tires NISSAN TIIDA 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3749 of 4331

Tire "

Rotation "

Rotation "

Tire Pressure Monitor-

ing System (TPMS)

t ransmitter compo-

nents Replace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age. WT-8 Wheel Align-

ment Inspection " and

WT-7, " Balancing

Wheels "

LOCKS, HING-

ES AND HOOD LATCH :

Lubricating Locks, Hing-

es and Hood Latch "

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak. —

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Seats Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Page 3789 of 4331

MA-46< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

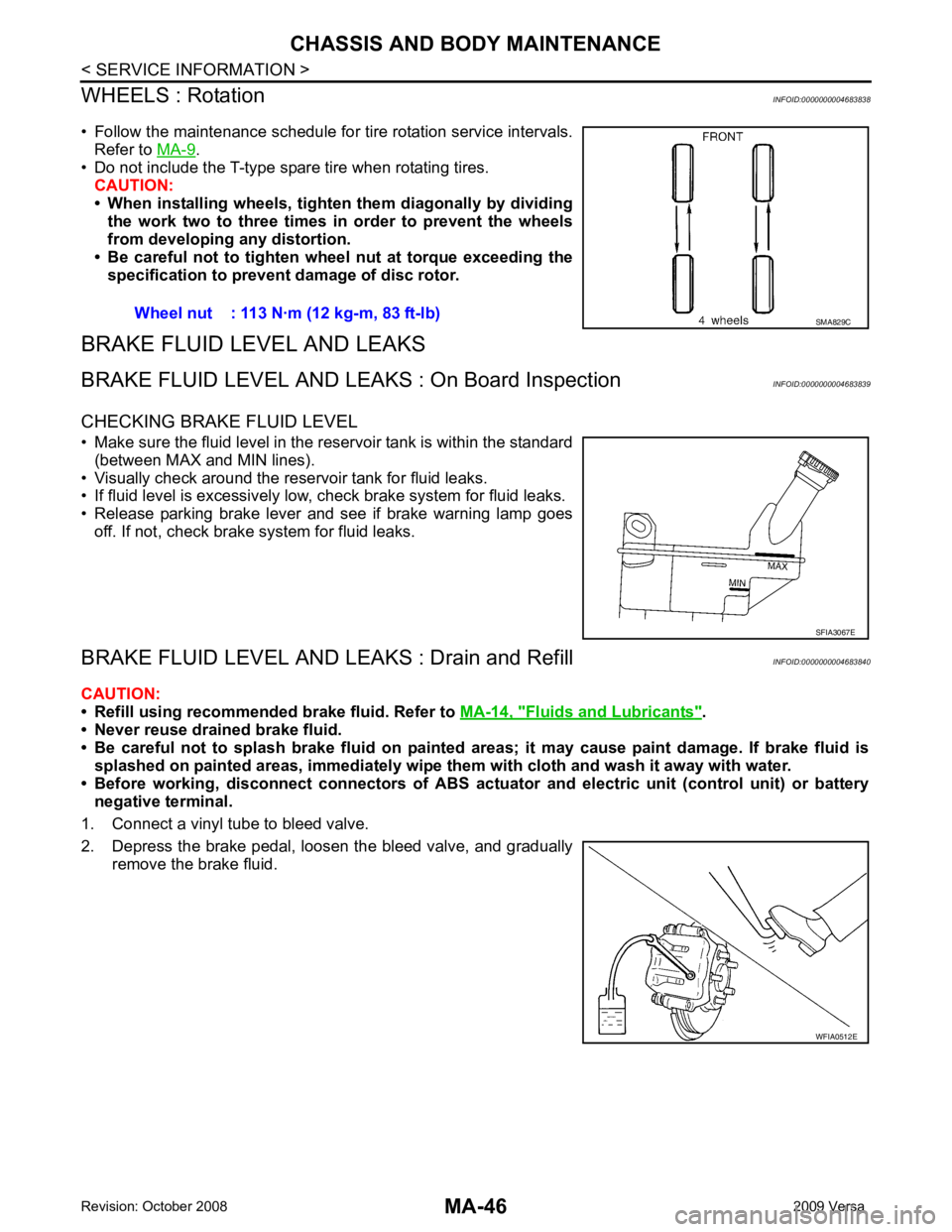

WHEELS : Rotation INFOID:0000000004683838

• Follow the maintenance schedule for tire rotation service intervals. Refer to MA-9 .

• Do not include the T-type spare tire when rotating tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the specification to prevent damage of disc rotor.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAK S : On Board Inspection INFOID:0000000004683839

CHECKING BRAKE FLUID LEVEL

• Make sure the fluid level in the reservoir tank is within the standard (between MAX and MIN lines).

• Visually check around the reservoir tank for fluid leaks.

• If fluid level is excessively low, check brake system for fluid leaks.

• Release parking brake lever and see if brake warning lamp goes off. If not, check brake system for fluid leaks.

BRAKE FLUID LEVEL AND LE AKS : Drain and Refill INFOID:0000000004683840

CAUTION:

• Refill using recommended brake fluid. Refer to MA-14, " Fluids and Lubricants " .

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe th em with cloth and wash it away with water.

• Before working, disconnect connectors of ABS actua tor and electric unit (control unit) or battery

negative terminal.

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually remove the brake fluid.Wheel nut : 113 N·m (12 kg-m, 83 ft-lb) SMA829C

SFIA3067E

WFIA0512E

Page 4061 of 4331

PS

N

O P

NOISE, VIBRATION AND HARSHN

ESS (NVH) TROUBLESHOOTING

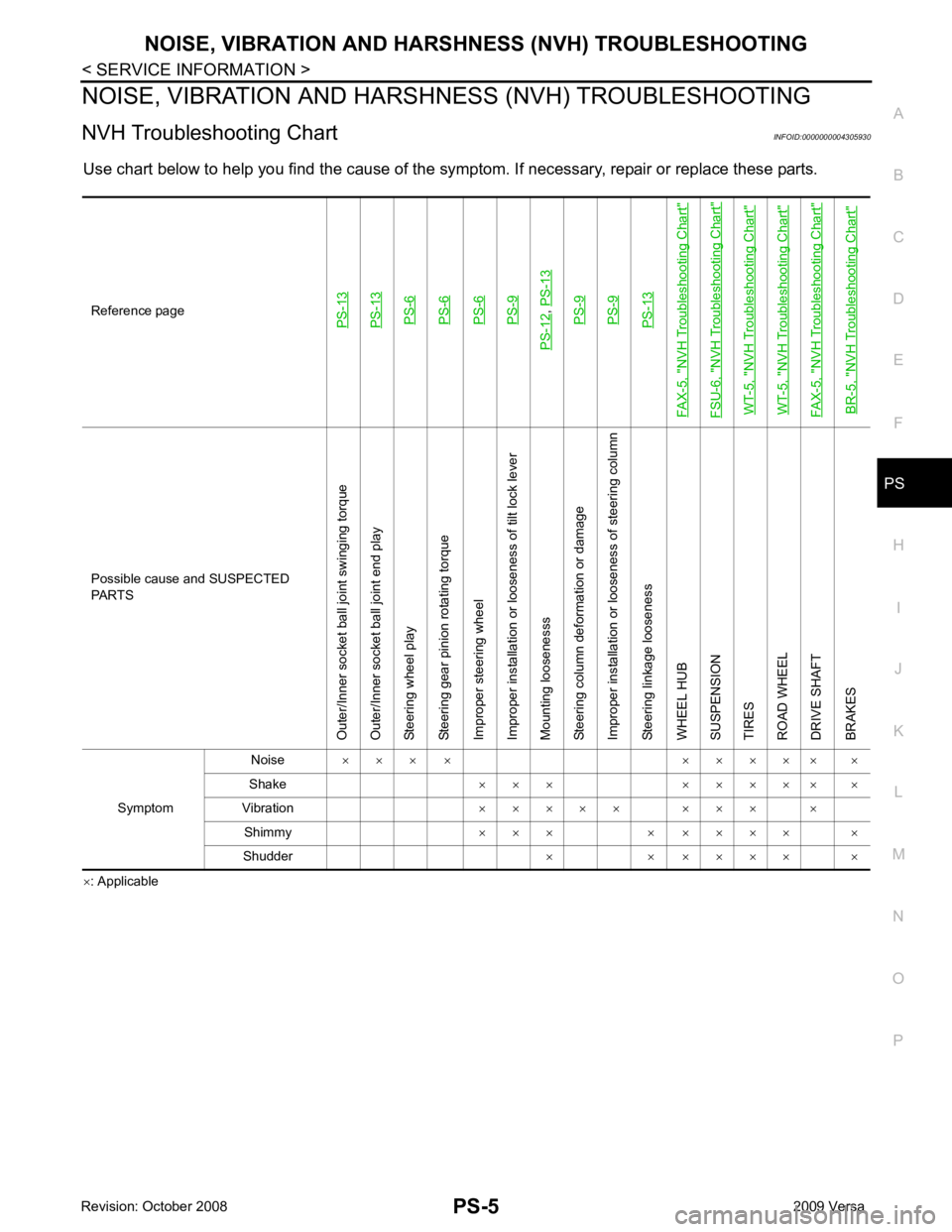

NVH Troubleshooting Chart INFOID:0000000004305930

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

× : ApplicableReference pagePS-13PS-13PS-6PS-6PS-6PS-9

PS-12

,

PS-13PS-9PS-9PS-13

FAX-5, "

NVH Troubleshooting Chart

"

FSU-6, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

" Possible cause and SUSPECTED

PARTS

Outer/Inner socket ball joint swinging torque

Outer/Inner socket ball joint end play

Steering wheel play

Steering gear pinion rotating torque

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting loosenesss

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom Noise

× × × × × × × × × ×

Shake × × × × × × × × ×

Vibration × × × × × × × × ×

Shimmy × × × × × × × × ×

Shudder × × × × × × ×

Page 4068 of 4331

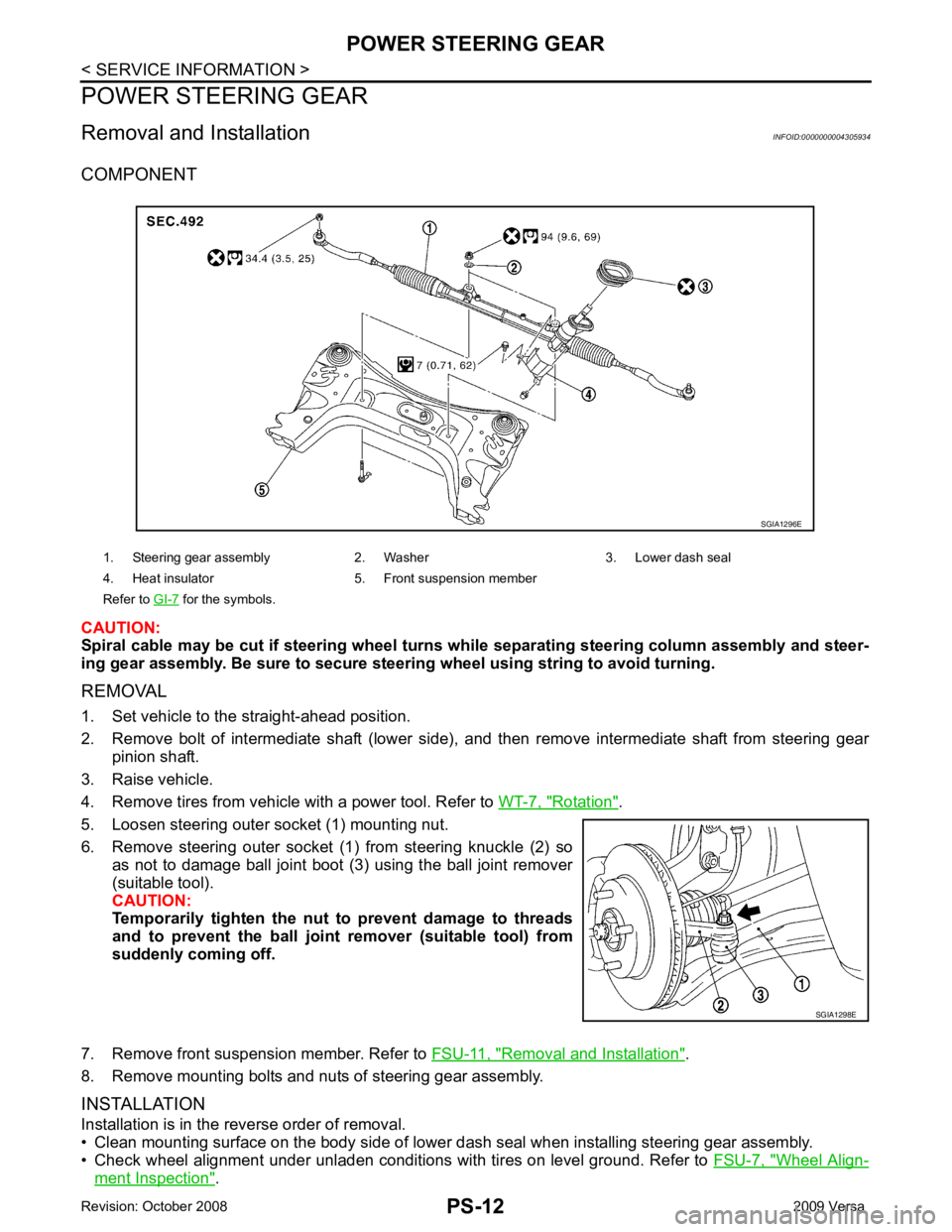

Rotation " .

5. Loosen steering outer socket (1) mounting nut.

6. Remove steering outer socket (1) from steering knuckle (2) so as not to damage ball joint boot (3) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

7. Remove front suspension member. Refer to FSU-11, " Removal and Installation " .

8. Remove mounting bolts and nuts of steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Clean mounting surface on the body side of lower dash seal when installing steering gear assembly.

• Check wheel alignment under unladen conditions with tires on level ground. Refer to FSU-7, " Wheel Align-

ment Inspection " .

1. Steering gear assembly 2. Washer 3. Lower dash seal

4. Heat insulator 5. Front suspension member

Refer to GI-7 for the symbols.

SGIA1298E

Page 4078 of 4331

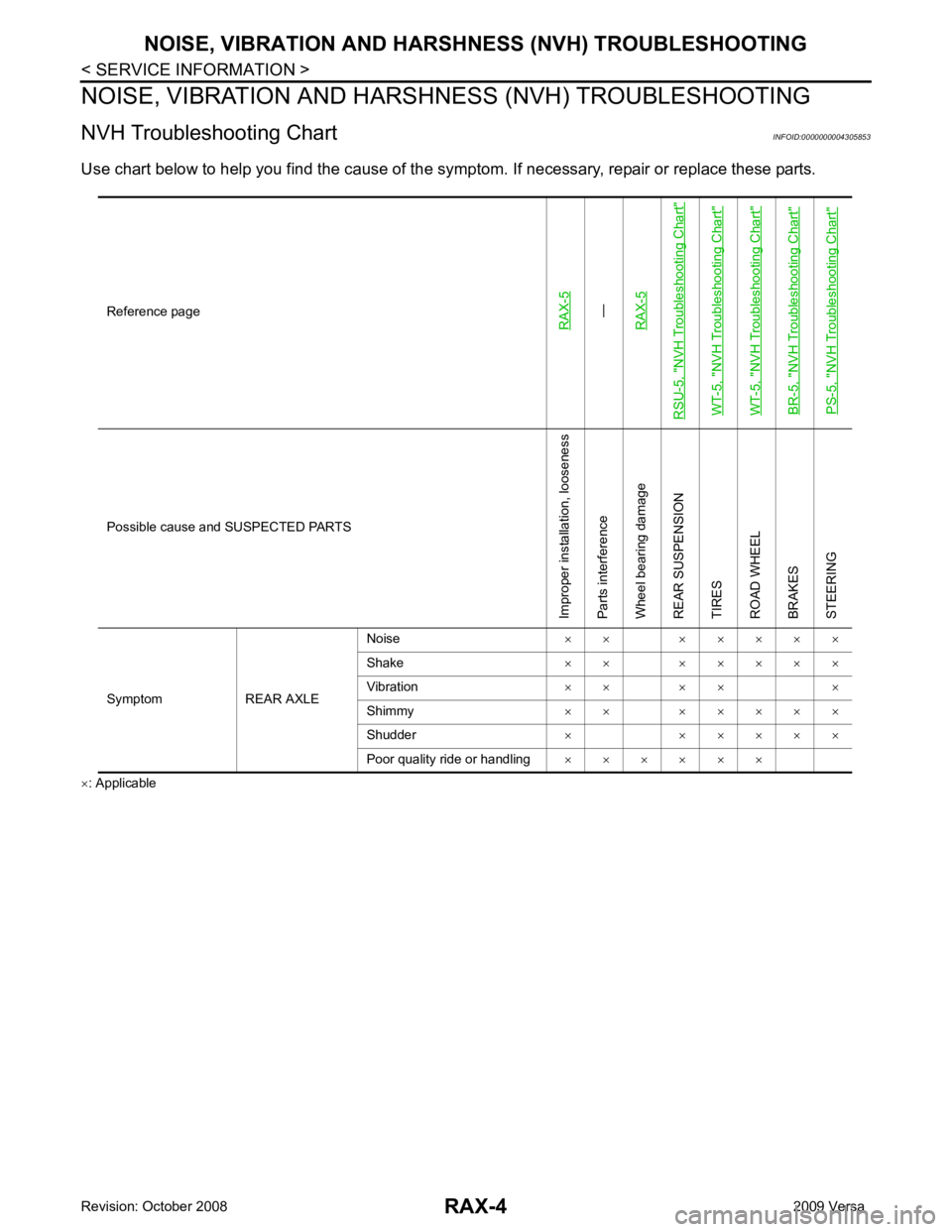

—

RAX-5

RSU-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

" Possible cause and SUSPECTED PARTS

Improper installation, looseness

Parts interference

Wheel bearing damage

REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom REAR AXLE Noise

× × × × × × ×

Shake × × × × × × ×

Vibration × × × × ×

Shimmy × × × × × × ×

Shudder × × × × × ×

Poor quality ride or handling × × × × × ×

Page 4079 of 4331

WHEEL HUB

RAX-5

< SERVICE INFORMATION >

C

E F

G H

I

J

K L

M A

B RAX

N

O P

WHEEL HUB

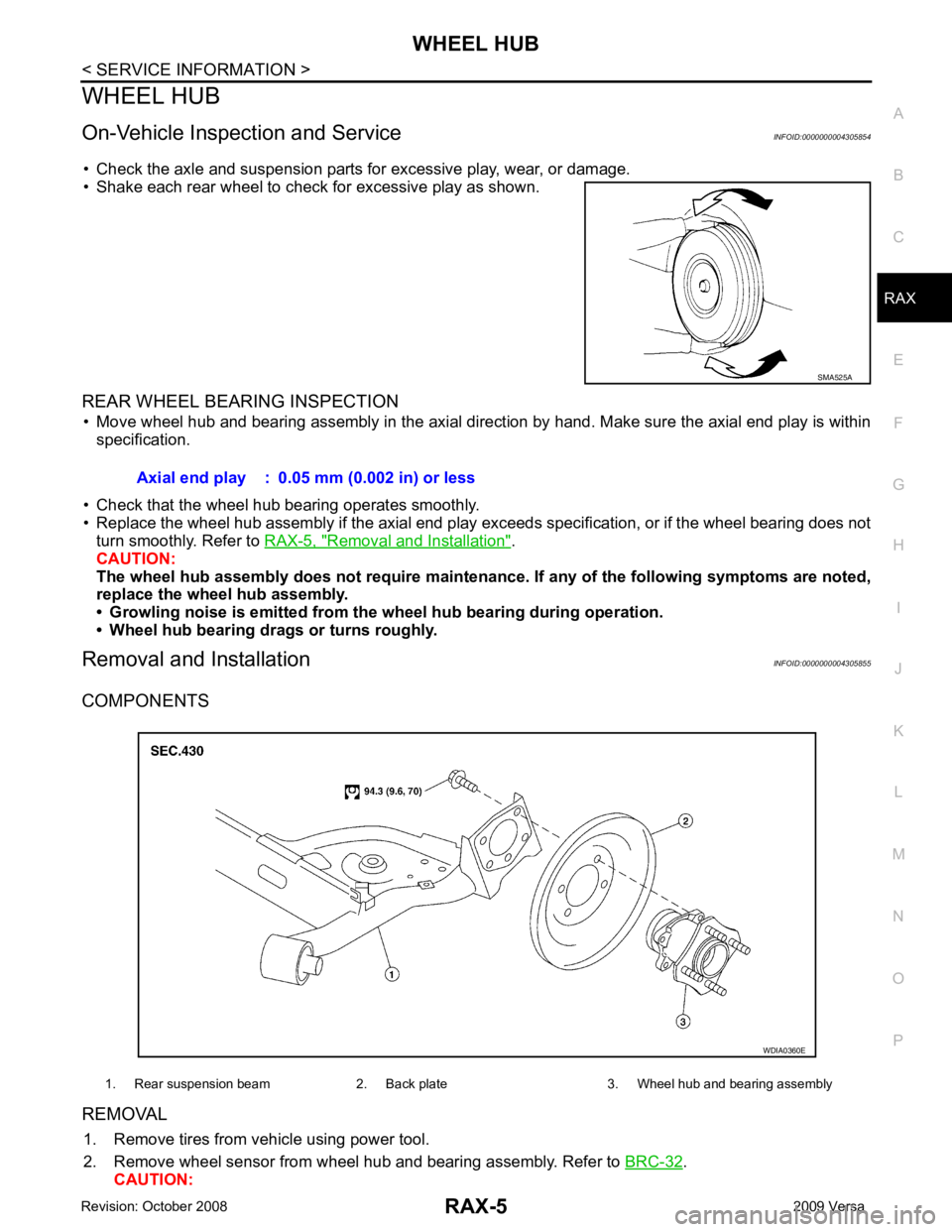

On-Vehicle Inspection and Service INFOID:0000000004305854

• Check the axle and suspension parts for excessive play, wear, or damage.

• Shake each rear wheel to check for excessive play as shown.

REAR WHEEL BEARING INSPECTION • Move wheel hub and bearing assembly in the axial direction by hand. Make sure the axial end play is within specification.

• Check that the wheel hub bearing operates smoothly.

• Replace the wheel hub assembly if the axial end play e xceeds specification, or if the wheel bearing does not

turn smoothly. Refer to RAX-5, " Removal and Installation " .

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from th e wheel hub bearing during operation.

• Wheel hub bearing dr ags or turns roughly.

Removal and Installation INFOID:0000000004305855

COMPONENTS

REMOVAL 1. Remove tires from vehicle using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to BRC-32 .

CAUTION: SMA525A

Axial end play : 0.05 mm (0.002 in) or less

1. Rear suspension beam 2. Back plate 3. Wheel hub and bearing assembly WDIA0360E

Page 4114 of 4331

RSU

N

O P

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Rear Suspension INFOID:0000000004305875

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and l ubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 4116 of 4331

RSU

N

O P

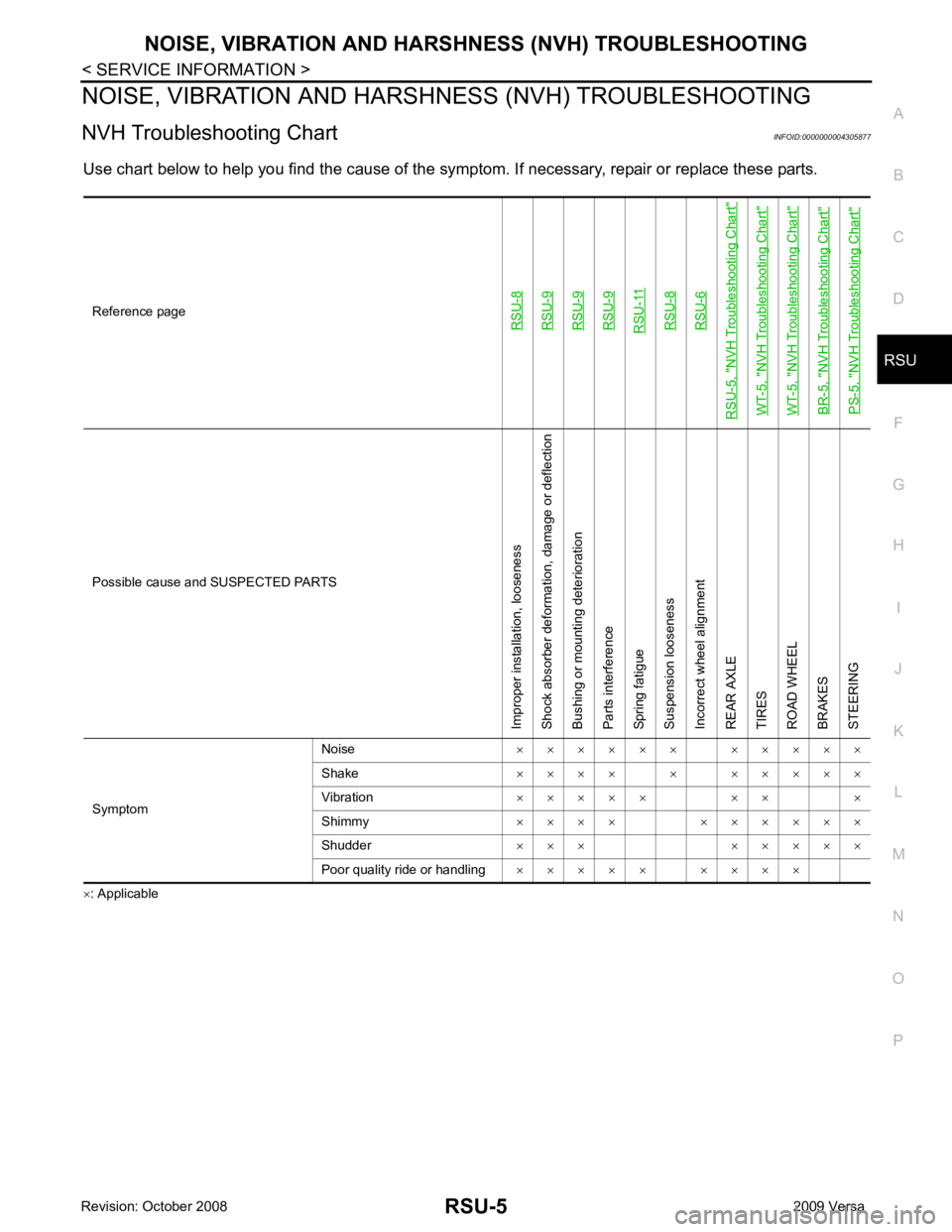

NOISE, VIBRATION AND HARSHN

ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart INFOID:0000000004305877

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

× : ApplicableReference pageRSU-8RSU-9RSU-9RSU-9RSU-11RSU-8RSU-6

RSU-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

" Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

REAR AXLE

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom Noise

× × × × × × × × × × ×

Shake × × × × × × × × × ×

Vibration × × × × × × × ×

Shimmy × × × × × × × × × ×

Shudder × × × × × × × ×

Poor quality ride or handling × × × × × × × × ×

Page 4118 of 4331

RSU

N

O P

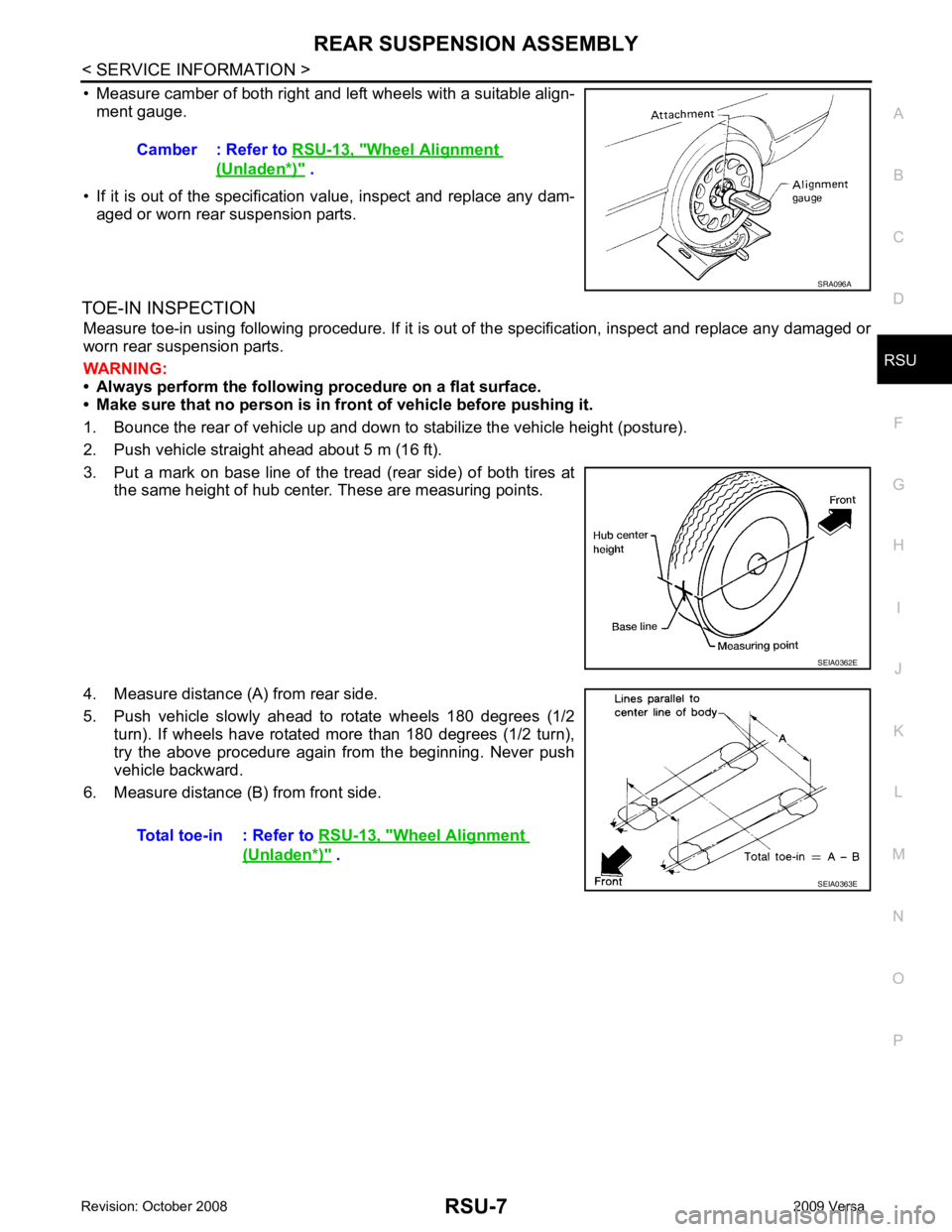

• Measure camber of both right and left wheels with a suitable align-

ment gauge.

• If it is out of the specificati on value, inspect and replace any dam-

aged or worn rear suspension parts.

TOE-IN INSPECTION Measure toe-in using following procedure. If it is out of the specification, inspect and replace any damaged or

worn rear suspension parts.

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fron t of vehicle before pushing it.

1. Bounce the rear of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

4. Measure distance (A) from rear side.

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2 turn). If wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance (B) from front side. Camber : Refer to

RSU-13, " Wheel Alignment

(Unladen*) " .

SEIA0362E

Wheel Alignment

(Unladen*) " .

Page 4123 of 4331

On-

Vehicle Service " .

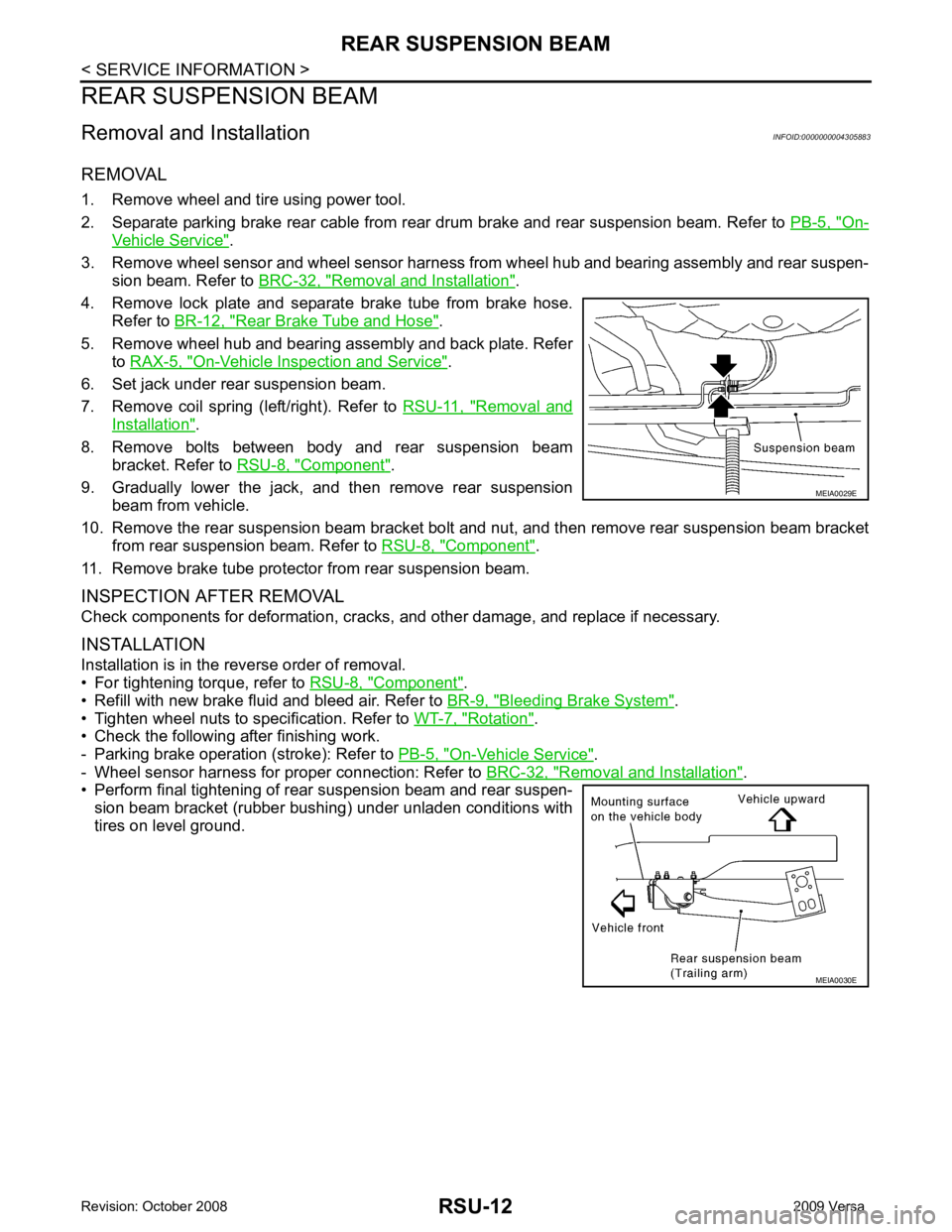

3. Remove wheel sensor and wheel sensor harness from wheel hub and bearing assembly and rear suspen-

sion beam. Refer to BRC-32, " Removal and Installation " .

4. Remove lock plate and separate brake tube from brake hose. Refer to BR-12, " Rear Brake Tube and Hose " .

5. Remove wheel hub and bearing assembly and back plate. Refer to RAX-5, " On-Vehicle Inspection and Service " .

6. Set jack under rear suspension beam.

7. Remove coil spring (left/right). Refer to RSU-11, " Removal and

Installation " .

8. Remove bolts between body and rear suspension beam bracket. Refer to RSU-8, " Component " .

9. Gradually lower the jack, and then remove rear suspension beam from vehicle.

10. Remove the rear suspension beam bracket bolt and nut, and then remove rear suspension beam bracket

from rear suspension beam. Refer to RSU-8, " Component " .

11. Remove brake tube protector from rear suspension beam.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage, and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, " Component " .

• Refill with new brake fluid and bleed air. Refer to BR-9, " Bleeding Brake System " .

• Tighten wheel nuts to specification. Refer to WT-7, " Rotation " .

• Check the following after finishing work.

- Parking brake operation (stroke): Refer to PB-5, " On-Vehicle Service " .

- Wheel sensor harness for proper connection: Refer to BRC-32, " Removal and Installation " .

• Perform final tightening of rear suspension beam and rear suspen-

sion beam bracket (rubber bushing) under unladen conditions with

tires on level ground. MEIA0030E