differential NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 16 of 4331

AT

N

O P

PREPARATION

Special Service Tool INFOID:0000000004305293

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

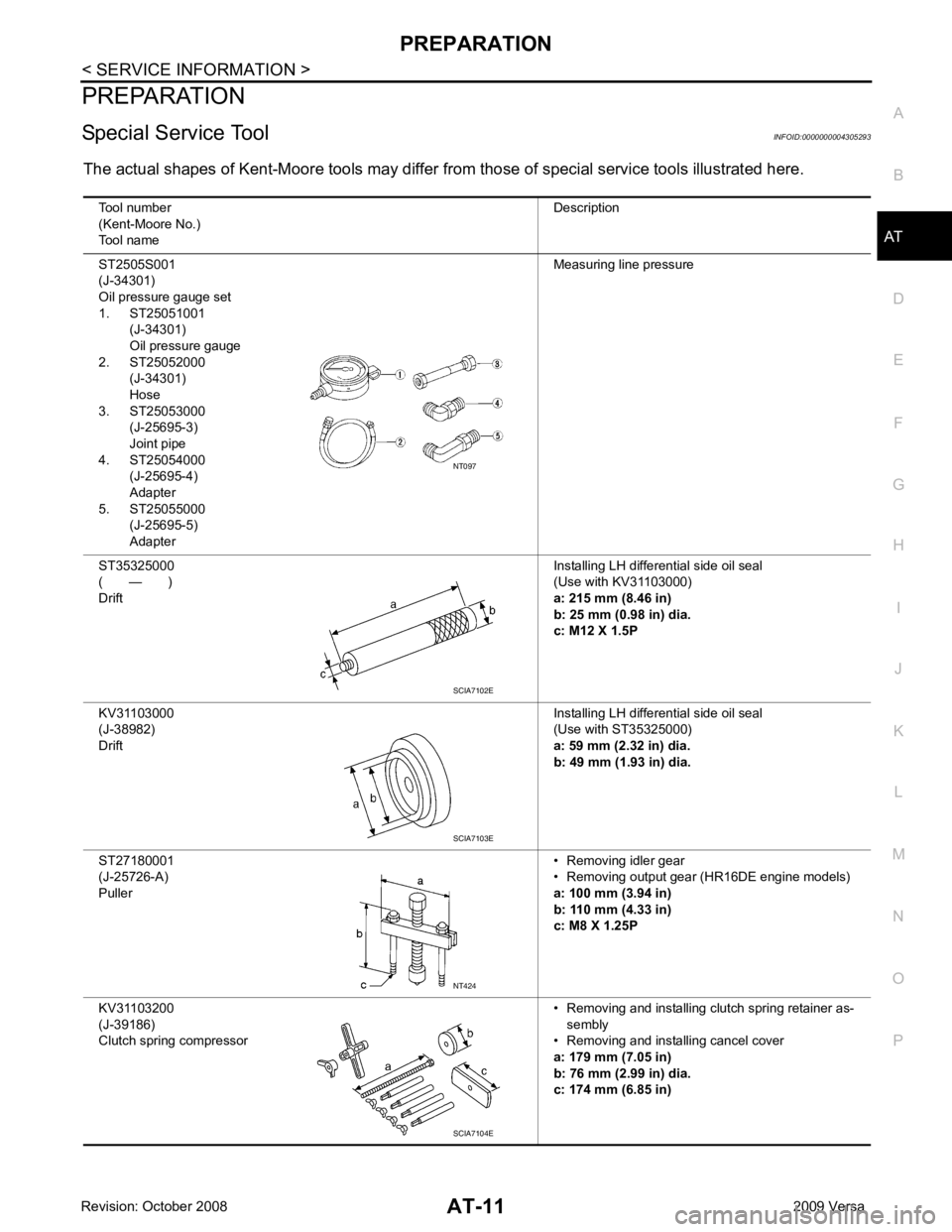

Tool number

(Kent-Moore No.)

Tool name Description

ST2505S001

(J-34301)

Oil pressure gauge set

1. ST25051001 (J-34301)

Oil pressure gauge

2. ST25052000 (J-34301)

Hose

3. ST25053000

(J-25695-3)

Joint pipe

4. ST25054000

(J-25695-4)

Adapter

5. ST25055000

(J-25695-5)

Adapter Measuring line pressure

ST35325000

( — )

Drift Installing LH differential side oil seal

(Use with KV31103000)

a: 215 mm (8.46 in)

b: 25 mm (0.98 in) dia.

c: M12 X 1.5P

KV31103000

(J-38982)

Drift Installing LH differential side oil seal

(Use with ST35325000)

a: 59 mm (2.32 in) dia.

b: 49 mm (1.93 in) dia.

ST27180001

(J-25726-A)

Puller • Removing idler gear

• Removing output gear (HR16DE engine models)

a: 100 mm (3.94 in)

b: 110 mm (4.33 in)

c: M8 X 1.25P

KV31103200

(J-39186)

Clutch spring compressor • Removing and installing clutch spring retainer as-

sembly

• Removing and installing cancel cover

a: 179 mm (7.05 in)

b: 76 mm (2.99 in) dia.

c: 174 mm (6.85 in) SCIA7102E

NT424

SCIA7104E

Page 18 of 4331

AT

N

O P

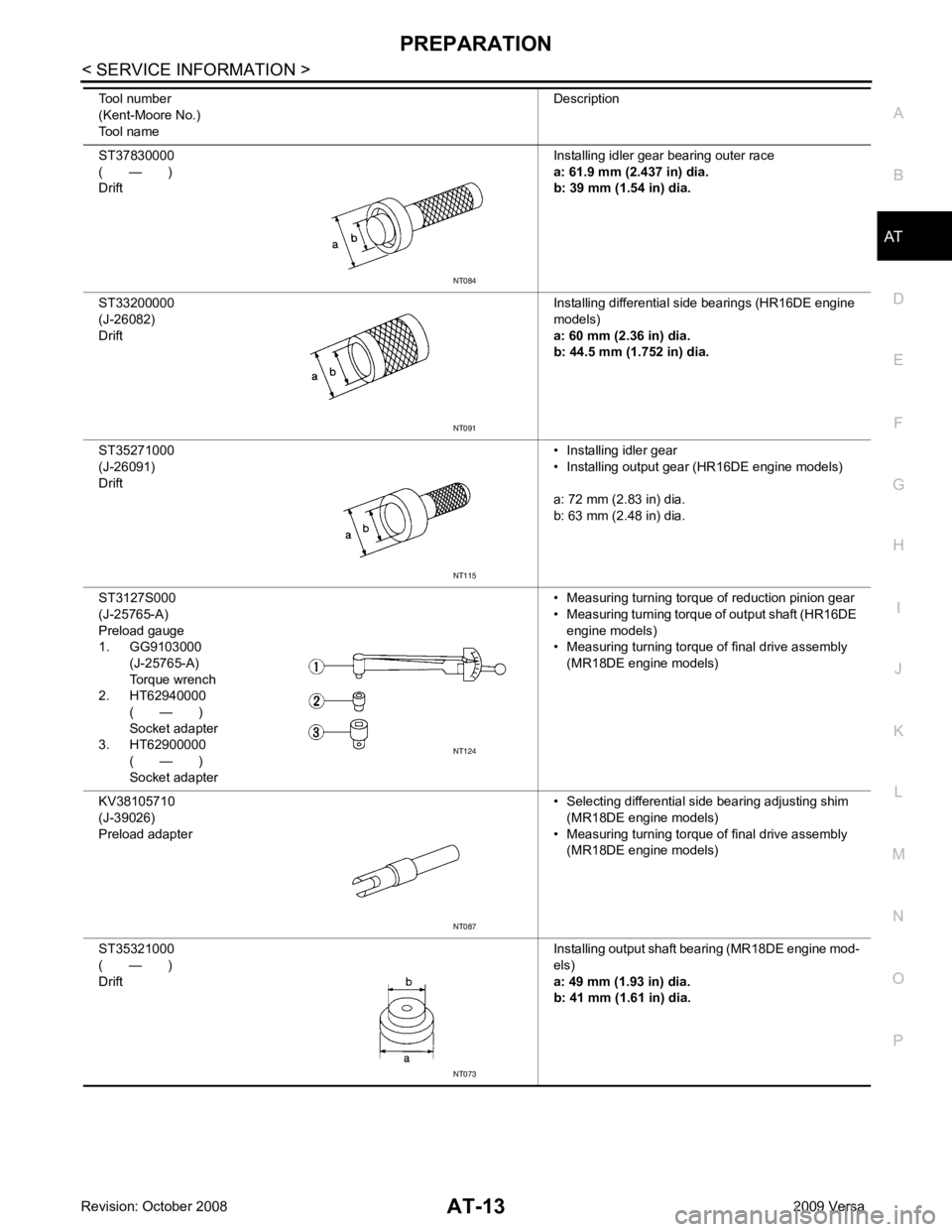

ST37830000

( — )

Drift Installing idler gear bearing outer race

a: 61.9 mm (2.437 in) dia.

b: 39 mm (1.54 in) dia.

ST33200000

(J-26082)

Drift Installing differential side bearings (HR16DE engine

models)

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

ST35271000

(J-26091)

Drift • Installing idler gear

• Installing output gear (HR16DE engine models)

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.

ST3127S000

(J-25765-A)

Preload gauge

1. GG9103000

(J-25765-A)

Torque wrench

2. HT62940000

( — )

Socket adapter

3. HT62900000

( — )

Socket adapter • Measuring turning torque of reduction pinion gear

• Measuring turning torque of output shaft (HR16DE engine models)

• Measuring turning torque of final drive assembly

(MR18DE engine models)

KV38105710

(J-39026)

Preload adapter • Selecting differential side bearing adjusting shim

(MR18DE engine models)

• Measuring turning torque of final drive assembly (MR18DE engine models)

ST35321000

( — )

Drift Installing output shaft bearing (MR18DE engine mod-

els)

a: 49 mm (1.93 in) dia.

b: 41 mm (1.61 in) dia.

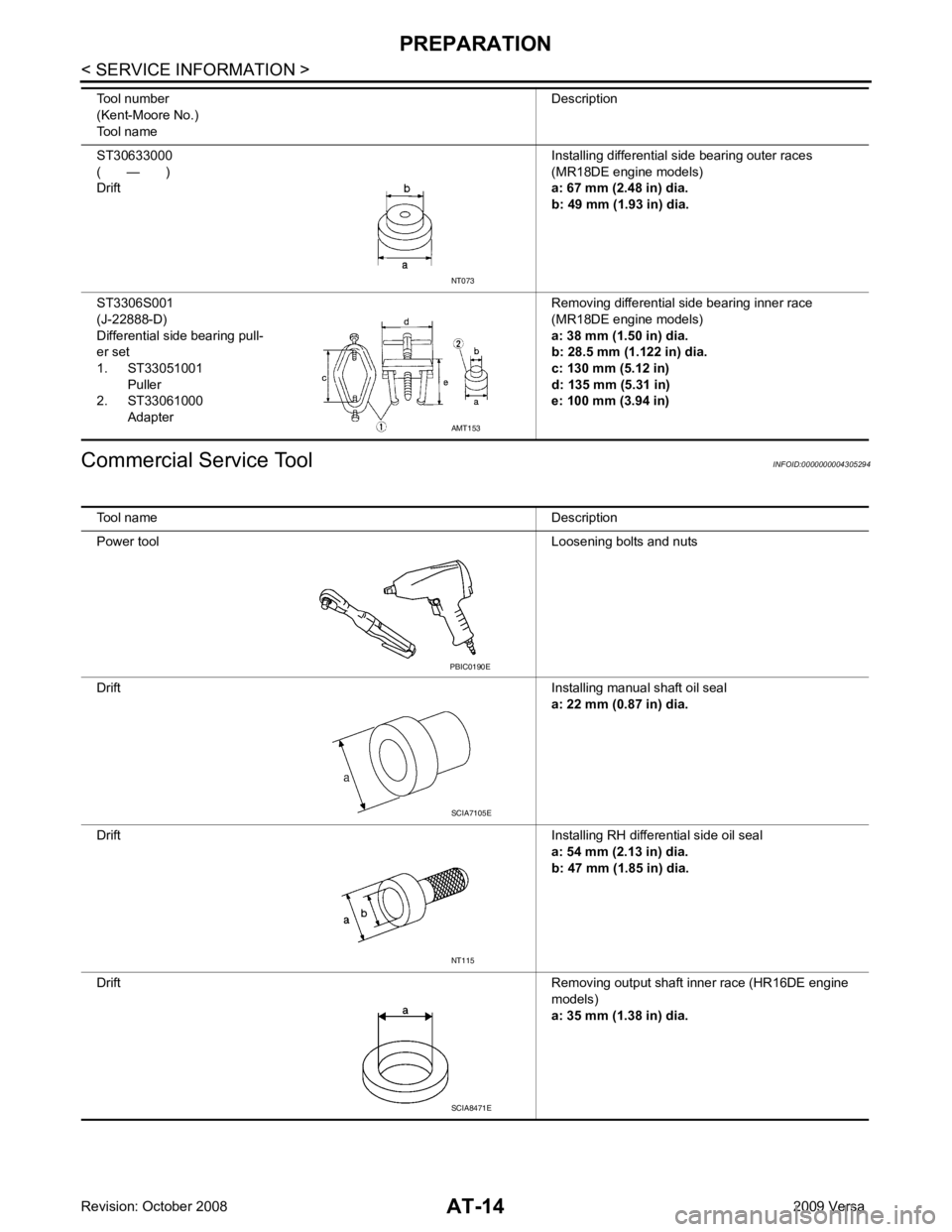

Tool number

(Kent-Moore No.)

Tool name DescriptionNT115

NT124

NT087

NT073

Page 19 of 4331

AMT153

Tool name Description

Power tool Loosening bolts and nuts

Drift Installing manual shaft oil seal

a: 22 mm (0.87 in) dia.

Drift Installing RH differential side oil seal

a: 54 mm (2.13 in) dia.

b: 47 mm (1.85 in) dia.

Drift Removing output shaft inner race (HR16DE engine

models)

a: 35 mm (1.38 in) dia. NT115

SCIA8471E

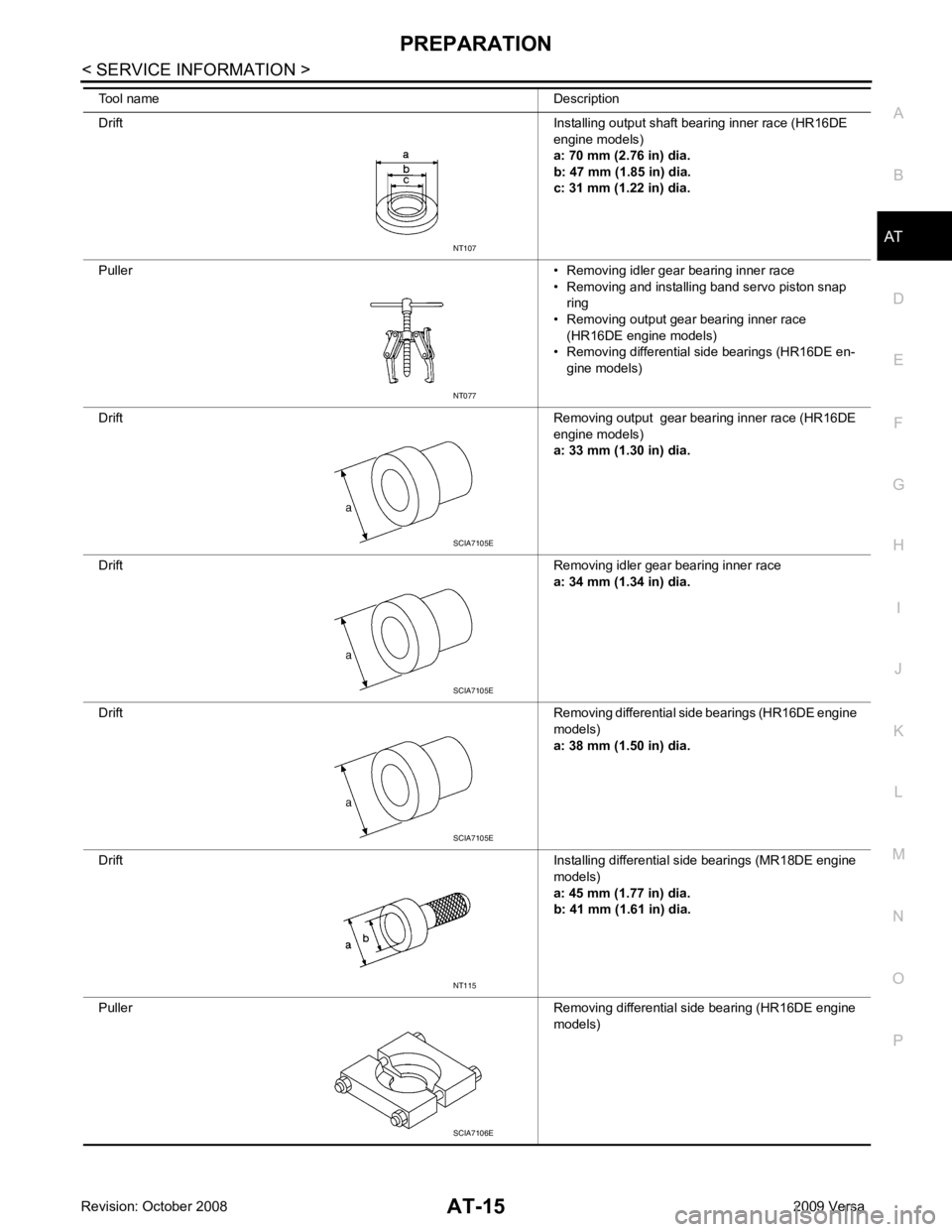

Page 20 of 4331

AT

N

O P

Drift

Installing output shaft bearing inner race (HR16DE

engine models)

a: 70 mm (2.76 in) dia.

b: 47 mm (1.85 in) dia.

c: 31 mm (1.22 in) dia.

Puller • Removing idler gear bearing inner race

• Removing and installing band servo piston snap ring

• Removing output gear bearing inner race (HR16DE engine models)

• Removing differential side bearings (HR16DE en-

gine models)

Drift Removing output gear bearing inner race (HR16DE

engine models)

a: 33 mm (1.30 in) dia.

Drift Removing idler gear bearing inner race

a: 34 mm (1.34 in) dia.

Drift Removing differential side bearings (HR16DE engine

models)

a: 38 mm (1.50 in) dia.

Drift Installing differential side bearings (MR18DE engine

models)

a: 45 mm (1.77 in) dia.

b: 41 mm (1.61 in) dia.

Puller Removing differential side bearing (HR16DE engine

models)

Tool name Description

NT077

SCIA7105E

SCIA7105E

NT115

SCIA7106E

Page 233 of 4331

.

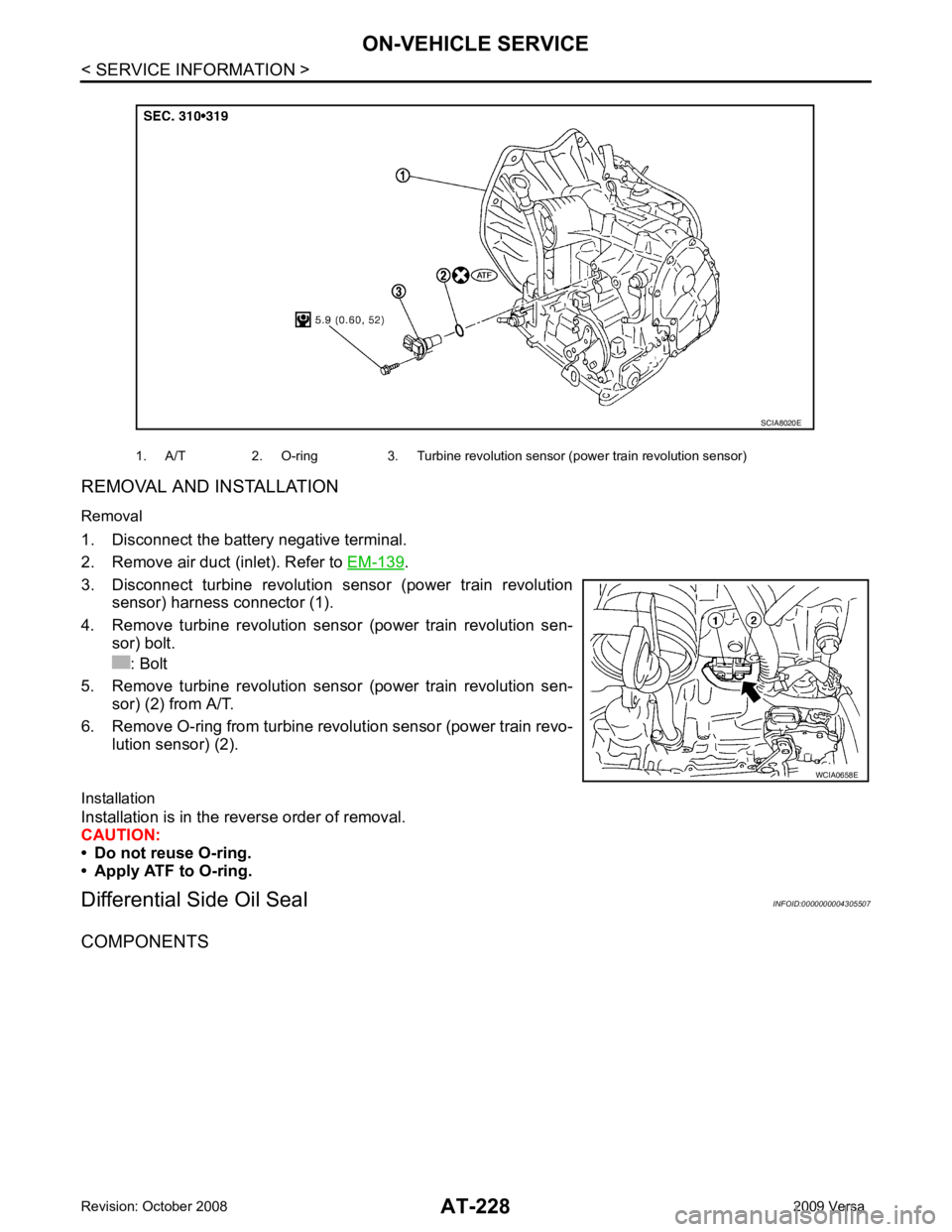

3. Disconnect turbine revolution sensor (power train revolution sensor) harness connector (1).

4. Remove turbine revolution sensor (power train revolution sen- sor) bolt.

: Bolt

5. Remove turbine revolution sensor (power train revolution sen- sor) (2) from A/T.

6. Remove O-ring from turbine revolution sensor (power train revo- lution sensor) (2).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

Differential Side Oil Seal INFOID:0000000004305507

COMPONENTS 1. A/T 2. O-ring 3. Turbine revolution sensor (power train revolution sensor)

Page 234 of 4331

AT

N

O P

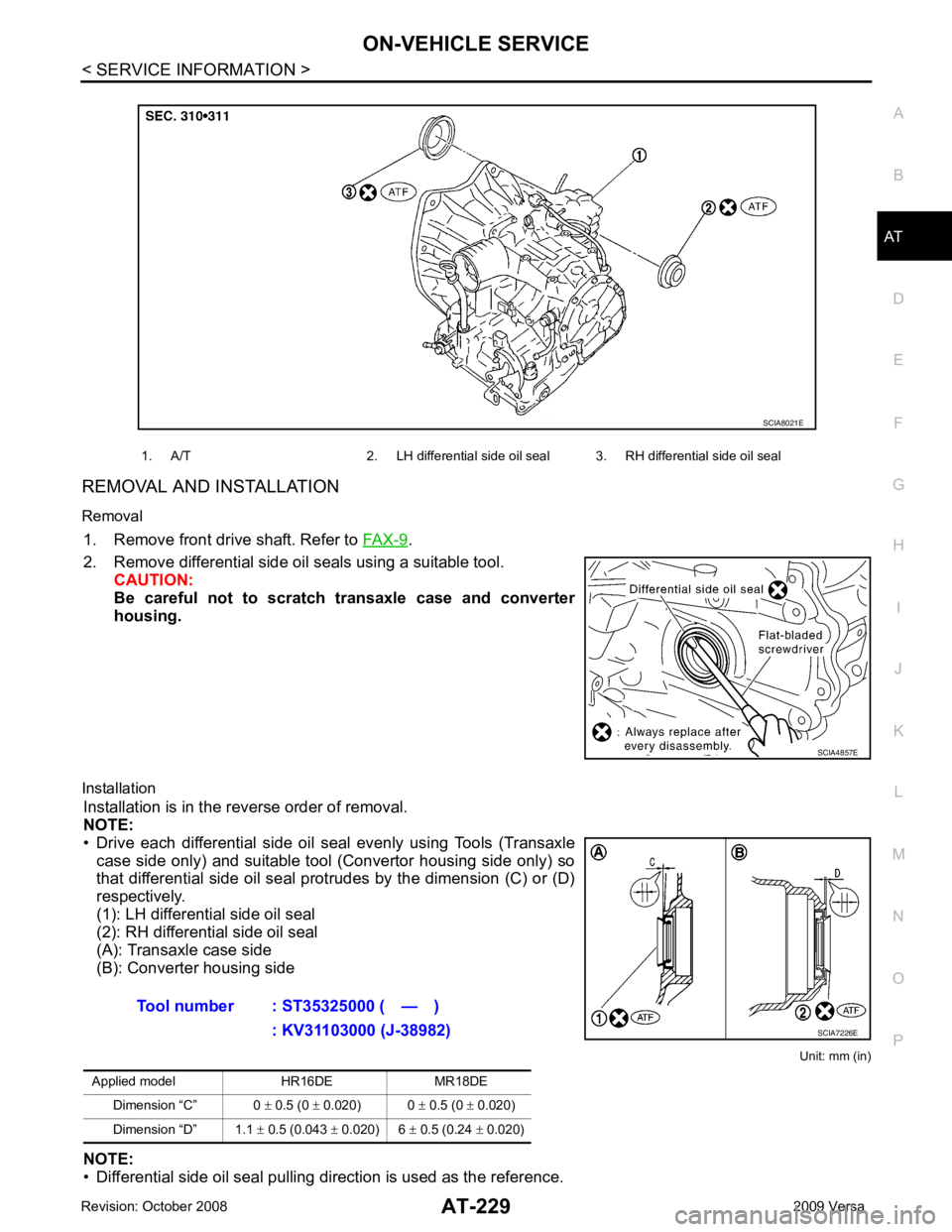

REMOVAL AND INSTALLATION

Removal 1. Remove front drive shaft. Refer to FAX-9 .

2. Remove differential side oil seals using a suitable tool. CAUTION:

Be careful not to scratch transaxle case and converter

housing.

Installation Installation is in the reverse order of removal.

NOTE:

• Drive each differential side oil seal evenly using Tools (Transaxle case side only) and suitable tool (Convertor housing side only) so

that differential side oil seal protrudes by the dimension (C) or (D)

respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

• Differential side oil seal pulling direction is used as the reference. 1. A/T 2. LH differential side oil seal 3. RH differential side oil seal

Page 242 of 4331

AT

N

O P

1. Pinion mate gear thrust washer 2. Pinion mate gear 3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing adjusting shim 12. Plug

13. O-ring 14. Bracket 15. RH differential side oil seal

16. Torque converter 17. Converter housing 18. Differential lubricant tube

19. Clip 20. O-ring 21. O-ring

22. Oil pump housing oil seal 23. Oil pump housing 24. Outer gear

25. Inner gear 26. Oil pump cover 27. Seal ring

28. Oil pump assembly

Page 250 of 4331

AT

N

O P

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing adjusting shim12. Speedometer pinion

13. O-ring 14. Bracket 15. RH differential side oil seal

16. Torque converter 17. Converter housing 18. Differential lubricant tube

19. Clip 20. O-ring 21. O-ring

22. Oil pump housing oil seal 23. Oil pump housing 24. Outer gear

25. Inner gear 26. Oil pump cover 27. Seal ring

28. Oil pump assembly

Page 254 of 4331

AT

N

O P

Oil Channel

INFOID:0000000004305511

HR16DE ENGINE MODELS 19. Oil pan 20. Drain plug gasket 21. Drain plug

22. Magnet 23. Oil pan bolt 24. Snap ring

25. O-ring 26. O-ring 27. N-D accumulator piston

28. Return spring 29. O-ring 30. Lip seal

31. Turbine revolution sensor (power train revolution sensor) 32. O-ring 33. Retaining pin

34. Detent spring 35. Retaining pin 36. Manual shaft

37. Manual shaft oil seal 38. Manual plate 39. Parking rod plate

40. Parking rod 41. OD servo piston retainer 42. Snap ring

43. O-ring 44. OD servo piston 45. D-ring

46. Servo piston retainer 47. O-ring 48. E-ring

49. Spring retainer 50. OD servo return spring 51. D-ring

52. Band servo piston 53. Band servo thrust washer 54. Band servo piston stem

55. 2nd servo return spring 56. PNP switch 57. Parking shaft

58. Return spring 59. Thrust needle bearing 60. Seal ring

61. Output shaft 62. Output shaft bearing 63. Output shaft adjusting shim

64. Side cover 65. Side cover bolt 66. Lock nut

67. Idler gear 68. Idler gear bearing 69. Reduction pinion gear adjusting shim

70. Parking actuator support 71. Parking pawl 72. LH differential side oil seal

73. Revolution sensor

: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Page 266 of 4331

AT

N

O P

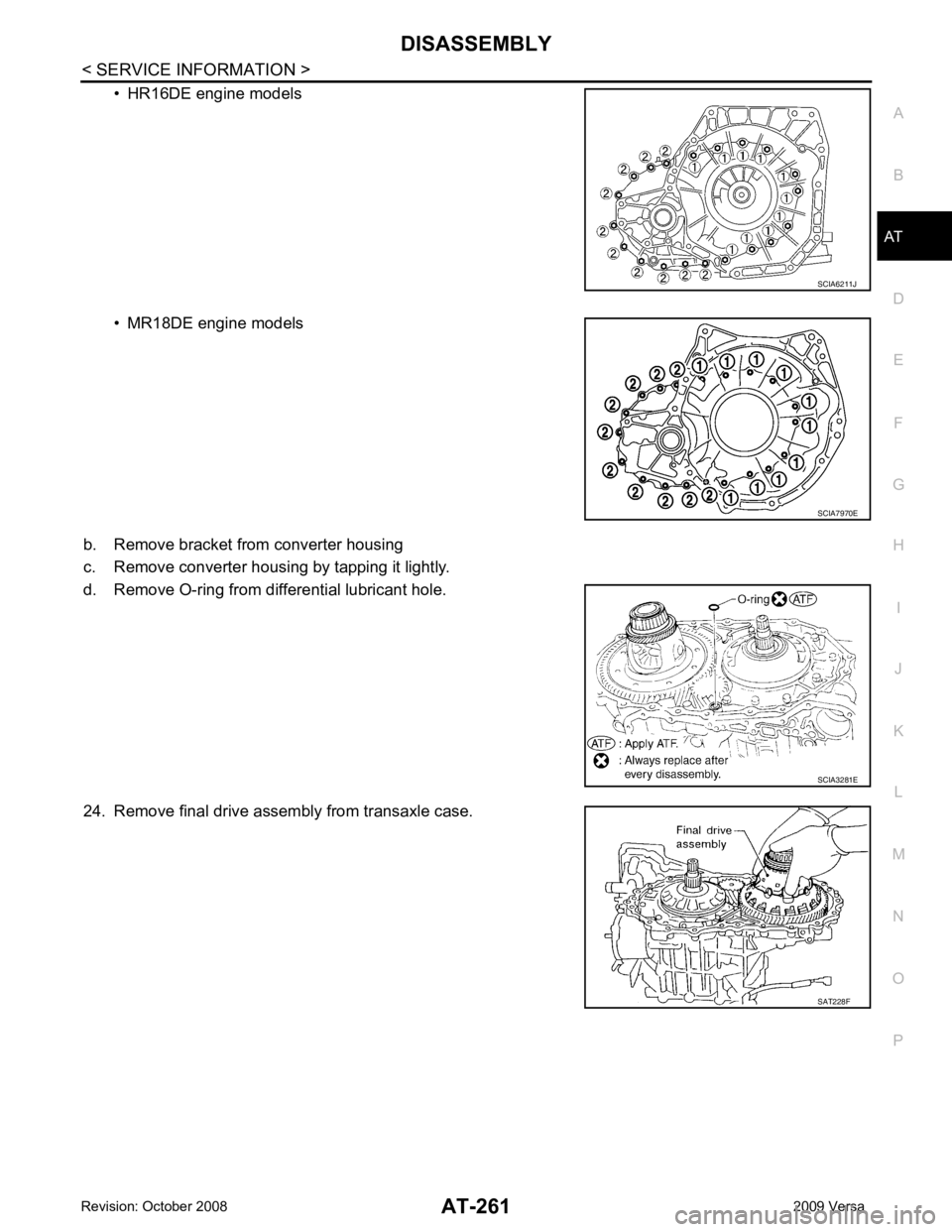

• HR16DE engine models

• MR18DE engine models

b. Remove bracket from converter housing

c. Remove converter housing by tapping it lightly.

d. Remove O-ring from differential lubricant hole.

24. Remove final drive assembly from transaxle case. SCIA7970E

SAT228F