wheel NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 433 of 4331

AV

N

O P

Bluetooth Control Unit

Self-Diagnosis Function INFOID:0000000004306987

The Bluetooth control unit has two diagnostic checks. The first diagnostic check is performed automatically

every ignition cycle during control unit initialization. The second diagnostic check is performed by the techni-

cian using the steering wheel audio control switches prior to trouble diagnosis.

BLUETOOTH CONTROL UNIT INITIALIZATION CHECKS

• Internal control unit failure

• Bluetooth antenna connection open or shorted

• Steering wheel audio control swit ches (SEND/END) stuck closed

• Vehicle speed pulse count

• Bluetooth Microphone connection test (with playback to operator)

• Bluetooth inquiry check

SELF-DIAGNOSIS MODE 15 (G) Ground

Bluetooth

ON indicator

LED Output – Bluetooth control

unit initialized

and paired with

phone Battery voltage

Bluetooth ON indica-

tor inoperative.

17 (GR) Ground Audio unit

switch 1 OutputACC/

ON Press Phone/End

switch 0V

Steering wheel audio

controls do not func-

tion.

Press SEEK UP

switch 0.75V

Press VOL UP

switch 2V

Except for above 5V

18 (P) Ground Audio unit

switch 2 OutputACC/

ON Press Phone/

Send switch 0V

Steering wheel audio

controls do not func-

tion.

Press SEEK

DOWN switch 0.75V

Press VOL

DOWN switch 2V

Except for above 5V

19 (B) Ground Audio unit

switch

ground Output – – – Steering wheel audio

controls do not func-

tion.

20 (B) – Cont-1 – – – – –

21 (B) – Cont-2 – – – – –

23 (B) – Cont-4 – – – – –

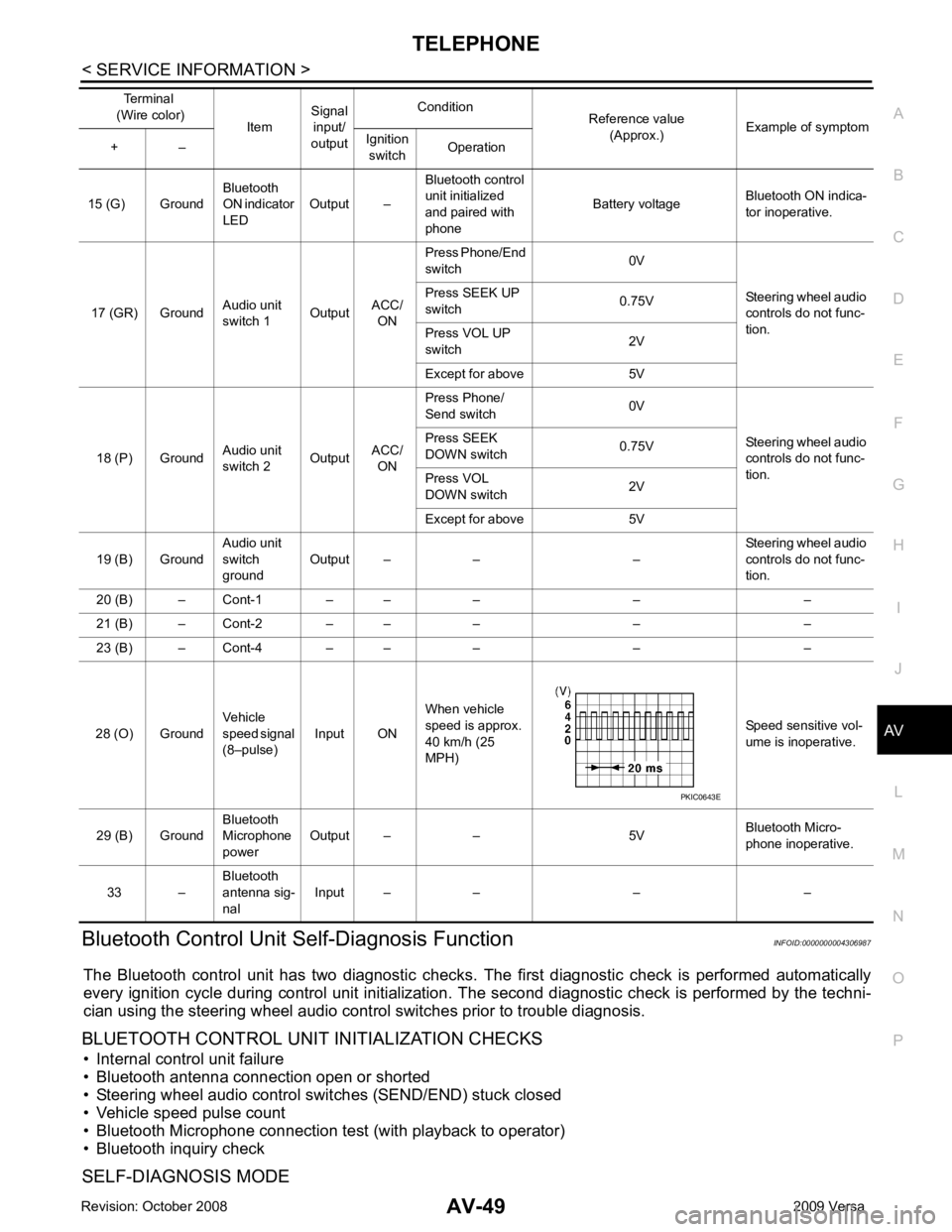

28 (O) Ground Vehicle

speed signal

(8–pulse) Input ON When vehicle

speed is approx.

40 km/h (25

MPH) Speed sensitive vol-

ume is inoperative.

29 (B) Ground Bluetooth

Microphone

power Output – – 5V

Bluetooth Micro-

phone inoperative.

33 – Bluetooth

antenna sig-

nal Input – – – –

Terminal

(Wire color) ItemSignal

input/

output Condition

Reference value

(Approx.) Example of symptom

+ – Ignition

switch Operation

Page 434 of 4331

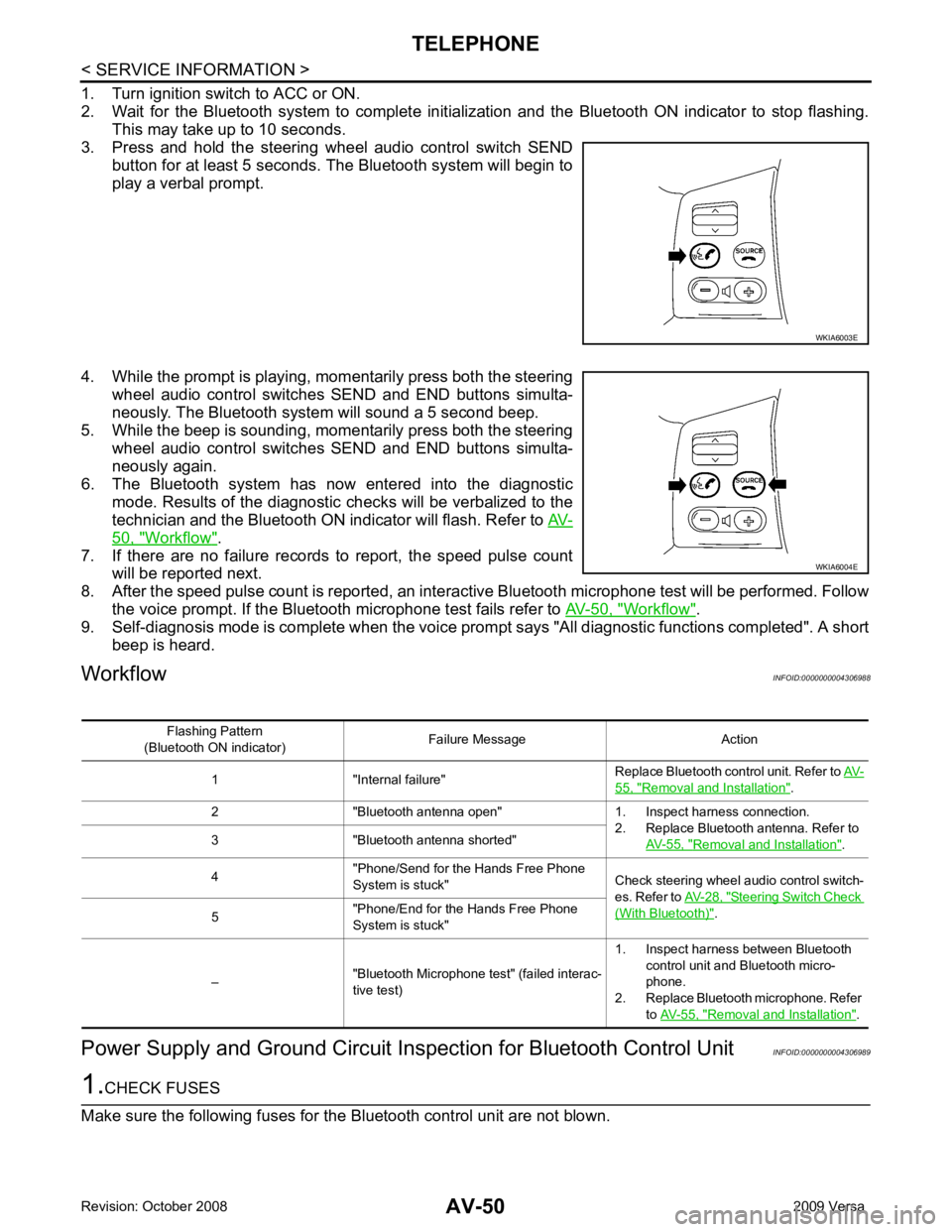

50, " Workflow " .

7. If there are no failure records to report, the speed pulse count will be reported next.

8. After the speed pulse count is reported, an intera ctive Bluetooth microphone test will be performed. Follow

the voice prompt. If the Bluetooth microphone test fails refer to AV-50, " Workflow " .

9. Self-diagnosis mode is complete when the voice prom pt says "All diagnostic functions completed". A short

beep is heard.

Workflow INFOID:0000000004306988

Power Supply and Ground Circuit Ins pection for Bluetooth Control Unit INFOID:0000000004306989 WKIA6004E

55, " Removal and Installation " .

2 "Bluetooth antenna open" 1. Inspect harness connection. 2. Replace Bluetooth antenna. Refer to AV-55, " Removal and Installation " .

3 "Bluetooth antenna shorted"

4 "Phone/Send for the Hands Free Phone

System is stuck" Check steering wheel audio control switch-

es. Refer to AV-28, " Steering Switch Check

(With Bluetooth) " .

5 "Phone/End for the Hands Free Phone

System is stuck"

– "Bluetooth Microphone test" (failed interac-

tive test) 1. Inspect harness between Bluetooth

control unit and Bluetooth micro-

phone.

2. Replace Bluetooth microphone. Refer to AV-55, " Removal and Installation " .

Page 436 of 4331

OK >> INSPECTION END

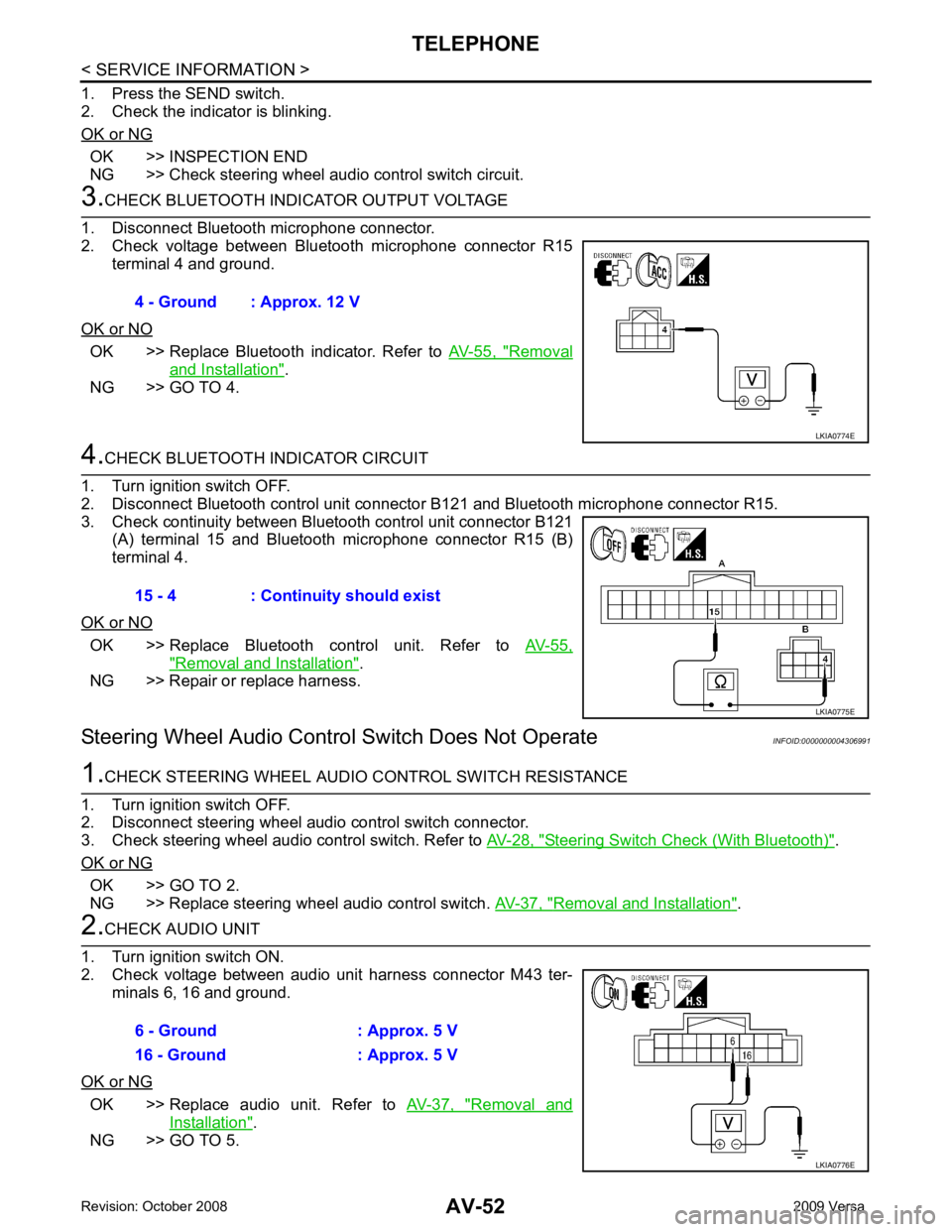

NG >> Check steering wheel audio control switch circuit. OK >> Replace Bluetooth indicator. Refer to

AV-55, " Removal

and Installation " .

NG >> GO TO 4. OK >> Replace Bluetooth control unit. Refer to

AV-55," Removal and Installation " .

NG >> Repair or replace harness.

Steering Wheel Audio Control Switch Does Not Operate INFOID:0000000004306991 Steering Switch Check (With Bluetooth) " .

OK or NG OK >> GO TO 2.

NG >> Replace steering wheel audio control switch. AV-37, " Removal and Installation " .

OK >> Replace audio unit. Refer to

AV-37, " Removal and

Installation " .

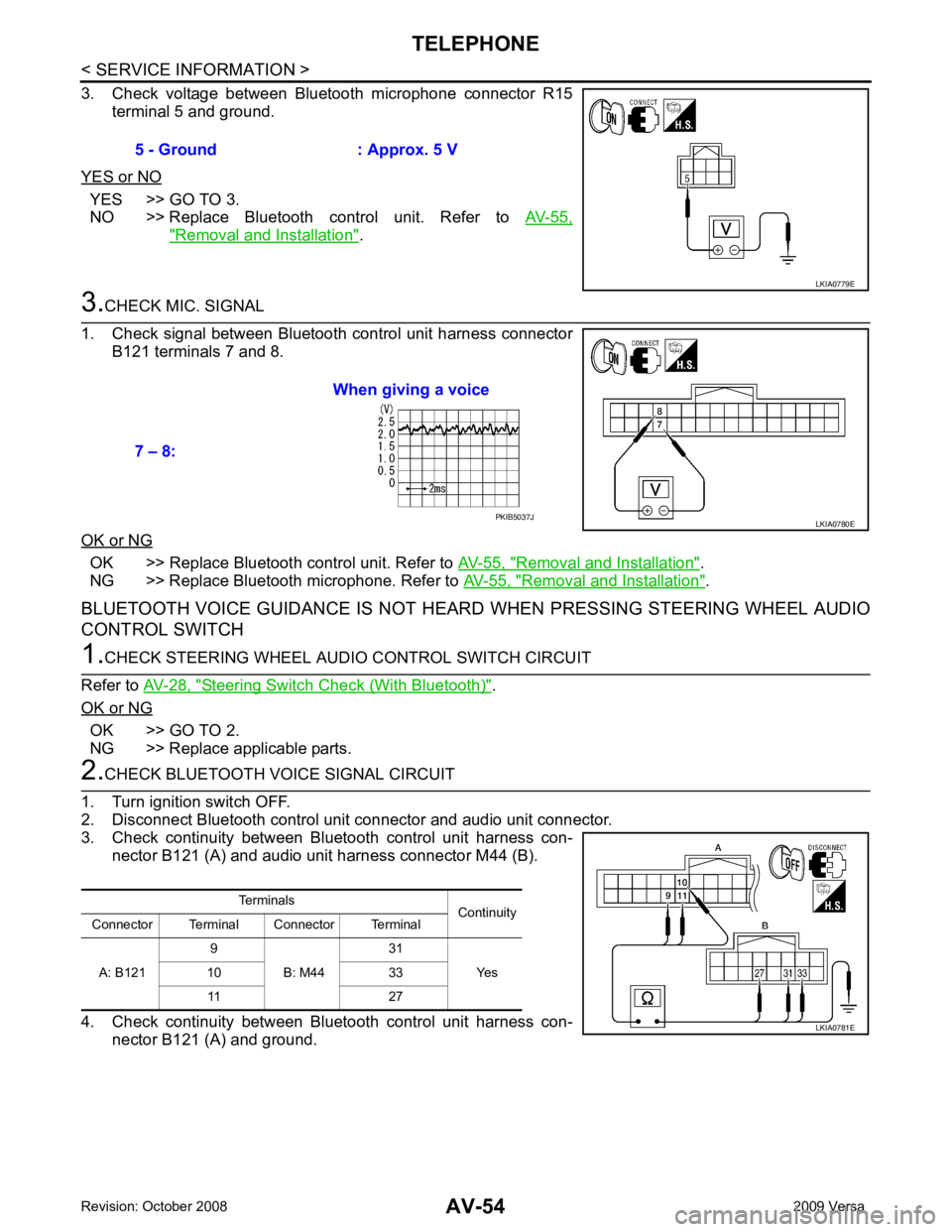

NG >> GO TO 5. 4 - Ground : Approx. 12 V

Page 437 of 4331

AV

N

O P OK >> Repair or replace harness.

NG >> Replace Bluetooth control unit. AV-55, " Removal and

Installation " .

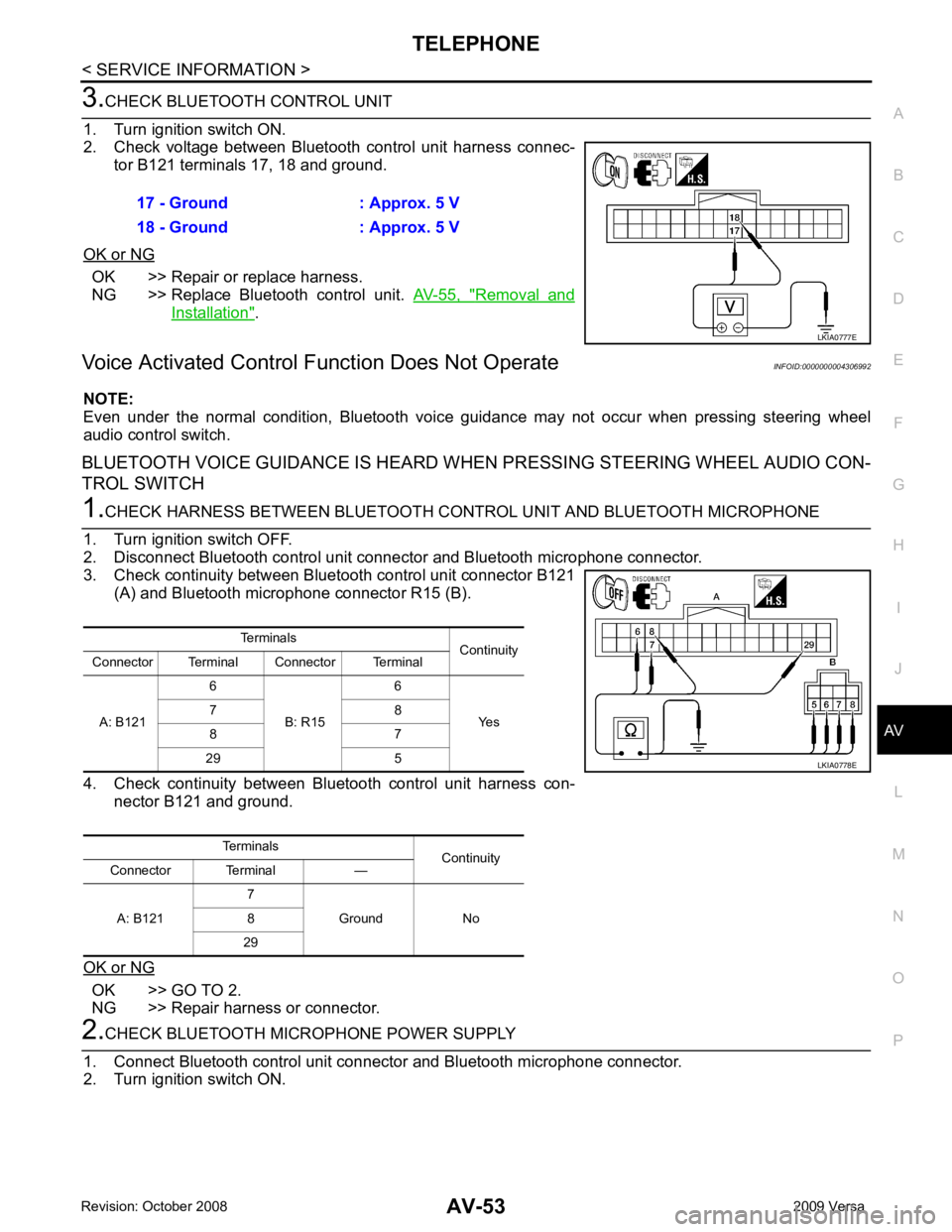

Voice Activated Control F unction Does Not Operate INFOID:0000000004306992

NOTE:

Even under the normal condition, Bluetooth voice guidance may not occur when pressing steering wheel

audio control switch.

BLUETOOTH VOICE GUIDANCE IS HEARD WHEN PRESSING STEERING WHEEL AUDIO CON-

TROL SWITCH OK >> GO TO 2.

NG >> Repair harness or connector.

Page 438 of 4331

YES >> GO TO 3.

NO >> Replace Bluetooth control unit. Refer to AV-55," Removal and Installation " .

OK >> Replace Bluetooth control unit. Refer to

AV-55, " Removal and Installation " .

NG >> Replace Bluetooth microphone. Refer to AV-55, " Removal and Installation " .

BLUETOOTH VOICE GUIDANCE IS NOT HEARD WHEN PRESSING STEERING WHEEL AUDIO

CONTROL SWITCH Steering Switch Check (With Bluetooth) " .

OK or NG OK >> GO TO 2.

NG >> Replace applicable parts. PKIB5037J

Terminals Continuity

Connector Terminal Connector Terminal

A: B121 9

B: M44 31

Yes

10 33

11 27

Page 462 of 4331

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ............................................ ......5

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool .................................... ......6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ...... ......9

Diagnostic Worksheet ......................................... ....11

HOOD ............................................................. ....13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspec tion .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ............................................ ....21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description ............................................. ....23

CAN Communication System Description ........... ....25

Schematic ........................................................... ....26

Wiring Diagram - D/LOCK - ................................. ....27

Schematic ........................................................... ....31

Wiring Diagram - D/LOCK - ................................. ....32 Terminal and Reference

Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (B CM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection ....43

Door Switch Check (Hatchback) .......................... ....44

Door Switch Check (Sedan) ................................ ....47

Key Switch (Insert) Check ................................... ....48

Door Lock and Unlock Switch Check .................. ....49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder S witch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM ............. 58

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

58

System Description .............................................. ....58

CAN Communication System Description ........... ....60

Schematic ............................................................ ....61

Wiring Diagram - KEYLES - ................................ ....62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ............................................... ....69

CONSULT-III Function (B CM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ...................... ....71

Keyfob Battery and Function Check .................... ....72

ACC Switch Check .............................................. ....74

Door Switch Check (Hatchback) .......................... ....74

Door Switch Check (Sedan) ................................ ....76

Key Switch (Insert) Check ................................... ....78

Hazard Function Check ....................................... ....78

Horn Function Check ........................................... ....79

Interior Lamp and Ignition Keyhole Illumination

Function Check .................................................... ....

79

Remote Keyless Entry Rece iver Check ...................80

Keyfob Function (Lock) Check ............................ ....82

Page 738 of 4331

BL

N

O P

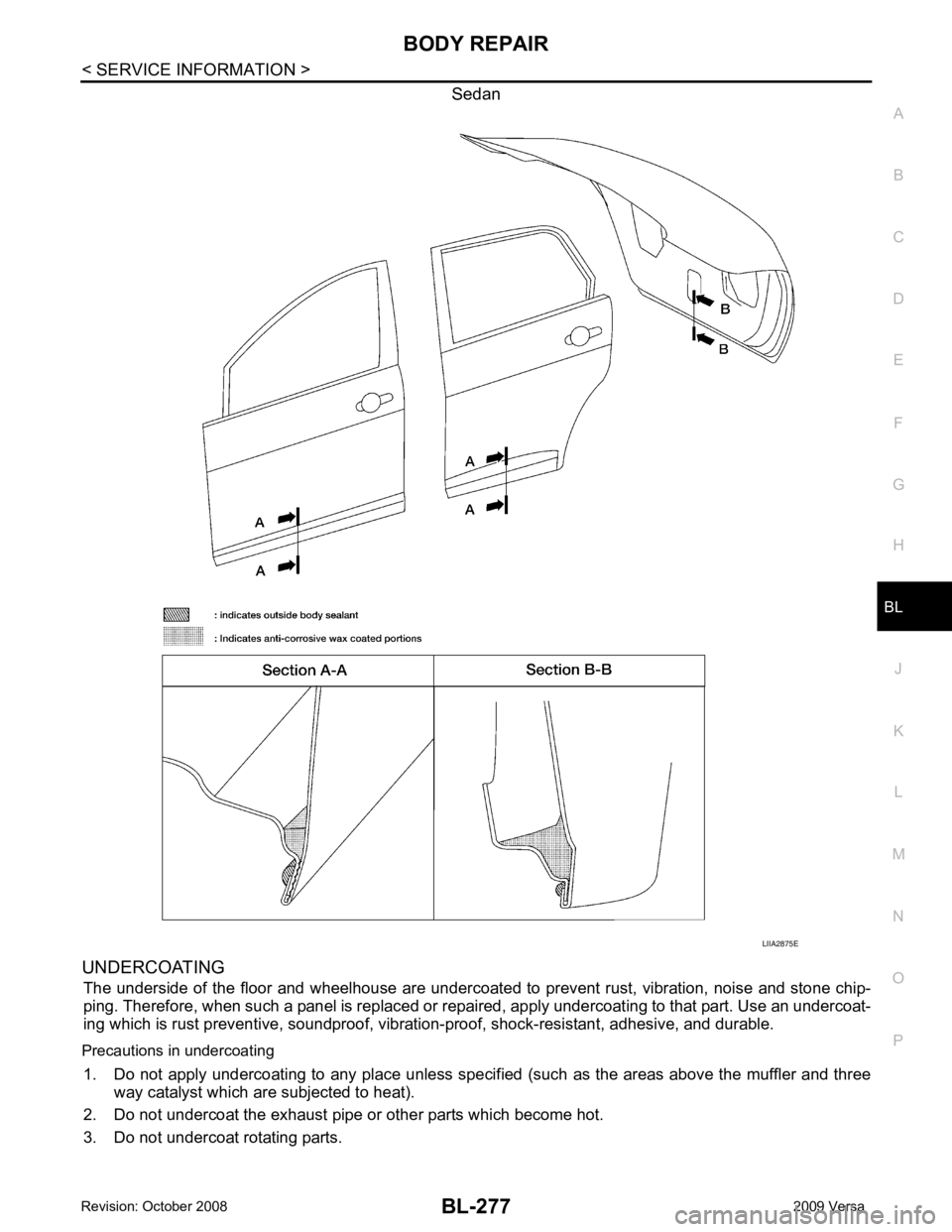

Sedan

UNDERCOATING The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or re paired, apply undercoating to that part. Use an undercoat-

ing which is rust preventive, soundproof, vibr ation-proof, shock-resistant, adhesive, and durable.

Precautions in undercoating 1. Do not apply undercoating to any place unless specif ied (such as the areas above the muffler and three

way catalyst which are subjected to heat).

2. Do not undercoat the exhaust pipe or other parts which become hot.

3. Do not undercoat rotating parts.

Page 770 of 4331

BL

N

O P

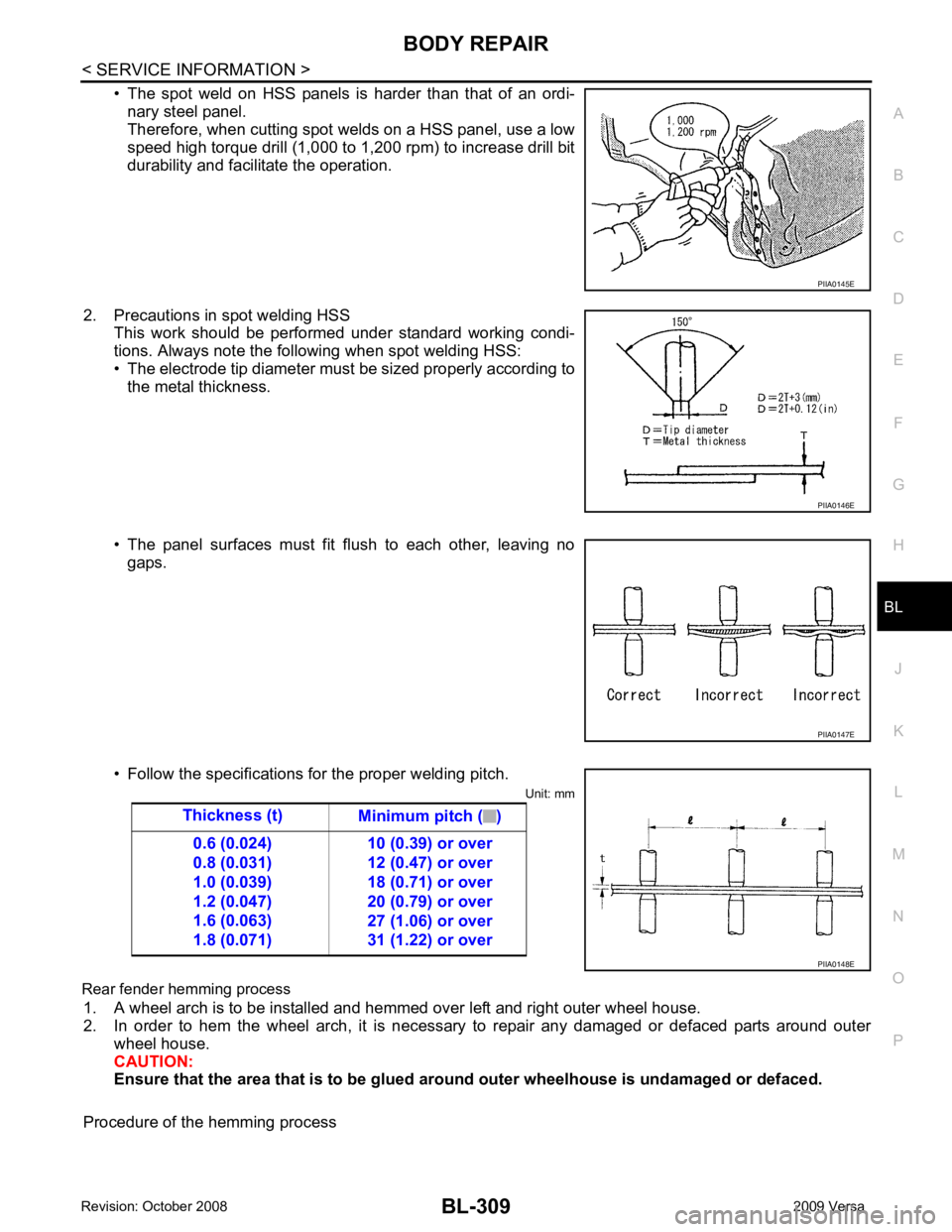

• The spot weld on HSS panels is harder than that of an ordi-

nary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

2. Precautions in spot welding HSS This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according to the metal thickness.

• The panel surfaces must fit flush to each other, leaving no gaps.

• Follow the specifications for the proper welding pitch. Unit: mm

Rear fender hemming process 1. A wheel arch is to be installed and hemmed over left and right outer wheel house.

2. In order to hem the wheel arch, it is necessary to repair any damaged or defaced parts around outer

wheel house.

CAUTION:

Ensure that the area that is to be glued around outer wheelhouse is undamaged or defaced.

Procedure of the hemming process PIIA0146E

PIIA0147E

Page 772 of 4331

BL

N

O P

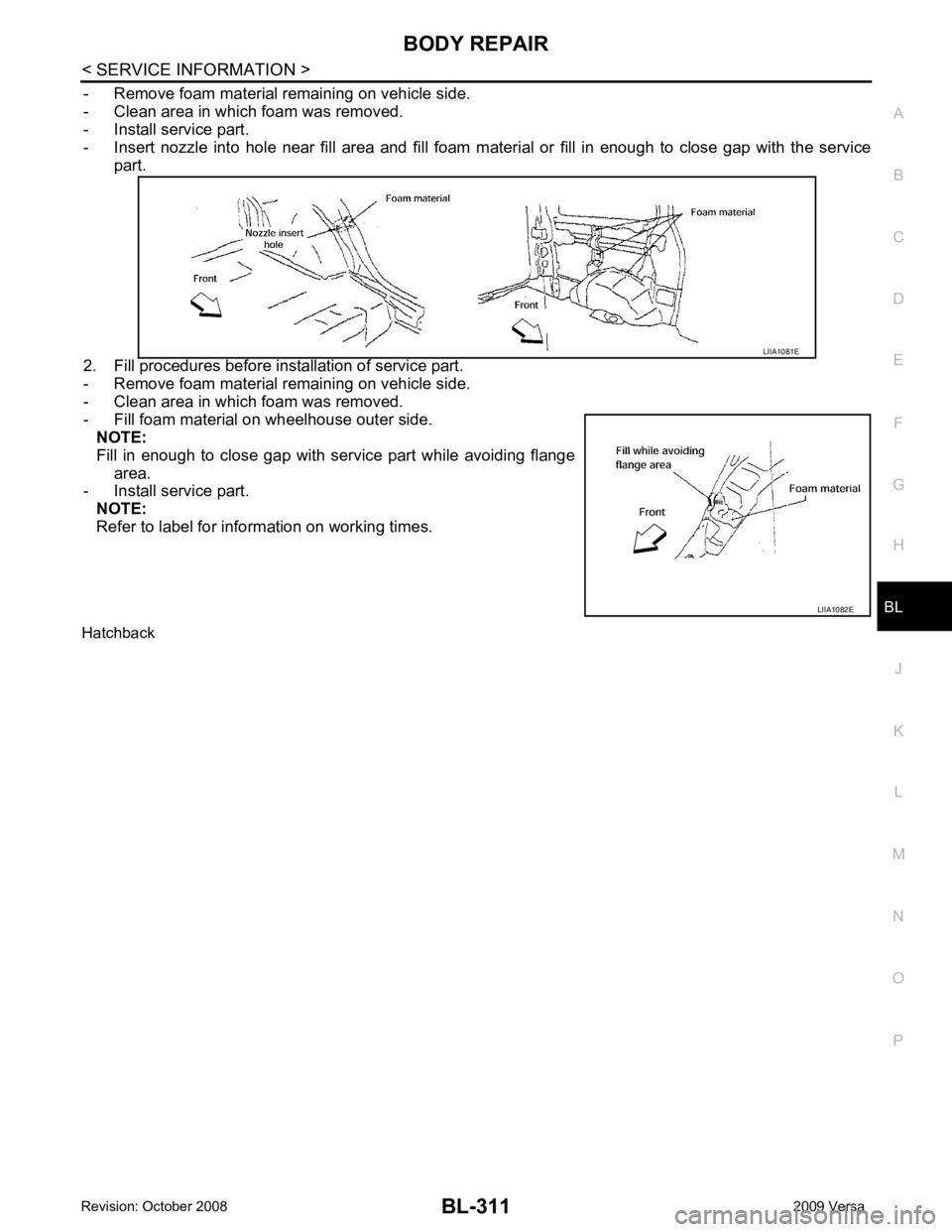

- Remove foam material remaining on vehicle side.

- Clean area in which foam was removed.

- Install service part.

- Insert nozzle into hole near fill area and fill foam material or fill in enough to close gap with the service

part.

2. Fill procedures before installation of service part.

- Remove foam material remaining on vehicle side.

- Clean area in which foam was removed.

- Fill foam material on wheelhouse outer side. NOTE:

Fill in enough to close gap with service part while avoiding flange area.

- Install service part.

NOTE:

Refer to label for information on working times.

Hatchback LIIA1082E

Page 801 of 4331

BR

N

O P

CONTENTS

BRAKE SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Brake System .............................. ......3

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool .................................... ......4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....5

NVH Troubleshooting Chart ................................ ......5

BRAKE PEDAL .............................................. .....6

Inspection and Adjustment .................................. ......6

Removal and Installation ...........................................7

BRAKE FLUID .....................................................9

On Board Inspection ........................................... ......9

Drain and Refill .................................................... ......9

Bleeding Brake System ....................................... ......9

BRAKE TUBE AND HOSE ............................ ....11

Hydraulic Circuit .................................................. ....11

Front Brake Tube and Hose ................................ ....12

Rear Brake Tube and Hose ................................ ....12

Inspection After Installation ................................. ....13

DUAL PROPORTIONING VALVE ................. ....14

Removal and Installation .........................................14

Inspection ............................................................ ....14

BRAKE MASTER CY LINDER ........................ ....15

On-Board Inspection ........................................... ....15 Removal and Installation .....................................

....15

Disassembly and Assembly ................................. ....16

BRAKE BOOSTER ........................................... 20

On Board Inspection ............................................ ....20

Removal and Installation ..................................... ....21

VACUUM LINES ............................................... 23

Component .......................................................... ....23

Removal and Installation ..................................... ....23

Inspection ............................................................ ....23

FRONT DISC BRAKE ....................................... 25

On Board Inspection ............................................ ....25

Component .......................................................... ....25

Removal and Installation of Brake Pad ...................26

Removal and Installation of Brake Caliper Assem-

bly ........................................................................ ....

28

Disassembly and Assembly of Brake Caliper As-

sembly ................................................................. ....

29

Brake Burnishing Procedure ................................ ....32

REAR DRUM B RAKE ....................................... 33

Component .......................................................... ....33

Removal and Installation of Drum Brake Assembly ....34

Removal and Installation of Wheel Cylinder ........ ....37

Disassembly and Assembly of Wheel Cylinder ... ....37

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................. 38

General Specification .......................................... ....38

Brake Pedal ......................................................... ....39

Check Valve ........................................................ ....39

Brake Booster ...................................................... ....40

Front Disc Brake .................................................. ....40

Rear Drum Brake ................................................. ....40