door lock NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 406 of 4331

35, " Sound Is Not Heard from S

ubwoofer (Premium System) " .

• The majority of the audio malfunctions are the result of outside causes (damaged CD, electromagnetic inter-

ference, etc.). Check the symptom s below to diagnose the malfunction.

• The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and oper-

ation of each piece of electrical equipment, and then determine the cause.

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or external noise

from trains and other sources. It is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun- tains or buildings blocking the signal.

• Multi-path noise: This noise results from the waves s ent directly from the broadcast station arriving at the

antenna at a different time from the waves that reflect off of mountains or buildings.

Noise Inspection INFOID:0000000004306967

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

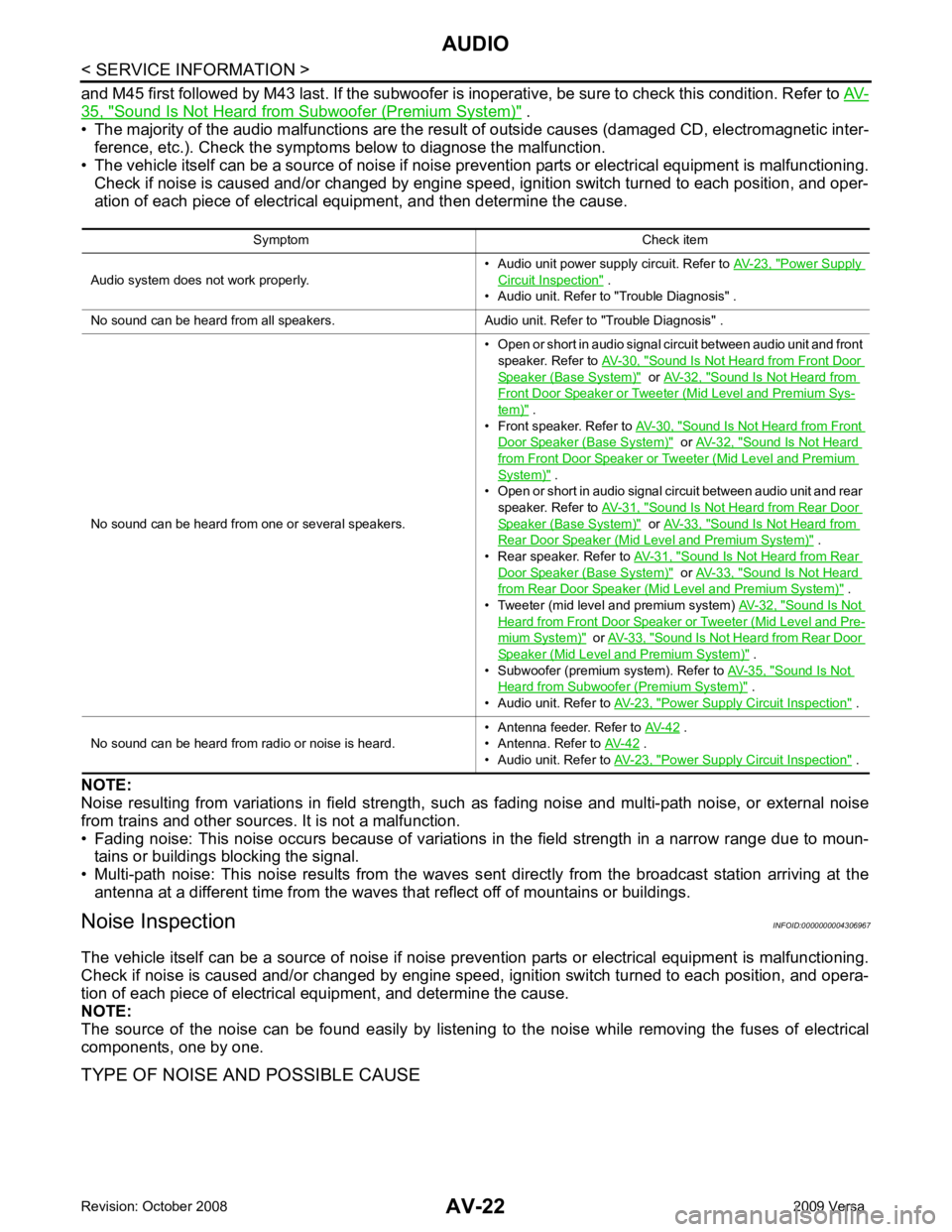

TYPE OF NOISE AND POSSIBLE CAUSE Symptom Check item

Audio system does not work properly. • Audio unit power supply circuit. Refer to

AV-23, " Power Supply

Circuit Inspection " .

• Audio unit. Refer to "Trouble Diagnosis" .

No sound can be heard from all speakers. Audio unit. Refer to "Trouble Diagnosis" .

No sound can be heard from one or several speakers. • Open or short in audio signal circuit between audio unit and front

speaker. Refer to AV-30, " Sound Is Not Heard from Front Door

Speaker (Base System) " or

AV-32, " Sound Is Not Heard from

Front Door Speaker or Tweeter (Mid Level and Premium Sys-

tem) " .

• Front speaker. Refer to AV-30, " Sound Is Not Heard from Front

Door Speaker (Base System) " or

AV-32, " Sound Is Not Heard

from Front Door Speaker or Tweeter (Mid Level and Premium

System) " .

• Open or short in audio signal circuit between audio unit and rear

speaker. Refer to AV-31, " Sound Is Not Heard from Rear Door

Speaker (Base System) " or

AV-33, " Sound Is Not Heard from

Rear Door Speaker (Mid Level and Premium System) " .

• Rear speaker. Refer to AV-31, " Sound Is Not Heard from Rear

Door Speaker (Base System) " or

AV-33, " Sound Is Not Heard

from Rear Door Speaker (Mid Level and Premium System) " .

• Tweeter (mid level and premium system) AV-32, " Sound Is Not

Heard from Front Door Speaker or Tweeter (Mid Level and Pre-

mium System) " or

AV-33, " Sound Is Not Heard from Rear Door

Speaker (Mid Level and Premium System) " .

• Subwoofer (premium system). Refer to AV-35, " Sound Is Not

Heard from Subwoofer (Premium System) " .

• Audio unit. Refer to AV-23, " Power Supply Circuit Inspection " .

No sound can be heard from radio or noise is heard. • Antenna feeder. Refer to

AV-42 .

• Antenna. Refer to AV-42 .

• Audio unit. Refer to AV-23, " Power Supply Circuit Inspection " .

Page 448 of 4331

System Description " .

• Remote keyless entry system. Refer to BL-58, " System Description " .

• Power window system (with power windows). Refer to GW-19, " System Description " .

NOTE

• Sunroof system (with sunroof). Refer to RF-11, " System Description " .

NOTE

• Room lamp timer. Refer to LT-91, " System Description " .

• Rear wiper and washer system (Hatchback). Refer to WW-25, " System Description " .

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-58, " System Description " .

• Vehicle security (theft warning) system. Refer to BL-219, " System Description " .

• NVIS(NATS) system. Refer to BL-248, " System Description " .

• Headlamp, tail lamp and battery saver control systems. Refer to LT-73, " System Description " ,

LT-4, " System

Description " or

LT-25, " System Description " .

• Front fog lamp (with front fog lamps). Refer to LT-39, " System Description " .

• Front wiper and washer system. Refer to WW-3, " System Description " .

• Rear window defogger system. Refer to GW-51, " System Description " .

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

• Warning chime. Refer to DI-42, " System Description " .

• Turn signal and hazard warning lamps. Refer to LT-48, " System Description " .

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT (WITH INTELLIGENT KEY)

• Intelligent Key system. Refer to BL-88, " System Description " .

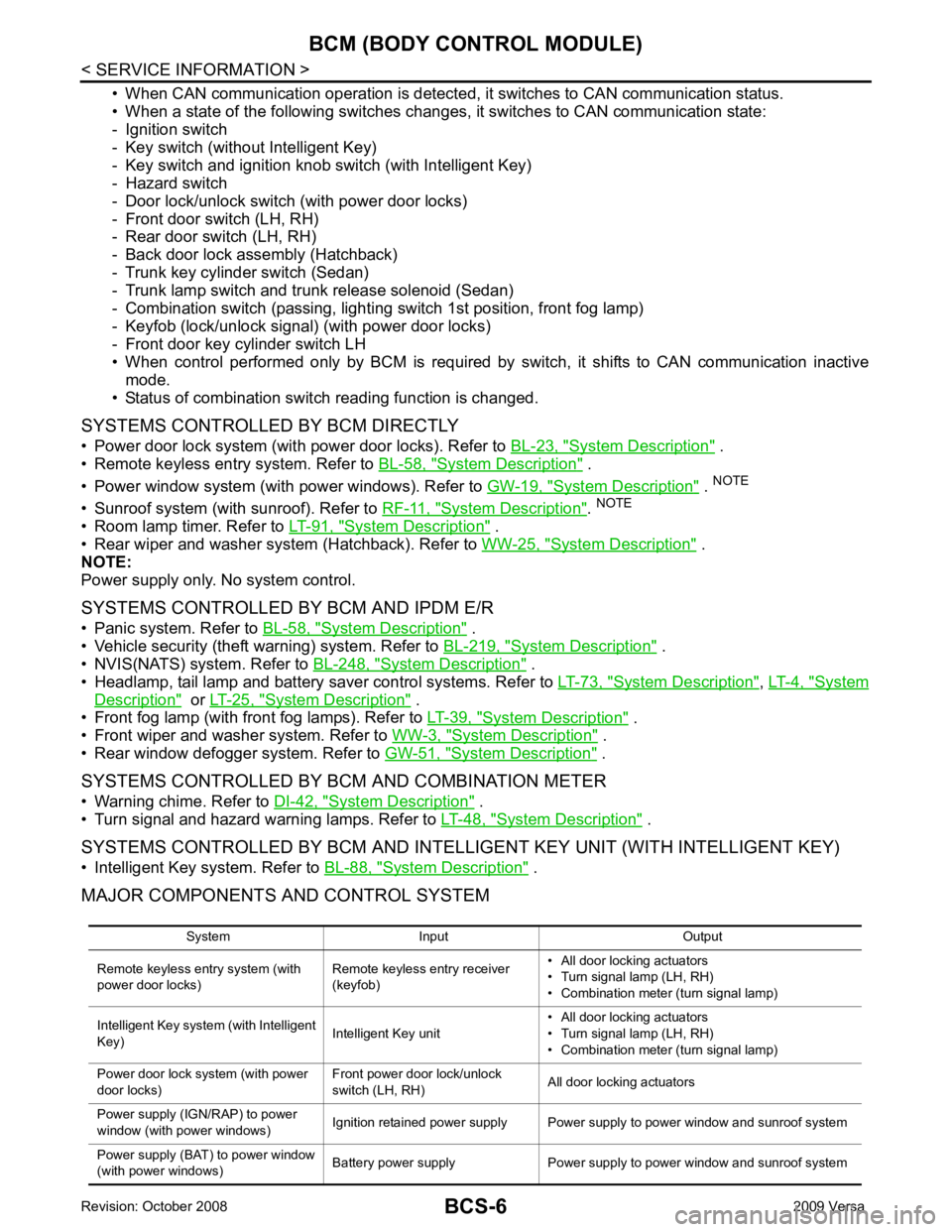

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system (with

power door locks) Remote keyless entry receiver

(keyfob) • All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Intelligent Key system (with Intelligent

Key) Intelligent Key unit• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Power door lock system (with power

door locks) Front power door lock/unlock

switch (LH, RH) All door locking actuators

Power supply (IGN/RAP) to power

window (with power windows) Ignition retained power supply Power supply to power window and sunroof system

Power supply (BAT) to power window

(with power windows) Battery power supply Power supply to power window and sunroof system

Page 449 of 4331

BCS

N

O P

CAN Communication System Description INFOID:0000000004306834

Refer to LAN-8, " System Description " .

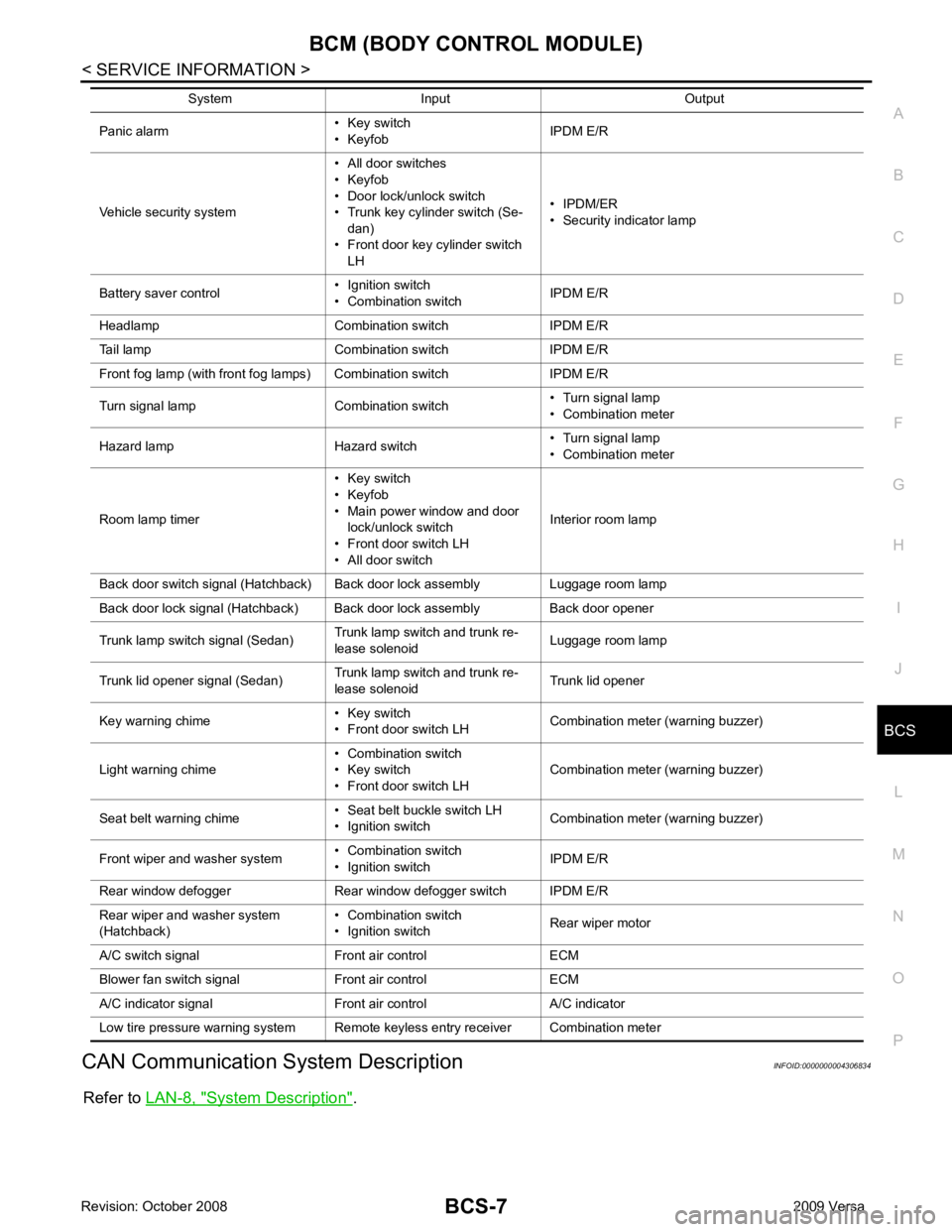

Panic alarm

• Key switch

• Keyfob IPDM E/R

Vehicle security system • All door switches

• Keyfob

• Door lock/unlock switch

• Trunk key cylinder switch (Se-

dan)

• Front door key cylinder switch LH • IPDM/ER

• Security indicator lamp

Battery saver control • Ignition switch

• Combination switch IPDM E/R

Headlamp Combination switch IPDM E/R

Tail lamp Combination switch IPDM E/R

Front fog lamp (with front fog lamps) Combination switch IPDM E/R

Turn signal lamp Combination switch • Turn signal lamp

• Combination meter

Hazard lamp Hazard switch • Turn signal lamp

• Combination meter

Room lamp timer • Key switch

• Keyfob

• Main power window and door lock/unlock switch

• Front door switch LH

• All door switch Interior room lamp

Back door switch signal (Hatchback) Back door lock assembly Luggage room lamp

Back door lock signal (Hatchback) Back door lock assembly Back door opener

Trunk lamp switch signal (Sedan) Trunk lamp switch and trunk re-

lease solenoid Luggage room lamp

Trunk lid opener signal (Sedan) Trunk lamp switch and trunk re-

lease solenoid Trunk lid opener

Key warning chime • Key switch

• Front door switch LH Combination meter (warning buzzer)

Light warning chime • Combination switch

• Key switch

• Front door switch LH Combination meter (warning buzzer)

Seat belt warning chime • Seat belt buckle switch LH

• Ignition switch Combination meter (warning buzzer)

Front wiper and washer system • Combination switch

• Ignition switch IPDM E/R

Rear window defogger Rear window defogger switch IPDM E/R

Rear wiper and washer system

(Hatchback) • Combination switch

• Ignition switch Rear wiper motor

A/C switch signal Front air control ECM

Blower fan switch signal Front air control ECM

A/C indicator signal Front air control A/C indicator

Low tire pressure warning system Remote keyless entry receiver Combination meter System Input Output

Page 453 of 4331

BCS

N

O P

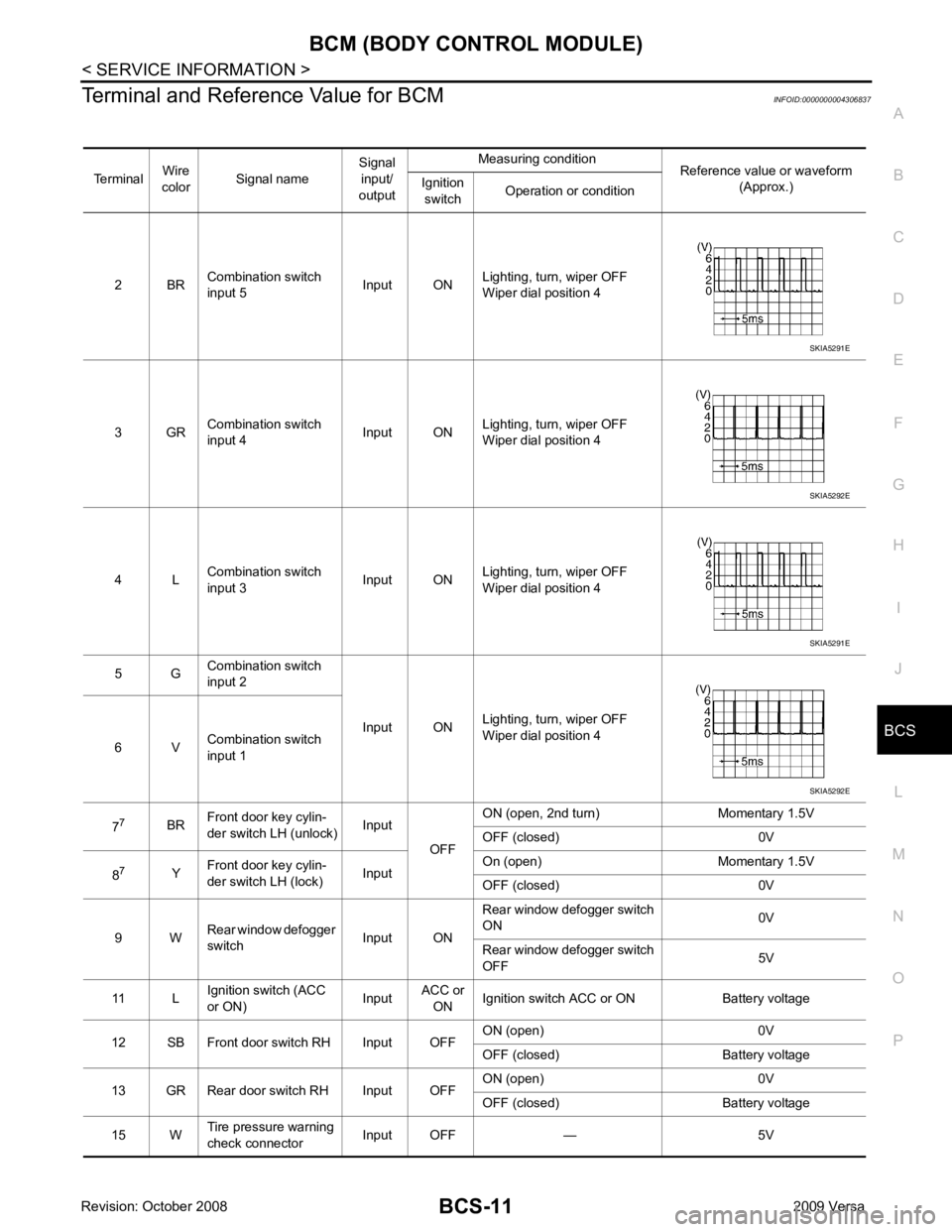

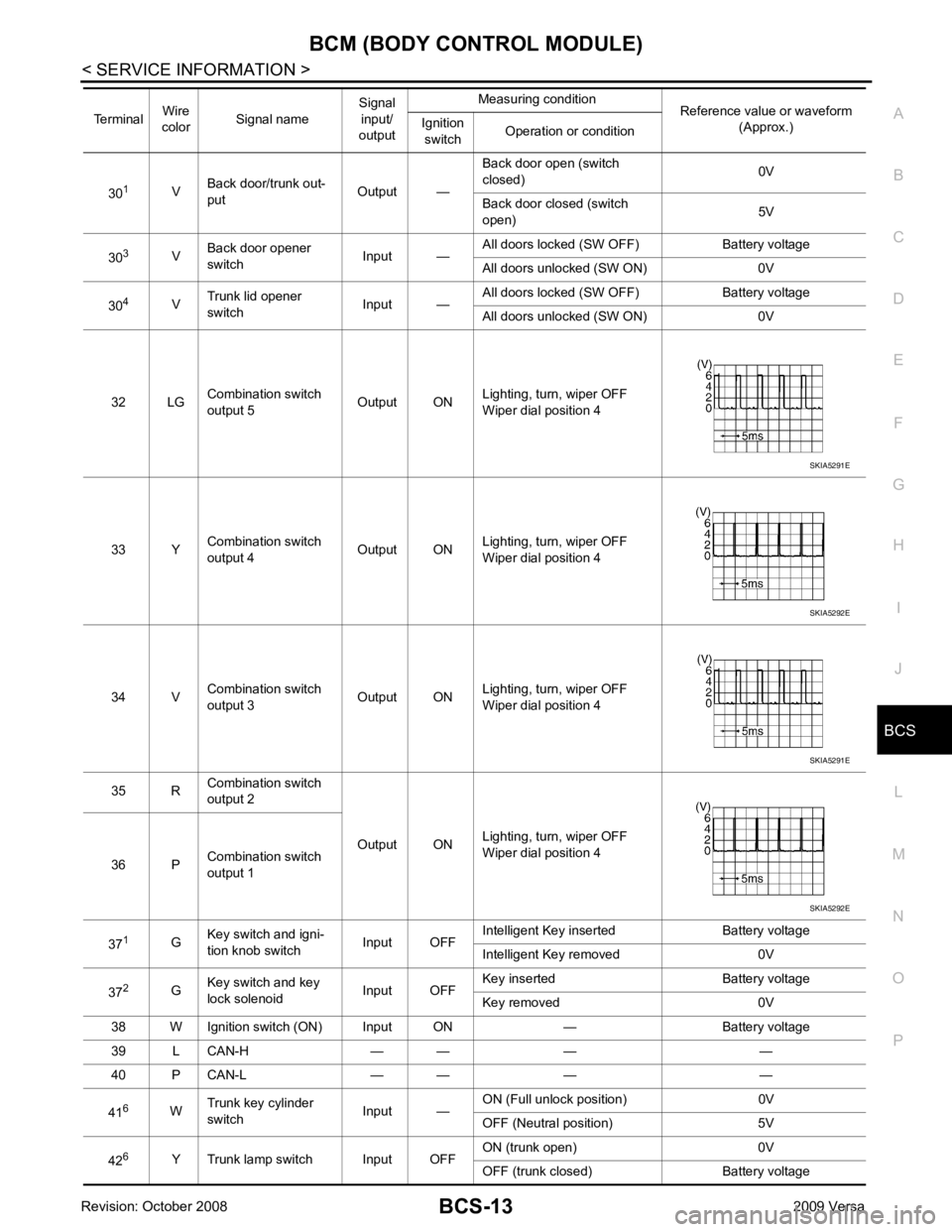

Terminal and Reference Value for BCM

INFOID:0000000004306837

Terminal Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

2 BR Combination switch

input 5 Input ONLighting, turn, wiper OFF

Wiper dial position 4

3 GR Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4 L Combination switch

input 3 Input ONLighting, turn, wiper OFF

Wiper dial position 4

5 G Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6 V Combination switch

input 1

7 7

BRFront door key cylin-

der switch LH (unlock) Input

OFFON (open, 2nd turn) Momentary 1.5V

OFF (closed) 0V

8 7

YFront door key cylin-

der switch LH (lock) InputOn (open) Momentary 1.5V

OFF (closed) 0V

9 W Rear window defogger

switch Input ONRear window defogger switch

ON 0V

Rear window defogger switch

OFF 5V

11 L Ignition switch (ACC

or ON) InputACC or

ON Ignition switch ACC or ON Battery voltage

12 SB Front door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

15 W Tire pressure warning

check connector Input OFF — 5V

Page 455 of 4331

BCM (BODY CONTROL MODULE)

BCS-13

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B BCS

N

O P

30

1

VBack door/trunk out-

put Output —Back door open (switch

closed) 0V

Back door closed (switch

open) 5V

30 3

VBack door opener

switch Input —All doors locked (SW OFF) Battery voltage

All doors unlocked (SW ON) 0V

30 4

VTrunk lid opener

switch Input —All doors locked (SW OFF) Battery voltage

All doors unlocked (SW ON) 0V

32 LG Combination switch

output 5 Output ONLighting, turn, wiper OFF

Wiper dial position 4

33 Y Combination switch

output 4 Output ON

Lighting, turn, wiper OFF

Wiper dial position 4

34 V Combination switch

output 3 Output ONLighting, turn, wiper OFF

Wiper dial position 4

35 R Combination switch

output 2

Output ONLighting, turn, wiper OFF

Wiper dial position 4

36 P Combination switch

output 1

37 1

GKey switch and igni-

tion knob switch Input OFFIntelligent Key inserted Battery voltage

Intelligent Key removed 0V

37 2

GKey switch and key

lock solenoid Input OFFKey inserted Battery voltage

Key removed 0V

38 W Ignition switch (ON) Input ON — Battery voltage

39 L CAN-H — — — —

40 P CAN-L — — — —

41 6

WTrunk key cylinder

switch Input —ON (Full unlock position) 0V

OFF (Neutral position) 5V

42 6

Y Trunk lamp switch Input OFF ON (trunk open) 0V

OFF (trunk closed) Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Page 457 of 4331

BCS

N

O P

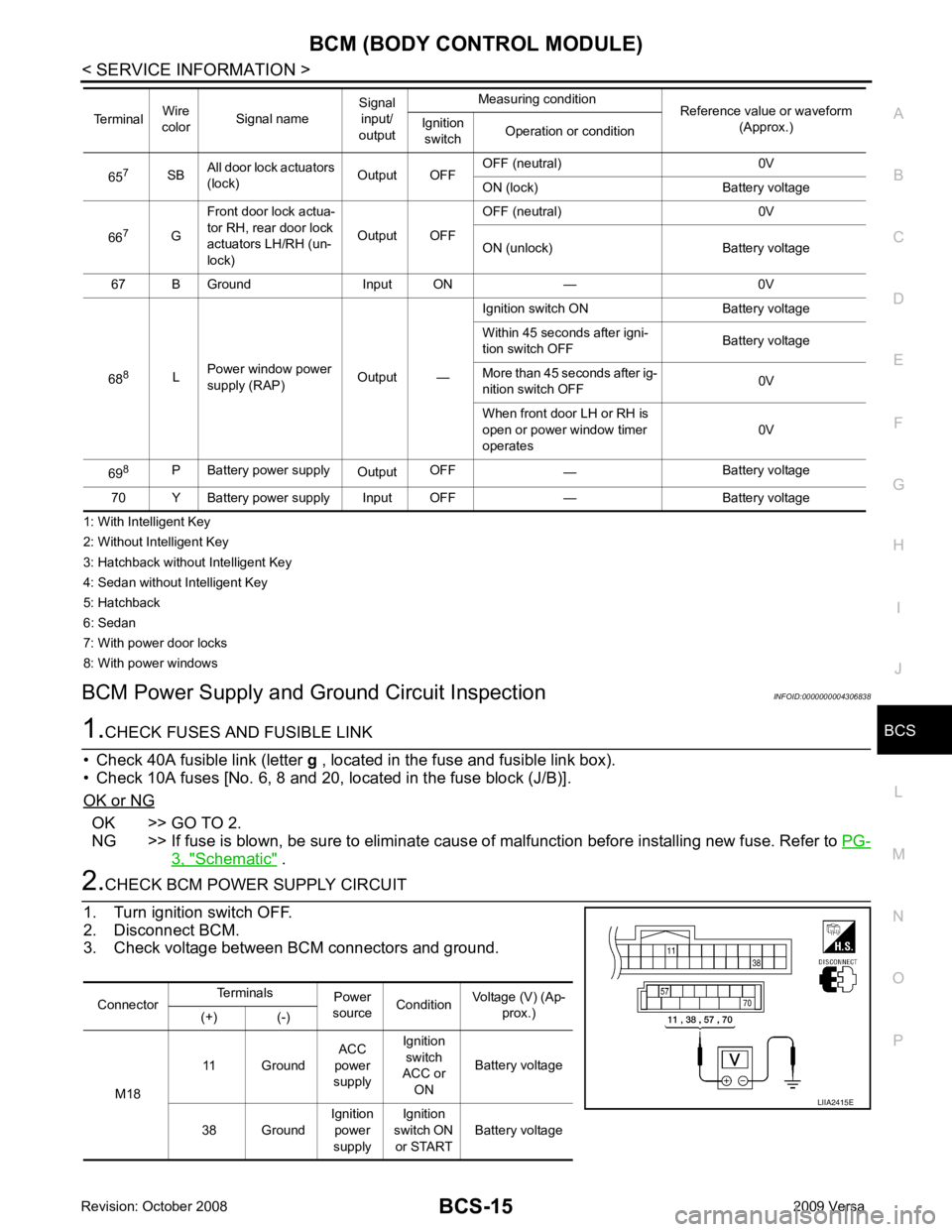

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

BCM Power Supply and Gr ound Circuit Inspection INFOID:0000000004306838OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-3, " Schematic " .

Connector

Terminals

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or

ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

Page 458 of 4331

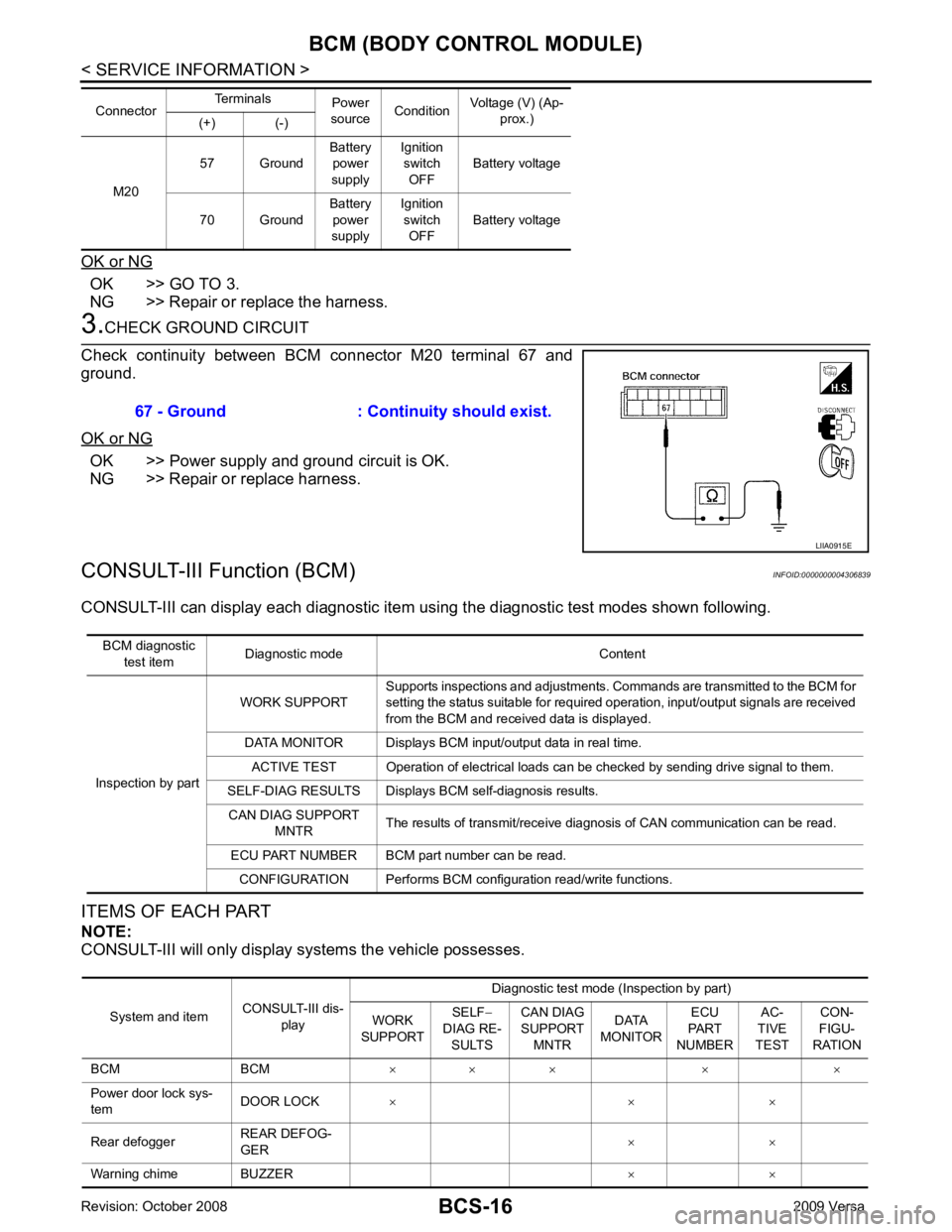

OK >> GO TO 3.

NG >> Repair or replace the harness. OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

CONSULT-III Function (BCM) INFOID:0000000004306839

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

ITEMS OF EACH PART

NOTE:

CONSULT-III will only display systems the vehicle possesses. M20

57 Ground

Battery

power

supply Ignition

switch

OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

Connector

Terminals

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-) System and item

CONSULT-III dis-

play Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

−

DIAG RE- SULTS CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

PART

NUMBER AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM × × × × ×

Power door lock sys-

tem DOOR LOCK

× × ×

Rear defogger REAR DEFOG-

GER × ×

Warning chime BUZZER × ×

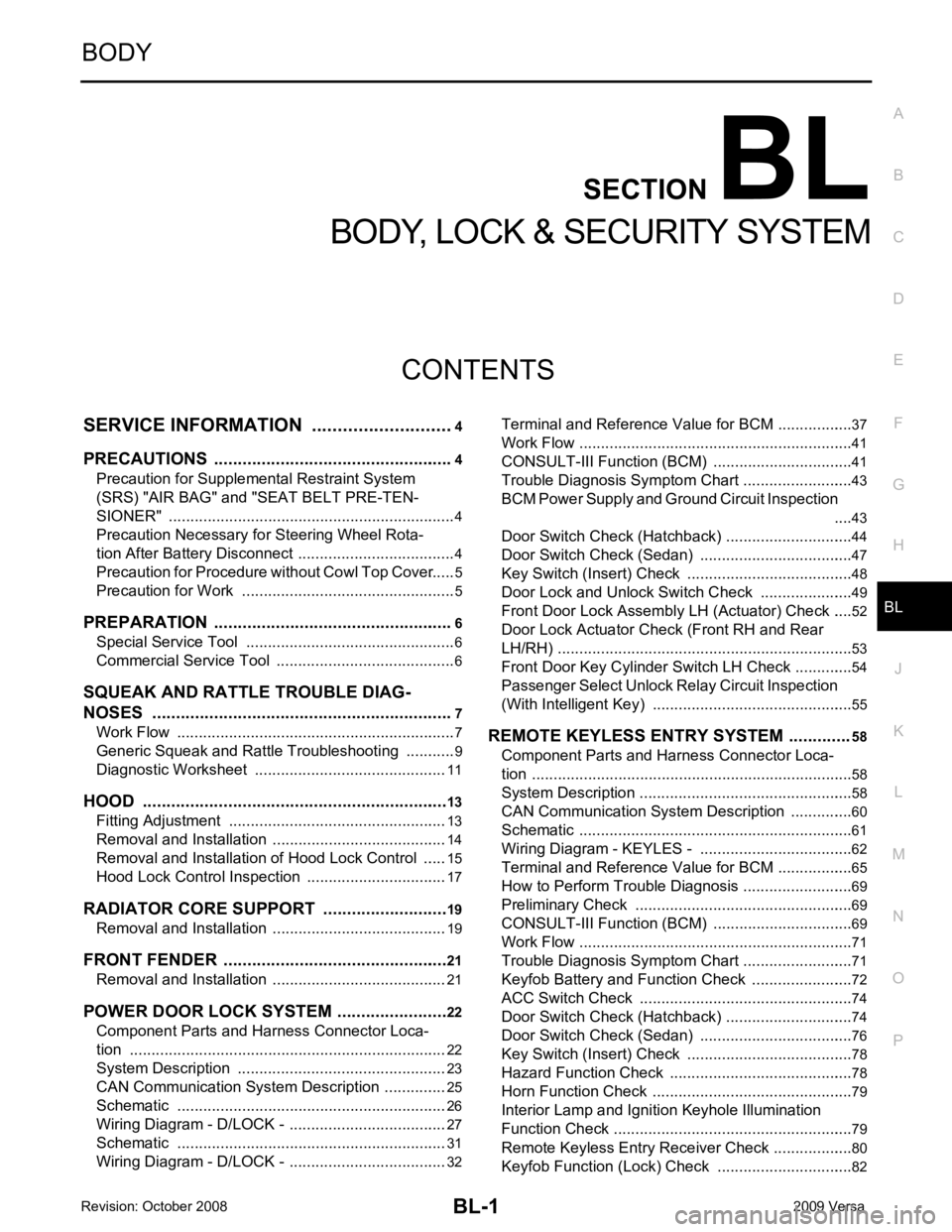

Page 462 of 4331

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ............................................ ......5

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool .................................... ......6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ...... ......9

Diagnostic Worksheet ......................................... ....11

HOOD ............................................................. ....13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspec tion .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ............................................ ....21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description ............................................. ....23

CAN Communication System Description ........... ....25

Schematic ........................................................... ....26

Wiring Diagram - D/LOCK - ................................. ....27

Schematic ........................................................... ....31

Wiring Diagram - D/LOCK - ................................. ....32 Terminal and Reference

Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (B CM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection ....43

Door Switch Check (Hatchback) .......................... ....44

Door Switch Check (Sedan) ................................ ....47

Key Switch (Insert) Check ................................... ....48

Door Lock and Unlock Switch Check .................. ....49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder S witch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM ............. 58

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

58

System Description .............................................. ....58

CAN Communication System Description ........... ....60

Schematic ............................................................ ....61

Wiring Diagram - KEYLES - ................................ ....62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ............................................... ....69

CONSULT-III Function (B CM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ...................... ....71

Keyfob Battery and Function Check .................... ....72

ACC Switch Check .............................................. ....74

Door Switch Check (Hatchback) .......................... ....74

Door Switch Check (Sedan) ................................ ....76

Key Switch (Insert) Check ................................... ....78

Hazard Function Check ....................................... ....78

Horn Function Check ........................................... ....79

Interior Lamp and Ignition Keyhole Illumination

Function Check .................................................... ....

79

Remote Keyless Entry Rece iver Check ...................80

Keyfob Function (Lock) Check ............................ ....82

Page 468 of 4331

BL

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

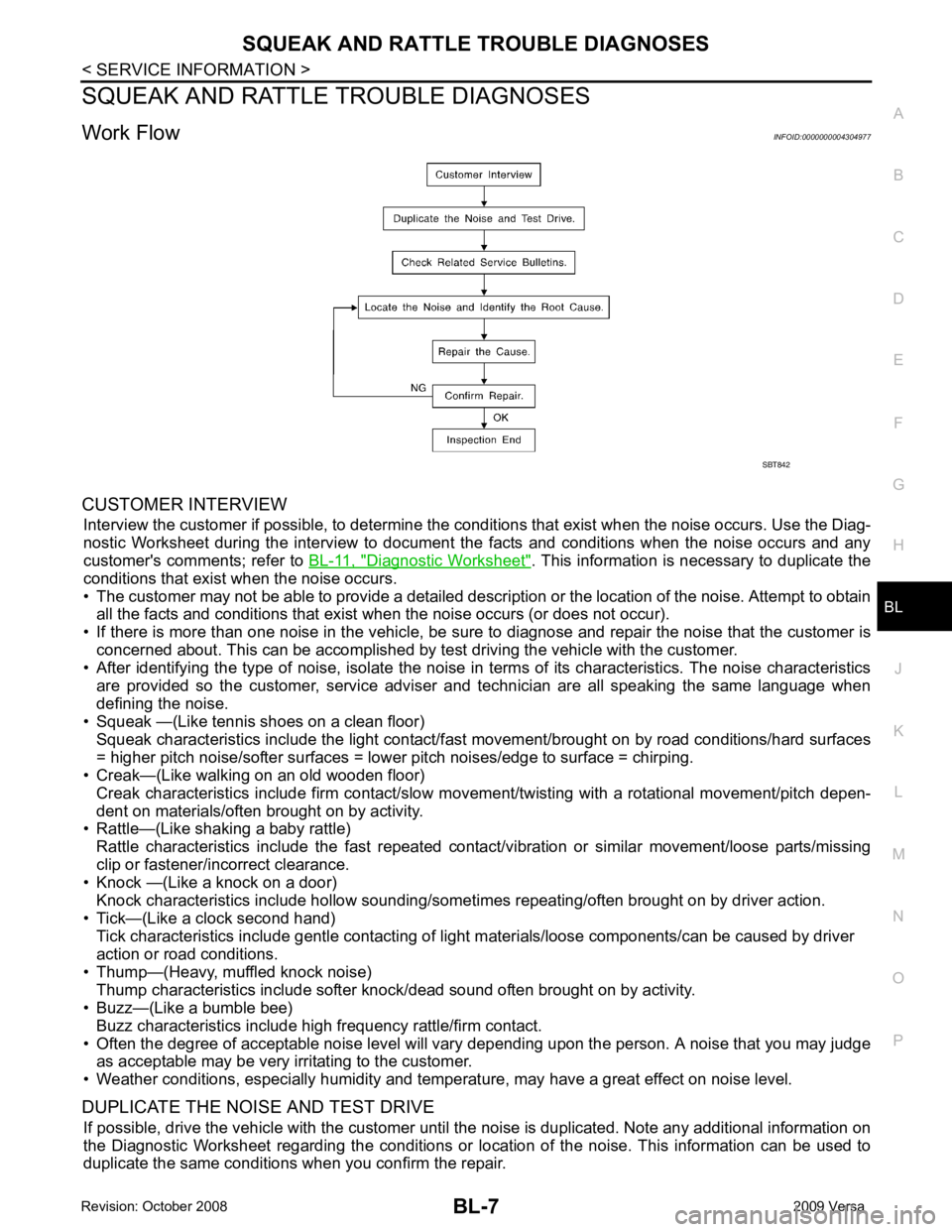

Work Flow INFOID:0000000004304977

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-11, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

Page 470 of 4331

BL

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting INFOID:0000000004304978

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket