engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2387 of 4331

EC

NP

O

*: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION If the engine speed is above 2,400 rpm under no load [for ex ample, the shift lever position is P or N (A/T,

CVT), Neutral (M/T) and engine speed is over 2,400 rpm] f uel will be cut off after some time. The exact time

when the fuel is cut off varies based on engine speed.

Fuel cut will be operated until the engine speed reaches 1,500 rpm, then fuel cut will be cancelled.

NOTE:

This function is different from deceleration control listed under EC-1027, " Multiport Fuel Injection (MFI) Sys-

tem " .

Page 2389 of 4331

EC

NP

O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description INFOID:0000000004499911

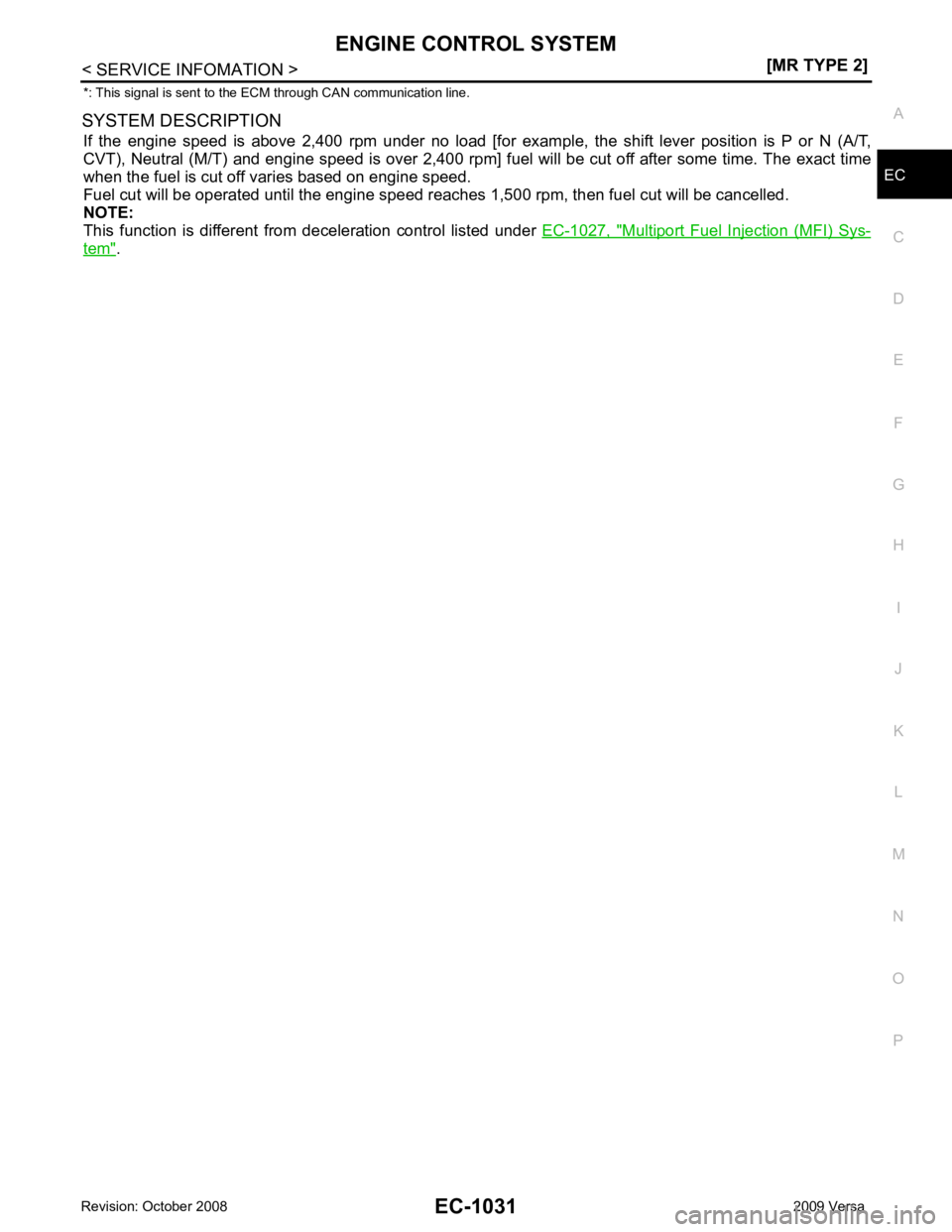

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

BASIC ASCD SYSTEM Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric thro ttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE i ndicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION Press MAIN switch. (The CRUISE indicato r in combination meter illuminates.)

When vehicle speed reaches a desired speed between appr oximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indi cator in combination meter illuminates.)

ACCELERATE OPERATION If the RESUME/ACCELERATE switch is depressed during cruise control driving, increase the vehicle speed

until the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION When any of following conditions exis t, cruise operation will be canceled.

• CANCEL switch is pressed

• More than two switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Clutch pedal is depressed or gear position is changed to the neutral position (M/T models)

• Selector lever is changed to N, P, R position (A/T and CVT models)

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to t he normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator

Stop lamp switch Brake pedal operation

ASCD clutch switch (M/T models) Clutch pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) switch Gear position

ABS actuator and electric unit (con-

trol unit) Vehicle speed*

Combination meter

TCM Powertrain revolution*

Page 2392 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1036< SERVICE INFOMATION >

[MR TYPE 2]

EVAPORATIVE EMISSION SYSTEM

EVAPORATIVE EMISSION SYSTEM

Description INFOID:0000000004499914

SYSTEM DESCRIPTION

The evaporative emission system is used t NISSAN TIIDA 2009 Service Repair Manual EC-1036< SERVICE INFOMATION >

[MR TYPE 2]

EVAPORATIVE EMISSION SYSTEM

EVAPORATIVE EMISSION SYSTEM

Description INFOID:0000000004499914

SYSTEM DESCRIPTION

The evaporative emission system is used t](/img/5/57398/w960_57398-2391.png)

EC-1036< SERVICE INFOMATION >

[MR TYPE 2]

EVAPORATIVE EMISSION SYSTEM

EVAPORATIVE EMISSION SYSTEM

Description INFOID:0000000004499914

SYSTEM DESCRIPTION

The evaporative emission system is used to reduce hydr ocarbons emitted into the atmosphere from the fuel

system. This reduction of hydrocarbons is accomplis hed by activated charcoals in the EVAP canister.

The fuel vapor in the sealed fuel tank is led into t he EVAP canister which contains activated carbon and the

vapor is stored there when the engine is not oper ating or when refueling to the fuel tank.

The vapor in the EVAP canister is purged by the air through the purge line to the intake manifold when the

engine is operating. EVAP canister purge volume contro l solenoid valve is controlled by ECM. When the

engine operates, the flow rate of vapor controlled by EVAP canister purge volume control solenoid valve is

proportionally regulated as the air flow increases.

EVAP canister purge volume control solenoid valve al so shuts off the vapor purge line during decelerating.

EVAPORATIVE EMISSION LINE DRAWING PBIB3639E

Page 2396 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1040< SERVICE INFOMATION >

[MR TYPE 2]

EVAPORATIVE EMISSION SYSTEM

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor leak age in the EVAP system occurs, NISSAN TIIDA 2009 Service Repair Manual EC-1040< SERVICE INFOMATION >

[MR TYPE 2]

EVAPORATIVE EMISSION SYSTEM

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor leak age in the EVAP system occurs,](/img/5/57398/w960_57398-2395.png)

EC-1040< SERVICE INFOMATION >

[MR TYPE 2]

EVAPORATIVE EMISSION SYSTEM

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor leak age in the EVAP system occurs, use a

leak detector to locate the leak.

Removal and Installation INFOID:0000000004499916

EVAP CANISTER

Tighten EVAP canister as shown in the figure.

EVAP CANISTER VENT CONTROL VALVE

1. Turn EVAP canister vent control valve counterclockwise.

• Lock (A)

• Unlock (B)

2. Remove the EVAP canister vent control valve.

Always replace O-ring with a new one.

How to Detect Fuel Vapor Leakage INFOID:0000000004499917

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in EVAP system.

NOTE:

• Do not start engine.

• Improper installation of EVAP service port adapter to the EVAP service port may cause a leak.

WITH CONSULT-III

1. Attach the EVAP service port adapter securely to the EVAP service port.

2. Also attach the pressure pump and hose to the EVAP service port adapter. SEF462UC

PBIB1214E

PBIB3091E

Page 2398 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1042< SERVICE INFOMATION >

[MR TYPE 2]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System Description INFOID:0000000004499918

From the beginning of refueli NISSAN TIIDA 2009 Service Repair Manual EC-1042< SERVICE INFOMATION >

[MR TYPE 2]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System Description INFOID:0000000004499918

From the beginning of refueli](/img/5/57398/w960_57398-2397.png)

EC-1042< SERVICE INFOMATION >

[MR TYPE 2]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System Description INFOID:0000000004499918

From the beginning of refueling, the air and vapor insi de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspections below, be sure to observe the following:

• Put a “CAUTION: FLAMMABLE” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO 2

fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-pr oof container and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-1086, " Fuel Pressure Check " .

- Disconnect negative battery cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine an d check for fuel leaks at connection.

• Do not attempt to top off the fuel tank afte r the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, r esulting in fuel spray and possibly a fire.

Diagnosis Procedure INFOID:0000000004499919

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG. 1.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

OK or NG OK >> GO TO 2.

NG >> GO TO 3. 2.

CHECK IF EVAP CANISTER SATURATED WITH WATER PBIB1387E

Page 2407 of 4331

EC

NP

O

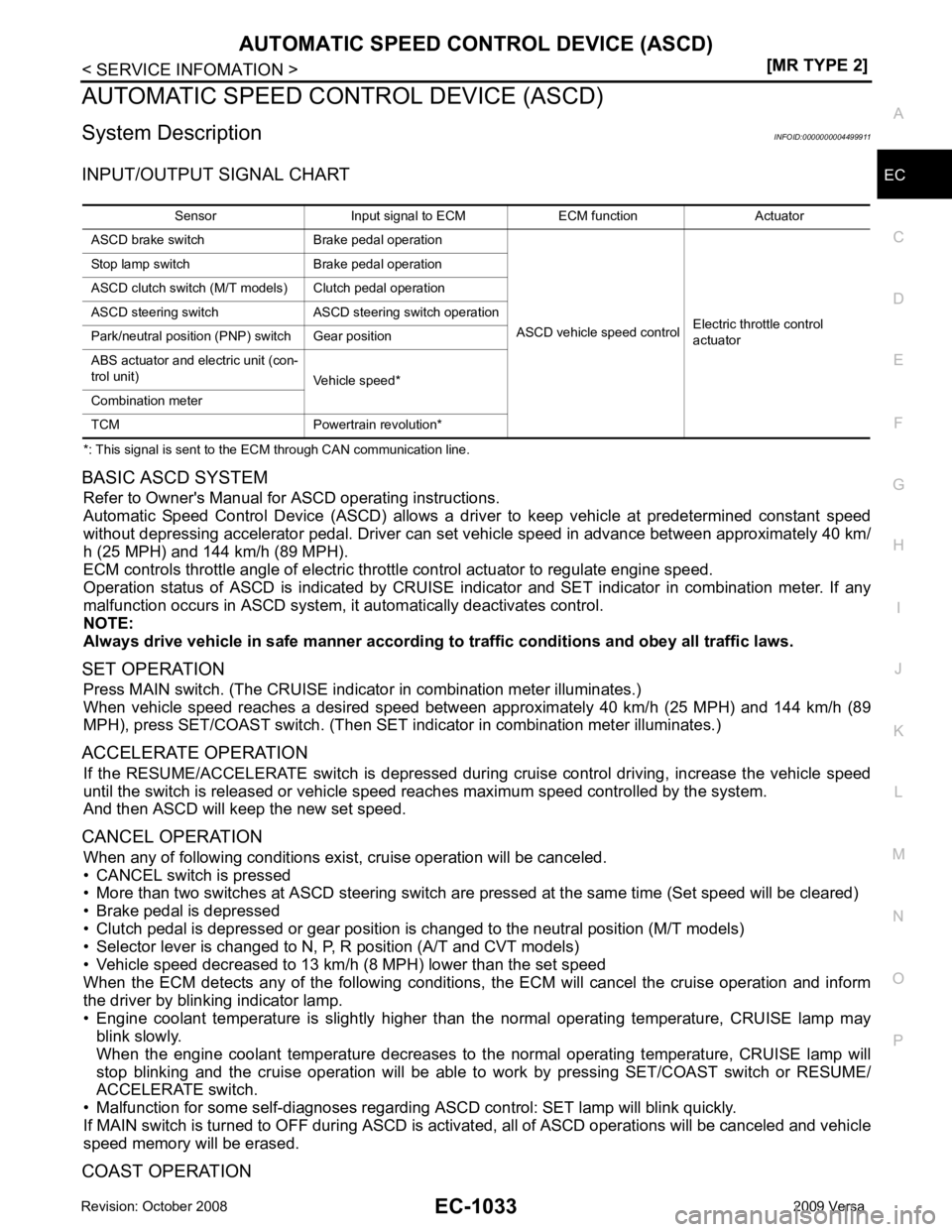

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Introduction INFOID:0000000004499924

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emis sion-related diagnostic information including:

The above information can be checked using procedures listed in the table below. ×: Applicable —: Not applicable

*: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator lamp (MIL) on the instrument panel lights up when the same malfunction is detected

in two consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode.

(Refer to EC-1094, " Fail-Safe Chart " .)

Two Trip Detection Logic INFOID:0000000004499925

When a malfunction is detected for the first time, 1st tr ip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MIL will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MIL lights up. The MIL lights up at the same time when the DTC is stored. <2nd

trip> The “trip” in the “Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic item s will cause the ECM to light up or blink the MIL,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

×: Applicable —: Not applicable

When there is an open circuit on MIL circuit, the ECM c annot warn the driver by MIL lighting up when there is

malfunction on engine control system. Emission-related diagnostic information Diagnostic service

Diagnostic Tr ouble Code (DTC) Service $03 of SAE J1979

Freeze Frame data Service $02 of SAE J1979

System Readiness Test (SRT) code Service $01 of SAE J1979

1st Trip Diagnostic Trou ble Code (1st Trip DTC) Service $07 of SAE J1979

1st Trip Freeze Frame data

Test values and Test limi ts Service $06 of SAE J1979

Calibration ID Servic e $09 of SAE J1979

DTC 1st trip DTC Freeze Frame

data 1st trip Freeze

Frame data SRT code SRT status Test value

CONSULT-III × × × × × × —

GST × × × —× × ×

ECM × ×* — — — ×— Items

MIL DTC 1st trip DTC

1st trip 2nd trip 1st trip

displaying 2nd trip

displaying 1st trip

displaying 2nd trip

display-

ing

Blinking Lighting

up Blinking

Lighting

up

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected ×

— — — — — ×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected — —

×— — ×— —

One trip detection diagnoses

(Refer to EC-1052, " Emission-relat-

ed Diagnostic Information " .)

—

×— — ×— — —

Except above — — — ×— × × —

Page 2410 of 4331

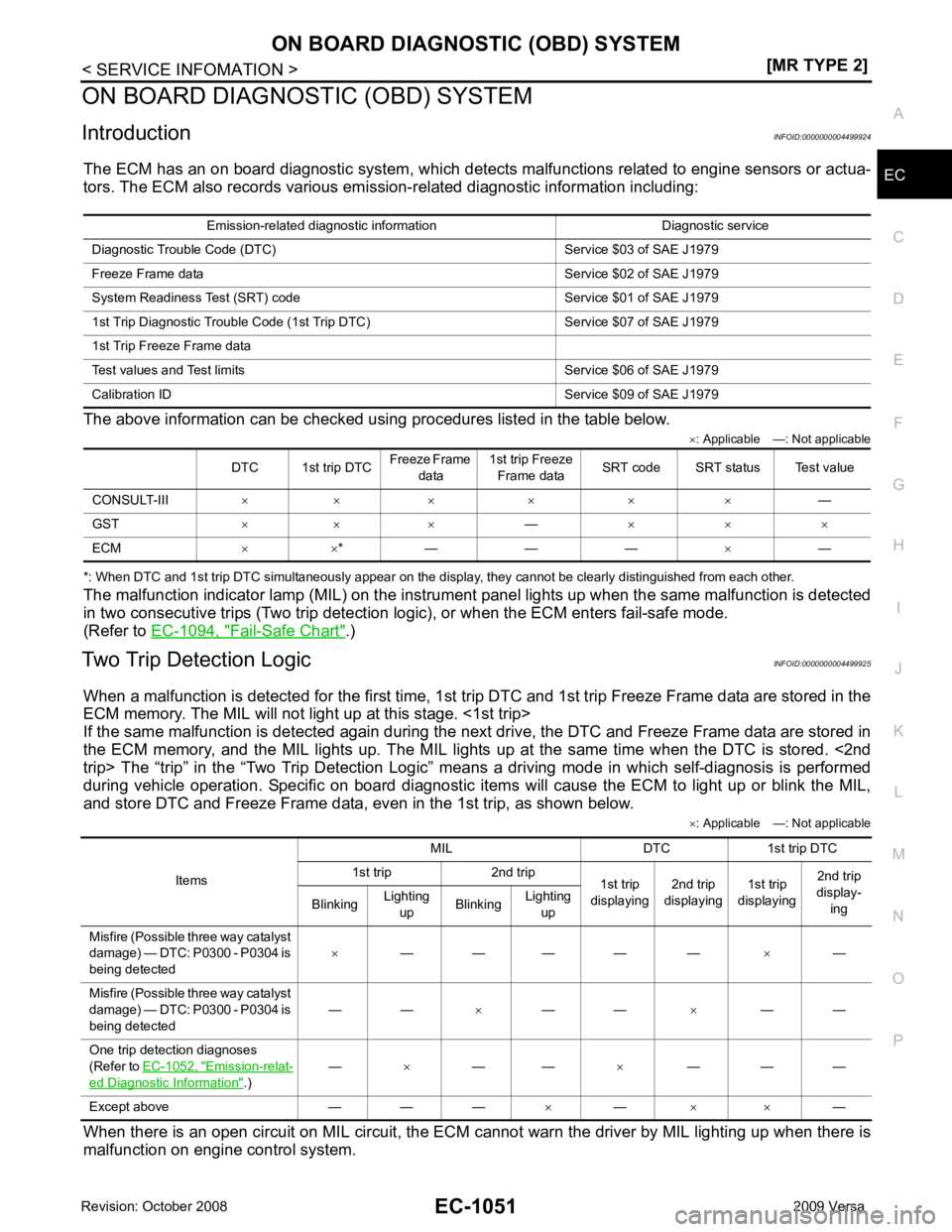

(A/T)

CVT-249 (CVT)

INPUT SPD SEN/CIRC P0715 0715 — 2 ×CVT-254 VEH SPD SEN/CIR AT*

7

P0720 0720 — 2 ×AT-101 (A/T)

CVT-258 (CVT)

ENGINE SPEED SIG P0725 0725 — 2 ×

(A/T)

— (CVT) AT-106 (A/T)

CVT-263 (CVT)

A/T 1ST GR FNCTN* 8

P0731 0731 — 2 ×AT-110 A/T 2ND GR FNCTN*

8

P0732 0732 — 2 ×AT-113 A/T 3RD GR FNCTN*

8

P0733 0733 — 2 ×AT-116 A/T 4TH GR FNCTN*

8

P0734 0734 — 2 ×AT-119 TCC SOLENOID/CIRC P0740 0740 — 2

×AT-124 (A/T)

CVT-266 (CVT)

A/T TCC S/V FNCTN P0744 0744 — 2 ×AT-129 (A/T)

CVT-271 (CVT)

L/PRESS SOL/CIRC P0745 0745 — 2 ×AT-134 (A/T)

CVT-273 (CVT)

PRS CNT SOL/A FCTN P0746 0746 — 1 ×CVT-278 SFT SOL A/CIRC P0750 0750 — 1

×AT-139 SFT SOL B/CIRC P0755 0755 — 1

×AT-144 PRS CNT SOL/B FCTN P0776 0776 — 2

×CVT-280 PRS CNT SOL/B CIRC P0778 0778 — 2

×CVT-282 TR PRS SENS/A CIRC P0840 0840 — 2

×CVT-287 P-N POS SW/CIRCUIT P0850 0850 — 2

×EC-1401 CLOSED LOOP-B1 P1148 1148 — 1

×EC-1407 ENG OVER TEMP P1217 1217 — 1

×EC-1408 CTP LEARNING-B1 P1225 1225 — 2 —

EC-1417CTP LEARNING-B1 P1226 1226 — 2 —

EC-1419COLD START CONTROL P1421 1421 — 2

×EC-1421 ASCD SW P1564 1564 — 1 —

EC-1423ASCD BRAKE SW P1572 1572 — 1 —

EC-1429ASCD VHL SPD SEN P1574 1574 — 1 —

EC-1438LOCK MODE P1610 1610 — 2 —

BL-259ID DISCORD,IMMU-ECM P1611 1611 — 2 —

BL-259CHAIN OF ECM-IMMU P1612 1612 — 2 —

BL-259CHAIN OF IMMU-KEY P1614 1614 — 2 —

BL-259DIFFERENCE OF KEY P1615 1615 — 2 —

BL-259IN PULY SPEED P1715 1715 — 2 —

EC-1440 (A/T)

EC-1441 (CVT)

LU-SLCT SOL/CIRC P1740 1740 — 2 ×CVT-306 O/R CLTCH SOL/CIRC P1760 1760 — 2

×AT-149 STEP MOTR CIRC P1777 1777 — 1

×CVT-311 STEP MOTR FNC P1778 1778 — 2

×CVT-315 BRAKE SW/CIRCUIT P1805 1805 — 2 —

EC-1443Items

(CONSULT-III screen terms) DTC*

1

SRT code Trip MIL lighting up Reference

CONSULT-III

GST* 2

ECM*3

Page 2418 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1062< SERVICE INFOMATION >

[MR TYPE 2]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

• Sea level

• Flat road

• Ambient air temperature: 20 - 30 °C (68 - 86 °F)

• Diagnosis is performed as quickly as NISSAN TIIDA 2009 Service Repair Manual EC-1062< SERVICE INFOMATION >

[MR TYPE 2]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

• Sea level

• Flat road

• Ambient air temperature: 20 - 30 °C (68 - 86 °F)

• Diagnosis is performed as quickly as](/img/5/57398/w960_57398-2417.png)

EC-1062< SERVICE INFOMATION >

[MR TYPE 2]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

• Sea level

• Flat road

• Ambient air temperature: 20 - 30 °C (68 - 86 °F)

• Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30 °C (68 - 86 °F)], diagno-

sis may also be performed.

Pattern 1:

• The engine is started at the engine coolant temperature of −10 to 35 °C (14 to 95 °F)

(where the voltage between the ECM te rminal 38 and ground is 3.0 - 4.3V).

• The engine must be operated at idle speed until the engine coolant temperature is greater than 70°C

(158 °F) (where the voltage between the ECM te rminal 38 and ground is lower than 1.4V).

• The engine is started at the fuel tank temperature of warmer than 0 °C (32 °F) (where the voltage

between the ECM terminal 43 and ground is less than 4.1V).

Pattern 2:

• When steady-state driving is performed again even afte r it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

Pattern 3:

• Operate vehicle following the driving pattern shown in the figure.

• Release the accelerator pedal during decelerating vehicle speed

from 90 km/h (56 MPH) to 0 km/h (0 MPH).

Pattern 4:

• The accelerator pedal must be held very steady during steady-

state driving.

• If the accelerator pedal is moved, the test must be conducted all

over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56

MPH), then release the accelerator pedal and keep it released for

more than 10 seconds. Depress the accelerator pedal until vehicle

speed is 90 km/h (56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Po sition for A/T and CVT Models

Set the selector lever in the D position (CVT), D position with the overdrive switch turned ON (A/T).

Suggested upshift speeds for M/T models

Shown below are suggested vehicle speeds for shifting into a higher gear. These suggestions relate to fuel

economy and vehicle performance. Actual upshift speeds will vary according to road conditions, the weather

and individual driving habits.

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoothly, or if you need to accelerate.

Do not exceed the maximum suggested speed (shown below) in any gear. For level road driving, use the high-

est gear suggested for that speed. Always observe post ed speed limits and drive according to the road condi-

tions to ensure safe operation. Do not over-rev the engine when shifting to a lower gear as it may cause

engine damage or loss of vehicle control. PBIB2244E

For normal accelera

tion in low alti-

tude areas

[less than 1,219 m (4,000 ft)]: For quick acceleration in low alti-

tude areas For high attitude areas

[over 1,219m (4,000 ft)]:

Gear change ACCEL shift point km/h (MPH) km/h (MPH) km/h (MPH)

1st to 2nd 13 (8) 24 (15) 24 (15)

2nd to 3rd 27 (17) 40 (25) 40 (25)

3rd to 4th 40 (25) 53 (33) 65 (40)

4th to 5th 58 (36) 71 (44) 73 (45)

5th to 6th 82 (51) 82 (51) 82 (51)

Page 2440 of 4331

Idle Air Volume Learning " .

VIN Registration INFOID:0000000004499932

DESCRIPTION

VIN Registration is an operation to registering VIN in ECM. It must be performed each time ECM is replaced.

NOTE:

Accurate VIN which is registered in ECM ma y be required for Inspection & Maintenance (I/M).

OPERATION PROCEDURE

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to GI-43, " Model Variation " .

2. Turn ignition switch ON and engine stopped.

3. Select “VIN REGISTRATION ” in “WORK SUPPORT” mode.

4. Follow the instruction of CONSULT-III display.

Accelerator Pedal Released Position Learning INFOID:0000000004499933

DESCRIPTION

Accelerator Pedal Released Position Learning is an operati on to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal positi on sensor output signal. It must be performed each time

harness connector of accelerator pedal pos ition sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Clos ed Position Learning INFOID:0000000004499934

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to l earn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal . It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume Learning INFOID:0000000004499935

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9V (At idle)

• Engine coolant temperature: 70 - 95 °C (158 - 203 °F)

• Park/neutral position (PNP) switch: ON

• Electric load switch: OFF

Page 2445 of 4331

![NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

EC-1089

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004499937

INTRODUCTION The engine has an ECM NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

EC-1089

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004499937

INTRODUCTION The engine has an ECM](/img/5/57398/w960_57398-2444.png)

TROUBLE DIAGNOSIS

EC-1089

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

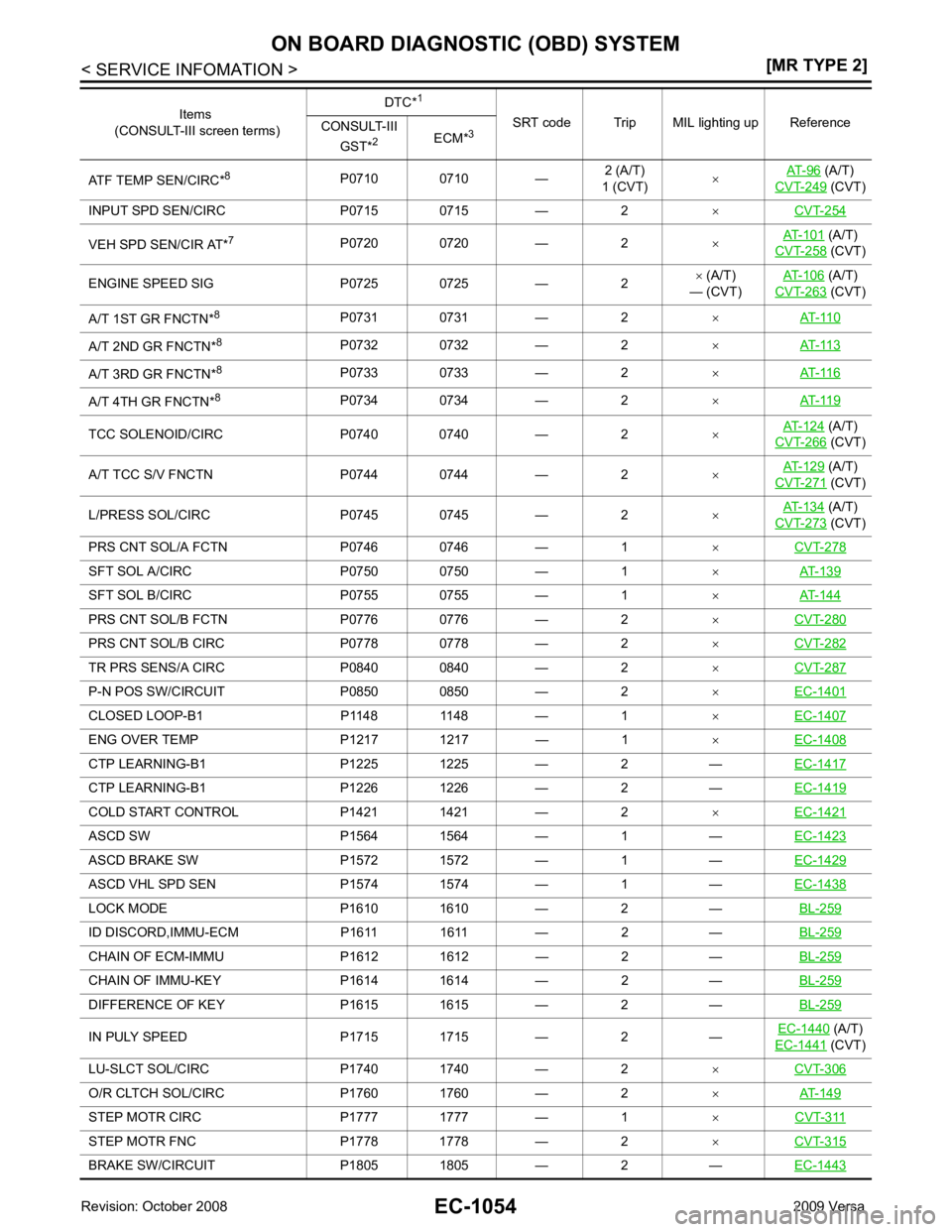

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004499937

INTRODUCTION The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find t he cause of the incidents. A road

test with CONSULT-III (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on "WORK FLOW".

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driv ability complaint. The customer

can supply good information about such incidents, especially inter-

mittent ones. Find out what symptoms are present and under what

conditions they occur. A Diagnosti c Worksheet like the example on

"Worksheet Sample" should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot drivability malfunctions on an electroni-

cally controlled engine vehicle.

WORK FLOW MEF036D

SEF233G

SEF234G