fuel pressure NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2474 of 4331

Emission-related Diagnostic Information " .

*3: Always “COMPLT” is displayed.

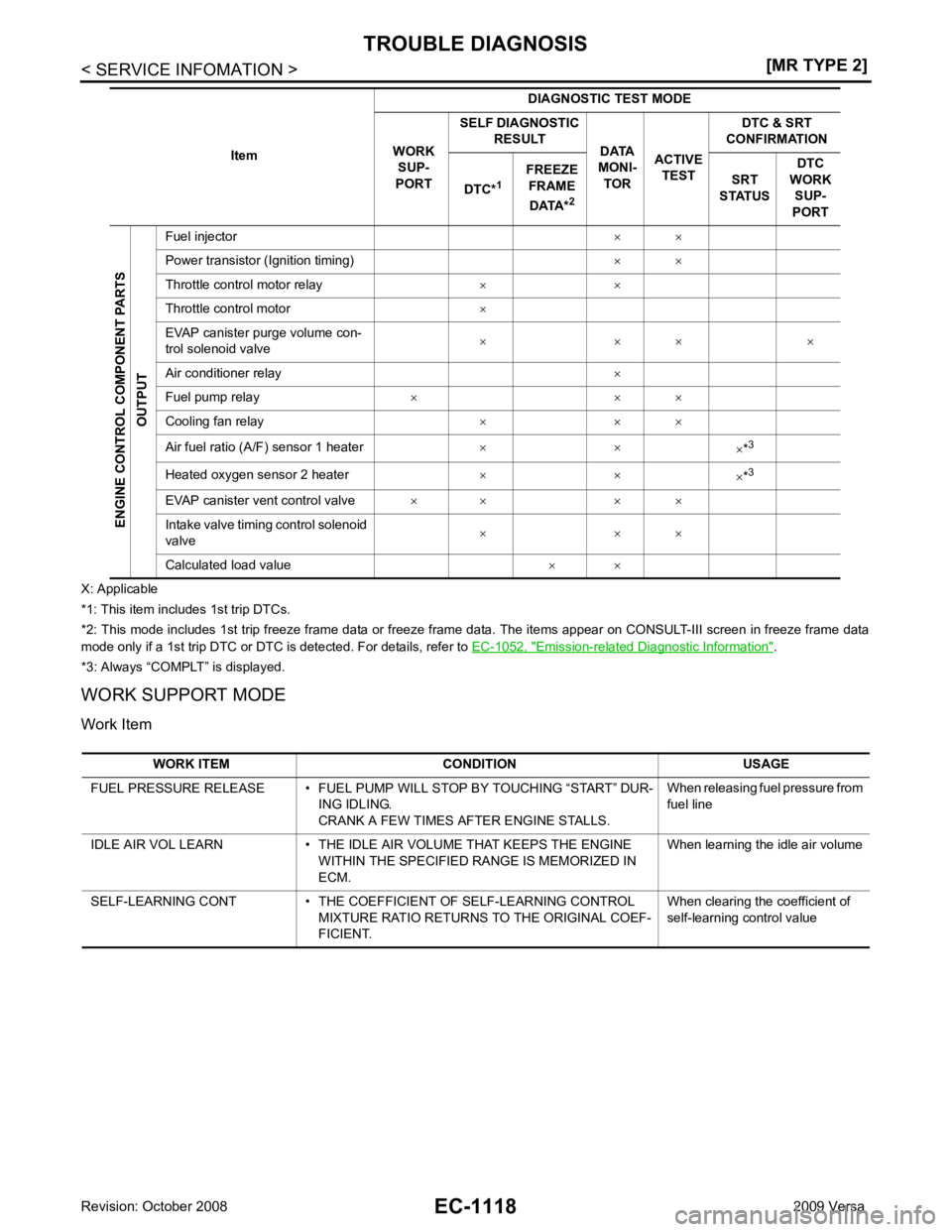

WORK SUPPORT MODE

Work ItemENGINE CONTROL COMPONENT PARTS OUTPUT

Fuel injector × ×

Power transistor (Ignition timing) × ×

Throttle contro l motor relay × ×

Throttle control motor ×

EVAP canister purge volume con-

trol solenoid valve × × × ×

Air conditioner relay ×

Fuel pump relay × × ×

Cooling fan relay × × ×

Air fuel ratio (A/F) sensor 1 heater × ×

×*3

Heated oxygen sensor 2 heater × ×

×*3

EVAP canister vent control valve × × × ×

Intake valve timing control solenoid

valve × × ×

Calculated load value × ×

Item

DIAGNOSTIC TEST MODE

WORK SUP-

PORT SELF DIAGNOSTIC

RESULT DATA

MONI- TOR ACTIVE

TEST DTC & SRT

CONFIRMATION

DTC* 1 FREEZE

FRAME

DATA* 2 SRT

STATUS DTC

WORK SUP-

PORT WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASE • FUEL PUMP WILL STOP BY TOUCHING “START” DUR- ING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS. When releasing fuel pressure from

fuel line

IDLE AIR VOL LEARN • THE IDLE AIR VOLUME THAT KEEPS THE ENGINE WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM. When learning the idle air volume

SELF-LEARNING CONT • THE COEFFICI ENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT. When clearing the coefficient of

self-learning control value

Page 2475 of 4331

EC

NP

O

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item Regarding items of DTC and 1st trip DTC, refer to EC-1052, " Emission-related Diagnostic Information " .

Freeze Frame Data and 1st Trip Freeze Frame Data EVAP SYSTEM CLOSE CLOSE THE EVAP CANISTER VENT CONTROL VALVE IN

ORDER TO MAKE EVAP SYSTEM CLOSE UNDER THE

FOLLOWING CONDITIONS.

• IGN SW “ON”

• ENGINE NOT RUNNING

• AMBIENT TEMPERATURE IS ABOVE 0 °C (32 °F).

• NO VACUUM AND NO HIGH PRESSURE IN EVAP SYS- TEM

• FUEL TANK TEMP. IS MORE THAN 0 °C (32 °F).

• WITHIN 10 MINUTES AFTER STARTING “EVAP SYS- TEM CLOSE”

• WHEN TRYING TO EXECUTE “EVAP SYSTEM CLOSE” UNDER THE CONDITION EXCEPT ABOVE, CONSULT-

III WILL DISCONTINUE IT AND DISPLAY APPROPRI-

ATE INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-III MAY DIS-

PLAY “BATTERY VOLTAGE IS LOW. CHARGE BAT-

TERY”, EVEN IN USING CHARGED BATTERY. When detecting EVAP vapor leak

point of EVAP system

TARGET IDLE RPM ADJ* • IDLE CONDITION When setting target idle speed

TARGET IGN TIM ADJ* • IDLE CONDITION Wh en adjusting target ignition tim-

ing

VIN REGISTRATION • IN THIS MODE, VIN IS REGISTERED IN ECM. When registering VIN in ECM WORK ITEM CONDITION USAGE )

FUEL SYS-B1 • “Fuel injection system status” at the moment a malfunction is detected is displayed.

• One mode in the following is displayed.

Mode2: Open loop due to detected system malfunction

Mode3: Open loop due to driving conditions (power enrichment, deceleration enleanment)

Mode4: Closed loop - using oxygen sensor(s) as feedback for fuel control

Mode5: Open loop - has not yet satisfied condition to go to closed loop

CAL/LD VALUE [%] • The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP

[ ° C] or [ °F] • The engine coolant temperature at the moment a malfunction is detected is displayed.

L-FUEL TRM-B1 [%] • “Long-term fuel trim” at the moment a malfunction is detected is displayed.

• The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule than short-term fuel trim.

S-FUEL TRM-B1 [%] • “Short-term fuel trim” at the moment a malfunction is detected is displayed.

• The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel schedule.

ENGINE SPEED [rpm] • The engine sp eed at the moment a malfunction is de tected is displayed.

VEHICL SPEED

[km/h] or [mph] • The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL TH-P/S [%] • The throttle valve opening angle at the moment a malfunction is detected is displayed.

B/FUEL SCHDL [msec] • The ba se fuel schedule at the moment a malfunctio n is detected is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake air temperature at the moment a malfunction is detected is displayed.

Page 2477 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake ai NISSAN TIIDA 2009 Service Repair Manual EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake ai](/img/5/57398/w960_57398-2476.png)

EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake air temperature (determined by the signal voltage

of the intake air temperature sensor) is indicated.

EVAP SYS PRES

[V] • The signal voltage of EVAP control system pressure sensor

is displayed.

FUEL LEVEL SE

[V] • The signal voltage of the fuel level sensor is displayed.

START SIGNAL

[ON/OFF] • Indicates start signal status [ON/OFF] computed by the ECM

according to the signals of engine speed and battery voltage. • After starting the engine, [OFF] is displayed

regardless of the starter signal.

CLSD THL POS

[ON/OFF] • Indicates idle position [ON/OFF] computed by the ECM ac-

cording to the accelerator pedal position sensor signal.

AIR COND SIG

[ON/OFF] • Indicates [ON/OFF] condition of the air conditioner switch as

determined by the air conditioner signal.

P/N POSI SW

[ON/OFF] • Indicates [ON/OFF] condition from the park/neutral position

(PNP) switch signal.

PW/ST SIGNAL

[ON/OFF] • [ON/OFF] condition of the power steering system (deter-

mined by the signal sent from EPS control unit) is indicated.

LOAD SIGNAL

[ON/OFF] • Indicates [ON/OFF] condition from the electrical load signal.

ON: Rear window defogger switch is ON and/or lighting

switch is in 2nd position.

OFF: Both rear window defogger switch and lighting switch

are OFF.

IGNITION SW

[ON/OFF] • Indicates [ON/OFF] condition from ignition switch.

HEATER FAN SW

[ON/OFF] • Indicates [ON/OFF] condition from the heater fan switch sig-

nal.

BRAKE SW

[ON/OFF] • Indicates [ON/OFF] condition from the stop lamp switch sig-

nal.

INJ PULSE-B1

[msec] • Indicates the actual fuel injection pulse width compensated

by ECM according to the input signals. • When the engine is stopped, a certain com-

puted value is indicated.

IGN TIMING

[BTDC] • Indicates the ignition timing computed by ECM according to

the input signals. • When the engine is stopped, a certain value

is indicated.

CAL/LD VALUE

[%] • “Calculated load value” indicates the value of the current air-

flow divided by peak airflow.

MASS AIRFLOW

[g·m/s] • Indicates the mass airflow computed by ECM according to

the signal voltage of the mass air flow sensor.

PURG VOL C/V

[%] • Indicates the EVAP canister purge volume control solenoid

valve control value computed by the ECM according to the in-

put signals.

• The opening becomes larger as the value increases.

INT/V TIM (B1)

[ ° CA] • Indicates [

°CA] of intake camshaft advanced angle.

INT/V SOL (B1)

[%] • The control value of the intake valve timing control solenoid

valve (determined by ECM according to the input signal) is in-

dicated.

• The advance angle becomes larger as the value increases

AIR COND RLY

[ON/OFF] • The air conditioner relay control condition (determined by

ECM according to the input signals) is indicated.

FUEL PUMP RLY

[ON/OFF] • Indicates the fuel pump relay control condition determined by

ECM according to the input signals.

Monitored item [Unit] Description Remarks

Page 2481 of 4331

![NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

EC-1125

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect GST to data link connector (1), which NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

EC-1125

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect GST to data link connector (1), which](/img/5/57398/w960_57398-2480.png)

TROUBLE DIAGNOSIS

EC-1125

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect GST to data link connector (1), which is located under LH dash panel.

3. Turn ignition switch ON.

4. Enter the program according to instruction on the screen or in the operation manual.

(*: Regarding GST screens in this section, sample screens are

shown.) Diagnostic test mode Function

Service $01 READINESS TESTS This diagnostic service gains access to current emission-related data values, including an-

alog inputs and outputs, digital inputs and outputs, and system status information.

Service $02 (FREEZE DATA) This diagnostic service gains access to emission-related data value which were stored by

ECM during the freeze frame. For details, refer to EC-1116, " CONSULT-III Function (EN-

GINE) " .

Service $03 DTCs This diagnostic service gains access to emission-related power train trouble codes which

were stored by ECM.

Service $04 CLEAR DIAG INFO This diagnostic service can clear all emission-related diagnostic information. This in-

cludes:

• Clear number of diagnostic trouble codes (Service $01)

• Clear diagnostic trouble codes (Service $03)

• Clear trouble code for freeze frame data (Service $01)

• Clear freeze frame data (Service $02)

• Reset status of system monitoring test (Service $01)

• Clear on board monitoring test results (Service $06 and $07)

Service $06 (ON BOARD TESTS) This diagnostic service accesses the results of on board diagnostic monitoring tests of

specific components/systems that are not continuously monitored.

Service $07 (ON BOARD TESTS) This diagnostic service enables the off board test drive to obtain test results for emission-

related powertrain components/systems that are continuously monitored during normal

driving conditions.

Service $08 — This diagnostic service can close EVAP system in ignition switch ON position (Engine

stopped). When this diagnostic service is performed, EVAP canister vent control valve can

be closed. In the following conditions, this diagnostic service cannot function.

• Low ambient temperature

• Low battery voltage

• Engine running

• Ignition switch OFF

• Low fuel temperature

• Too much pressure is applied to EVAP system

Service $09 (CALIBRATION ID) This diagnostic service enables the off-board test device to request specific vehicle infor-

mation such as Vehicle Identification Number (VIN) and Calibration IDs. BBIA0734E

SEF398S

Page 2489 of 4331

EC

NP

O

Check “A/F ALPHA-B1” for approximately 1 minute because t

hey may fluctuate. It is NG if the indication is

out of the SP value even a little.

OK or NG OK >> GO TO 17.

NG (Less than the SP value)>>GO TO 2.

NG (More than the SP value)>>GO TO 3. OK >> GO TO 4.

NG (More than the SP value)>>GO TO 19. OK >> GO TO 6.

NG (More than the SP value)>>GO TO 6.

NG (Less than the SP value)>>GO TO 25. OK >> GO TO 5.

NG >> GO TO 6. Changing Engine Oil " .

NOTE:

This symptom may occur when a large amount of gas oline is mixed with engine oil because of driving

conditions (such as when engine oil temperature does not rise enough since a journey distance is too

short during winter). The symptom will not be detect ed after changing engine oil or changing driving con-

dition.

>>INSPECTION END Fuel Pressure Check " .)

OK or NG OK >> GO TO 9.

NG (Fuel pressure is too high)>>Replace fuel pressure regulator, refer to EC-1086, " Fuel Pressure Check " .

GO TO 8.

NG (Fuel pressure is too low)>>GO TO 7. .)

2. If NG, repair or replace the malfunctioning part. (Refer to EC-1086, " Fuel Pressure Check " .)

If OK, replace fuel pressure regulator.

Page 2490 of 4331

OK >>

INSPECTION END

NG >> GO TO 9. OK >> GO TO 12.

NG >> GO TO 10. .)

- Fuel injector and its circuit (Refer to EC-1508 .)

- Intake air leakage

- Low compression pressure (Refer to EM-185, " On-Vehicle Service " .)

2. If NG, repair or replace the malfunctioning part.

If OK, replace fuel injector. (It may be caus ed by leakage from fuel injector or clogging.)

>> GO TO 11. OK >>

INSPECTION END

NG >> GO TO 12. DTC Confirmation Procedure " .

• For DTC P0131, refer to EC-1216, " DTC Confirmation Procedure " .

• For DTC P0132, refer to EC-1222, " DTC Confirmation Procedure " .

• For DTC P0133, refer to EC-1228, " DTC Confirmation Procedure " .

• For DTC P2A00, refer to EC-1488, " DTC Confirmation Procedure " .

OK or NG OK >> GO TO 15.

NG >> GO TO 13.

Page 2584 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1228< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0133 A/F SENSOR 1

DTC P0133 A/F SENSOR 1

Component Description INFOID:0000000004501136

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit curre NISSAN TIIDA 2009 Service Repair Manual EC-1228< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0133 A/F SENSOR 1

DTC P0133 A/F SENSOR 1

Component Description INFOID:0000000004501136

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit curre](/img/5/57398/w960_57398-2583.png)

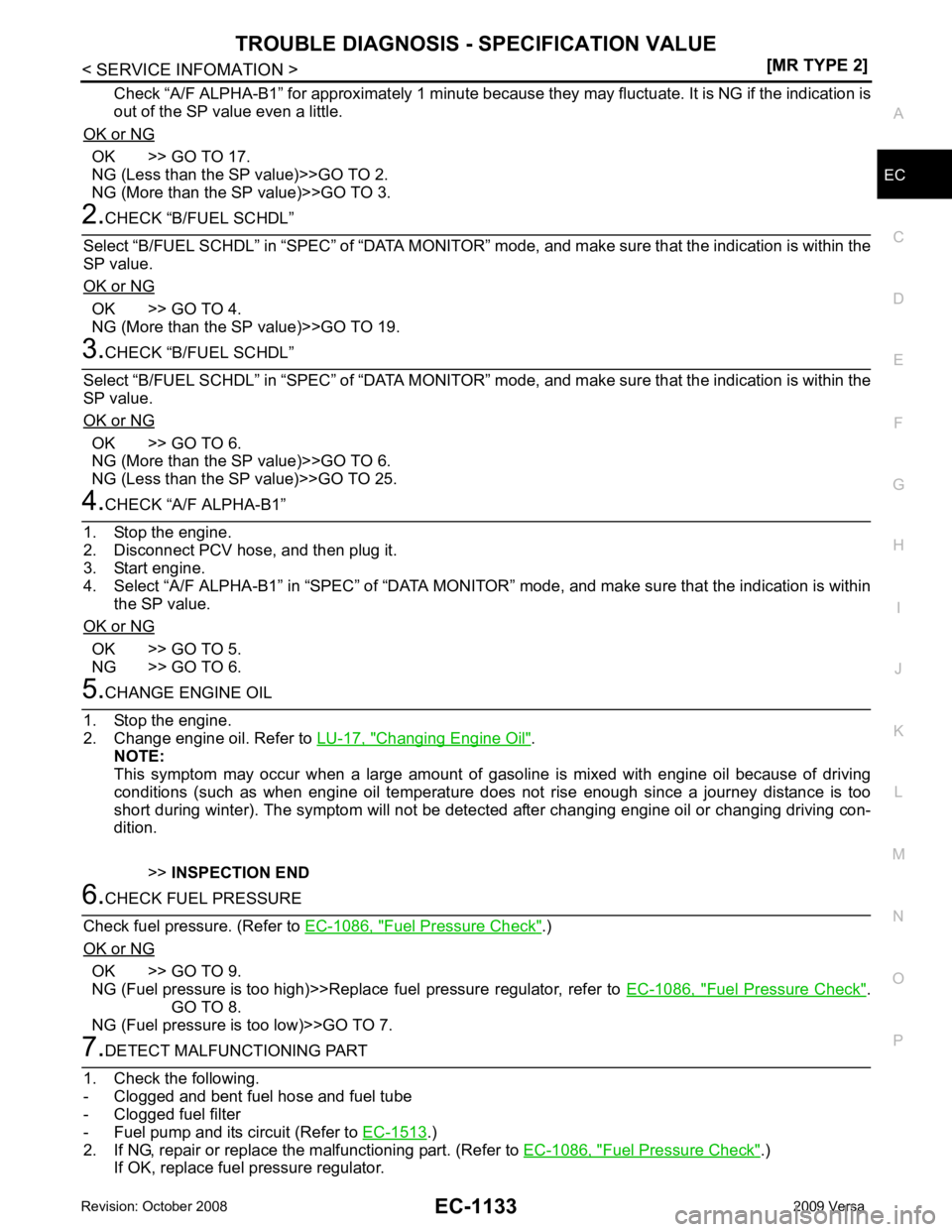

EC-1228< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0133 A/F SENSOR 1

DTC P0133 A/F SENSOR 1

Component Description INFOID:0000000004501136

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000004501137

Specification data are reference values.

On Board Diagn osis Logic INFOID:0000000004500078

To judge the malfunction of air fuel ratio (A/F) sensor 1, this diagnosis measures response time of the A/F sig-

nal computed by ECM from the air fuel ratio (A/F) s ensor 1 signal. The time is compensated by engine operat-

ing (speed and load), fuel feedback control constant, and the air fuel ratio (A/F) sensor 1 temperature index.

Judgment is based on whether the compensated time (the A/F sensor 1 signal cycling time index) is inordi-

nately long or not.

DTC Confirmation Procedure INFOID:0000000004500079

NOTE: PBIB3353E

PBIB3354E

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1) • Engine: After warming up Maintaining engine speed at

2,000 rpm Fluctuates around 2.2VDTC No.

Trouble diag-

nosis name DTC detecting condition Possible Cause

P0133

0133 Air fuel ratio

(A/F) sensor 1

circuit slow re-

sponse The response of the A/F signal computed by ECM from

A/F sensor 1 signal takes more than the specified time. • Harness or connectors

[Air fuel ratio (A/F) sensor circuit is open

or shorted.]

• Air fuel ratio (A/F) sensor 1

• Air fuel ratio (A/F) sensor heater 1

• Fuel pressure

• Fuel injector

• Intake air leaks

• Exhaust gas leaks

• PCV

• Mass air flow sensor

Page 2585 of 4331

EC

NP

O

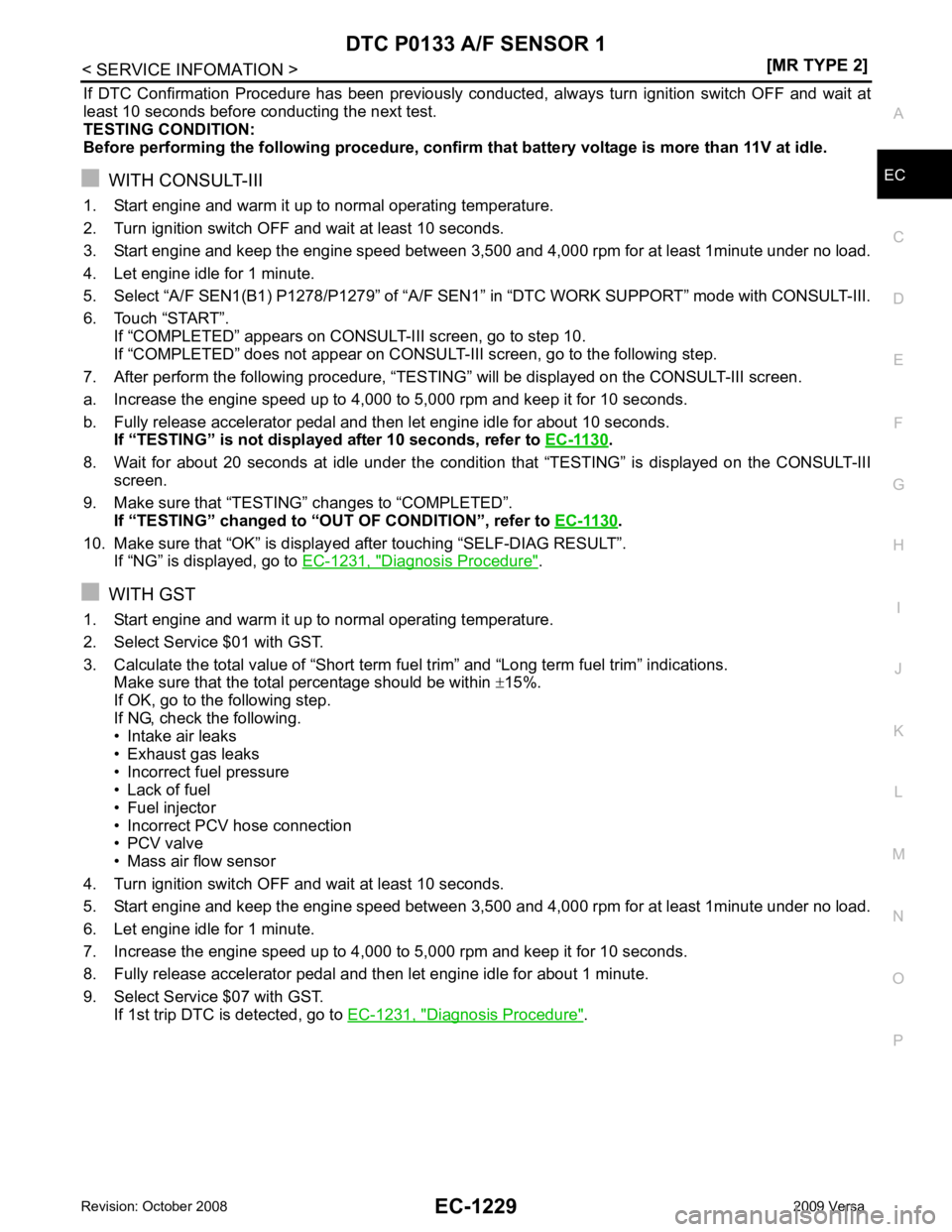

If DTC Confirmation Procedure has been previously conduc

ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1minute under no load.

4. Let engine idle for 1 minute.

5. Select “A/F SEN1(B1) P1278/P1279” of “A/F SEN1 ” in “DTC WORK SUPPORT” mode with CONSULT-III.

6. Touch “START”. If “COMPLETED” appears on CONSULT-III screen, go to step 10.

If “COMPLETED” does not appear on CONSULT- III screen, go to the following step.

7. After perform the following procedure, “TESTIN G” will be displayed on the CONSULT-III screen.

a. Increase the engine speed up to 4,000 to 5,000 rpm and keep it for 10 seconds.

b. Fully release accelerator pedal and then let engine idle for about 10 seconds. If “TESTING” is not displayed after 10 seconds, refer to EC-1130 .

8. Wait for about 20 seconds at idle under the conditi on that “TESTING” is displayed on the CONSULT-III

screen.

9. Make sure that “TESTING” changes to “COMPLETED”. If “TESTING” changed to “OUT OF CONDITION”, refer to EC-1130 .

10. Make sure that “OK” is display ed after touching “SELF-DIAG RESULT”.

If “NG” is displayed, go to EC-1231, " Diagnosis Procedure " .

WITH GST

1. Start engine and warm it up to normal operating temperature.

2. Select Service $01 with GST.

3. Calculate the total value of “Short term f uel trim” and “Long term fuel trim” indications.

Make sure that the total percentage should be within ±15%.

If OK, go to the following step.

If NG, check the following.

• Intake air leaks

• Exhaust gas leaks

• Incorrect fuel pressure

• Lack of fuel

• Fuel injector

• Incorrect PCV hose connection

• PCV valve

• Mass air flow sensor

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1minute under no load.

6. Let engine idle for 1 minute.

7. Increase the engine speed up to 4,000 to 5,000 rpm and keep it for 10 seconds.

8. Fully release accelerator pedal and then let engine idle for about 1 minute.

9. Select Service $07 with GST. If 1st trip DTC is detected, go to EC-1231, " Diagnosis Procedure " .

Page 2591 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0137 HO2S2

EC-1235

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0137 HO2S2

Component Description INFOID:0000000004500083

The heated oxygen sensor 2, after three NISSAN TIIDA 2009 Service Repair Manual DTC P0137 HO2S2

EC-1235

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0137 HO2S2

Component Description INFOID:0000000004500083

The heated oxygen sensor 2, after three](/img/5/57398/w960_57398-2590.png)

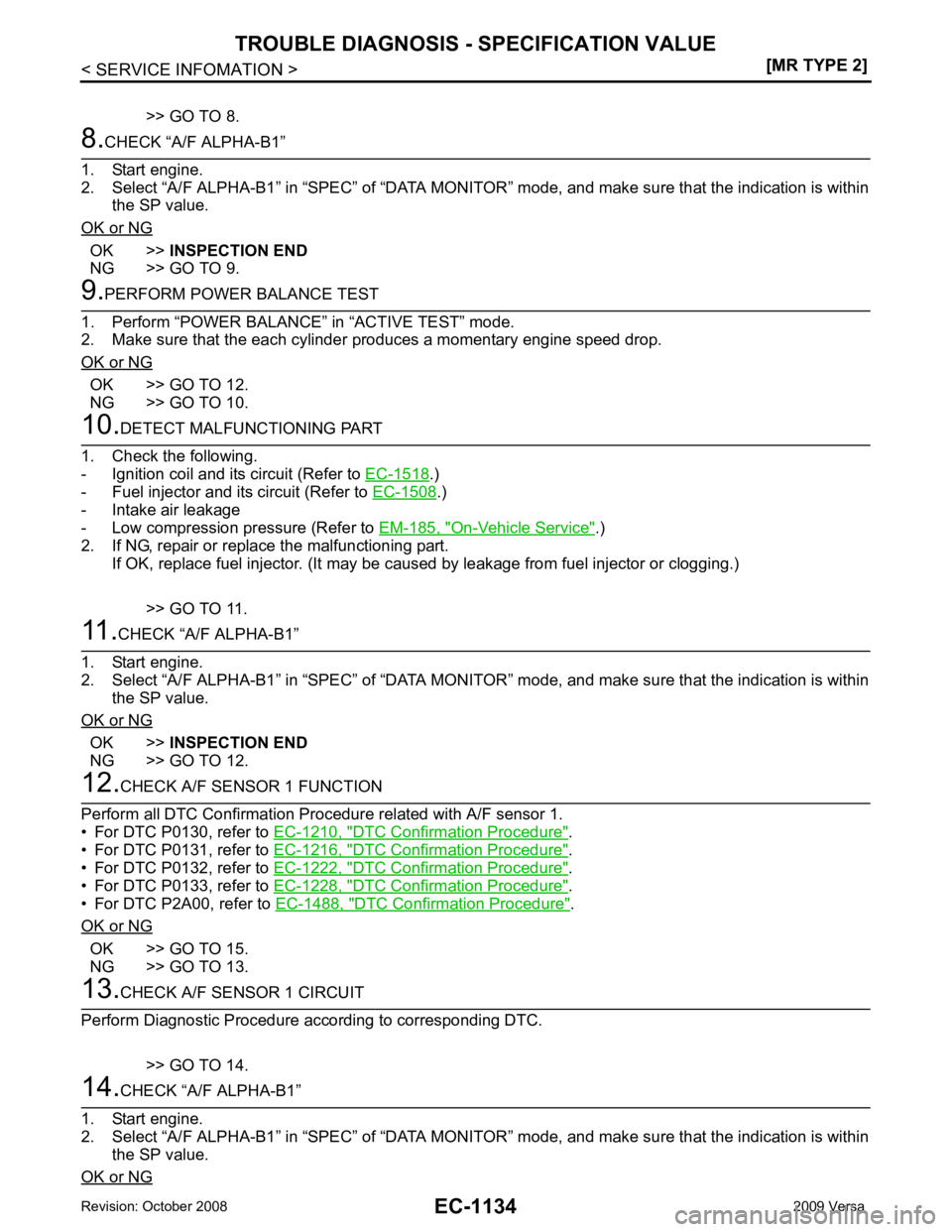

DTC P0137 HO2S2

EC-1235

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0137 HO2S2

Component Description INFOID:0000000004500083

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air/fuel ratio is c ontrolled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500084

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500085

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity before the three way catalyst (manifold) causes

the longer switching time. To judge the malfunctions of heated oxy-

gen sensor 2, ECM monitors whether the maximum voltage of the

sensor is sufficiently high during the various driving condition such

as fuel-cut.

DTC Confirmation Procedure INFOID:0000000004500086

NOTE:

If DTC confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

TESTING CONDITION:

For the best results, perform DTC WORK SUPPORT at a temperature of 0 to 30°C (32 to 86 °F). SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1) • Revving engine from idle to 3,000 rpm quickly after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load 0 - 0.3V

←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1) LEAN ←→ RICH SEF259VA

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0137

0137 Heated oxygen sensor 2 cir-

cuit low voltage The maximum voltage from the sensor is not

reached to the specified voltage. • Harness or connectors

(Heated oxygen sensor 2 circuit open or

shorted.)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks

Page 2599 of 4331

EC

NP

O

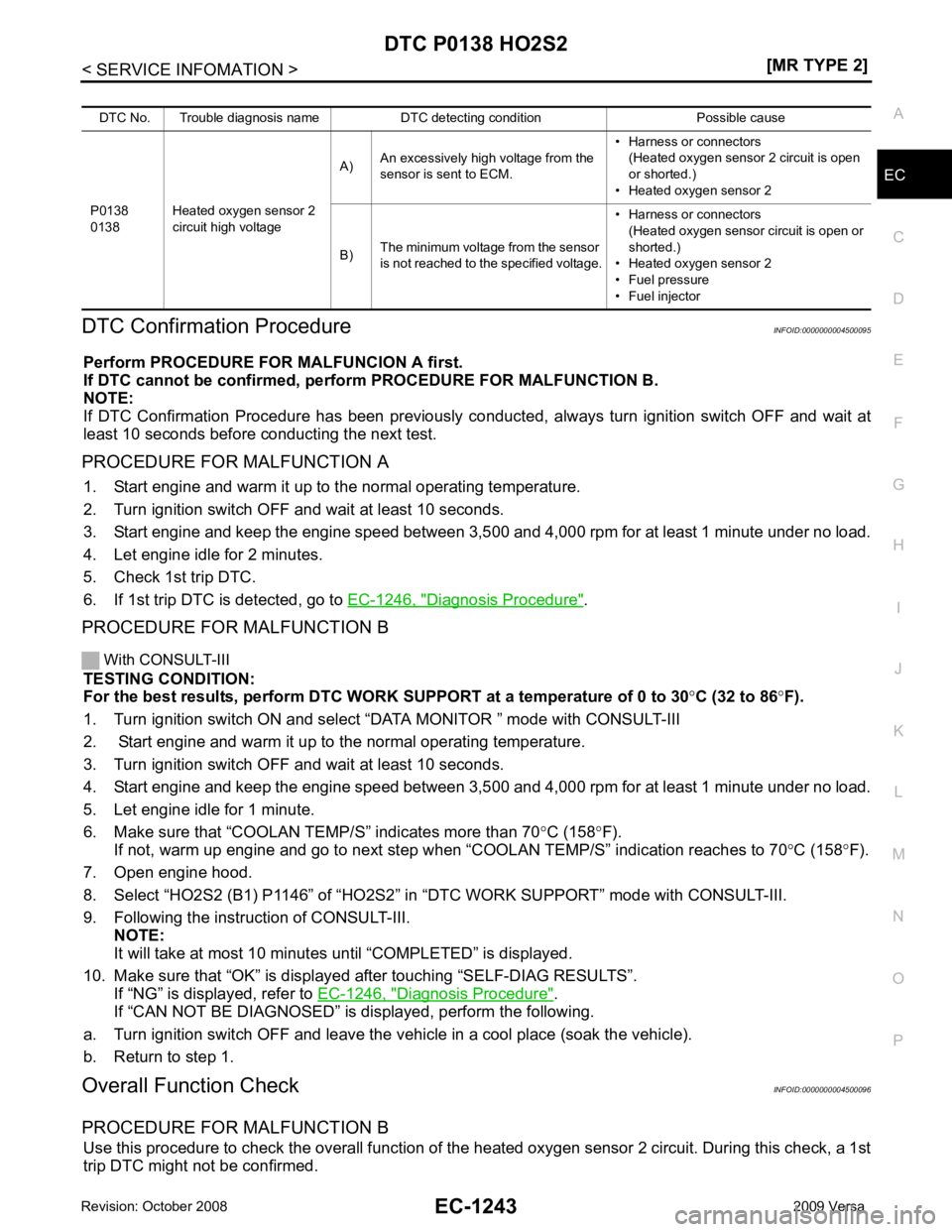

DTC Confirmation Procedure

INFOID:0000000004500095

Perform PROCEDURE FOR MALFUNCION A first.

If DTC cannot be confirmed, perform PROCEDURE FOR MALFUNCTION B.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION A 1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 2 minutes.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-1246, " Diagnosis Procedure " .

PROCEDURE FOR MALFUNCTION B

With CONSULT-III

TESTING CONDITION:

For the best results, perform DTC WORK SUPPORT at a temperature of 0 to 30°C (32 to 86 °F).

1. Turn ignition switch ON and select “DATA MONITOR ” mode with CONSULT-III

2. Start engine and warm it up to the normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70 °C (158 °F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158 °F).

7. Open engine hood.

8. Select “HO2S2 (B1) P1146” of “HO2S2” in “DTC WORK SUPPORT” mode with CONSULT-III.

9. Following the instruction of CONSULT-III. NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

10. Make sure that “OK” is display ed after touching “SELF-DIAG RESULTS”.

If “NG” is displayed, refer to EC-1246, " Diagnosis Procedure " .

If “CAN NOT BE DIAGNOSED” is displayed, perform the following.

a. Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

b. Return to step 1.

Overall Function Check INFOID:0000000004500096

PROCEDURE FOR MALFUNCTION B Use this procedure to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st

trip DTC might not be confirmed. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0138

0138 Heated oxygen sensor 2

circuit high voltage A)

An excessively high voltage from the

sensor is sent to ECM. • Harness or connectors

(Heated oxygen sensor 2 circuit is open

or shorted.)

• Heated oxygen sensor 2

B) The minimum voltage from the sensor

is not reached to the specified voltage. • Harness or connectors

(Heated oxygen sensor circuit is open or

shorted.)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector