check engine NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2539 of 4331

EC

NP

O

2. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

OK or NG OK >> GO TO 9.

NG >> Replace mass air flow sensor. .

>> INSPECTION END

Component Inspection INFOID:0000000004501160

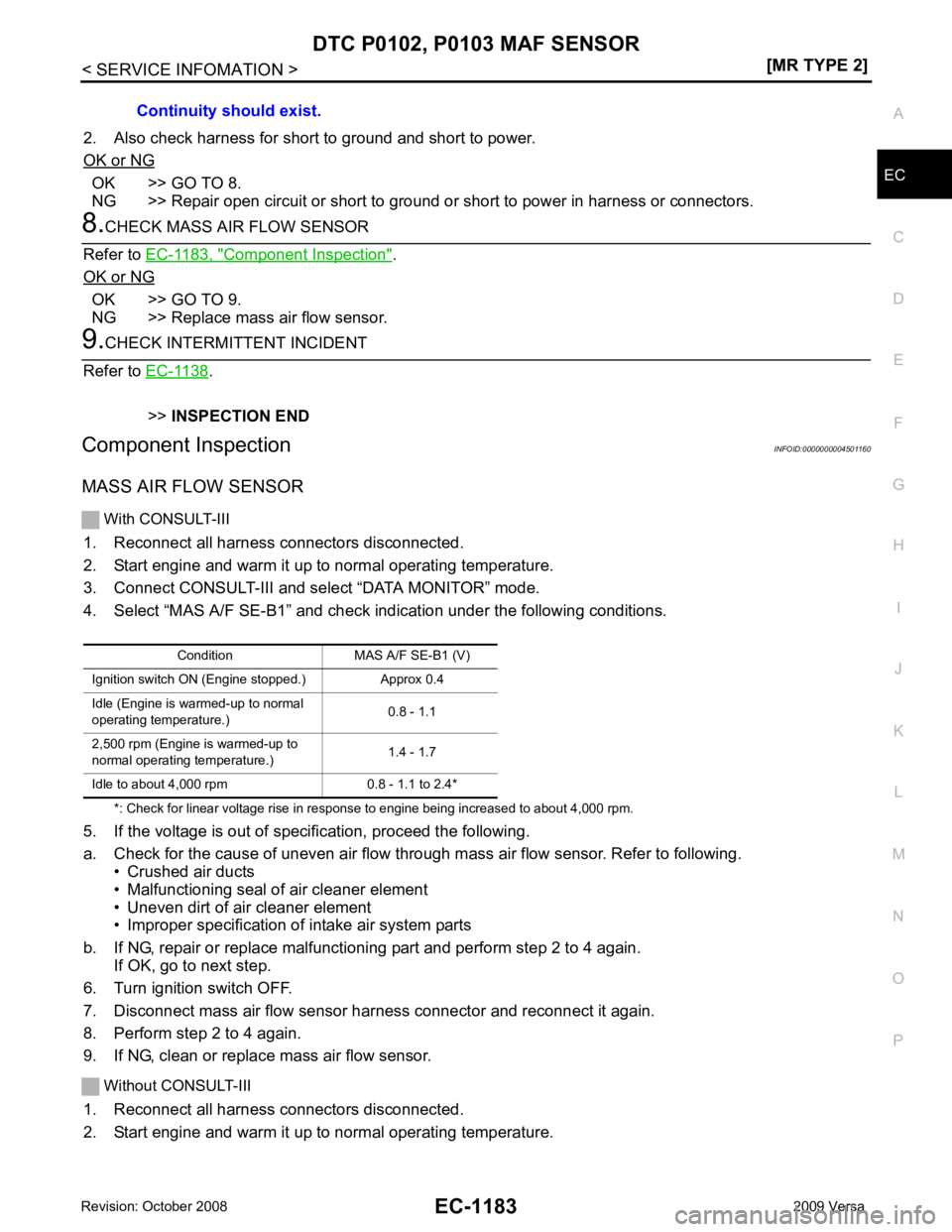

MASS AIR FLOW SENSOR With CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-III and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check i ndication under the following conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of spec ification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following. • Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again. If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor har ness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature. Continuity should exist.

Page 2540 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1184< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0102, P0103 MAF SENSOR

3. Check voltage between ECM terminal 45 (Mass air flow sensor signal) and ground.

*: Check for linear voltage rise in re NISSAN TIIDA 2009 Service Repair Manual EC-1184< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0102, P0103 MAF SENSOR

3. Check voltage between ECM terminal 45 (Mass air flow sensor signal) and ground.

*: Check for linear voltage rise in re](/img/5/57398/w960_57398-2539.png)

EC-1184< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0102, P0103 MAF SENSOR

3. Check voltage between ECM terminal 45 (Mass air flow sensor signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

4. If the voltage is out of spec ification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following. • Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunc tioning part and perform step 2 and 3 again.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and Installation INFOID:0000000004501161

MASS AIR FLOW SENSOR

Refer to EM-139, " Removal and Installation " .

Condition Voltage V

Ignition switch ON (Engine stopped.) Approx 0.4

Idle (Engine is warmed-up to normal

operating temperature.) 0.8 - 1.1

2,500 rpm (Engine is warmed-up to

normal operating temperature.) 1.4 - 1.7

Idle to about 4,000 rpm 0.8 - 1.1 to 2.4* PBIA9564J

Page 2543 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0112, P0113 IAT SENSOR

EC-1187

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK INTAKE AIR TEMPERATU NISSAN TIIDA 2009 Service Repair Manual DTC P0112, P0113 IAT SENSOR

EC-1187

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK INTAKE AIR TEMPERATU](/img/5/57398/w960_57398-2542.png)

DTC P0112, P0113 IAT SENSOR

EC-1187

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect mass air flow sensor (with intake air temperature sensor) (1) harness connector.

2. Turn ignition switch ON.

3. Check voltage between mass air flow sensor terminal 5 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. 3.

CHECK INTAKE AIR TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between mass air flow sensor terminal 6 and ECM terminal 55. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK INTAKE AIR TEMPERATURE SENSOR:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

BBIA0701E

Voltage: Approximately 5V

PBIB1169E

Continuity should exist.

Page 2545 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0116 ECT SENSOR

EC-1189

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0116 ECT SENSOR

Component Description INFOID:0000000004500022

The engine coolant temperature sensor NISSAN TIIDA 2009 Service Repair Manual DTC P0116 ECT SENSOR

EC-1189

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0116 ECT SENSOR

Component Description INFOID:0000000004500022

The engine coolant temperature sensor](/img/5/57398/w960_57398-2544.png)

DTC P0116 ECT SENSOR

EC-1189

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0116 ECT SENSOR

Component Description INFOID:0000000004500022

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

*: This data is reference value and is measured between ECM terminal 38 (Engine

coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals wh en measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground.

On Board Diagnosis Logic INFOID:0000000004477349

NOTE:

If DTC P0116 is displayed with P0117 or P0118, first perform the trouble diagnosis for DTC P0117,

P0118. Refer to EC-1193, " DTC Confirmation Procedure " .

DTC Confirmation Procedure INFOID:0000000004477350

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, do not add fuel.

1. Start engine and warm it up to normal operating temperature.

2. Rev engine up to 2,000 rpm for more than10 minutes.

3. Move the vehicle to a cool place, then stop engine and turn ignition switch OFF.

4. Check resistance between “fuel level s ensor unit and fuel pump” terminals 4 and 5.

5. Soak the vehicle until the resistance between “fuel level sensor unit and fuel pump” terminals 4 and 5

becomes 0.5 k Ω higher than the value measured before soaking.

CAUTION:

Never turn ignition switch ON during soaking time. SEF594K

Engine coolant temperature

°C ( °F) Voltage* V Resistance k

Ω

–10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260 SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0116

0116 Engine coolant tempera-

ture sensor circuit range/

performance Engine coolant temperature signal from engine

coolant temperature sensor does not fluctuate,

even when some time has passed after starting

the engine with pre-warming up condition. • Harness or connectors

(High or low resistance in the circuit)

• Engine coolant temperature sensor

Page 2546 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1190< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0116 ECT SENSOR

NOTE:

Soak time changes depending on ambient ai r temperature. It may take several hours.

6. Start engine and let it idle for 5 minutes.

NISSAN TIIDA 2009 Service Repair Manual EC-1190< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0116 ECT SENSOR

NOTE:

Soak time changes depending on ambient ai r temperature. It may take several hours.

6. Start engine and let it idle for 5 minutes.](/img/5/57398/w960_57398-2545.png)

EC-1190< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0116 ECT SENSOR

NOTE:

Soak time changes depending on ambient ai r temperature. It may take several hours.

6. Start engine and let it idle for 5 minutes.

7. Check 1st trip DTC.

8. If 1st trip DTC is detected, go to EC-1190, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:00000000044773511.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-1190, " Component Inspection " .

OK or NG OK >> GO TO 3.

NG >> Replace engine coolant temperature sensor. 3.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

Refer to EC-1194, " Wiring Diagram " .

>> INSPECTION END

Component Inspection INFOID:0000000004500027

ENGINE COOLANT TEMPERATURE SENSOR

1. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

PBIB2005E

Page 2549 of 4331

EC

NP

O

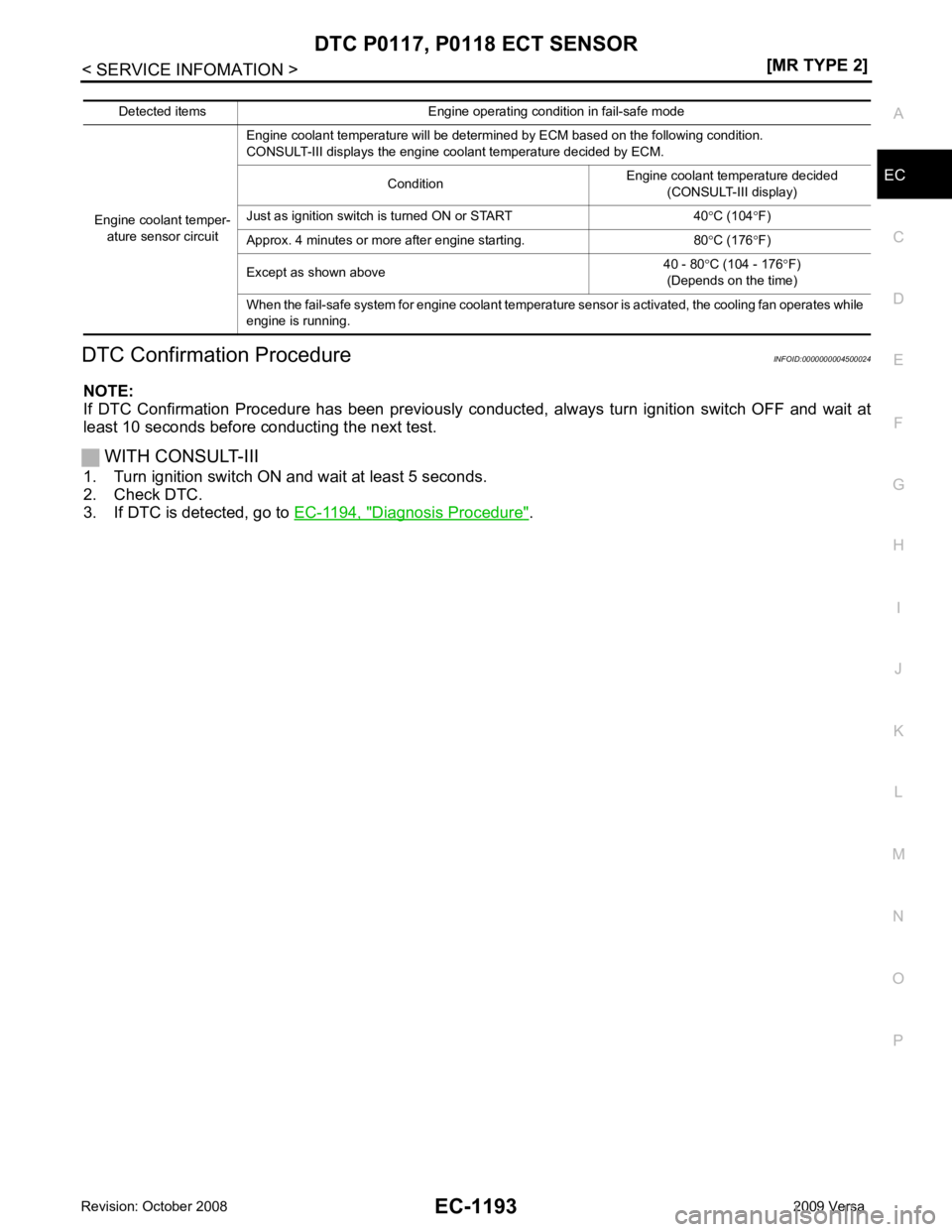

DTC Confirmation Procedure

INFOID:0000000004500024

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check DTC.

3. If DTC is detected, go to EC-1194, " Diagnosis Procedure " .

Detected items Engine operating condition in fail-safe mode

Engine coolant temper- ature sensor circuit Engine coolant temperature will be determined by ECM based on the following condition.

CONSULT-III displays the engine coolant temperature decided by ECM.

Condition Engine coolant temperature decided

(CONSULT-III display)

Just as ignition switch is turned ON or START 40 °C (104 °F)

Approx. 4 minutes or more after engine starting. 80 °C (176 °F)

Except as shown above 40 - 80

°C (104 - 176 °F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates while

engine is running.

Page 2551 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0117, P0118 ECT SENSOR

EC-1195

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK ECT SENSOR POWER SUP NISSAN TIIDA 2009 Service Repair Manual DTC P0117, P0118 ECT SENSOR

EC-1195

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK ECT SENSOR POWER SUP](/img/5/57398/w960_57398-2550.png)

DTC P0117, P0118 ECT SENSOR

EC-1195

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK ECT SENSOR POWER SUPPLY CIRCUIT

1. Disconnect engine coolant temperature (ECT) sensor (1) har- ness connector.

- : Vehicle front

2. Turn ignition switch ON.

3. Check voltage between ECT sensor terminal 1 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. 3.

CHECK ECT SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 44 and ECT sensor terminal 2. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK ENGINE COOLANT TEMPERATURE SENSOR:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

PBIB3324E

Voltage: Approximately 5V

PBIB0080E

Continuity should exist.

Page 2552 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1196< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0117, P0118 ECT SENSOR

Refer to EC-1190, " Component Inspection " .

OK or NG OK >> GO TO 5.

NG >> Replace engine coolant temperature sensor. 5.

CHECK IN NISSAN TIIDA 2009 Service Repair Manual EC-1196< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0117, P0118 ECT SENSOR

Refer to EC-1190, " Component Inspection " .

OK or NG OK >> GO TO 5.

NG >> Replace engine coolant temperature sensor. 5.

CHECK IN](/img/5/57398/w960_57398-2551.png)

EC-1196< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0117, P0118 ECT SENSOR

Refer to EC-1190, " Component Inspection " .

OK or NG OK >> GO TO 5.

NG >> Replace engine coolant temperature sensor. 5.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004501094

ENGINE COOLANT TEMPERATURE SENSOR

1. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

2. If NG, replace engine coolant temperature sensor.

Removal and Installation INFOID:0000000004501095

ENGINE COOLANT TEMPERATURE SENSOR

Refer to CO-47, " Component " . PBIB2005E

Temperature

°C ( °F) Resistance k Ω

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260 SEF012P

Page 2553 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0122, P

0123 TP SENSOR

EC-1197

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0122, P0123 TP SENSOR

Component Description INFOID:0000000004500029

Electric throttle cont NISSAN TIIDA 2009 Service Repair Manual DTC P0122, P

0123 TP SENSOR

EC-1197

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0122, P0123 TP SENSOR

Component Description INFOID:0000000004500029

Electric throttle cont](/img/5/57398/w960_57398-2552.png)

DTC P0122, P

0123 TP SENSOR

EC-1197

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0122, P0123 TP SENSOR

Component Description INFOID:0000000004500029

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500030

Specification data are reference values.

*: Throttle position sensor 2 signal is converted by ECM internally. Thus, it differs from ECM terminal voltage signal.

On Board Diagnosis Logic INFOID:0000000004500031

These self-diagnoses have the on e trip detection logic.

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-1396 .

FAIL-SAFE MODE When the malfunction is detected, ECM ent ers fail-safe mode and the MIL lights up.

DTC Confirmation Procedure INFOID:0000000004500032

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

1. Start engine and let it idle for 1 second.

2. Check DTC.

3. If DTC is detected, go to EC-1199, " Diagnosis Procedure " . PBIB0145E

MONITOR ITEM CONDITION SPECIFICATION

TP SEN 1-B1

TP SEN 2-B1* • Ignition switch: ON

(Engine stopped)

• Shift lever: D (A/T, CVT),

1st (M/T) Accelerator pedal: Fully released More than 0.36V

Accelerator pedal: Fully depressed Less than 4.75V DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0122

0122 Throttle position sensor

2 circuit low input An excessively low voltage from the TP sensor

2 is sent to ECM. • Harness or connectors

(TP sensor 2 circuit is open or shorted.)

• Electric throttle control actuator (TP sensor 2)

P0123

0123 Throttle position sensor

2 circuit high input An excessively high voltage from the TP sensor

2 is sent to ECM. Engine operation condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

Page 2555 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0122, P

0123 TP SENSOR

EC-1199

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045000341.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OF NISSAN TIIDA 2009 Service Repair Manual DTC P0122, P

0123 TP SENSOR

EC-1199

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045000341.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OF](/img/5/57398/w960_57398-2554.png)

DTC P0122, P

0123 TP SENSOR

EC-1199

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045000341.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK THROTTLE POSITION SEN SOR 2 POWER SUPPLY CIRCUIT

TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 LG Throttle position sensor 1 [Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully released More than 0.36V

[Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully depressed Less than 4.75V

34 O Throttle position sensor 2 [Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully released Less than 4.75V

[Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully depressed More than 0.36V

36 Y Sensor ground

(Throttle position sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

72 V Sensor power supply

(Throttle position sensor) [Ignition switch: ON]

Approximately 5V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground E16

4. Body ground E15 BBIA0698E