engine overheat NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 14 of 4331

AT

N

O P

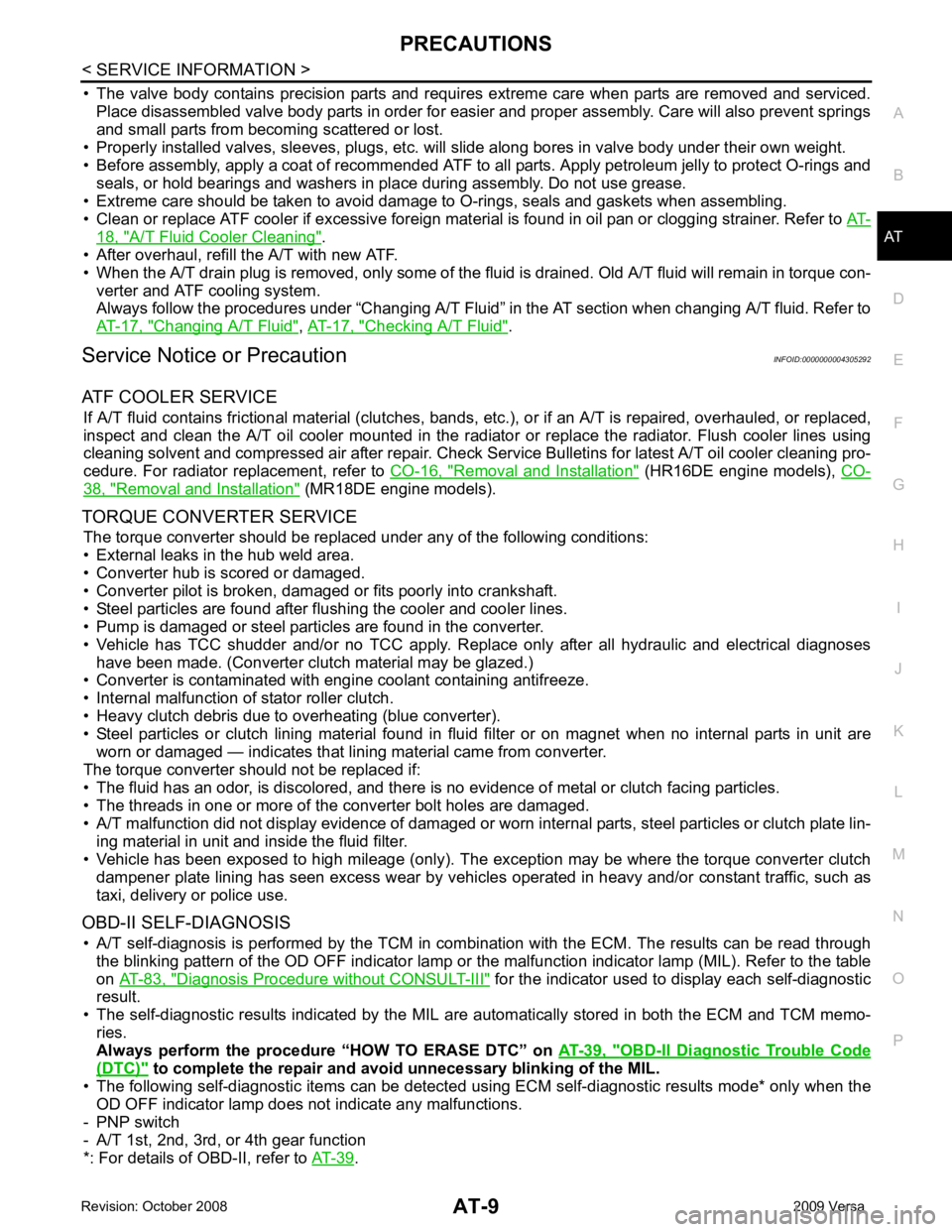

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in pl ace during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-18, " A/T Fluid Cooler Cleaning " .

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-17, " Changing A/T Fluid " ,

AT-17, " Checking A/T Fluid " .

Service Notice or Precaution INFOID:0000000004305292

ATF COOLER SERVICE If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Serv ice Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to CO-16, " Removal and Installation " (HR16DE engine models),

CO-38, " Removal and Installation " (MR18DE engine models).

TORQUE CONVERTER SERVICE The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engi ne coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in flui d filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The e xception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS • A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-83, " Diagnosis Procedure without CONSULT-III " for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-39, " OBD-II Diagnostic Trouble Code

(DTC) " to complete the repair and avo

id unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected us ing ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

- PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD-II, refer to AT-39 .

Page 81 of 4331

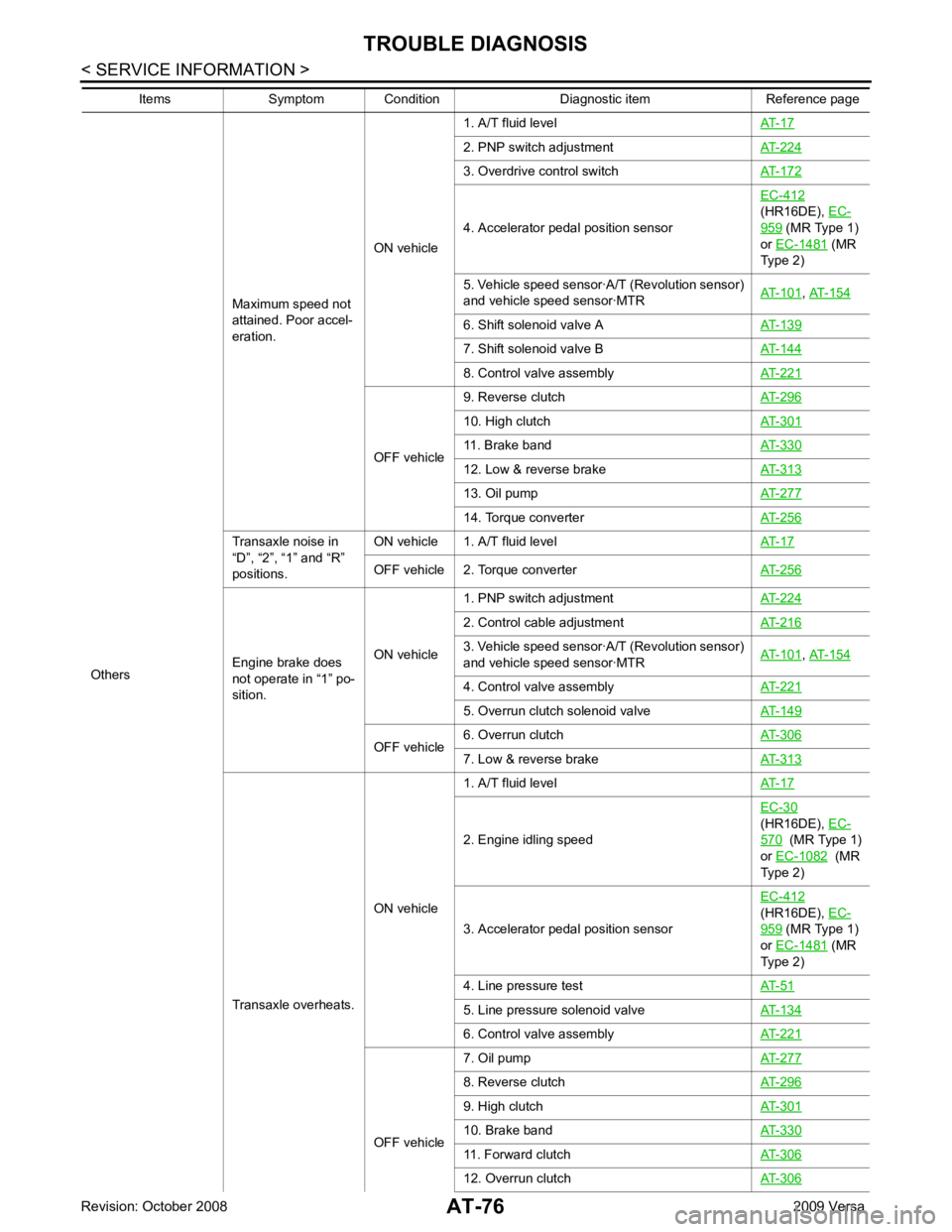

2. PNP switch adjustment

AT-224 3. Overdrive control switch

AT-172 4. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

5. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTR AT-101 ,

AT-154 6. Shift solenoid valve A

AT-139 7. Shift solenoid valve B

AT-144 8. Control valve assembly

AT-221 OFF vehicle

9. Reverse clutch

AT-296 10. High clutch

AT-301 11. Brake band

AT-330 12. Low & reverse brake

AT-313 13. Oil pump

AT-277 14. Torque converter

AT-256Transaxle noise in

“D”, “2”, “1” and “R”

positions. ON vehicle 1. A/T fluid level

AT-17OFF vehicle 2. Torque converter

AT-256Engine brake does

not operate in “1” po-

sition. ON vehicle1. PNP switch adjustment

AT-224 2. Control cable adjustment

AT-216 3. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTR AT-101 ,

AT-154 4. Control valve assembly

AT-221 5. Overrun clutch solenoid valve

AT-149 OFF vehicle

6. Overrun clutch

AT-306 7. Low & reverse brake

AT-313Transaxle overheats.

ON vehicle1. A/T fluid level

AT-17 2. Engine idling speed

EC-30

(HR16DE), EC- 570 (MR Type 1)

or EC-1082 (MR

Type 2)

3. Accelerator pedal position sensor EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

4. Line pressure test AT-51 5. Line pressure solenoid valve

AT-134 6. Control valve assembly

AT-221 OFF vehicle

7. Oil pump

AT-277 8. Reverse clutch

AT-296 9. High clutch

AT-301 10. Brake band

AT-330 11. Forward clutch

AT-306 12. Overrun clutch

AT-306Items Symptom Condition Diagnostic item Reference page

Page 895 of 4331

CO

N

O P

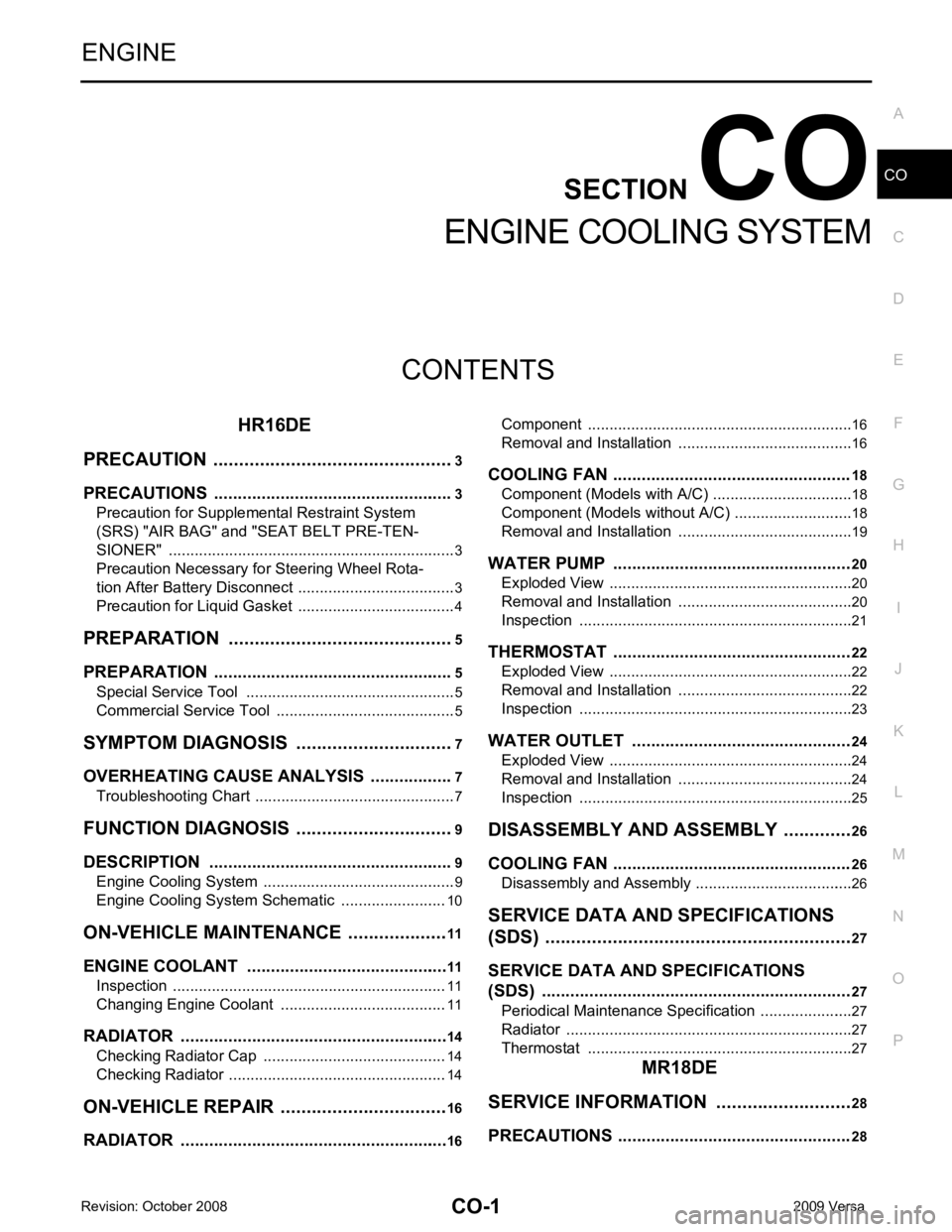

CONTENTS

ENGINE COOLING SYSTEM

HR16DE

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Liquid Gasket ............................... ......4

PREPARATION .... ........................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool .................................... ......5

SYMPTOM DIAGNOSIS ..... ..........................7

OVERHEATING CAUSE ANALYSIS ............. .....7

Troubleshooting Chart ..... ..........................................7

FUNCTION DIAGNOSIS .. .............................9

DESCRIPTION ............................................... .....9

Engine Cooling System ....................................... ......9

Engine Cooling System Schematic ..................... ....10

ON-VEHICLE MAINTENA NCE ....................11

ENGINE COOLANT ....................................... ....11

Inspection ............................................................ ....11

Changing Engine Coolant ................................... ....11

RADIATOR ..................................................... ....14

Checking Radiator Cap ....................................... ....14

Checking Radiator ............................................... ....14

ON-VEHICLE REPAIR .... .............................16

RADIATOR ..................................................... ....16 Component ..........................................................

....16

Removal and Installation ..................................... ....16

COOLING FAN .................................................. 18

Component (Models with A/C) ............................. ....18

Component (Models without A/C) ........................ ....18

Removal and Installation ..................................... ....19

WATER PUMP .................................................. 20

Exploded View ..................................................... ....20

Removal and Installation ..................................... ....20

Inspection ............................................................ ....21

THERMOSTAT .................................................. 22

Exploded View ..................................................... ....22

Removal and Installation ..................................... ....22

Inspection ............................................................ ....23

WATER OUTLET .............................................. 24

Exploded View ..................................................... ....24

Removal and Installation ..................................... ....24

Inspection ............................................................ ....25

DISASSEMBLY AND AS SEMBLY ..............26

COOLING FAN .................................................. 26

Disassembly and Assembly ................................. ....26

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

27

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................. 27

Periodical Maintenance Specification .................. ....27

Radiator ............................................................... ....27

Thermostat .......................................................... ....27

MR18DE

SERVICE INFORMATION .. .........................28

PRECAUTIONS ................................................. 28

Page 901 of 4331

CO

NP

O

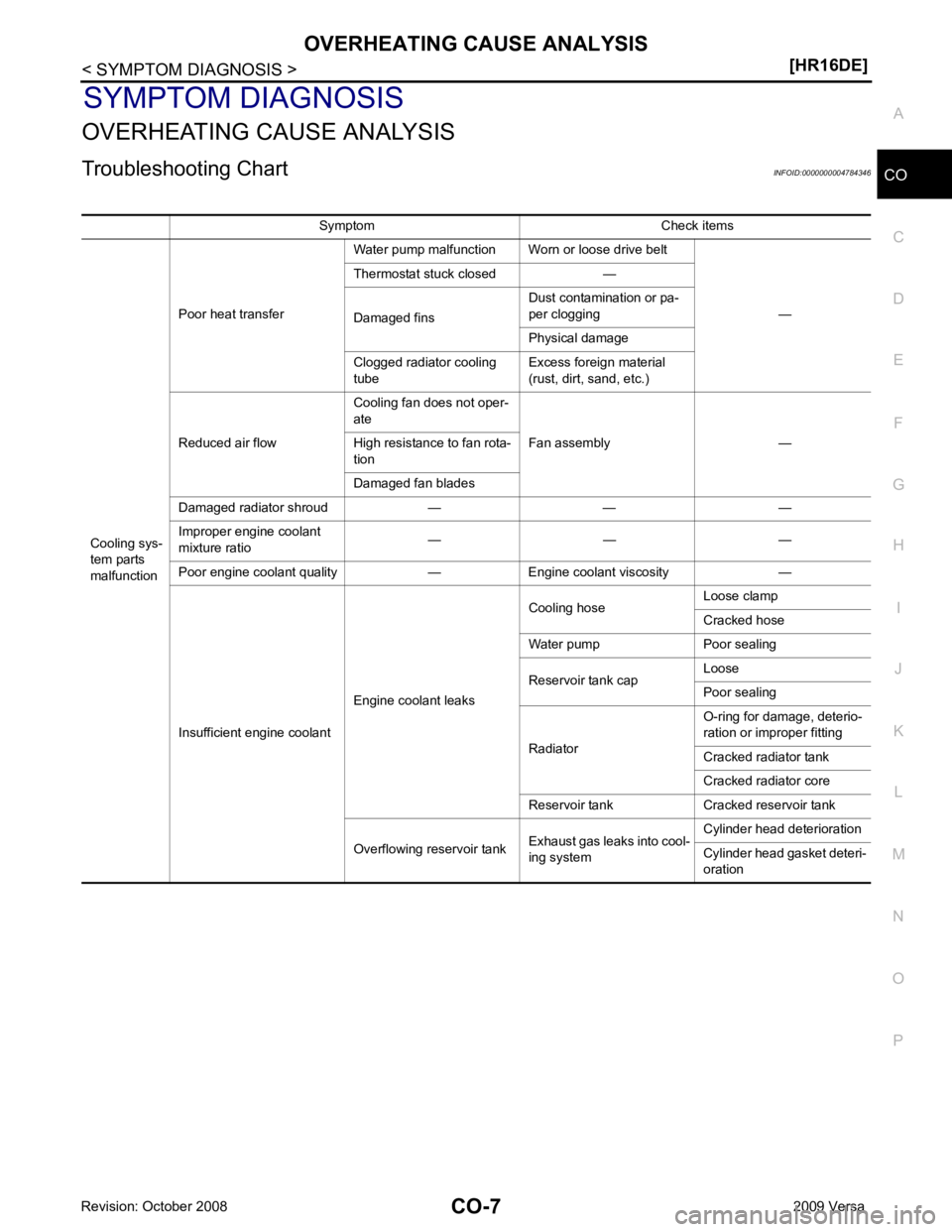

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting Chart INFOID:0000000004784346

Symptom Check items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed —

Damaged fins Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio — — —

Poor engine coolant quality — Engine coolant viscosity —

Insufficient engine coolant Engine coolant leaks Cooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Reservoir tank cap Loose

Poor sealing

Radiator O-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leaks into cool-

ing system Cylinder head deterioration

Cylinder head gasket deteri-

oration

Page 1375 of 4331

EC

A

N

O P

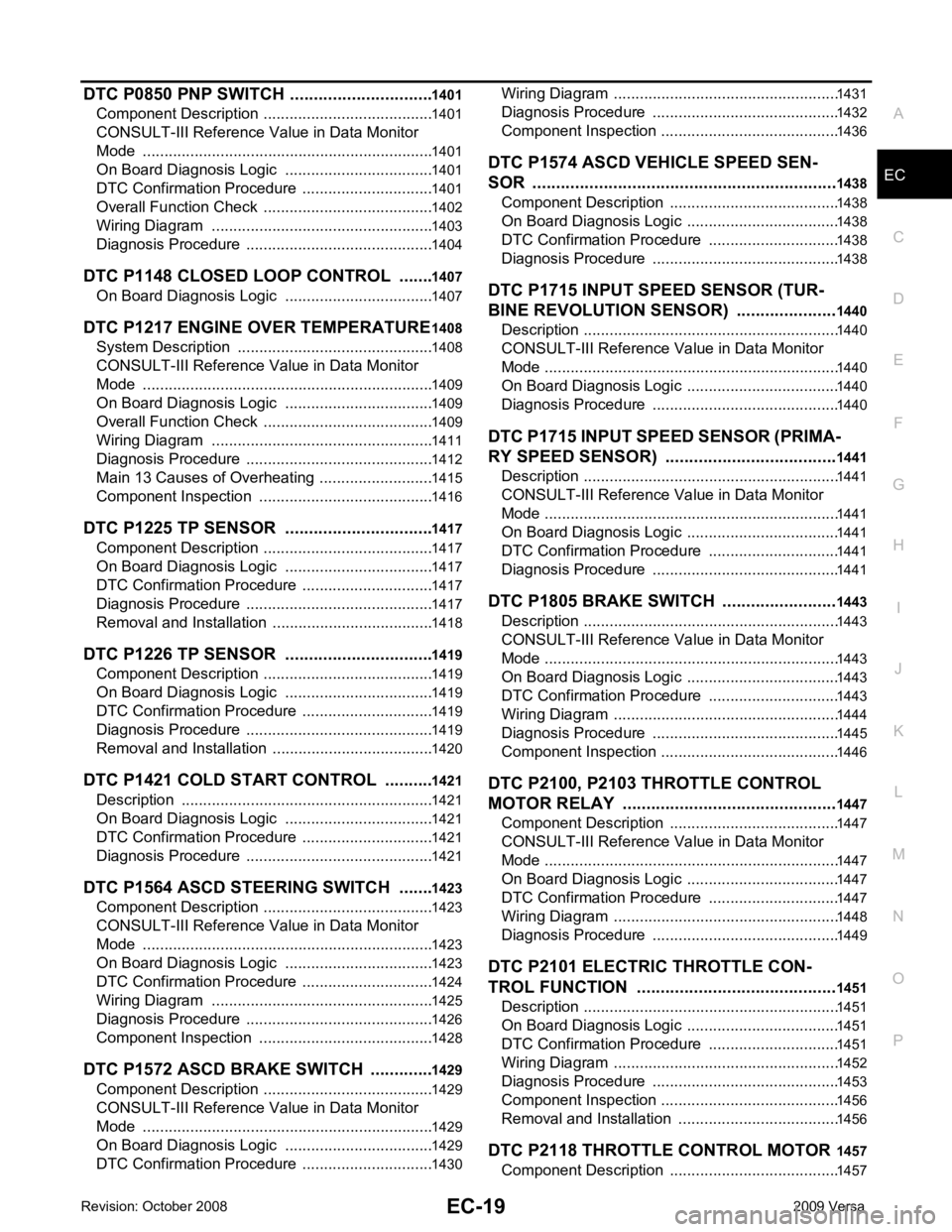

DTC P0850 PNP SWITCH ..............................

1401

Component Description ....................................... 1401

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1401

On Board Diagnosis Logic .................................. 1401

DTC Confirmation Procedure .............................. 1401

Overall Function Check ....................................... 1402

Wiring Diagram ................................................... 1403

Diagnosis Procedure ........................................... 1404

DTC P1148 CLOSED LOOP CONTROL ....... 1407

On Board Diagnosis Logic .................................. 1407

DTC P1217 ENGINE OVER TEMPERATURE 1408

System Description ............................................. 1408

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1409

On Board Diagnosis Logic .................................. 1409

Overall Function Check ....................................... 1409

Wiring Diagram ................................................... 1411

Diagnosis Procedure ........................................... 1412

Main 13 Causes of Overheating .......................... 1415

Component Inspection ........................................ 1416

DTC P1225 TP SENSOR ............................... 1417

Component Description ....................................... 1417

On Board Diagnosis Logic .................................. 1417

DTC Confirmation Procedure .............................. 1417

Diagnosis Procedure ........................................... 1417

Removal and Installation .....................................1418

DTC P1226 TP SENSOR ............................... 1419

Component Description ....................................... 1419

On Board Diagnosis Logic .................................. 1419

DTC Confirmation Procedure .............................. 1419

Diagnosis Procedure ........................................... 1419

Removal and Installation .....................................1420

DTC P1421 COLD START CONTROL .......... 1421

Description .......................................................... 1421

On Board Diagnosis Logic .................................. 1421

DTC Confirmation Procedure .............................. 1421

Diagnosis Procedure ........................................... 1421

DTC P1564 ASCD STEERING SWITCH ....... 1423

Component Description ....................................... 1423

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1423

On Board Diagnosis Logic .................................. 1423

DTC Confirmation Procedure .............................. 1424

Wiring Diagram ................................................... 1425

Diagnosis Procedure ........................................... 1426

Component Inspection ........................................ 1428

DTC P1572 ASCD BRAKE SWITCH ............. 1429

Component Description ....................................... 1429

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1429

On Board Diagnosis Logic .................................. 1429

DTC Confirmation Procedure .............................. 1430Wiring Diagram ....................................................

1431

Diagnosis Procedure ........................................... 1432

Component Inspection ......................................... 1436

DTC P1574 ASCD VEH ICLE SPEED SEN-

SOR ................................................................ 1438

Component Description ....................................... 1438

On Board Diagnosis Logic ................................... 1438

DTC Confirmation Procedure .............................. 1438

Diagnosis Procedure ........................................... 1438

DTC P1715 INPUT SPEED SENSOR (TUR-

BINE REVOLUTION SENSOR) ..................... 1440

Description ........................................................... 1440

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1440

On Board Diagnosis Logic ................................... 1440

Diagnosis Procedure ........................................... 1440

DTC P1715 INPUT SPEED SENSOR (PRIMA-

RY SPEED SENSOR) ....................................

1441

Description ........................................................... 1441

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1441

On Board Diagnosis Logic ................................... 1441

DTC Confirmation Procedure .............................. 1441

Diagnosis Procedure ........................................... 1441

DTC P1805 BRAKE SWITCH ........................ 1443

Description ........................................................... 1443

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1443

On Board Diagnosis Logic ................................... 1443

DTC Confirmation Procedure .............................. 1443

Wiring Diagram .................................................... 1444

Diagnosis Procedure ........................................... 1445

Component Inspection ......................................... 1446

DTC P2100, P2103 THROTTLE CONTROL

MOTOR RELAY ............................................. 1447

Component Description ....................................... 1447

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1447

On Board Diagnosis Logic ................................... 1447

DTC Confirmation Procedure .............................. 1447

Wiring Diagram .................................................... 1448

Diagnosis Procedure ........................................... 1449

DTC P2101 ELECTRIC THROTTLE CON-

TROL FUNCTION .......................................... 1451

Description ........................................................... 1451

On Board Diagnosis Logic ................................... 1451

DTC Confirmation Procedure .............................. 1451

Wiring Diagram .................................................... 1452

Diagnosis Procedure ........................................... 1453

Component Inspection ......................................... 1456

Removal and Installation ..................................... 1456

DTC P2118 THROTTLE CONTROL MOTOR 1457

Component Description ....................................... 1457

Page 1465 of 4331

EC

NP

O

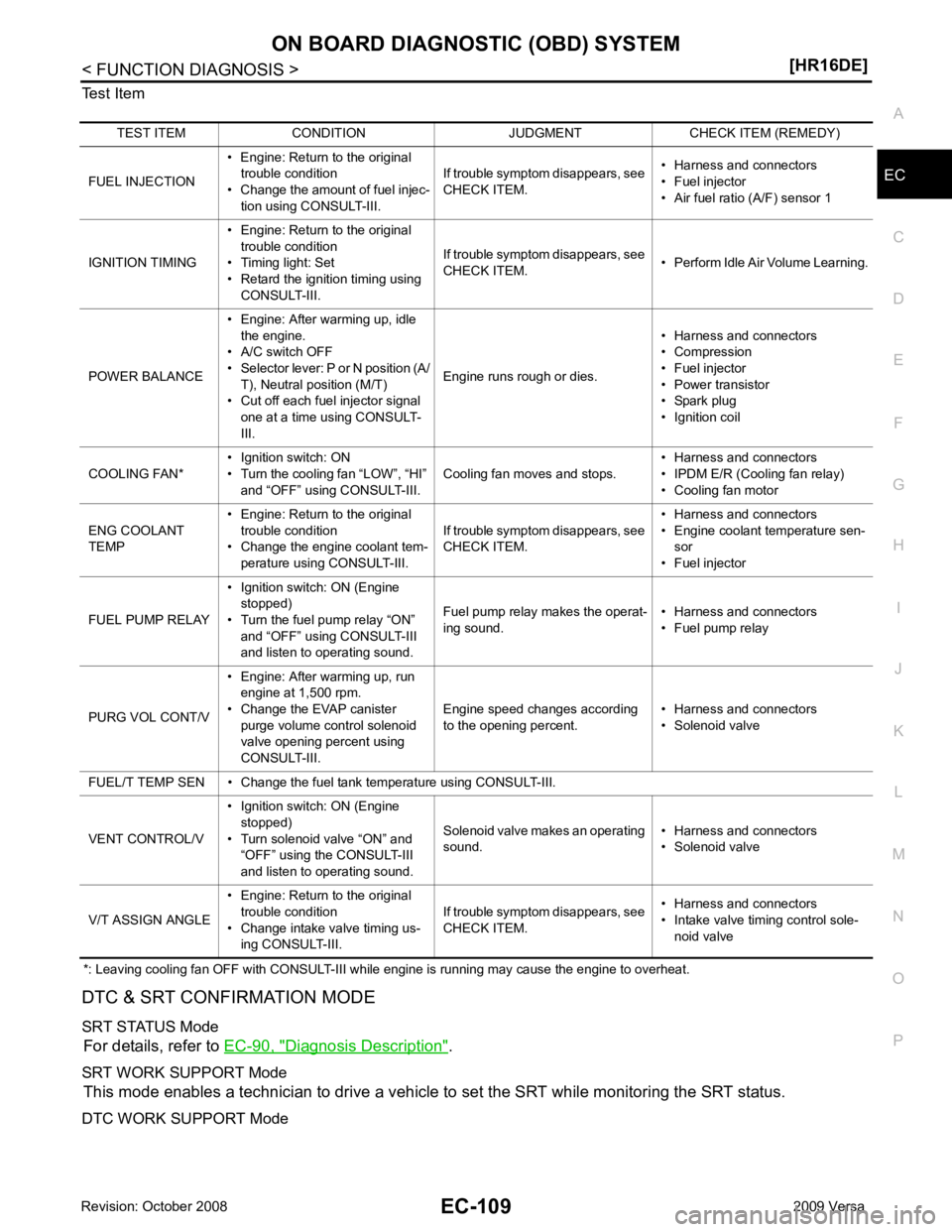

Test Item

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode For details, refer to EC-90, " Diagnosis Description " .

SRT WORK SUPPORT Mode This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode TEST ITEM CONDITION JUDGMENT CHECK ITEM (REMEDY)

FUEL INJECTION • Engine: Return to the original

trouble condition

• Change the amount of fuel injec- tion using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

IGNITION TIMING • Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using

CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Perform Idle Air Volume Learning.

POWER BALANCE • Engine: After warming up, idle

the engine.

• A/C switch OFF

• Selector lever: P or N position (A/ T), Neutral position (M/T)

• Cut off each fuel injector signal

one at a time using CONSULT-

III. Engine runs rough or dies.

• Harness and connectors

• Compression

• Fuel injector

• Power transistor

• Spark plug

• Ignition coil

COOLING FAN* • Ignition switch: ON

• Turn the cooling fan “LOW”, “HI”

and “OFF” using CONSULT-III. Cooling fan moves and stops.

• Harness and connectors

• IPDM E/R (Cooling fan relay)

• Cooling fan motor

ENG COOLANT

TEMP • Engine: Return to the original

trouble condition

• Change the engine coolant tem-

perature using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Engine coolant temperature sen- sor

• Fuel injector

FUEL PUMP RELAY • Ignition switch: ON (Engine

stopped)

• Turn the fuel pump relay “ON”

and “OFF” using CONSULT-III

and listen to operating sound. Fuel pump relay makes the operat-

ing sound. • Harness and connectors

• Fuel pump relay

PURG VOL CONT/V • Engine: After warming up, run

engine at 1,500 rpm.

• Change the EVAP canister purge volume control solenoid

valve opening percent using

CONSULT-III. Engine speed changes according

to the opening percent. • Harness and connectors

• Solenoid valve

FUEL/T TEMP SEN • Change the fuel tank temperature using CONSULT-III.

VENT CONTROL/V • Ignition switch: ON (Engine

stopped)

• Turn solenoid valve “ON” and “OFF” using th e CONSULT-III

and listen to operating sound. Solenoid valve makes an operating

sound. • Harness and connectors

• Solenoid valve

V/T ASSIGN ANGLE • Engine: Return to the original

trouble condition

• Change intake valve timing us-

ing CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Intake valve timing control sole- noid valve

Page 1609 of 4331

EC

NP

O

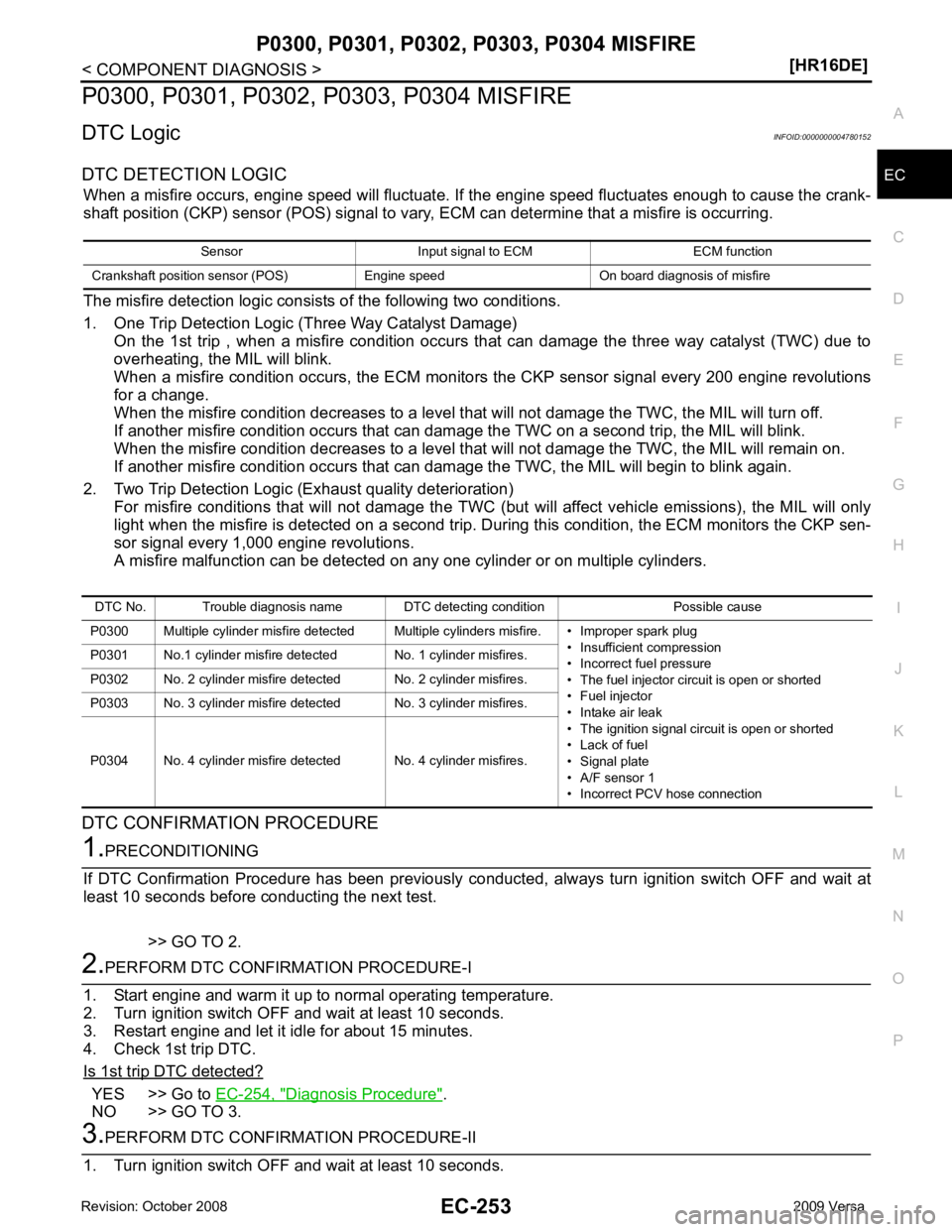

P0300, P0301, P0302, P0303, P0304 MISFIRE

DTC Logic INFOID:0000000004780152

DTC DETECTION LOGIC When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip , when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC CONFIRMATION PROCEDURE YES >> Go to

EC-254, " Diagnosis Procedure " .

NO >> GO TO 3. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300 Multiple cylinder misfire detected Multiple cylinders misfire. • Improper spark plug • Insufficient compression

• Incorrect fuel pressure

• The fuel injector circuit is open or shorted

• Fuel injector

• Intake air leak

• The ignition signal circuit is open or shorted

• Lack of fuel

• Signal plate

• A/F sensor 1

• Incorrect PCV hose connection

P0301 No.1 cylinder misfire detected No. 1 cylinder misfires.

P0302 No. 2 cylinder misfire detected No. 2 cylinder misfires.

P0303 No. 3 cylinder misfire detected No. 3 cylinder misfires.

P0304 No. 4 cylinder misfire detected No. 4 cylinder misfires.

Page 1831 of 4331

EC

NP

O

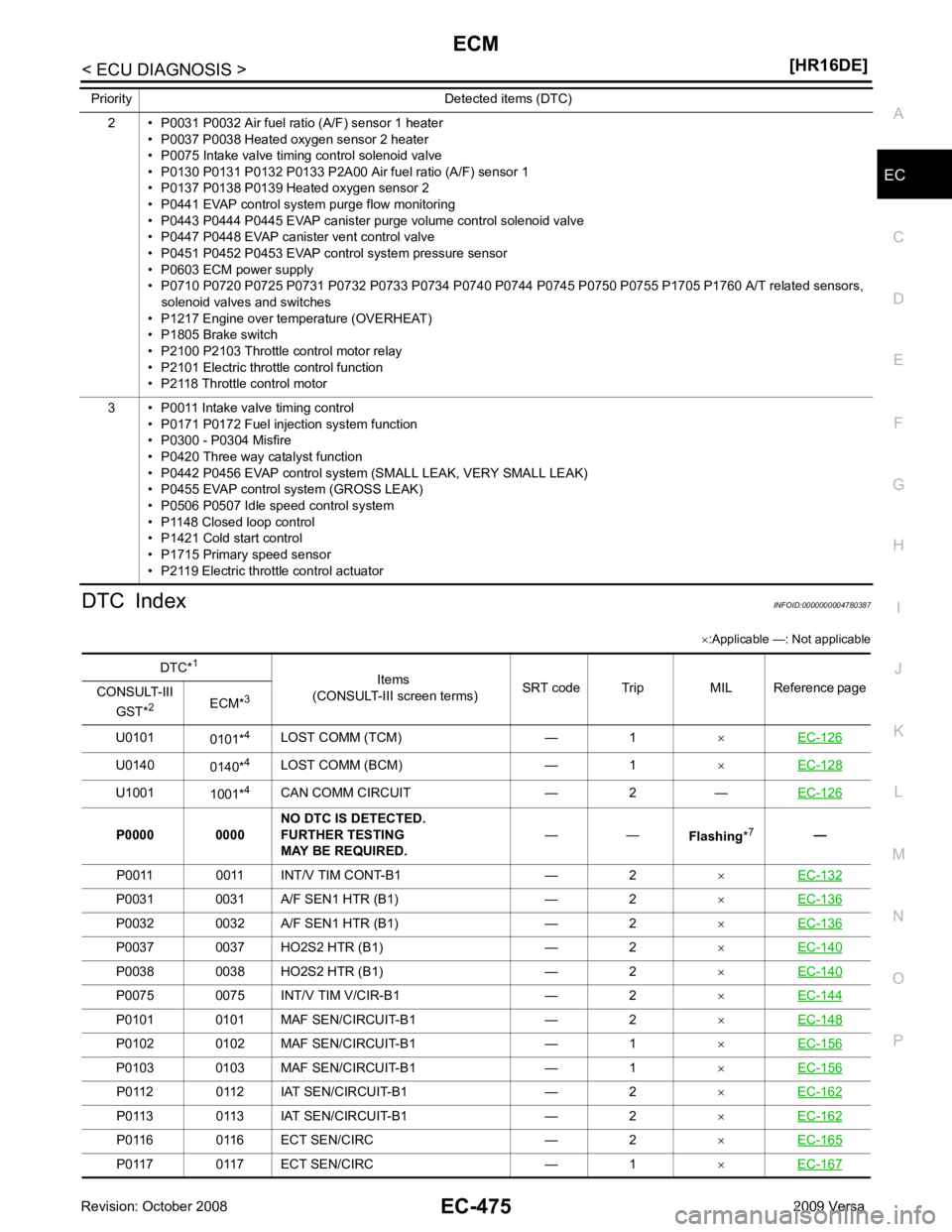

DTC Index

INFOID:0000000004780387

× :Applicable —: Not applicable

2 • P0031 P0032 Air fuel ratio (A/F) sensor 1 heater

• P0037 P0038 Heated oxygen sensor 2 heater

• P0075 Intake valve timing control solenoid valve

• P0130 P0131 P0132 P0133 P2A00 Air fuel ratio (A/F) sensor 1

• P0137 P0138 P0139 Heated oxygen sensor 2

• P0441 EVAP control system purge flow monitoring

• P0443 P0444 P0445 EVAP canister purge volume control solenoid valve

• P0447 P0448 EVAP canister vent control valve

• P0451 P0452 P0453 EVAP control system pressure sensor

• P0603 ECM power supply

• P0710 P0720 P0725 P0731 P0732 P0733 P0734 P0740 P0744 P0745 P0750 P0755 P1705 P1760 A/T related sensors,

solenoid valves and switches

• P1217 Engine over temperature (OVERHEAT)

• P1805 Brake switch

• P2100 P2103 Throttle control motor relay

• P2101 Electric throttle control function

• P2118 Throttle control motor

3 • P0011 Intake valve timing control • P0171 P0172 Fuel injection system function

• P0300 - P0304 Misfire

• P0420 Three way catalyst function

• P0442 P0456 EVAP control system (SMALL LEAK, VERY SMALL LEAK)

• P0455 EVAP control system (GROSS LEAK)

• P0506 P0507 Idle speed control system

• P1148 Closed loop control

• P1421 Cold start control

• P1715 Primary speed sensor

• P2119 Electric throttle control actuator

Priority Detected items (DTC) DTC*

1

Items

(CONSULT-III screen terms) SRT code Trip MIL Reference page

CONSULT-III

GST* 2

ECM*3

U0101 0101*4

LOST COMM (TCM) — 1 ×EC-126 U0140

0140*4

LOST COMM (BCM) — 1 ×EC-128 U1001

1001*4

CAN COMM CIRCUIT — 2 — EC-126P0031 0031 A/F SEN1 HTR (B1) — 2

×EC-136 P0032 0032 A/F SEN1 HTR (B1) — 2

×EC-136 P0037 0037 HO2S2 HTR (B1) — 2

×EC-140 P0038 0038 HO2S2 HTR (B1) — 2

×EC-140 P0075 0075 INT/V TIM V/CIR-B1 — 2

×EC-144 P0101 0101 MAF SEN/CIRCUIT-B1 — 2

×EC-148 P0102 0102 MAF SEN/CIRCUIT-B1 — 1

×EC-156 P0103 0103 MAF SEN/CIRCUIT-B1 — 1

×EC-156 P0112 0112 IAT SEN/CIRCUIT-B1 — 2

×EC-162 P0113 0113 IAT SEN/CIRCUIT-B1 — 2

×EC-162 P0116 0116 ECT SEN/CIRC — 2

×EC-165 P0117 0117 ECT SEN/CIRC — 1

×EC-167

Page 1843 of 4331

EC

NP

O

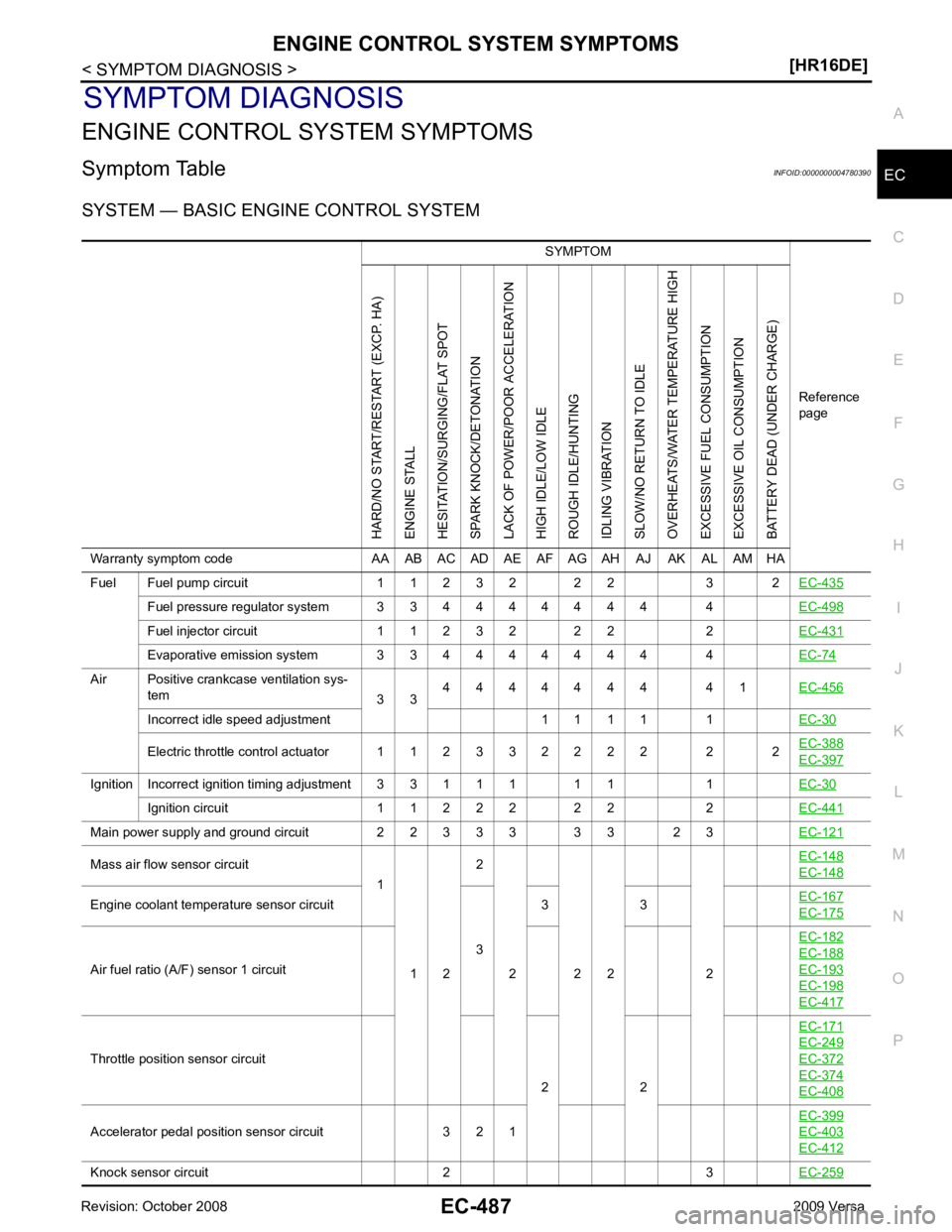

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom Table INFOID:0000000004780390

SYSTEM — BASIC ENGINE CONTROL SYSTEM SYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit 1 1 2 3 2 2 2 3 2 EC-435Fuel pressure regulator system 3 3 4 4 4 4 4 4 4 4

EC-498Fuel injector circuit 1 1 2 3 2 2 2 2

EC-431Evaporative emission system 3 3 4 4 4 4 4 4 4 4

EC-74Air Positive crankcase ventilation sys-

tem 3 34 4 4 4 4 4 4 4 1

EC-456Incorrect idle speed adjustment 1 1 1 1 1

EC-30Electric throttle control actuator 1 1 2 3 3 2 2 2 2 2 2

EC-388 EC-397

Ignition Incorrect ignition timing adjustment 3 3 1 1 1 1 1 1

EC-30Ignition circuit 1 1 2 2 2 2 2 2

EC-441Main power supply and ground circuit 2 2 3 3 3 3 3 2 3

EC-121Mass air flow sensor circuit

1

1 2 2

2 2 2 2 EC-148 EC-148

Engine coolant temperature sensor circuit

33 3

EC-167 EC-175

Air fuel ratio (A/F) sensor 1 circuit

EC-182 EC-188

EC-193

EC-198

EC-417

Throttle position sensor circuit

2 2EC-171 EC-249

EC-372

EC-374

EC-408

Accelerator pedal position sensor circuit 3 2 1

EC-399 EC-403

EC-412

Knock sensor circuit 2 3

EC-259

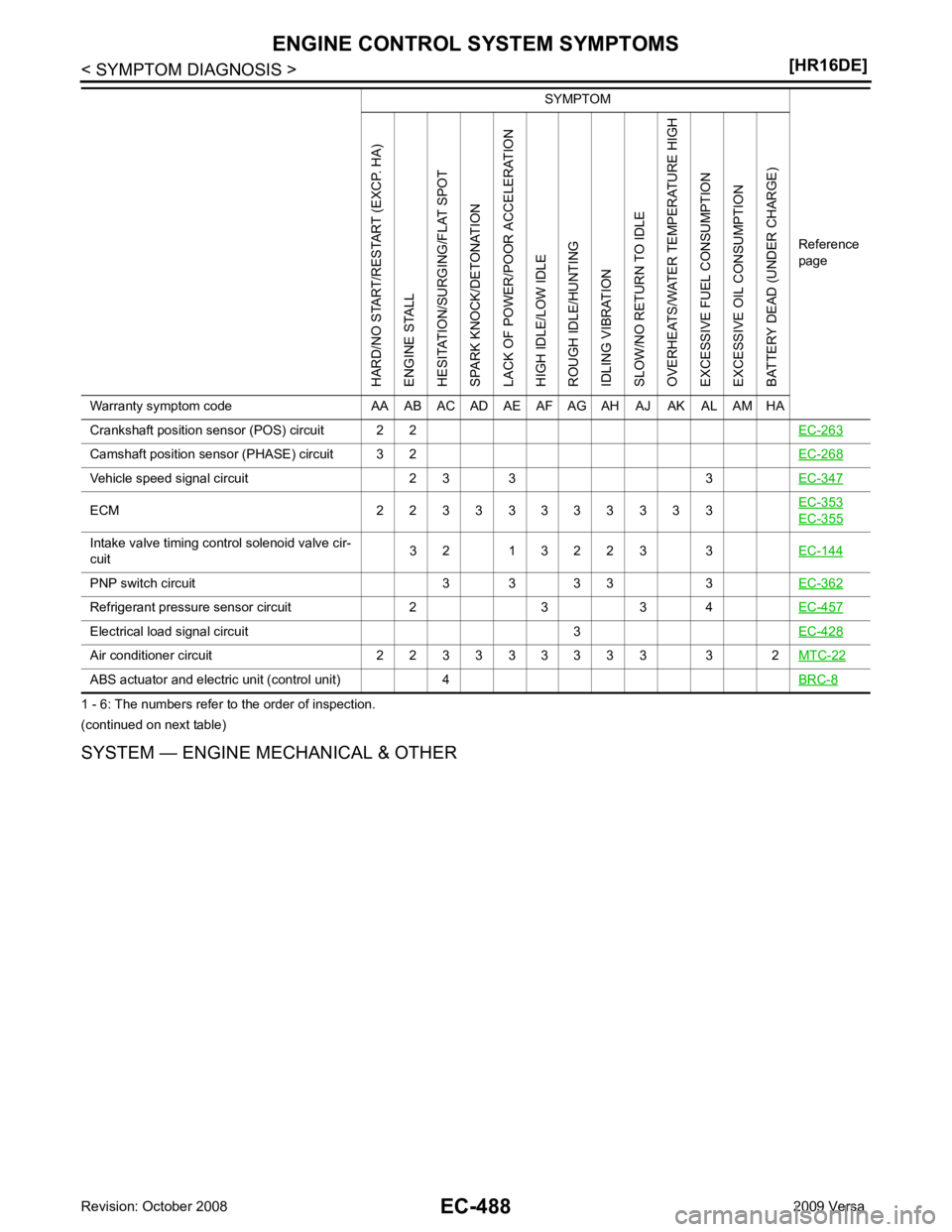

Page 1844 of 4331

Camshaft position sensor (PHASE) circuit 3 2

EC-268Vehicle speed signal circuit 2 3 3 3

EC-347ECM 2 2 3 3 3 3 3 3 3 3 3

EC-353 EC-355

Intake valve timing control solenoid valve cir-

cuit 3 2 1 3 2 2 3 3

EC-144PNP switch circuit 3 3 3 3 3

EC-362Refrigerant pressure sensor circuit 2 3 3 4

EC-457Electrical load signal circuit 3

EC-428Air conditioner circuit 2 2 3 3 3 3 3 3 3 3 2

MTC-22ABS actuator and electric unit (control unit) 4

BRC-8SYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA