fuel pressure NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2869 of 4331

![NISSAN TIIDA 2009 Service Repair Manual FUEL PUMP

EC-1513

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004500415

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the s NISSAN TIIDA 2009 Service Repair Manual FUEL PUMP

EC-1513

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004500415

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the s](/img/5/57398/w960_57398-2868.png)

FUEL PUMP

EC-1513

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004500415

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

start ability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engi ne is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition s witch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel

pump. It controls the ON/OFF fuel pump rela y, which in turn controls the fuel pump.

COMPONENT DESCRIPTION A turbine type design fuel pump is used in the fuel tank.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

• Fuel tank temperature sensor (4)

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500416

Specification data are reference values. Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage* Condition Fuel pump operation

Ignition switch is turned to ON Operates for 1 second

Engine running and cranking Operates

Engine: Stopped Stops in 1.5 seconds

Except as shown above Stops BBIA0704E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY • For 1 second after turning ignition switch ON

• Engine running or cranking ON

• Except above conditions OFF

Page 2871 of 4331

![NISSAN TIIDA 2009 Service Repair Manual FUEL PUMP

EC-1515

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045004181.

CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed NISSAN TIIDA 2009 Service Repair Manual FUEL PUMP

EC-1515

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045004181.

CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed](/img/5/57398/w960_57398-2870.png)

FUEL PUMP

EC-1515

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045004181.

CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose (1) with two fingers.

- Illustration shows the view with intake air duct removed.

OK or NG OK >>

INSPECTION END

NG >> GO TO 2. 2.

CHECK FUEL PUMP POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

4. Check voltage between ECM terminal 23 and ground with CON-

SULT-III or tester.

OK or NG OK >> GO TO 5.

NG >> GO TO 3. 3.

CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E46.

3. Turn ignition switch ON.

4. Check voltage between IPDM E/R terminal 47 and ground with

CONSULT-III or tester.

OK or NG OK >> GO TO 4.

NG >> GO TO 11.

TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

23 GR Fuel pump relay [Ignition switch: ON]

• For 1 second after turning ignition switch ON

[Engine is running] 0 - 1.0V

[Ignition switch: ON]

• More than 1 second after turning ignition

switch ON BATTERY VOLTAGE

(11 - 14V) Fuel pressure pulsation should

be felt on the fuel feed

hose for 1 second after ignition switch is turned ON. BBIA0712E

Voltage: Battery voltage

PBIA9573J

Voltage: Battery voltage

PBIB3319E

Page 2882 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1526< SERVICE INFOMATION >

[MR TYPE 2]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or f NISSAN TIIDA 2009 Service Repair Manual EC-1526< SERVICE INFOMATION >

[MR TYPE 2]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or f](/img/5/57398/w960_57398-2881.png)

EC-1526< SERVICE INFOMATION >

[MR TYPE 2]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel

pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

3. Check resistance between condenser-2 terminals 1 and 2.

4. If NG, replace condenser-2.

Removal and Installation INFOID:0000000004500425

IGNITION COIL WITH POWER TRANSISTOR

Refer to EM-153 .

Spark should be generated. PBIB2958E

PBIB2325E

Resistance: Above 1 M

Ω [at 25 °C (77 °F)] PBIB0794E

Page 2948 of 4331

EM

N

O P

CONTENTS

ENGINE MECHANICAL

HR16DE

PRECAUTION ....... ........................................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Drain Cool ant .....................................5

Precaution for Disconnecting Fuel Piping ........... ......5

Precaution for Removal and Disassembly ................5

Precaution for Inspection, Repair and Replace-

ment .................................................................... ......

5

Precaution for Assembly and Installation ..................5

Parts Requiring Angular Tightening ..........................6

Precaution for Liquid Gasket ............................... ......6

PREPARATION .... ........................................8

PREPARATION .............................................. .....8

Special Service Tools .......................................... ......8

Commercial Service Tools .................................. ......9

SYMPTOM DIAGNOSIS ..... .........................12

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

12

NVH Troubleshooting - Engine Noise ................. ....12

Use the Chart Below to Help You Find the Cause

of the Symptom ................................................... ....

13

ON-VEHICLE MAINTENA NCE ....................14

DRIVE BELTS ................................................ ....14

Checking ............................................................. ....14

Tension Adjustment ............................................ ....14

Removal and Installation .........................................15

AIR CLEANER FILTER .................................. ....17 Removal and Installation .....................................

....17

SPARK PLUG ................................................... 18

Exploded View ..................................................... ....18

Removal and Installation ..................................... ....18

CAMSHAFT VALVE CLEARANCE .................. 20

Inspection and Adjustment .................................. ....20

COMPRESSION PRESSURE ........................... 23

Inspection ............................................................ ....23

ON-VEHICLE REPAIR ..... ............................24

DRIVE BELT IDLER PULLEY .......................... 24

Exploded View ..................................................... ....24

Removal and Installation ..................................... ....24

AIR CLEANER AND AIR DUCT ....................... 26

Exploded View ..................................................... ....26

Removal and Installation ..................................... ....26

Inspection ............................................................ ....27

INTAKE MANIFOLD ......................................... 28

Exploded View ..................................................... ....28

Removal and Installation ..................................... ....28

EXHAUST MANIFOLD ...................................... 31

Exploded View ..................................................... ....31

Removal and Installation ..................................... ....31

FUEL INJECTOR AND FUEL TUBE ................ 34

Exploded View ..................................................... ....34

Removal and Installation ..................................... ....34

Inspection ............................................................ ....38

OIL PAN (LOWER) ........................................... 39

Exploded View ..................................................... ....39

Removal and Installation ..................................... ....39

Inspection ............................................................ ....41

OIL PAN (UPPER) AND OIL STRAINER ......... 42

Component .......................................................... ....42

Page 2952 of 4331

![NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EM-5

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

t NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EM-5

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

t](/img/5/57398/w960_57398-2951.png)

PRECAUTIONS

EM-5

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Procedur e without Cowl Top Cover INFOID:0000000004784258

When performing the procedure after removing cowl top cover, cover

the lower end of windshield.

Precaution for Drain Coolant INFOID:0000000004784260

• Drain coolant when engine is cooled.

Precaution for Disco nnecting Fuel Piping INFOID:0000000004784261

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and Disassembly INFOID:0000000004784262

• When instructed to use special service tools, use the spec ified tools. Always be careful to work safely, avoid

forceful or uninstructed operations.

• Exercise maximum care to avoid damage to mating or sliding surfaces.

• Cover openings of engine system with tape or the equiva lent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organized way for easy troubleshooting and assembly.

• When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specif ied, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and Replacement INFOID:0000000004784263

• Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and Installation INFOID:0000000004784264

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction

and blockage.

• Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

• Release air within route after draining coolant.

• Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then make sure that there are no leaks at fuel line connections.

• After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems for leakage. PIIB3706J

Page 2970 of 4331

EM

NP

O

COMPRESSION PRESSURE

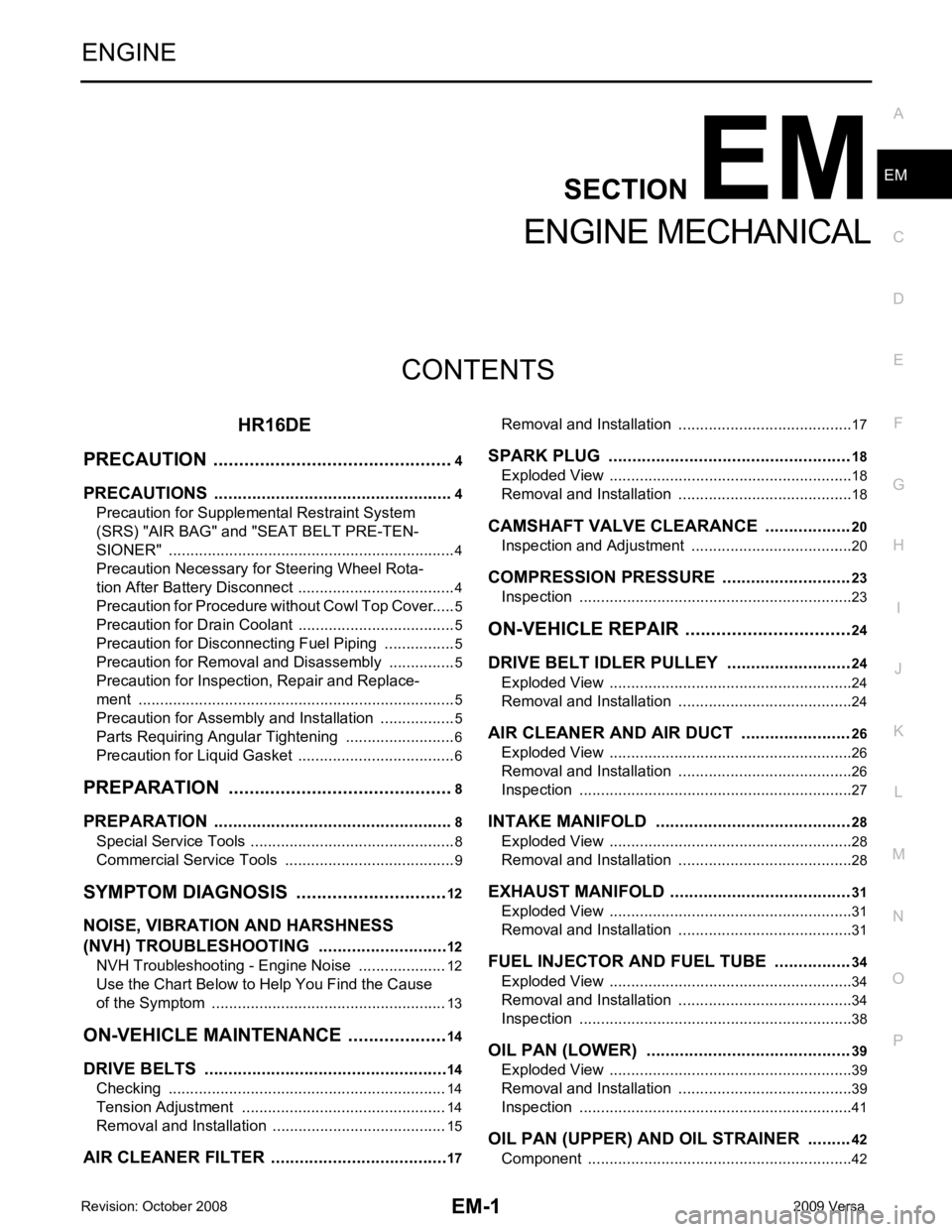

Inspection INFOID:0000000004784276

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-498, " Inspection " .

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-46, " Exploded View " .

4. Connect an engine tachometer (not required in use of CONSULT-III).

5. Install a compression tester (B) with an adapter (commercial service tool) (A) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plug hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

6. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

CAUTION:

Always use fully a charged battery to obtain the specified engine speed.

• If the engine speed is out of the specified range, c heck battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

• If compression pressure is below minimum value, check valve clearances and parts associated with combustion chamber (Valve, valve seat, piston, pi ston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure the compression pressure again.

• If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal- functioning. Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, cylinder head gasket is leaking. In such a case, replace cylinder

head gasket.

7. After inspection is completed, install removed parts.

8. Start the engine, and confirm that the engine runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-112, " Description " . SBIA0533E

General Specification " .

Page 2985 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EM-38< ON-VEHICLE REPAIR >

[HR16DE]

FUEL INJECTOR AND FUEL TUBE

c. Align center to insert quick connector straightly into fuel tube. • Insert quick connector to fuel tube until the top spoo NISSAN TIIDA 2009 Service Repair Manual EM-38< ON-VEHICLE REPAIR >

[HR16DE]

FUEL INJECTOR AND FUEL TUBE

c. Align center to insert quick connector straightly into fuel tube. • Insert quick connector to fuel tube until the top spoo](/img/5/57398/w960_57398-2984.png)

EM-38< ON-VEHICLE REPAIR >

[HR16DE]

FUEL INJECTOR AND FUEL TUBE

c. Align center to insert quick connector straightly into fuel tube. • Insert quick connector to fuel tube until the top spool on fueltube is inserted completely and the 2nd level spool is posi-

tioned slightly below quick connector bottom end.

CAUTION:

• Hold “A” position shown when inserting fuel tube into

quick connector.

• Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

• Insert until you hear a “click” sound and actually feel

the engagement.

• To avoid misidentification of engagement with a similar sound, be sure to pe rform the next step.

d. Before clamping fuel feed hose with hose clamp, pull quick connector hard by hand holding “A” position.

Make sure it is completely engaged (connected) so that it does not come out from fuel tube.

e. Install quick connector cap (1) to quick connector connection. • Install quick connector cap with the side arrow facing quick

connector side (fuel feed hose side).

CAUTION:

• Make sure that the quick connector and fuel tube are

securely engaged with the quick connector cap mount-

ing groove.

• Quick connector may not be connected correctly if quick connector cap cannot be installed easily. Remove

the quick connector cap, and then check the connection

of quick connector again.

f. Install fuel feed hose to hose clamp.

7. Installation of the remaining components is in the reverse order of removal.

Inspection INFOID:0000000004784288

INSPECTION AFTER INSTALLATION

Check on Fuel Leakage

1. Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, make sure

there are no fuel leaks at connection points.

NOTE:

Use mirrors for checking at points out of clear sight.

2. Start the engine. With engine speed increased, make su re again that there are no fuel leaks at connection

points.

CAUTION:

Never touch the engine immediately after it is stopped, as the engine becomes extremely hot. KBIA0272E

PBIC3664E

Page 3004 of 4331

EM

NP

O

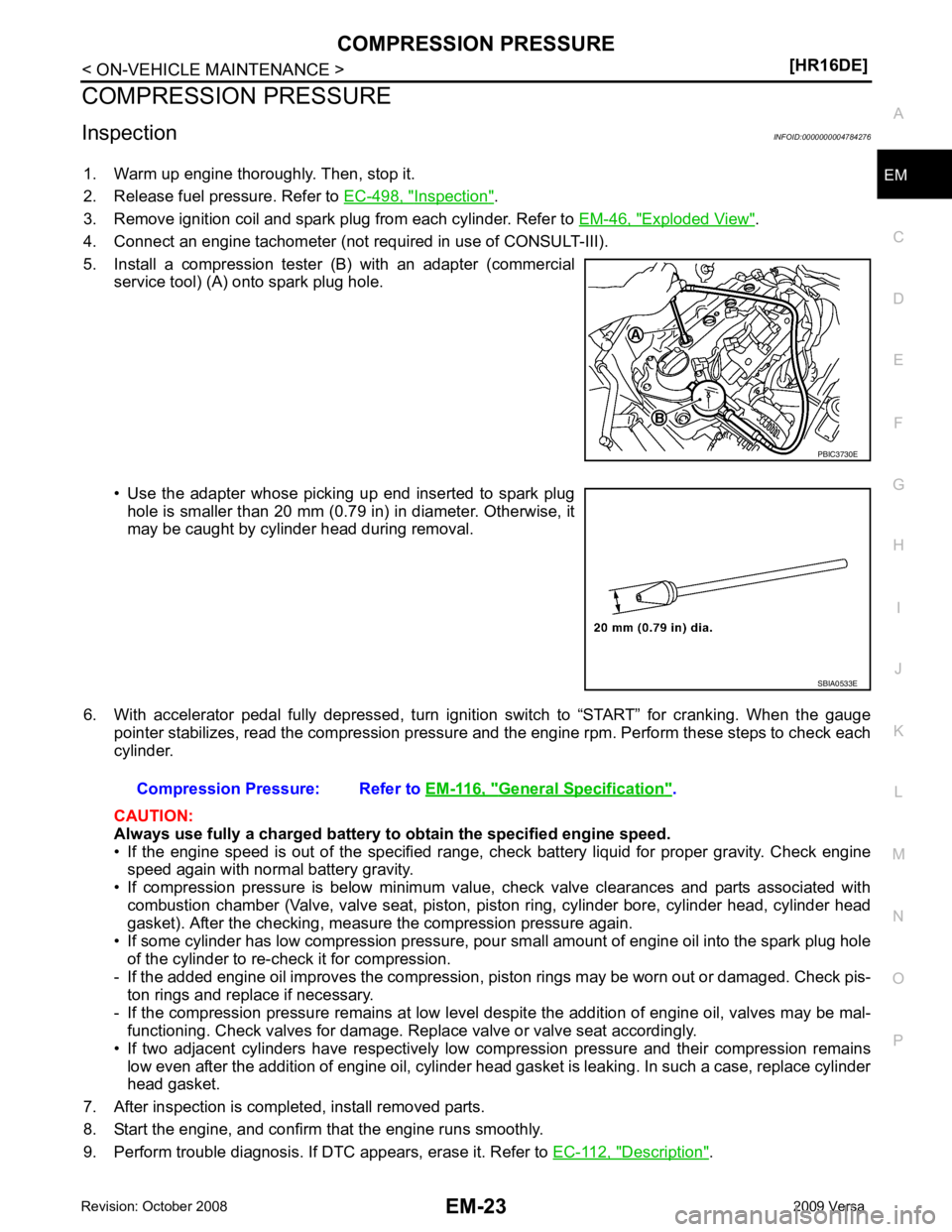

Check for cracks (A) and any excessive wear (B) at link plates and

roller links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLATION

Inspection for Leaks • Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, " Fluids and Lubricants " .

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak age of fuel, or any oil/fluids including engine oil and

engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

Summary of the inspection items:

* Transaxle fluid, power steering fluid, brake fluid, etc.

Page 3021 of 4331

Fluids and Lubricants " .

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

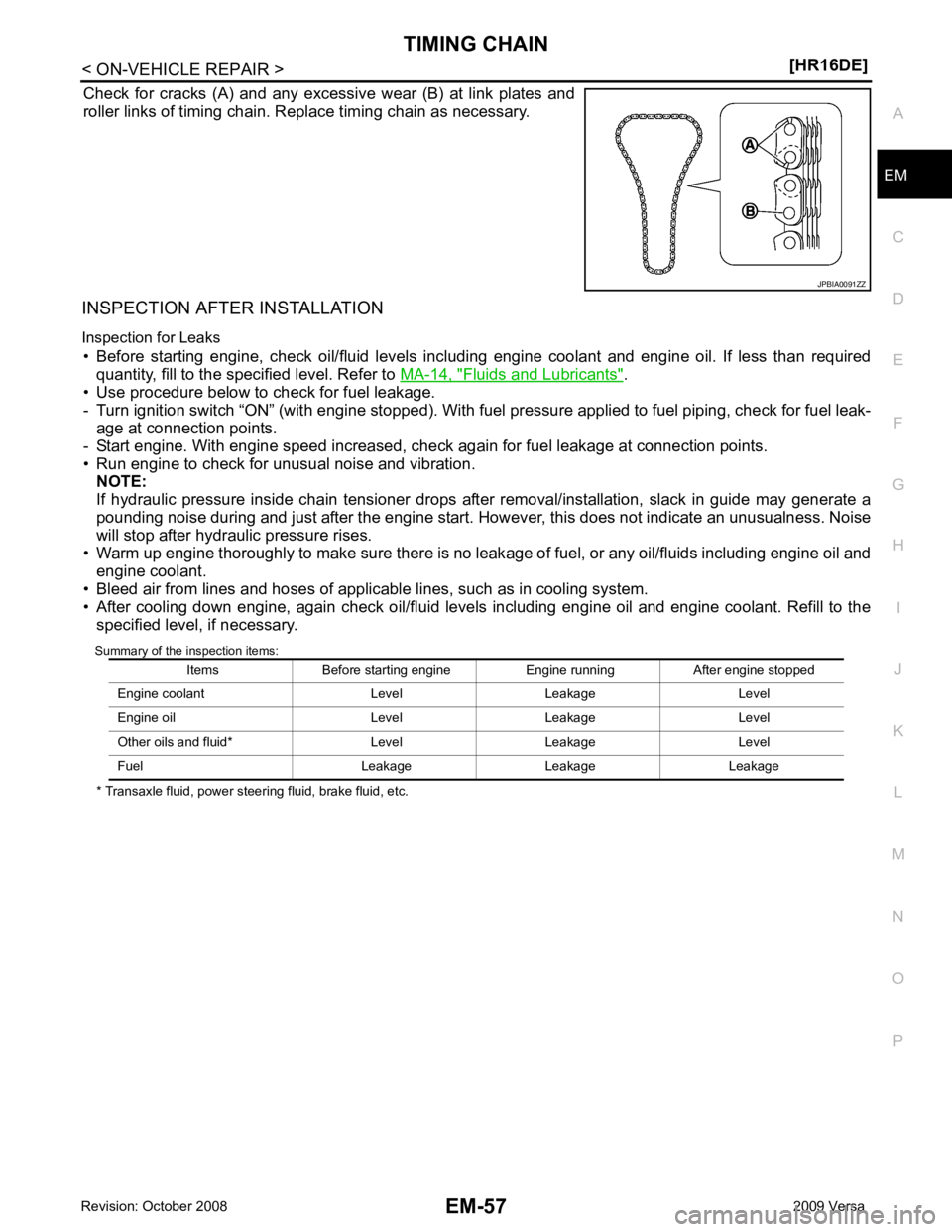

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 is de tected in self-diagnostic results of CONSULT-III

and it is directed according to inspect ion procedure of EC section. Refer to EC-133, " Diagnosis Pro-

cedure " .

• Check when engine is cold so as to pr event burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-7, " Inspection " .

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release the fuel pressure. Refer to EC-498, " Inspection " .

b. Remove intake manifold. Refer to EM-28, " Exploded View " .

c. Disconnect ignition coil and injector harness connectors. Refer to EM-46, " Exploded View " .

3. Remove intake valve timing control solenoid valve. Refer to EM-49, " Exploded View " .

4. Crank engine, and then make sure that engine oil comes out from intake valve timing control solenoid valve hole (A). End

crank after checking.

WARNING:

Be careful not to touch rotating parts (drive belts, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

• Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil an d so as to prevent engine oil contamination.

• Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts,

engine mounting insulator, etc. Wipe engi ne oil off immediately if it is splashed.

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage 1 : Plug

:Engine front

Page 3026 of 4331

EM

NP

O

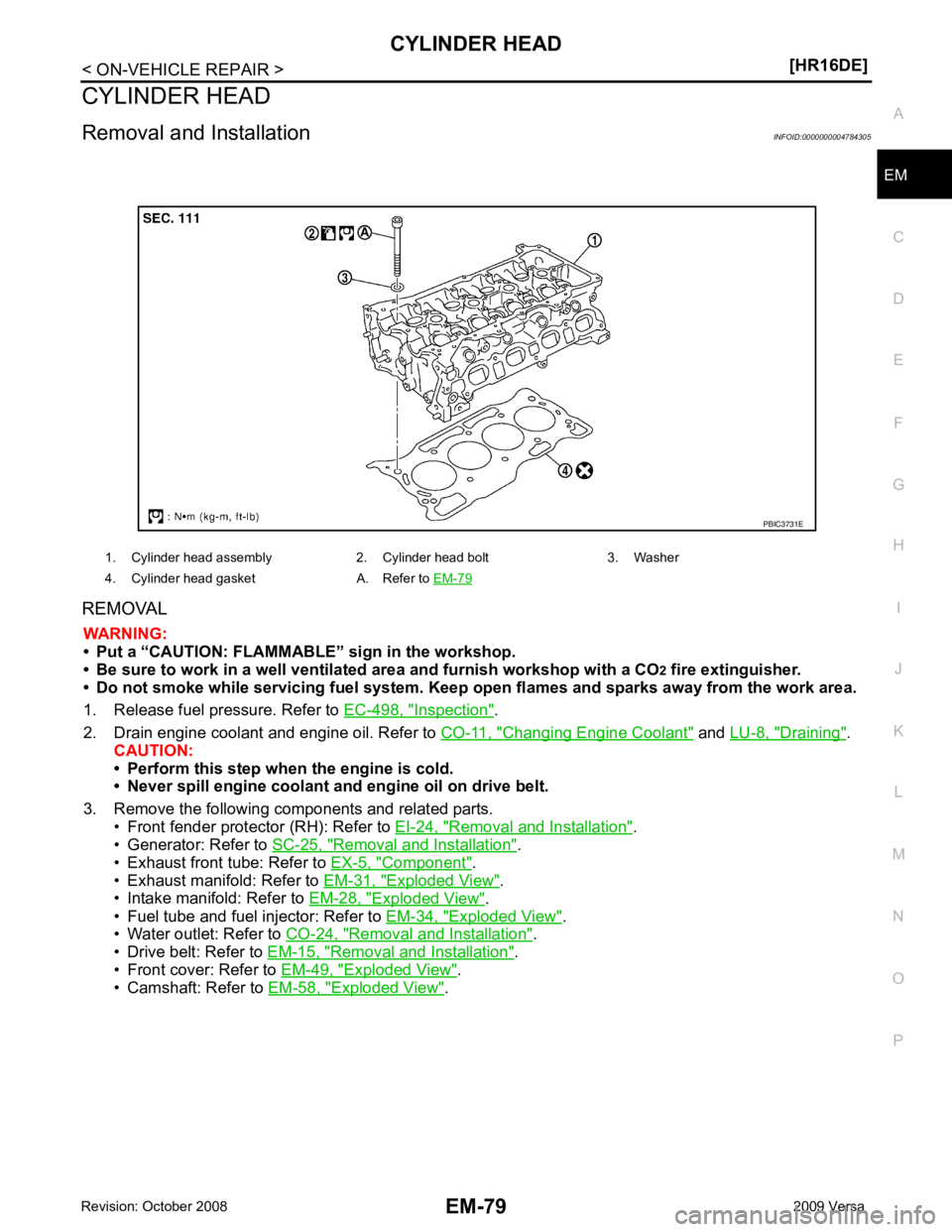

CYLINDER HEAD

Removal and Installation INFOID:0000000004784305

REMOVAL WARNING:

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventila ted area and furnish workshop with a CO

2 fire extinguisher.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

1. Release fuel pressure. Refer to EC-498, " Inspection " .

2. Drain engine coolant and engine oil. Refer to CO-11, " Changing Engine Coolant " and

LU-8, " Draining " .

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant an d engine oil on drive belt.

3. Remove the following components and related parts. • Front fender protector (RH): Refer to EI-24, " Removal and Installation " .

• Generator: Refer to SC-25, " Removal and Installation " .

• Exhaust front tube: Refer to EX-5, " Component " .

• Exhaust manifold: Refer to EM-31, " Exploded View " .

• Intake manifold: Refer to EM-28, " Exploded View " .

• Fuel tube and fuel injector: Refer to EM-34, " Exploded View " .

• Water outlet: Refer to CO-24, " Removal and Installation " .

• Drive belt: Refer to EM-15, " Removal and Installation " .

• Front cover: Refer to EM-49, " Exploded View " .

• Camshaft: Refer to EM-58, " Exploded View " .

1. Cylinder head assembly 2. Cylinder head bolt 3. Washer

4. Cylinder head gasket A. Refer to EM-79