length NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 229 of 4331

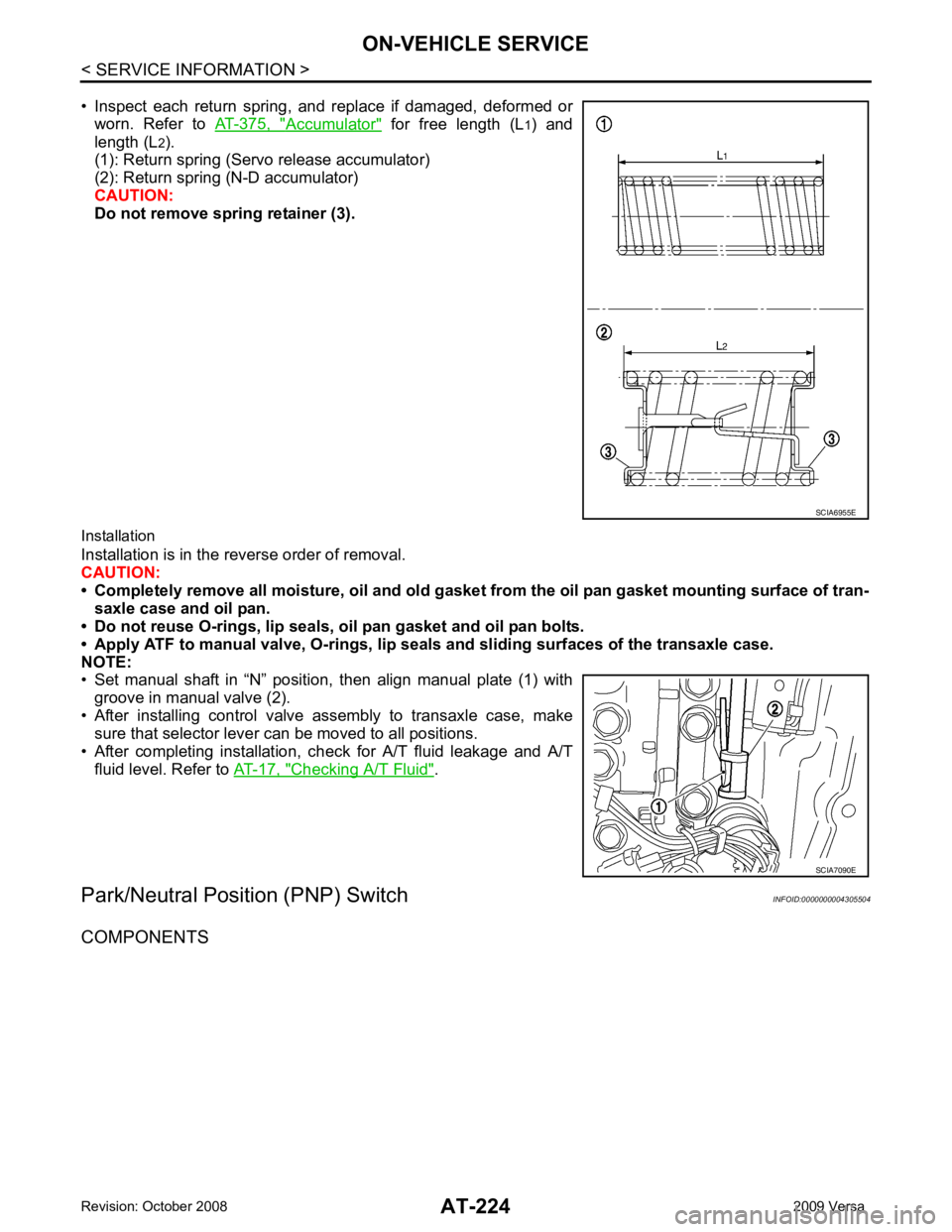

Accumulator " for free length (L

1) and

length (L 2

).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Completely remove all moisture, oil and old gasket from the oil pan gasket mounting surface of tran-

saxle case and oil pan.

• Do not reuse O-rings, lip seals, oil pan gasket and oil pan bolts.

• Apply ATF to manual valve, O-rings, li p seals and sliding surfaces of the transaxle case.

NOTE:

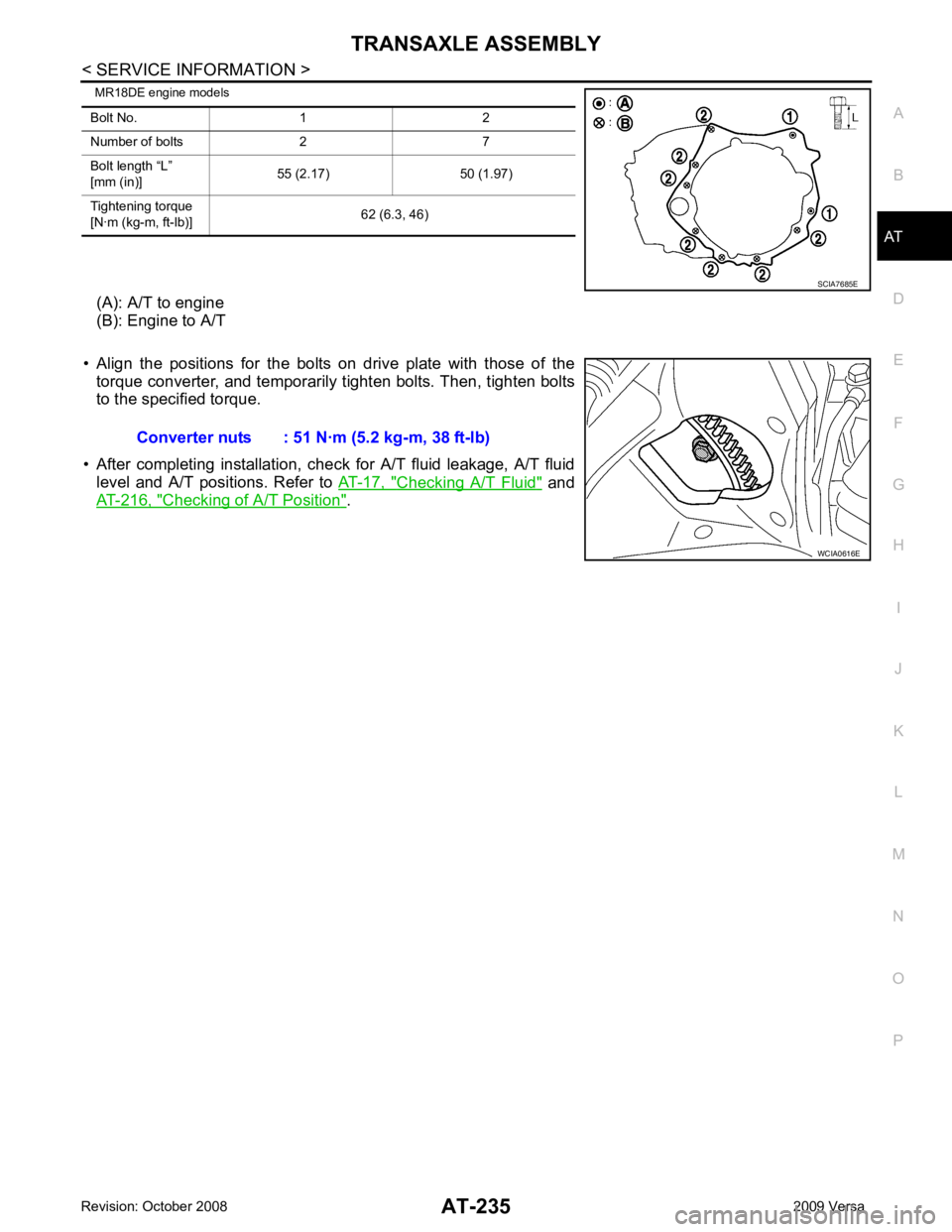

• Set manual shaft in “N” position, then align manual plate (1) with

groove in manual valve (2).

• After installing control valve assembly to transaxle case, make sure that selector lever can be moved to all positions.

• After completing installation, check for A/T fluid leakage and A/T fluid level. Refer to AT-17, " Checking A/T Fluid " .

Park/Neutral Position (PNP) Switch INFOID:0000000004305504

COMPONENTS

Page 240 of 4331

AT

N

O P

MR18DE engine models

(A): A/T to engine

(B): Engine to A/T

• Align the positions for the bolts on drive plate with those of the torque converter, and temporarily tighten bolts. Then, tighten bolts

to the specified torque.

• After completing installation, chec k for A/T fluid leakage, A/T fluid

level and A/T positions. Refer to AT-17, " Checking A/T Fluid " and

AT-216, " Checking of A/T Position " .

Bolt No. 1 2

Number of bolts 2 7

Bolt length “L”

[mm (in)] 55 (2.17) 50 (1.97)

Tightening torque

[N·m (kg-m, ft-lb)] 62 (6.3, 46)

Page 263 of 4331

.

14. Remove magnets from oil pan.

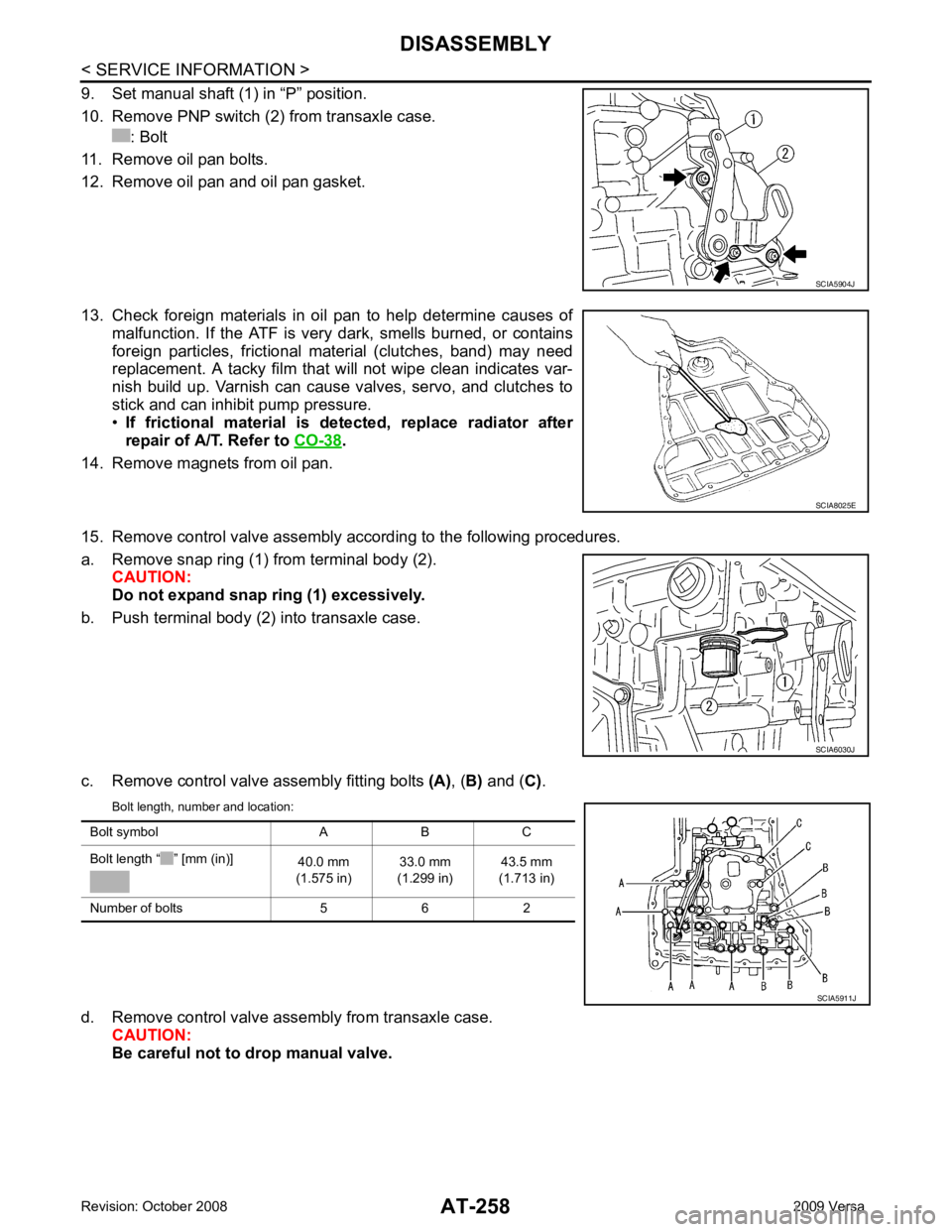

15. Remove control valve assembly according to the following procedures.

a. Remove snap ring (1) from terminal body (2). CAUTION:

Do not expand snap ring (1) excessively.

b. Push terminal body (2) into transaxle case.

c. Remove control valve assembly fitting bolts (A), (B) and ( C).

Bolt length, number and location:

d. Remove control valve assembly from transaxle case. CAUTION:

Be careful not to drop manual valve. SCIA8025E

SCIA6030J

Page 265 of 4331

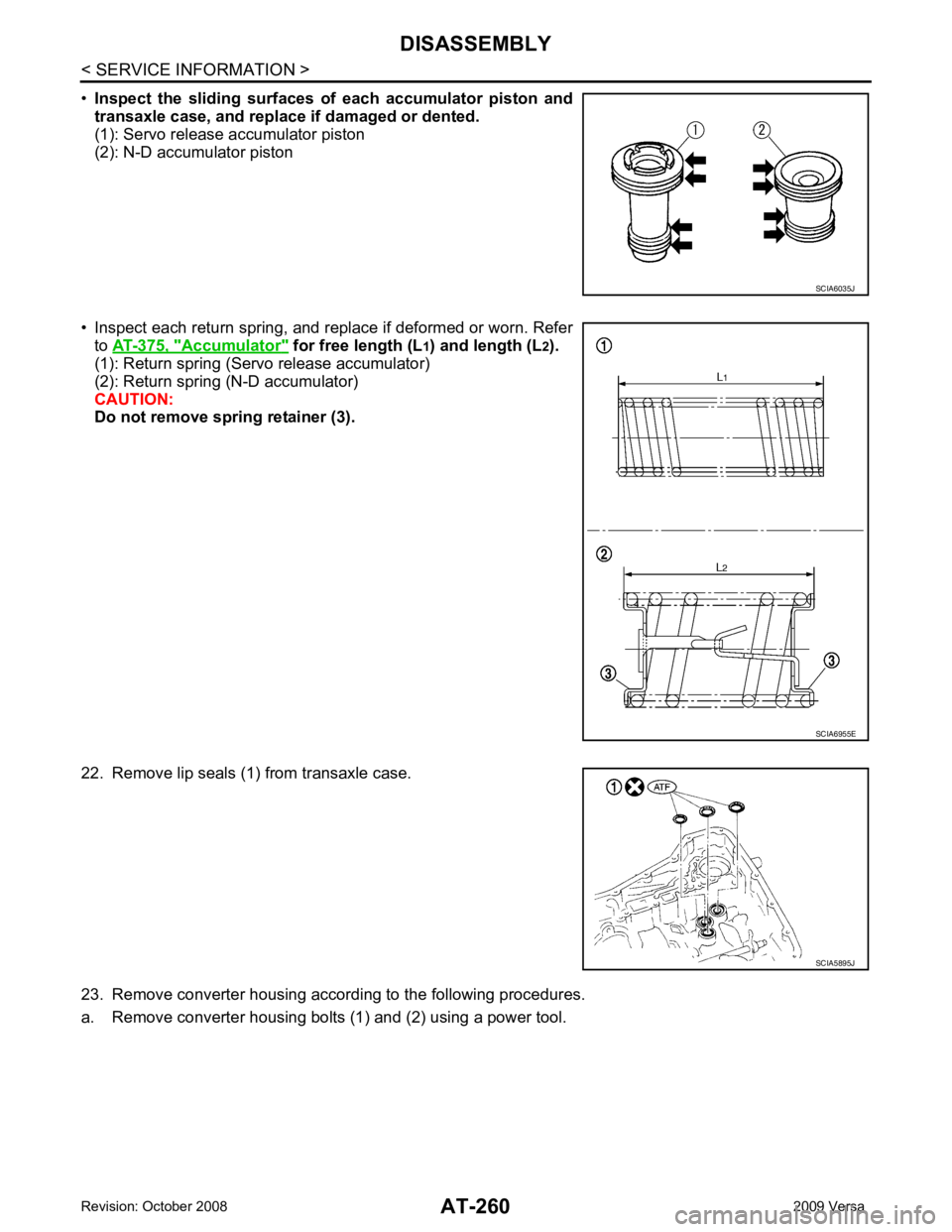

Accumulator " for free length (L

1) and length (L 2).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

22. Remove lip seals (1) from transaxle case.

23. Remove converter housing according to the following procedures.

a. Remove converter housing bolts (1) and (2) using a power tool. SCIA6955E

SCIA5895J

Page 290 of 4331

AT

N

O P

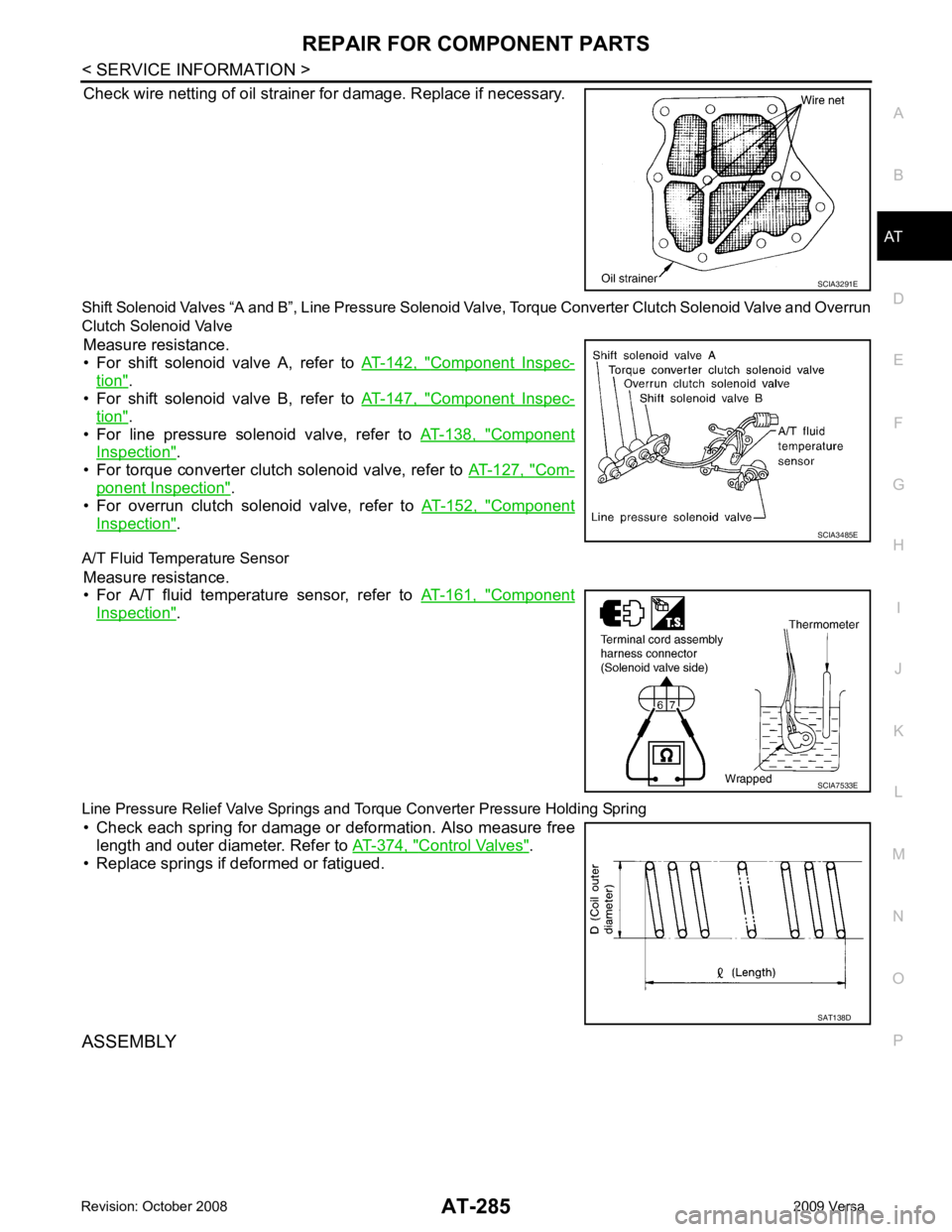

Check wire netting of oil strainer for damage. Replace if necessary.

Shift Solenoid Valves “A and B”, Line Pressure Solenoid Valve, Torque Conv erter Clutch Solenoid Valve and Overrun

Clutch Solenoid Valve

Measure resistance.

• For shift solenoid valve A, refer to AT-142, " Component Inspec-

tion " .

• For shift solenoid valve B, refer to AT-147, " Component Inspec-

tion " .

• For line pressure solenoid valve, refer to AT-138, " Component

Inspection " .

• For torque converter clutch solenoid valve, refer to AT-127, " Com-

ponent Inspection " .

• For overrun clutch solenoid valve, refer to AT-152, " Component

Inspection " .

A/T Fluid Temperature Sensor Measure resistance.

• For A/T fluid temperature sensor, refer to AT-161, " Component

Inspection " .

Line Pressure Relief Valve Springs and To rque Converter Pressure Holding Spring

• Check each spring for damage or deformation. Also measure free length and outer diameter. Refer to AT-374, " Control Valves " .

• Replace springs if deformed or fatigued.

ASSEMBLY SCIA3485E

SAT138D

Page 300 of 4331

REPAIR FOR COMPONENT PARTS

AT-295

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

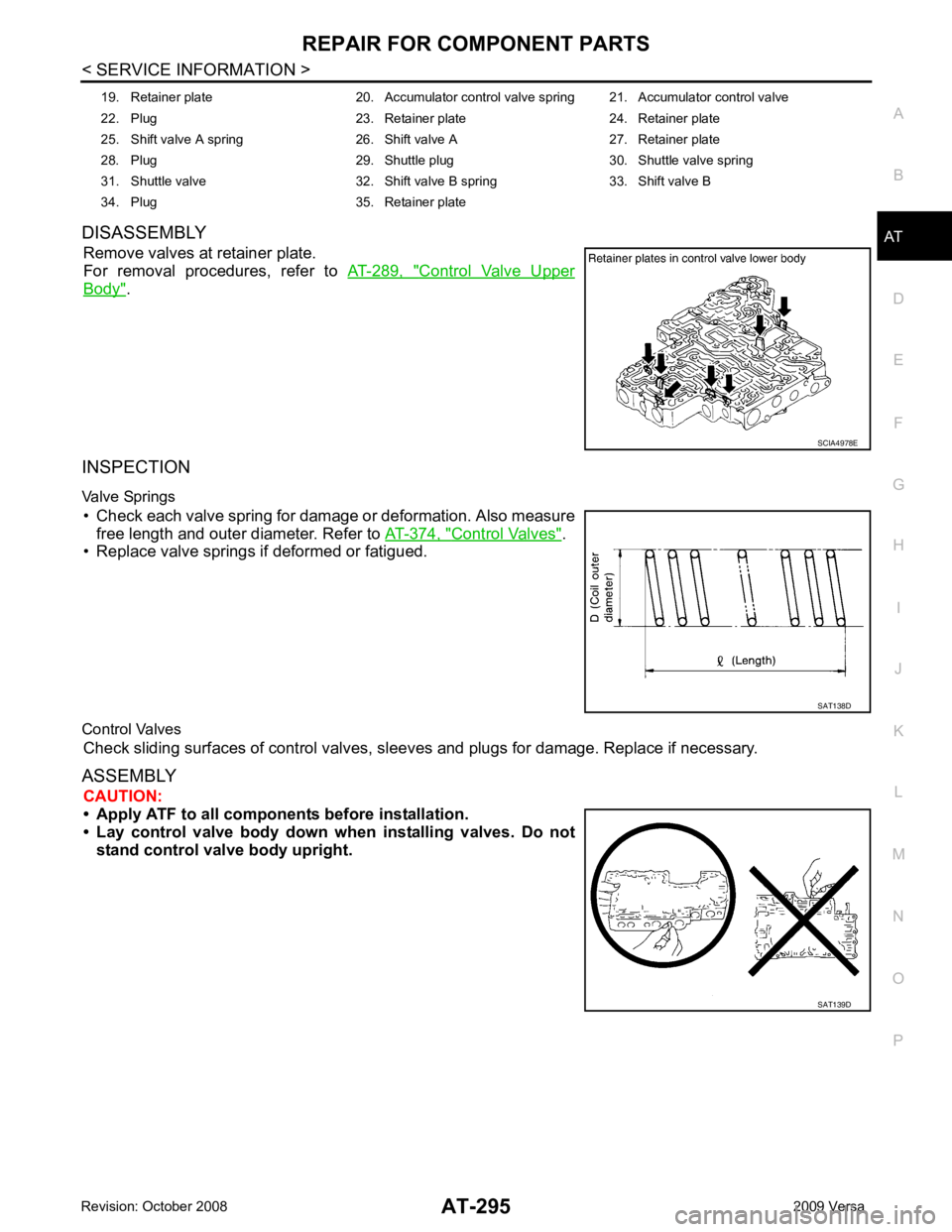

DISASSEMBLY

Remove valves at retainer plate.

For removal procedures, refer to AT-289, " Control Valve Upper

Body " .

INSPECTION

Valve Springs • Check each valve spring for damage or deformation. Also measure free length and outer diameter. Refer to AT-374, " Control Valves " .

• Replace valve springs if deformed or fatigued.

Control Valves Check sliding surfaces of control valves, sl eeves and plugs for damage. Replace if necessary.

ASSEMBLY CAUTION:

• Apply ATF to all componen ts before installation.

• Lay control valve body down wh en installing valves. Do not

stand control valve body upright. 19. Retainer plate 20. Accumulator control valve spring 21. Accumulator control valve

22. Plug 23. Retainer plate 24. Retainer plate

25. Shift valve A spring 26. Shift valve A 27. Retainer plate

28. Plug 29. Shuttle plug 30. Shuttle valve spring

31. Shuttle valve 32. Shift valve B spring 33. Shift valve B

34. Plug 35. Retainer plate SCIA4978E

SAT138D

SAT139D

Page 301 of 4331

AT-296< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

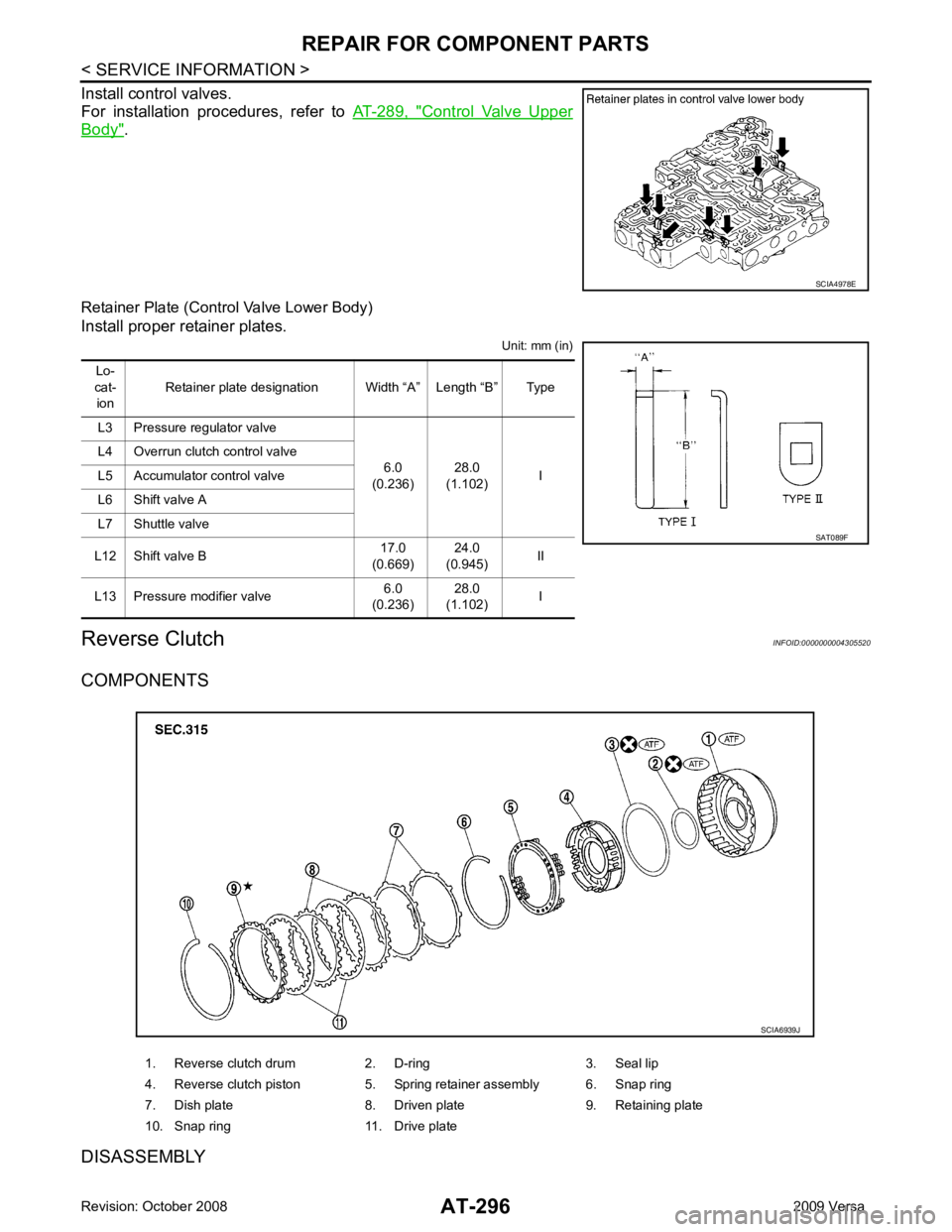

Install control valves.

For installation procedures, refer to AT-289, " Control Valve Upper

Body " .

Retainer Plate (Control Valve Lower Body)

Install proper retainer plates. Unit: mm (in)

Reverse Clutch INFOID:0000000004305520

COMPONENTS

DISASSEMBLY SCIA4978E

Lo-

cat- ion Retainer plate designation Width “A” Length “B” Type

L3 Pressure regulator valve 6.0

(0.236) 28.0

(1.102) I

L4 Overrun clutch control valve

L5 Accumulator control valve

L6 Shift valve A

L7 Shuttle valve

L12 Shift valve B 17.0

(0.669) 24.0

(0.945) II

L13 Pressure modifier valve 6.0

(0.236) 28.0

(1.102) I SAT089F

1. Reverse clutch drum 2. D-ring 3. Seal lip

4. Reverse clutch piston 5. Spring retainer assembly 6. Snap ring

7. Dish plate 8. Driven plate 9. Retaining plate

10. Snap ring 11. Drive plate SCIA6939J

Page 308 of 4331

AT

N

O P

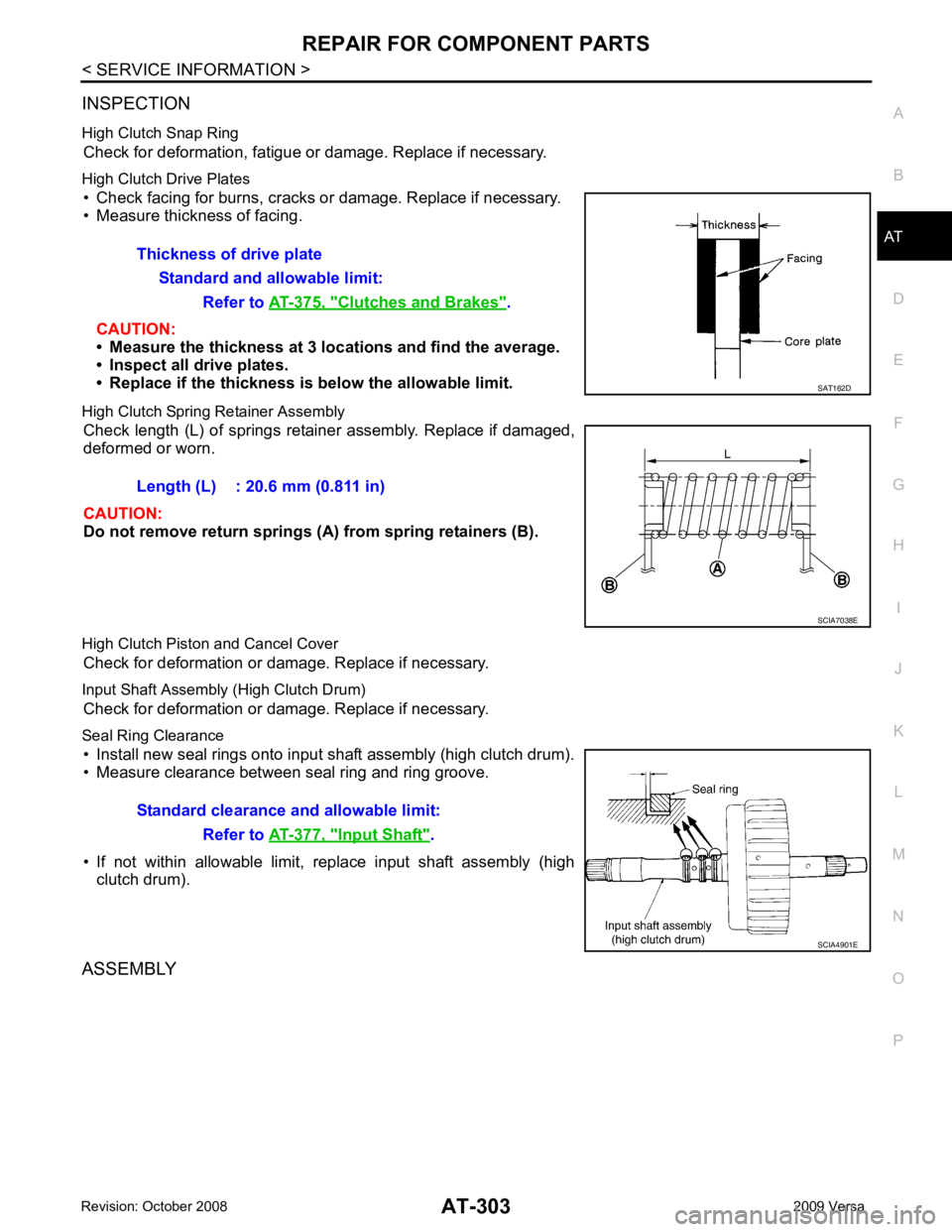

INSPECTION

High Clutch Snap Ring Check for deformation, fatigue or damage. Replace if necessary.

High Clutch Drive Plates • Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 lo cations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

High Clutch Spring Retainer Assembly Check length (L) of springs retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainers (B).

High Clutch Piston and Cancel Cover Check for deformation or damage. Replace if necessary.

Input Shaft Assembly (High Clutch Drum) Check for deformation or damage. Replace if necessary.

Seal Ring Clearance • Install new seal rings onto input shaft assembly (high clutch drum).

• Measure clearance between seal ring and ring groove.

• If not within allowable limit, replace input shaft assembly (high clutch drum).

ASSEMBLY Thickness of drive plate

Standard and allowable limit: Refer to AT-375, " Clutches and Brakes " .

Input Shaft " .

Page 314 of 4331

REPAIR FOR COMPONENT PARTS

AT-309

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

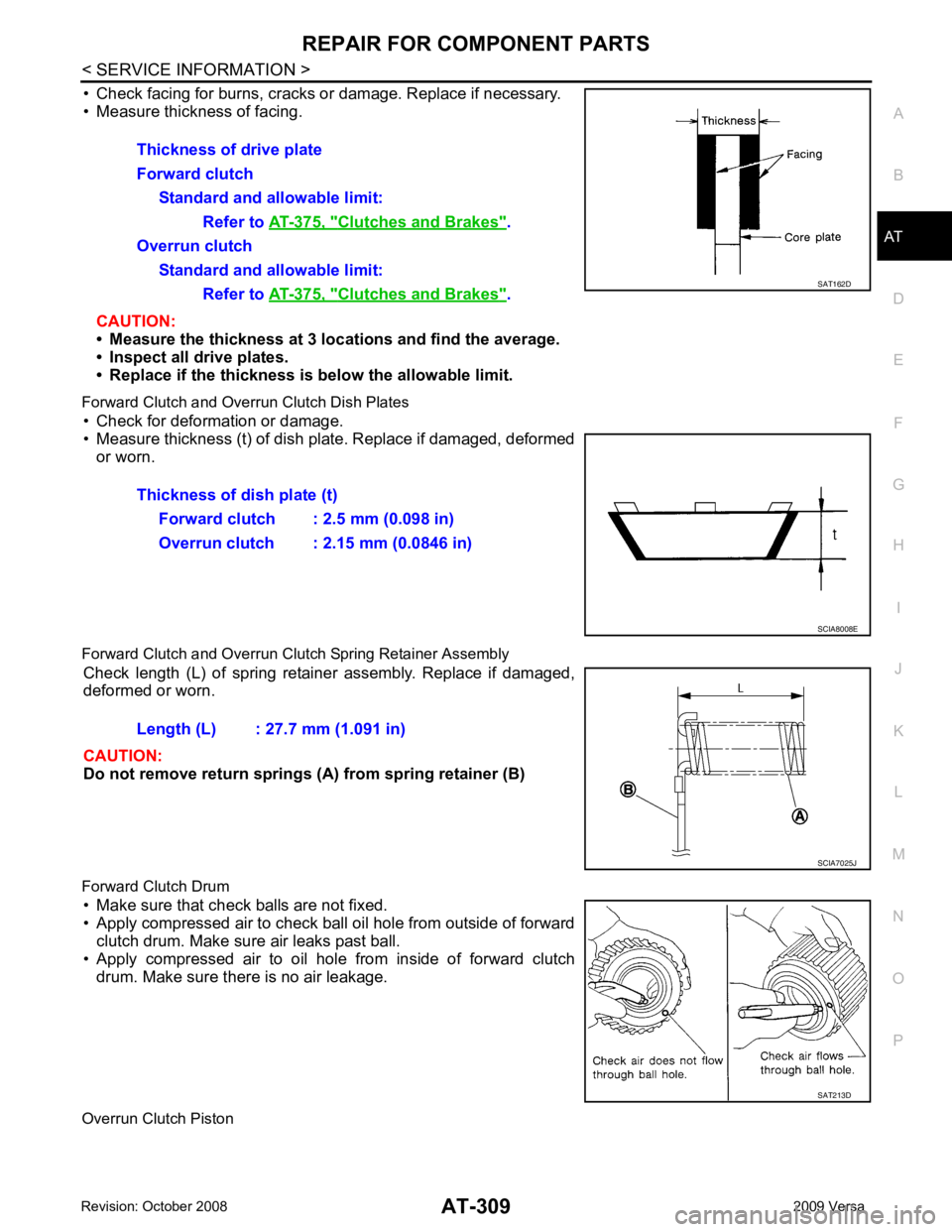

• Check facing for burns, cracks or

damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 lo cations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Forward Clutch and Overrun Clutch Dish Plates • Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed or worn.

Forward Clutch and Overrun Clutch Spring Retainer Assembly Check length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainer (B)

Forward Clutch Drum • Make sure that check balls are not fixed.

• Apply compressed air to check ball oil hole from outside of forward

clutch drum. Make sure air leaks past ball.

• Apply compressed air to oil hole from inside of forward clutch drum. Make sure there is no air leakage.

Overrun Clutch Piston Thickness of drive plate

Forward clutch Standard and allowable limit:

Refer to AT-375, " Clutches and Brakes " .

Overrun clutch Standard and allowable limit:

Refer to AT-375, " Clutches and Brakes " . SAT162D

Thickness of dish plate (t)

Forward clutch : 2.5 mm (0.098 in)

Overrun clutch : 2.15 mm (0.0846 in) SCIA8008E

Length (L) : 27.7 mm (1.091 in)

SCIA7025J

SAT213D

Page 320 of 4331

REPAIR FOR COMPONENT PARTS

AT-315

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

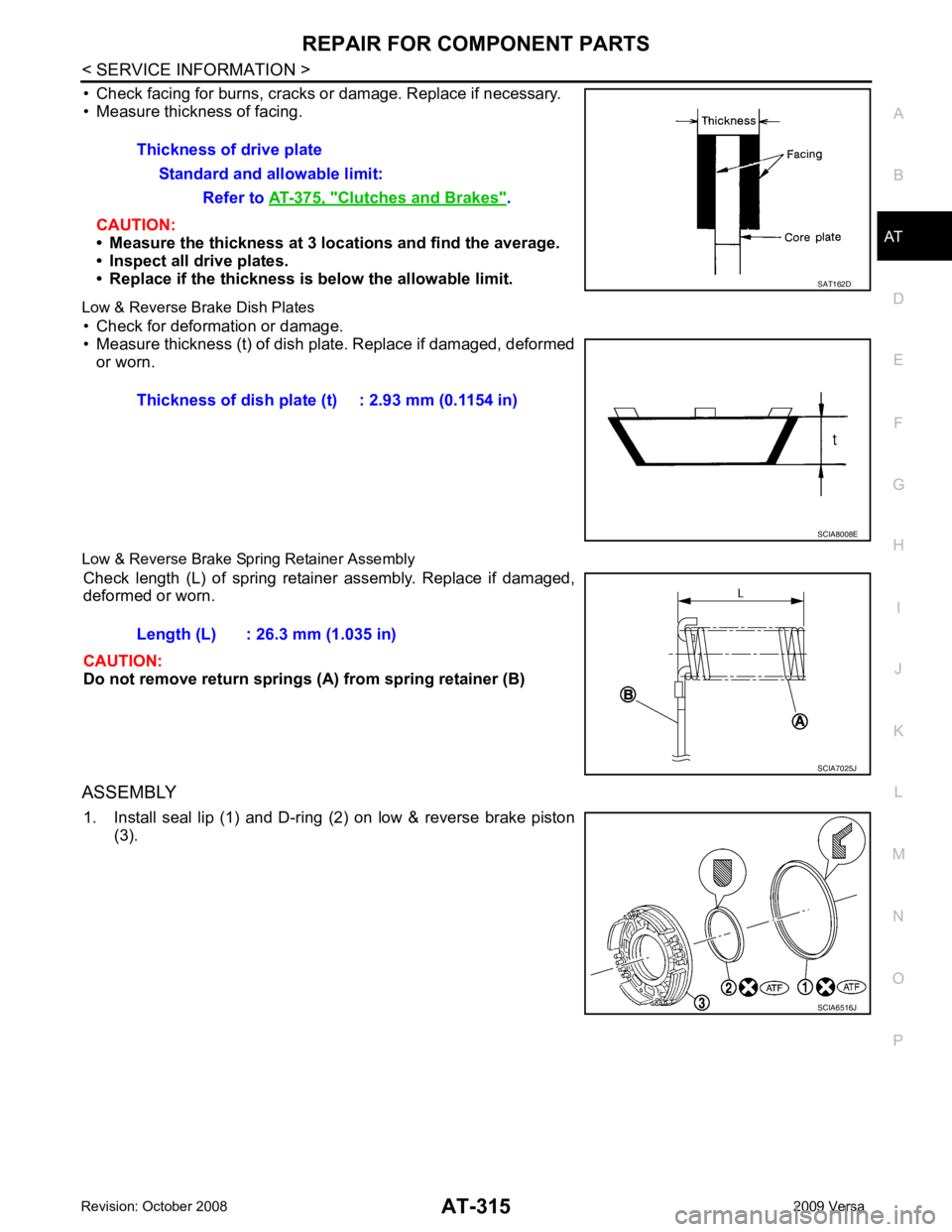

• Check facing for burns, cracks or

damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 lo cations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Low & Reverse Brake Dish Plates • Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed

or worn.

Low & Reverse Brake Spring Retainer Assembly Check length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainer (B)

ASSEMBLY 1. Install seal lip (1) and D-ring (2) on low & reverse brake piston (3).Thickness of drive plate

Standard and allowable limit:

Refer to AT-375, " Clutches and Brakes " .

SAT162D

Thickness of dish plate (t) : 2.93 mm (0.1154 in)

SCIA8008E

Length (L) : 26.3 mm (1.035 in)

SCIA7025J

SCIA6516J