check engine NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1171 of 4331

![NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

CVT-227

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

3. Accelerate vehicle to full depression depressing accelerator

pedal constantly.

Read vehicle sp NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

CVT-227

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

3. Accelerate vehicle to full depression depressing accelerator

pedal constantly.

Read vehicle sp](/img/5/57398/w960_57398-1170.png)

TROUBLE DIAGNOSIS

CVT-227

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

3. Accelerate vehicle to full depression depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT- 228, " Vehicle Speed When Shifting Gears " .

OK or NG OK >> GO TO 5.

NG >> Mark the box of CVT-331, " Vehicle Speed Does Not

Change in "L" Position " on the

CVT-213, " How to Per-

form Trouble Diagnosis for Quick and Accurate Repair " .

Continue “Road Test”. 5.

CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 5

1. Park vehicle on flat surface.

2. Move selector lever to “D” position.

3. Push overdrive control switch. (O/D OFF indicator lamp is on.)

4. Accelerate vehicle to full depressing depressing accelerator pedal constantly.

Read vehicle speed and engine speed. Refer to CVT- 228, " Vehicle Speed When Shifting Gears " .

OK or NG OK >> GO TO 6.

NG >> Mark the box of CVT-332, " Vehicle Speed Does Not

Change in overdrive-off mode " on the

CVT-213, " How

to Perform Trouble Diagnosis for Quick and Accurate

Repair " . Continue “Road Test”.

6.

CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 6

1. Park vehicle on flat surface.

2. Move selector lever to “D” position.

3. Push overdrive control switch. (O/D OFF indicator lamp is off.)

4. Accelerate vehicle to full depression depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT- 228, " Vehicle Speed When Shifting Gears " .

OK or NG OK >> GO TO 7.

NG >> Mark the box of CVT-333, " Vehicle Speed Does Not

Change in "D" Position " on the

CVT-213, " How to Per-

form Trouble Diagnosis for Quick and Accurate Repair " .

Continue “Road Test”. 7.

CHECK ENGINE BRAKE FUNCTION — PART 1

1. Release accelerator pedal.

2. Check engine brake. (O/D OFF indicator lamp is off.)

Does engine braking effectively reduce speed in “ D ” position?

YES >> GO TO 8.

NO >> Mark the box of CVT-333, " Vehicle Does Not Decelerate by Engine Brake " on the

CVT-213, " How

to Perform Trouble Diagnosis for Quick and Accurate Repair " . Continue “Road Test”.

8.

CHECK ENGINE BRAKE FUNCTION — PART 2

1. Push overdrive control switch. (O/D OFF indicator lamp is on.)

2. Check engine brake.

Does engine braking effectively reduce speed in “ D ” position?

YES >> GO TO 9.

NO >> Mark the box of CVT-333, " Vehicle Does Not Decelerate by Engine Brake " on the

CVT-213, " How

to Perform Trouble Diagnosis for Quick and Accurate Repair " . Continue “Road Test”. SCIA4366E

SCIA4366E

SCIA4366E

Page 1172 of 4331

![NISSAN TIIDA 2009 Service Repair Manual CVT-228< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS 9.

CHECK ENGINE BRAKE FUNCTION — PART 3

1. Move selector lever to “L” position.

2. Check engine brake.

Does engine braking effectively NISSAN TIIDA 2009 Service Repair Manual CVT-228< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS 9.

CHECK ENGINE BRAKE FUNCTION — PART 3

1. Move selector lever to “L” position.

2. Check engine brake.

Does engine braking effectively](/img/5/57398/w960_57398-1171.png)

CVT-228< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS 9.

CHECK ENGINE BRAKE FUNCTION — PART 3

1. Move selector lever to “L” position.

2. Check engine brake.

Does engine braking effectively reduce speed in “ L ” position?

YES >> 1. Stop the vehicle.

2. Perform self-diagnosis. Refer to CVT-230, " CONSULT-III Function (TRANSMISSION) " .

NO >> Mark the box of CVT-333, " Vehicle Does Not Decelerate by Engine Brake " on the

CVT-213, " How

to Perform Trouble Diagnosis for Quick and Accurate Repair " . Then continue trouble diagnosis.

Vehicle Speed When Shifting Gears INFOID:0000000004305598

Numerical value data are reference values.

CAUTION:

Lock-up clutch is engaged when vehicle speed is approximately 18 km/h (11 MPH) to 90 km/h (56 MPH).

TCM Terminal and Reference Value INFOID:0000000004305599

TCM HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR TCM

Data are reference values and are measured between each terminal and ground. Engine type Throttle position Shift pattern

Engine speed (rpm)

At 40 km/h (25 MPH) At 60 km/h (37 MPH)

MR18DE 8/8

“D” position

Overdrive-off mode “L” position 3,600 - 4,500 4,400 - 5,300

2/8 “D” position 1,300 - 3,100 1,400 - 3,500

Overdrive-off mode 2,200 - 3,000 2,800 - 3,600 “L” position 3,100 - 4,000 3,800 - 4,700 WCIA0717E

Terminal

Wire

color Item Condition Data (Approx.)

1 GR Pressure control

solenoid valve A

(Line pressure

solenoid valve)

and Release your foot from the accelerator pedal. 5.0 - 7.0 V

Press the accelerator pedal all the way down. 1.0 - 3.0 V

2 LG Pressure control

solenoid valve B

(Secondary

pressure sole-

noid valve) Release your foot from the accelerator pedal. 5.0 - 7.0 V

Press the accelerator pedal all the way down. 3.0 - 4.0 V

3 SB Torque converter

clutch solenoid

valve When vehi-

cle cruises in

“D” position. When CVT performs lock-up. 6.0 V

When CVT does not perform lock-up. 1.0 V

Page 1176 of 4331

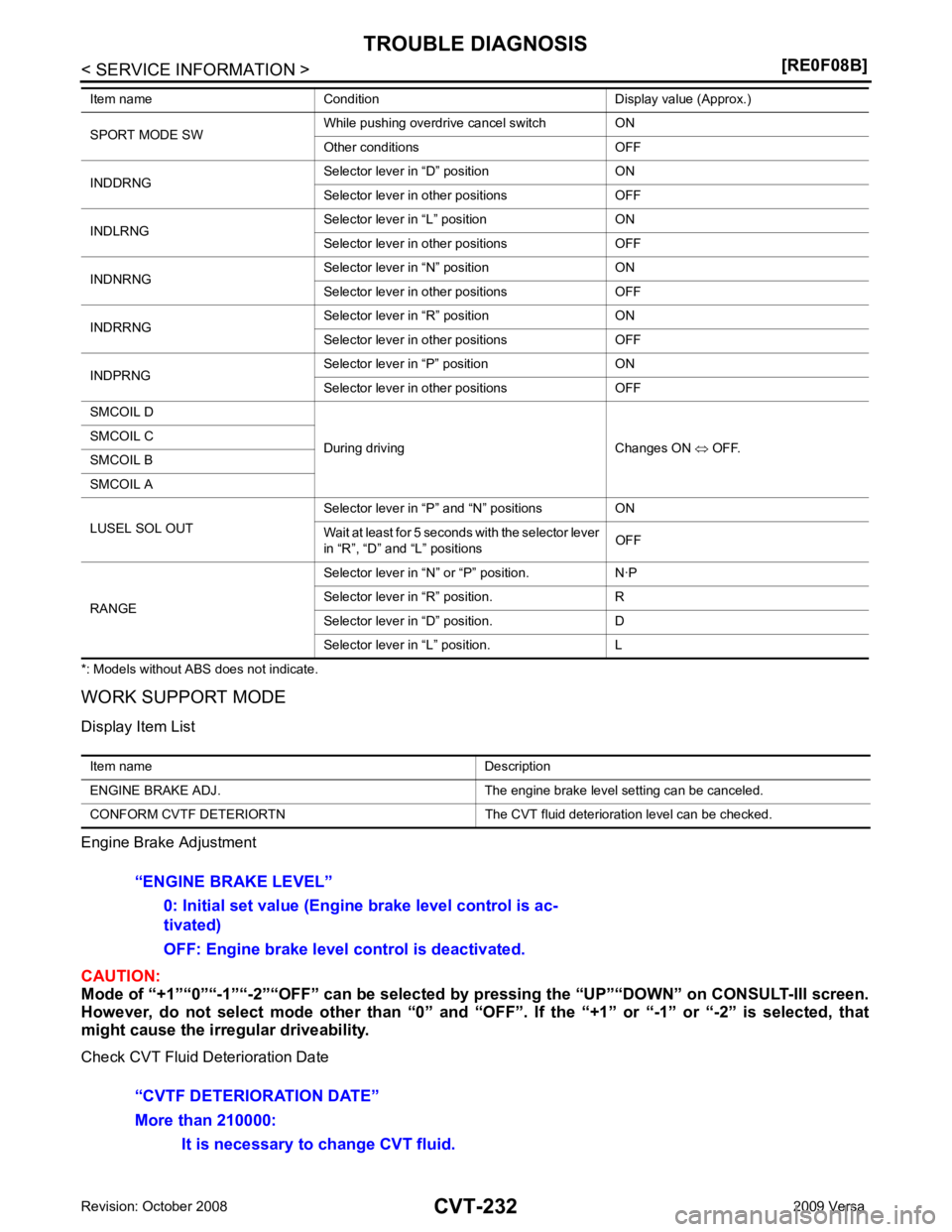

Item name Description

ENGINE BRAKE ADJ. The engine brake level setting can be canceled.

CONFORM CVTF DETERIORTN The CVT fluid deterioration level can be checked.

Page 1177 of 4331

CVT

N

O P

CAUTION:

Touch “CLEAR” after changing CVT fluid, and then erase “CVTF DETERIORATION DATE”.

SELF-DIAGNOSTIC RESULT MODE After performing self-diagnosis, place check marks for results on the CVT-213, " How to Perform Trouble Diag-

nosis for Quick and Accurate Repair " . Reference pages are provided following the items.

Display Items List X: Applicable —: Not applicable

Less than 210000:

It is not necessary to change CVT fluid.

“CVTF DETERIORATION DATE”

Items (CONSULT-

III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-III (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN- GINE” with

CONSULT-III

or GST

CAN COMM CIR-

CUIT When TCM is not transmitting or receiving CAN communica-

tion signal for 2 seconds or more U1000 U1000

CVT-238CONTROL

UNIT(CAN) When detecting error during the initial diagnosis of CAN con-

troller of TCM U1010 U1010

CVT-241BRAKE SW/CIRC When the brake switch does not switch to ON or OFF P0703 —

CVT-242PNP SW/CIRC

When TCM does not receive the the correct voltage signal

(based on the gear position) from the switch P0705 P0705

CVT-244ATF TEMP SEN/

CIRC During running, the CVT fluid temperature sensor signal volt-

age is excessively high or low P0710 P0710

CVT-249INPUT SPD SEN/

CIRC • Input speed sensor (primary speed sensor) signal is not in-

put due to an open circuit

• An unexpected signal is input when vehicle is being driven P0715 P0715

CVT-254VEH SPD SEN/

CIR AT • Signal from vehicle speed sensor CVT [Output speed sen-

sor (Secondary speed sensor)] not input due to open or

short circuit

• Unexpected signal input during running P0720 P0720

CVT-258ENGINE SPEED

SIG • TCM does not receive the CAN communication signal from

the ECM

• Engine speed is too low while driving P0725 —

CVT-263BELT DAMG Unexpected gear ratio detected P0730 —

CVT-265TCC SOLENOID/

CIRC Normal voltage not applied to solenoid due to open or short

circuit P0740 P0740

CVT-266A/T TCC S/V

FNCTN • CVT cannot perform lock-up even if electrical circuit is good

• TCM detects as irregular by comparing difference value with slip rotation

• There is big difference engine speed and primary speed

when TCM lock-up signal is on P0744 P0744

CVT-271L/PRESS SOL/

CIRC • Normal voltage not applied to solenoid due to open or short

circuit

• TCM detects as irregular by comparing target value with

monitor value P0745 P0745

CVT-273PRS CNT SOL/A

FCTN Unexpected gear ratio was detected in the LOW side due to

excessively low line pressure P0746 P0746

CVT-278PRS CNT SOL/B

FCTN Secondary pressure is too high or too low compared with the

commanded value while driving P0776 P0776

CVT-280

Page 1190 of 4331

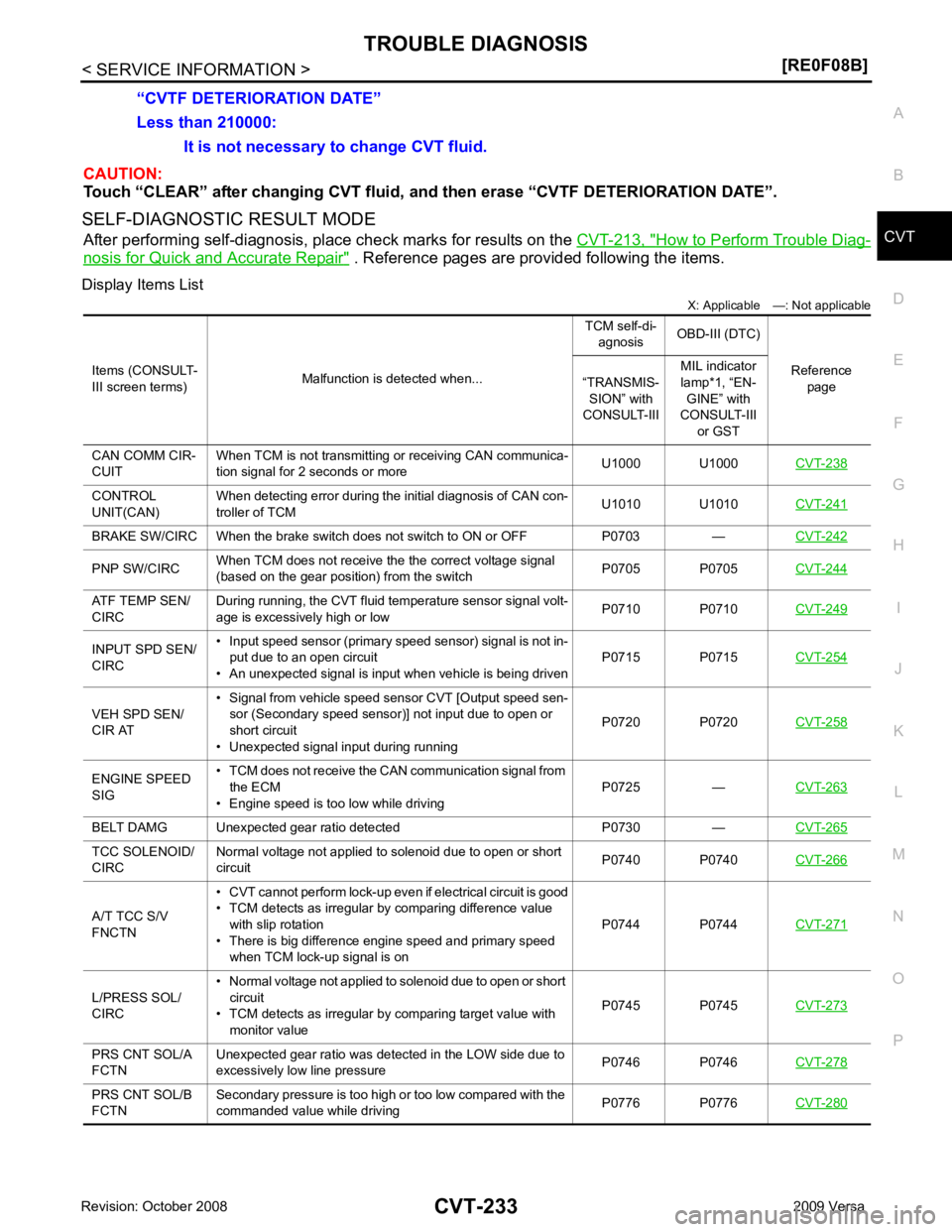

CONSULT-III

Reference Value in Data Monitor Mode " .

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Change selector lever to “P“, “R”, “N”, “D” and “L” positions to

check voltage between the CVT unit harness connector termi-

nals and ground.

OK or NG OK >> GO TO 6.

NG >> GO TO 2. OK >> GO TO 6.

NG >> GO TO 3. Shift

position Connector E31, E32

Terminal

18 - Ground 22 - Ground 26 - Ground 43 - Ground 44 - Ground

P Battery volt-

age 0 V 0 V 0 V 0 V

R 0 V Battery volt-

age 0 V 0 V 0 V

N 0 V 0 V Battery volt-

age 0 V 0 V

D 0 V 0 V 0 V Battery volt-

age 0 V

L 0 V 0 V 0 V 0 V Battery volt-

age B

Page 1195 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0710 CVT FLUID TEMP

ERATURE SENSOR CIRCUIT

CVT-251

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Diagnosis Procedure

INFOID:00000000043056401.

CHECK CVT FLUID TEMP ERATURE NISSAN TIIDA 2009 Service Repair Manual DTC P0710 CVT FLUID TEMP

ERATURE SENSOR CIRCUIT

CVT-251

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Diagnosis Procedure

INFOID:00000000043056401.

CHECK CVT FLUID TEMP ERATURE](/img/5/57398/w960_57398-1194.png)

DTC P0710 CVT FLUID TEMP

ERATURE SENSOR CIRCUIT

CVT-251

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Diagnosis Procedure

INFOID:00000000043056401.

CHECK CVT FLUID TEMP ERATURE SENSOR SIGNAL

With CONSULT-III

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “ATF TEMP SEN”.

Without CONSULT-III

1. Start engine.

2. Check voltage between TCM connector terminals.

3. Turn ignition switch OFF.

4. Disconnect TCM connector.

5. Check if there is continuity between connector terminal and

ground.

OK or NG OK >> GO TO 5.

NG >> GO TO 2. 2.

CHECK CVT FLUID TEMP ERATURE SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check resistance between TCM connector terminals.

OK or NG OK >> GO TO 5.

NG >> GO TO 3. 3.

CHECK CVT FLUID TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector. Item name Condition

Display value

(Approx.)

ATF TEMP SEN When CVT fluid temperature is 20

°C

(68 °F). 2.0 V

When CVT fluid temperature is 80 °C

(176 °F). 1.0 VName Connector Terminal

Temperature

°C ( °F) Voltage

(Approx.)

CVT fluid tem-

perature sen-

sor E32 47 - 42 20 (68) 2.0 V

80 (176) 1.0 V SCIA2027E

Name Connector Terminal

Temperature

°C ( °F) Resistance

(Approx.)

CVT fluid tem-

perature sensor E32 47 - 42 20 (68) 6.5 k

Ω

80 (176) 0.9 k Ω SCIA2510E

Page 1204 of 4331

![NISSAN TIIDA 2009 Service Repair Manual CVT-260< SERVICE INFORMATION >

[RE0F08B]

DTC P0720 VEHICLE SPEED SENSOR

CVT (SECONDARY SPEED SENSOR)

Diagnosis Procedure INFOID:00000000043056551.

CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine. NISSAN TIIDA 2009 Service Repair Manual CVT-260< SERVICE INFORMATION >

[RE0F08B]

DTC P0720 VEHICLE SPEED SENSOR

CVT (SECONDARY SPEED SENSOR)

Diagnosis Procedure INFOID:00000000043056551.

CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.](/img/5/57398/w960_57398-1203.png)

CVT-260< SERVICE INFORMATION >

[RE0F08B]

DTC P0720 VEHICLE SPEED SENSOR

CVT (SECONDARY SPEED SENSOR)

Diagnosis Procedure INFOID:00000000043056551.

CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start vehicle and read out the value of “VSP SENSOR”.

OK or NG OK >> GO TO 8.

NG >> GO TO 2. 2.

CHECK SECONDARY SPEED SENSOR

With CONSULT-III

1. Start engine.

2. Check power supply to output speed sensor (s econdary speed sensor) by voltage between TCM connec-

tor terminals 10, 19 and 42. Refer to CVT-219, " Circuit Diagram " .

3. If OK, check the pulse when vehicle cruises.

OK or NG OK >> GO TO 8.

NG >> GO TO 3. 3.

CHECK POWER AND SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect the output speed sensor (s econdary speed sensor) harness connector.

3. Turn ignition switch ON. Item name Condition Display value

VSP SENSOR During driving Approximately matches

the speedometer reading. Item Connector Terminal Data (Approx.)

TCM E31, E32 10 - 42

Battery voltage

19 - 42

Name Condition

Output speed sen-

sor (Secondary

speed sensor) When running at 20 km/h (12 MPH) in “D” position, use the

CONSULT-III pulse frequency measuring function.

CAUTION:

Connect the data link connector to the vehicle-side diag-

nosis connector.

Item Connector Terminal Name Data (Ap-

prox.)

TCM E32 29 Output speed sensor (Sec-

ondary speed sensor) 570 Hz SCIA2344E

Page 1207 of 4331

CVT

N

O P

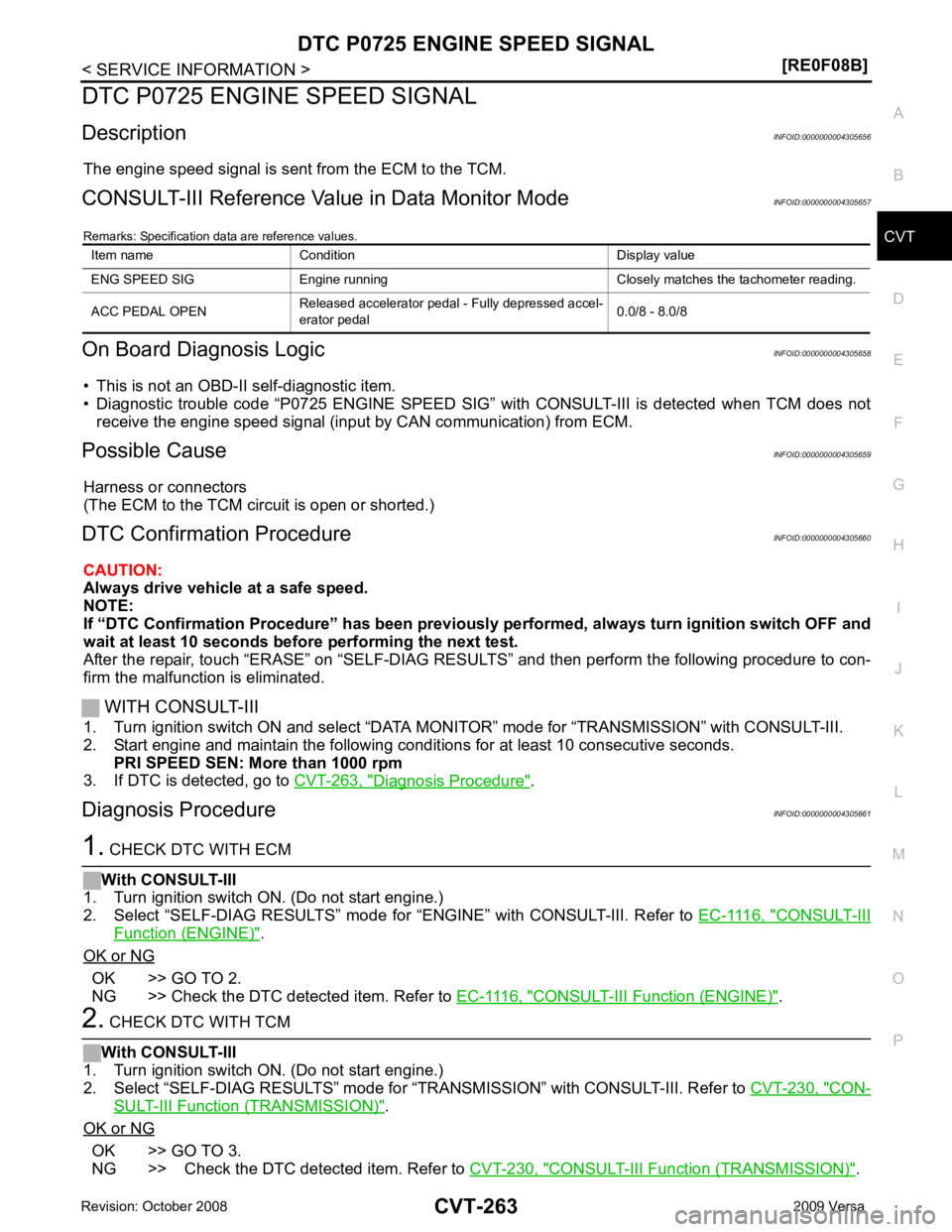

DTC P0725 ENGINE SPEED SIGNAL

Description INFOID:0000000004305656

The engine speed signal is sent from the ECM to the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305657

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305658

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0725 ENGINE SPEED SIG” with CONSULT-III is detected when TCM does not

receive the engine speed signal (input by CAN communication) from ECM.

Possible Cause INFOID:0000000004305659

Harness or connectors

(The ECM to the TCM circuit is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004305660

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Start engine and maintain the following conditions for at least 10 consecutive seconds. PRI SPEED SEN: More than 1000 rpm

3. If DTC is detected, go to CVT-263, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004305661 CONSULT-III

Function (ENGINE) " .

OK or NG OK >> GO TO 2.

NG >> Check the DTC detected item. Refer to EC-1116, " CONSULT-III Function (ENGINE) " .

CON-

SULT-III Functi

on (TRANSMISSION) " .

OK or NG OK >> GO TO 3.

NG >> Check the DTC detected item. Refer to CVT-230, " CONSULT-III Function (TRANSMISSION) " .

Item name Condition Display value

ENG SPEED SIG Engine running Closely matches the tachometer reading.

ACC PEDAL OPEN Released accelerator pedal - Fully depressed accel-

erator pedal 0.0/8 - 8.0/8

Page 1208 of 4331

.

OK >> GO TO 4.

NG >> Check ignition signal circuit. Refer to EC-1518, " Component Description " .

DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 5. TCM Terminal and Reference Value " .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Item name Condition Display value

ENG SPEED SIG Engine running Closely matches the ta-

chometer reading.

ACC PEDAL OPEN Released accelerator

pedal - Fully depressed

accelerator pedal 0.0/8 - 8.0/8

Page 1209 of 4331

CVT

N

O P

DTC P0730 BELT DAMAGE

Description INFOID:0000000004305662

TCM selects the gear ratio using the engine load (throttle position), the primary pulley revolution speed, and

the secondary pulley revolution speed as input signal. T hen it changes the operating pressure of the primary

pulley and the secondary pulley and changes the groove width of the pulley.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305663

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305664

• This is not an OBD-II self-diagnostic item.

• TCM calculates the actual gear ratio with input speed sensor (primary speed sensor) and output speed sen-

sor (secondary speed sensor).

• Diagnostic trouble code “P0730 BELT DAMG” with CONSUL T-III is detected, when TCM receives an unex-

pected gear ratio signal.

Possible Cause INFOID:0000000004305665

Transaxle assembly

DTC Confirmation Procedure INFOID:0000000004305666

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds.

TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-265, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004305667DTC Confirmation Procedure " .

Are any DTC displayed? YES - 1>> DTC except for “P0730 BELT DAMG” is displa

yed: Go to Check the DTC detected item. Refer to

CVT-230, " CONSULT-III Function (TRANSMISSION) " .

YES - 2>> DTC for “P0730 BELT DAMG” is displayed: Replace the transaxle assembly. Refer to CVT-354," Removal and Installation " .

NO >> INSPECTION END

Item name Condition Display value (Approx.)

GEAR RATIO During driving 2.56 - 0.43