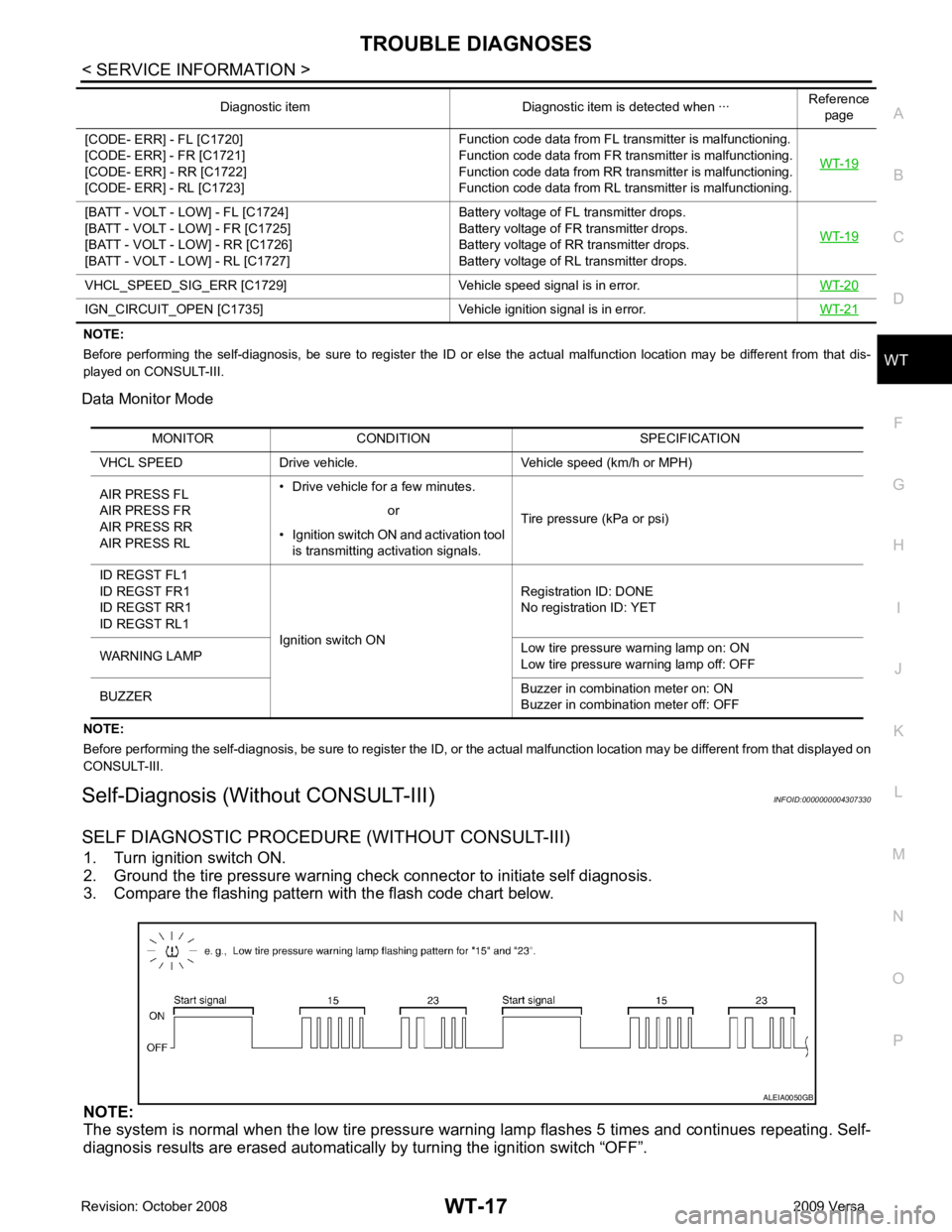

Self-Diagnosis (Without CONSULT-III) INFOID:0000000004307330

SELF DIAGNOSTIC PROCE DURE (WITHOUT CONSULT-III)

1. Turn ignition switch ON.

2. Ground the tire pressure warning check connector to initiate self diagnosis.

3. Compare the flashing pattern with the flash code chart below.

NOTE:

The system is normal when the low tire pressure warni ng lamp flashes 5 times and continues repeating. Self-

diagnosis results are erased automatically by turning the ignition switch “OFF”.

[CODE- ERR] - FL [C1720]

[CODE- ERR] - FR [C1721]

[CODE- ERR] - RR [C1722]

[CODE- ERR] - RL [C1723] Function code data from FL transmitter is malfunctioning.

Function code data from FR transmitter is malfunctioning.

Function code data from RR transmitter is malfunctioning.

Function code data from RL transmitter is malfunctioning. WT-19[BATT - VOLT - LOW] - FL [C1724]

[BATT - VOLT - LOW] - FR [C1725]

[BATT - VOLT - LOW] - RR [C1726]

[BATT - VOLT - LOW] - RL [C1727] Battery voltage of FL transmitter drops.

Battery voltage of FR transmitter drops.

Battery voltage of RR transmitter drops.

Battery voltage of RL transmitter drops. WT-19VHCL_SPEED_SIG_ERR [C1729] Vehicle

speed signal is in error.WT-20IGN_CIRCUIT_OPEN [C1735] Vehicle

ignition signal is in error. WT-21Diagnostic item Diagnostic item is detected when ···

Reference

page MONITOR CONDITION SPECIFICATION

VHCL SPEED Drive vehicle. Vehicle speed (km/h or MPH)

AIR PRESS FL

AIR PRESS FR

AIR PRESS RR

AIR PRESS RL • Drive vehicle for a few minutes.

Tire pressure (kPa or psi)

or

• Ignition switch ON and activation tool is transmitting activation signals.

ID REGST FL1

ID REGST FR1

ID REGST RR1

ID REGST RL1 Ignition switch ON Registration ID: DONE

No registration ID: YET

WARNING LAMP Low tire pressure

warning lamp on: ON

Low tire pressure warning lamp off: OFF

BUZZER Buzzer in combination meter on: ON

Buzzer in combination meter off: OFF

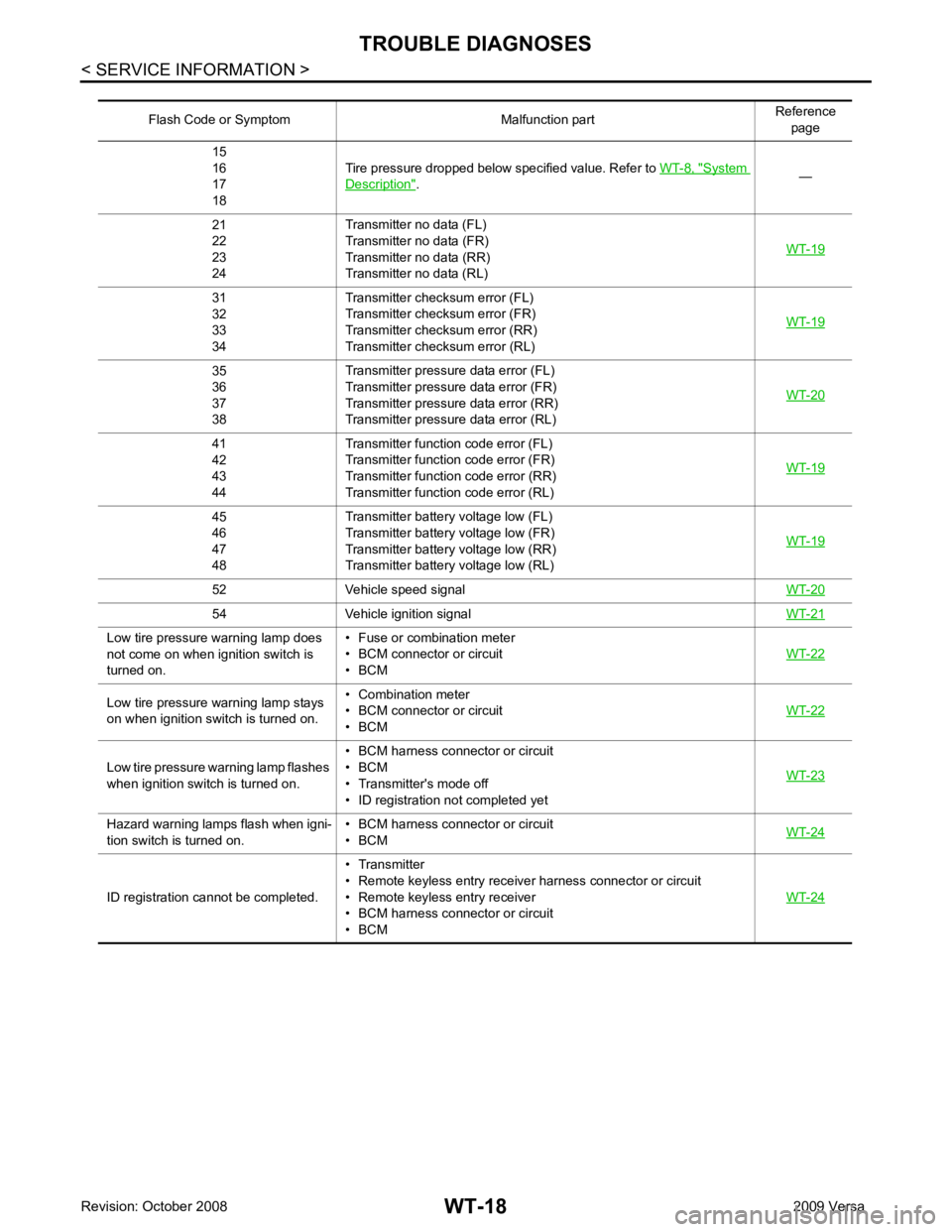

Page 4283 of 4331

System

Description " .

—

21

22

23

24 Transmitter no data (FL)

Transmitter no data (FR)

Transmitter no data (RR)

Transmitter no data (RL) WT-1931

32

33

34 Transmitter chec

ksum error (FL)

Transmitter chec ksum error (FR)

Transmitter chec ksum error (RR)

Transmitter chec ksum error (RL) WT-1935

36

37

38 Transmitter pressure

data error (FL)

Transmitter pressure data error (FR)

Transmitter pressure data error (RR)

Transmitter pressure data error (RL) WT-2041

42

43

44 Transmitter function

code error (FL)

Transmitter function code error (FR)

Transmitter function code error (RR)

Transmitter function code error (RL) WT-1945

46

47

48 Transmitter battery voltage low (FL)

Transmitter battery voltage low (FR)

Transmitter battery voltage low (RR)

Transmitter battery voltage low (RL) WT-1952 Vehicle speed signal

WT-2054 Vehicle ignition signal

WT-21Low tire pressure warning lamp does

not come on when ignition switch is

turned on. • Fuse or combination meter

• BCM connector or circuit

• BCM WT-22Low tire pressure

warning lamp stays

on when ignition switch is turned on. • Combination meter

• BCM connector or circuit

• BCM WT-22Low tire pressure wa

rning lamp flashes

when ignition switch is turned on. • BCM harness connector or circuit

• BCM

• Transmitter's mode off

• ID registration not completed yet WT-23Hazard warning lamps flash when igni-

tion switch is turned on. • BCM harness connector or circuit

• BCM WT-24ID registration cannot be completed.

• Transmitter

• Remote keyless entry receiver harness connector or circuit

• Remote keyless entry receiver

• BCM harness connector or circuit

• BCM WT-24

Page 4286 of 4331

WT

N

O P

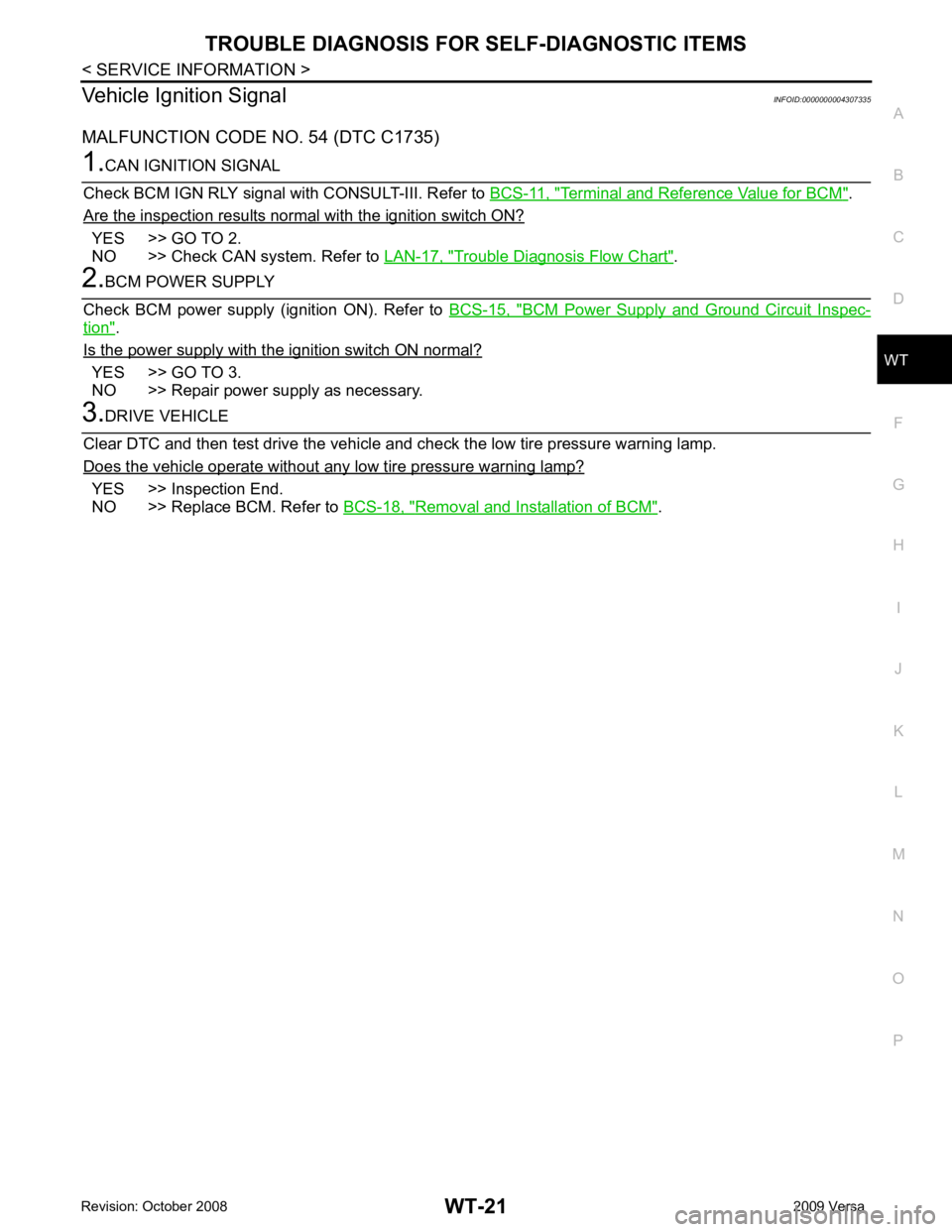

Vehicle Ignition Signal

INFOID:0000000004307335

MALFUNCTION CODE NO. 54 (DTC C1735) Terminal and Reference Value for BCM " .

Are the inspection results normal with the ignition switch ON? YES >> GO TO 2.

NO >> Check CAN system. Refer to LAN-17, " Trouble Diagnosis Flow Chart " .

BCM Power Supply and Ground Circuit Inspec-

tion " .

Is the power supply with the ignition switch ON normal? YES >> GO TO 3.

NO >> Repair power supply as necessary. YES >> Inspection End.

NO >> Replace BCM. Refer to BCS-18, " Removal and Installation of BCM " .

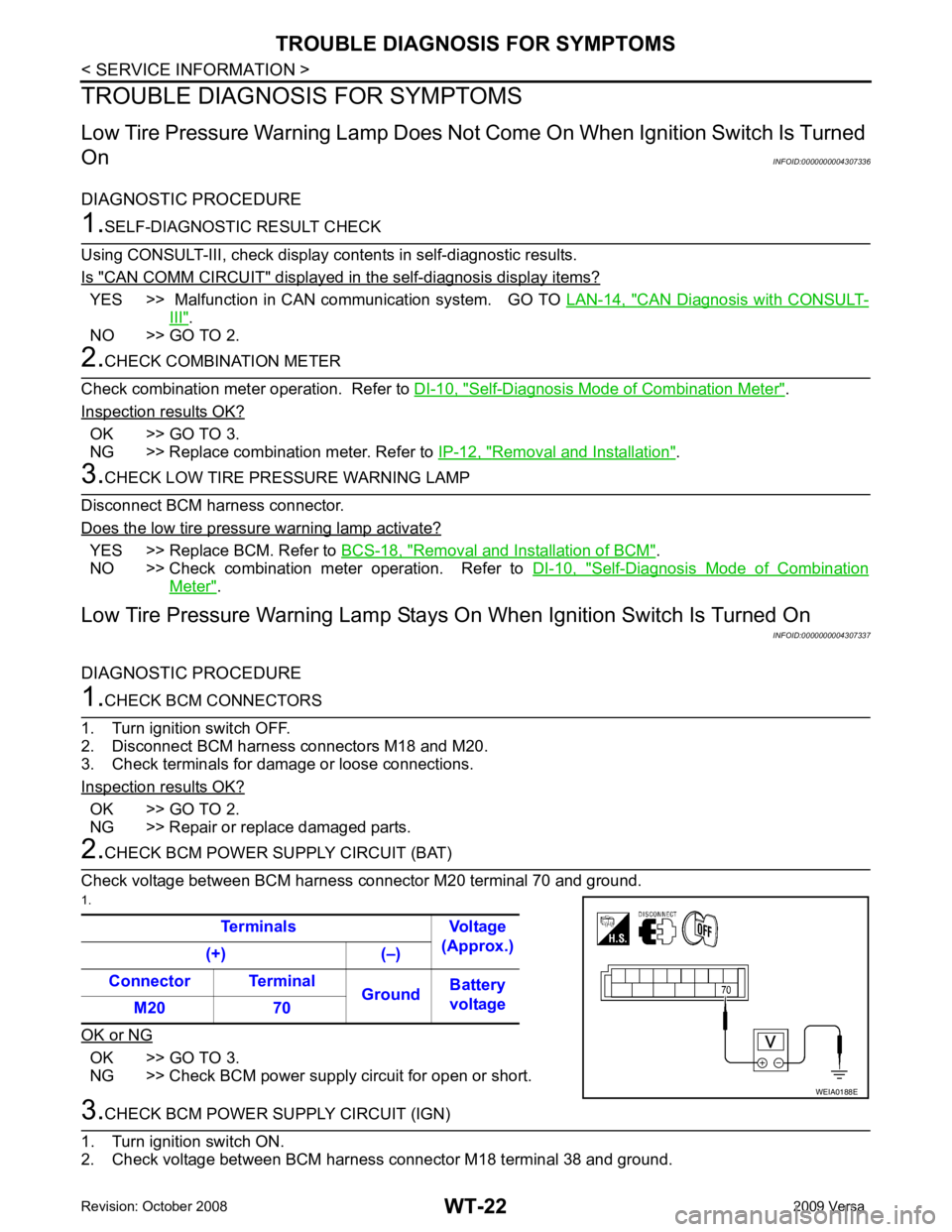

Page 4287 of 4331

YES >> Malfunction in CAN communication system. GO TO

LAN-14, " CAN Diagnosis with CONSULT-

III " .

NO >> GO TO 2. Self-Diagnosis Mode of Combination Meter " .

Inspection results OK? OK >> GO TO 3.

NG >> Replace combination meter. Refer to IP-12, " Removal and Installation " .

YES >> Replace BCM. Refer to

BCS-18, " Removal and Installation of BCM " .

NO >> Check combination meter operation. Refer to DI-10, " Self-Diagnosis Mode of Combination

Meter " .

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000004307337

DIAGNOSTIC PROCEDURE OK >> GO TO 2.

NG >> Repair or replace damaged parts. OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

Page 4288 of 4331

WT

N

O P

OK or NG OK >> GO TO 4.

NG >> Check BCM power supply circuit for open or short. OK >> Replace BCM. Refer to

BCS-18, " Removal and Installa-

tion of BCM " .

NG >> Repair BCM ground circuit.

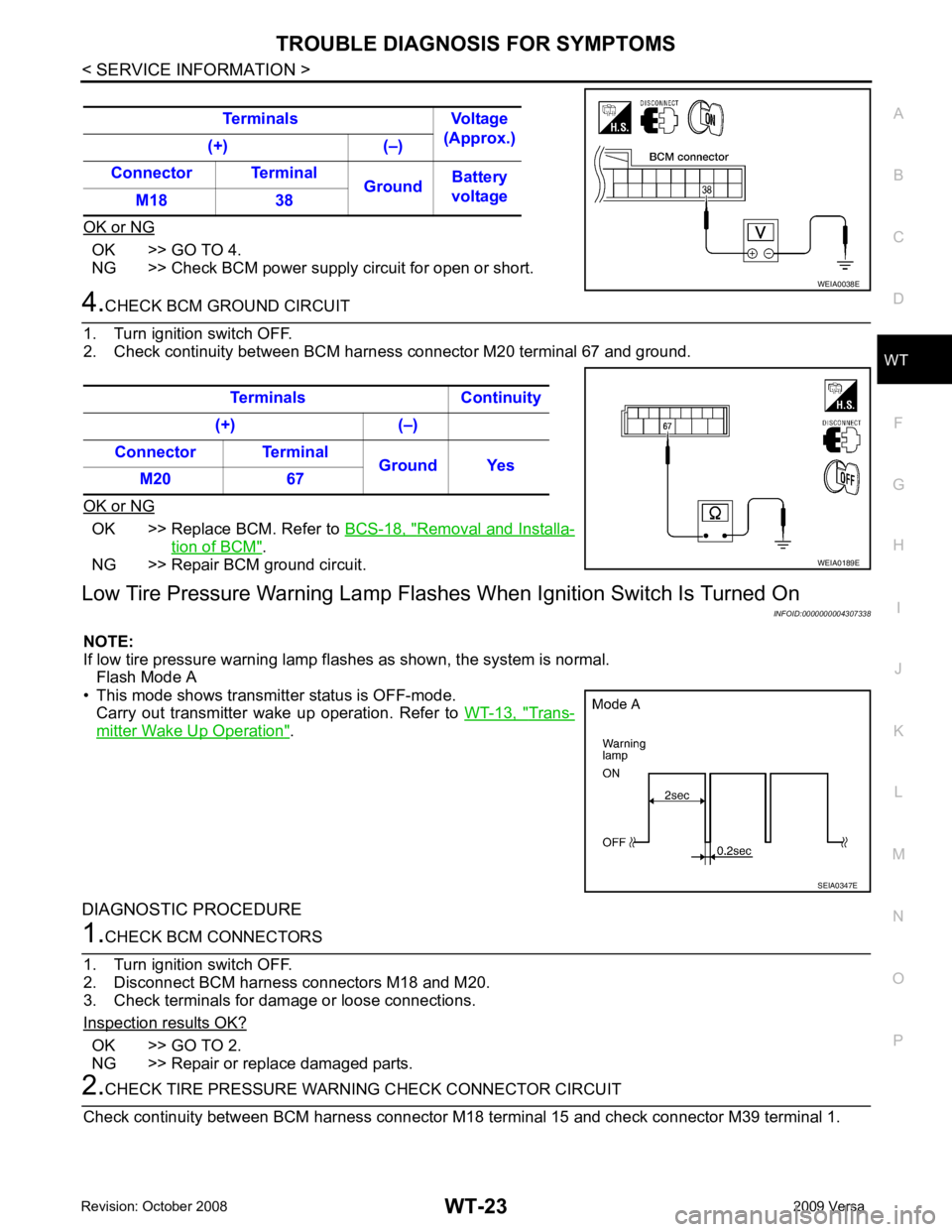

Low Tire Pressure Warning Lamp Flas hes When Ignition Switch Is Turned On

INFOID:0000000004307338

NOTE:

If low tire pressure warning lamp fl ashes as shown, the system is normal.

Flash Mode A

• This mode shows transmitter status is OFF-mode. Carry out transmitter wake up operation. Refer to WT-13, " Trans-

mitter Wake Up Operation " .

DIAGNOSTIC PROCEDURE OK >> GO TO 2.

NG >> Repair or replace damaged parts.

Page 4289 of 4331

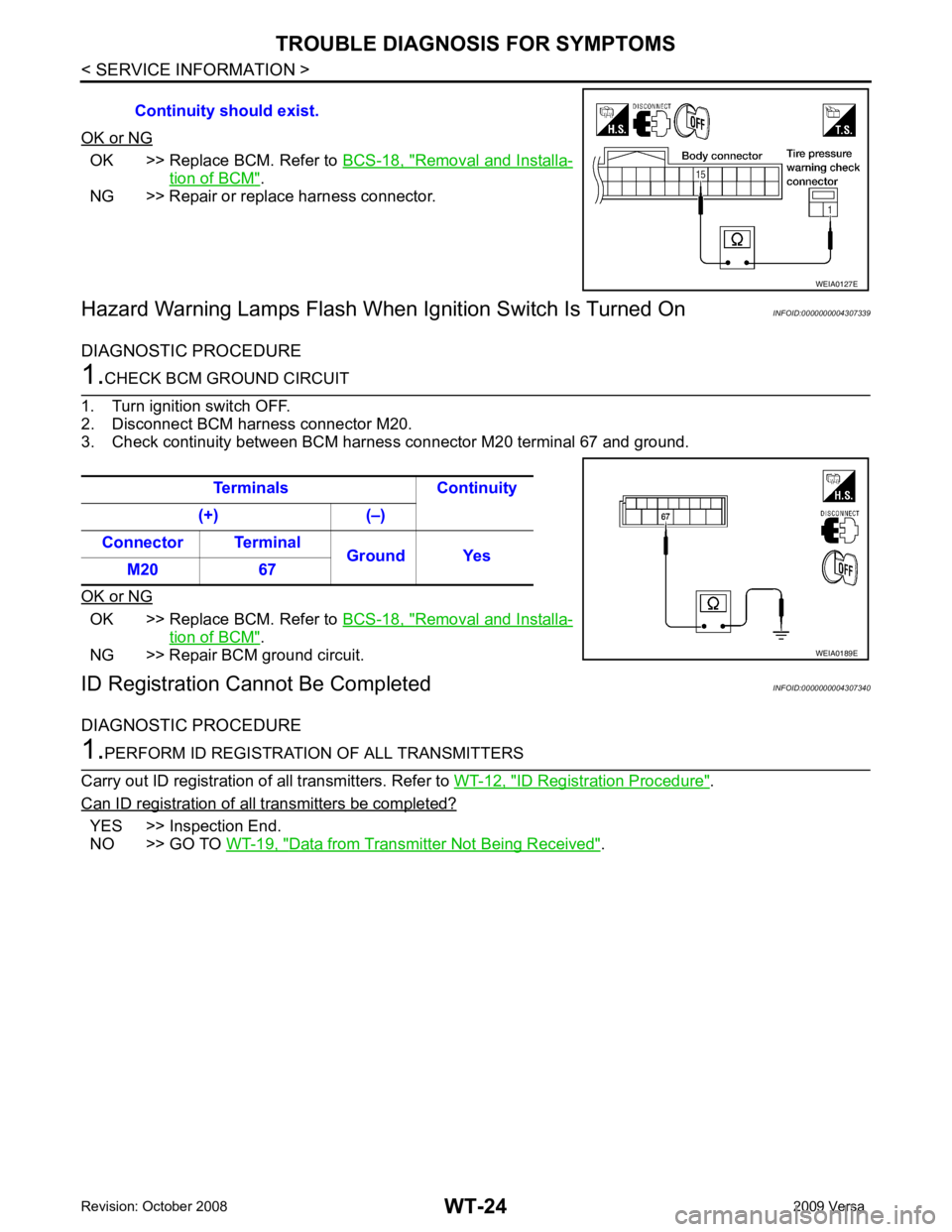

OK >> Replace BCM. Refer to

BCS-18, " Removal and Installa-

tion of BCM " .

NG >> Repair or replace harness connector.

Hazard Warning Lamps Flash When Ignition Switch Is Turned On INFOID:0000000004307339

DIAGNOSTIC PROCEDURE OK >> Replace BCM. Refer to

BCS-18, " Removal and Installa-

tion of BCM " .

NG >> Repair BCM ground circuit.

ID Registration Ca nnot Be Completed INFOID:0000000004307340

DIAGNOSTIC PROCEDURE ID Registration Procedure " .

Can ID registration of all transmitters be completed? YES >> Inspection End.

NO >> GO TO WT-19, " Data from Transmitter Not Being Received " .

Continuity should exist.

Page 4295 of 4331

WW

N

O P

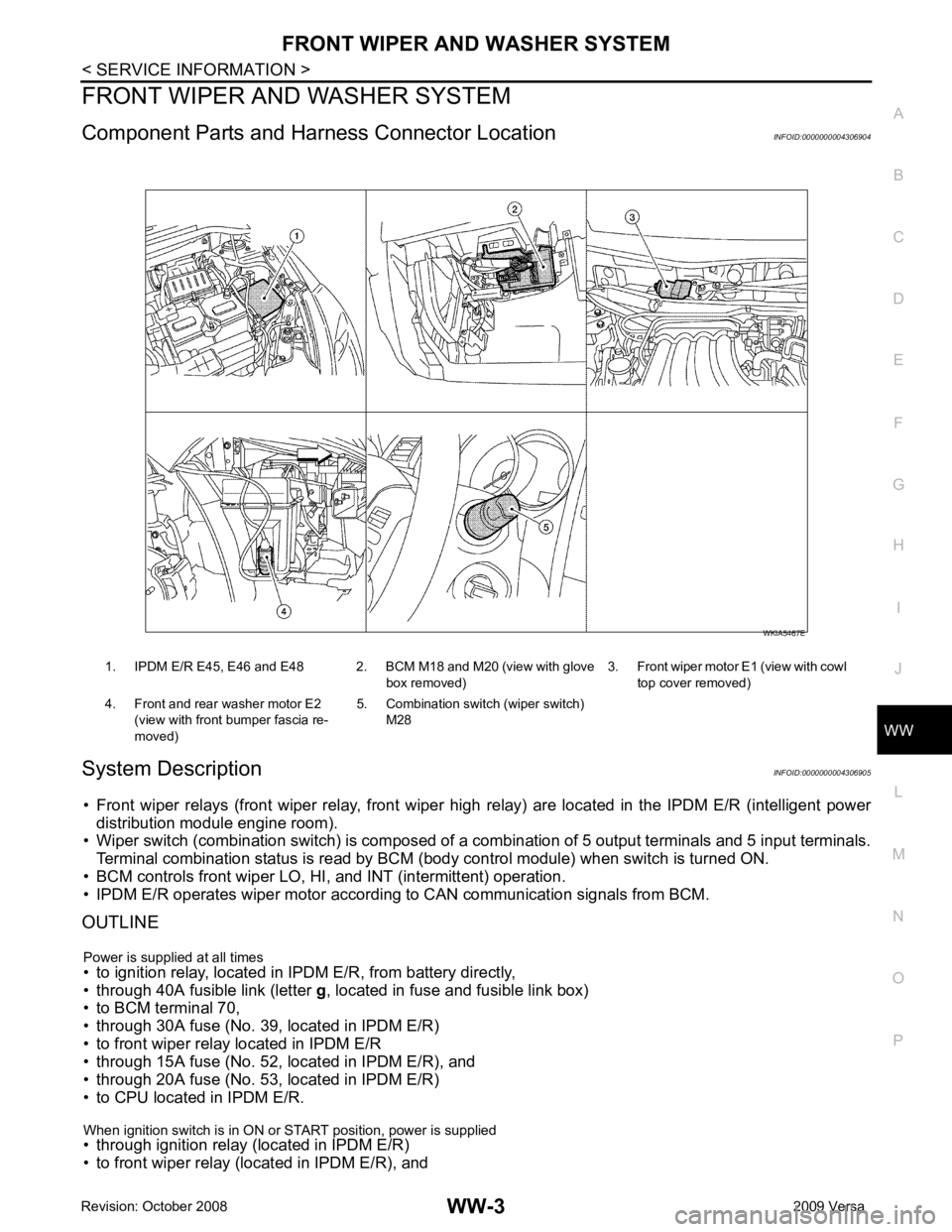

FRONT WIPER AND WASHER SYSTEM

Component Parts and Har ness Connector Location INFOID:0000000004306904

System Description INFOID:0000000004306905

• Front wiper relays (front wiper relay, front wiper hi gh relay) are located in the IPDM E/R (intelligent power

distribution module engine room).

• Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM (body control module) when switch is turned ON.

• BCM controls front wiper LO, HI, and INT (intermittent) operation.

• IPDM E/R operates wiper motor accordi ng to CAN communication signals from BCM.

OUTLINE

Power is supplied at all times

• to ignition relay, located in IPDM E/R, from battery directly,

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70,

• through 30A fuse (No. 39, located in IPDM E/R)

• to front wiper relay located in IPDM E/R

• through 15A fuse (No. 52, located in IPDM E/R), and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R.

When ignition switch is in ON or START position, power is supplied

• through ignition relay (located in IPDM E/R)

• to front wiper relay (located in IPDM E/R), and 1. IPDM E/R E45, E46 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Front wiper motor E1

(view with cowl

top cover removed)

4. Front and rear washer motor E2 (view with front bumper fascia re-

moved) 5. Combination switch (wiper switch)

M28

Page 4297 of 4331

WW

N

O P

AUTO STOP OPERATION

With wiper switch turned OFF, wiper motor will cont inue to operate until wiper arms reach windshield base.

When the wiper arms are not located at base of wi ndshield with wiper switch OFF, ground is supplied

• from IPDM E/R terminal 33

• to front wiper motor terminal 3, in order to continue wiper motor operation at low speed.

When the wiper arms reach base of windshield, fr ont wiper motor terminals 4 and 2 are connected, and

ground is supplied

• to IPDM E/R terminal 38

• through front wiper motor terminals 4 and 2, and

• through grounds E15 and E24.

Then the IPDM E/R sends auto stop operation signal to BCM with CAN communication line.

When the BCM receives auto-stop operation signal, BCM sends wiper stop signal to IPDM E/R with CAN com-

munication line.

IPDM E/R stops wiper motor. Wiper motor wi ll then stop wiper arms at the STOP position.

WASHER OPERATION When the wiper switch is in front wiper washer positi on, BCM detect front wiper washer signal by BCM combi-

nation switch reading function. Refer to BCS-3, " System Description " .

Combination switch power is supplied

• through combination switch terminal 14

• to washer motor terminal 1.

Ground is supplied

• to front washer motor terminal 2

• through combination switch terminal 11, and

• through combination switch terminal 12

• through grounds M57 and M61.

With ground supplied, front washer motor is operated.

When the BCM detects that front washer motor has operated for 0.4 seconds or longer, BCM operates front

wiper motor for low speed.

When the BCM detects washer switch is OFF, low speed operation cycles approximately 2 times and stops.

MIST OPERATION When the wiper switch is turned to the mist positi on, wiper low speed operation cycles once and then stops.

For additional information about wiper operation under th is condition, refer to "LOW SPEED WIPER OPERA-

TION" .

If switch is held in mist posit ion, low speed operation continues.

FAIL-SAFE FUNCTION If an abnormality occurs in CAN communications, IPDM E/ R holds the condition just before fail-safe status is

initiated until ignition switch is turned OFF. (If wipers we re operating in LO just before the initiation of fail-safe

status, they continue to operate in LO until ignition switch is turned OFF.)

COMBINATION SWITCH READING FUNCTION Refer to BCS-3, " System Description " .

CAN Communication System Description INFOID:0000000004306906

Refer to LAN-8, " System Description " .

Page 4302 of 4331

Terminal and Reference Value for BCM " .

Terminal and Reference Value for IPDM E/R INFOID:0000000004306910

Refer to PG-24, " Terminal and Reference Value for IPDM E/R " .

How to Proceed with Trouble Diagnosis INFOID:0000000004306911

1. Confirm symptoms and customer complaint.

2. Understand operation description and function description. Refer to WW-3, " System Description " .

3. Perform preliminary check. Refer to WW-10, " Preliminary Check " .

4. Check symptom and repair or replace malfunctioning parts.

5. Does front wiper and washer operate normally ? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End.

Preliminary Check INFOID:0000000004306912

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-15, " BCM Power Supply and Ground Circuit Inspection "

Item Description CONSULT-III Factory setting

WIPER SPEED SETTING Vehicle speed sensing type wiper control mode can be changed in this mode. ON

×

OFF — ALL SIGNALS Monitors all the signals.

SELECTION FROM MENU Selects items and monitor them. Monitor item Contents

IGN ON SW “ON/OFF” Displays “ignition switch ON (ON)/Other OFF or ACC (OFF)” status as judged from ignition

switch signal.

IGN SW CAN “ON/OFF” Displays “ignition switch ON (ON)/Other OFF or ACC (OFF)” status as judged from CAN com-

munication signal.

FR WIPER HI “ON/OFF” Displays “FRONT WI PER HI (ON)/Other (OFF)” status as judged from wiper switch signal.

FR WIPER LOW “ON/OFF” Displays “FRONT WIPER LOW (ON)/Other (OFF)” status as judged from wiper switch signal.

Page 4317 of 4331

WW

N

O P

REAR WIPER AND WASHER SYSTEM

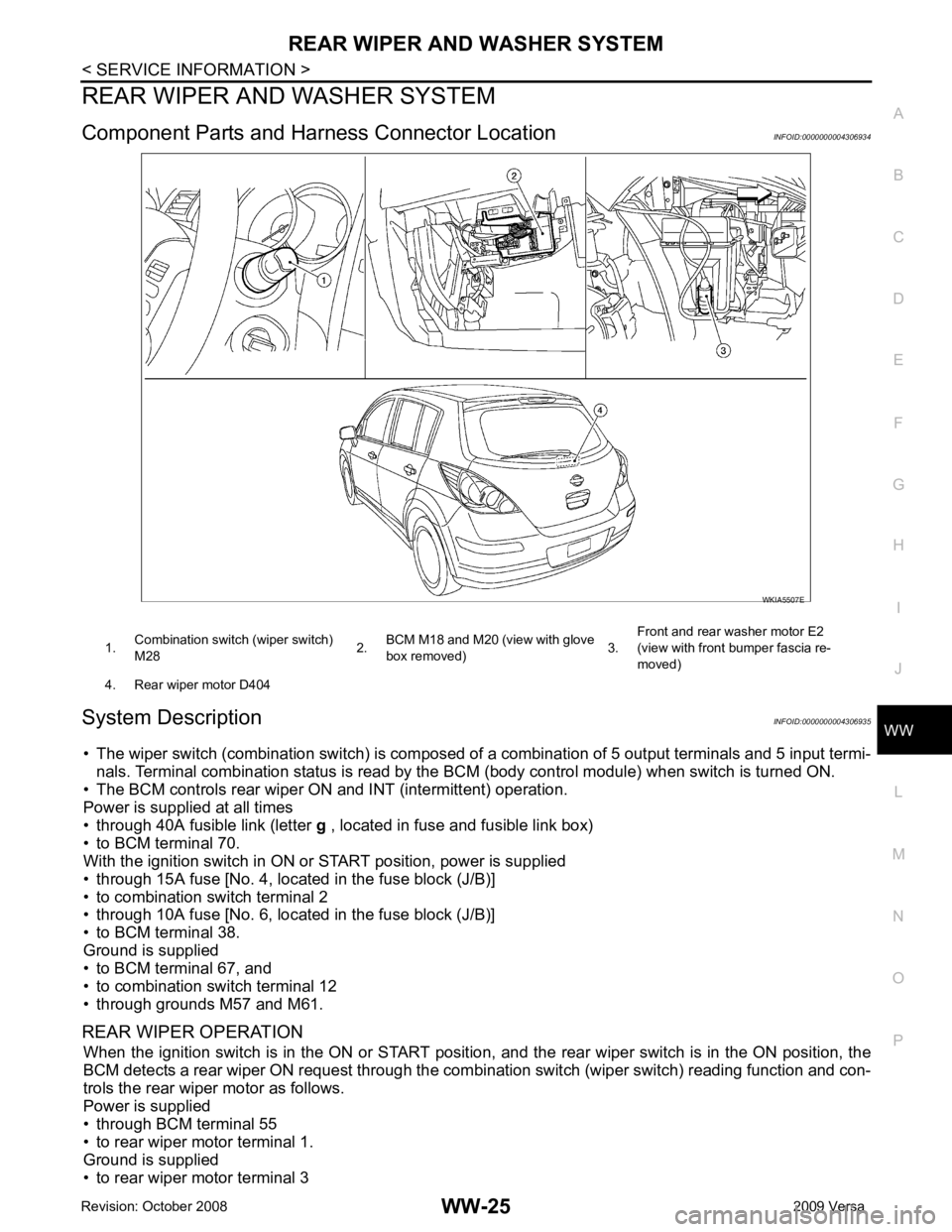

Component Parts and Har ness Connector Location INFOID:0000000004306934

System Description INFOID:0000000004306935

• The wiper switch (combination switch ) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by the BCM (body control module) when switch is turned ON.

• The BCM controls rear wiper ON and INT (intermittent) operation.

Power is supplied at all times

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch in ON or START position, power is supplied

• through 15A fuse [No. 4, located in the fuse block (J/B)]

• to combination switch terminal 2

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67, and

• to combination switch terminal 12

• through grounds M57 and M61.

REAR WIPER OPERATION When the ignition switch is in the ON or START position, and the rear wiper switch is in the ON position, the

BCM detects a rear wiper ON request through the combi nation switch (wiper switch) reading function and con-

trols the rear wiper motor as follows.

Power is supplied

• through BCM terminal 55

• to rear wiper motor terminal 1.

Ground is supplied

• to rear wiper motor terminal 3