Electric motor NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 841 of 4331

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

SERVICE INFORMATION .. ..........................

2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Brake System .............................. ......2

Precaution for Brake Cont rol .....................................3

Precaution for CAN System ................................ ......3

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool .................................... ......4

SYSTEM DESCRIPTION ................................ .....5

System Component ............................................. ......5

ABS Function ...................................................... ......5

EBD Function ...................................................... ......5

Fail-Safe Function ............................................... ......5

Hydraulic Circuit Diagram .........................................6

CAN COMMUNICATION ................................ .....7

System Description ............................................. ......7

TROUBLE DIAGNOSIS ................................. .....8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........... .............................................

8

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

11

Schematic ........................................................... ....12

Wiring Diagram - ABS - ... ........................................13 Basic Inspection ..................................................

....16

Warning Lamp and Indicator Timing .................... ....17

Control Unit Input/Output Signal Standard .......... ....17

CONSULT-III Function ( ABS) ..................................18

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ................................................. 24

Wheel Sensor System ......................................... ....24

ABS Control Unit Inspection ................................ ....25

Solenoid Valve System Inspection ...................... ....25

Actuator Motor, Motor Re lay, and Circuit Inspec-

tion ....................................................................... ....

26

ABS Control Unit Power and Ground Systems In-

spection ............................................................... ....

27

CAN Communication System Inspection ............. ....28

TROUBLE DIAGNOSES FOR SYMPTOMS ..... 29

ABS Works Frequently ........................................ ....29

Unexpected Pedal Action .................................... ....29

Long Stopping Distance ...................................... ....30

ABS Does Not Work ............................................ ....30

Pedal Vibration or ABS Op eration Noise .................30

WHEEL SENSORS ........................................... 32

Removal and Installation ..................................... ....32

SENSOR ROTOR .............................................. 34

Removal and Installation ..................................... ....34

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) .................................................................. 35

Removal and Installation ..................................... ....35

Page 843 of 4331

BRC

N

O P

Precaution for Brake Control

INFOID:0000000004307252

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check brake booster operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near t he control module, ABS function may have a malfunction

or error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

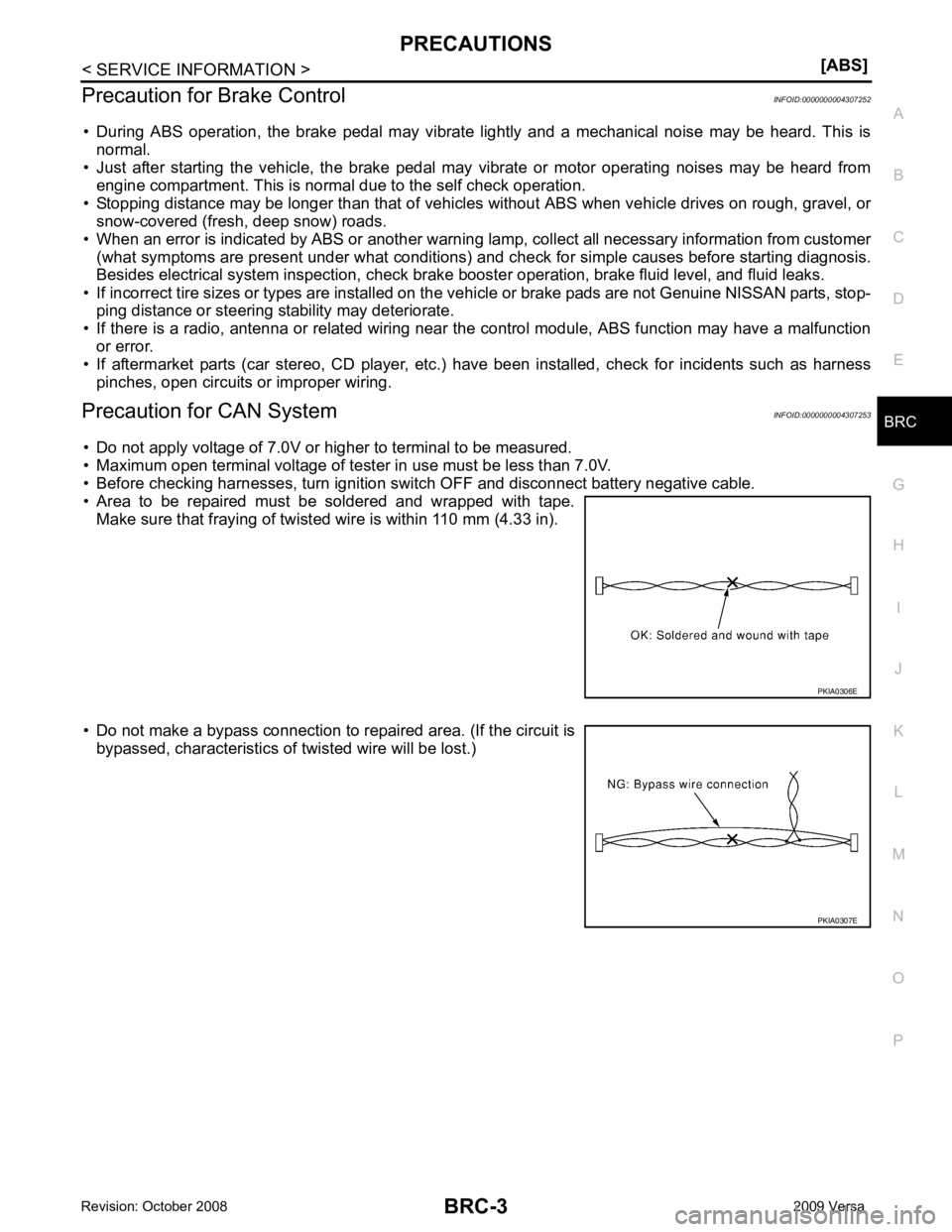

Precaution for CAN System INFOID:0000000004307253

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of tester in use must be less than 7.0V.

• Before checking harnesses, turn ignition switch OFF and disconnect battery negative cable.

• Area to be repaired must be soldered and wrapped with tape. Make sure that fraying of twisted wire is within 110 mm (4.33 in).

• Do not make a bypass connection to repaired area. (If the circuit is bypassed, characteristics of twisted wire will be lost.)

Page 845 of 4331

BRC

N

O P

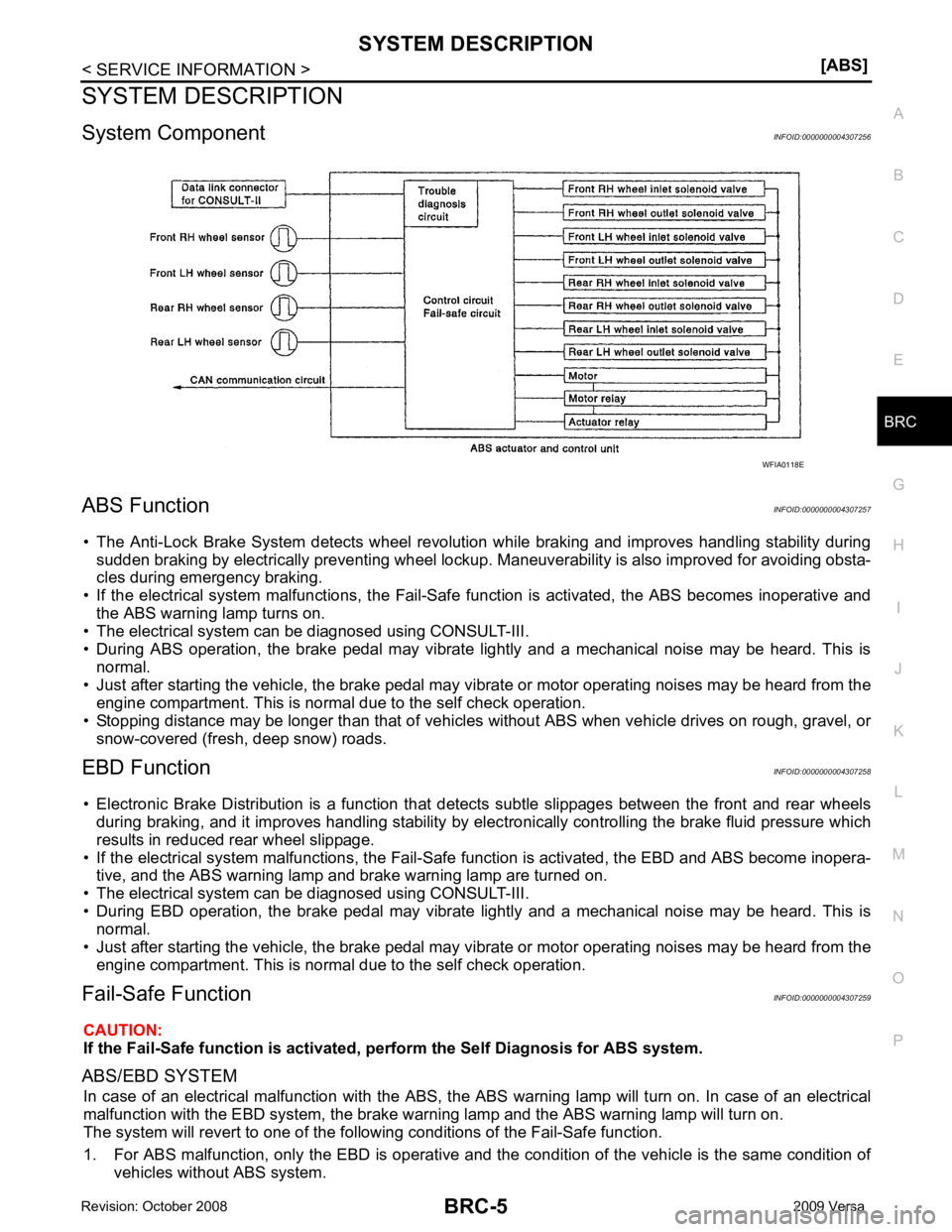

SYSTEM DESCRIPTION

System Component INFOID:0000000004307256

ABS Function INFOID:0000000004307257

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles during emergency braking.

• If the electrical system malfunctions, the Fail-Safe function is activated, the ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD Function INFOID:0000000004307258

• Electronic Brake Distribution is a function that detec ts subtle slippages between the front and rear wheels

during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera-

tive, and the ABS warning lamp and brake warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

Fail-Safe Function INFOID:0000000004307259

CAUTION:

If the Fail-Safe function is activated, perform the Self Diagnosis for ABS system.

ABS/EBD SYSTEM In case of an electrical malfunction with the ABS, the ABS warning lamp wi ll turn on. In case of an electrical

malfunction with the EBD system, the brake warni ng lamp and the ABS warning lamp will turn on.

The system will revert to one of the follo wing conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and t he condition of the vehicle is the same condition of

vehicles without ABS system.

Page 858 of 4331

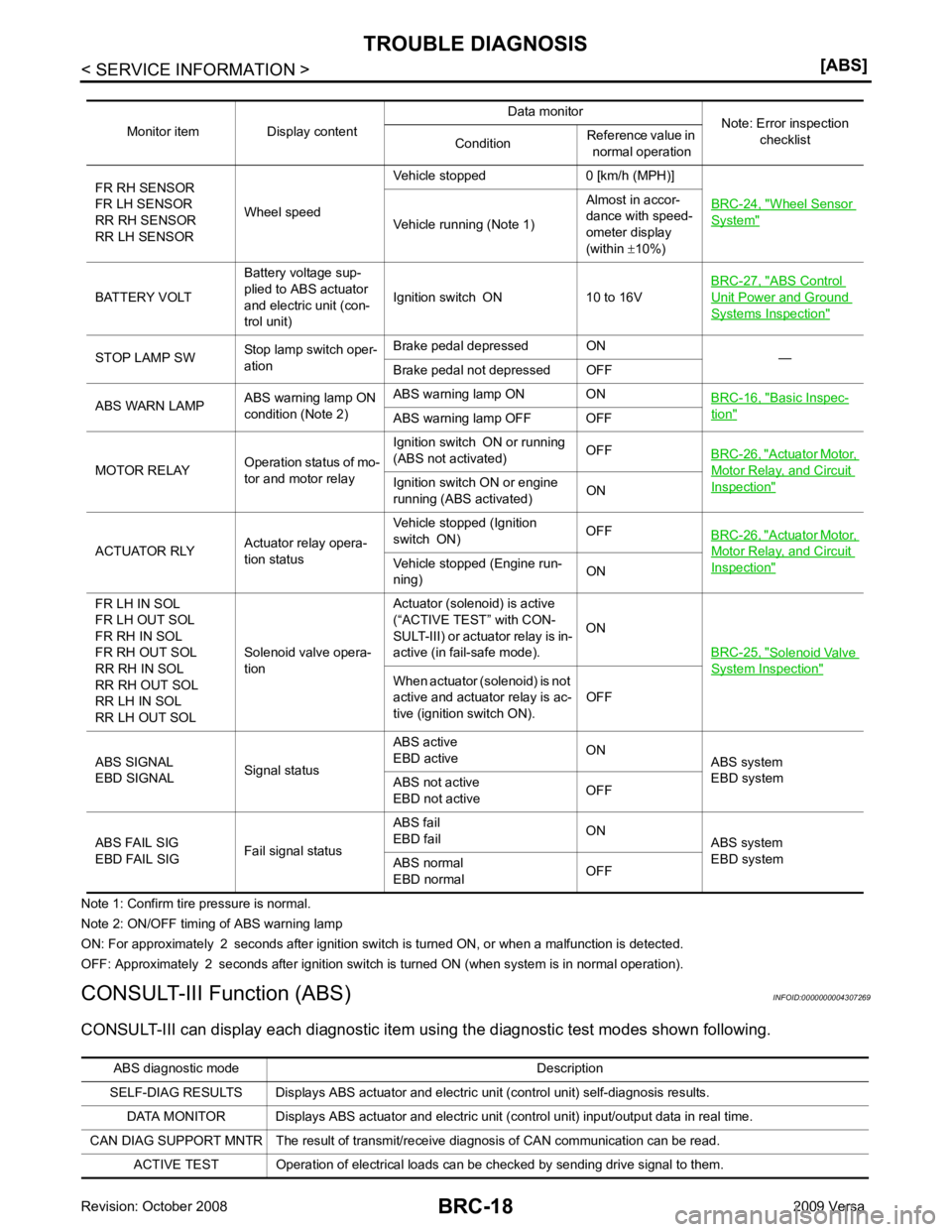

Wheel Sensor

System "

Vehicle running (Note 1)

Almost in accor-

dance with speed-

ometer display

(within ±10%)

BATTERY VOLT Battery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit) Ignition switch ON 10 to 16V

BRC-27, " ABS Control

Unit Power and Ground

Systems Inspection "

STOP LAMP SW

Stop lamp switch oper-

ation Brake pedal depressed ON

—

Brake pedal not depressed OFF

ABS WARN LAMP ABS warning lamp ON

condition (Note 2) ABS warning lamp ON ON

BRC-16, " Basic Inspec-

tion "

ABS warning lamp OFF OFF

MOTOR RELAY Operation status of mo-

tor and motor relay Ignition switch ON or running

(ABS not activated) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Ignition switch ON or engine

running (ABS activated) ON

ACTUATOR RLY Actuator relay opera-

tion status Vehicle stopped (Ignition

switch ON) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Vehicle stopped (Engine run-

ning) ON

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL Solenoid valve opera-

tion Actuator (solenoid) is active

(“ACTIVE TEST” with CON-

SULT-III) or actuator relay is in-

active (in fail-safe mode). ON

BRC-25, " Solenoid Valve

System Inspection "

When actuator (solenoid) is not

active and actuator relay is ac-

tive (ignition switch ON). OFF

ABS SIGNAL

EBD SIGNAL Signal statusABS active

EBD active ON

ABS system

EBD system

ABS not active

EBD not active OFF

ABS FAIL SIG

EBD FAIL SIG Fail signal statusABS fail

EBD fail ON

ABS system

EBD system

ABS normal

EBD normal OFFABS diagnostic mo

de Description

SELF-DIAG RESULTS Displays ABS actuator and electric unit (control unit) self-diagnosis results.

DATA MONITOR Displays ABS actuator and electric unit (control unit) input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 860 of 4331

![NISSAN TIIDA 2009 Service Repair Manual Wheel Sensor

System " (Note 1)

RR LH SENSOR-1

[C1102] Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of fron NISSAN TIIDA 2009 Service Repair Manual Wheel Sensor

System " (Note 1)

RR LH SENSOR-1

[C1102] Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of fron](/img/5/57398/w960_57398-859.png)

Wheel Sensor

System " (Note 1)

RR LH SENSOR-1

[C1102] Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of front LH wheel sensor is open.

RR RH SENSOR-2

[C1105] When the circuit in the rear RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2

[C1106] When the circuit in the rear LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2

[C1107] When the circuit in the front RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2

[C1108] When the circuit in the front LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

ABS SENSOR

[ABNORMAL SIGNAL]

[C1115] Wheel sensor input is abnormal.

BATTERY VOLTAGE

[ABNORMAL]

[C1109] ABS actuator and electric unit (control unit) power voltage is too

low. BRC-27, " ABS Control

Unit Power and Ground

Systems Inspection "

CONTROLLER FAILURE

[C1110] Internal malfunction of ABS actuator

and electric unit (control unit)BRC-25, " ABS Control

Unit Inspection "

PUMP MOTOR

[C1111] During actuator motor operation with ON, when actuator motor

turns OFF or when control line for actuator motor relay is open. BRC-26, " Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection "During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

FR LH IN ABS SOL

[C1120] Circuit of front LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-25, " Solenoid Valve

System Inspection "FR LH OUT ABS SOL

[C1121] Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122] Circuit of front RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123] Circuit of front RH OUT ABS solenoid is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124] Circuit of rear LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126] Circuit of rear RH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127] Circuit of rear RH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

Page 861 of 4331

BRC

N

O P

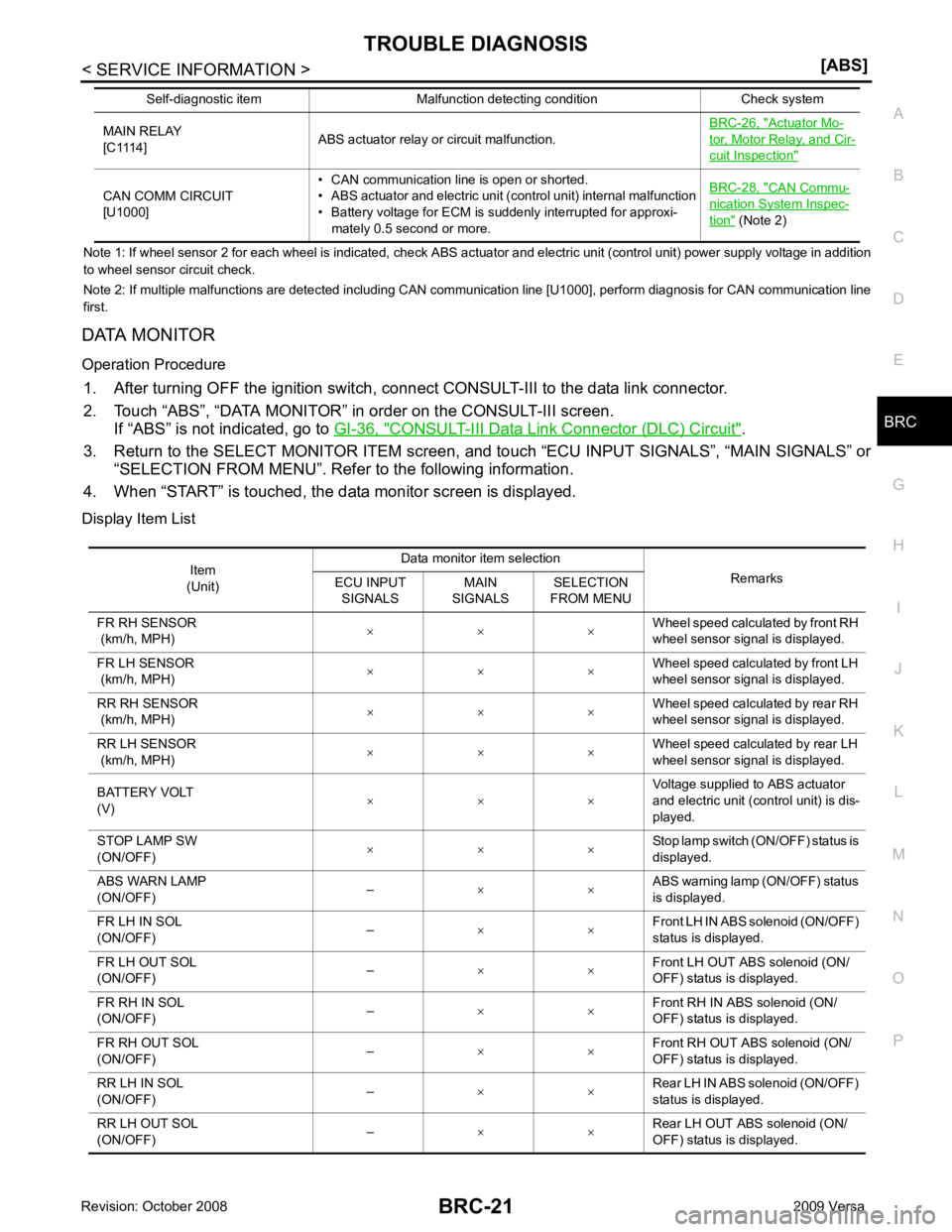

Note 1: If wheel sens

or 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power supply voltage in addition

to wheel sensor circuit check.

Note 2: If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for CAN communication line

first.

DATA MONITOR

Operation Procedure 1. After turning OFF the ignition switch, c onnect CONSULT-III to the data link connector.

2. Touch “ABS”, “DATA MONITOR” in order on the CONSULT-III screen. If “ABS” is not indicated, go to GI-36, " CONSULT-III Data Link Connector (DLC) Circuit " .

3. Return to the SELECT MONITOR ITEM screen, and touch “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”. Refer to the following information.

4. When “START” is touched, the data monitor screen is displayed.

Display Item List MAIN RELAY

[C1114] ABS actuator relay or circuit malfunction. BRC-26, " Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection "

CAN COMM CIRCUIT

[U1000] • CAN communication line is open or shorted.

• ABS actuator and electric unit (control unit) internal malfunction

• Battery voltage for ECM is suddenly interrupted for approxi-

mately 0.5 second or more. BRC-28, " CAN Commu-

nication System Inspec-

tion " (Note 2)

Self-diagnostic item Malfunction detecting condition Check system Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR RH SENSOR

(km/h, MPH) × × × Wheel speed calculated by front RH

wheel sensor signal is displayed.

FR LH SENSOR

(km/h, MPH) × × ×

Wheel speed calculated by front LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, MPH) × × × Wheel speed calculated by rear RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, MPH) × × × Wheel speed calculated by rear LH

wheel sensor signal is displayed.

BATTERY VOLT

(V) × × × Voltage supplied to ABS actuator

and electric unit (control unit) is dis-

played.

STOP LAMP SW

(ON/OFF) × × × Stop lamp switch (ON/OFF) status is

displayed.

ABS WARN LAMP

(ON/OFF) –

× × ABS warning lamp (ON/OFF) status

is displayed.

FR LH IN SOL

(ON/OFF) –

× × Front LH IN ABS solenoid (ON/OFF)

status is displayed.

FR LH OUT SOL

(ON/OFF) –

× × Front LH OUT ABS solenoid (ON/

OFF) status is displayed.

FR RH IN SOL

(ON/OFF) –

× × Front RH IN ABS solenoid (ON/

OFF) status is displayed.

FR RH OUT SOL

(ON/OFF) –

× × Front RH OUT ABS solenoid (ON/

OFF) status is displayed.

RR LH IN SOL

(ON/OFF) –

× × Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF) –

× × Rear LH OUT ABS solenoid (ON/

OFF) status is displayed.

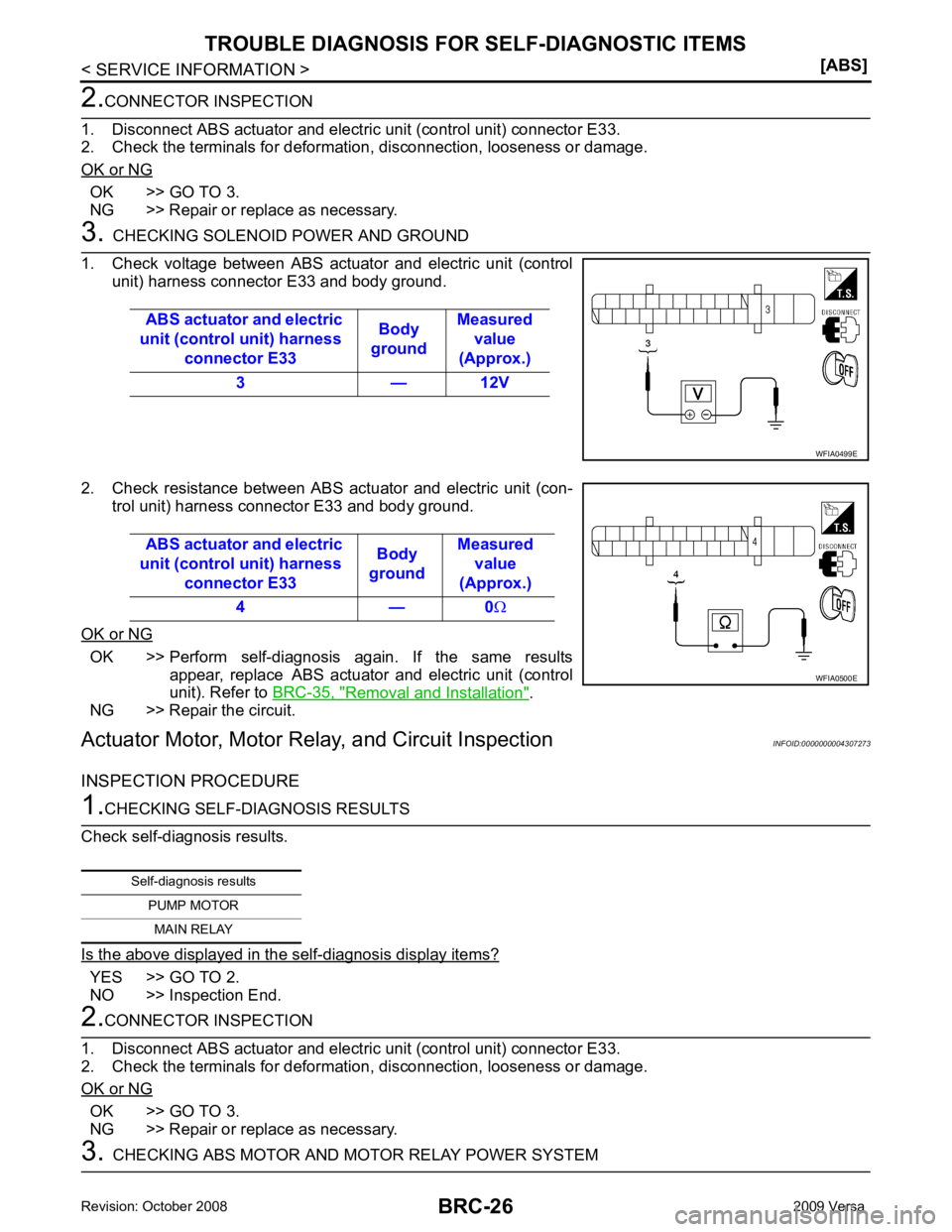

Page 866 of 4331

OK >> GO TO 3.

NG >> Repair or replace as necessary. OK >> Perform self-diagnosis again. If the same results

appear, replace ABS actuator and electric unit (control

unit). Refer to BRC-35, " Removal and Installation " .

NG >> Repair the circuit.

Actuator Motor, Motor Rela y, and Circuit Inspection INFOID:0000000004307273

INSPECTION PROCEDURE YES >> GO TO 2.

NO >> Inspection End. OK >> GO TO 3.

NG >> Repair or replace as necessary.

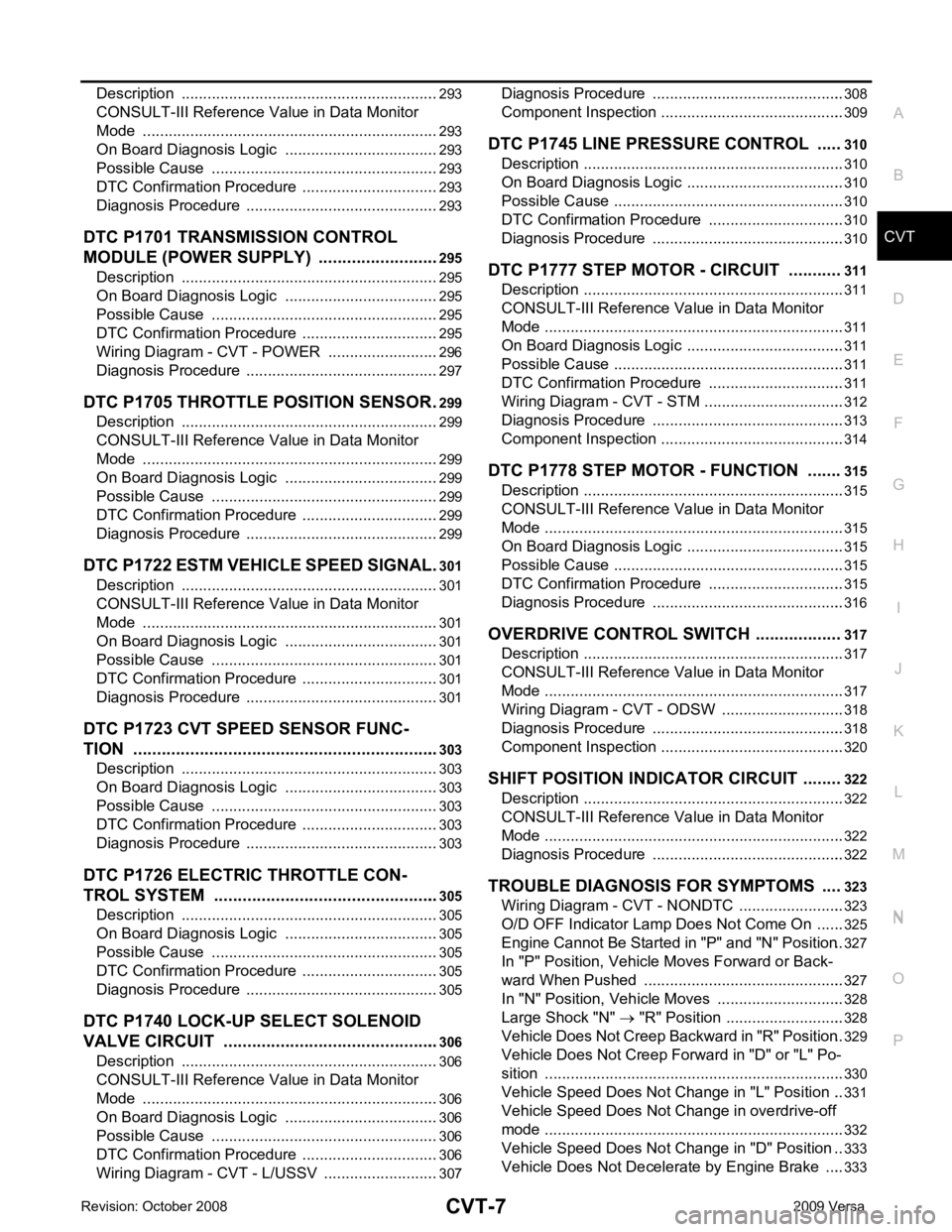

Page 951 of 4331

CVT

N

O

P

N

Description ..........................................................

..

293

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

293

On Board Diagnosis Logic .................................. ..293

Possible Cause ................................................... ..293

DTC Confirmation Procedure .............................. ..293

Diagnosis Procedure ........................................... ..293

DTC P1701 TRANSMISSION CONTROL

MODULE (POWER SUPPLY) ........................ ..295

Description .......................................................... ..295

On Board Diagnosis Logic .................................. ..295

Possible Cause ................................................... ..295

DTC Confirmation Procedure .............................. ..295

Wiring Diagram - CVT - POWER ........................ ..296

Diagnosis Procedure ........................................... ..297

DTC P1705 THROTTLE POSITION SENSOR ..299

Description .......................................................... ..299

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

299

On Board Diagnosis Logic .................................. ..299

Possible Cause ................................................... ..299

DTC Confirmation Procedure .............................. ..299

Diagnosis Procedure ........................................... ..299

DTC P1722 ESTM VEHICLE SPEED SIGNAL ..301

Description .......................................................... ..301

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

301

On Board Diagnosis Logic .................................. ..301

Possible Cause ................................................... ..301

DTC Confirmation Procedure .............................. ..301

Diagnosis Procedure ........................................... ..301

DTC P1723 CVT SPEED SENSOR FUNC-

TION ............................................................... ..303

Description .......................................................... ..303

On Board Diagnosis Logic .................................. ..303

Possible Cause ................................................... ..303

DTC Confirmation Procedure .............................. ..303

Diagnosis Procedure ........................................... ..303

DTC P1726 ELECTRIC THROTTLE CON-

TROL SYSTEM .............................................. ..

305

Description .......................................................... ..305

On Board Diagnosis Logic .................................. ..305

Possible Cause ................................................... ..305

DTC Confirmation Procedure .............................. ..305

Diagnosis Procedure ........................................... ..305

DTC P1740 LOCK-UP SELECT SOLENOID

VALVE CIRCUIT ............................................ ..

306

Description .......................................................... ..306

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

306

On Board Diagnosis Logic .................................. ..306

Possible Cause ................................................... ..306

DTC Confirmation Procedure .............................. ..306

Wiring Diagram - CVT - L/USSV ......................... ..307 Diagnosis Procedure ...........................................

..308

Component Inspection ......................................... ..309

DTC P1745 LINE PRESSURE CONTROL ..... 310

Description ........................................................... ..310

On Board Diagnosis Logic ................................... ..310

Possible Cause .................................................... ..310

DTC Confirmation Procedure .............................. ..310

Diagnosis Procedure ........................................... ..310

DTC P1777 STEP MOTOR - CIRCUIT ........... 311

Description ........................................................... ..311

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

311

On Board Diagnosis Logic ................................... ..311

Possible Cause .................................................... ..311

DTC Confirmation Procedure .............................. ..311

Wiring Diagram - CVT - STM ............................... ..312

Diagnosis Procedure ........................................... ..313

Component Inspection ......................................... ..314

DTC P1778 STEP MOTOR - FUNCTION ....... 315

Description ........................................................... ..315

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

315

On Board Diagnosis Logic ................................... ..315

Possible Cause .................................................... ..315

DTC Confirmation Procedure .............................. ..315

Diagnosis Procedure ........................................... ..316

OVERDRIVE CONTROL SWITCH .................. 317

Description ........................................................... ..317

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

317

Wiring Diagram - CVT - ODSW ........................... ..318

Diagnosis Procedure ........................................... ..318

Component Inspection ......................................... ..320

SHIFT POSITION INDICATOR CIRCUIT ........ 322

Description ........................................................... ..322

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

322

Diagnosis Procedure ........................................... ..322

TROUBLE DIAGNOSIS FOR SYMPTOMS .... 323

Wiring Diagram - CVT - NONDTC ....................... ..323

O/D OFF Indicator Lamp Does Not Come On ..... ..325

Engine Cannot Be Started in "P" and "N" Position ..327

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ............................................. ..

327

In "N" Position, Vehicle Moves ............................ ..328

Large Shock "N" → "R" Position .......................... ..328

Vehicle Does Not Creep Backward in "R" Position ..329

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition .................................................................... ..

330

Vehicle Speed Does Not Change in "L" Position . ..331

Vehicle Speed Does Not Change in overdrive-off

mode .................................................................... ..

332

Vehicle Speed Does Not Change in "D" Position .. 333

Vehicle Does Not Decelerate by Engine Brake ... ..333

Page 977 of 4331

CVT

N

O P

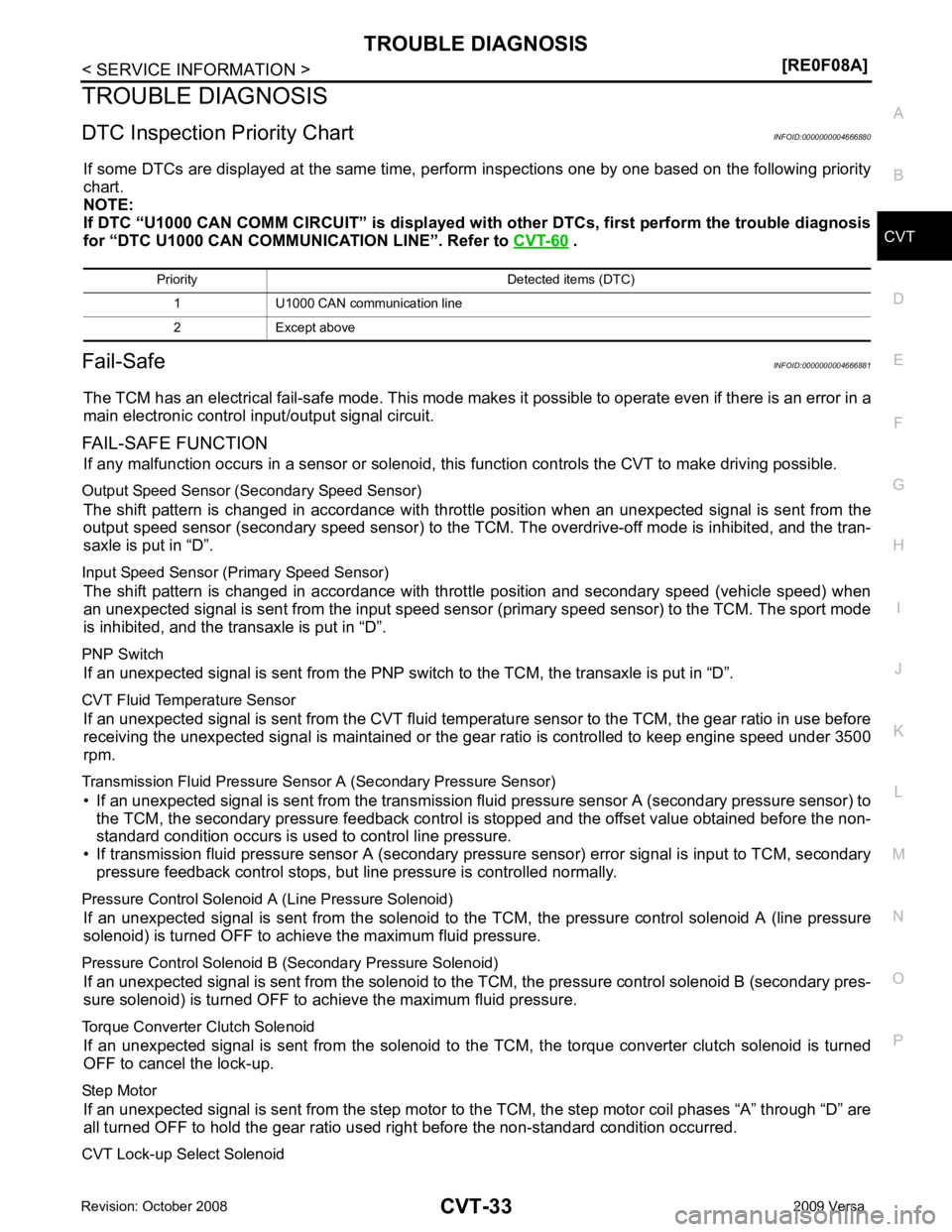

TROUBLE DIAGNOSIS

DTC Inspection Priority Chart INFOID:0000000004666880

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-60 .

Fail-Safe INFOID:0000000004666881

The TCM has an electrical fail-safe mode. This mode make s it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION If any malfunction occurs in a sensor or solenoid, th is function controls the CVT to make driving possible.

Output Speed Sensor (Secondary Speed Sensor) The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

output speed sensor (secondary speed sensor) to the TCM. The overdrive-off mode is inhibited, and the tran-

saxle is put in “D”.

Input Speed Sensor (Primary Speed Sensor) The shift pattern is changed in accordance with throttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the input speed sensor (primary speed sensor) to the TCM. The sport mode

is inhibited, and the transaxle is put in “D”.

PNP Switch If an unexpected signal is sent from the PNP switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor If an unexpected signal is sent from the CVT fluid temper ature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or the gear ratio is controlled to keep engine speed under 3500

rpm.

Transmission Fluid Pressure Sens or A (Secondary Pressure Sensor)

• If an unexpected signal is sent from the transmission fl uid pressure sensor A (secondary pressure sensor) to

the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-

standard condition occurs is used to control line pressure.

• If transmission fluid pressure sensor A (secondary pre ssure sensor) error signal is input to TCM, secondary

pressure feedback control stops, but line pressure is controlled normally.

Pressure Control Solenoid A (Line Pressure Solenoid) If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid A (line pressure

solenoid) is turned OFF to achieve the maximum fluid pressure.

Pressure Control Solenoid B (Secondary Pressure Solenoid) If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid B (secondary pres-

sure solenoid) is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid If an unexpected signal is sent from the solenoid to t he TCM, the torque converter clutch solenoid is turned

OFF to cancel the lock-up.

Step Motor If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used right before the non-standard condition occurred.

CVT Lock-up Select Solenoid Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 1073 of 4331

CVT

N

O P

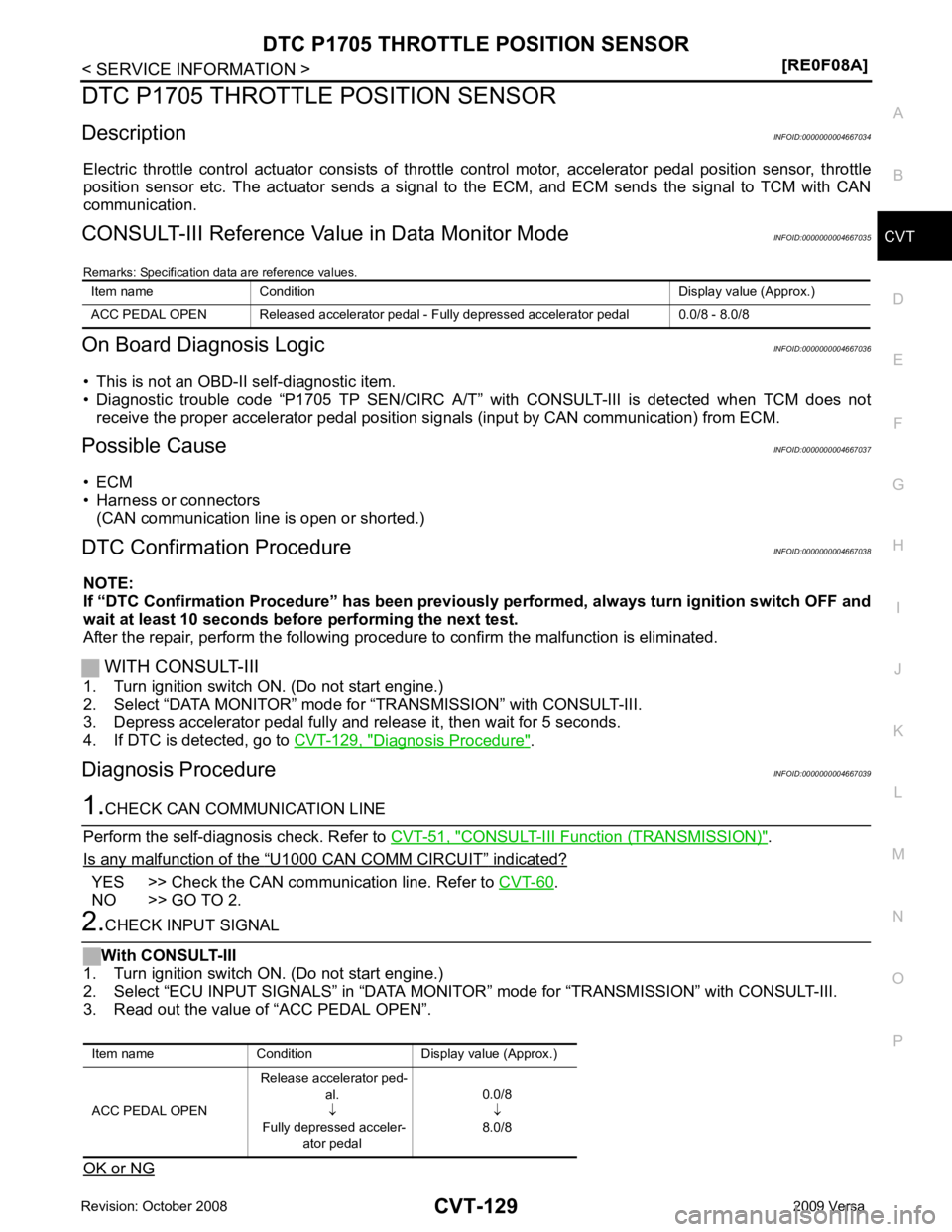

DTC P1705 THROTTLE POSITION SENSOR

Description INFOID:0000000004667034

Electric throttle control actuator consists of throttle control motor, accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the signal to TCM with CAN

communication.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004667035

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004667036

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1705 TP SEN/CIRC A/T” with CONSULT-III is detected when TCM does not

receive the proper accelerator pedal position si gnals (input by CAN communication) from ECM.

Possible Cause INFOID:0000000004667037

• ECM

• Harness or connectors

(CAN communication line is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004667038

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Depress accelerator pedal fully and release it, then wait for 5 seconds.

4. If DTC is detected, go to CVT-129, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004667039CONSULT-III Functi

on (TRANSMISSION) " .

Is any malfunction of the “ U1000 CAN COMM CIRCUIT ” indicated?

YES >> Check the CAN communication line. Refer to

CVT-60 .

NO >> GO TO 2. Item name Condition Display value (Approx.)

ACC PEDAL OPEN Release accelerator ped-

al.↓

Fully depressed acceler- ator pedal 0.0/8

↓

8.0/8